Patents

Literature

75results about How to "Reduce moving friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

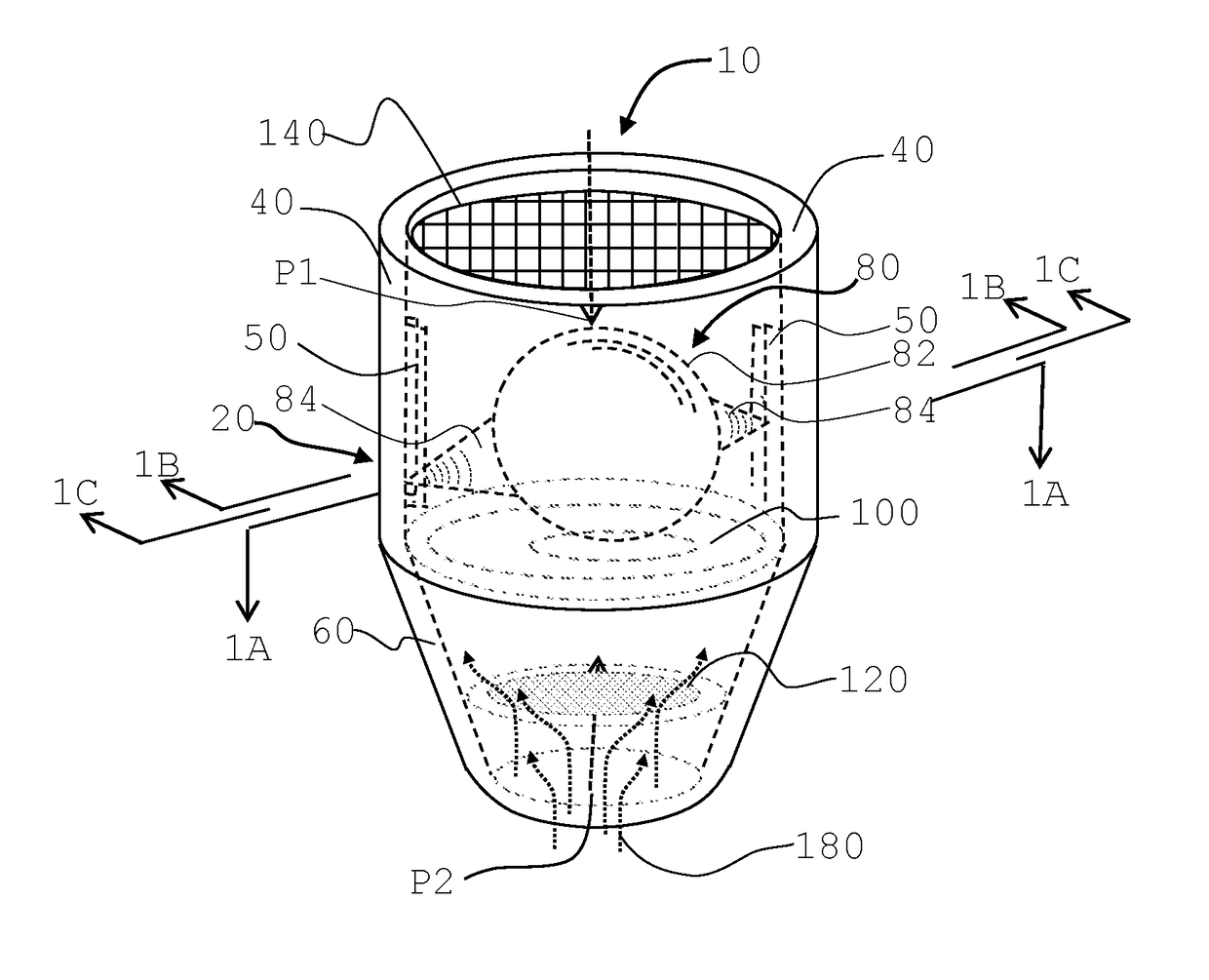

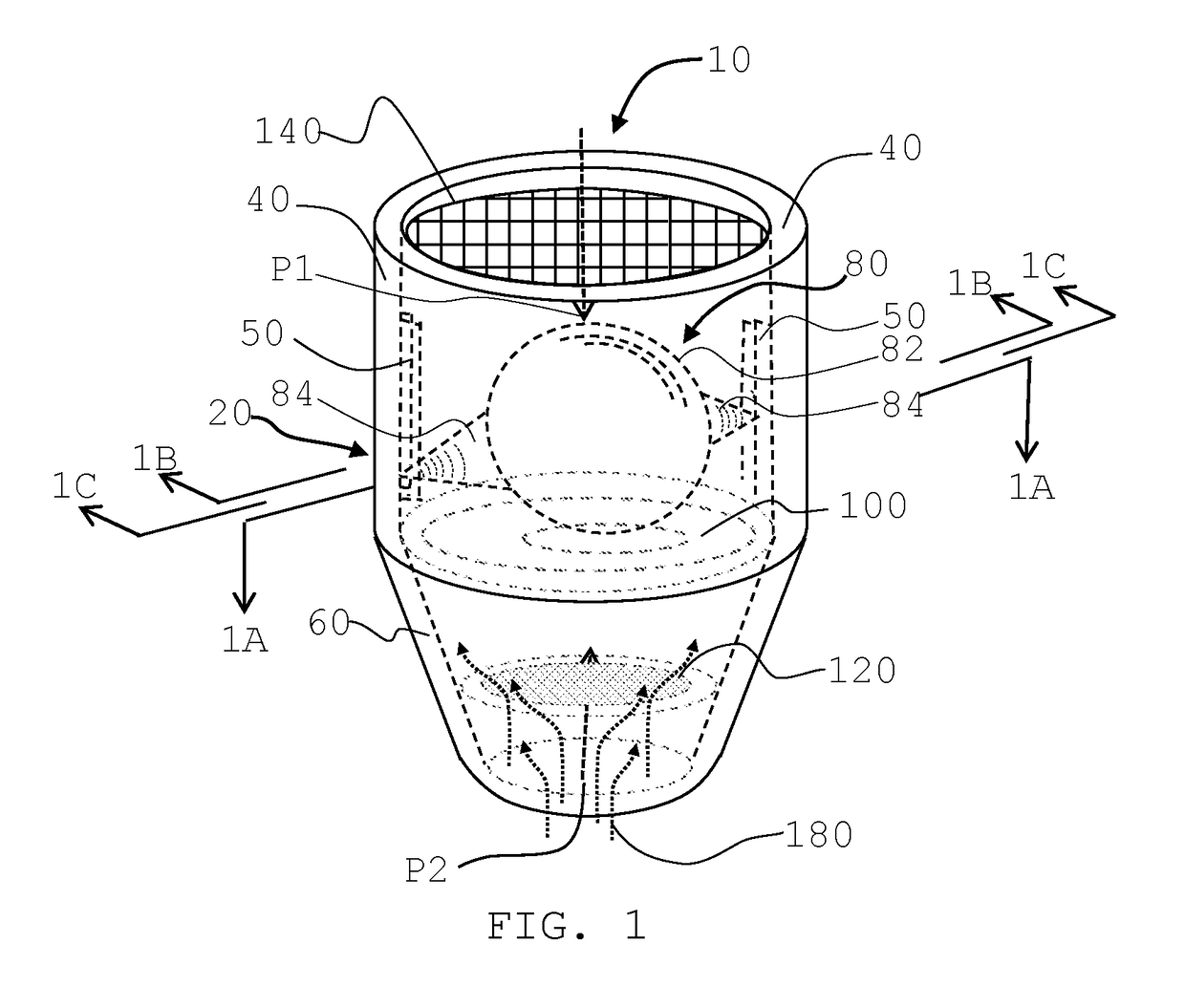

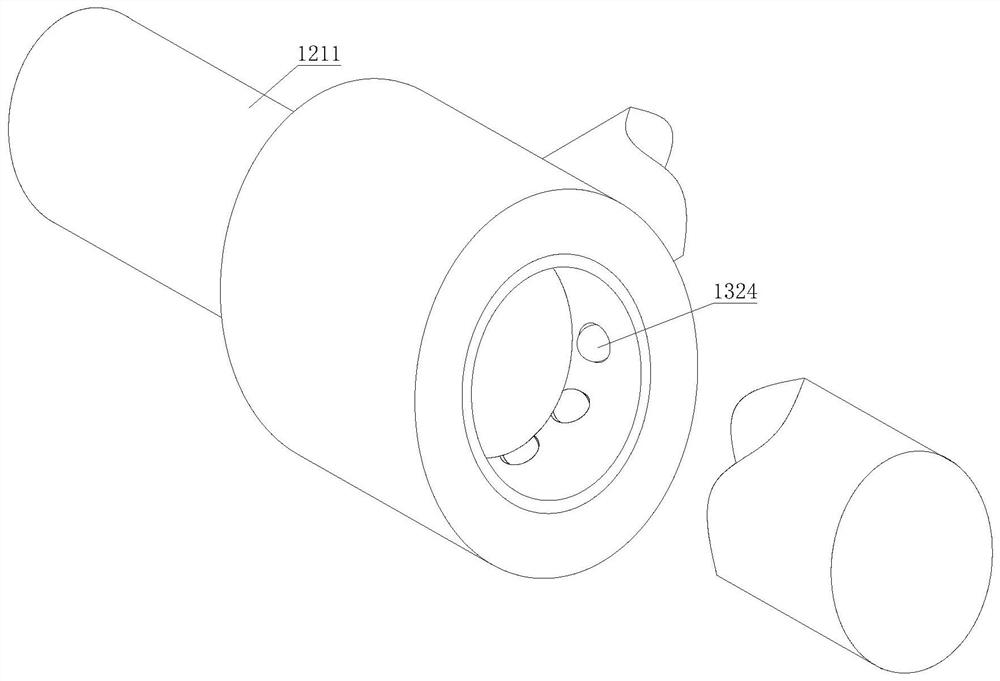

Air admittance and check valve

ActiveUS10030372B2Eliminate negative pressureProlong lifeDispersed particle filtrationCheck valvesRotary valveEngineering

An apparatus to allow or stop a flow into a piping system or an enclosed environment comprises (a) a housing having an upper flow passage and a lower flow passage; (b) a valve seat, wherein the valve seat is between the upper flow passage and the lower flow passage, wherein at least one opening is formed on the valve seat; (c) at least one rotary valve inside the housing, wherein each of the at least one rotary valve further comprises a main body and two guides mounted to the main body opposite to each other, and wherein the at least one rotary valve can move inside the upper flow passage and above the valve seat; and (d) at least two guide rails inside the upper flow passage for guiding each of the at least one rotary valve between an open position and a closed position.

