Multifunctional paper yarn wall paper compounding machine

A multi-functional, composite machine technology, applied in lamination devices, lamination auxiliary operations, lamination and other directions, can solve the problems of short service life, rapid color decolorization, poor quality and wear resistance, etc., to reduce production costs, High flexural and tensile strength and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

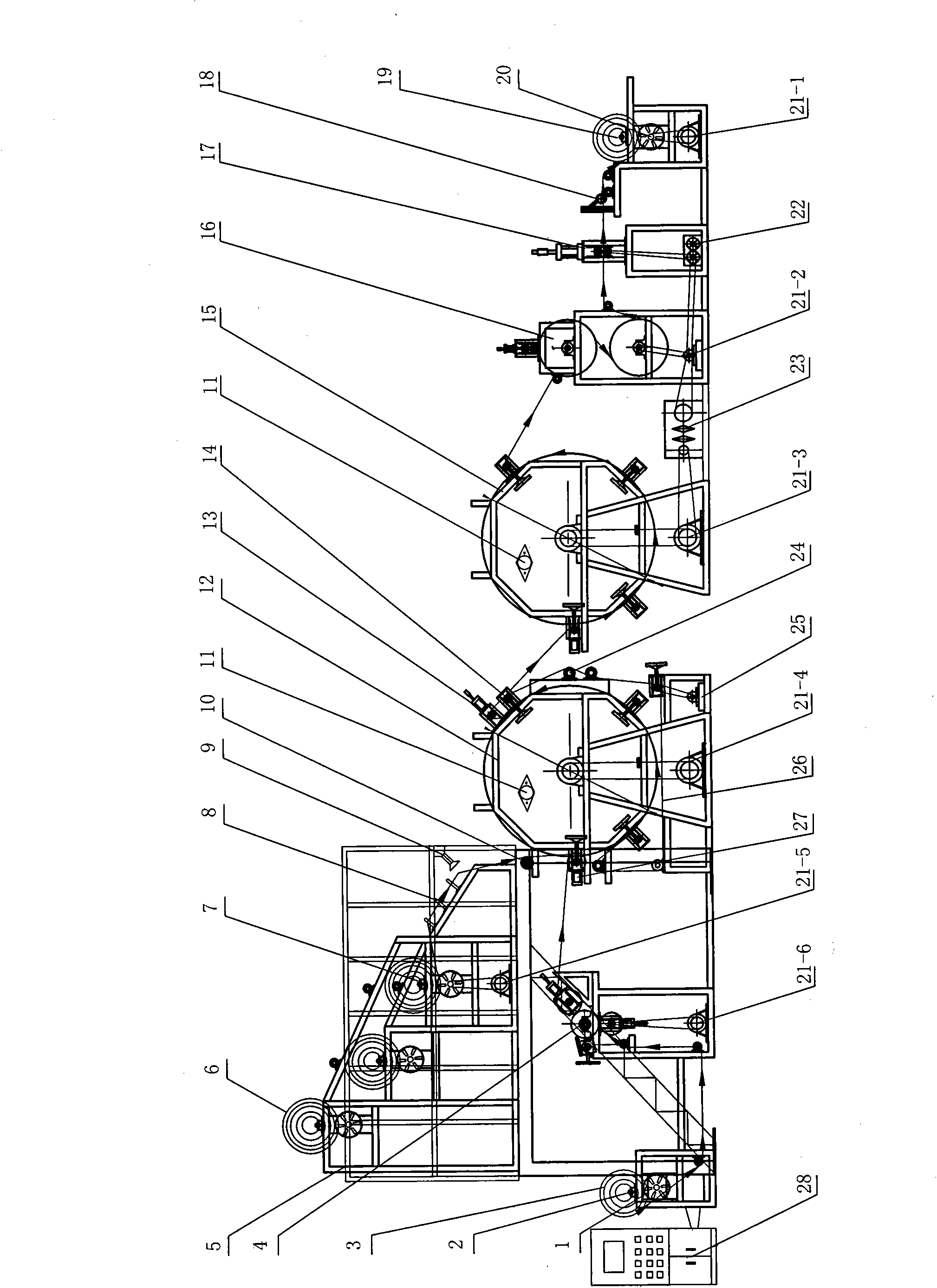

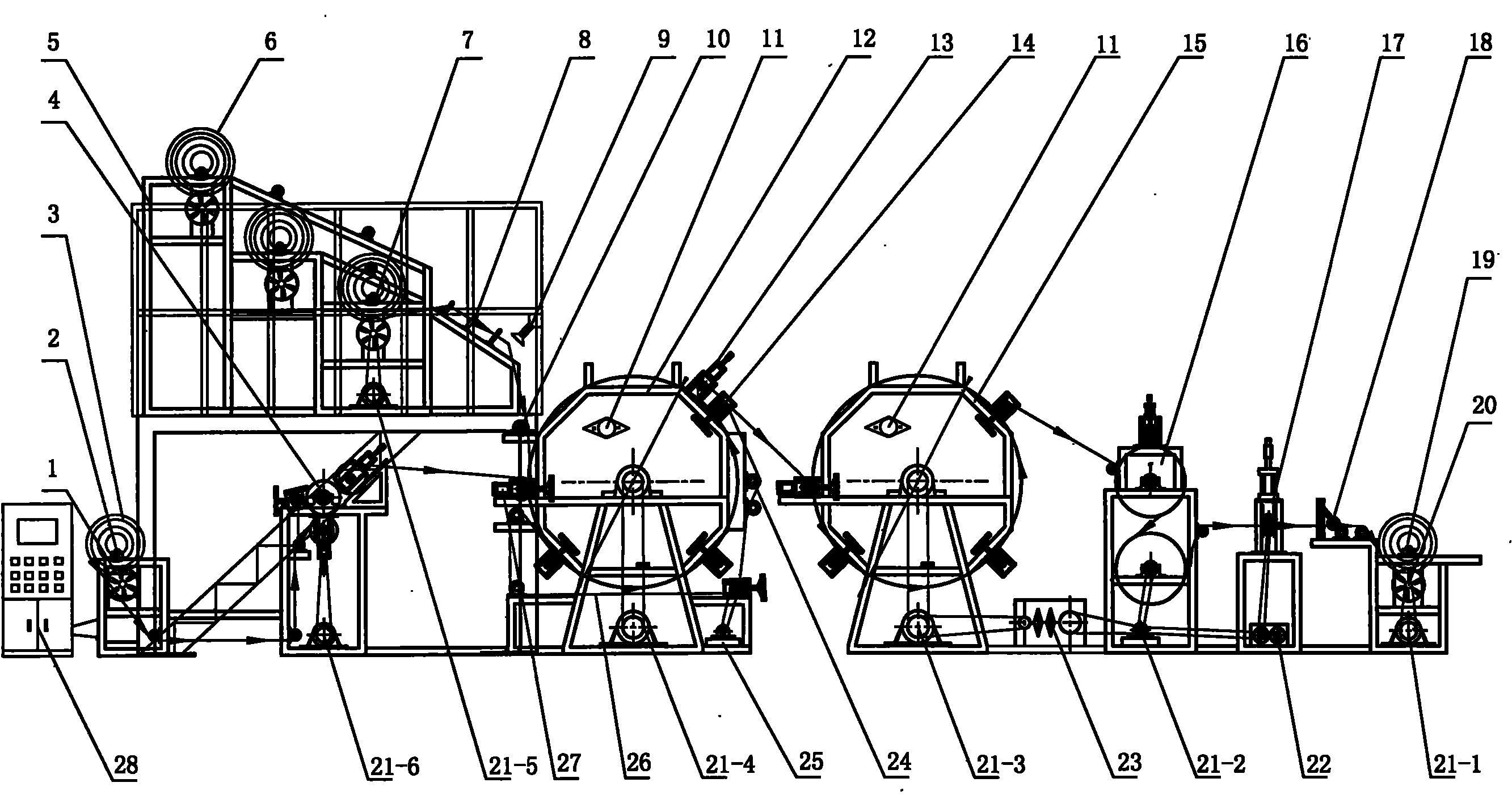

[0011] In the figure: the whole support body 5 is a cuboid shape, which is formed by connecting steel structures. Steel ladders are provided on both sides of the support body 5, and a constant tension unwinding device 2 is provided on the left bottom of the support body 5. There is an air expansion shaft, on which a paper roll 3 is placed, a magnetic powder brake 1 is provided directly below the constant tension unwinding device 2, and a gluing device 4 is provided on the upper right, between the constant tension unwinding device 2 and the gluing device 4 A constant tension multi-layer yarn unwinding device 7 is arranged on the upper bracket of the constant tension multi-layer yarn unwinding device 7, and an air expansion shaft is arranged on the constant tension multi-layer yarn unwinding device 7, and a yarn reel 6 is placed on the air expansion shaft. A magnetic powder brake 1 is provided, and a plurality of steel buckles 8 are arranged on the lower right bracket of the cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com