Patents

Literature

302results about "Aerating valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

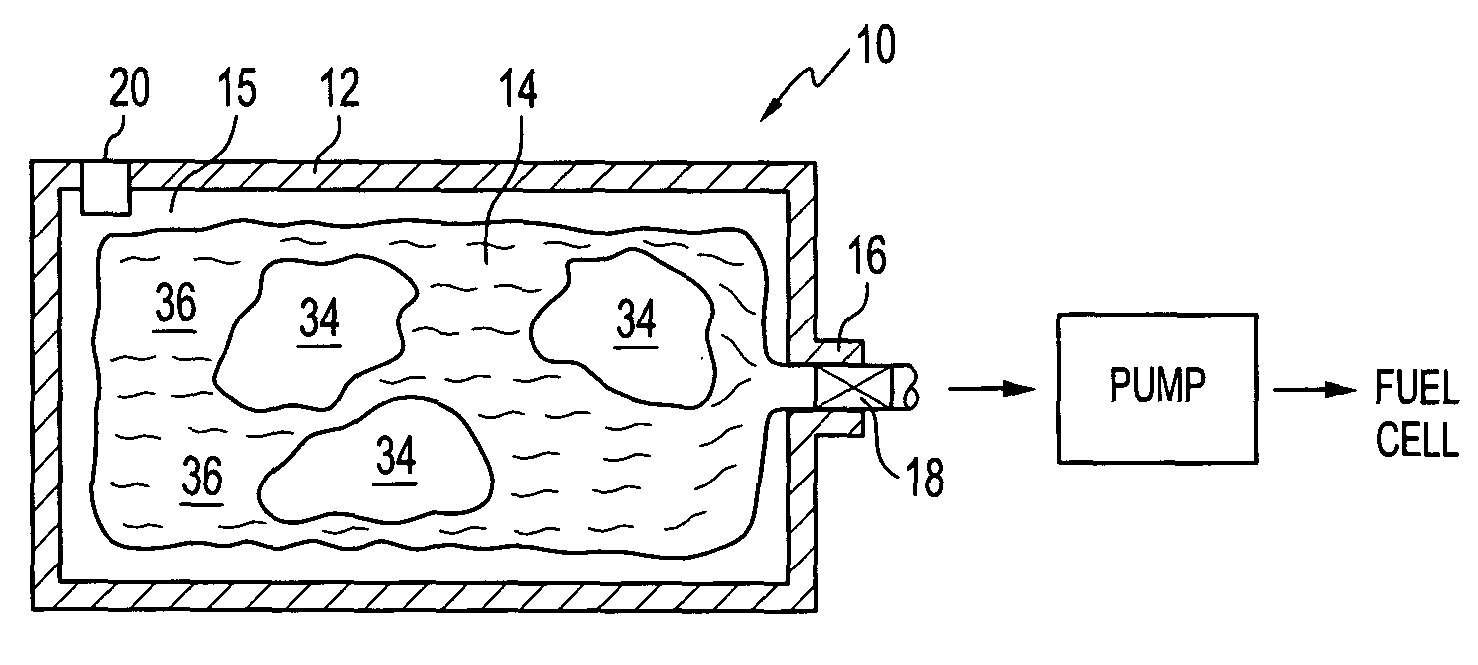

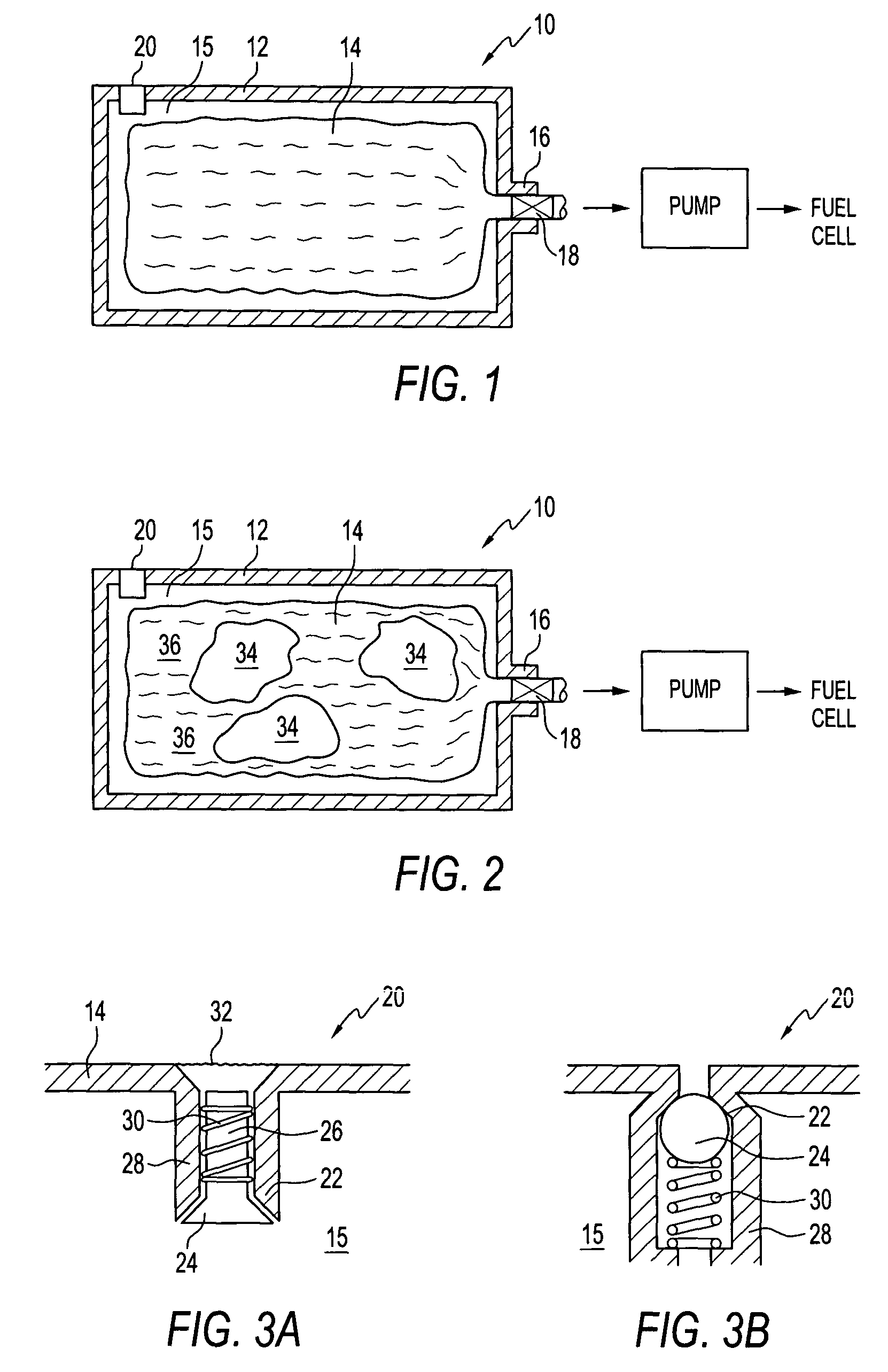

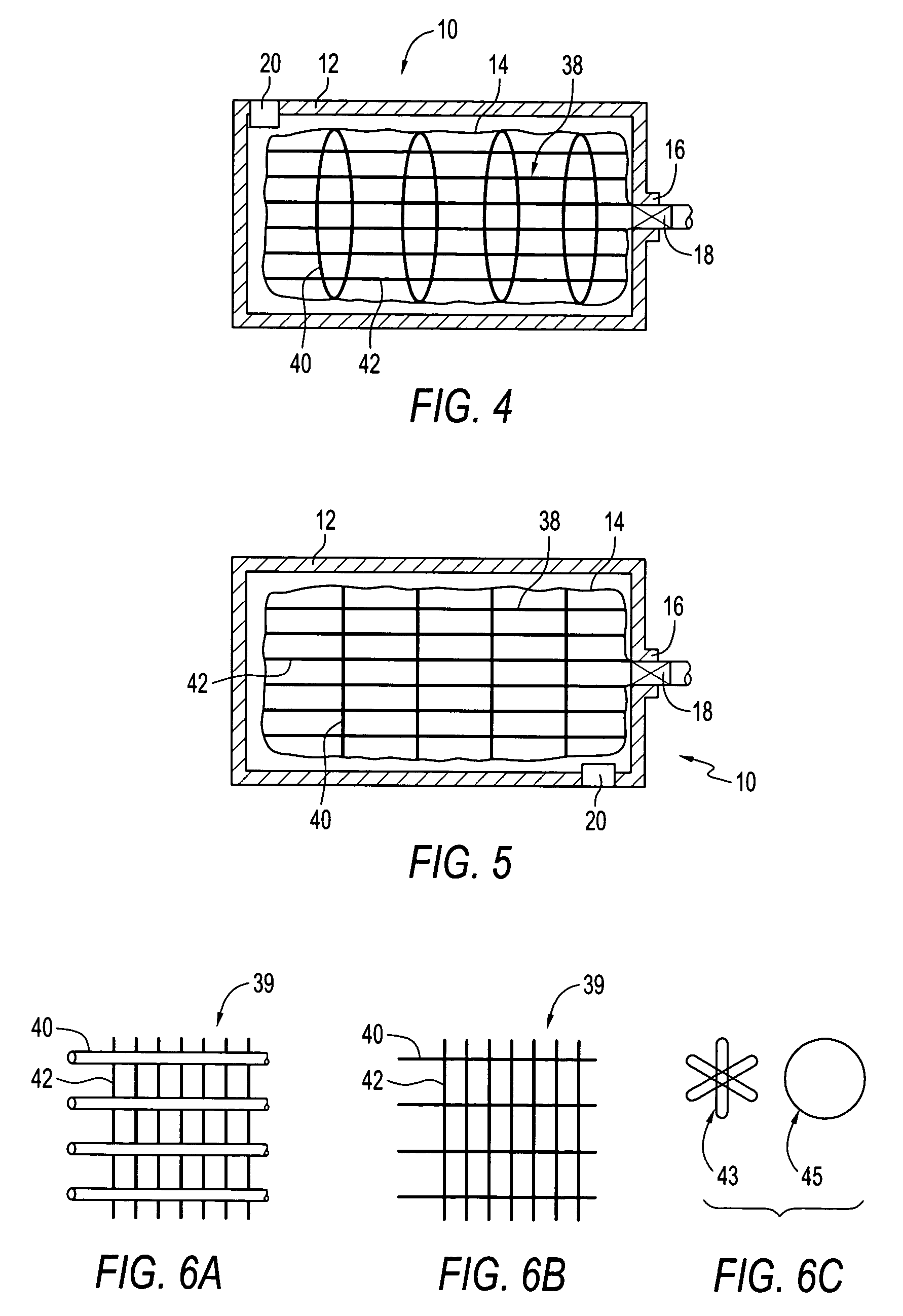

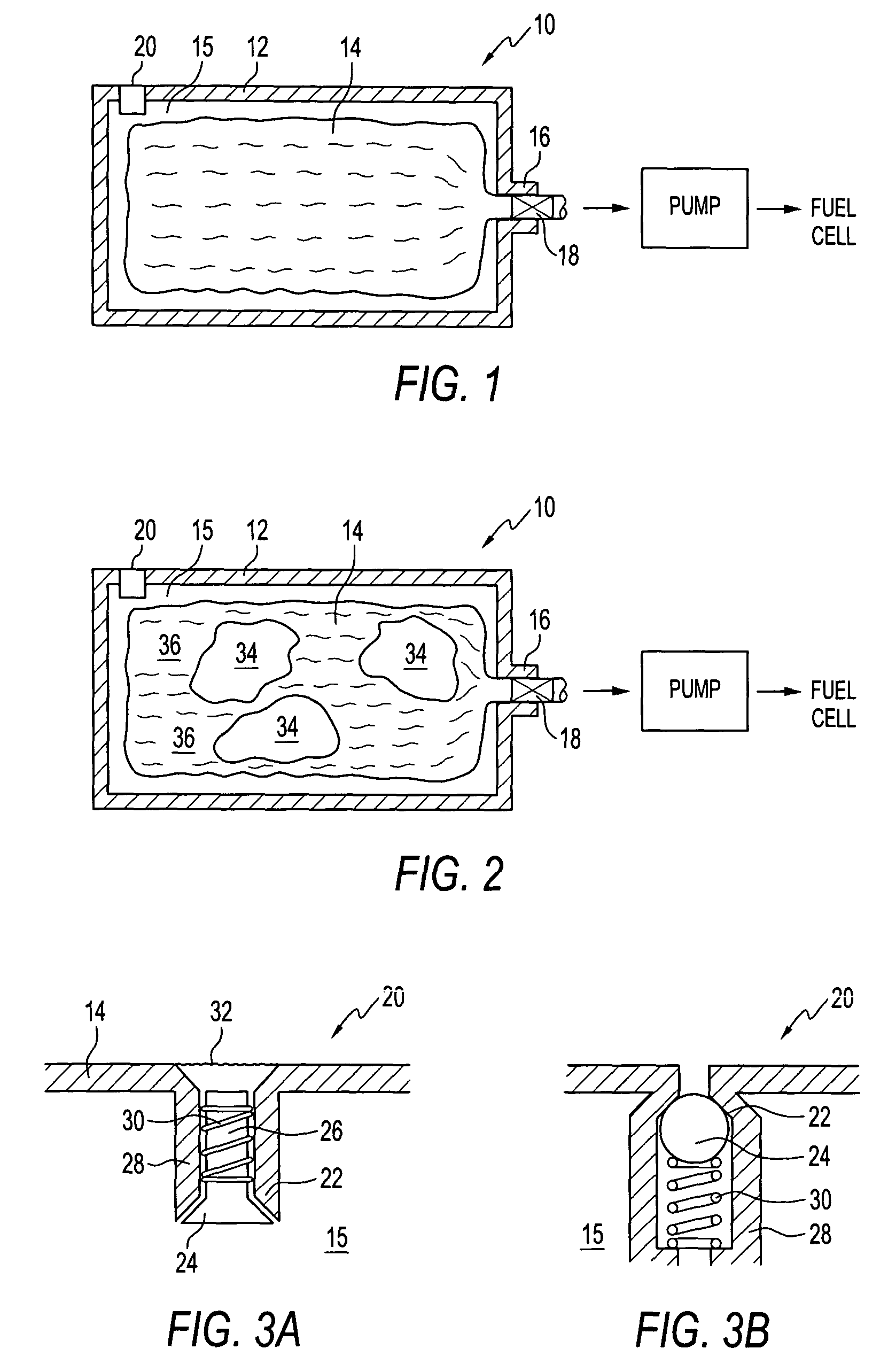

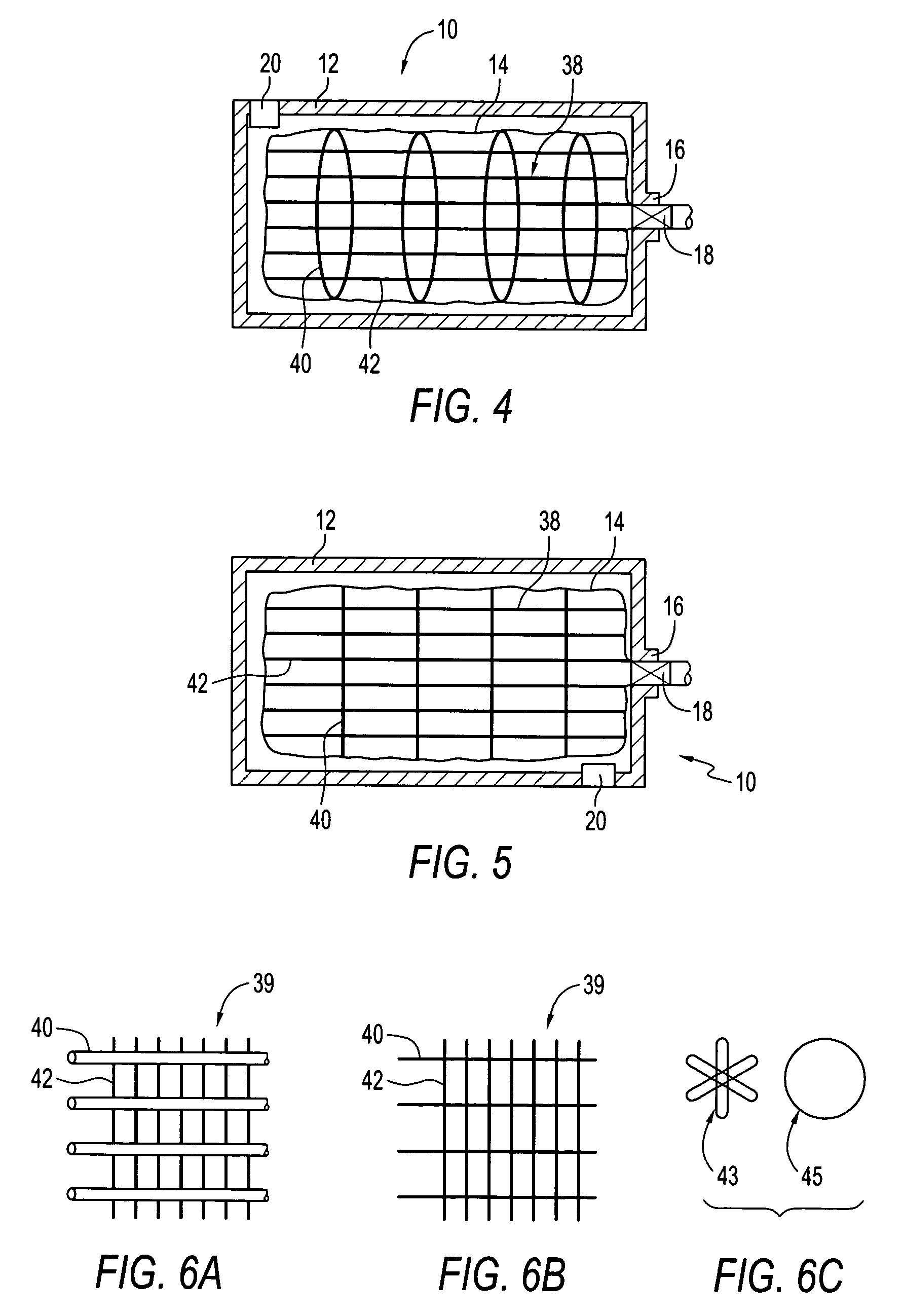

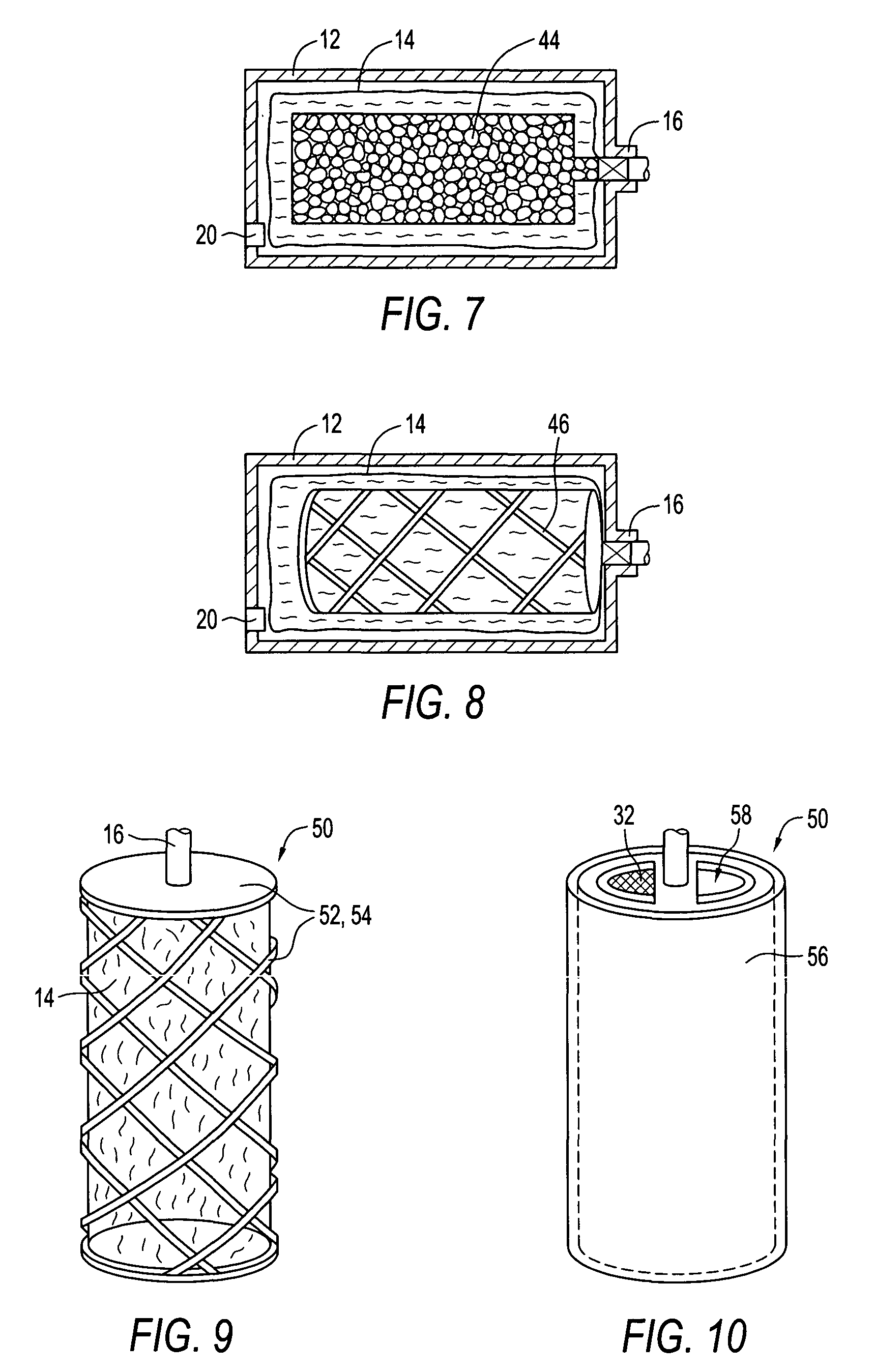

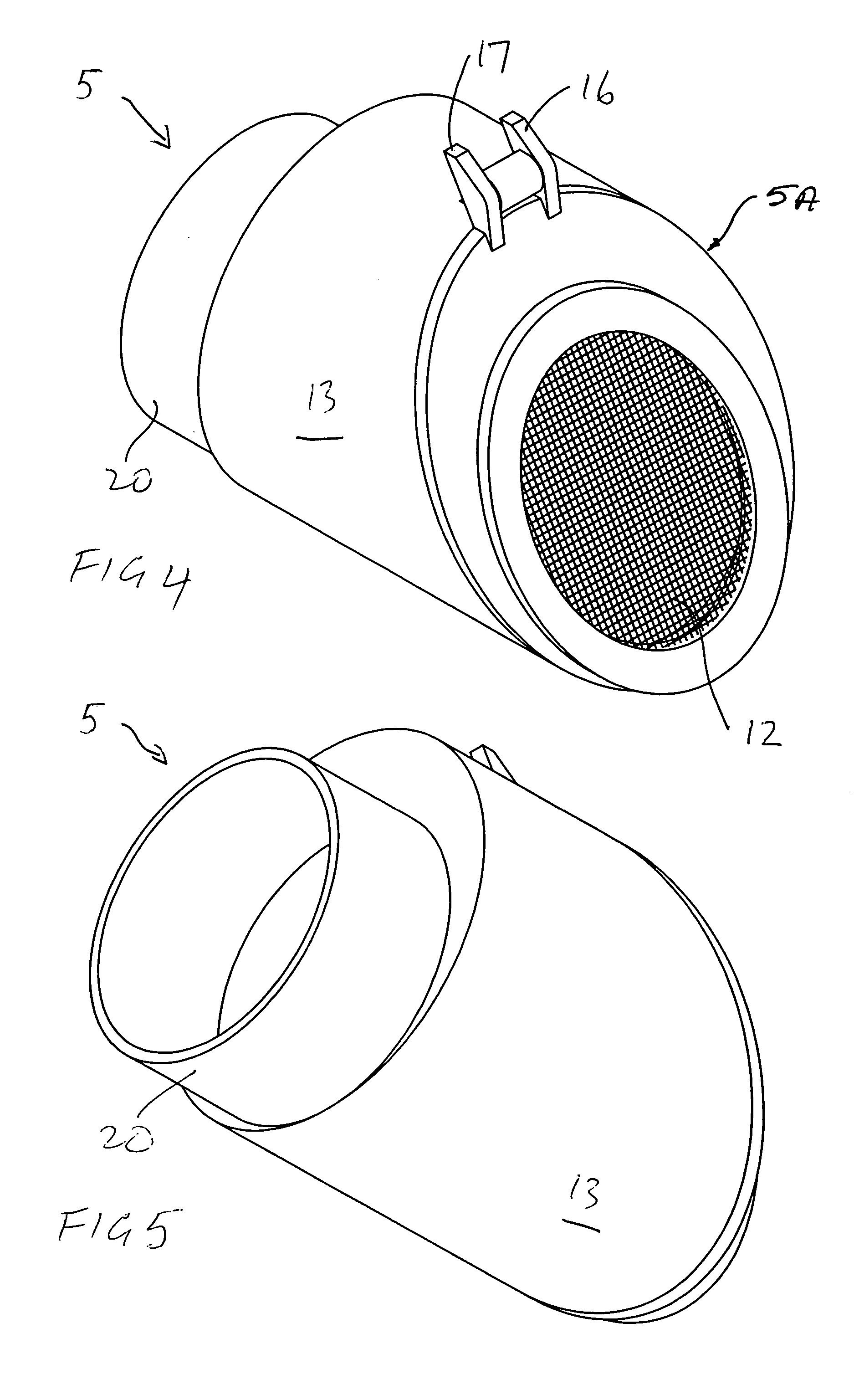

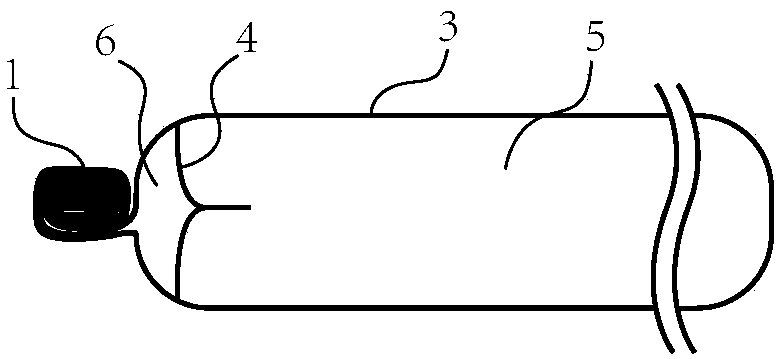

Fuel cartridge with flexible liner

A cartridge connectable to a fuel cell is disclosed. The cartridge comprises an outer casing and an inner flexible liner containing fuel for the fuel cell. The inner flexible liner may have an insert disposed inside the inner liner to facilitate the transport of fuel from the cartridge to the fuel cell. The insert minimizes the fuel that is trapped within the cartridge. The inner flexible liner can be used without the outer casing. The outer casing can be substantially rigid or flexible. The cartridge is also adaptable to receive byproducts from the fuel cell. The cartridge can also be pressurized to push fuel to the fuel cell. Unidirectional relief valves are also disclosed to prevent internal pressure in the cartridge from becoming too high or too low.