Owner:DI MONTE MICHAEL A

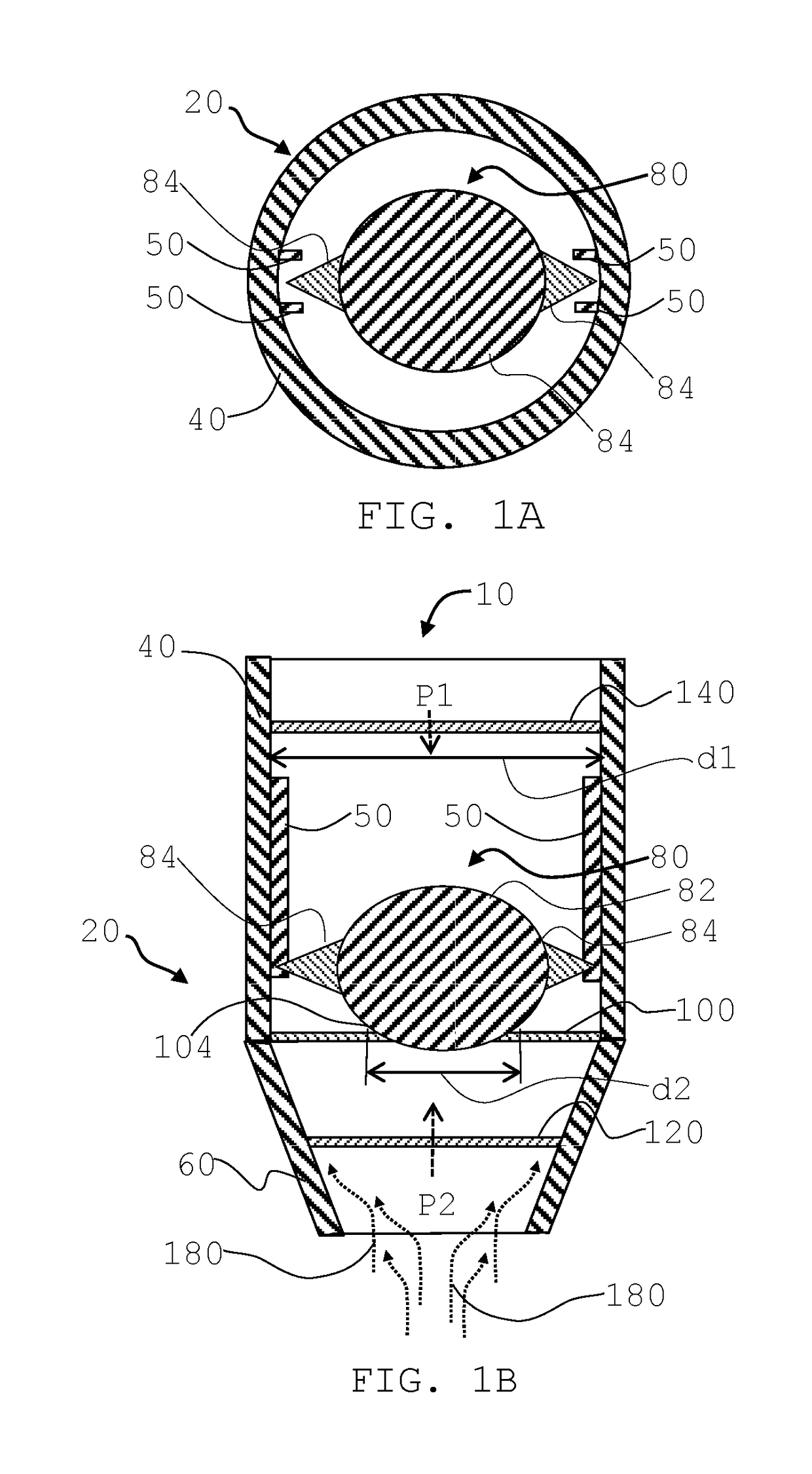

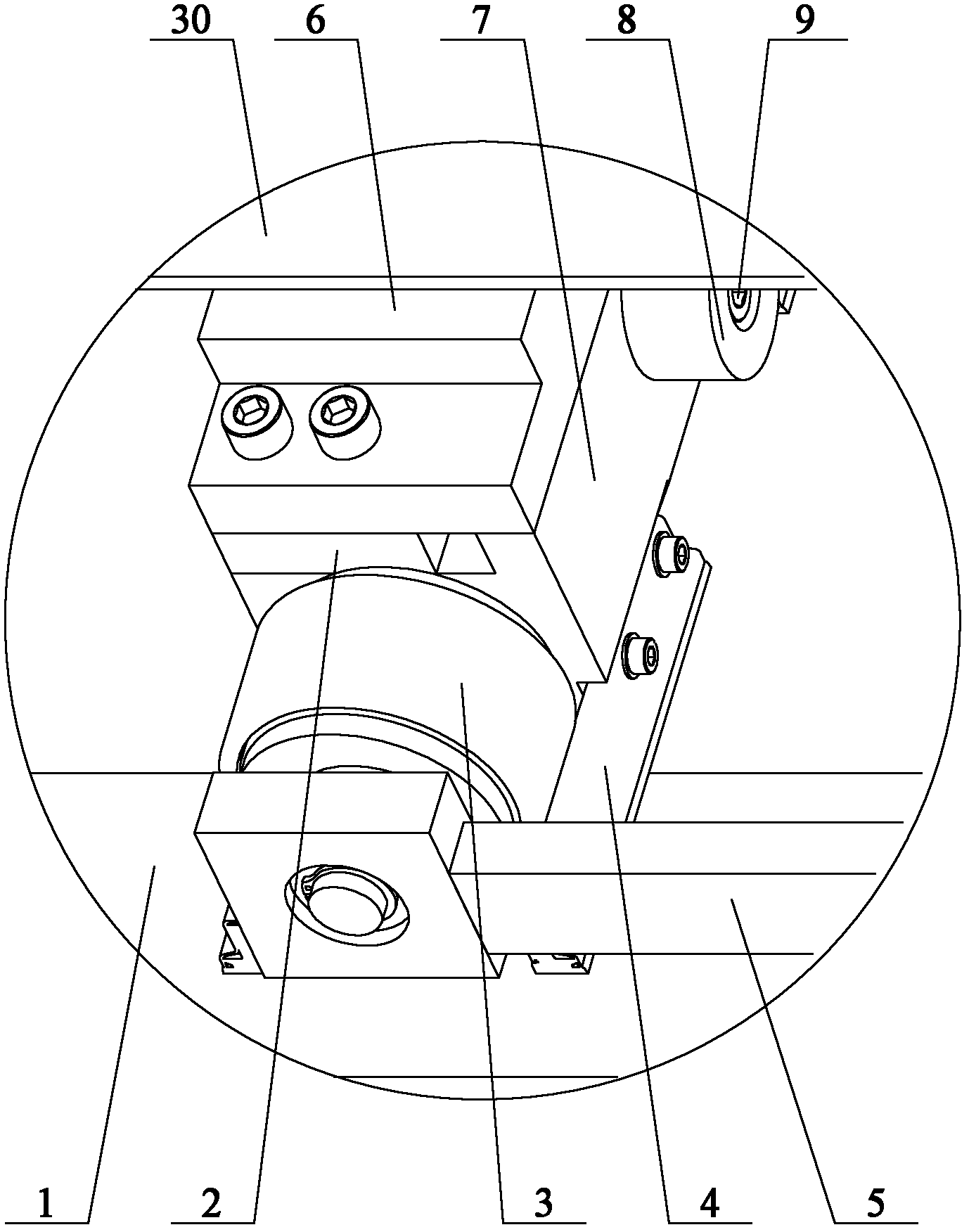

