Polypropylene honeycomb hollow plate material

A technology of polypropylene and hollow boards, which is applied in the field of special materials for polypropylene honeycomb hollow boards, and can solve problems such as unsteadiness, poor impact resistance, and deformation under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

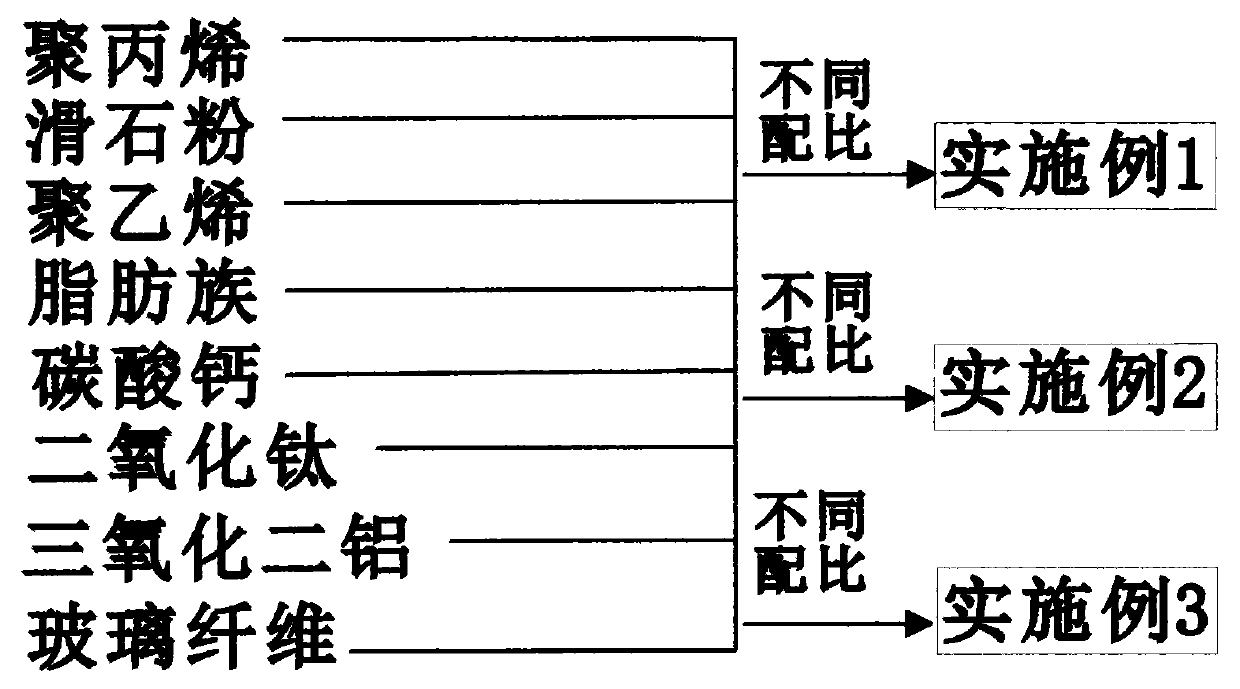

[0012] A kind of polypropylene honeycomb hollow board, the composition of its internal structure and its percentage weight ratio please refer to the attached figure 1 .

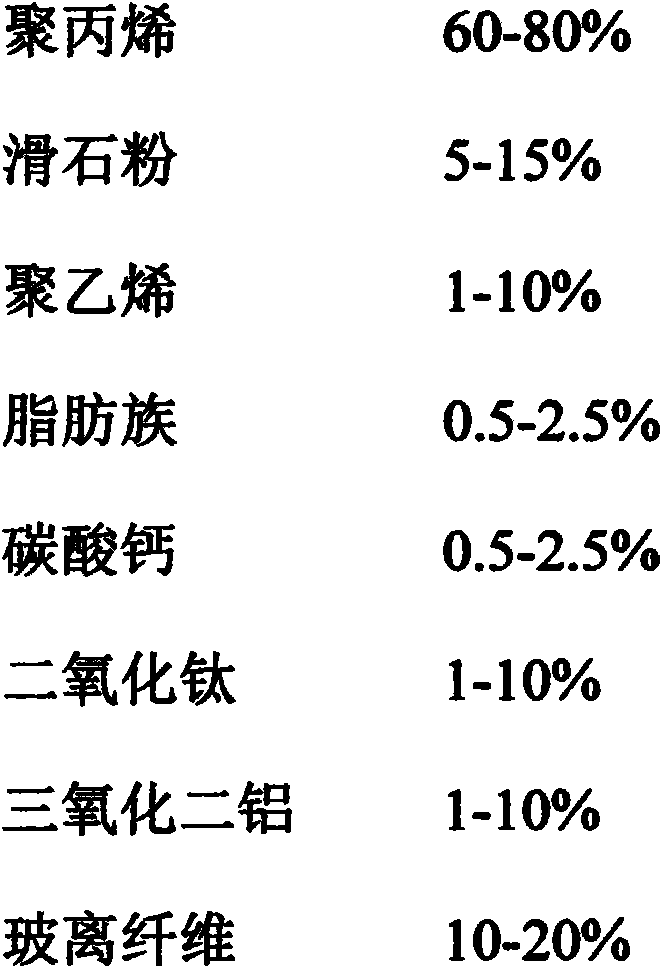

[0013] The percentage weight ratio of each component of a polypropylene honeycomb hollow sheet is:

[0014]

[0015] The components of a polypropylene honeycomb hollow sheet in Example 1 are calculated based on the percentage weight ratio of its internal structure.

Embodiment 2

[0017] A kind of polypropylene honeycomb hollow board, the composition of its internal structure and its percentage weight ratio please refer to the attached figure 1 .

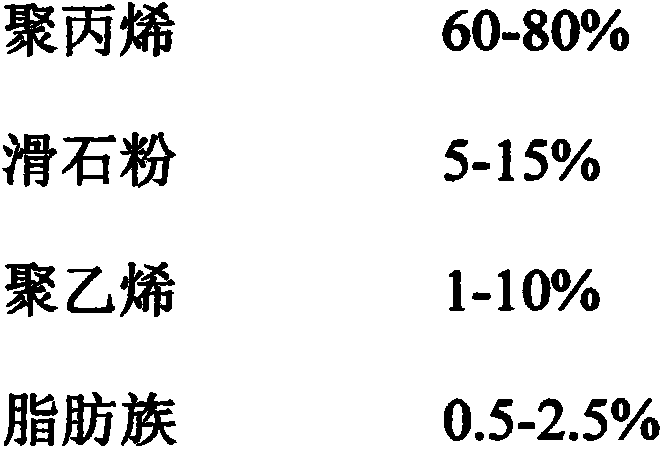

[0018] The percentage weight ratio of each component of a polypropylene honeycomb hollow sheet is:

[0019]

[0020] The components of a polypropylene honeycomb hollow sheet in Example 1 are calculated based on the percentage weight ratio of its internal structure.

Embodiment 3

[0022] A kind of polypropylene honeycomb hollow board, the composition of its internal structure and its percentage weight ratio please refer to the attached figure 1 .

[0023] The percentage weight ratio of each component of a polypropylene honeycomb hollow sheet is:

[0024]

[0025] The components of a polypropylene honeycomb hollow sheet in Example 1 are calculated based on the percentage weight ratio of its internal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com