Owner:INTELLIGENT ENERGY LTD

Fuel cartridge with flexible liner containing insert

Owner:INTELLIGENT ENERGY LTD

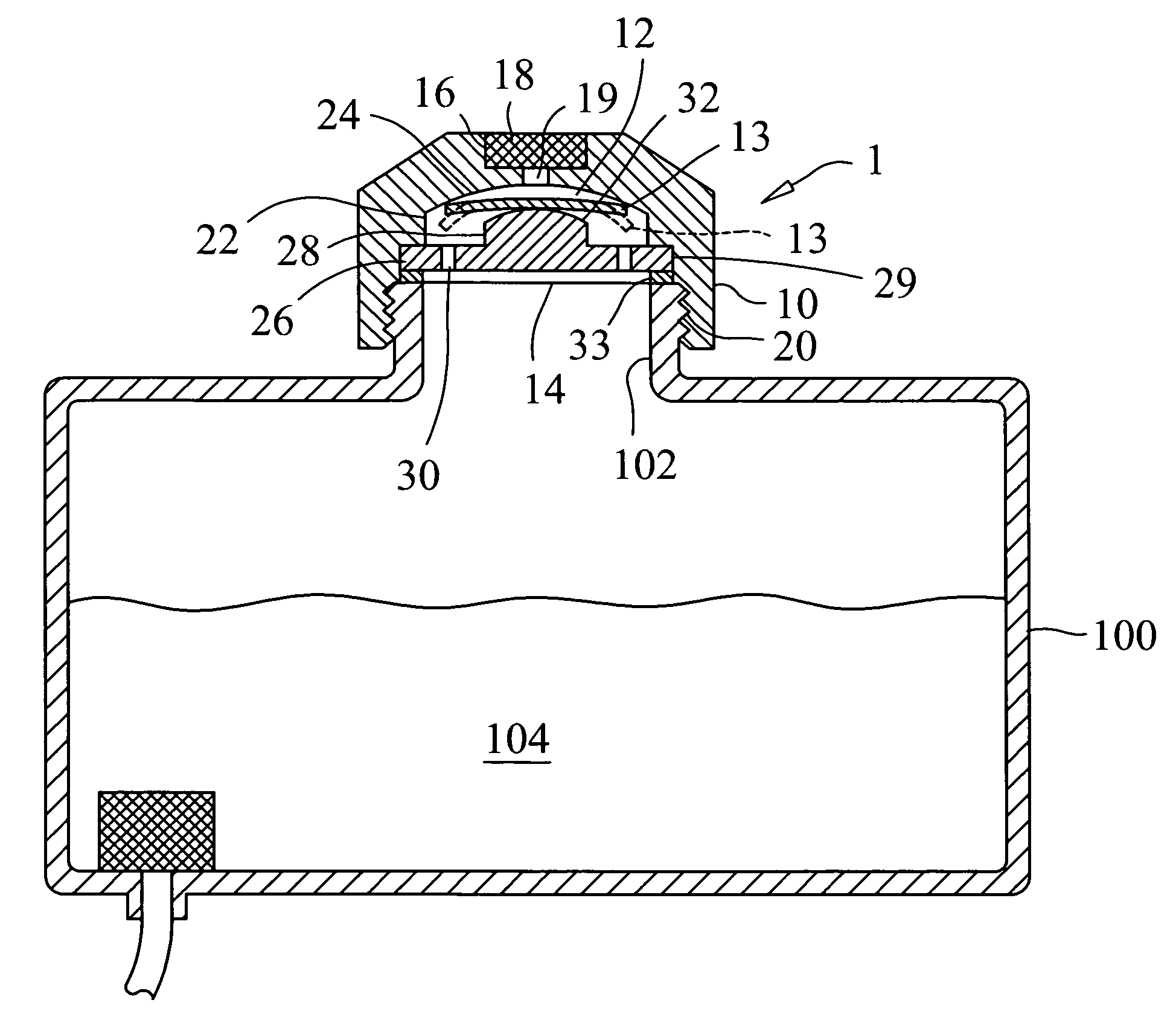

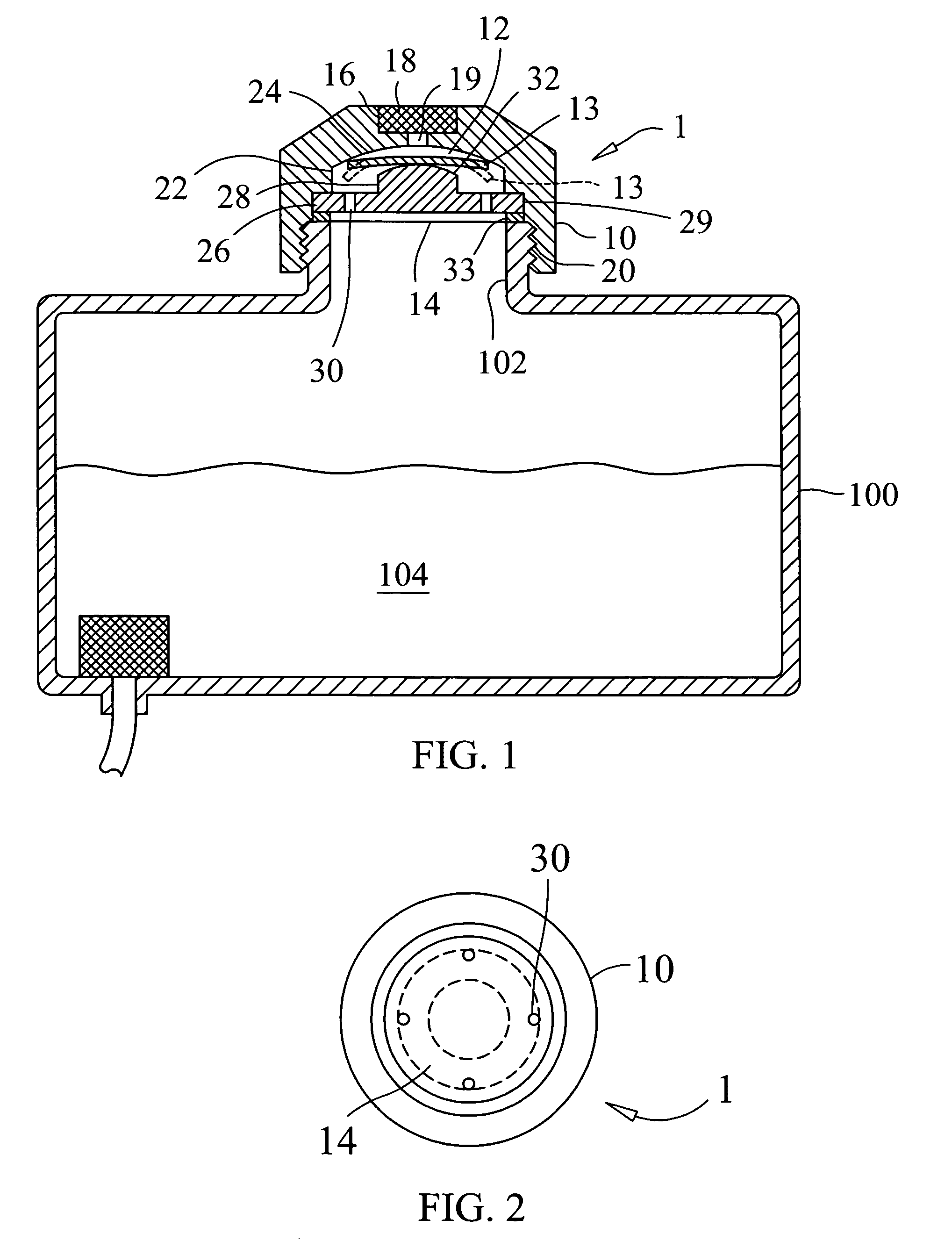

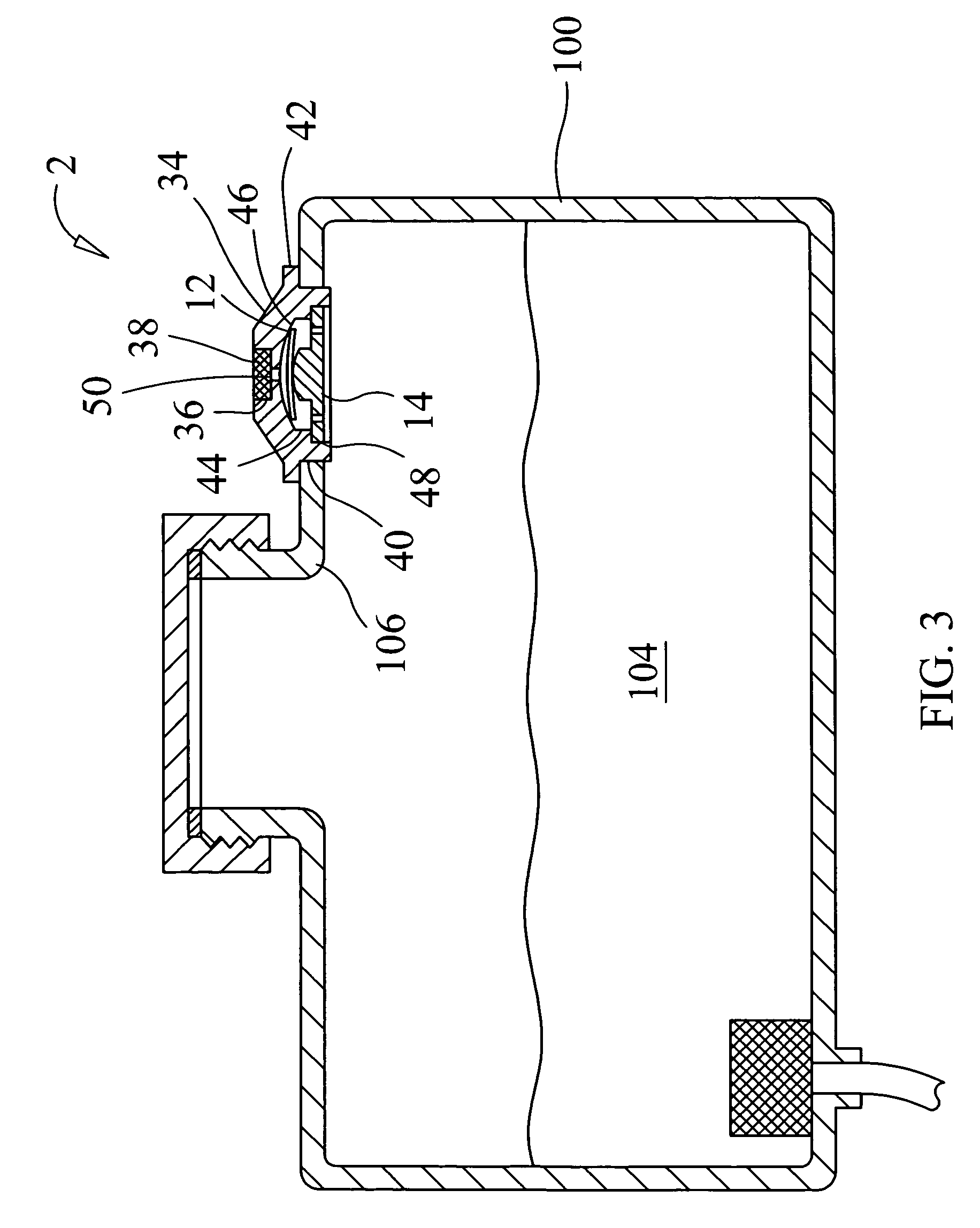

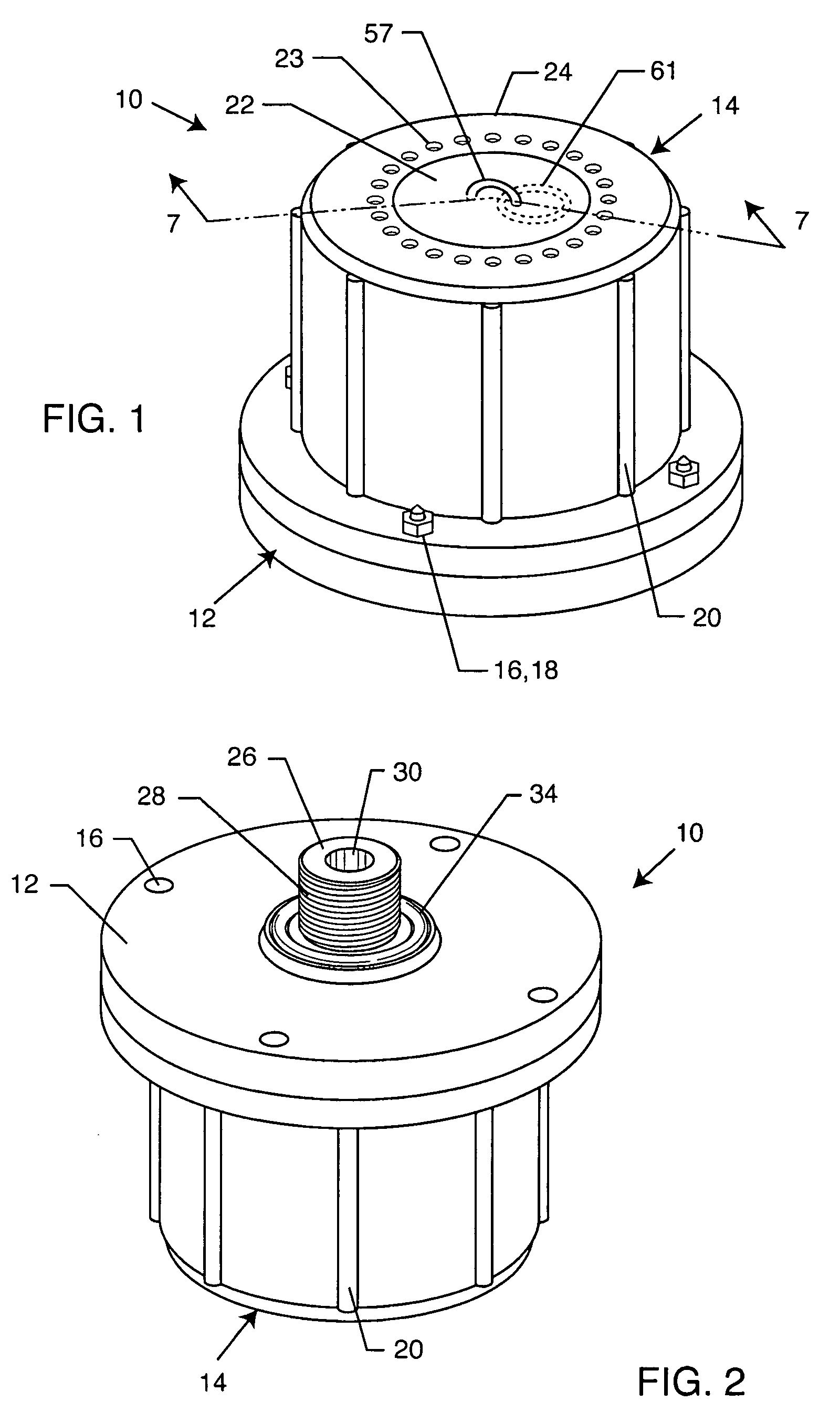

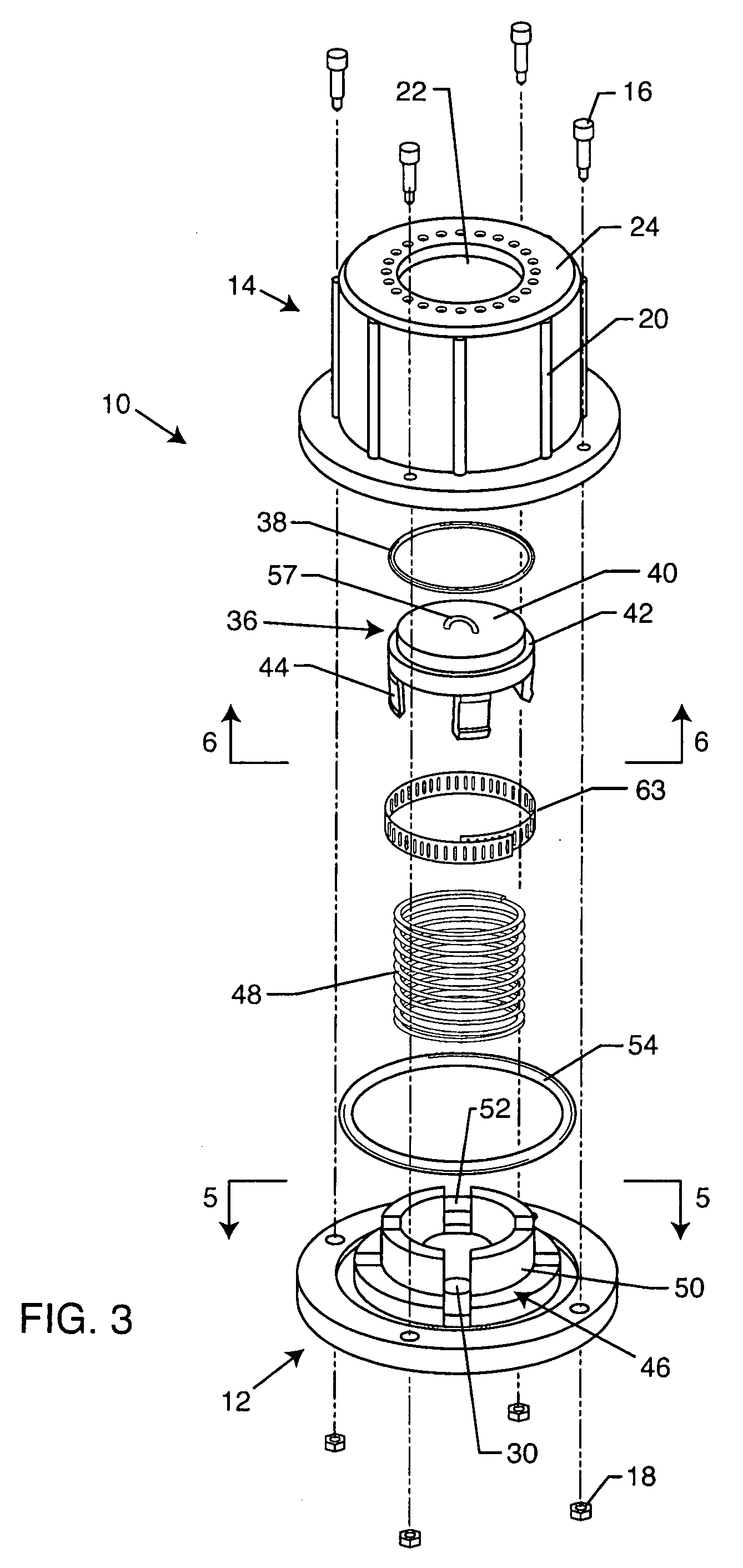

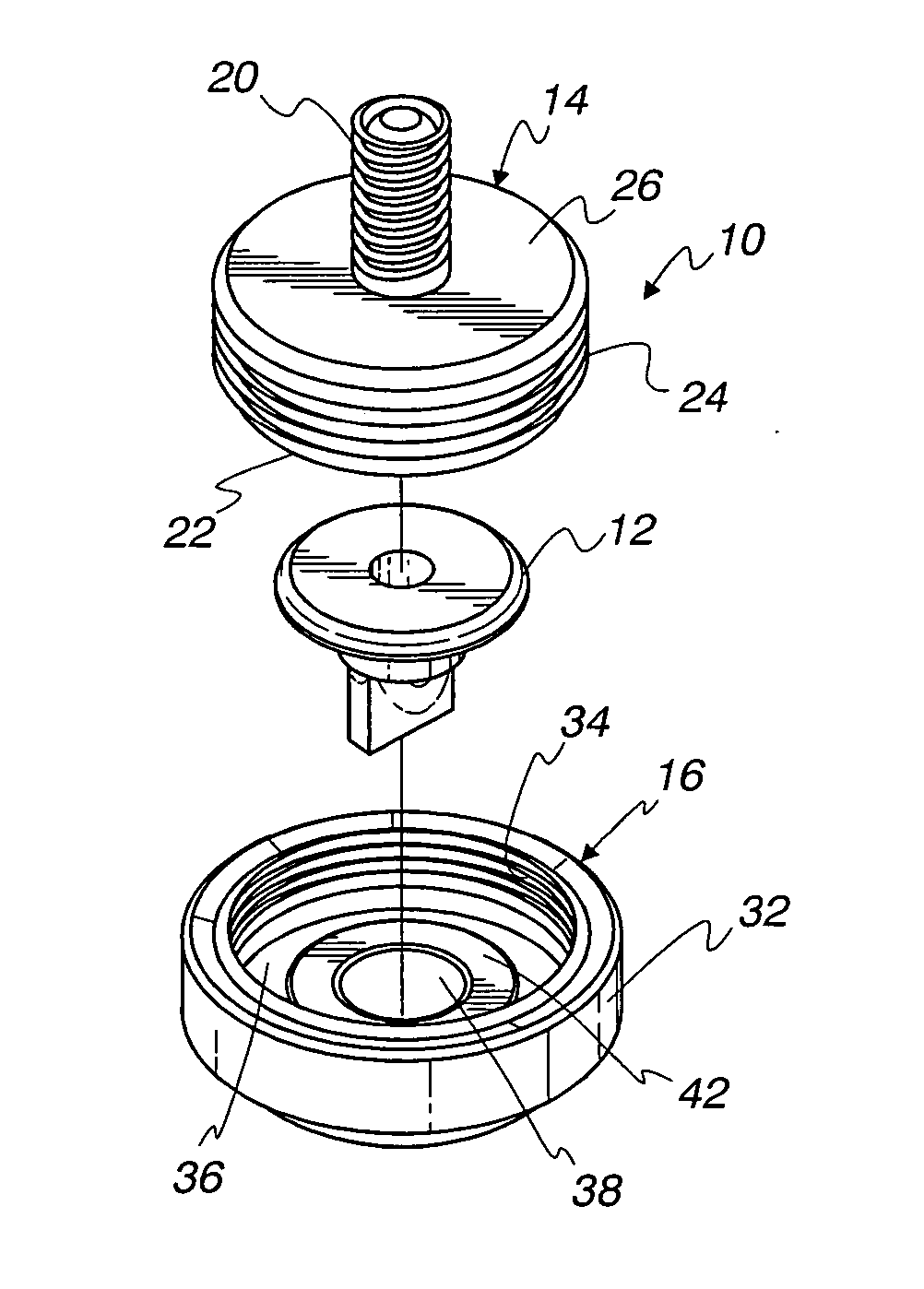

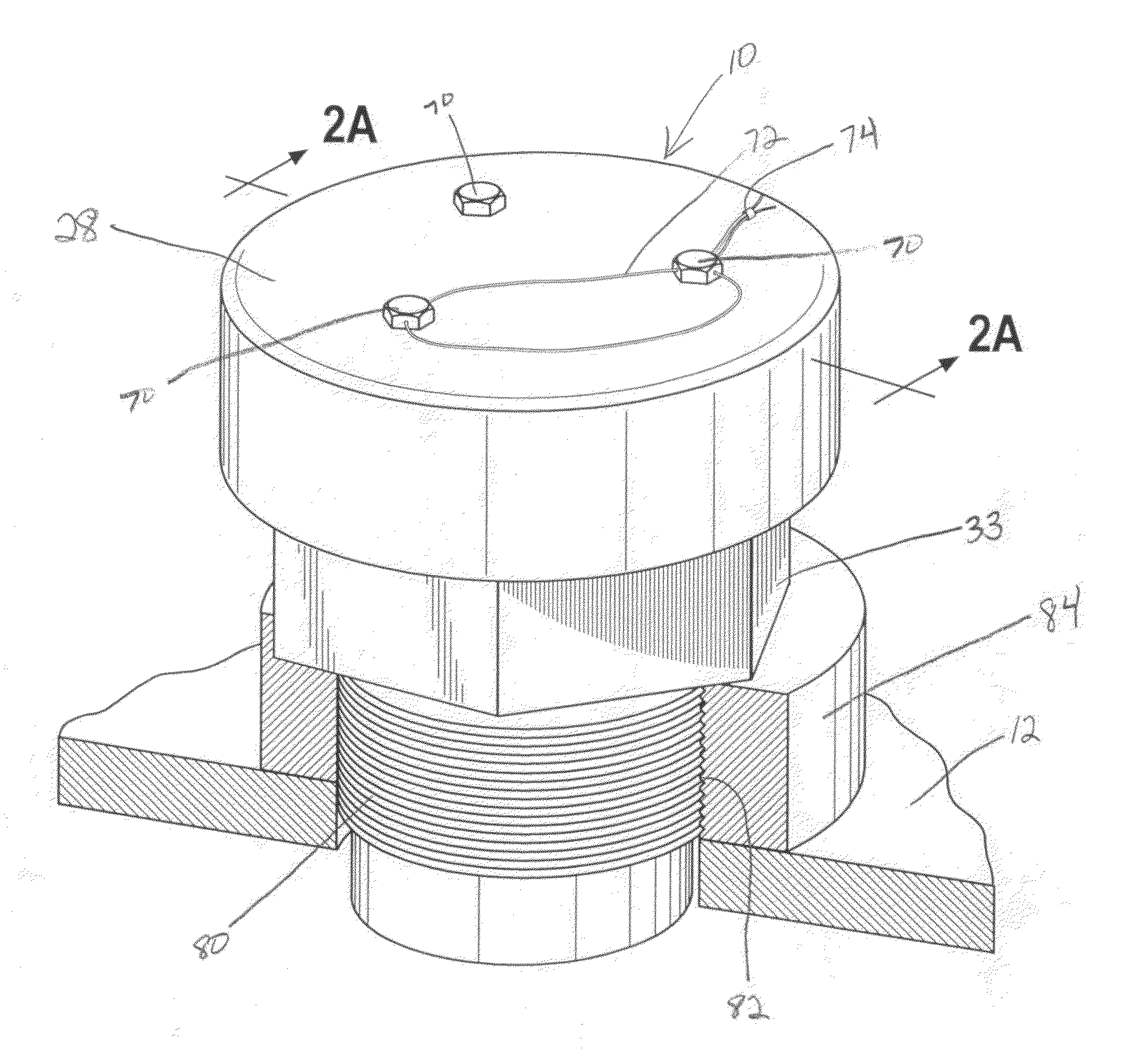

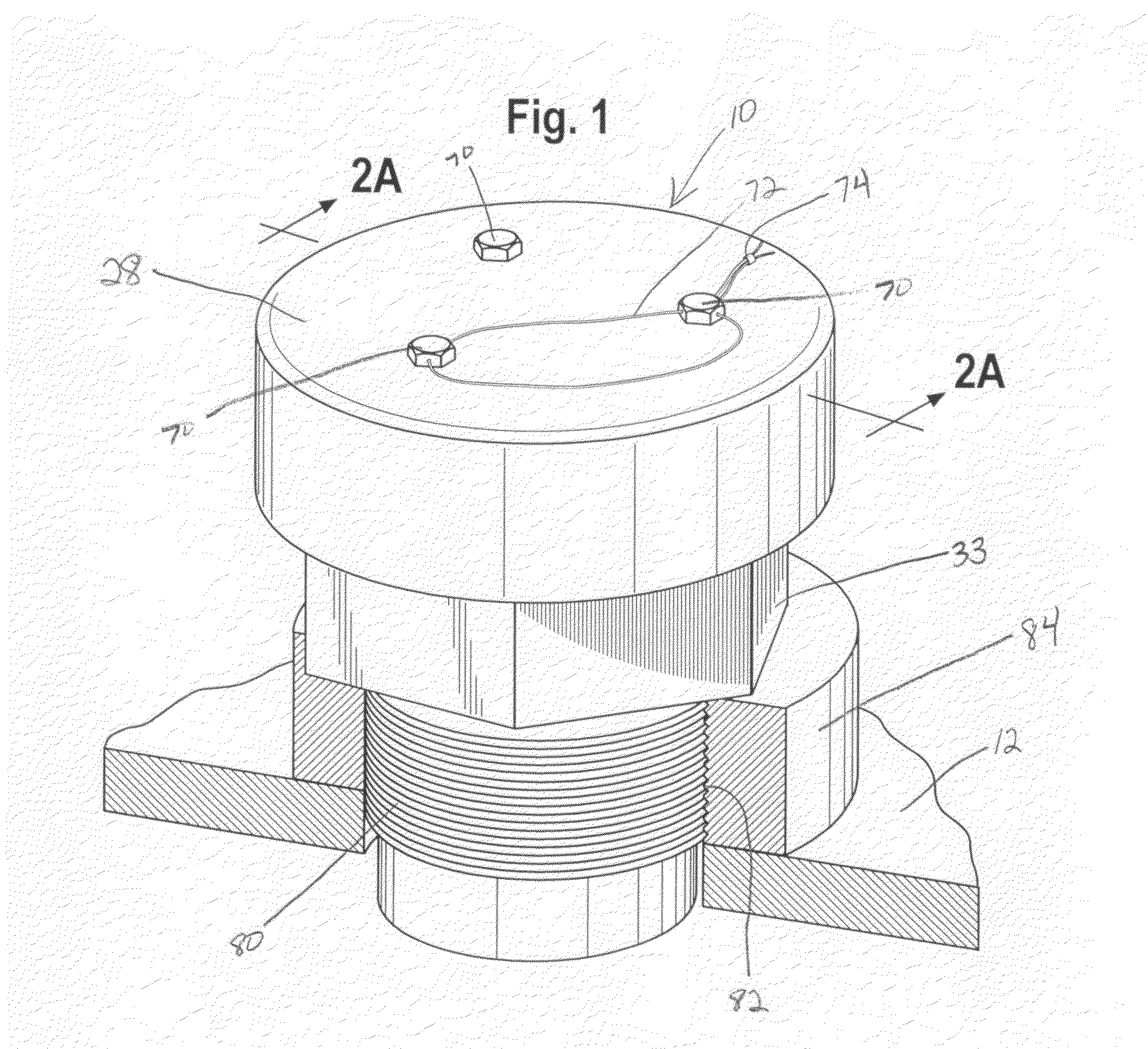

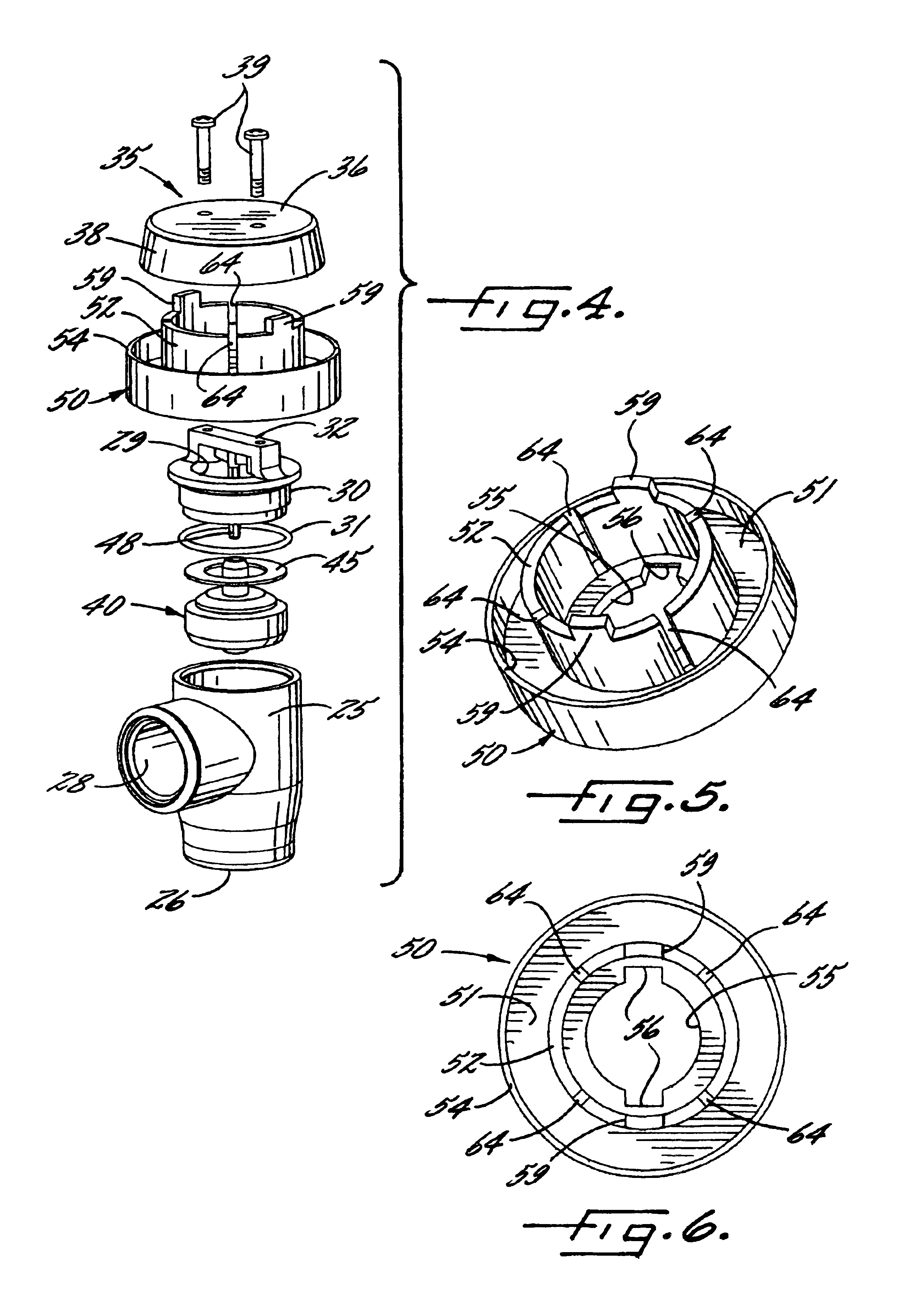

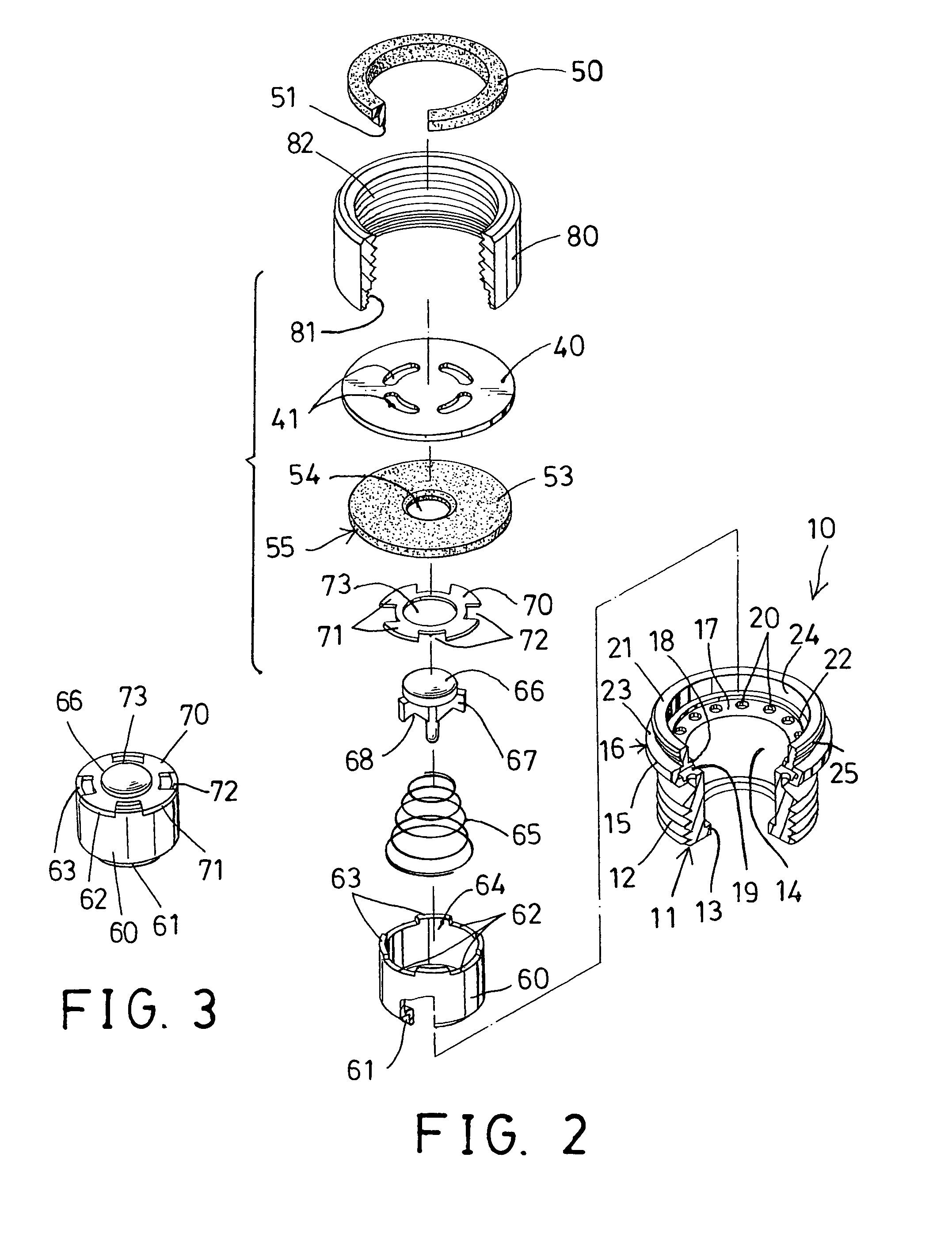

Fuel tank venting system

Owner:COUNTRY INDS TECH

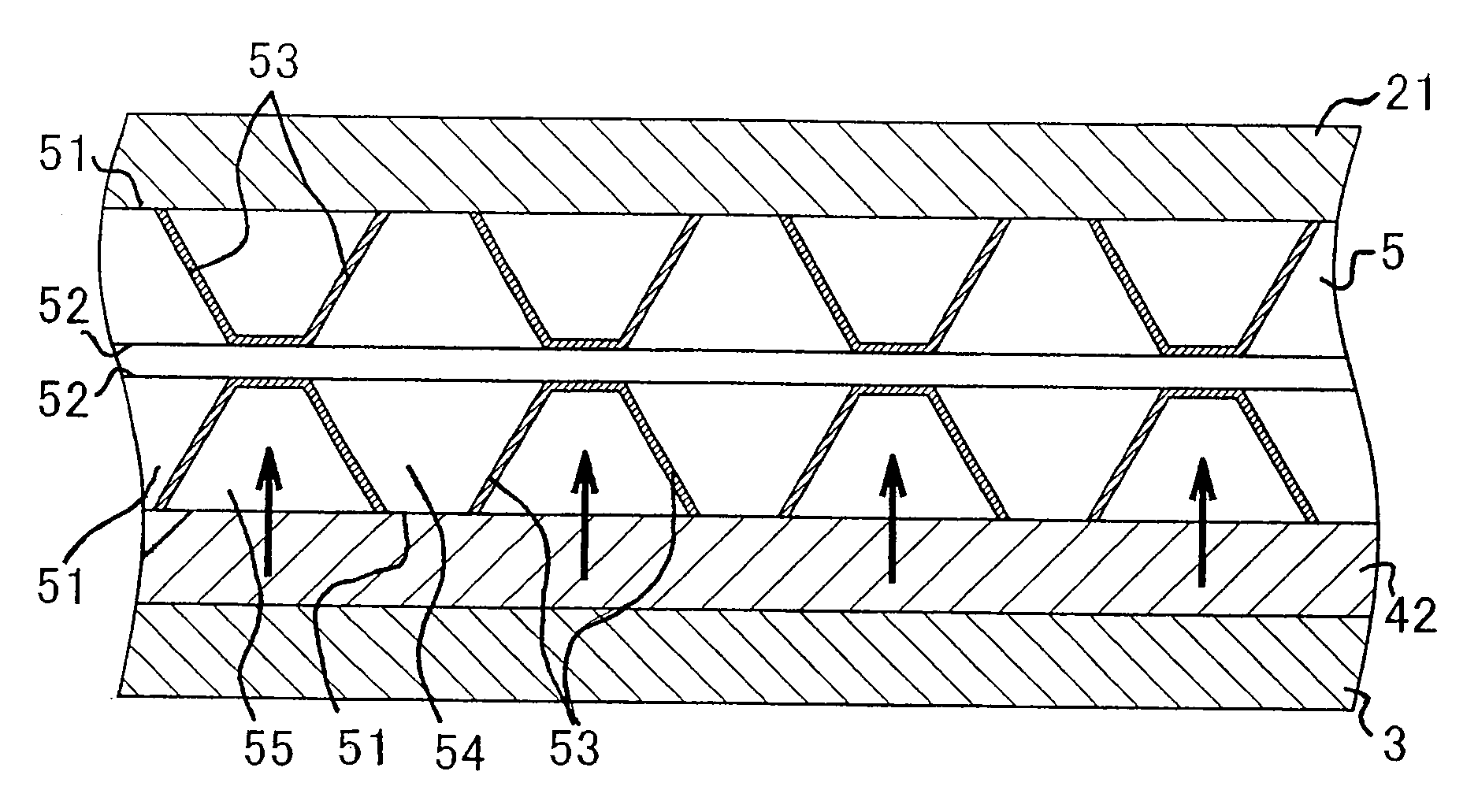

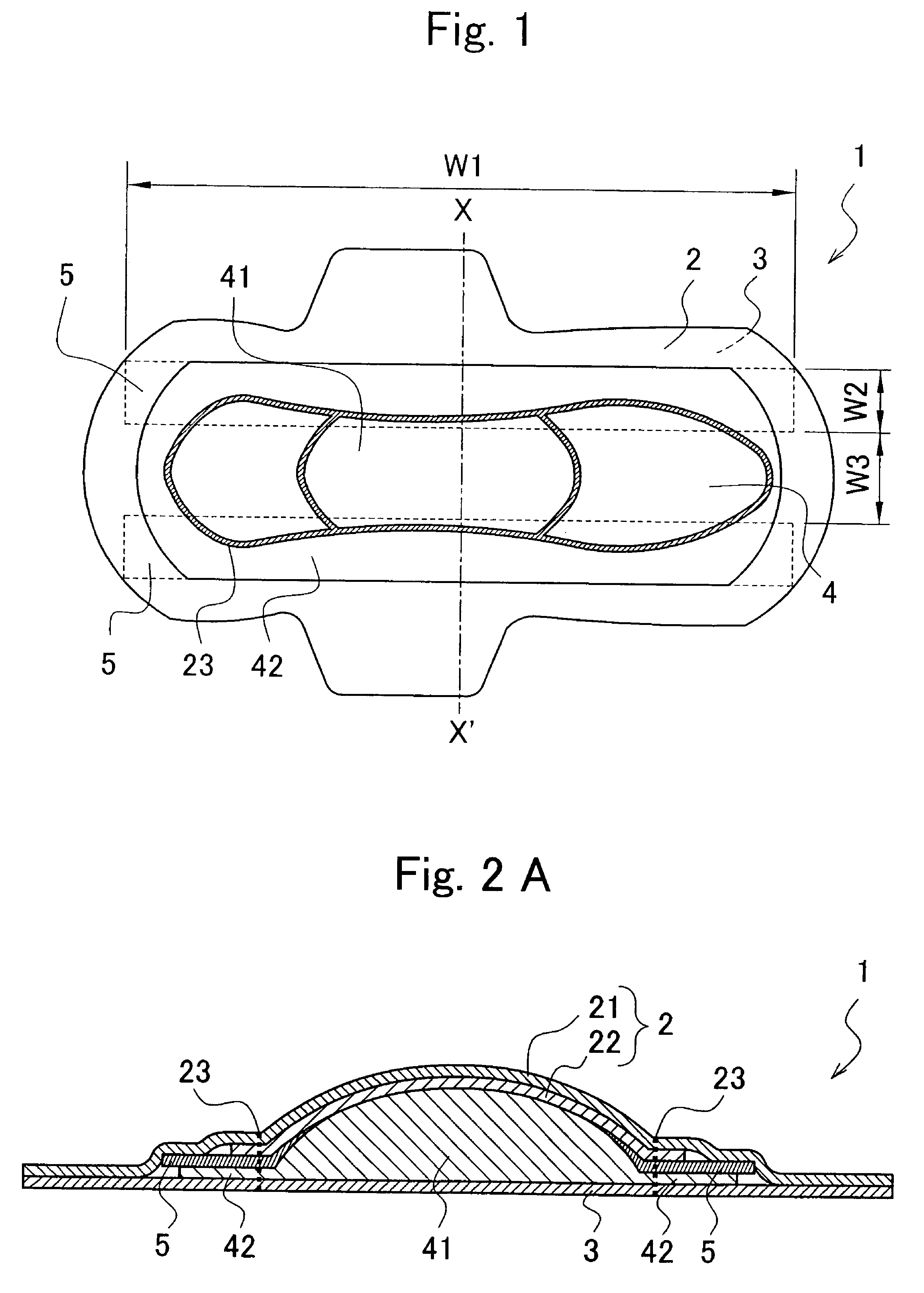

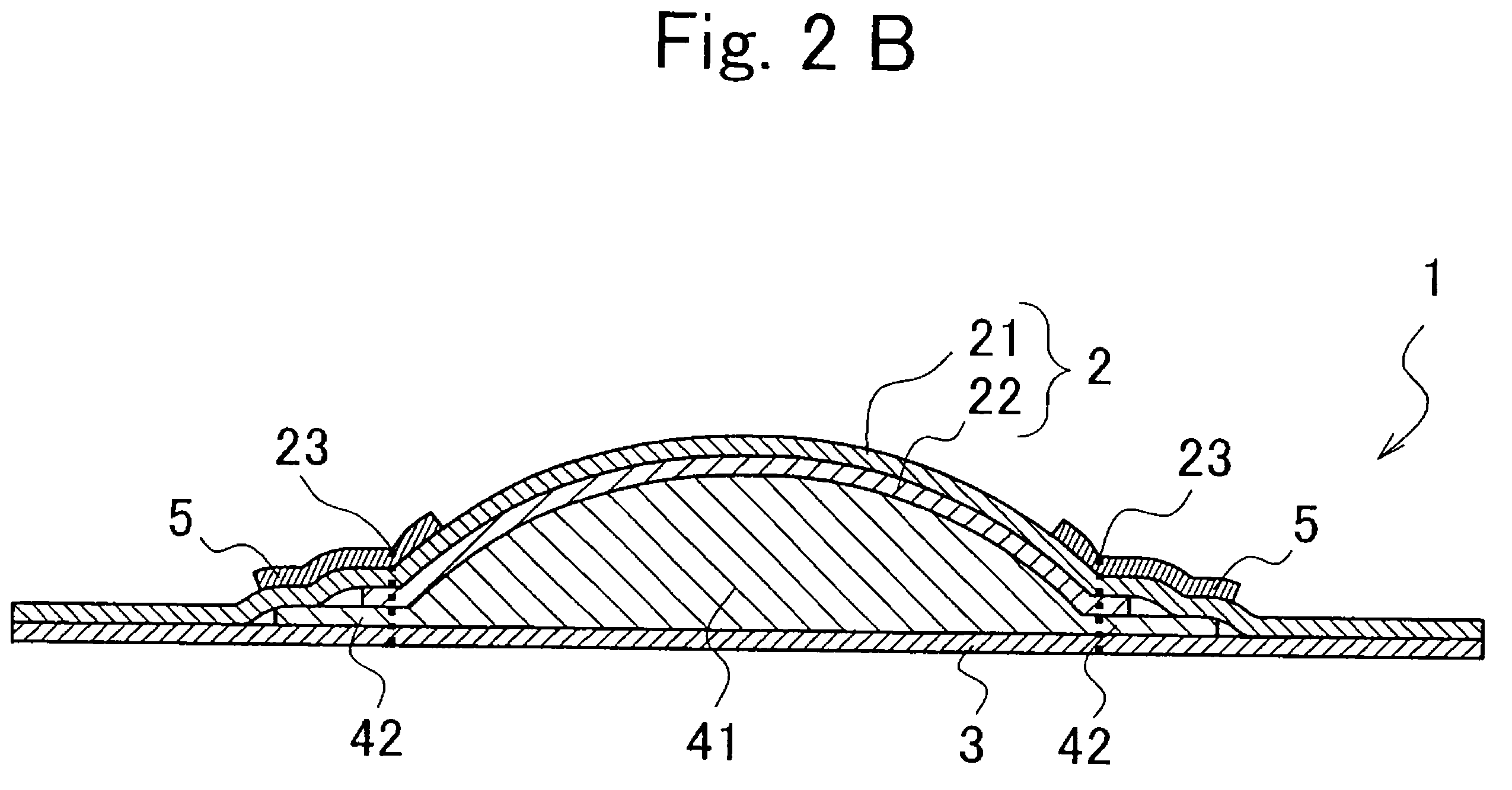

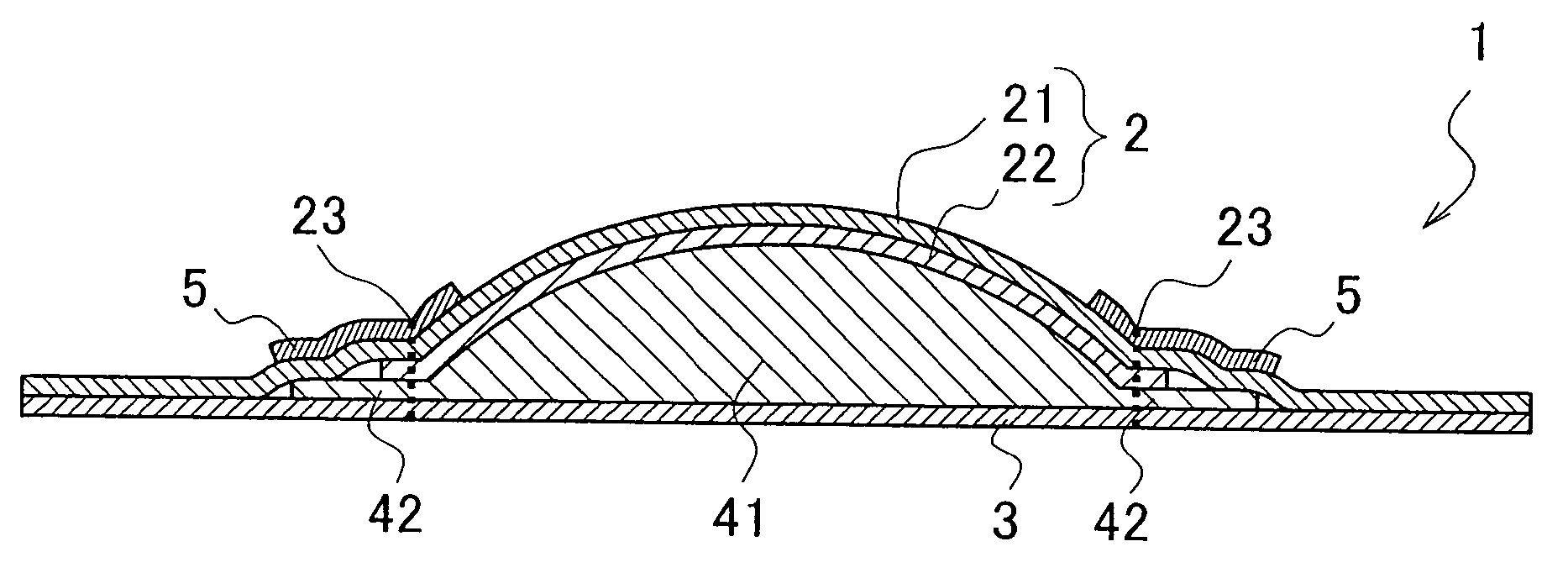

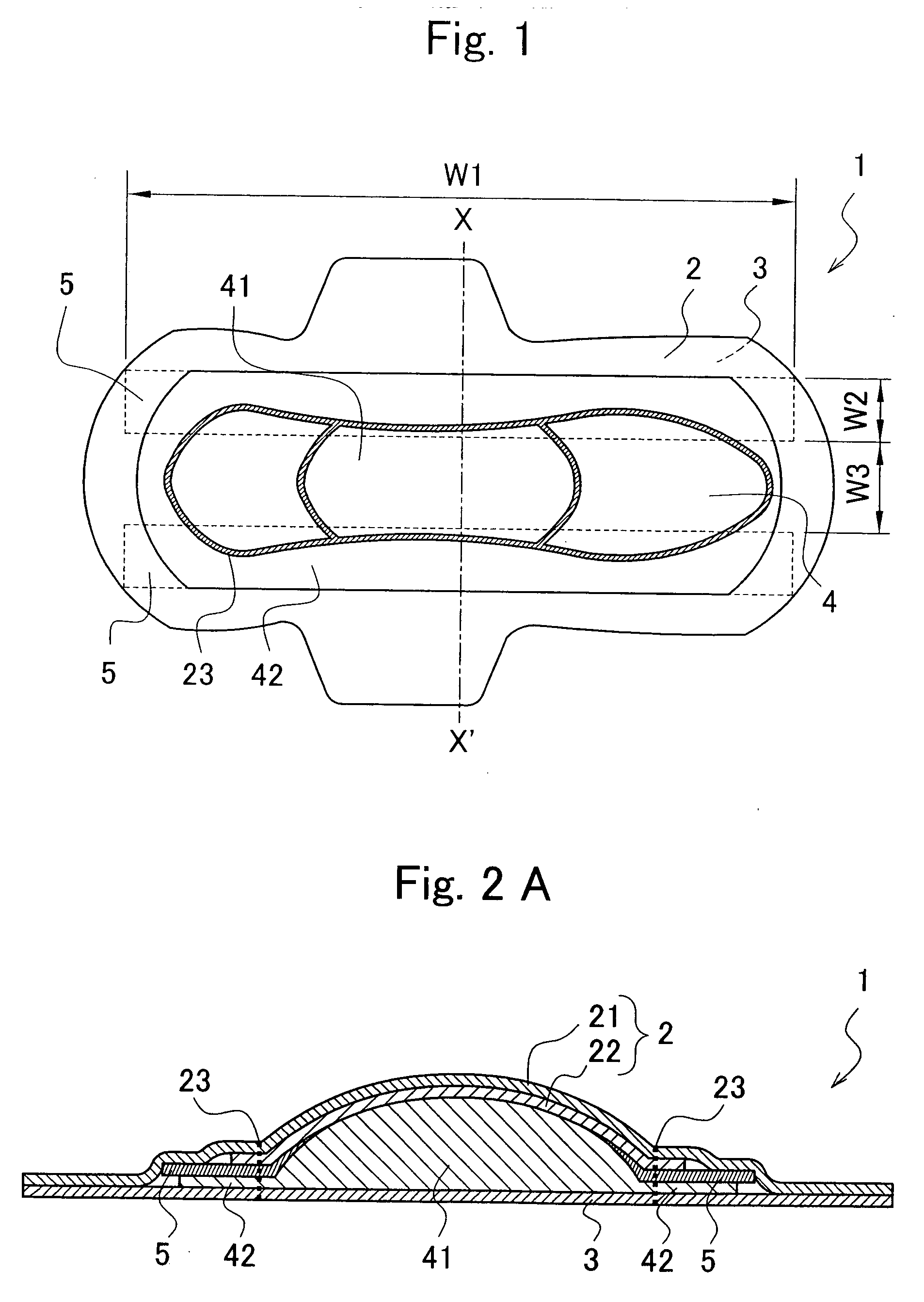

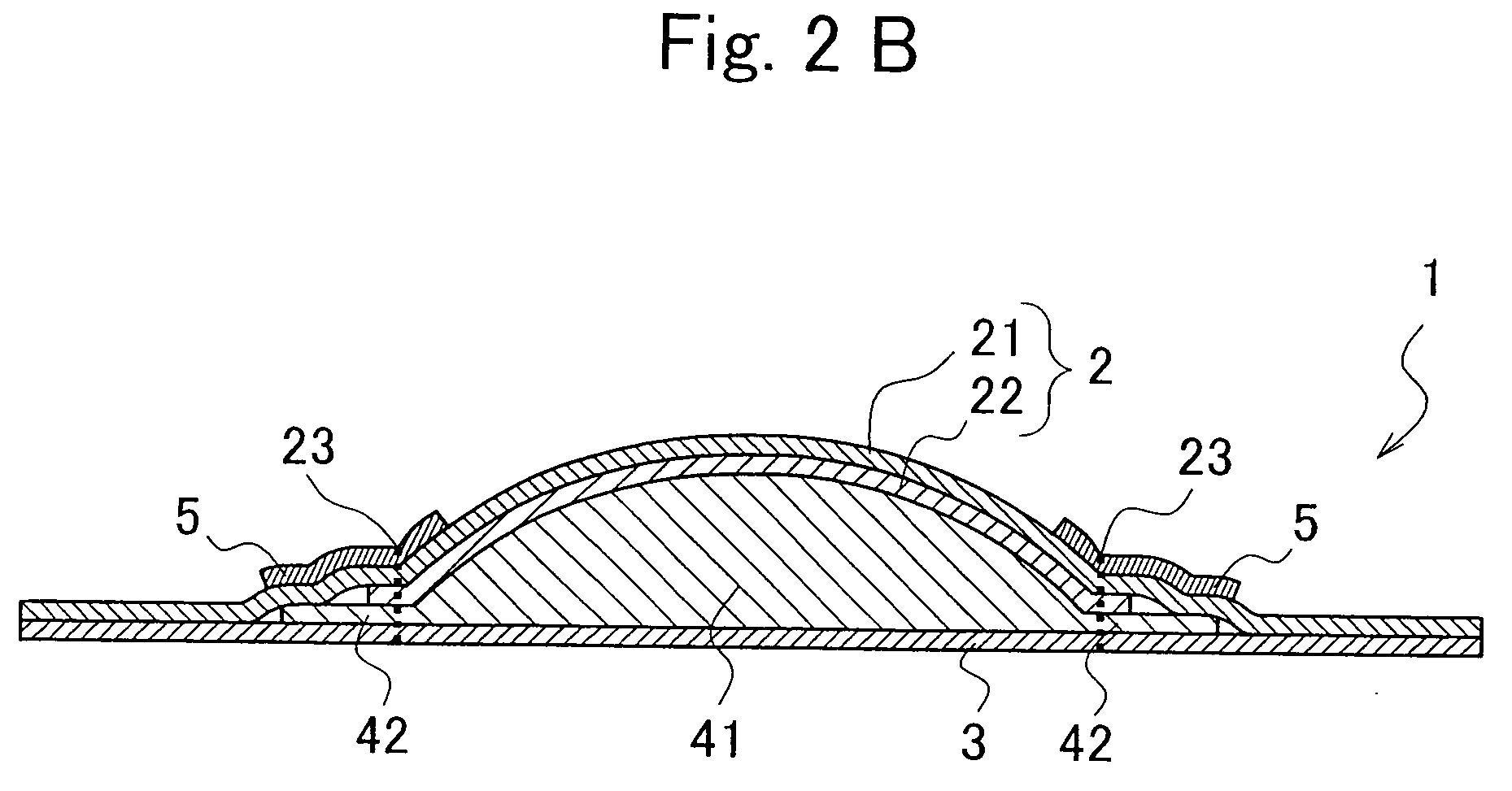

Absorbent article

InactiveUS7976524B2Exact replacement timeReduce feelingsValve members for absorbing fluid energyRefuse receptaclesEngineeringMechanical engineering

An absorbent article, in which an erroneous impression of replacement time is not given to a wearer, includes an absorbent body, a front sheet covering the absorbent body, and a rear sheet, a pair of masking members being disposed along a longitudinal direction of the absorbent body, close to two ends of a short direction of the absorbent body, the masking members being of porous film having pores continuous in the direction of thickness, the thickness thereof preferably being 0.4 mm or greater under a load of 20 g / cm2. By this means, seepage of fluid at the side margins of the front sheet is deferred and misunderstanding of replacement time by the wearer is prevented.