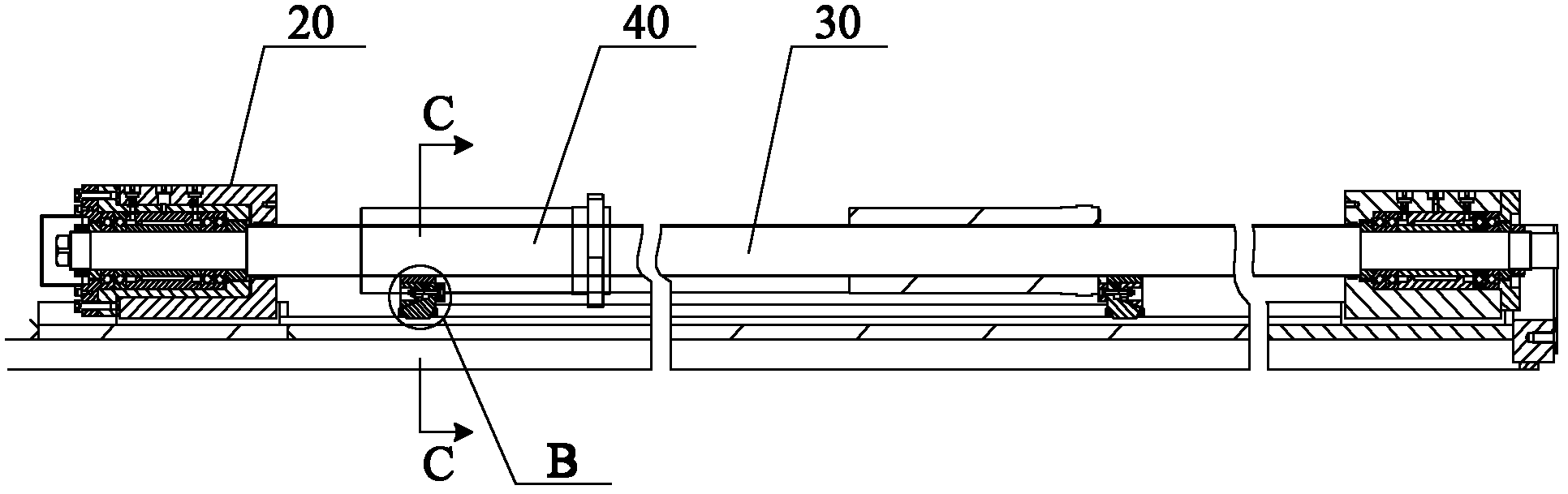

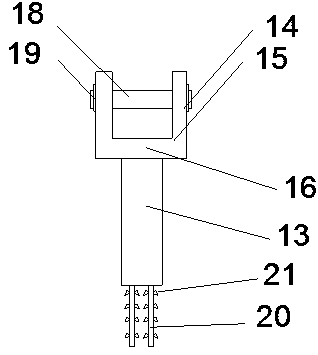