Owner:UNI CHARM CORP

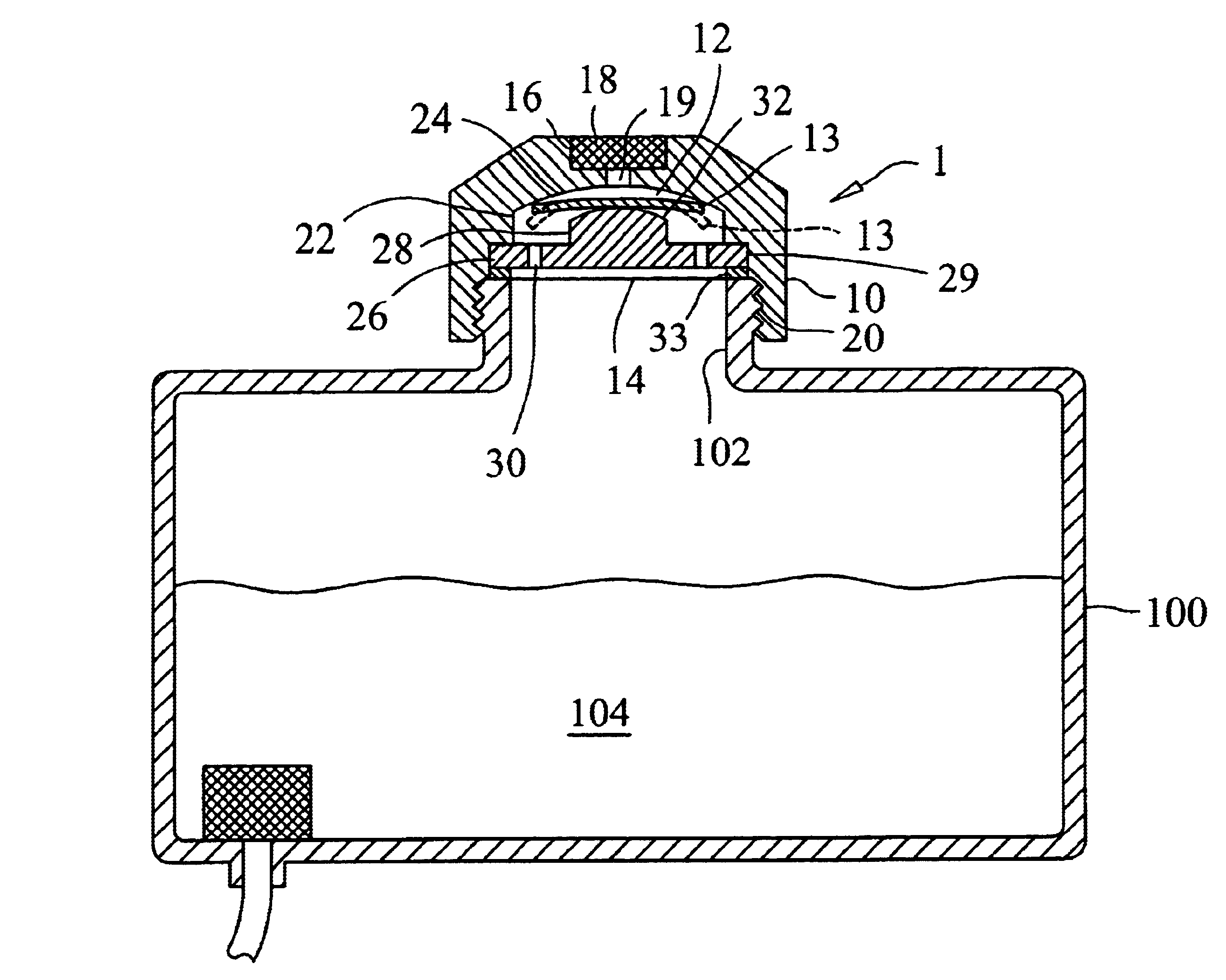

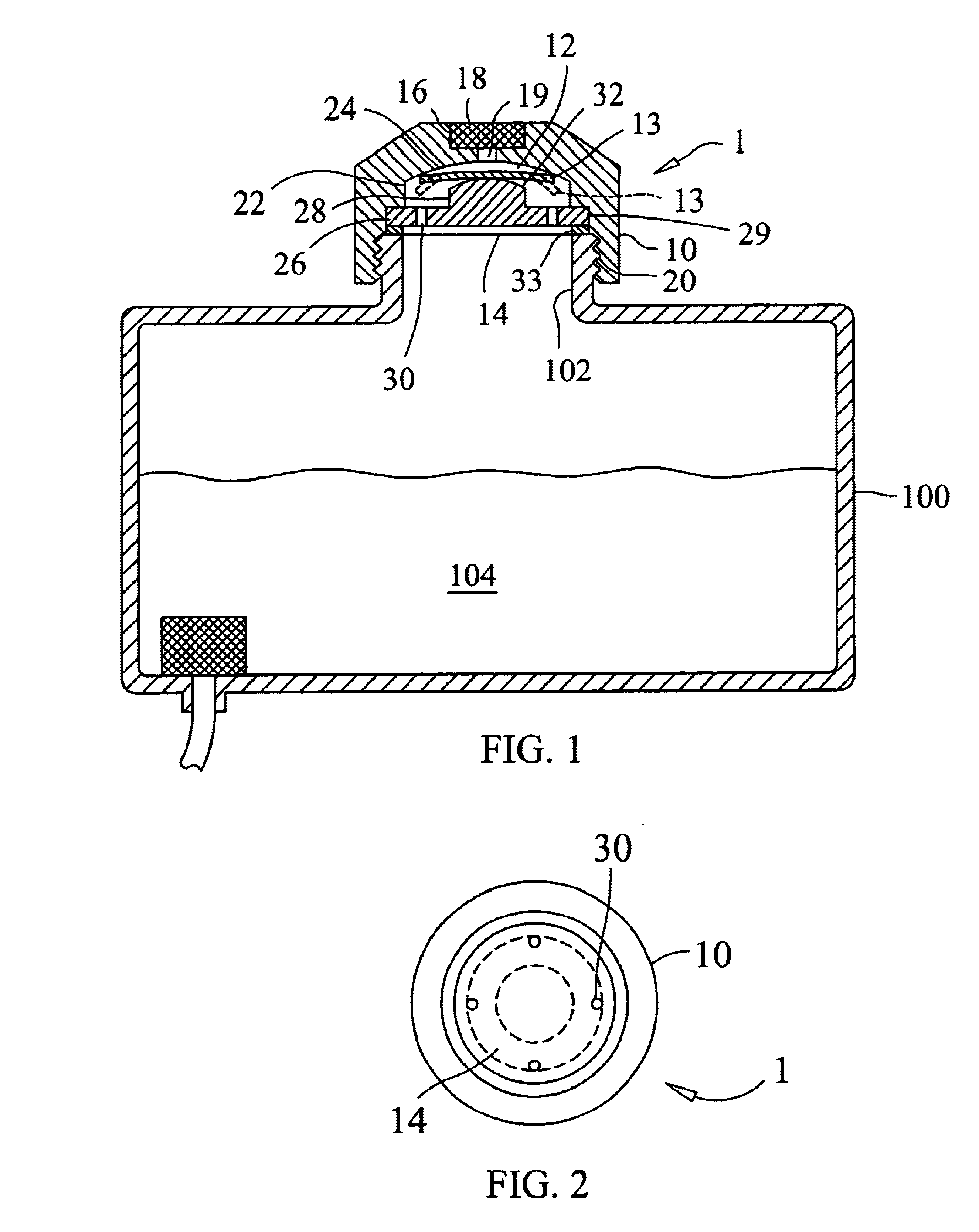

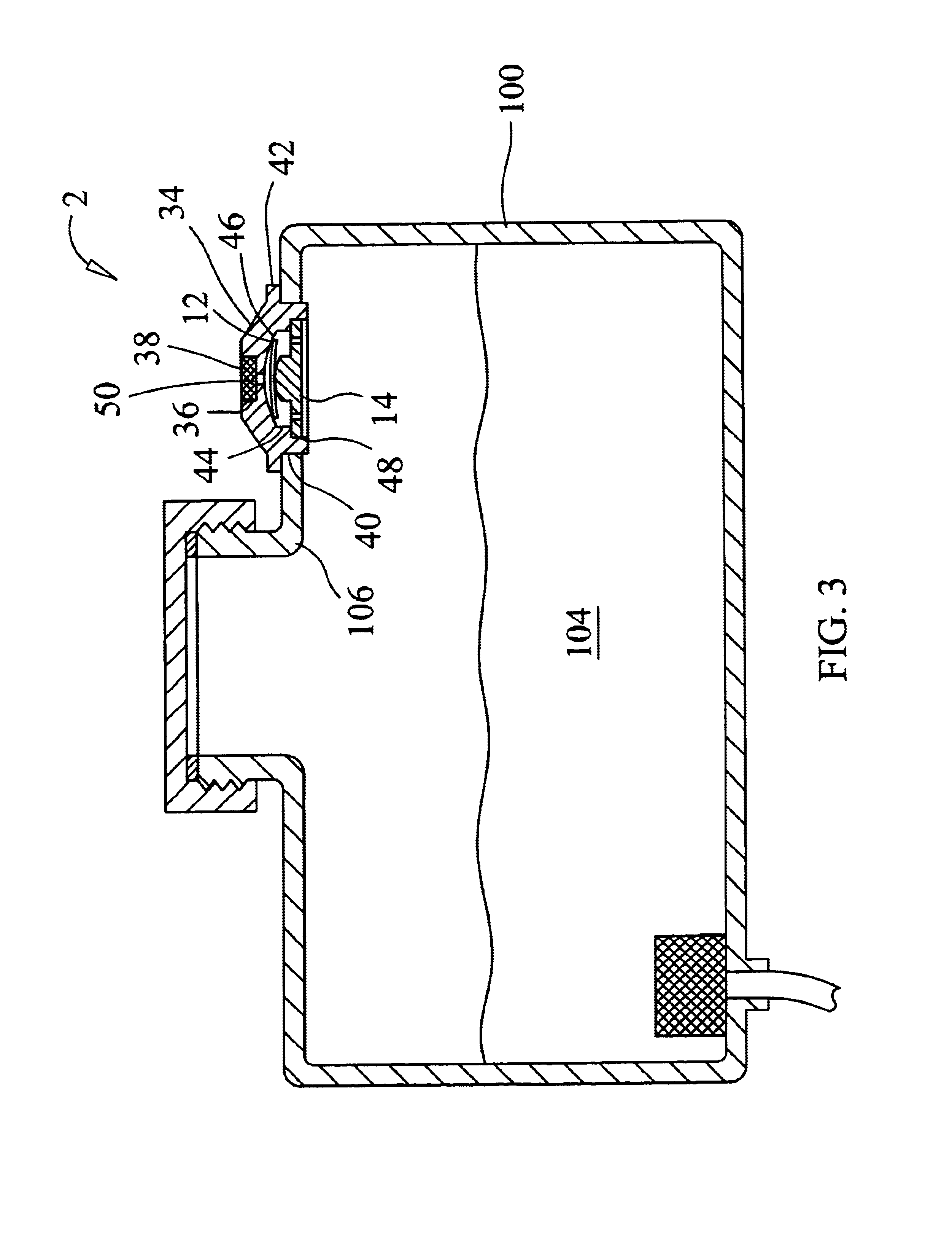

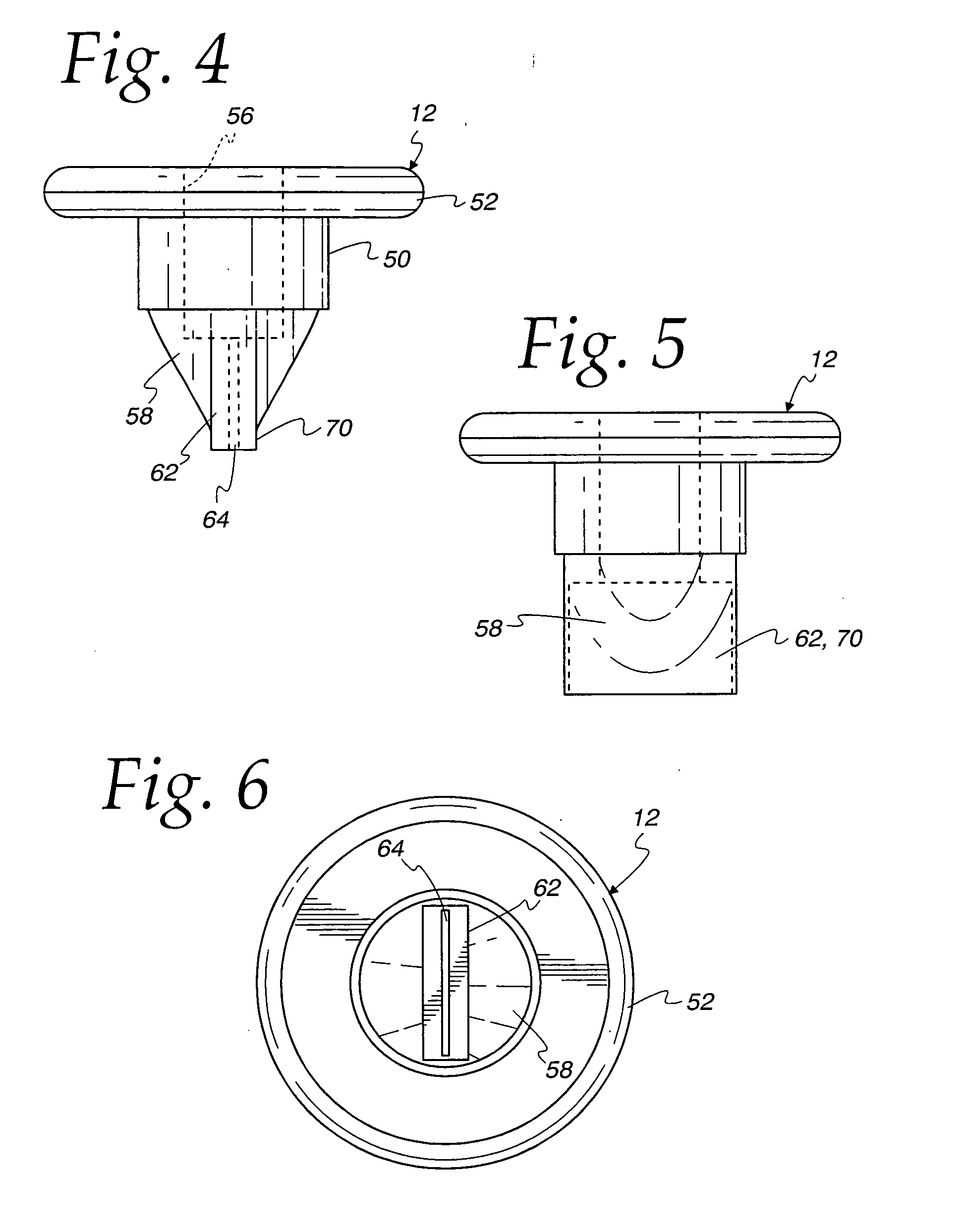

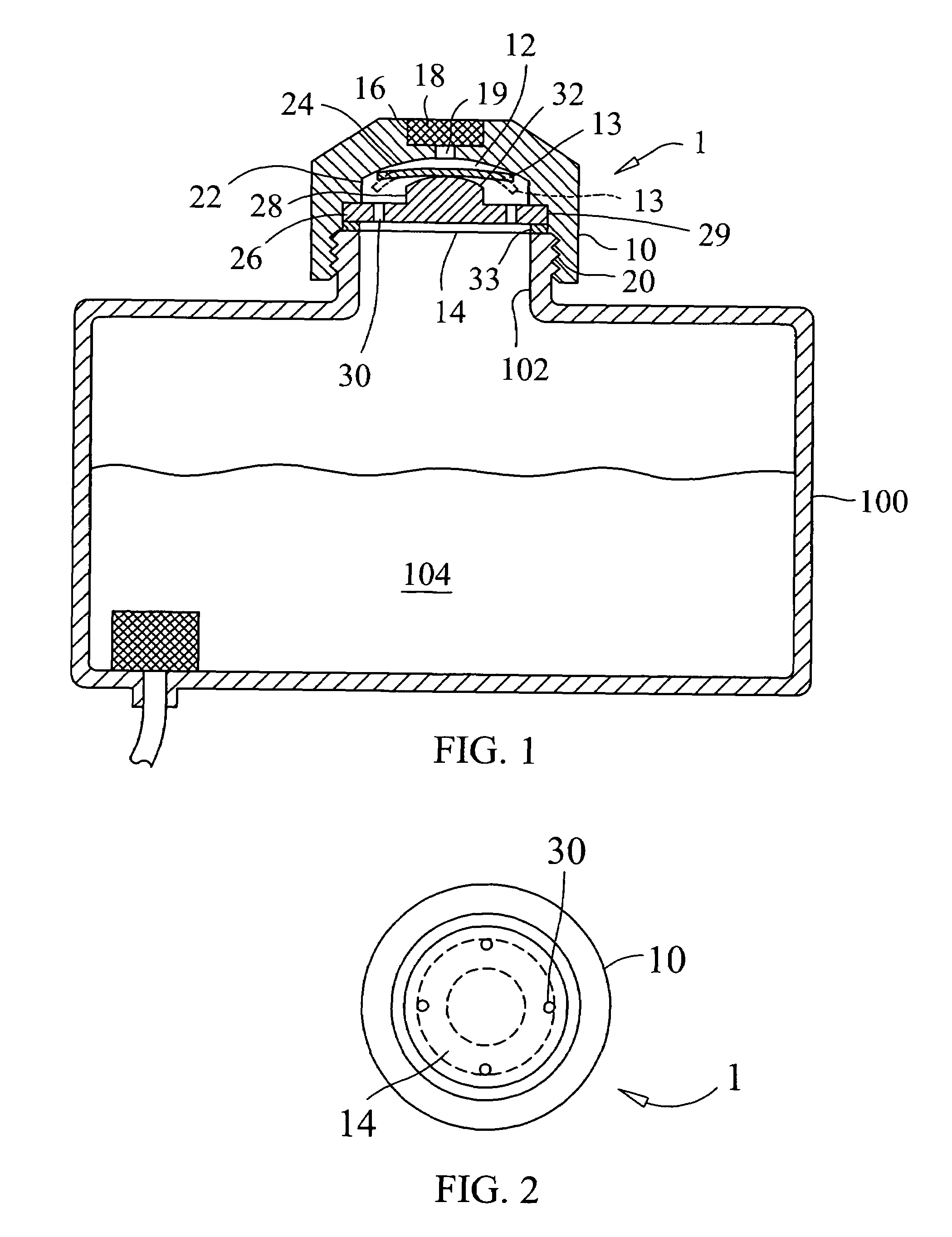

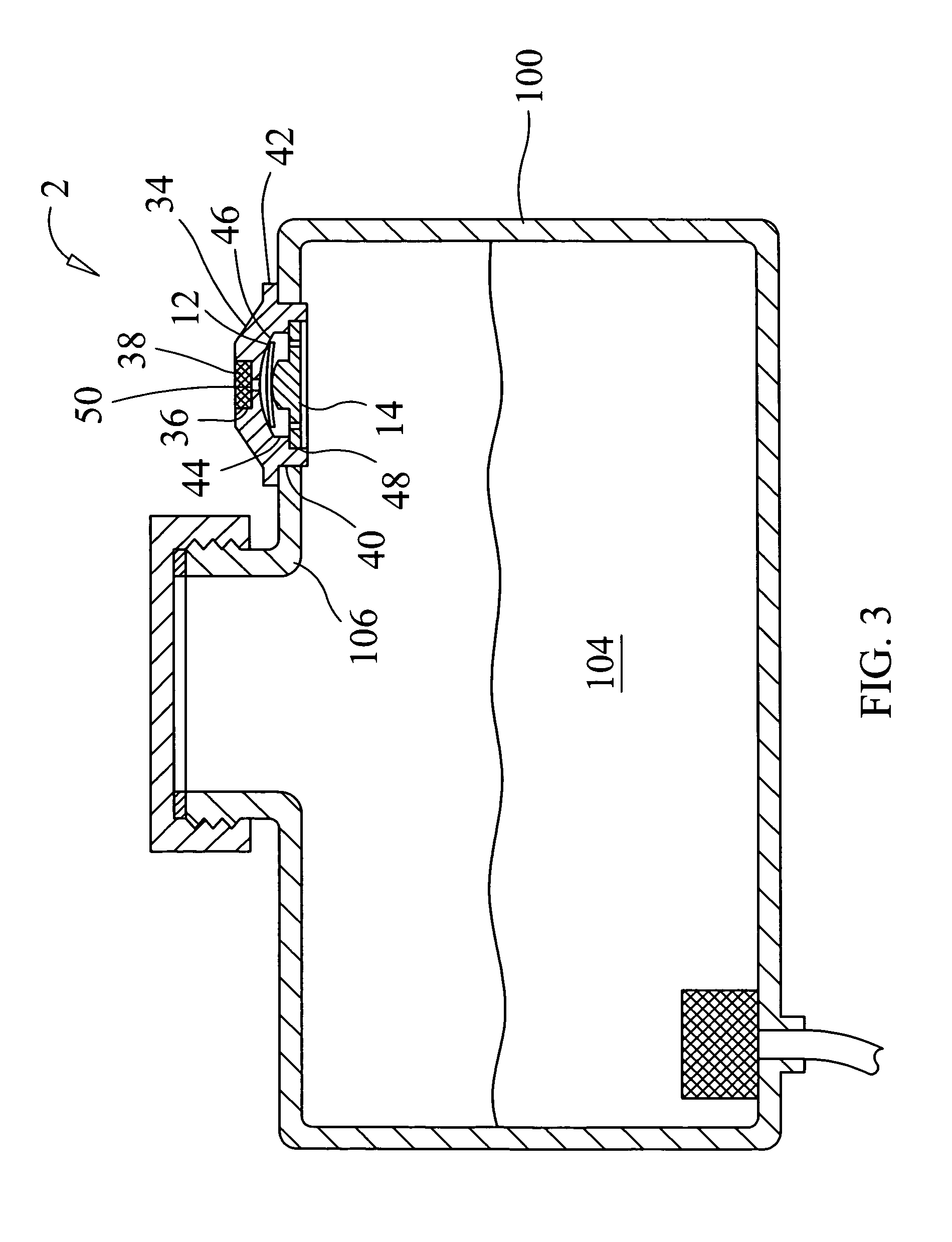

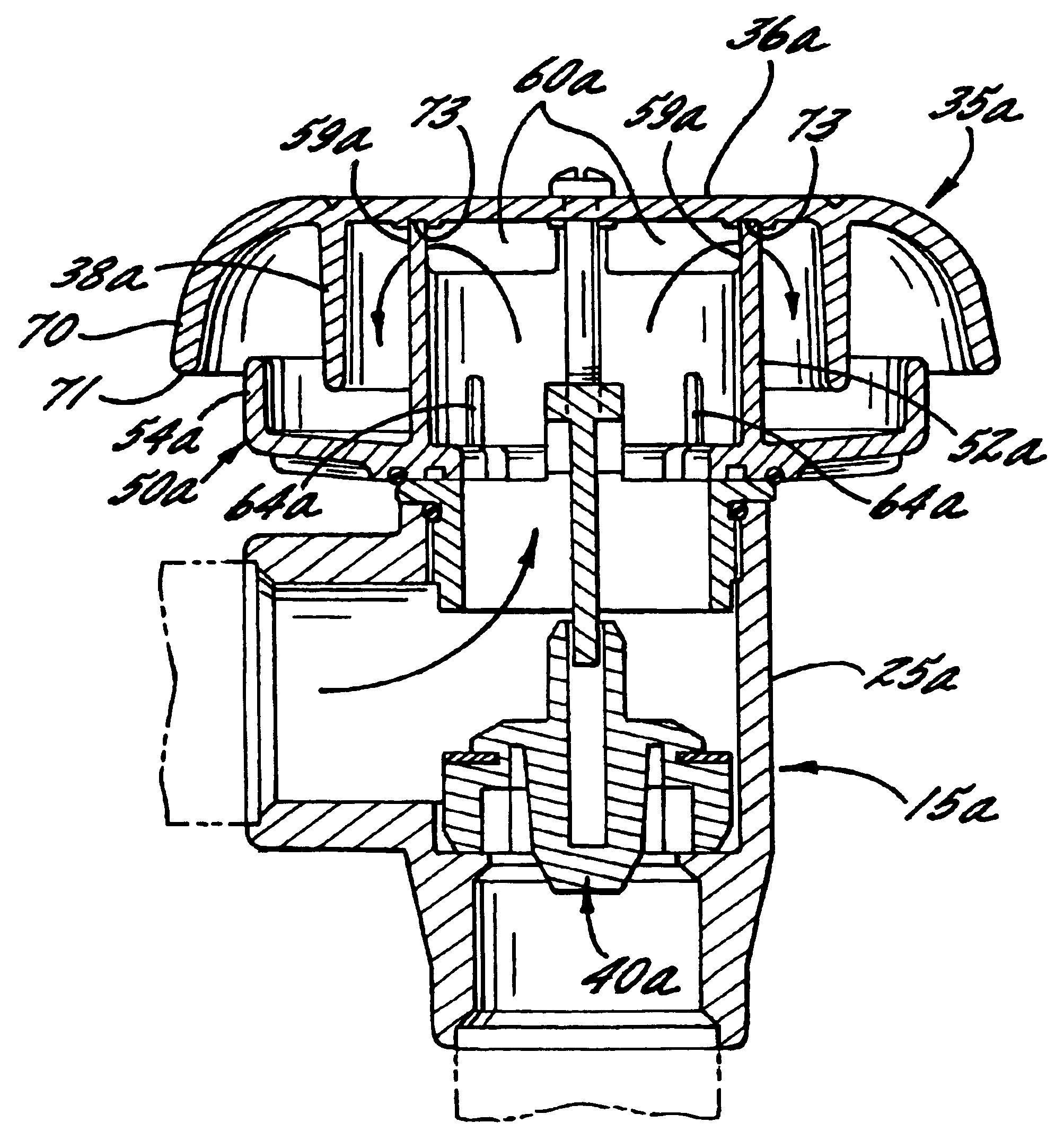

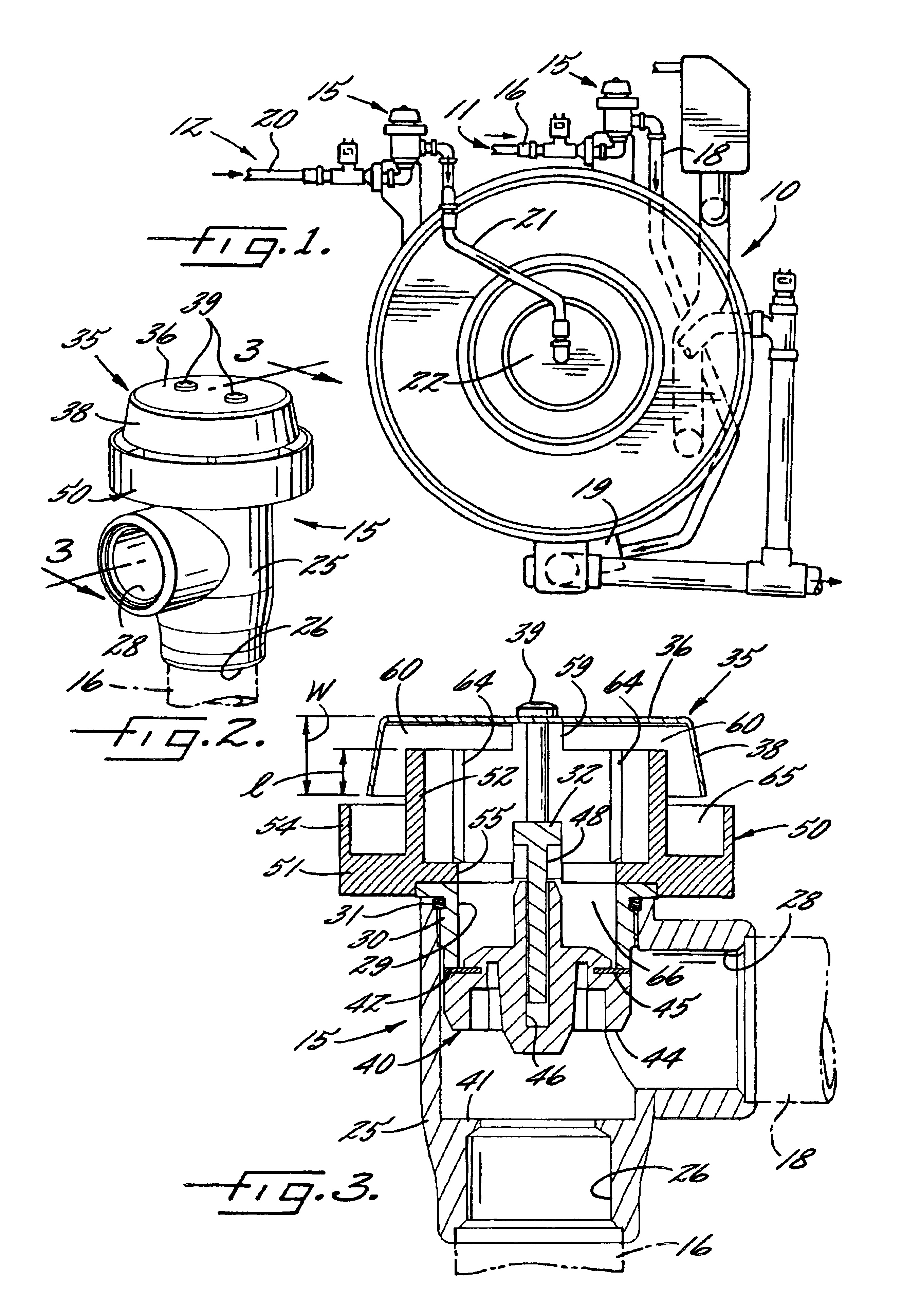

Fuel tank venting system

A fuel tank venting system includes a fuel cap, a vent diaphragm and a vent disc. A valve cavity with a substantially concave bottom is formed in a bottom of the fuel cap. At least one air passage is formed through the vent disc. A substantially convex surface is formed on a top of the diaphragm projection. The vent diaphragm is retained between the substantially concave bottom and the substantially convex surface. When air is needed for fuel flow, a vacuum within the fuel tank pulls the perimeter of the vent diaphragm downward, which breaks a seal with the substantially concave bottom to allow air flow. In a second embodiment, the fuel tank venting system is contained in a wall of the fuel tank. In a third embodiment, the fuel tank venting system is contained in a fuel vent body, which is attached to the fuel tank.

Owner:COUNTRY INDS TECH

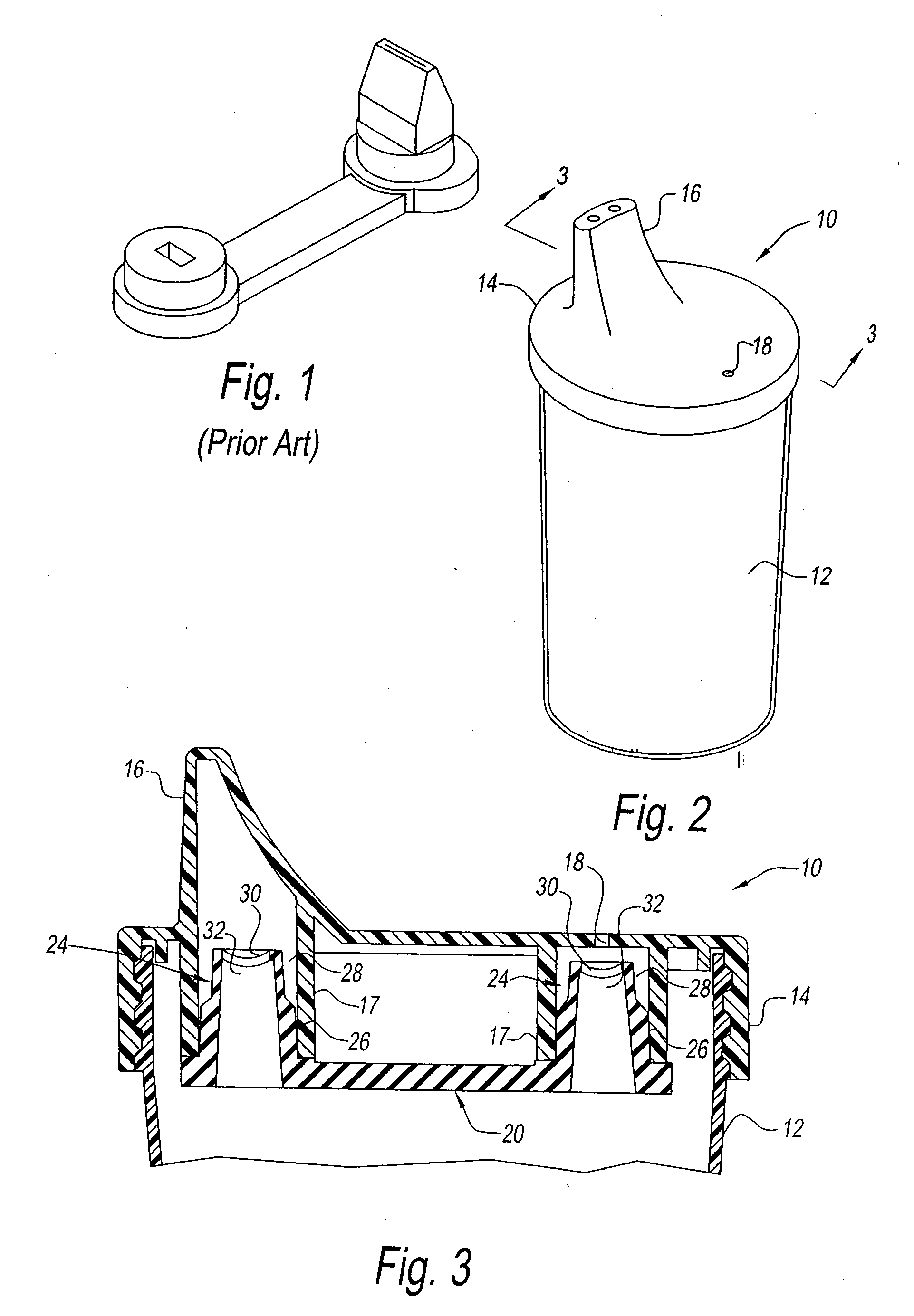

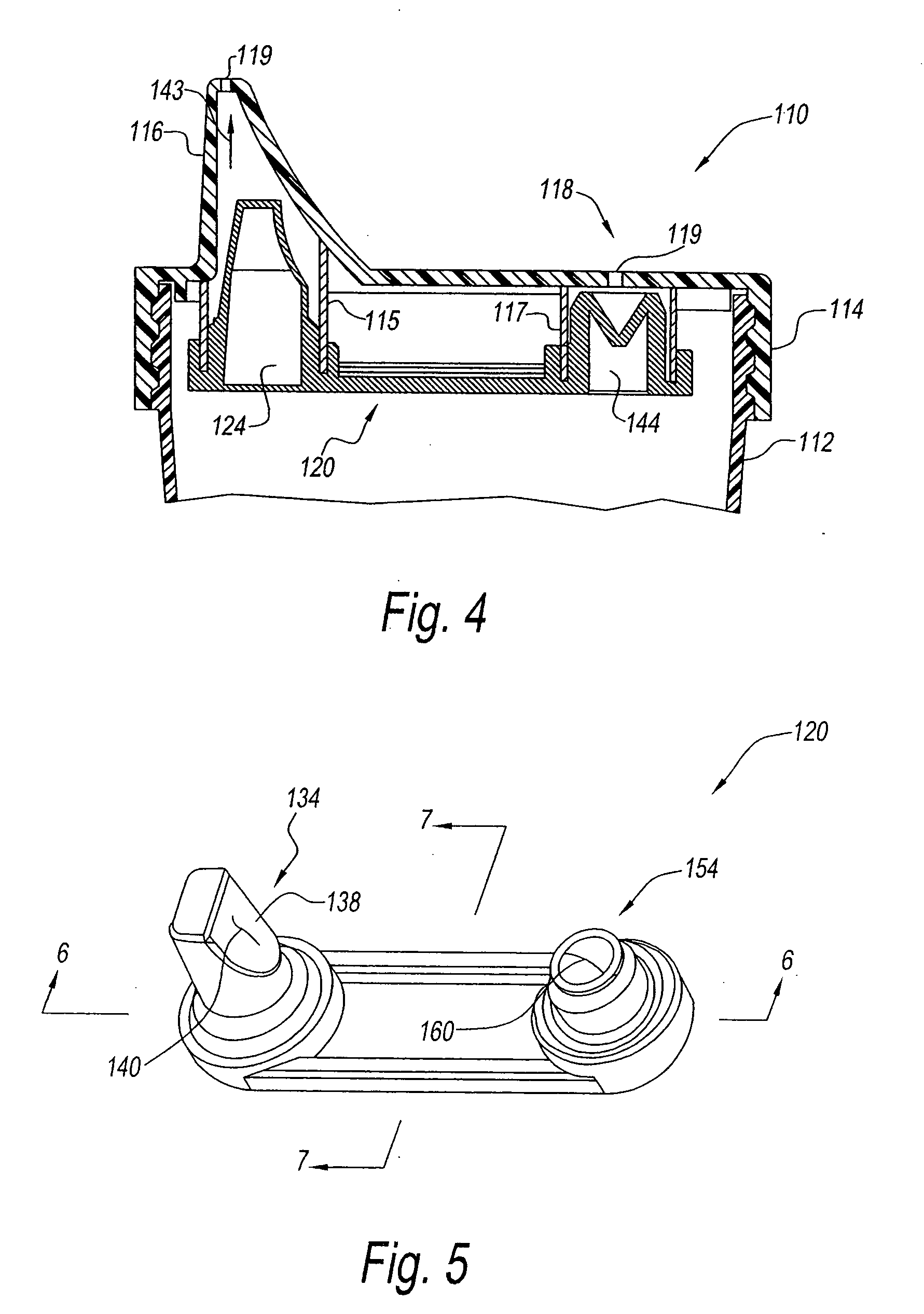

Flow control element for use with leak-proof cup assemblies

There is provided a flow control element for use with a drinking cup cap having a first mating member in fluid communication with a spout aperture. The flow control element has a first stack and a first valve. The first stack has an upper portion that can be positioned to be removably sealed in or with the cap. The first valve is defined in a sidewall of the first stack and is configured to provide selective fluid communication with the spout aperture.