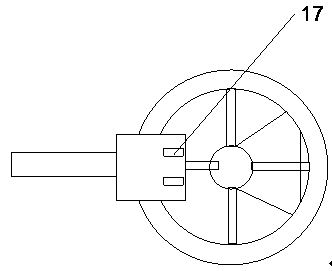

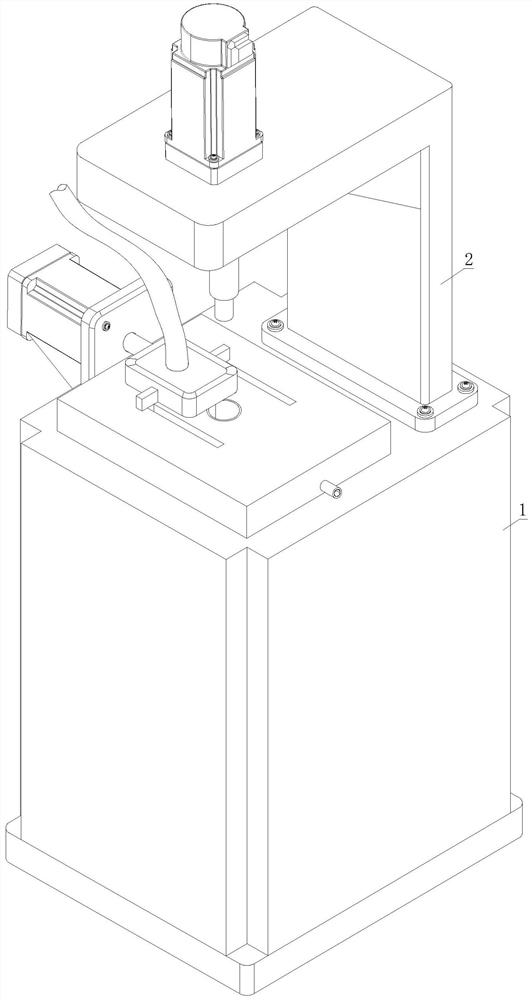