Owner:PLAYTEX PROD INC

Flap valve

InactiveUS20050092372A1Provide usageMost effective sealCheck valvesEqualizing valvesEngineeringFlap valve

A flap valve is disclosed having a first spigot and a closure flap with an annular extension adapted to snugly fit within an outlet end of the first spigot and a flange integral with the annular extension adapted to circumscribe the outlet end. The flap valve having a second spigot of smaller diameter than the first spigot forming an extension to the first spigot.

Owner:WADE RODNEY GEORGE

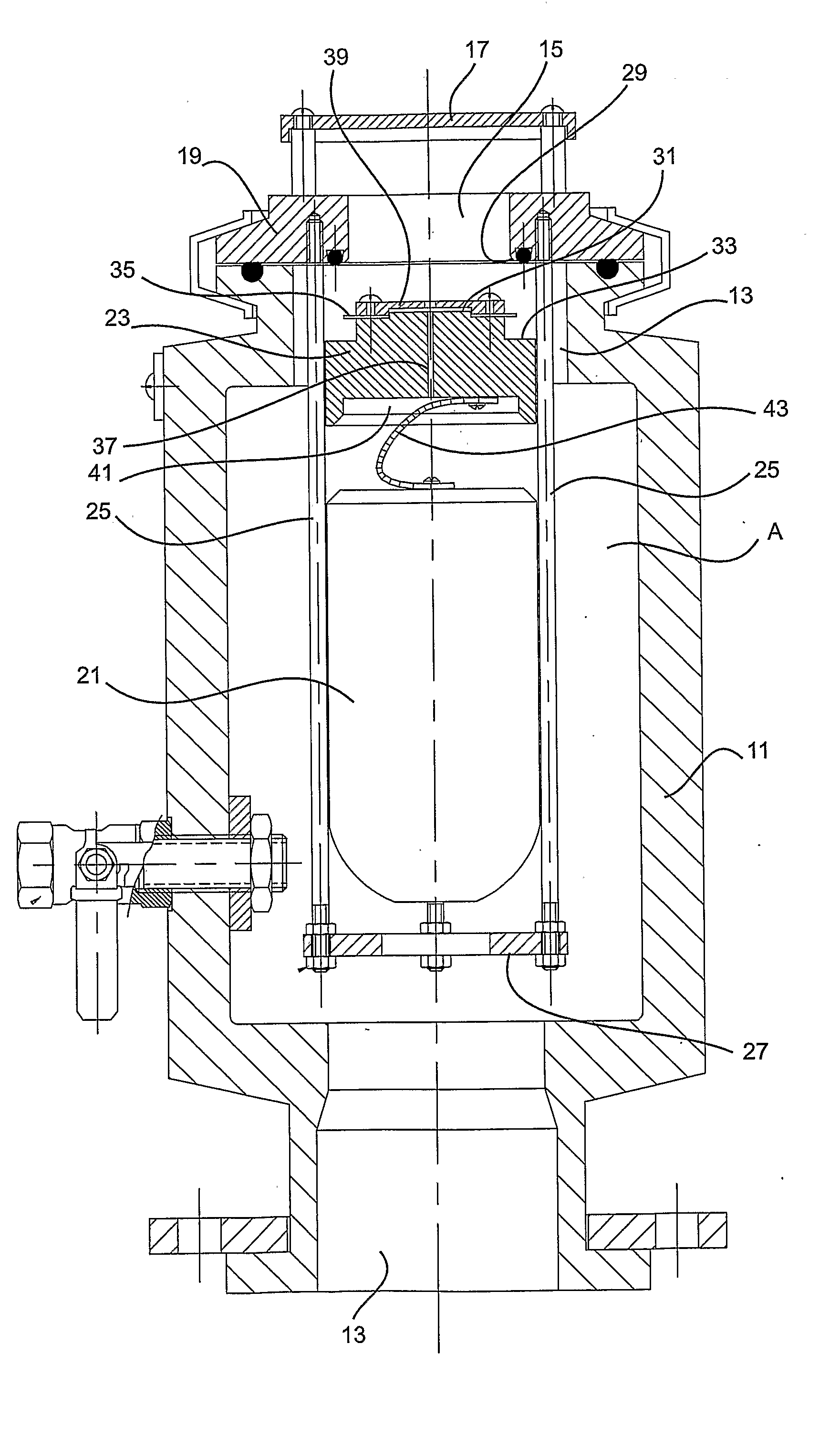

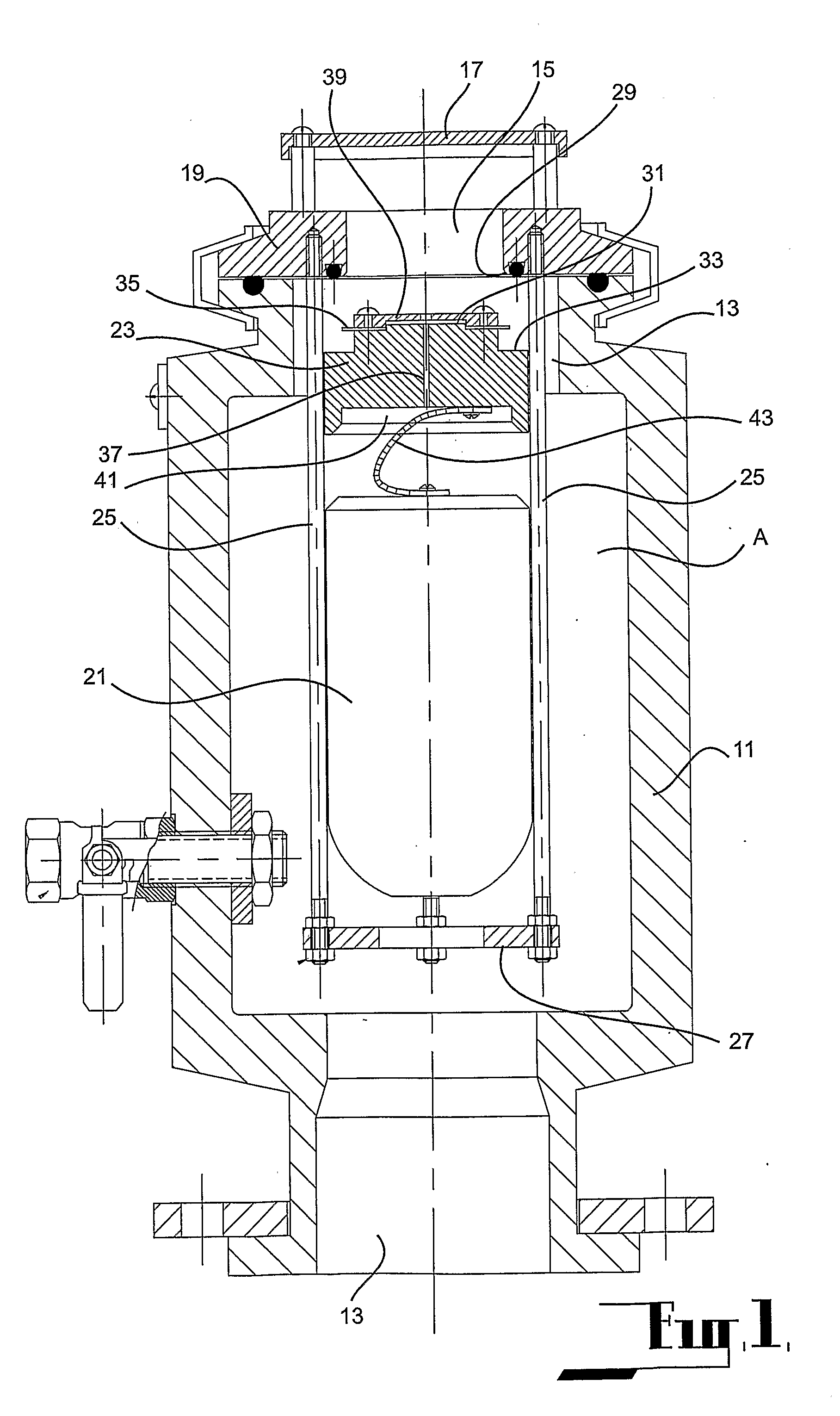

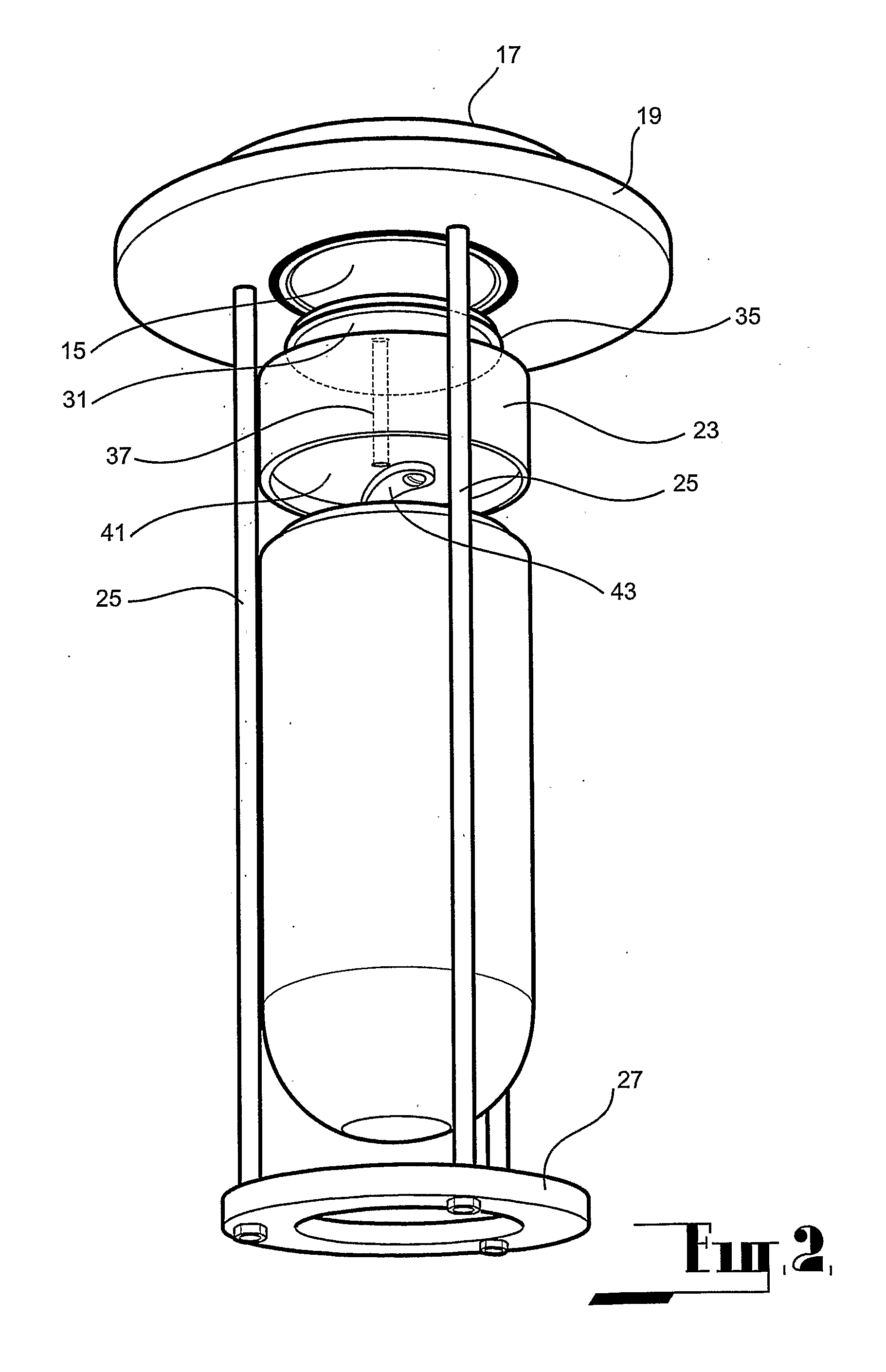

Vent valve

InactiveUS20090139581A1Operating means/releasing devices for valvesVenting valvesExhaust valveEngineering

A pipeline vent valve comprising a body (11) defining a chamber of clerestory configuration in which the upper portion (B) of the chamber is of reduced cross-sectional area, the chamber having an inlet (13) towards its lower end which is adapted to be connected to a pipeline and an outlet (15) in the upper portion, a valve body (23) supported in the upper portion of the chamber to be movable between a first position at which it is in sealing engagement with the outlet and a second position at which it is out of sealing engagement with the valve seat, said valve body being responsive to the level of liquid in the chamber in the chamber and being adapted to close on the liquid level in the chamber exceeding a predetermined level, said valve body having central passage (37) providing communication to each side of the valve body, a float member (21) supported within the chamber and adapted to cause said movement of said valve body between the first and second position as a result of the presence of liquid in the chamber, the float member being further adapted sealingly engage said central passage as the liquid in the chamber reaches the predetermined level and to and expose said passage on relative movement of the float member away from the valve body.

Owner:BWANOLAR

Absorbent article

ActiveUS20060161123A1Easy to bendEasy to installValve members for absorbing fluid energyRefuse receptaclesEngineeringMechanical engineering

An absorbent article, in which an erroneous impression of replacement time is not given to a wearer, includes an absorbent body, a front sheet covering the absorbent body, and a rear sheet, a pair of masking members being disposed along a longitudinal direction of the absorbent body, close to two ends of a short direction of the absorbent body, the masking members being of porous film having pores continuous in the direction of thickness, the thickness thereof preferably being 0.4 mm or greater under a load of 20 g / cm2. By this means, seepage of fluid at the side margins of the front sheet is deferred and misunderstanding of replacement time by the wearer is prevented.

Owner:UNI CHARM CORP

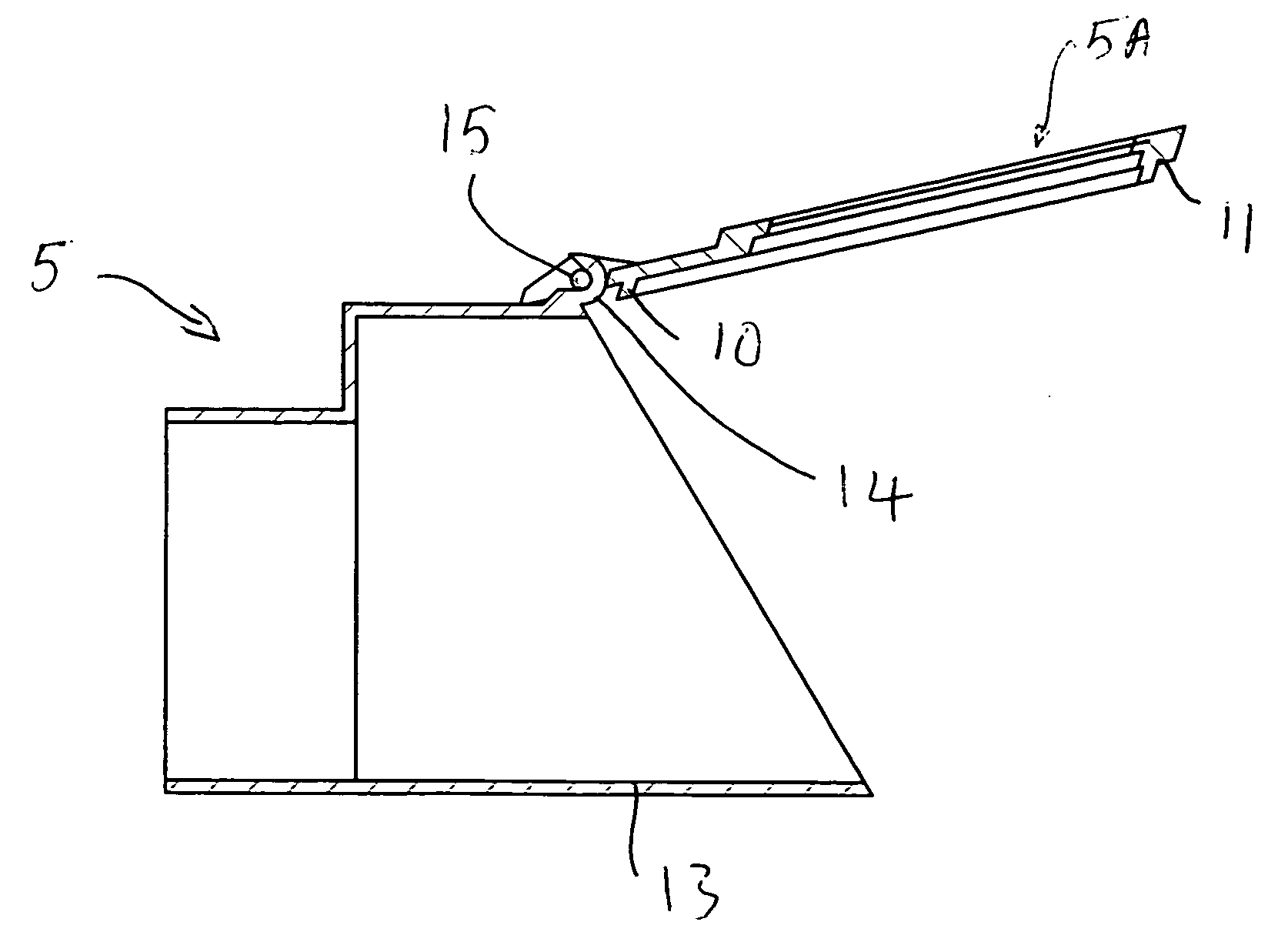

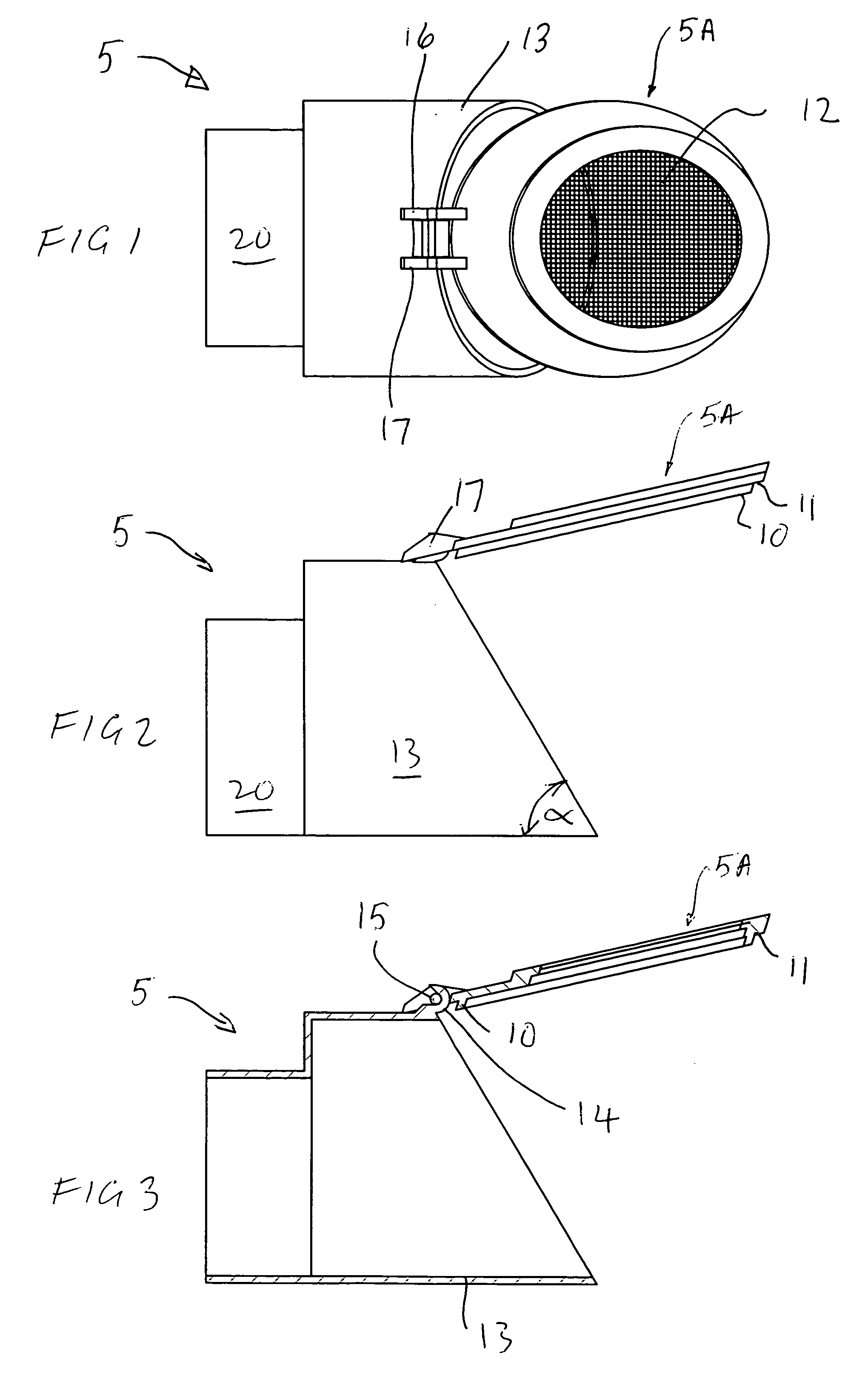

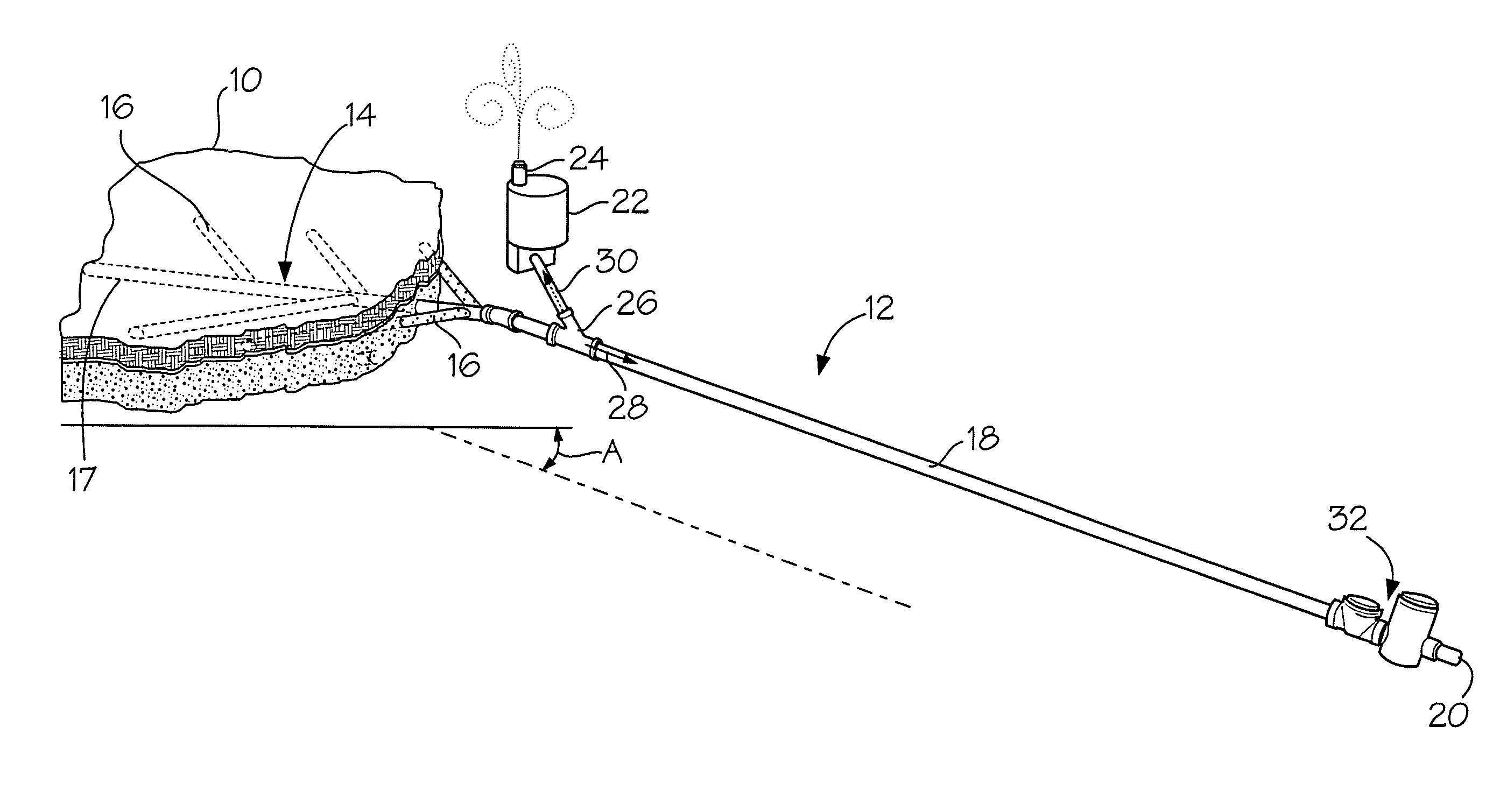

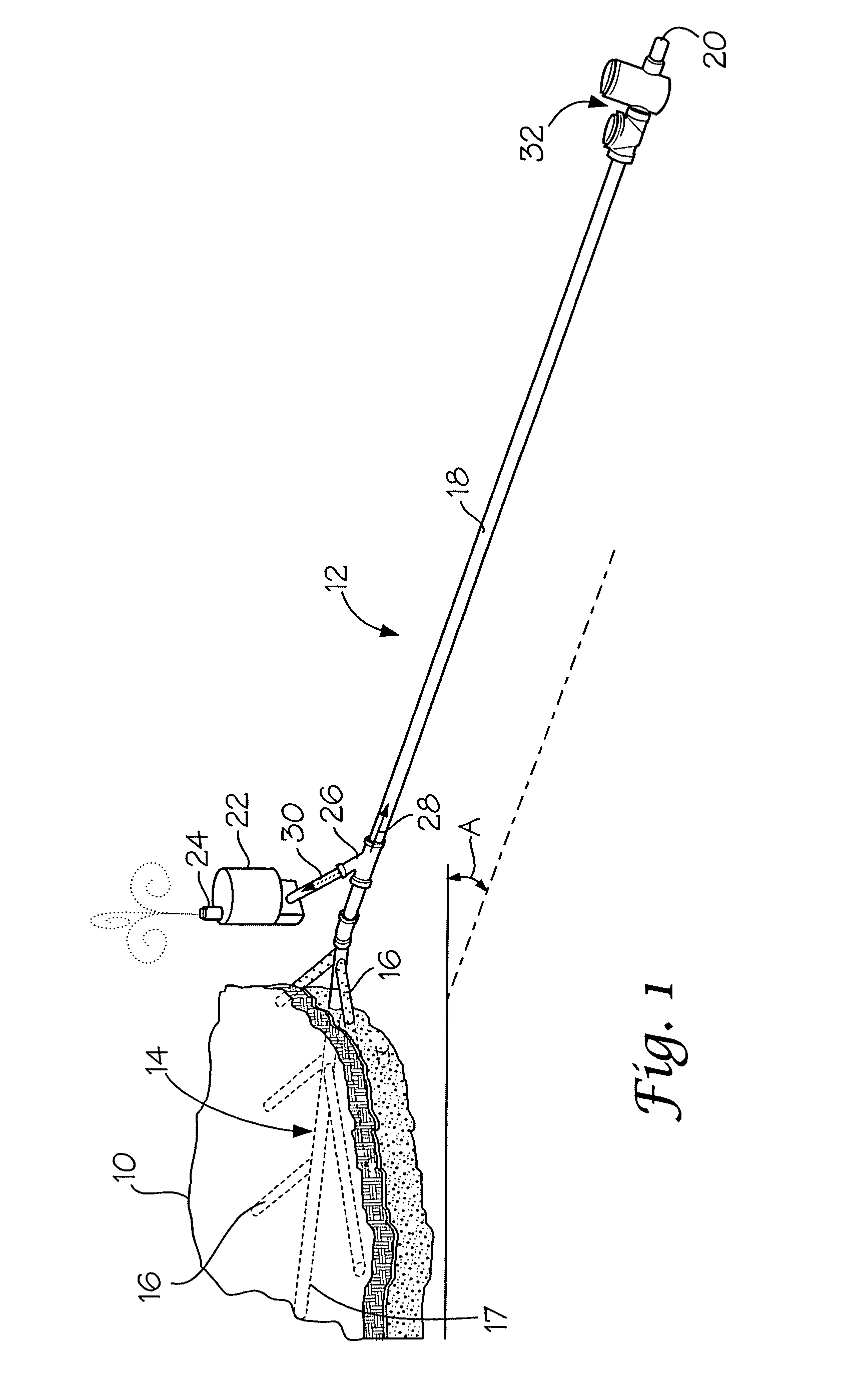

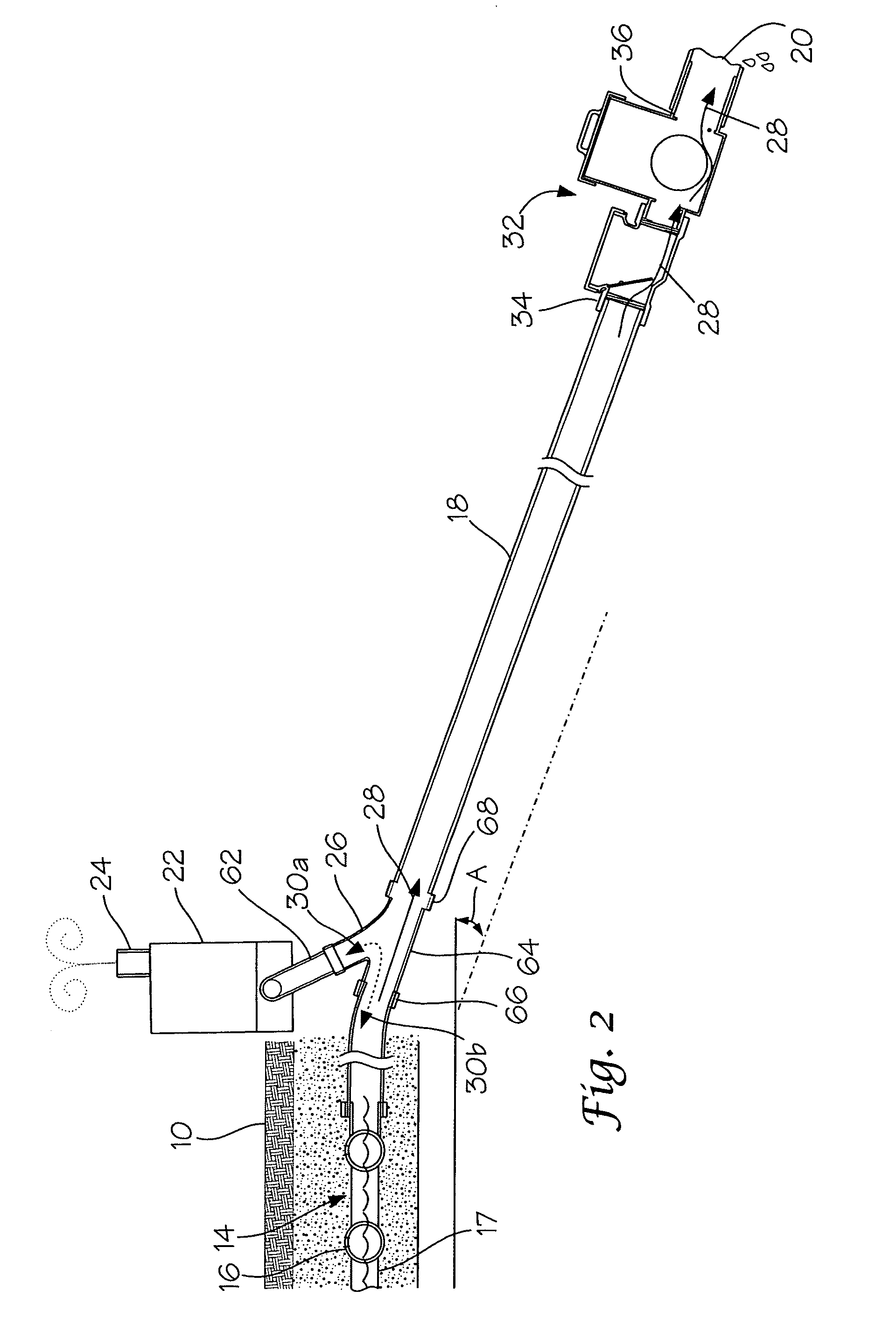

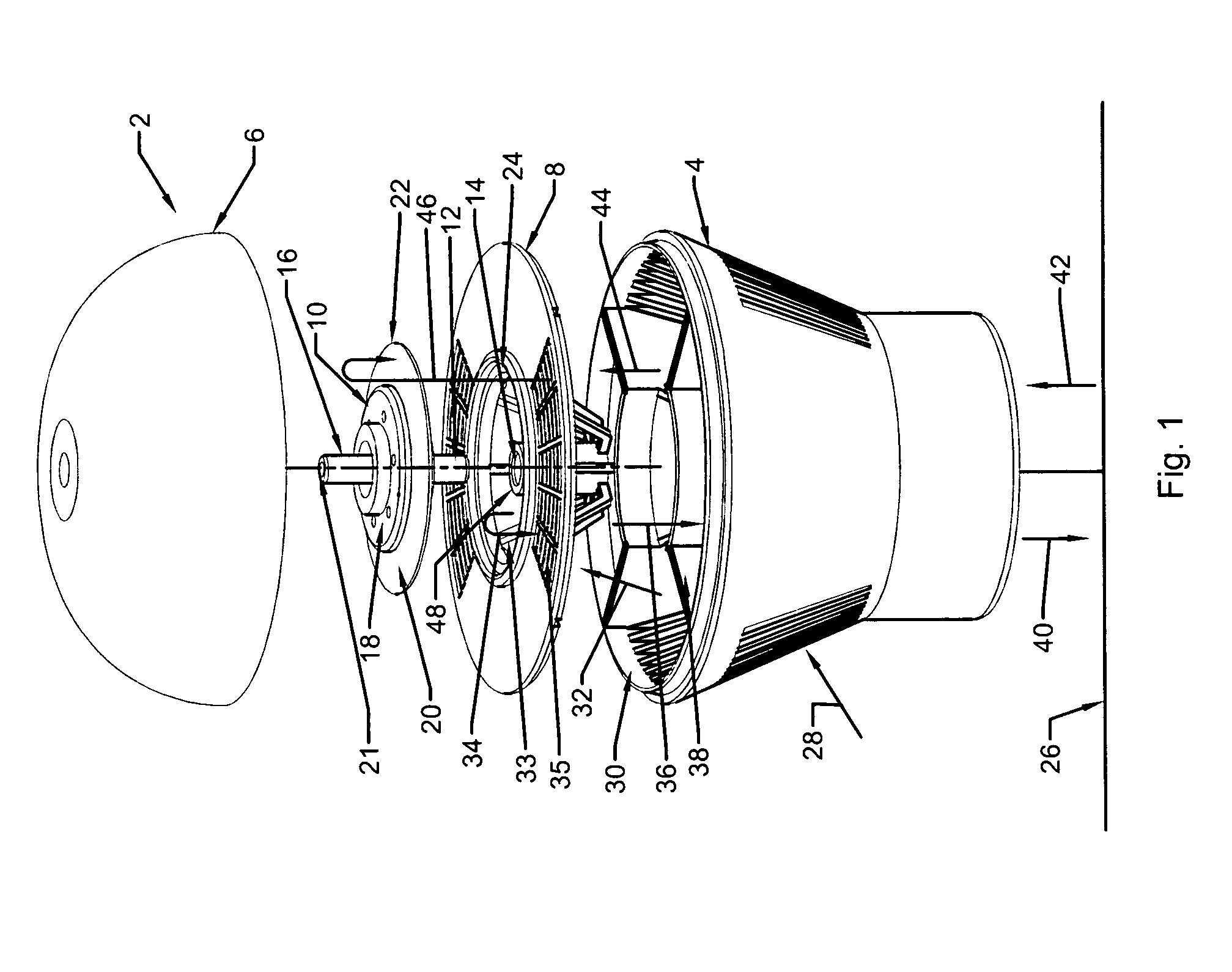

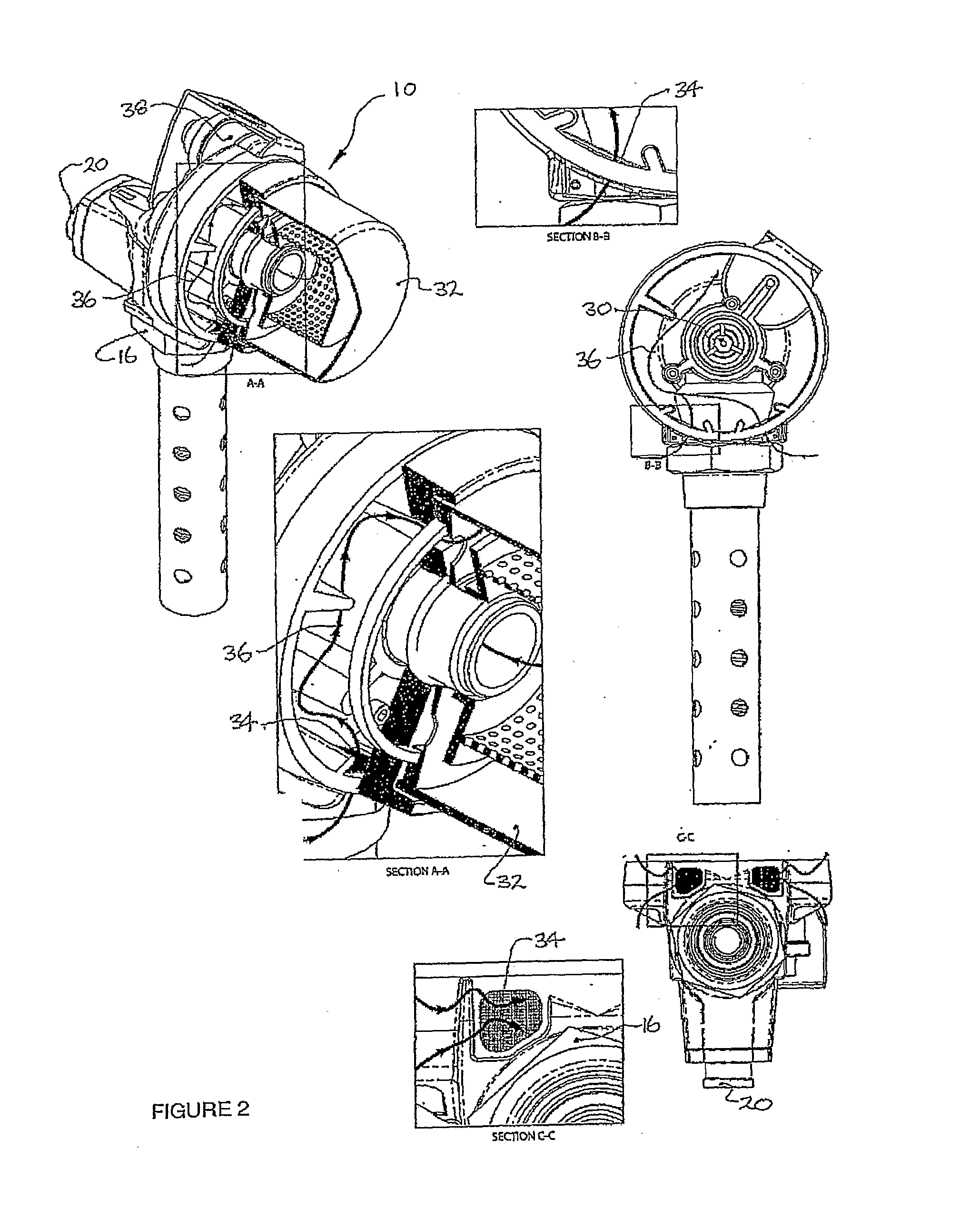

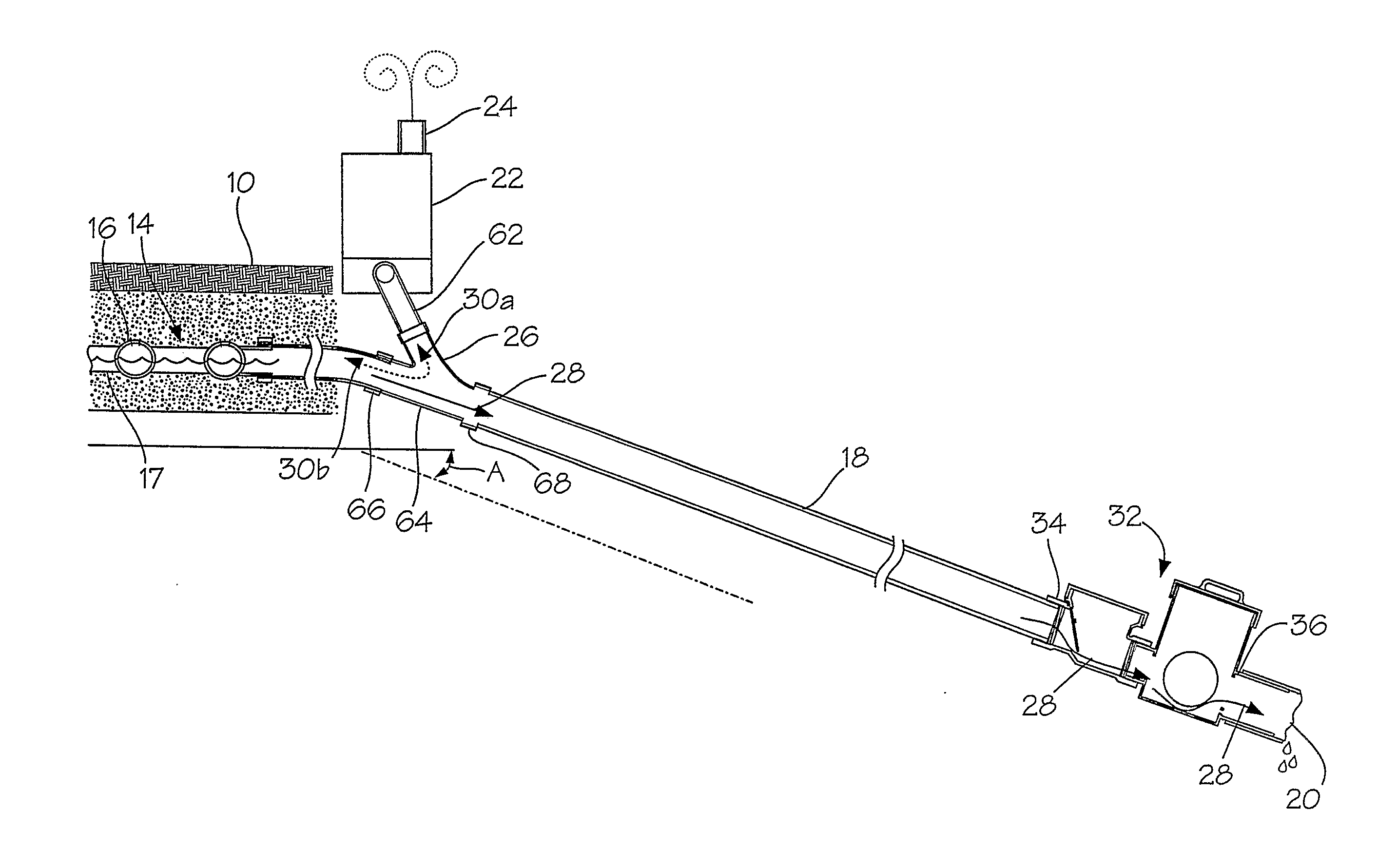

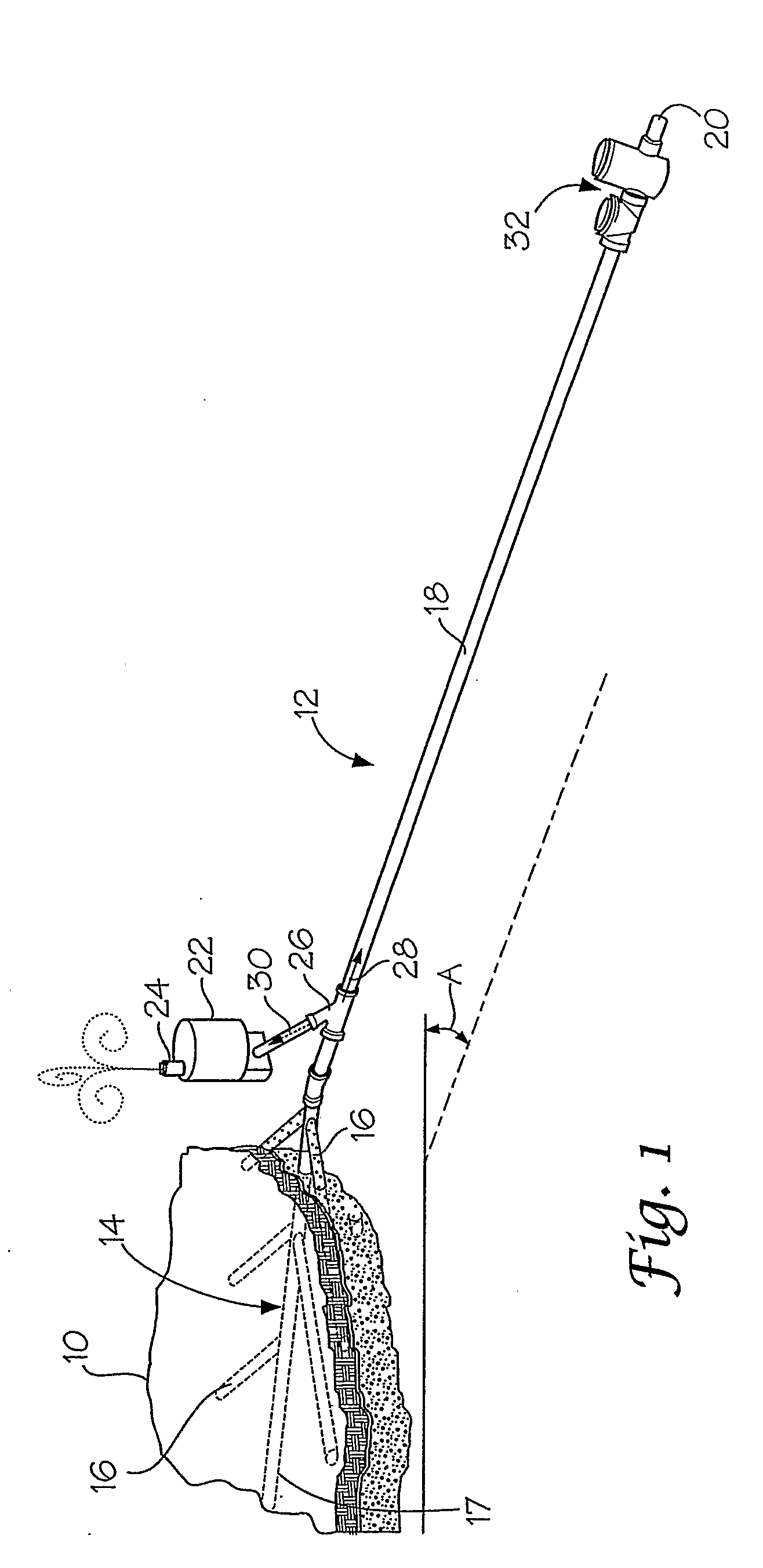

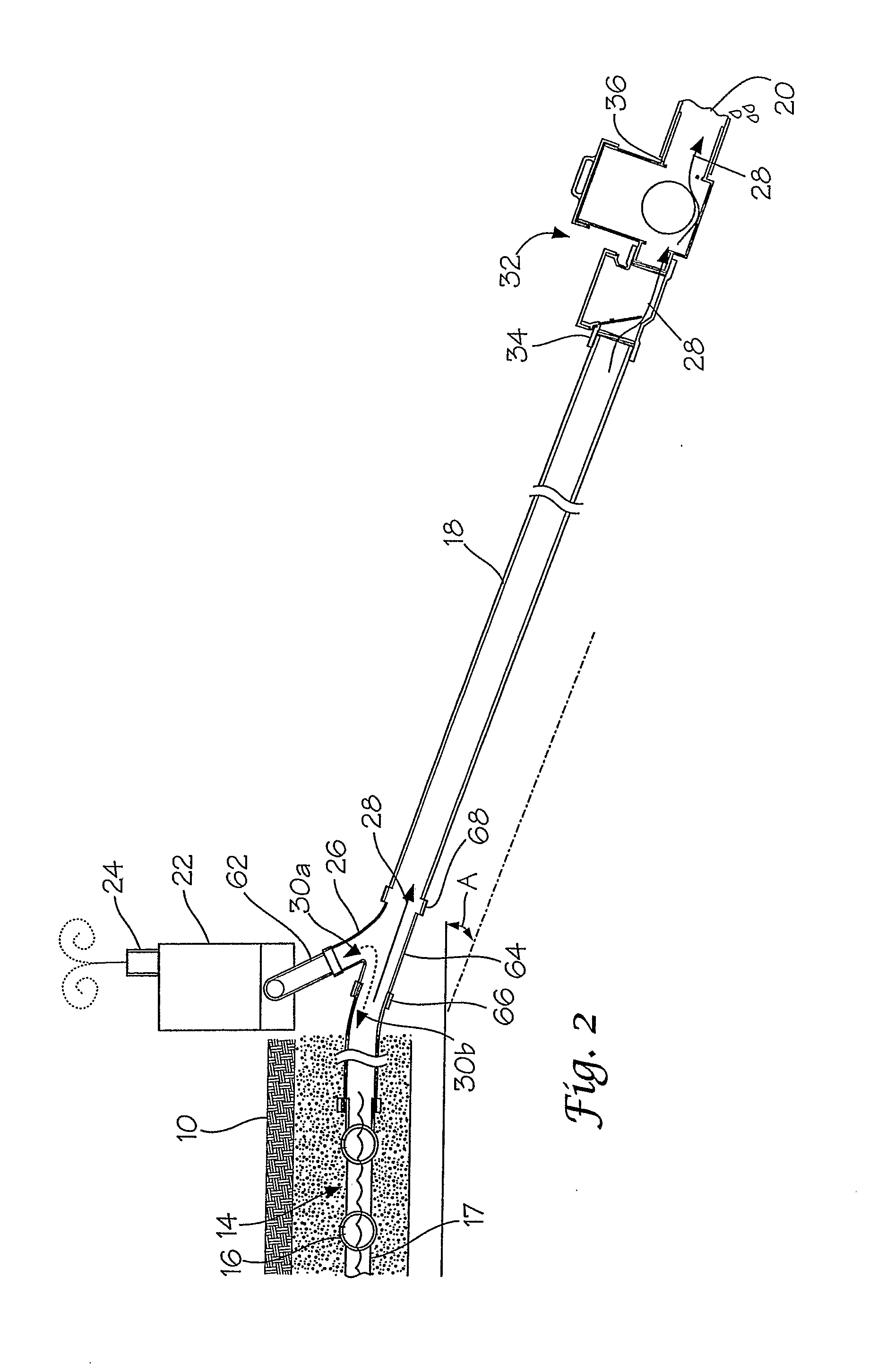

Turf playing surface aeration and drainage system

A perforated pipe network beneath a playing surface. A blower connected to the pipe network drawing an air flow through the pipe network to create a vacuum. A drain pipe connecting to the pipe network. An air / water separator connected upstream of the blower for separating water from the air flow prior to entering the blower and channeling the water into the drain pipe for discharge. A flow control unit having a unit inlet connected to the drain pipe downstream of the air / water separator and a unit outlet discharging water to a drain outlet. The flow control unit blocking air flow through the unit inlet into the drain pipe when the blower is in the vacuum mode, and opening the unit inlet when a waterhead buildup at the unit inlet exceeds the vacuum level established by the blower to discharge water through the drain outlet.

Owner:SUBAIR SYST

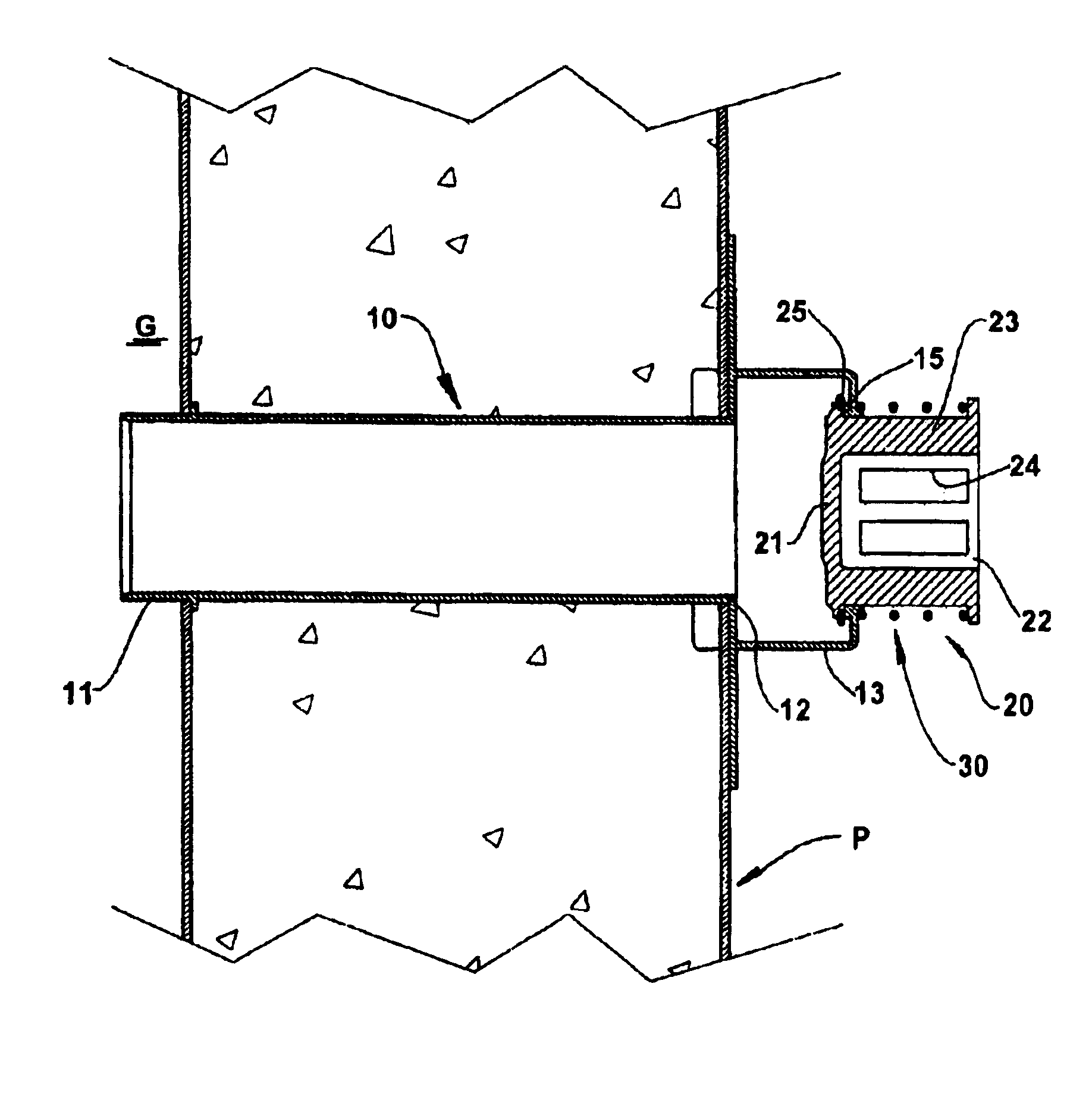

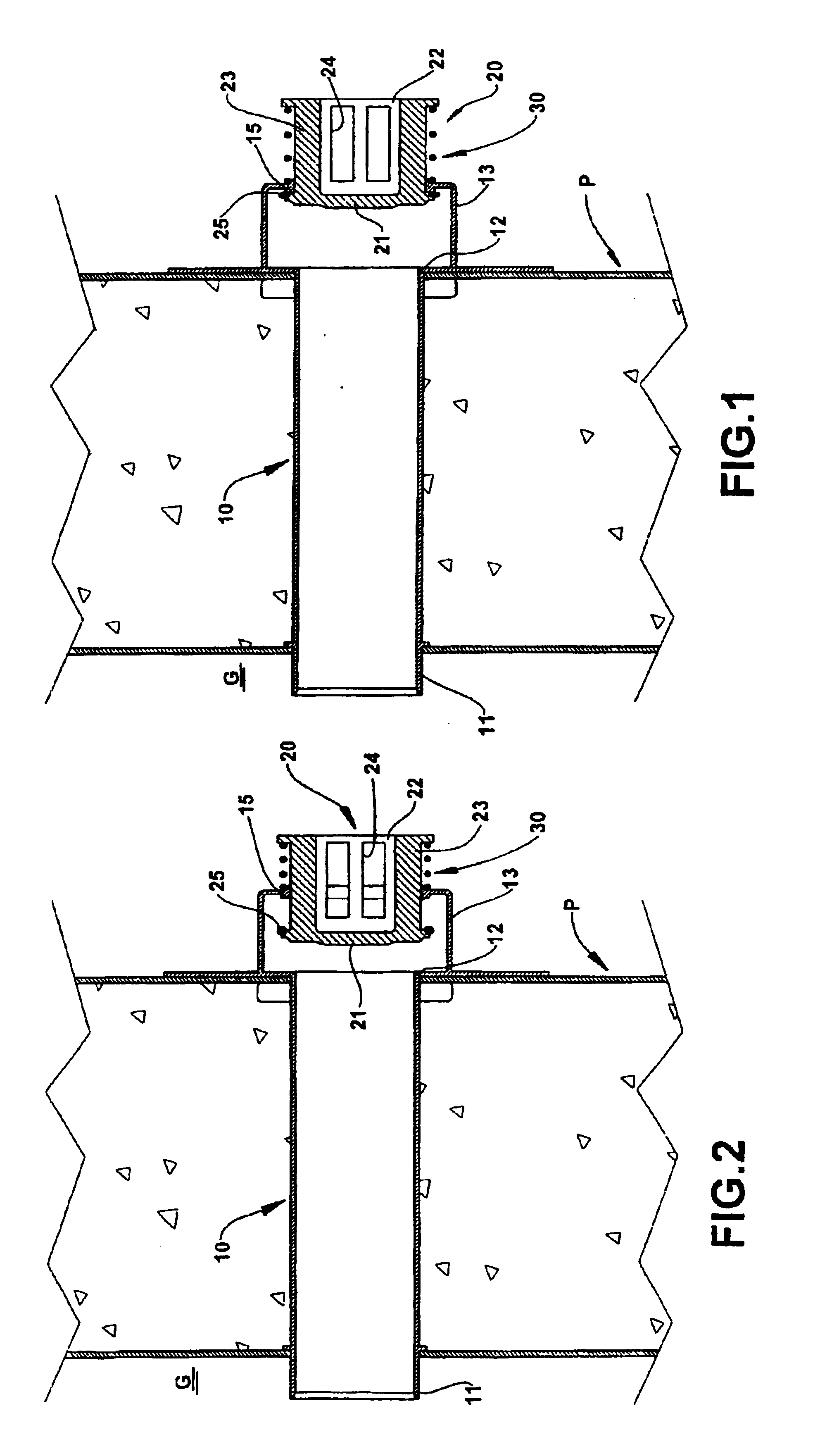

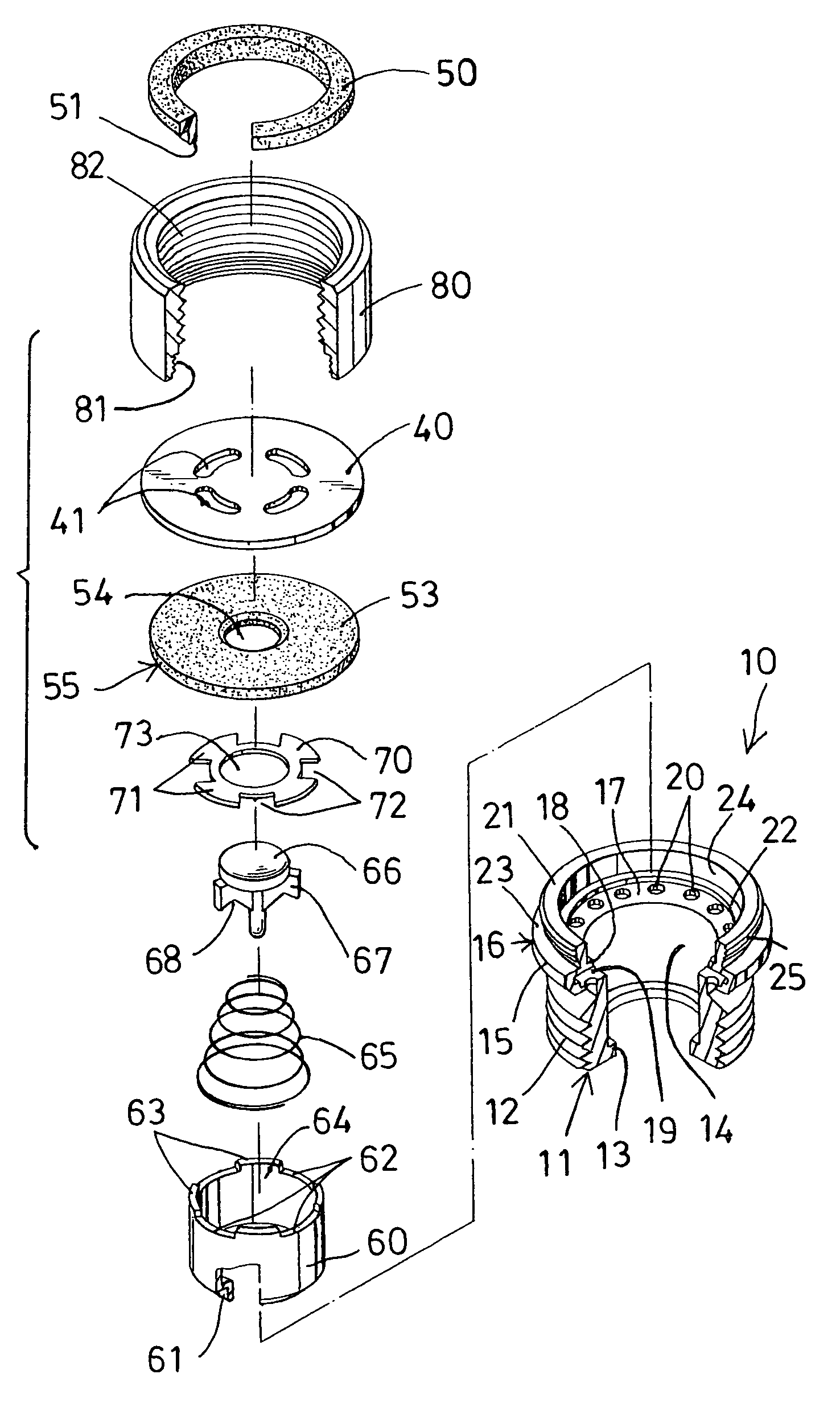

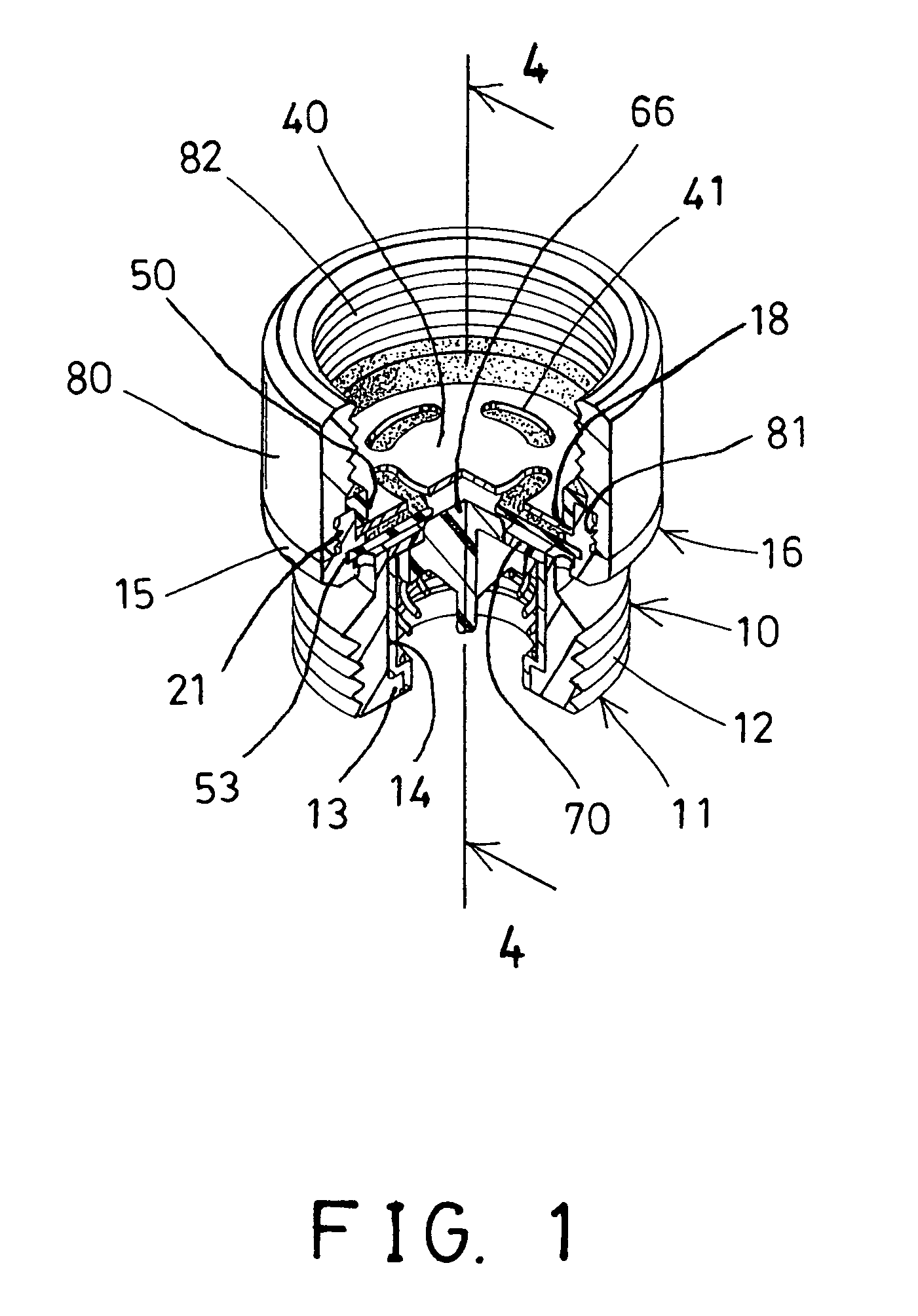

Vacuum-breaking valve for a refrigerated compartment

InactiveUS7107780B2Easy constructionGuaranteed uptimeLighting and heating apparatusCheck valvesEngineeringValve seat

A vaccum-breaking valve comprising: a tubular body (10) mounted through one of the walls (P) of the cabinet (G) and having inner (11) and outer (12) ends, a valve seat (15) defining a fluid communication between the inside and the outside of cabinet (G); and a seal constantly biased towards a closed position, blocking said fluid communication and dispalceable towards an open valve position. The seal comprises a slide (20), which is axially and slicingly mounted through the valve seat (15) and has a surrounding sealing ring (25), which is seated against the valve seat (15) when the slide (20) is displaced to the closed seal position, the slide (20) being provided with at least one air passage (24) interconnecting the upstream and downstream sides of the valve seat (15) when the slide (20) is in the open seal position.

Owner:MULTIBRAS SA ELETRODOMESTICOS

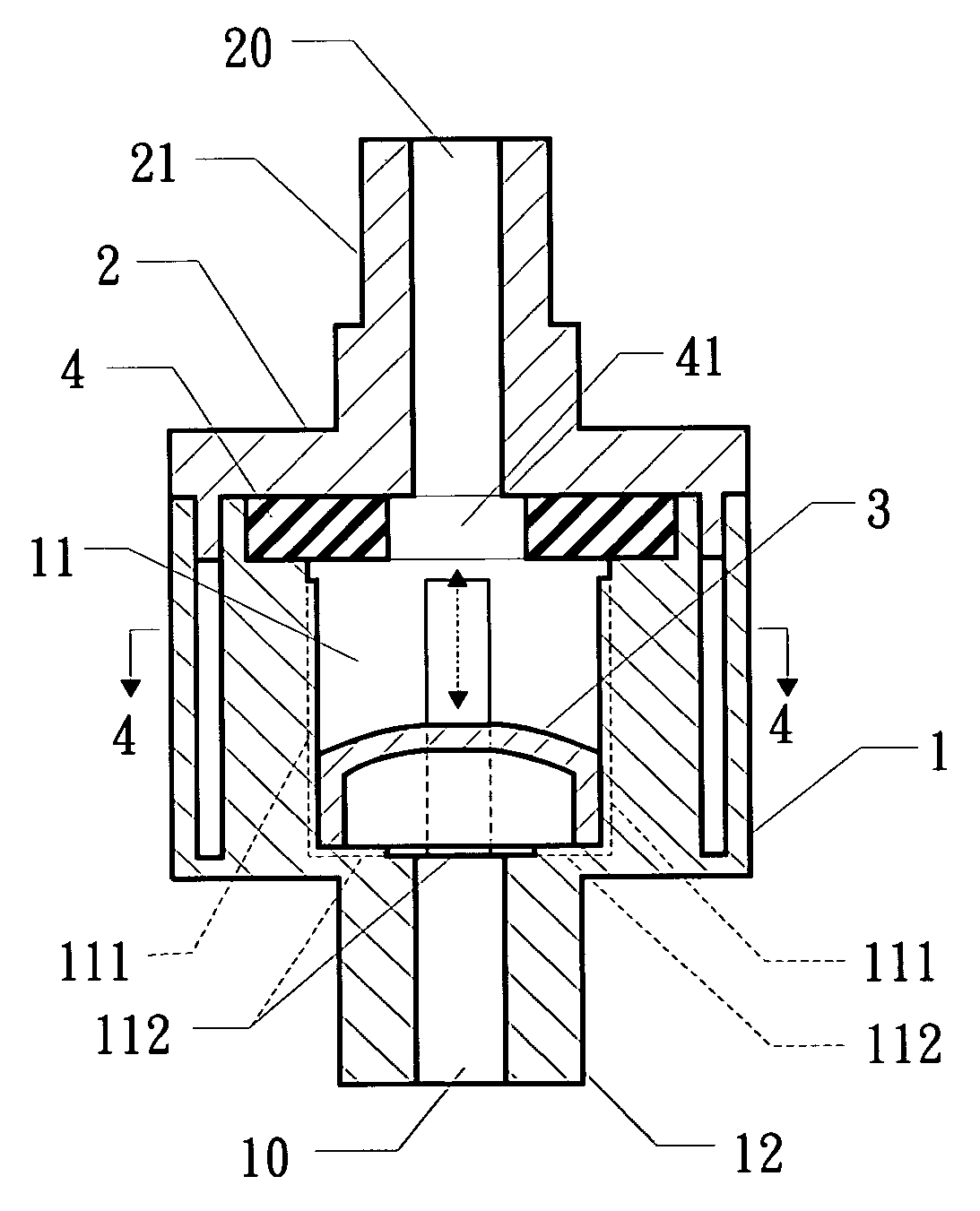

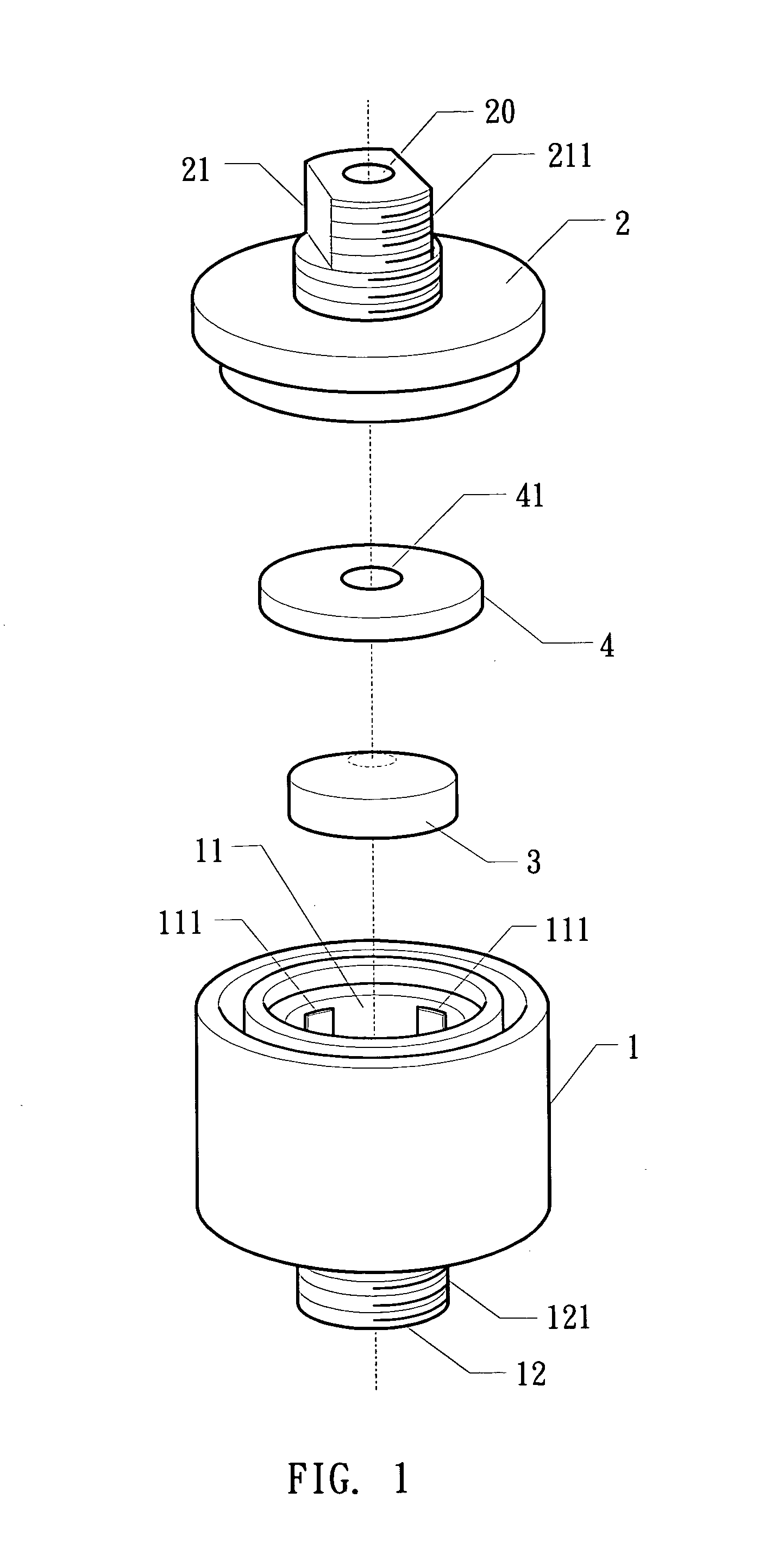

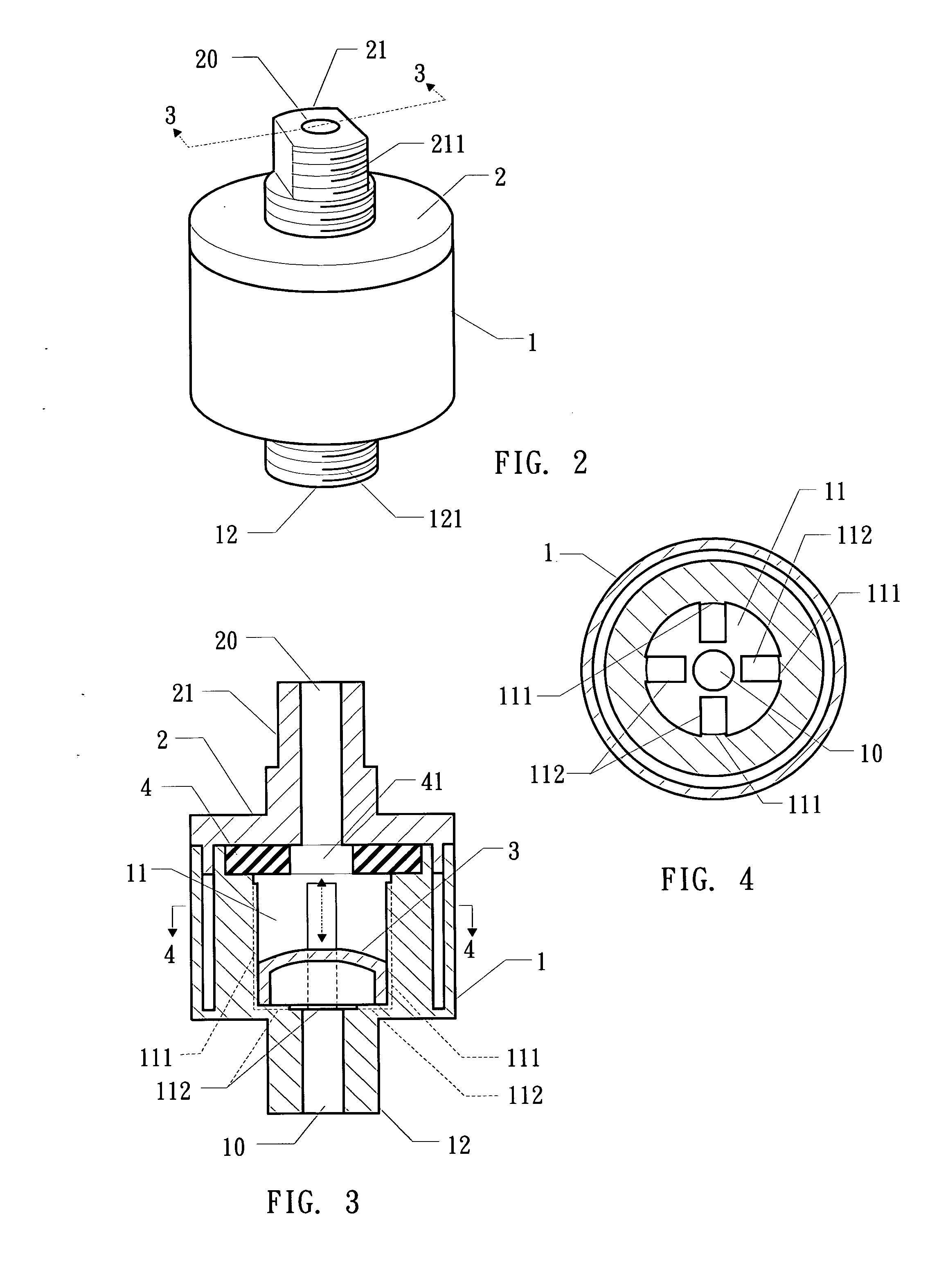

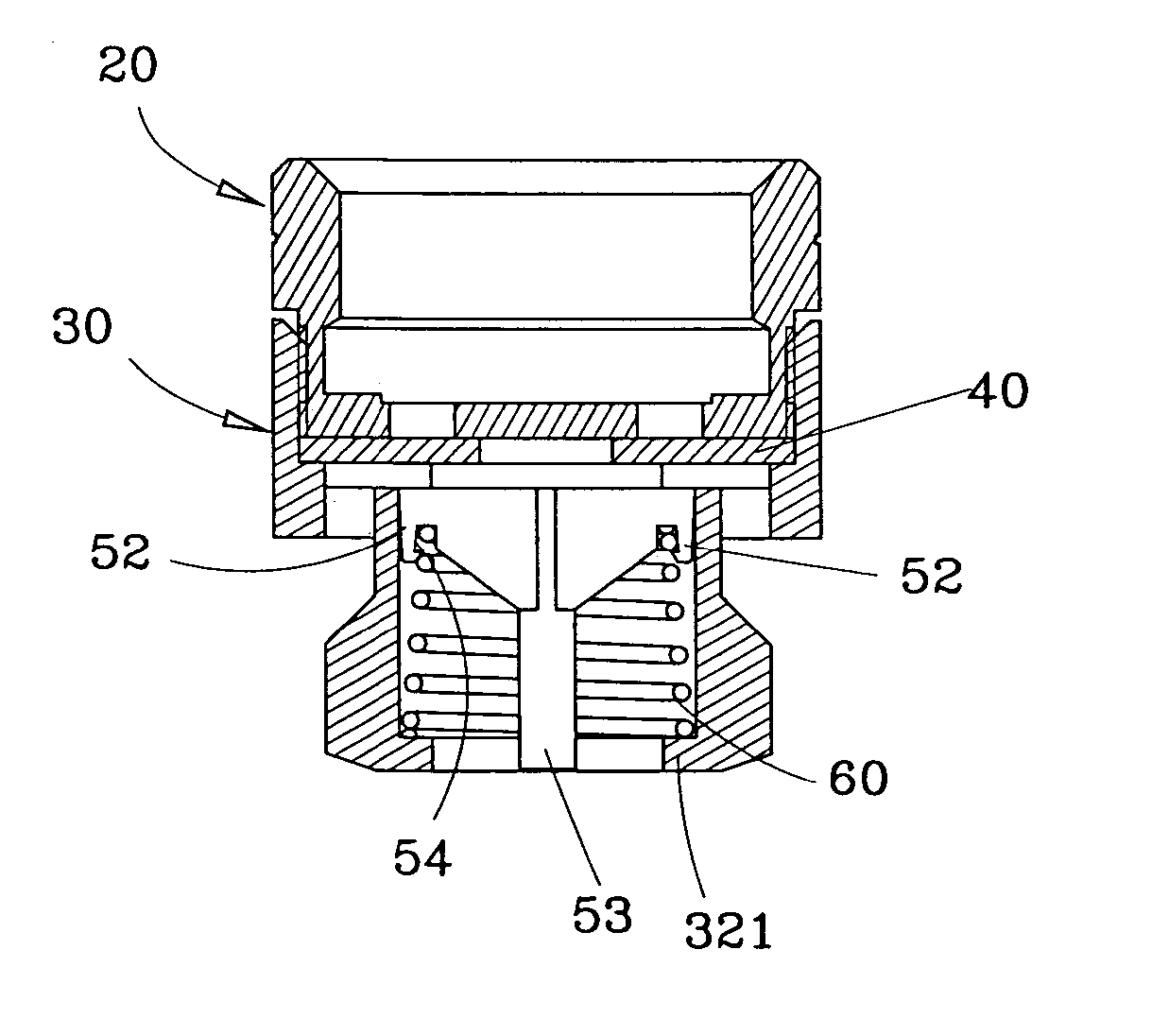

Negative check valve of a pneumatic transfer pipe

InactiveUS20080115843A1Easy to understandCheck valvesEqualizing valvesSuction forcePositive pressure

A negative check valve of a pneumatic transfer pipe comprises a casing having a hollow chamber and a channel which is communicated to the hollow chamber; a cover having a penetrating channel; a plug movably received in the hollow chamber of the casing; a washer installed between the casing and the cover; an center of the washer having an opening which can be sealed by the plug; wherein when a positive pressure is applied to the plug, the plug will be pushed upwards by floating force and the pressure so as to seal the opening of the washer to isolate the opening. When a negative pressure is applied to the plug by suction force of vacuum, the plug will descend to the bottom of the hollow chamber so that the opening is opened and gas or liquid flows through the washer.