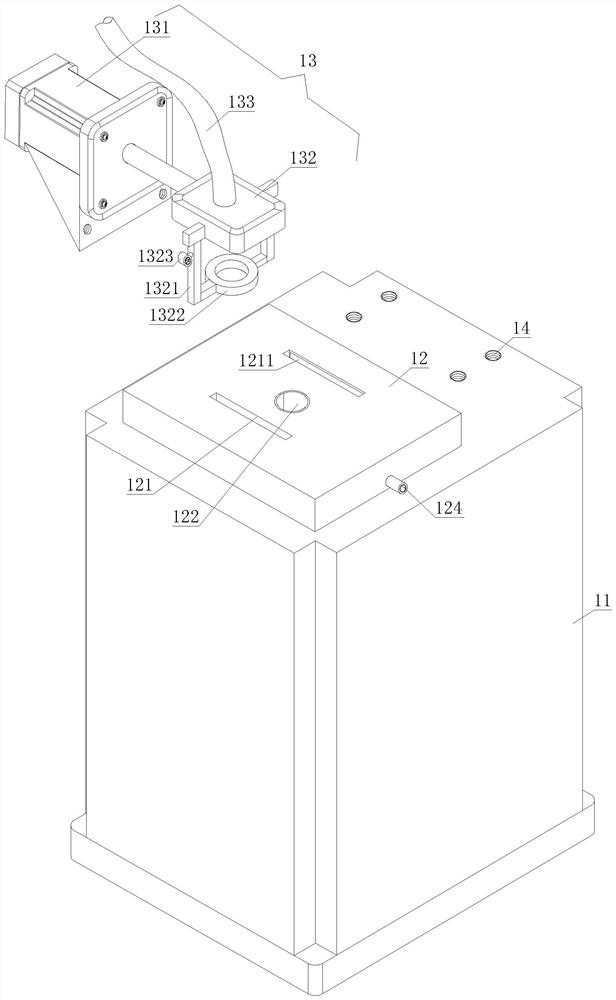

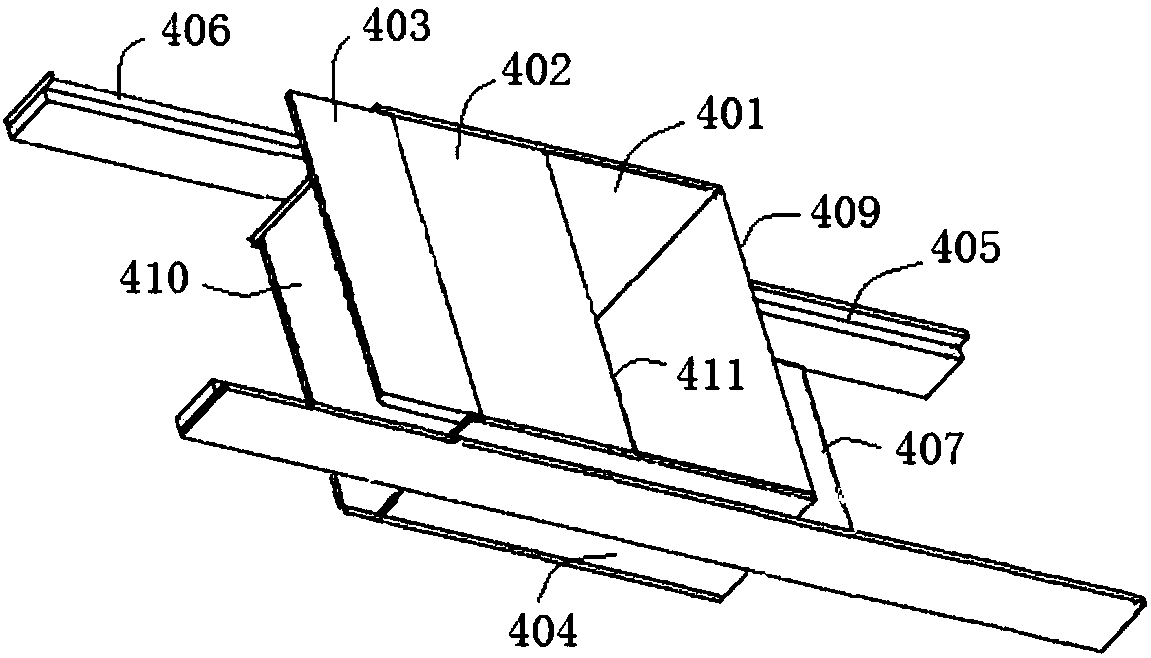

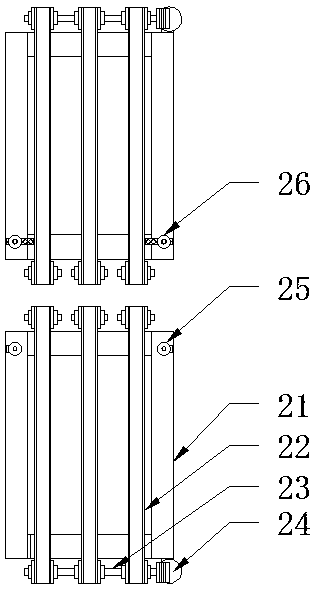