Owner:WANG CHI CHANG

Swimming pool vacuum relief safety valve

A vacuum relief safety valve includes a housing defining an inner chamber and attached to the suction-side of the swimming pool or spa pump. An air inlet aperture is formed in the housing so as to be open to ambient air. A sealing element is disposed within the housing and biased against the air inlet aperture by a spring so as to effectively seal the inner chamber of the housing from ambient air. When a maximum allowed vacuum level within the pump is exceeded, such as when a swimming pool drain is obstructed, the sealing element moves into the inner chamber and opens the air inlet aperture causing the pump to rapidly lose its prime and enabling removal of the entrapment.

Owner:HAMZA HASSAN H

Vacuum breaker arrangement

ActiveUS20070138189A1Precise positioningReduce pressureClosuresCheck valvesVALVE PORTVacuum interrupter

Owner:PROTECTOSEAL

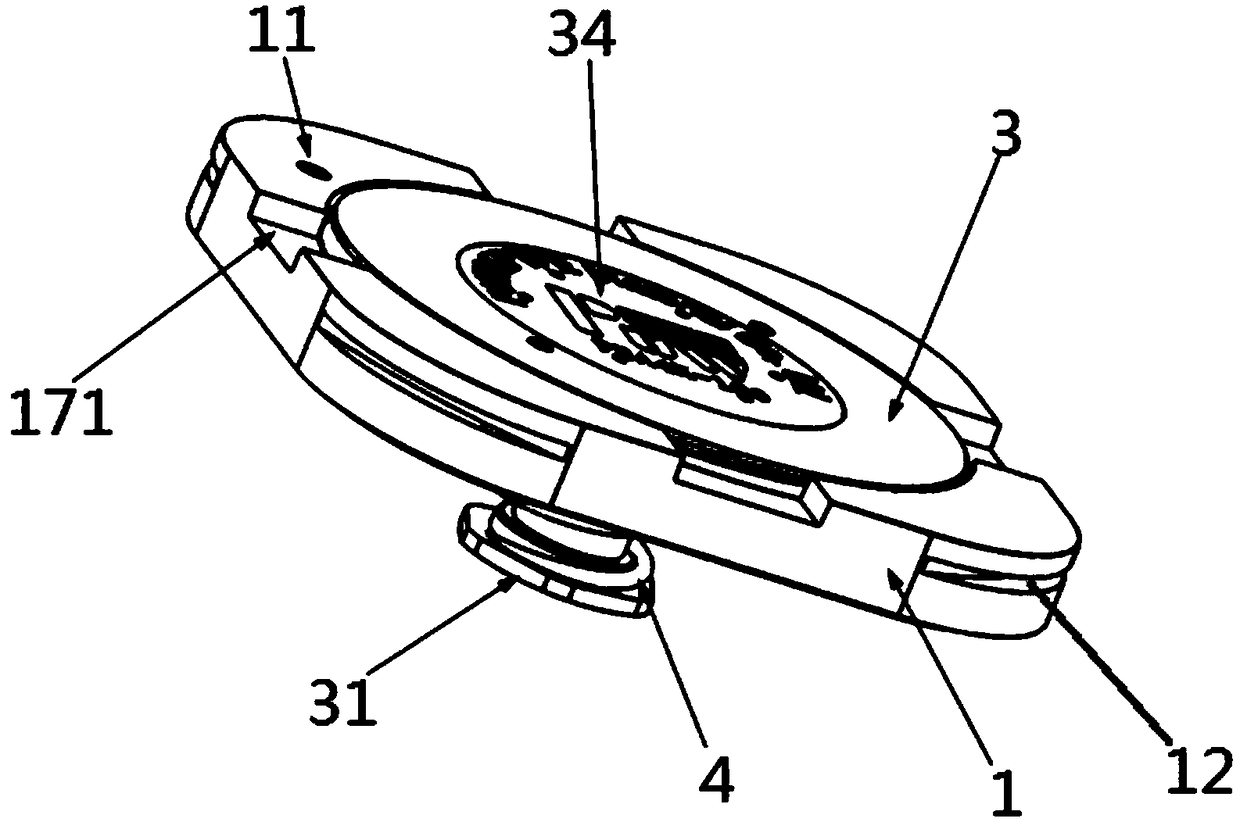

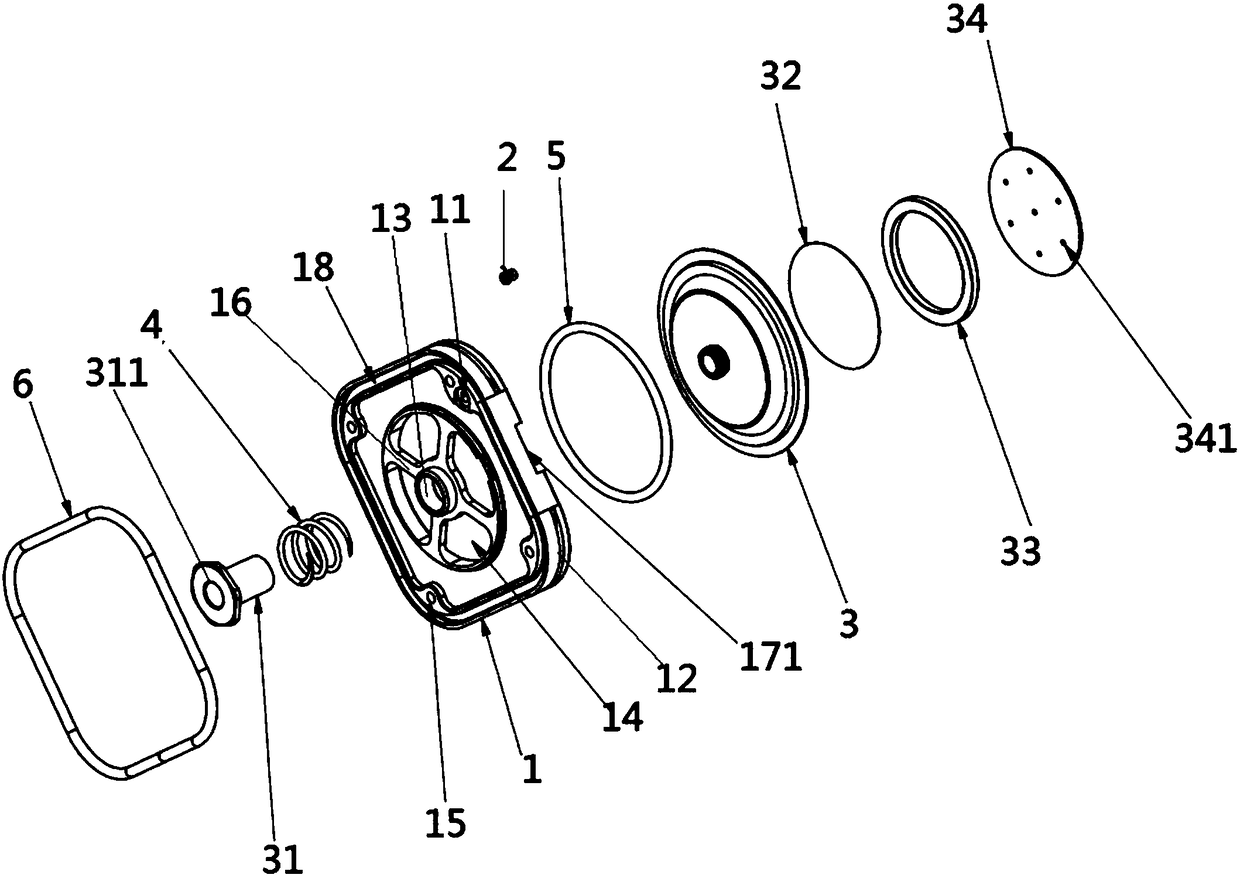

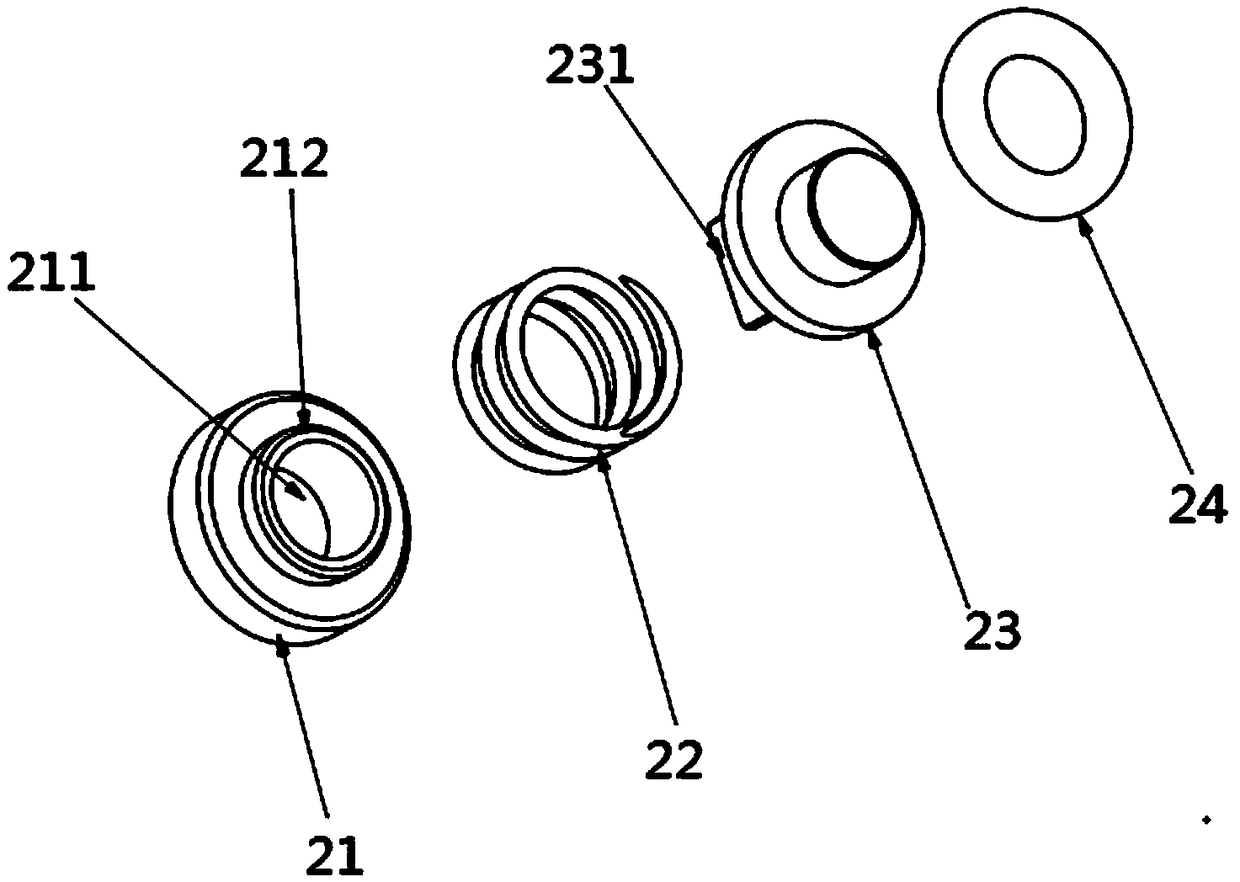

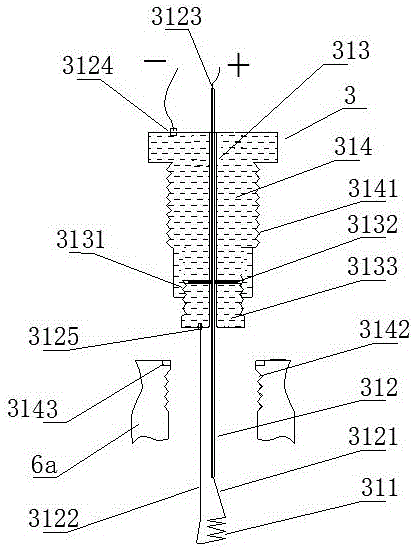

Inflation valve element, explosion-proof valve capable of detecting air tightness of box body through rapid inflation and detection method

PendingCN108533811AWill not cause damageIncrease intake speedMeasurement of fluid loss/gain rateEqualizing valvesEngineeringAir tightness

The invention discloses an inflation valve element. The inflation valve element comprises a fixing part, a compression spring, an inflation piston and a rubber seal, one end of the inflation piston isconnected to the fixing part through the compression spring, and the other end of the inflation piston is connected to the rubber seal. The inflation valve element is arranged on an explosion-proof valve, inflation is carried out from the inflation valve element, compared with a mode that inflation is carried out from an air-permeable membrane of the explosion-proof valve, the inflation valve element has the advantages that the air inlet speed is high, the used time is short, the detection efficiency is high, and in addition, the phenomena that the air-permeable membrane is damaged, and the explosion-proof valve is invalid can be avoided; and the air tightness detection inflation valve element and the explosion-proof valve are integrated into a whole, an inflation hole for air tightness detection does not need to be additionally formed in the sealed box body, after the detection is finished, the inflating piston is driven to automatically reset through the spring, the sealed state isrestored, a bolt does not need to be additionally arranged to seal the inflation hole, and therefore the risks that secondary seal is poor, and the protection grade requirement cannot be met can be avoided.

Owner:DONGGUAN PUW EPTFE MATERIAL CO LTD

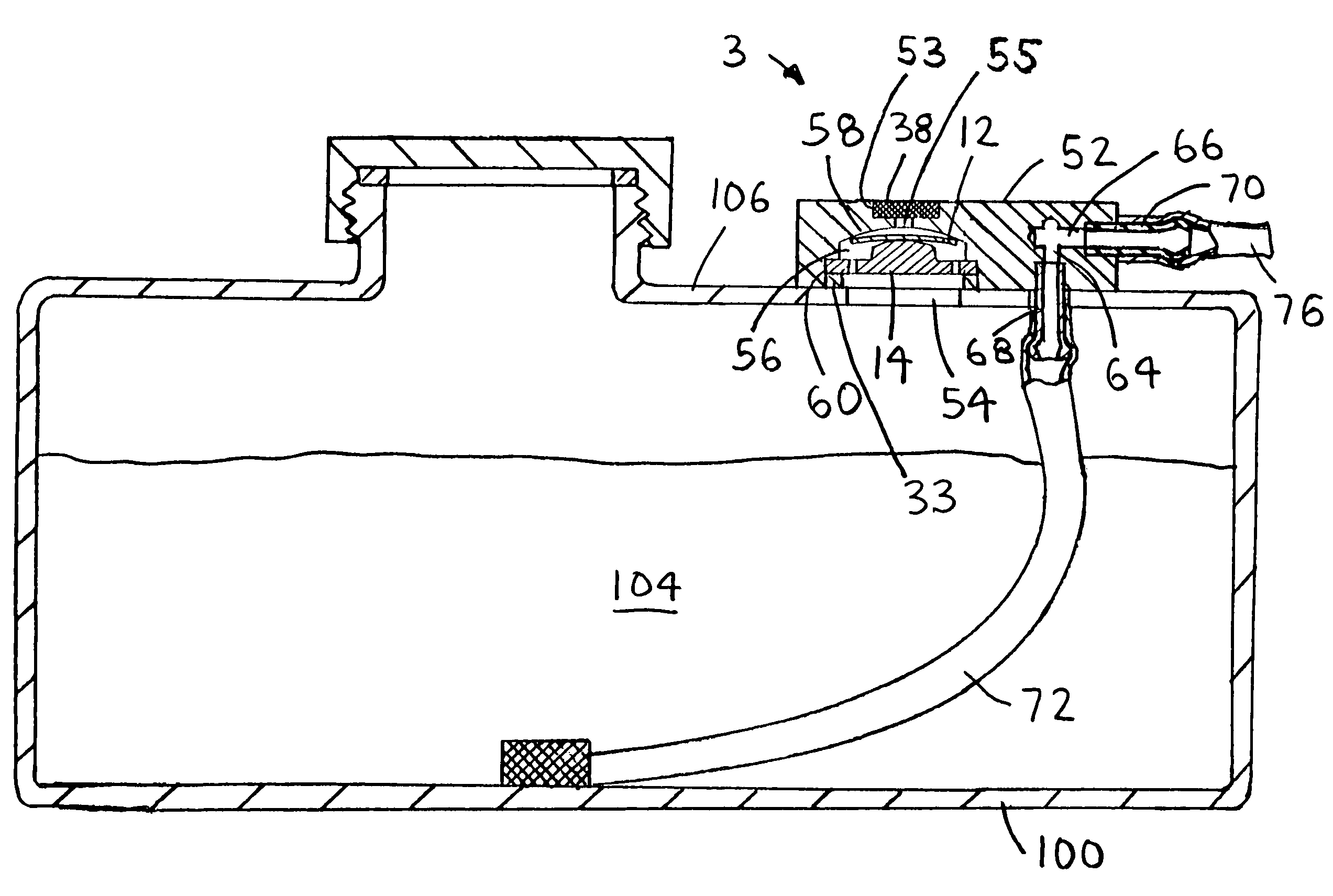

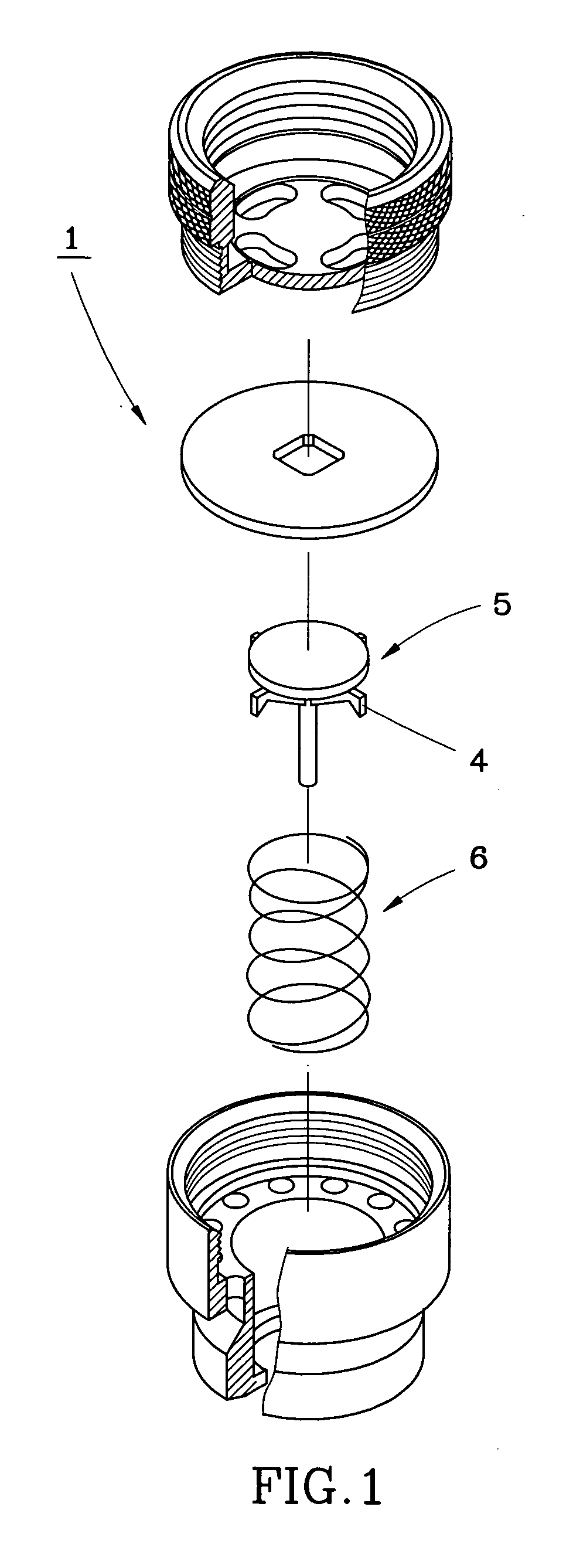

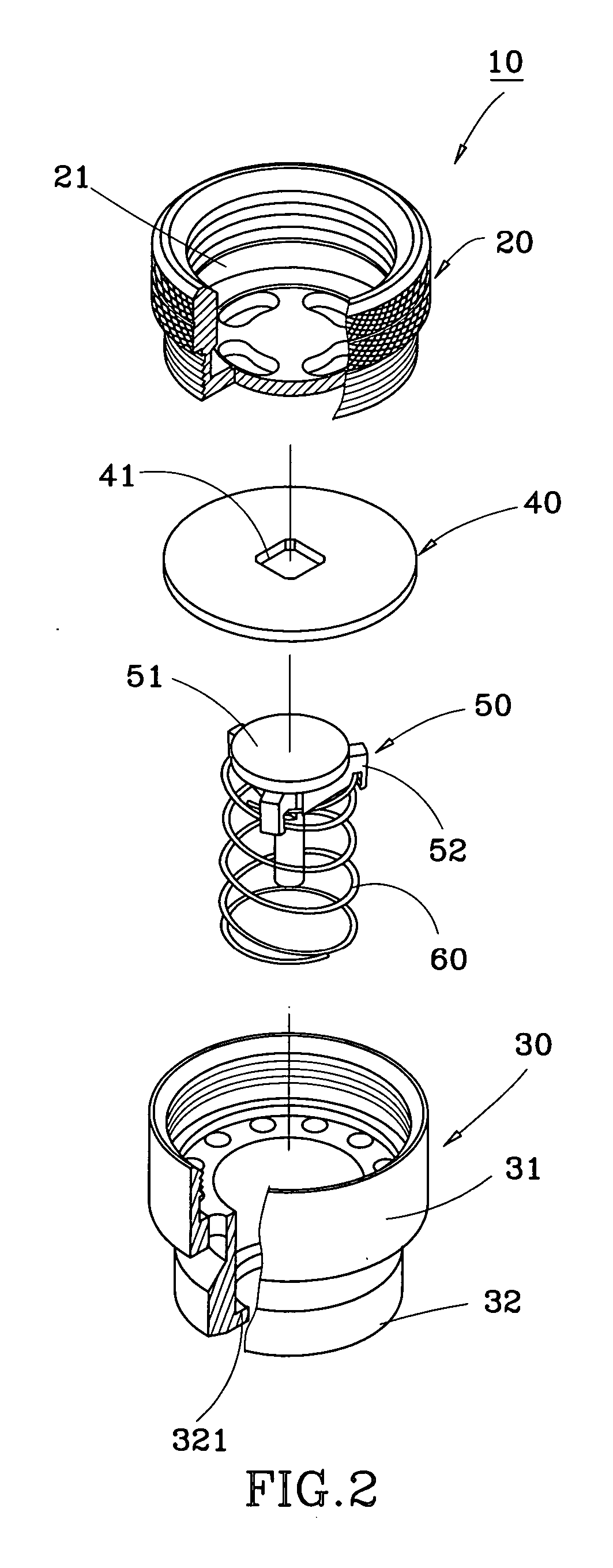

Fuel tank venting system

A fuel tank venting system includes a fuel cap, a vent diaphragm and a vent disc. A valve cavity with a substantially concave bottom is formed in a bottom of the fuel cap. At least one air passage is formed through the vent disc. A substantially convex surface is formed on a top of the diaphragm projection. The vent diaphragm is retained between the substantially concave bottom and the substantially convex surface. When air is needed for fuel flow, a vacuum within the fuel tank pulls the perimeter of the vent diaphragm downward, which breaks a seal with the substantially concave bottom to allow air flow. In a second embodiment, the fuel tank venting system is contained in a wall of the fuel tank. In a third embodiment, the fuel tank venting system is contained in a fuel vent body, which is attached to the fuel tank.

Owner:COUNTRY INDS TECH

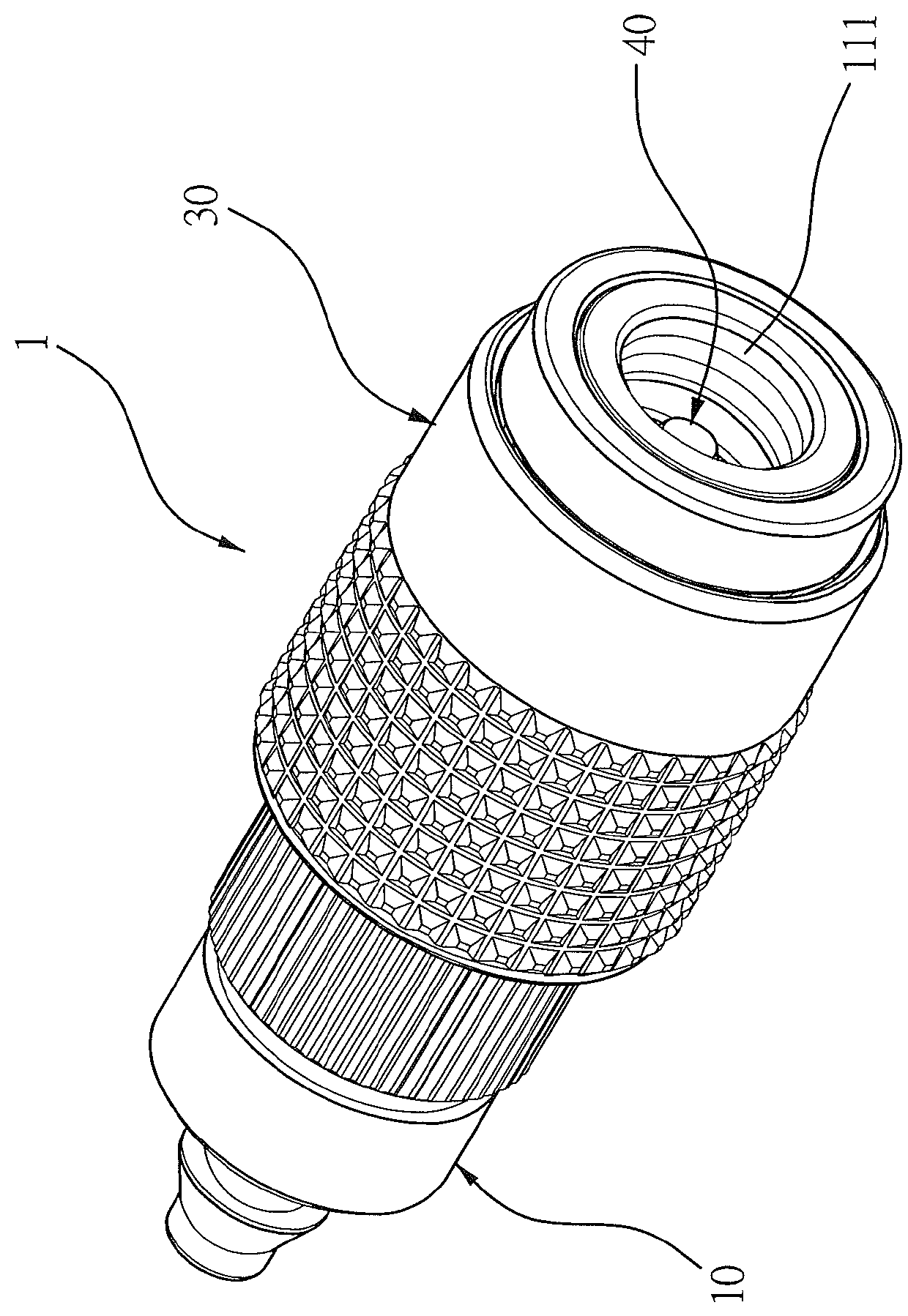

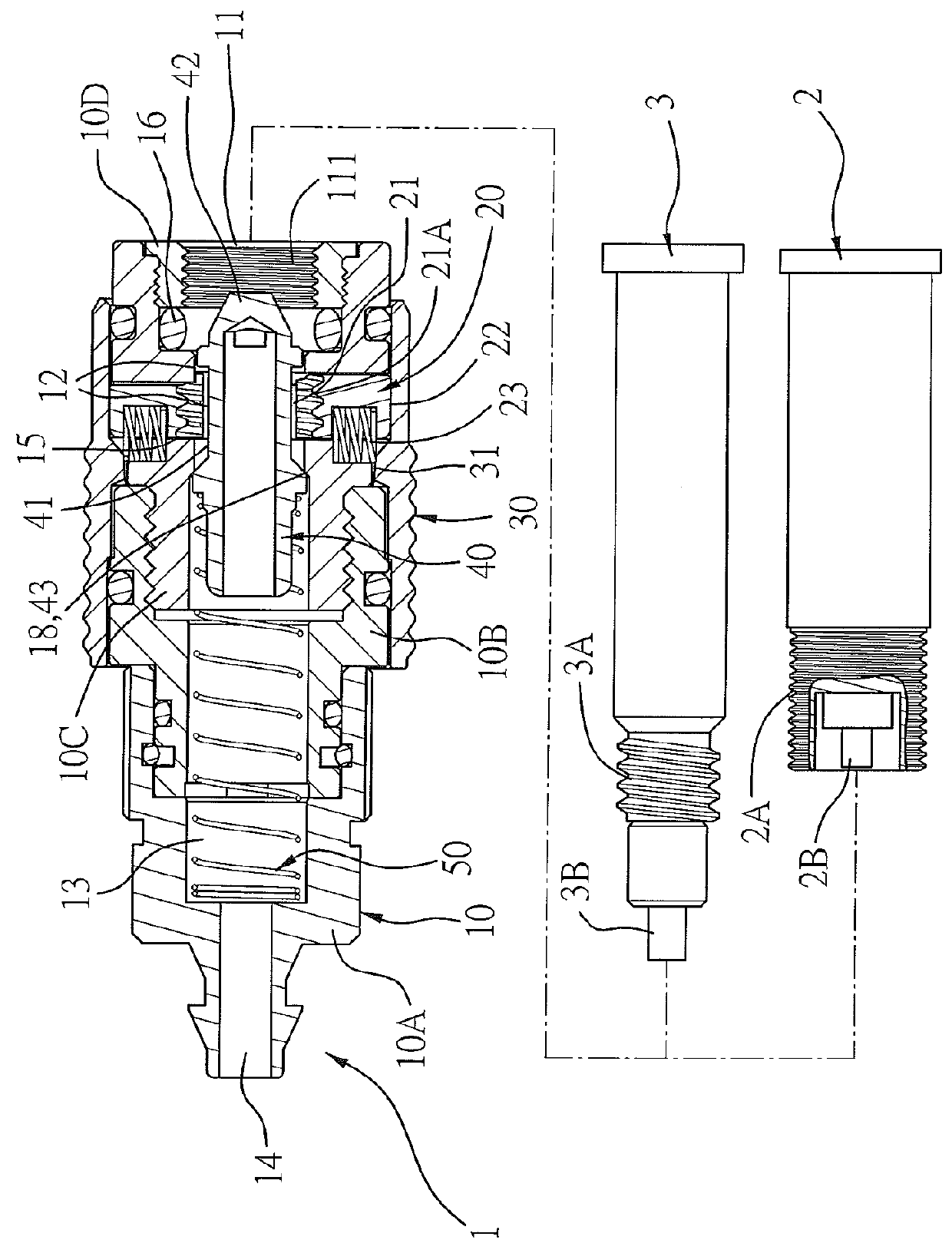

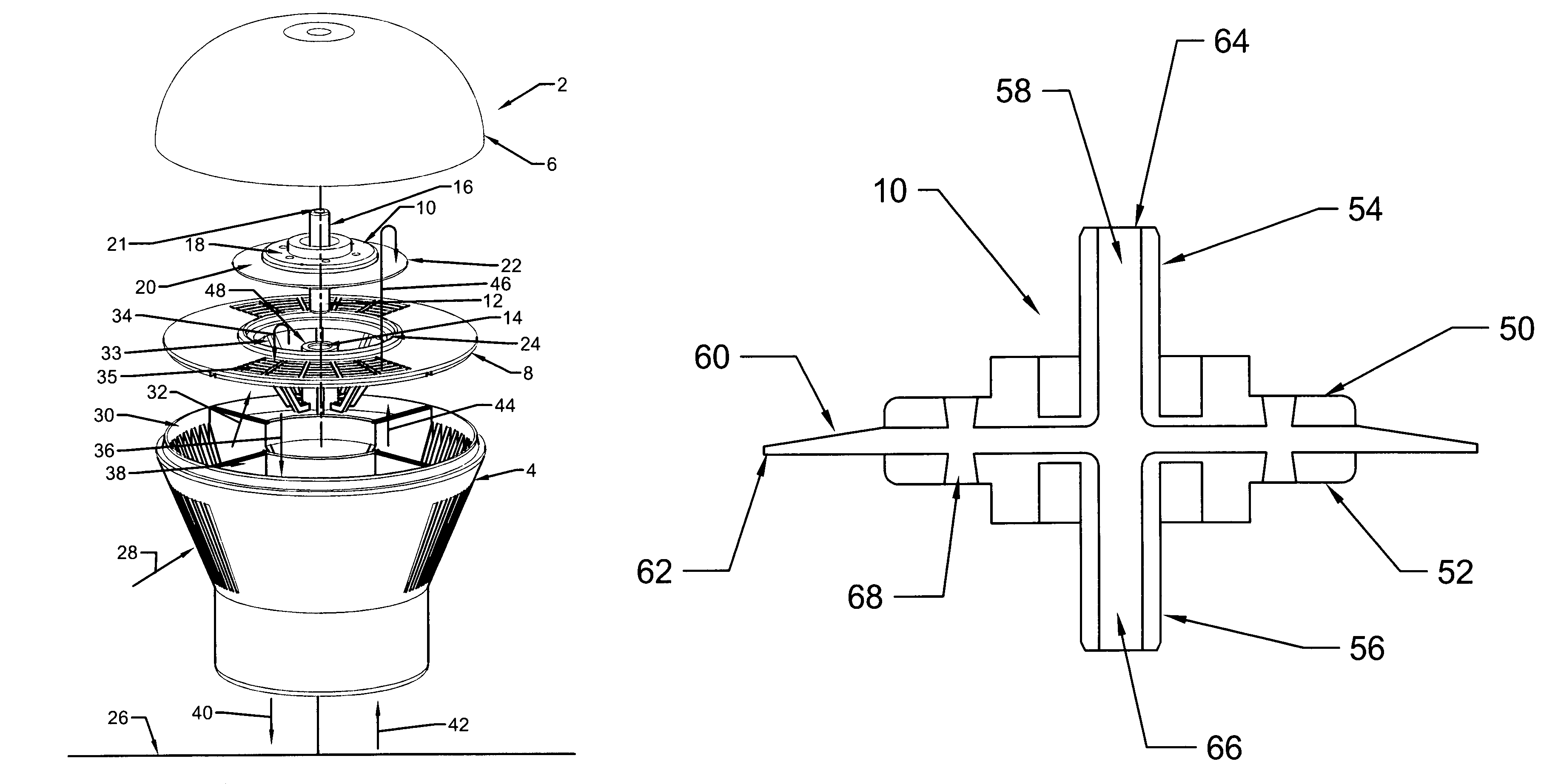

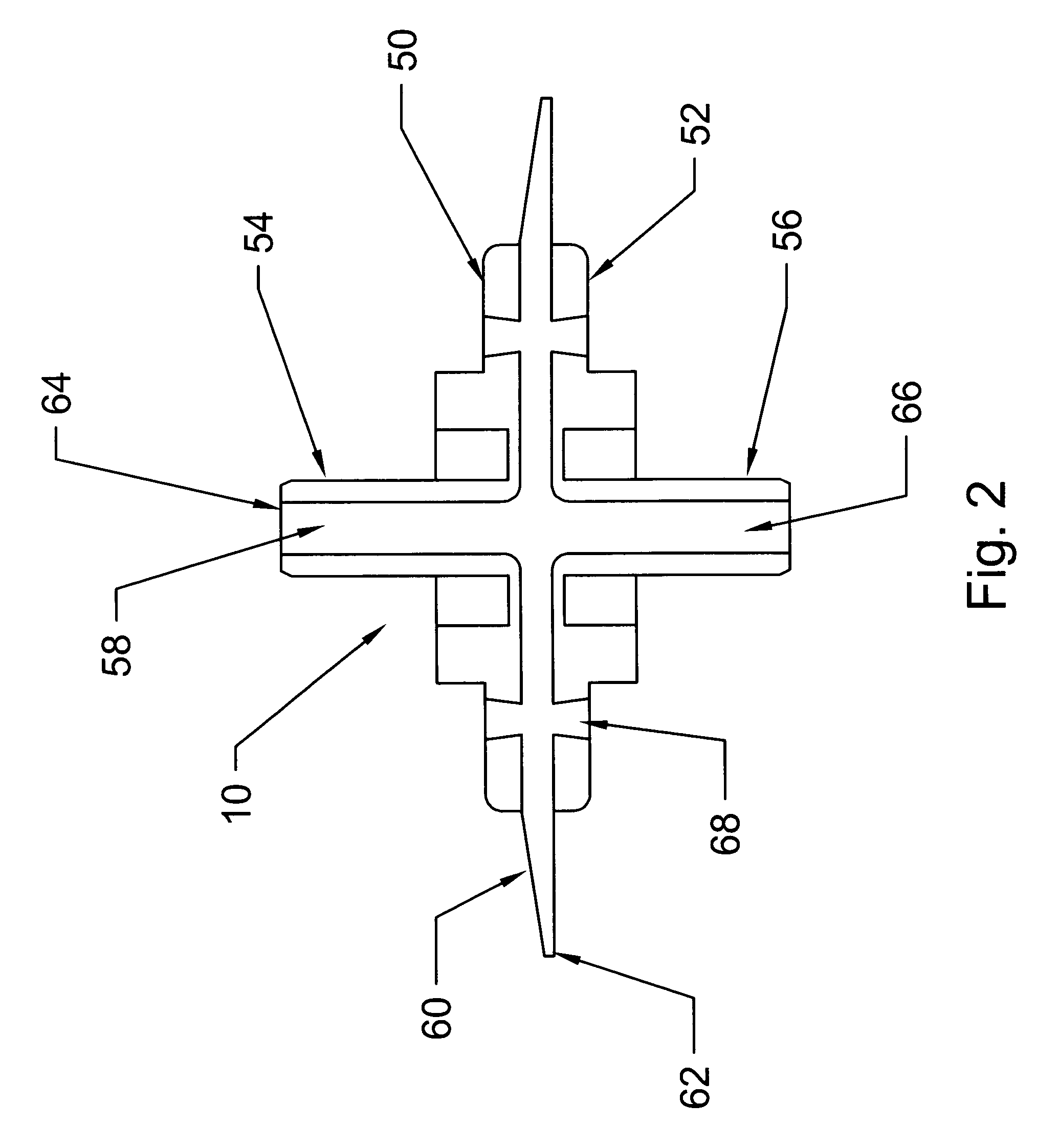

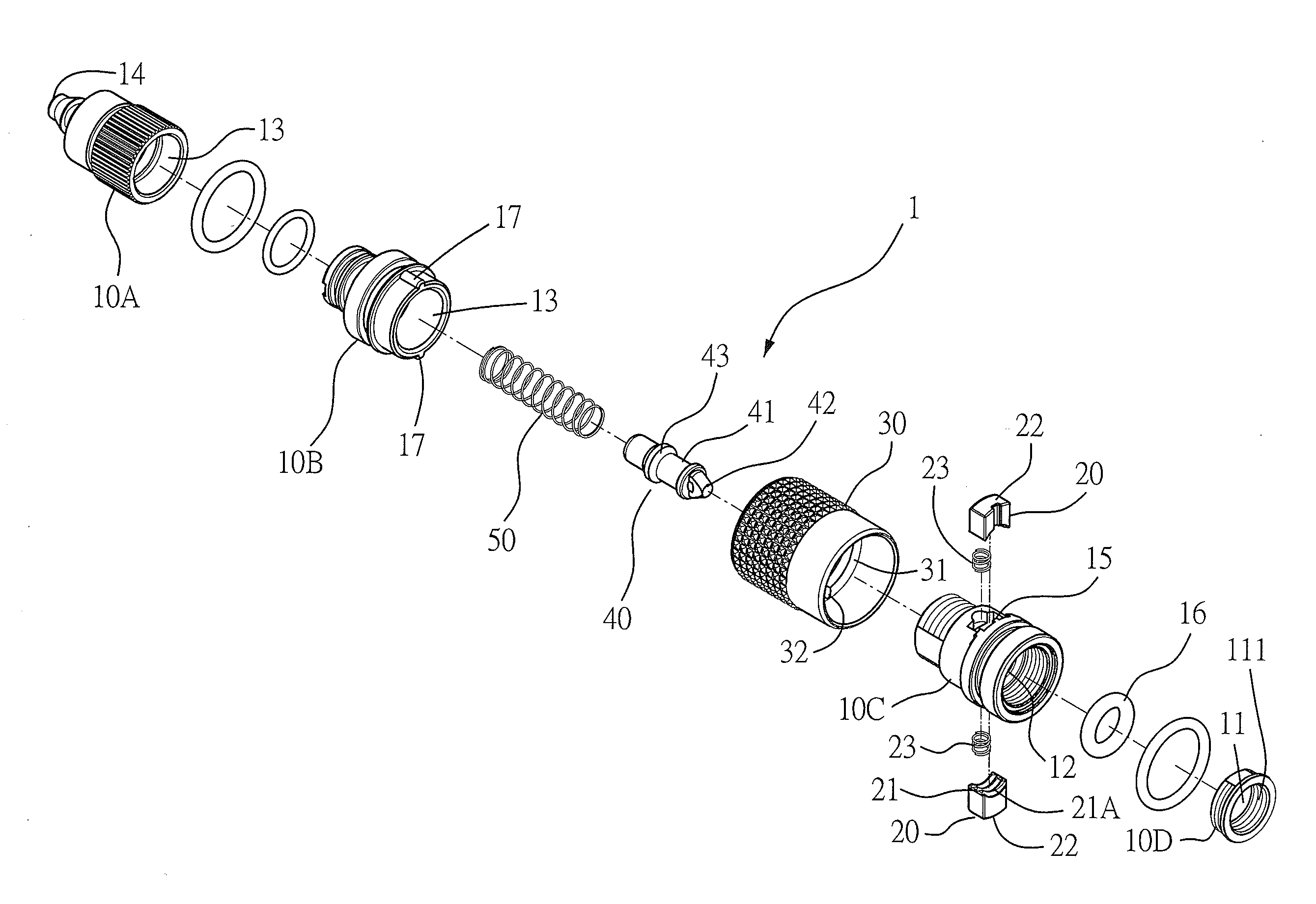

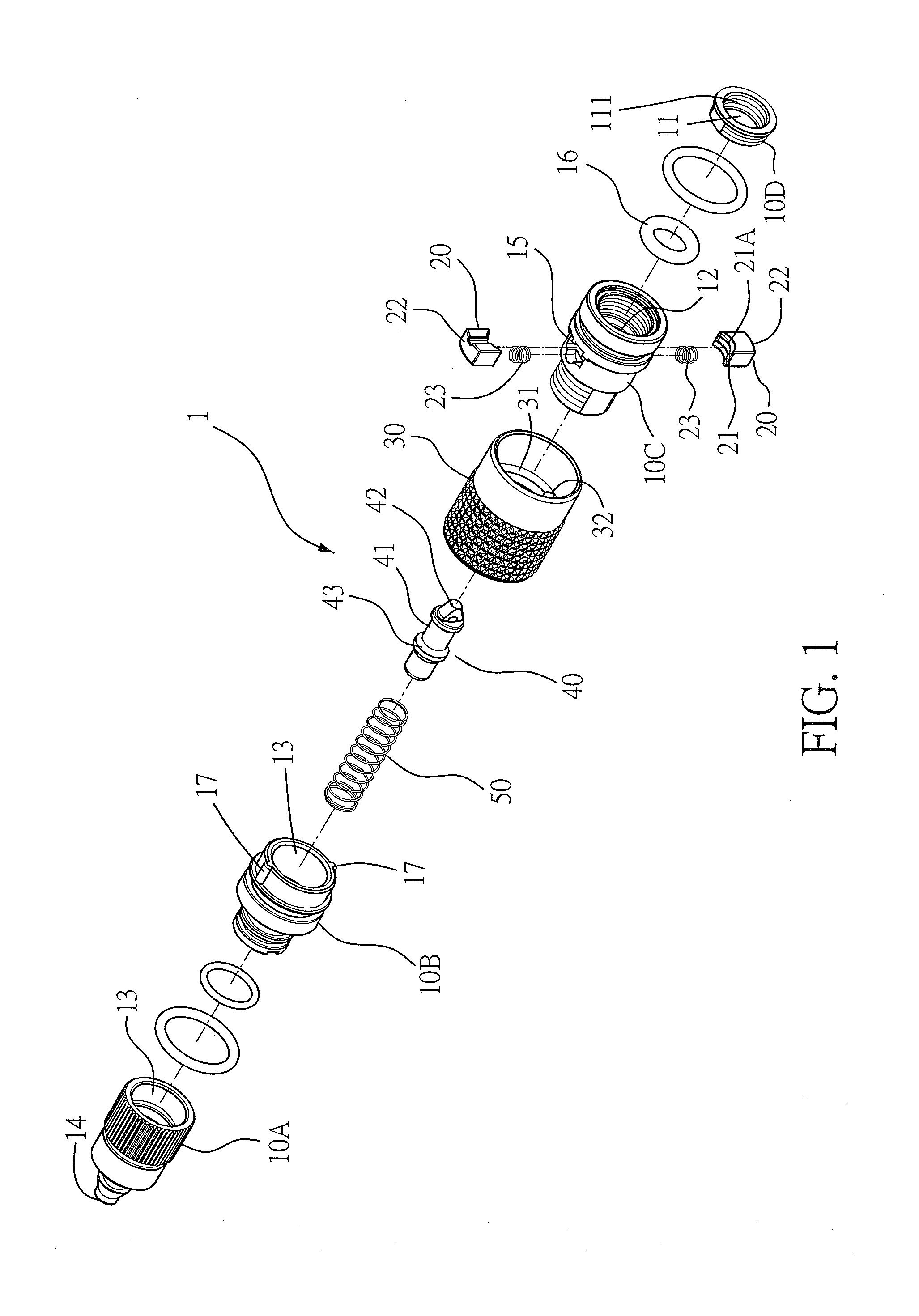

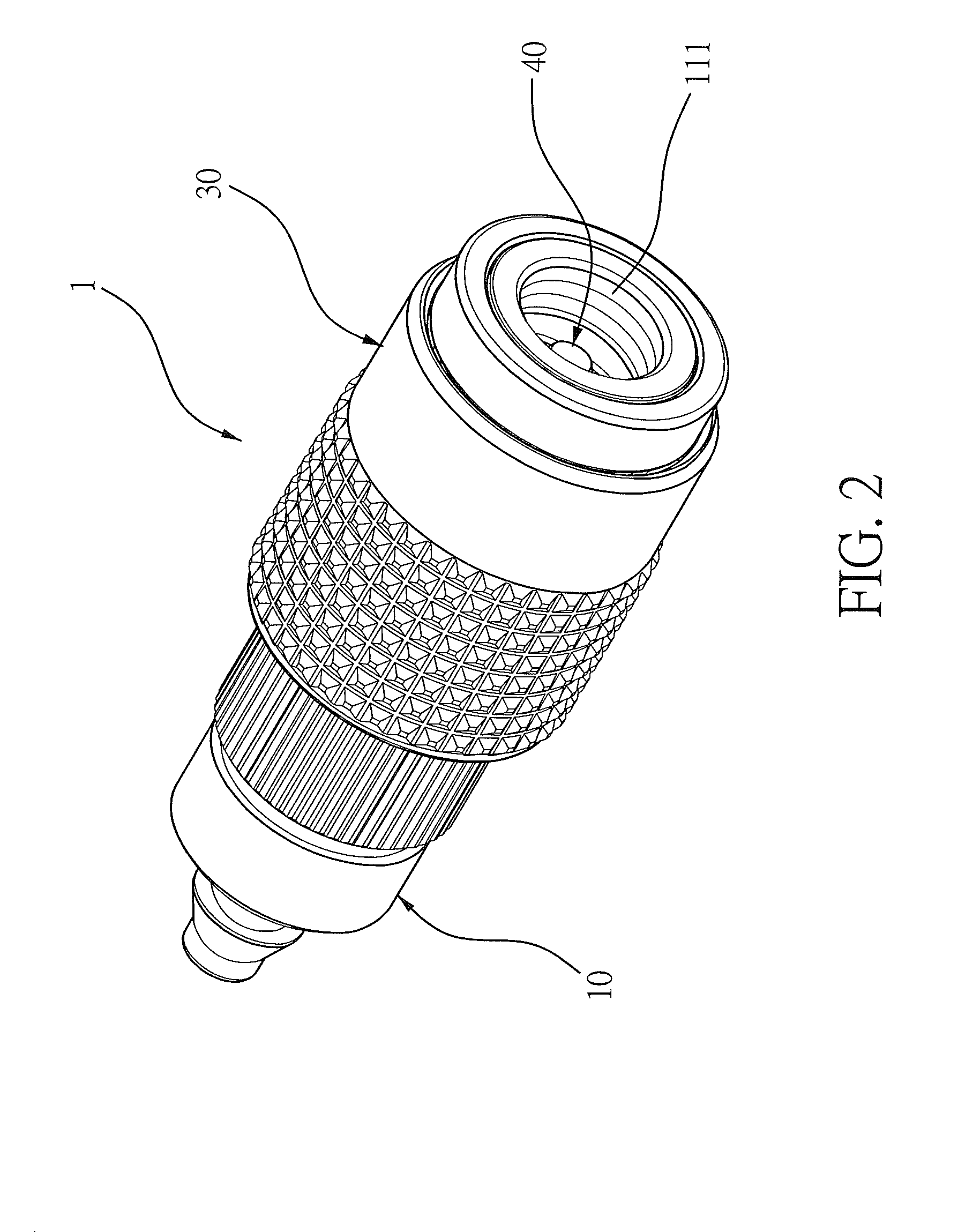

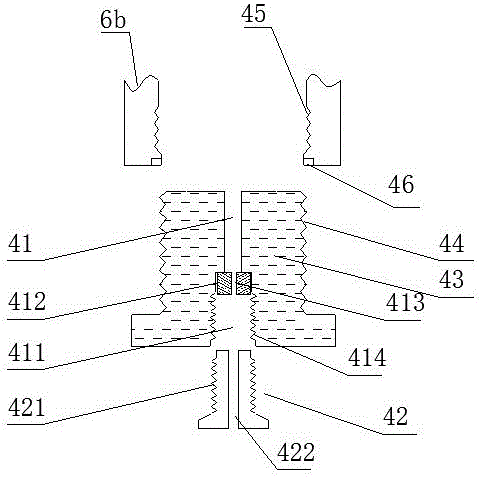

Connector structure for a Schrader (American) valve/Presta (French) valve

ActiveUS9249914B2Firmly connectedQuick breakCouplingsVehicle servicing/repairingControl setEngineering

A connector structure for a Schrader (American) valve or a Presta (French) valve contains an air connector connected with a Schrader (American) valve or a Presta (French) valve. The Schrader (American) valve includes Schrader (American) threads and a Schrader (American) inlet part; the Presta (French) valve includes Presta (French) threads and a Presta (French) inlet part. The air connector contains a body including a Schrader (American) inserting hole with a Schrader (American) screwing section, a Presta (French) inserting hole, a movable groove, an air intake, and at least one through orifice; a limiting block including a retaining segment with plural locking teeth and including a defining segment; a control set disposed on the body and controlling the defining segment; a stopping rod mounted in and limited by the movable groove, the stopping rod including a confining slot and an abutting segment which correspond to the Schrader (American) inserting hole.

Owner:DIRO TECH

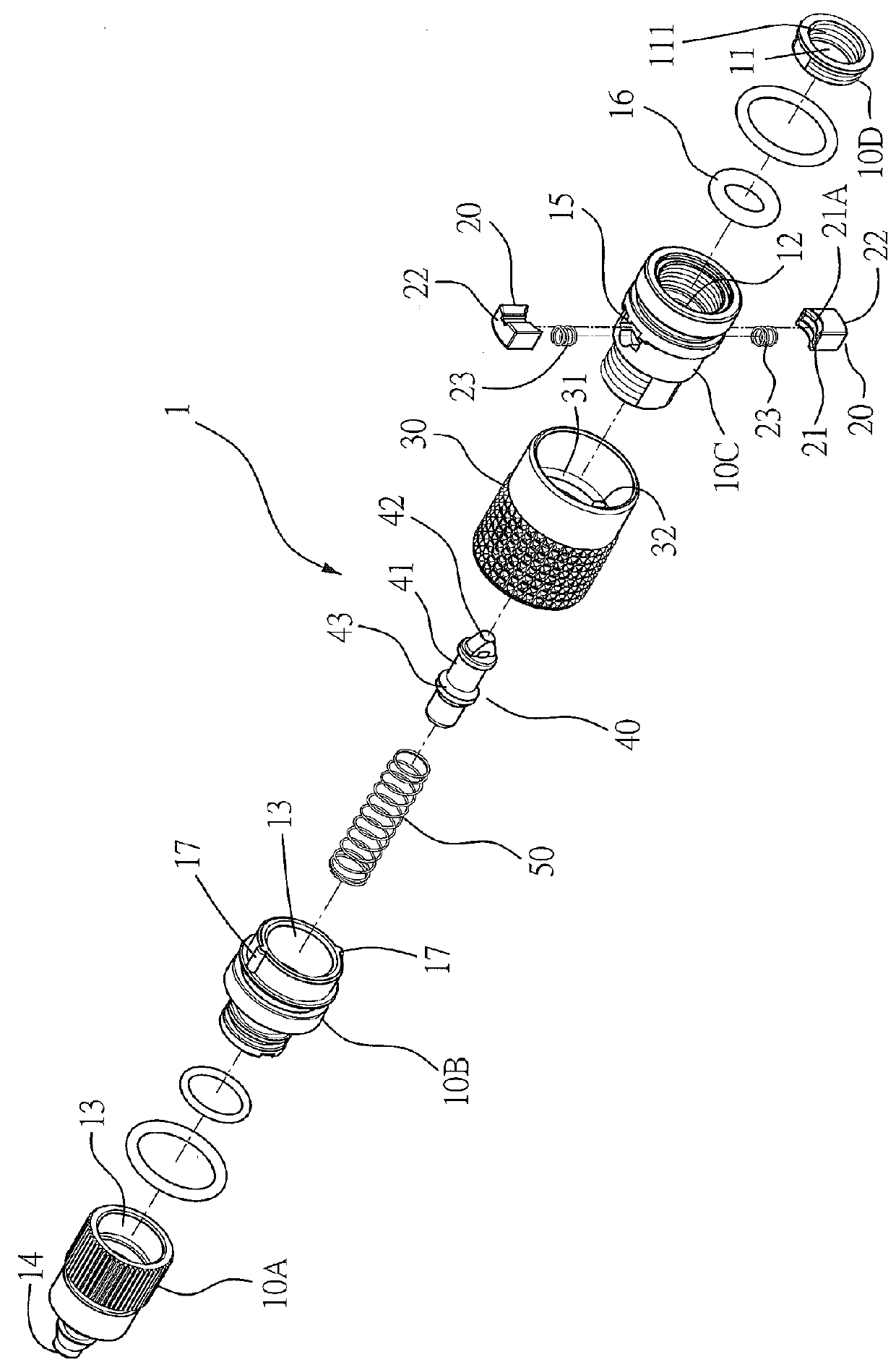

Vacuum relief valve

InactiveUS20110180163A1Simple structureAdditional operating advantageCheck valvesEqualizing valvesEngineeringValve stem

A vacuum relief valve is provided. The vacuum relief valve includes a valve body, a filter, a valve stem, a valve seal, a valve seat and valve biasing structure. The valve body includes an interior, an inlet side and a tank side. The inlet side is located substantially opposite the tank side. The filter is located at the inlet side. The valve stem is positioned on the interior the valve body. The valve seal is positioned about the valve stem. The valve seat cooperates with the valve seal to seal the vacuum relief valve. The valve biasing structure is located between the valve seal and the tank side. The valve biasing structure is configured to bias the valve seal towards the valve seat.

Owner:DELAWARE CAPITAL FORMATION

Self-draining vacuum breaker

A self-draining vacuum breaker includes a first valve having an inlet at its one end for connecting an outfall, a second valve having a coupling portion at its one end connected with the other end of the first valve, an outlet at its the other end for connecting a hose, and an annular fringe formed at an inner periphery thereof, a movable stopper having a stopping member and a plurality of claw hooks, which extends downwards from the stopping member and movably contacts against the inner periphery of the outlet of the second valve and each has a barb-like hook portion, and a spring having two ends respectively engaging the barb-like hook portions and lying against the annular fringe.

Owner:YANG YUNG FANG

Method of making three-flow-passage valve with a pressure indicator

InactiveUS20180120197A1Prolong lifeReduce moving frictionMachine gearing/transmission testingEngine fuctionsAccess portVALVE PORT

A method of making a three-flow-passage valve with a pressure indicator, comprising the steps of constructing a first half housing defining an upper flow passage, a middle flow passage, and a lower flow passage; constructing a second half housing defining the same flow passages; forming an access port through the housing in the middle flow passage; forming a first valve seat with one valve opening; assembling one movable valve opening stopper in the upper flow passage; adjusting the one movable valve opening stopper; forming a second valve seat with one valve opening; assembling one movable valve opening stopper in the upper flow passage; adjusting the one movable valve opening stopper to allow the one movable valve opening stopper in the middle flow passage; combining and sealing the first half housing with the second half housing; and mounting a pressure indicator to the access port.

Owner:DI MONTE MICHAEL ANTHONY

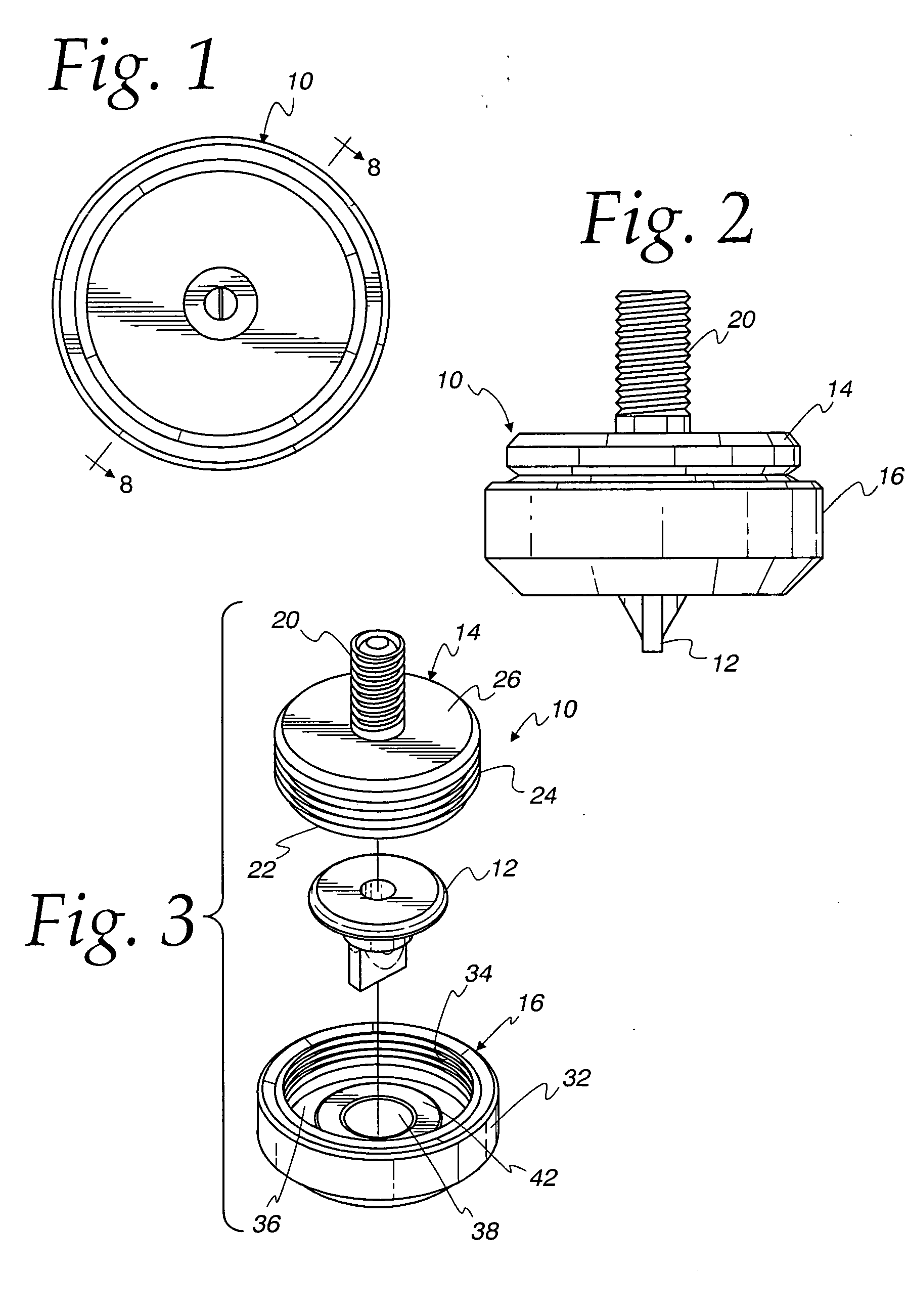

Air admittance valve

InactiveUS7395835B1Improved air admittance valveEasy to failCheck valvesEqualizing valvesMechanical engineeringAdmittance

In some embodiments, an air admittance valve includes a base, a screen plate and a diaphragm engageable with the screen plate. The diaphragm may include a first center disk having a stem and a membrane coupled to the first center disk. The membrane may have a continuous material sized to extend beyond a perimeter of the first center disk, be formed of a material more pliable than the first center disk and be adapted to be coupled to the first center disk through the center disk stem.

Owner:RECTORSEAL THE

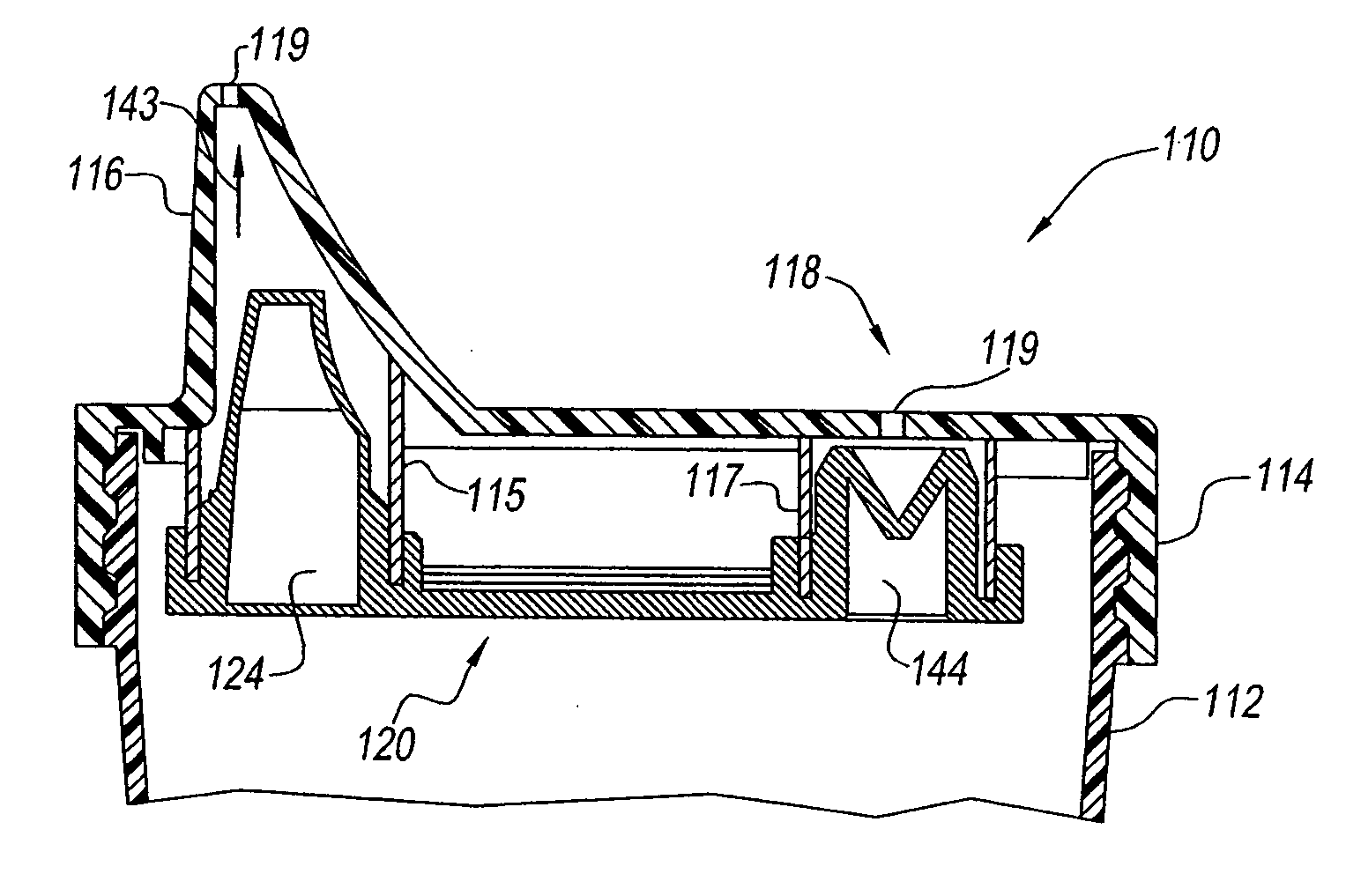

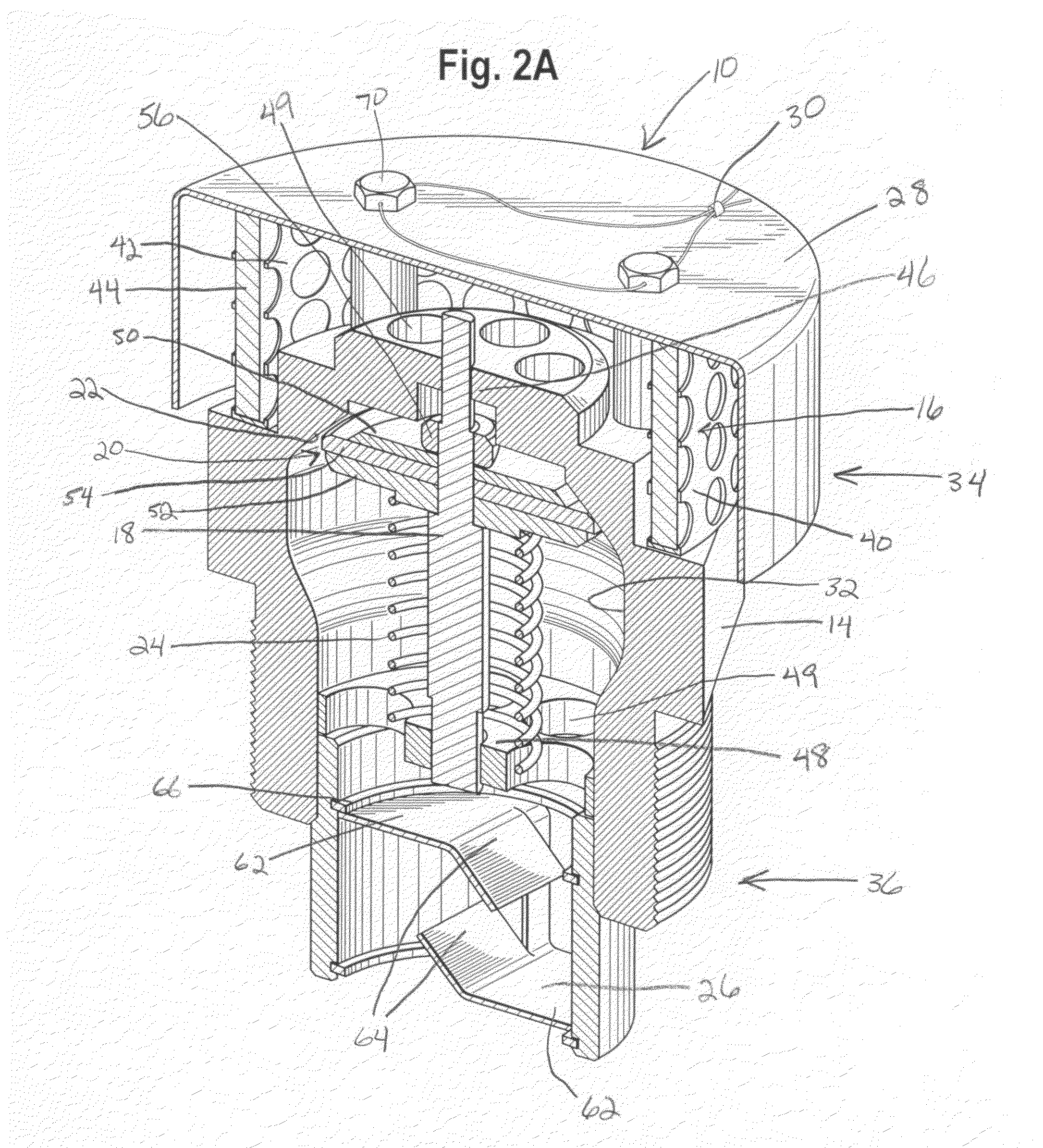

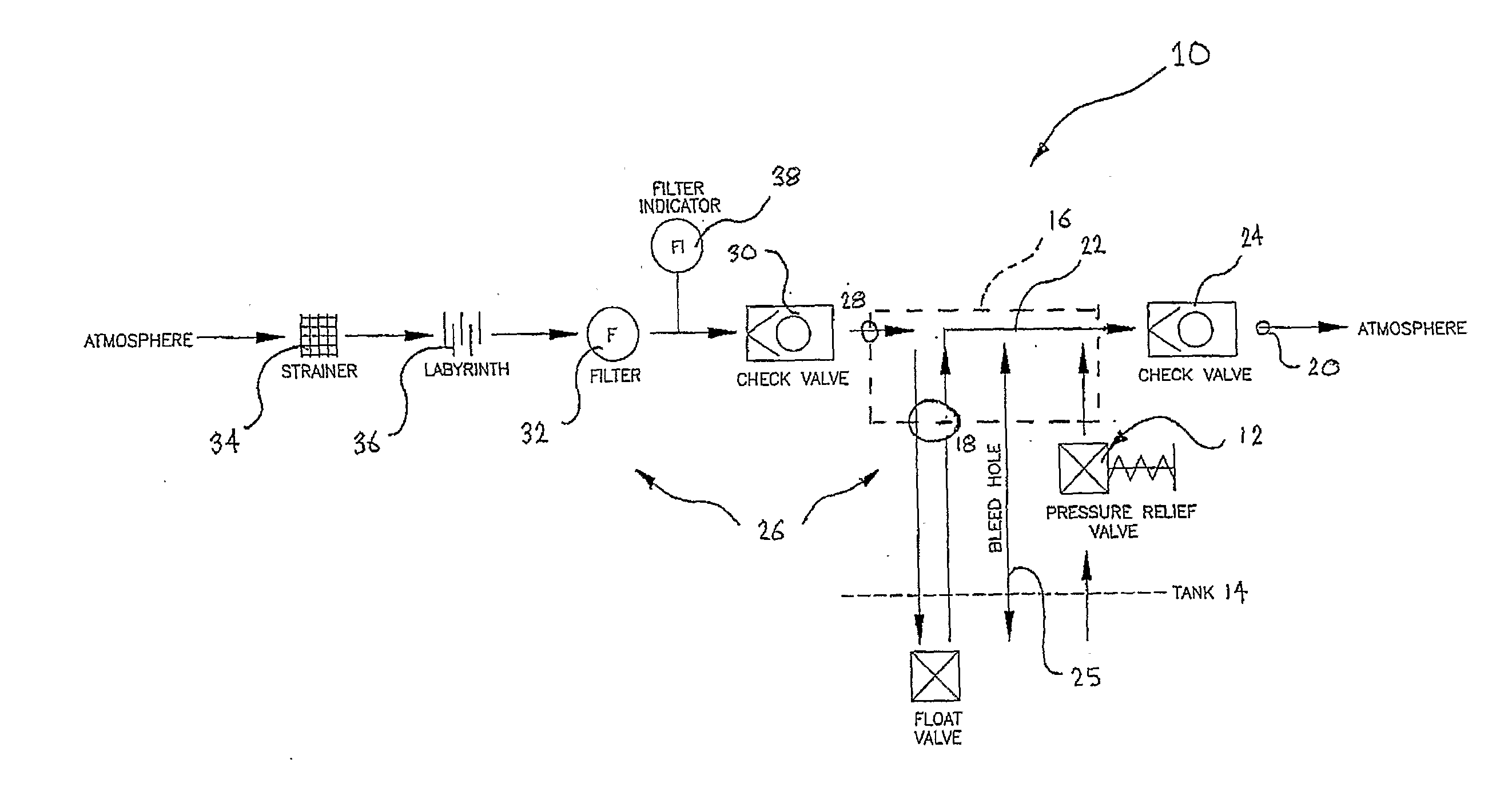

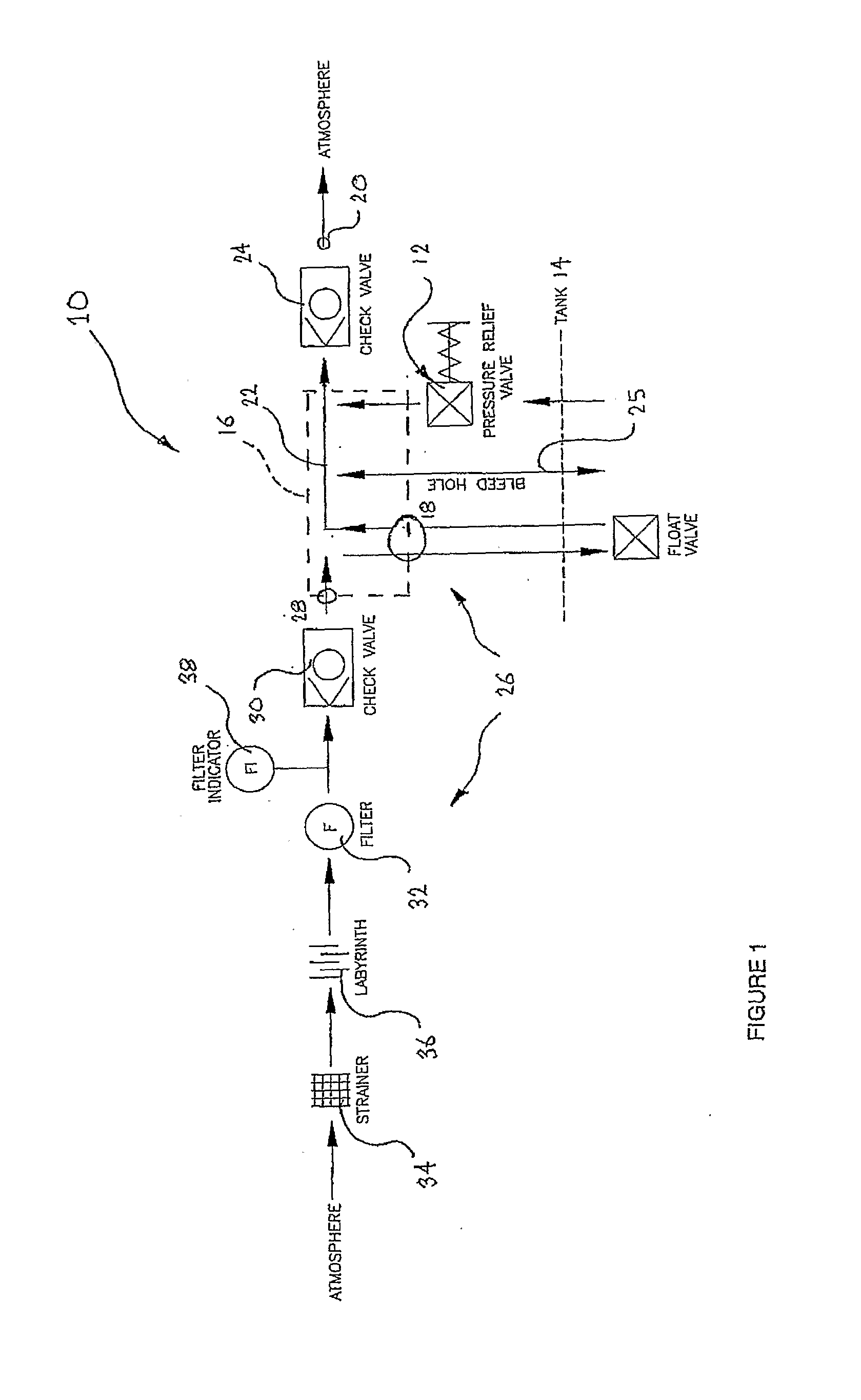

Pressure relief valve and vent assembly

The present invention relates broadly to a pressure relief valve and vent assembly (10) comprising a pressure relief valve (12) arranged to couple to a tank (14), and a tank vent (26). The tank vent (26) comprises a vent body (16) having a vent inlet (18) and a exhaust outlet (20) in communication with each other via a fluid passageway (22). The tank vent also comprises an exhaust check valve (24) connected to the vent body (16) at the exhaust outlet (20). The exhaust check valve (24) is arranged to allow fluid to flow through the fluid passageway (22) in one direction only from the tank (14) to atmosphere via the vent inlet (18) and the exhaust outlet (20). the pressure relief valve and vent assembly (10) also includes an ambient air inlet (28) in fluid communication with the fluid passageway (22). The ambient air inlet (28) is arranged to permit the flow of ambient air from atmosphere into the tank (14) via the vent inlet (18). The tank vent (26) also comprises an ambient air inlet check valve (30) configured to allow air flow in one direction only from atmosphere to the tank (14) via the air inlet (28).

Owner:WALNAB

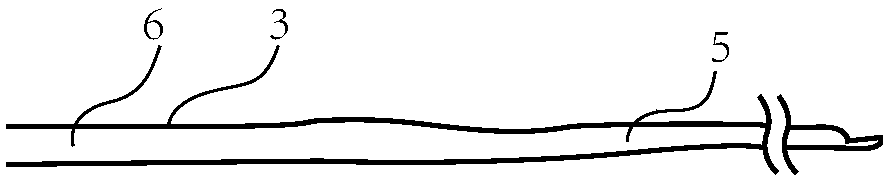

Inflatable product

PendingCN108443549AStrong inflation effectSmall structureDiaphragm valvesEngine diaphragmsEngineeringAirbag deployment

The invention relates to an inflatable product which at least comprises a manual fan surface, an air inlet, an air channel, an air bag body and a sealing structure. The air bag body is provided with at least one air inlet; and the perimeter of the air inlet and / or the air channel is at least 20cm. The manual fan surface is arranged on the air channel; and when the fan surface is waved, a large number of air can be waved into the air bag body. The sealing structure is arranged on the air inlet, and after the air bag body is inflated and formed, the air inlet is sealed appropriately, and the airin the air bag body can be compressed to reach to the required use pressure. The inflatable product provided by the invention is low in manufacturing cost, simple and production process, and capableof manufacturing inflatable products with different sizes and shapes according to different use environments and functions; during air inflation, no movement is needed, no special air inflation deviceis needed extraly, no power supply is needed, the air can be inflated quickly and simply at any time any where, and the required pressure is maintained; and during storage, the air can be quickly released, so that the product can be stored conveniently.

Owner:翁文灏

Connector Structure for a Schrader (American) Valve/Presta (French) Valve

ActiveUS20140326345A1Firmly connectedQuick breakCouplingsVehicle servicing/repairingControl setEngineering

A connector structure for a Schrader (American) valve or a Presta (French) valve contains an air connector connected with a Schrader (American) valve or a Presta (French) valve. The Schrader (American) valve includes Schrader (American) threads and a Schrader (American) inlet part; the Presta (French) valve includes Presta (French) threads and a Presta (French) inlet part. The air connector contains a body including a Schrader (American) inserting hole with a Schrader (American) screwing section, a Presta (French) inserting hole, a movable groove, an air intake, and at least one through orifice; a limiting block including a retaining segment with plural locking teeth and including a defining segment; a control set disposed on the body and controlling the defining segment; a stopping rod mounted in and limited by the movable groove, the stopping rod including a confining slot and an abutting segment which correspond to the Schrader (American) inserting hole.

Owner:DIRO TECH

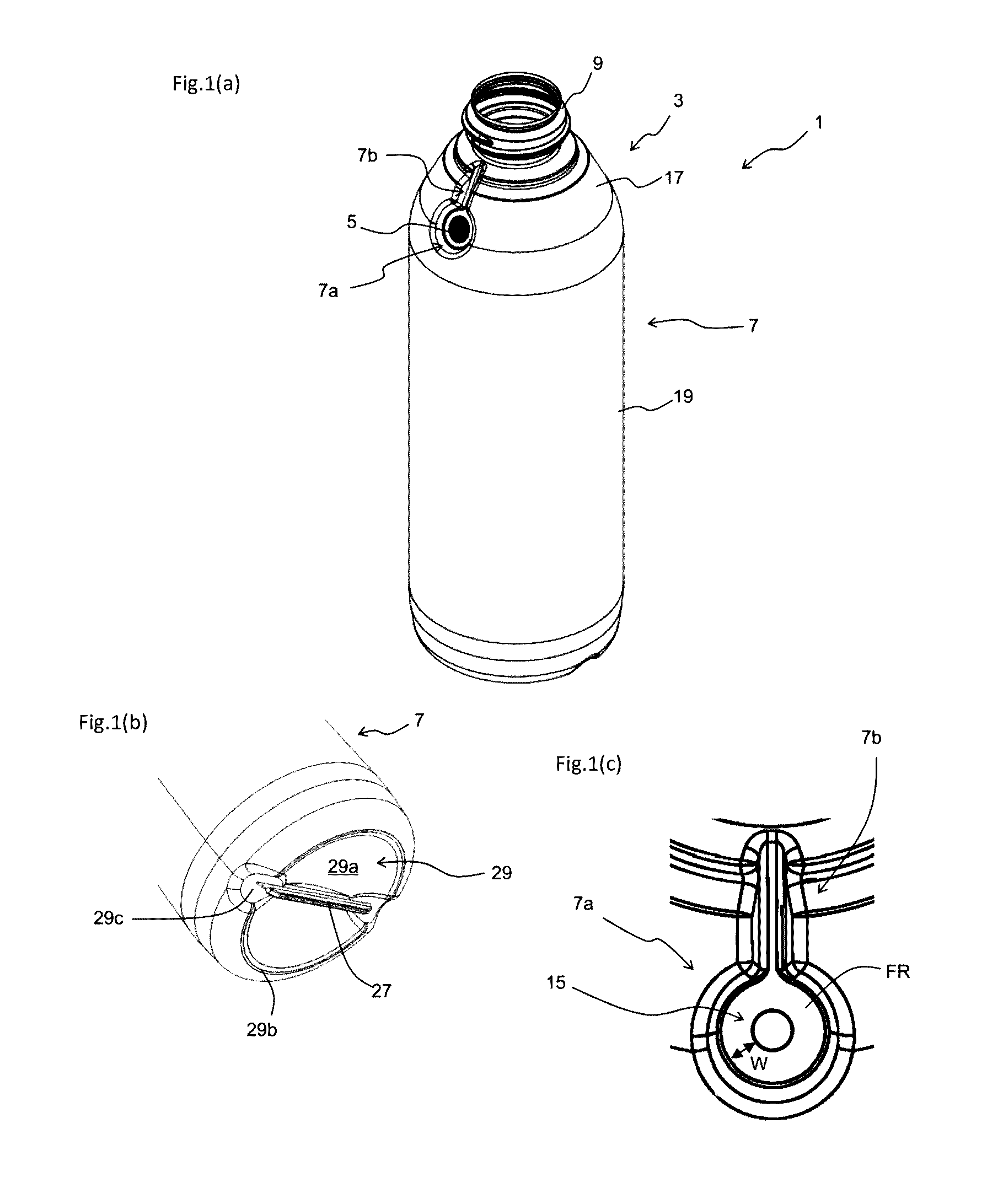

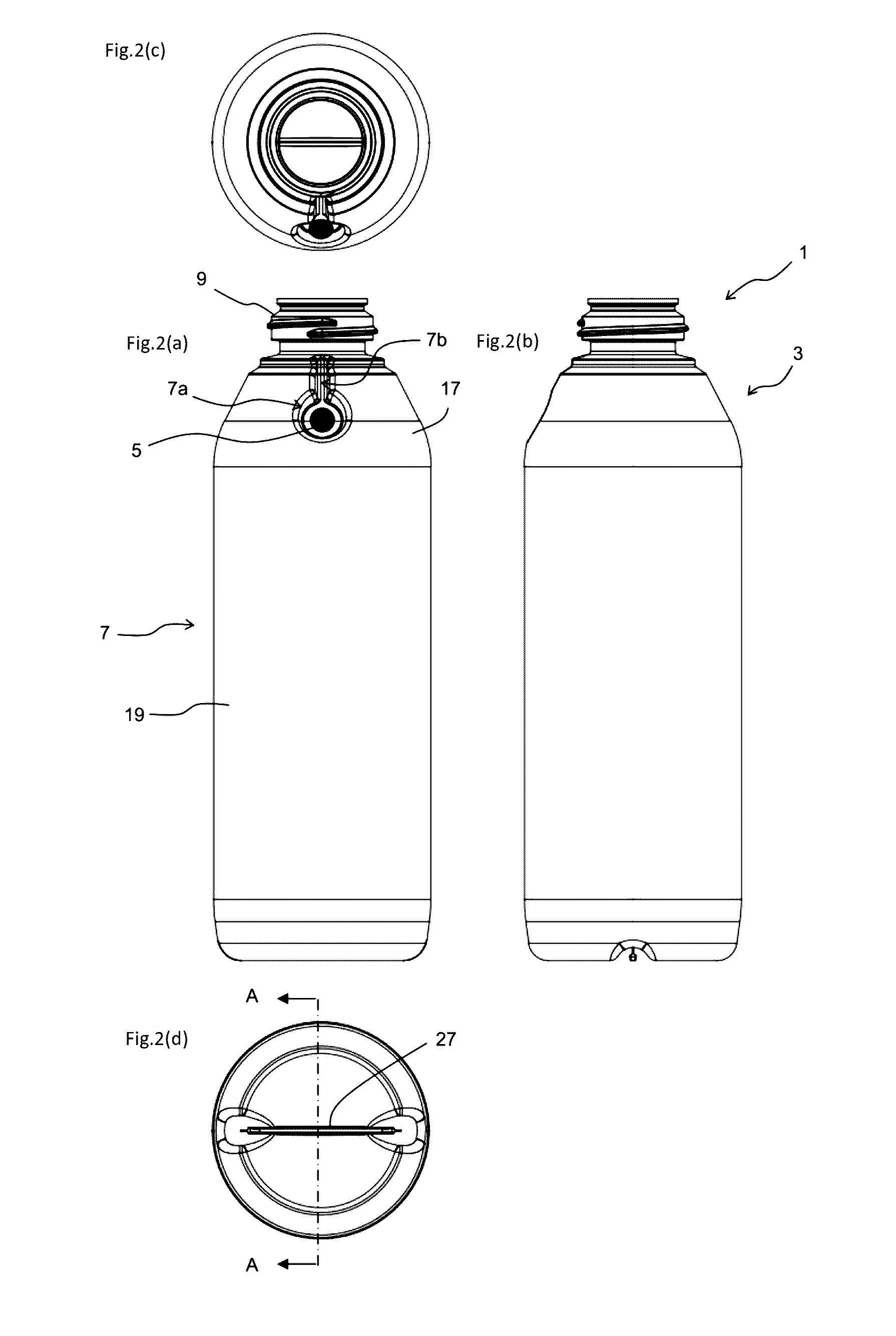

Vent Plug

Owner:W L GORE & ASSOC GK

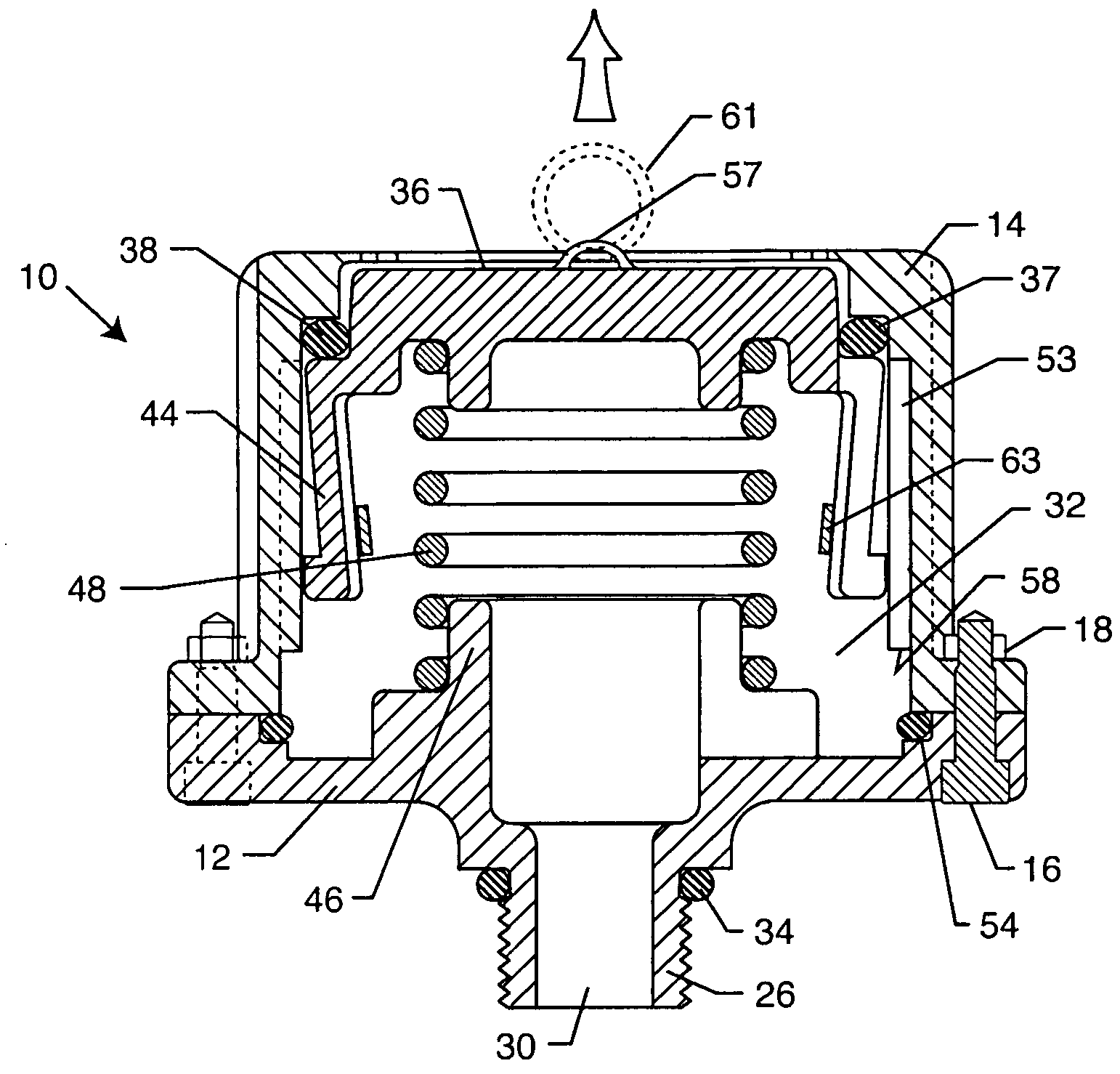

Vacuum breaker with water leak containment device

InactiveUS6904931B2Easy constructionLeak-free operationOther washing machinesDomestic plumbingEngineeringWater leak

A vacuum breaker having a floating piston that is movable in response to the communication of negative pressure to an inlet port of the vacuum breaker for permitting venting of fluid to the outside atmosphere through a vent opening. The vacuum breaker includes a liquid capture and containment device, which in conjunction with an outer hood, is effective for capturing and containing liquid in a fluid flow stream discharging from the vent opening and redirecting the captured liquid back into the vacuum breaker in order to prevent water leakage.

Owner:ALLIANCE LAUNDRY SYSTEMS

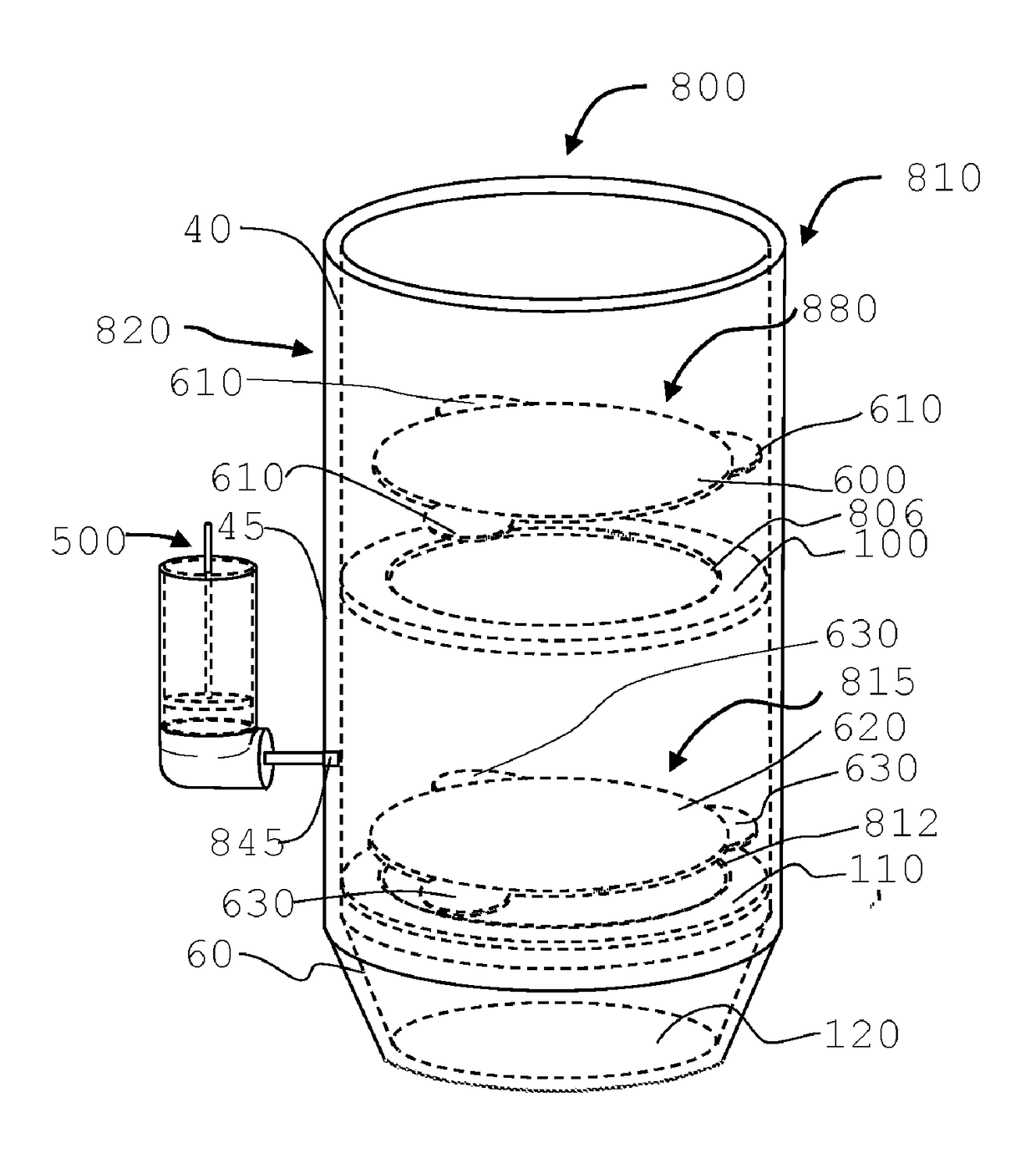

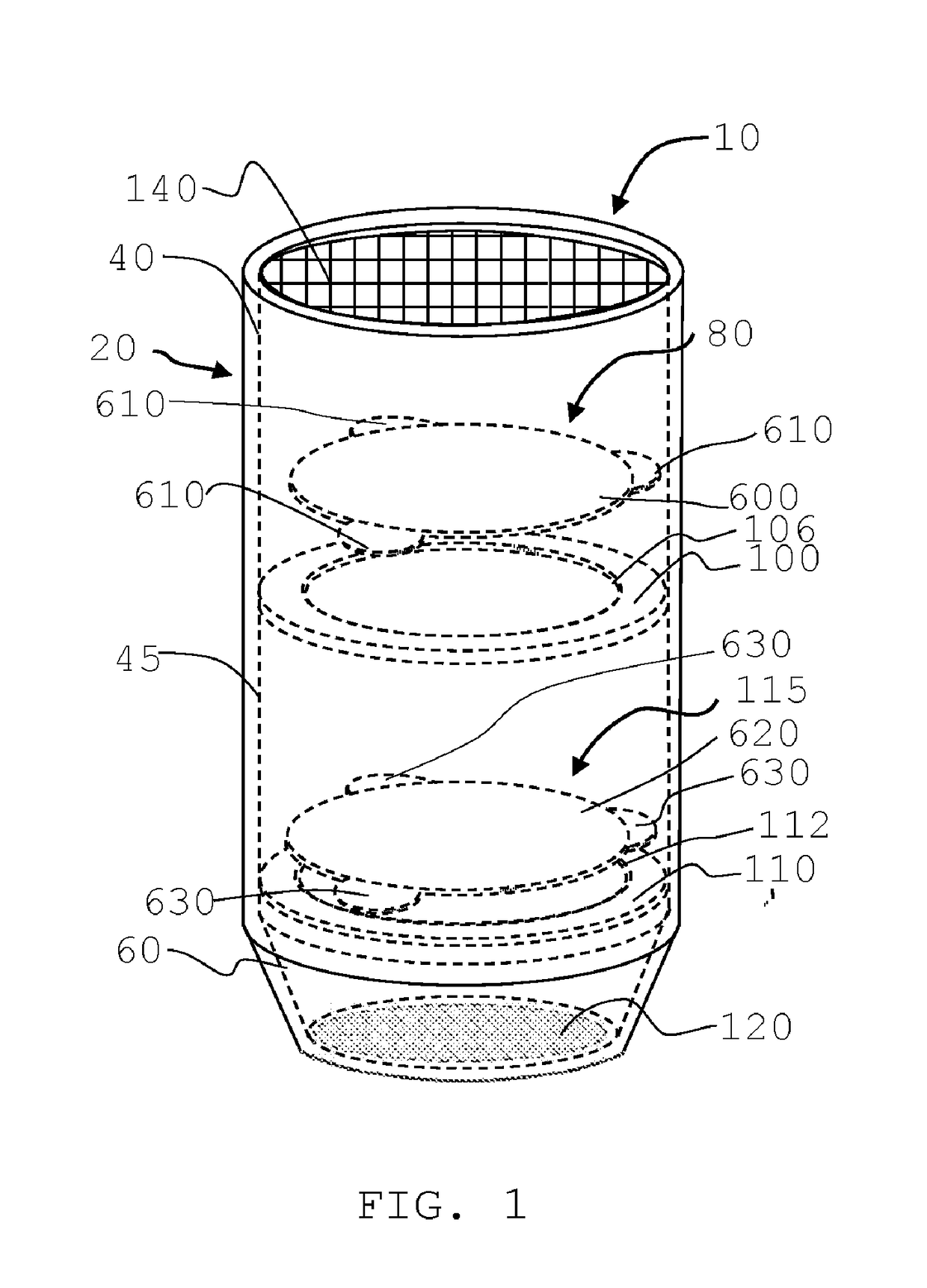

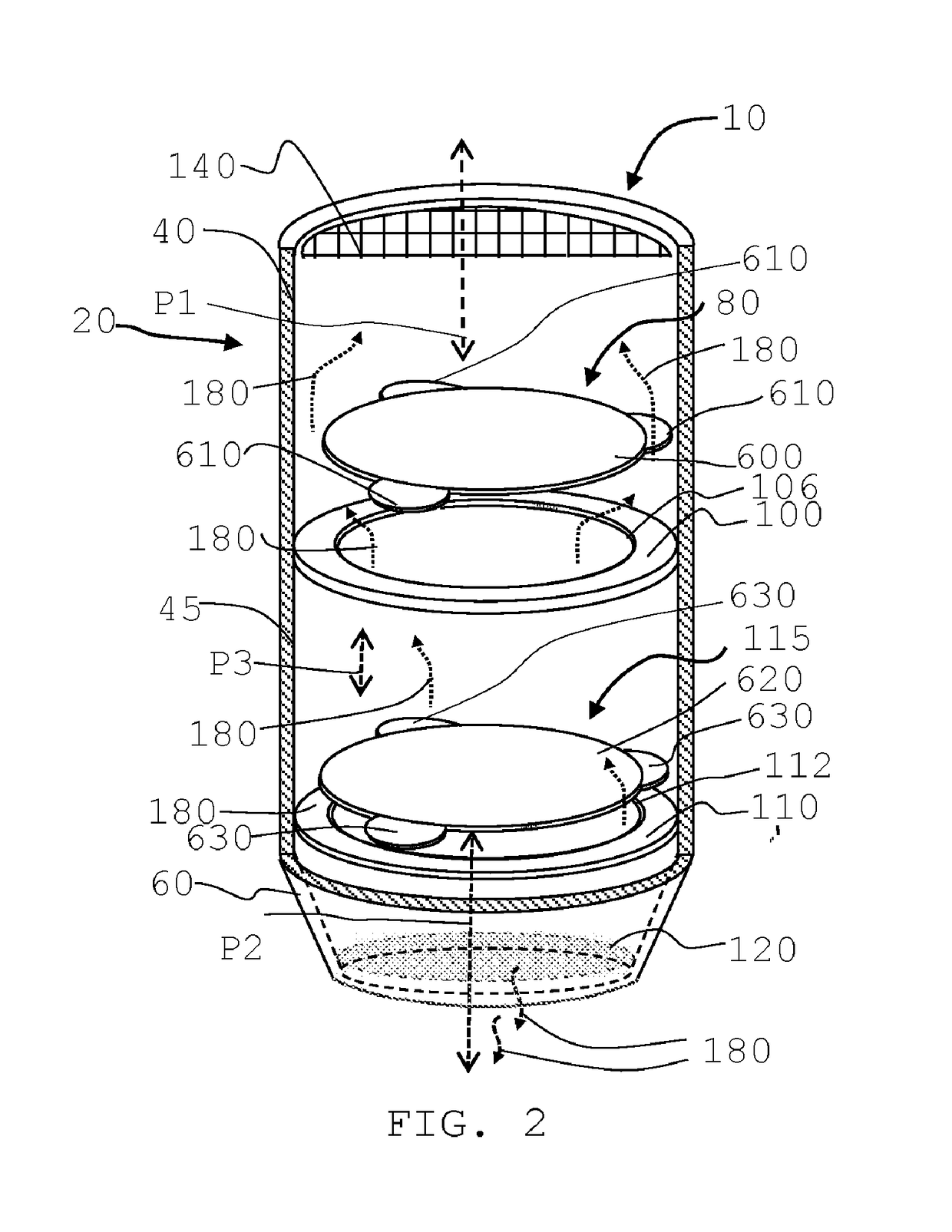

Turf Playing Surface Aeration and Drainage System

A perforated pipe network beneath a playing surface. A blower connected to the pipe network drawing an air flow through the pipe network to create a vacuum. A drain pipe connecting to the pipe network. An air / water separator connected upstream of the blower for separating water from the air flow prior to entering the blower and channeling the water into the drain pipe for discharge. A flow control unit having a unit inlet connected to the drain pipe downstream of the air / water separator and a unit outlet discharging water to a drain outlet. The flow control unit blocking air flow through the unit inlet into the drain pipe when the blower is in the vacuum mode, and opening the unit inlet when a waterhead buildup at the unit inlet exceeds the vacuum level established by the blower to discharge water through the drain outlet.

Owner:HUMMERT GEORGE T +1

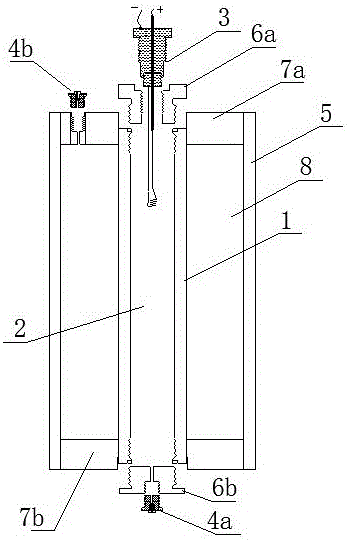

Gas-inflating-and-locking-integrated gas blaster

InactiveCN106643314AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesCheck valvesEngineeringLiquid carbon

The invention discloses a gas-inflating-and-locking-integrated gas blaster. The gas-inflating-and-locking-integrated gas blaster comprises an inner tube, an inner-tube filling cavity, an ignition mechanism, an inner-tube gas inflating mechanism and an outer tube. The inner-tube filling cavity is formed in the inner tube, a first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner tube in a sealed mode respectively, the outer tube is arranged on the outer layer of the inner tube, a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealed mode, the ignition mechanism and the inner-tube gas inflating mechanism are installed on the first sealing inner cover or the second sealing inner cover, and an outer-tube gas inflating mechanism is installed on the first sealing outer cover or the second sealing outer cover; a sealed cavity between the inner tube and the outer tube is an outer-tube filling cavity, the inner-tube filling cavity is filled with supercritical oxygen and carbonaceous organic materials, and the outer-tube filling cavity is filled with liquid easy-to-gasify materials such as liquid carbon dioxide or liquid nitrogen. The gas-inflating-and-locking-integrated gas blaster has the advantages that the manufacturing cost is low, the mixing uniformity of reaction materials is high, the heat releasing efficiency is high, the transportation safety is good, and the blasting power is large.

Owner:郭远军

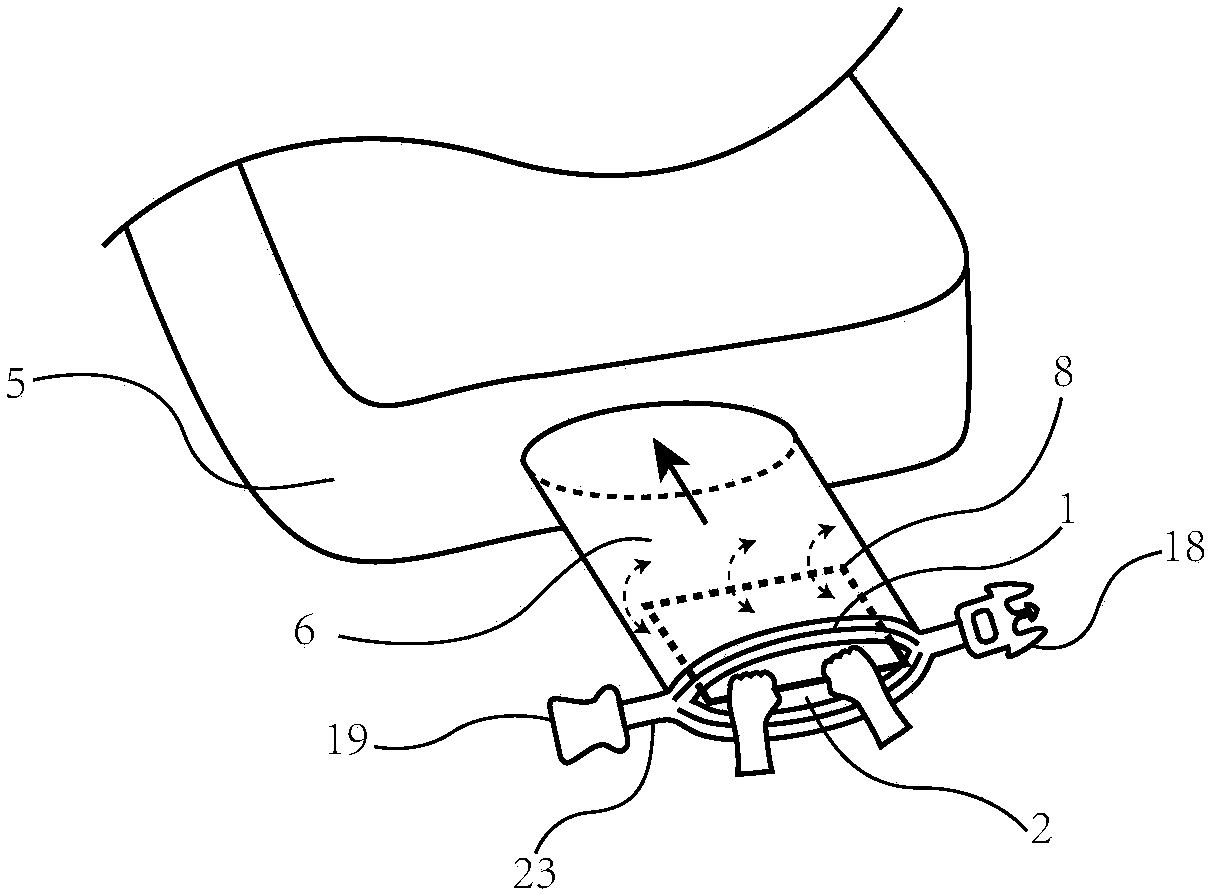

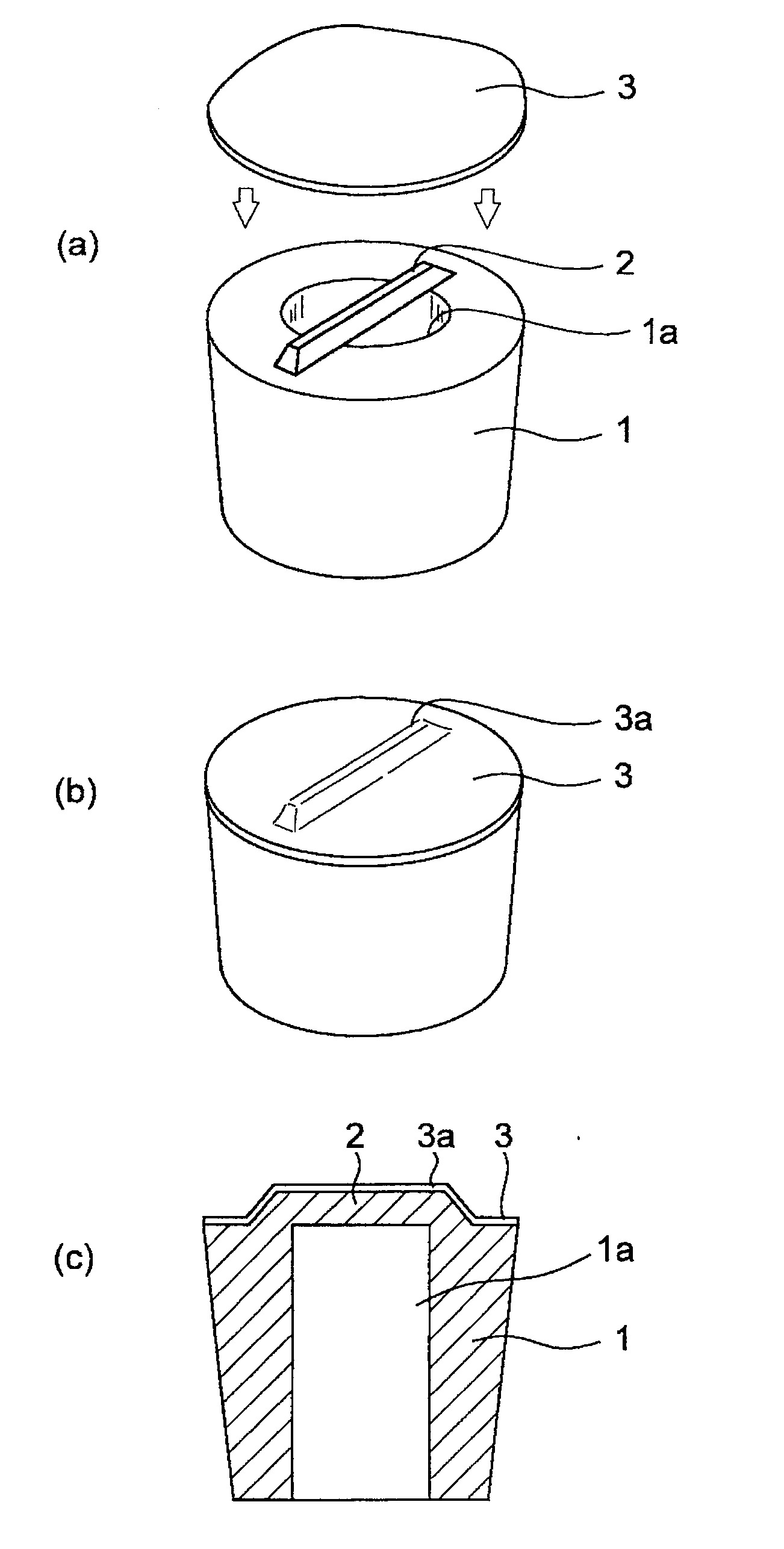

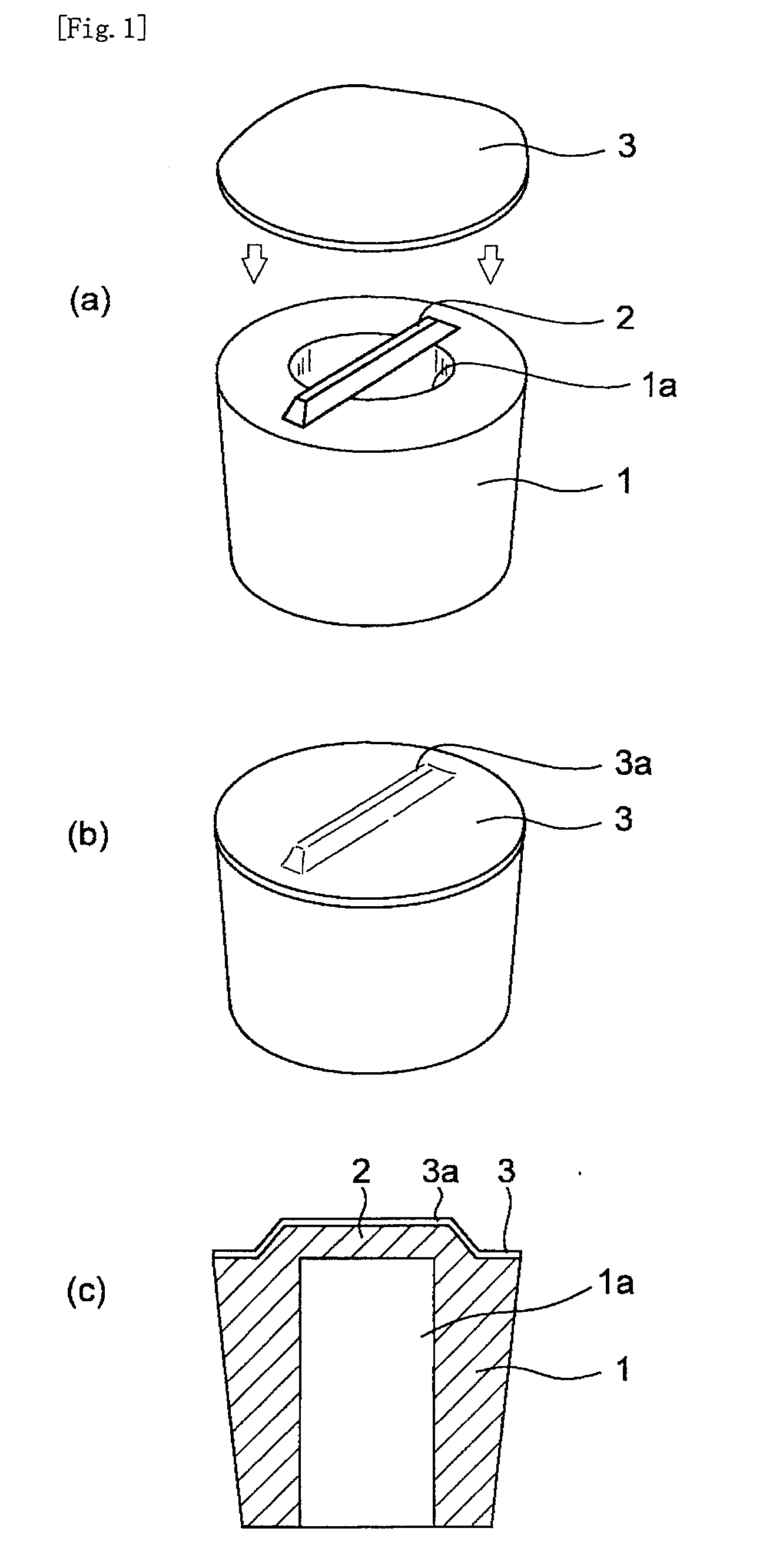

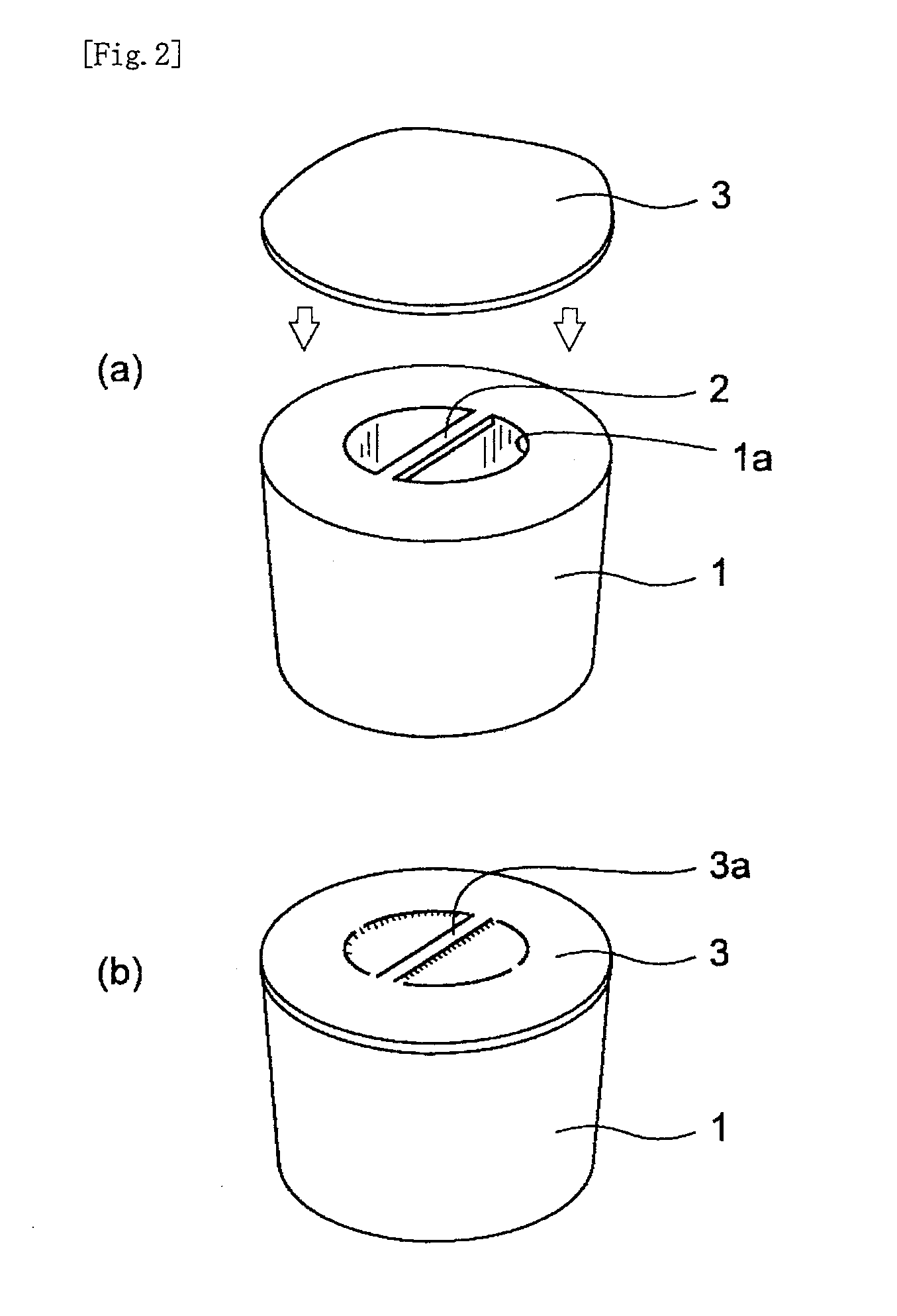

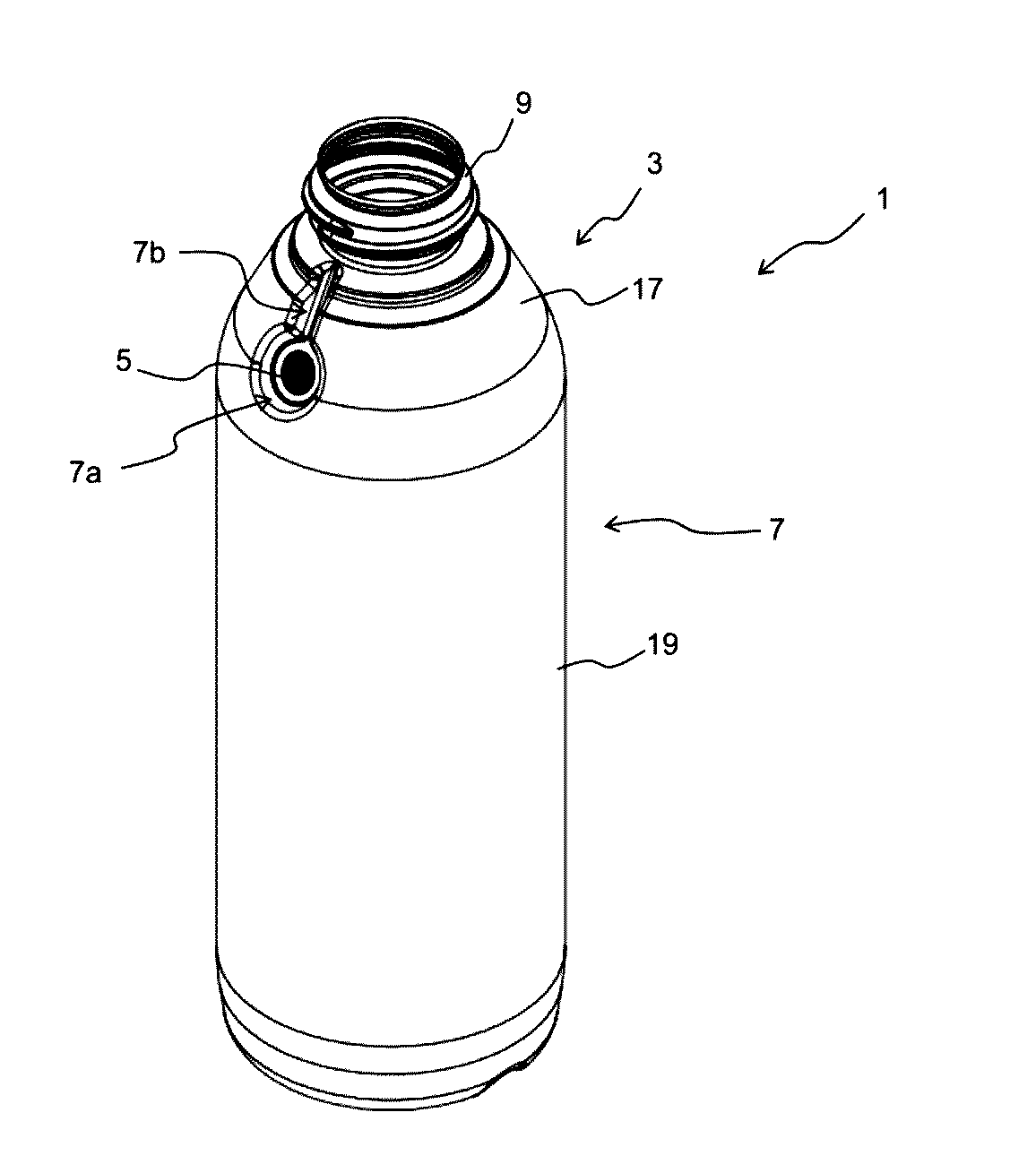

Delaminatable container, method of checking the same for a pinhole, and method of processing the same

ActiveUS20170029157A1Prevent air leakageShorten the timeDetection of fluid at leakage pointCapsEngineeringMechanical engineering

A delaminatable container, having: a container body having an outer shell and an inner bag, the inner bag delaminating from the outer shell with a decrease in contents and being shrunk. A valve member regulating entrance and exit of air between an external space of the container body and an intermediate space between the outer shell and the inner bag. The container body includes a storage portion and a mouth. The outer shell includes a fresh air inlet communicating the intermediate space with the external space in the storage portion, the valve member includes an axis inserted into the fresh air inlet, a lid provided on a side of the intermediate space in the axis and having a cross-sectional area greater than that of the axis, and a locking portion provided on a side of the external space.

Owner:KYORAKU CO LTD

Tube coupling device having check valve

Owner:KUO KUANG MING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com