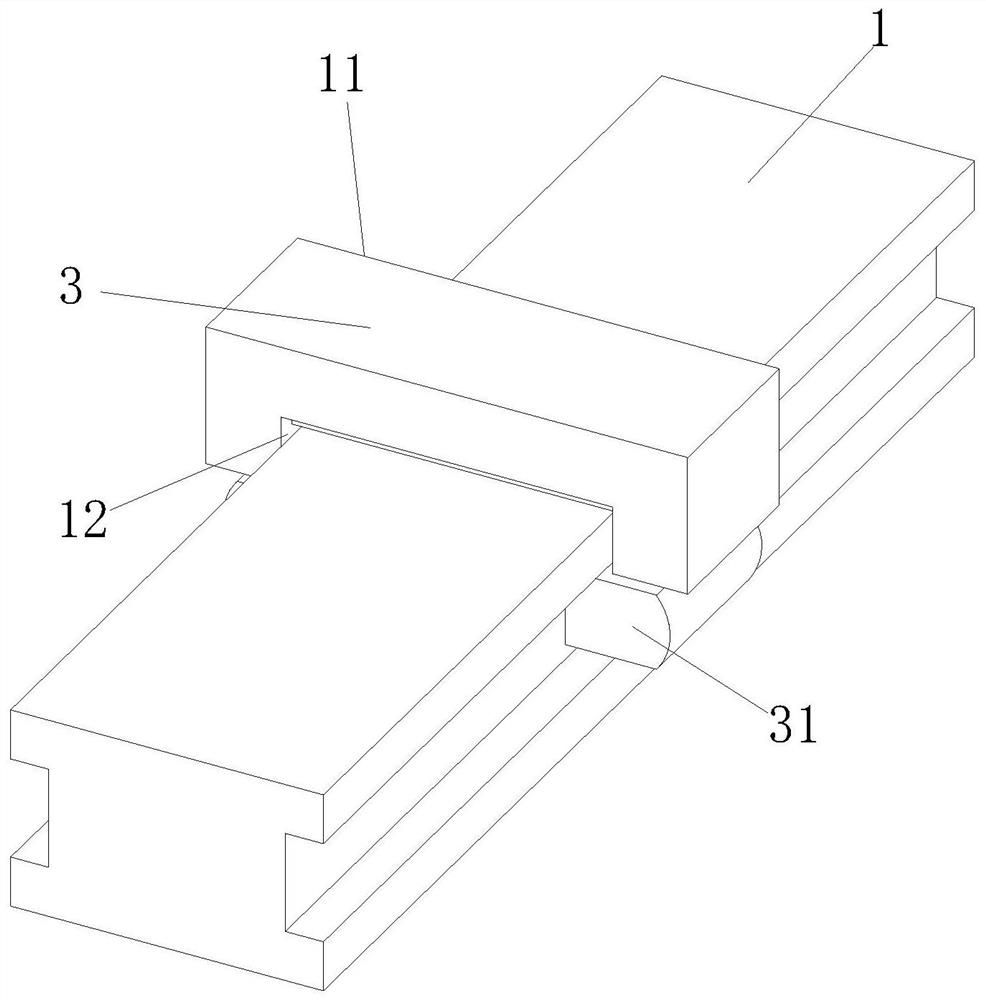

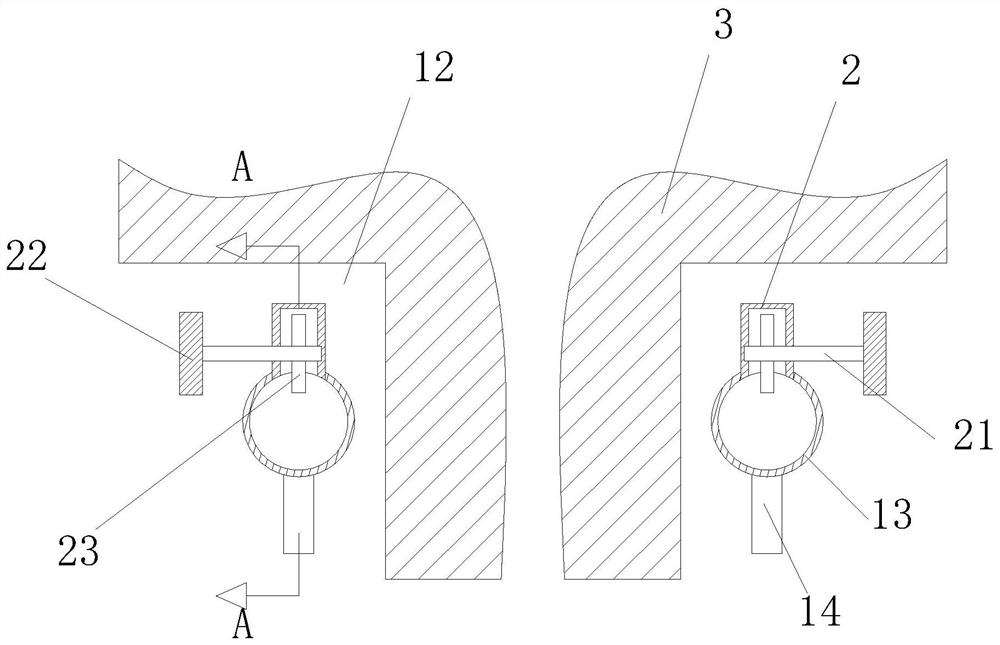

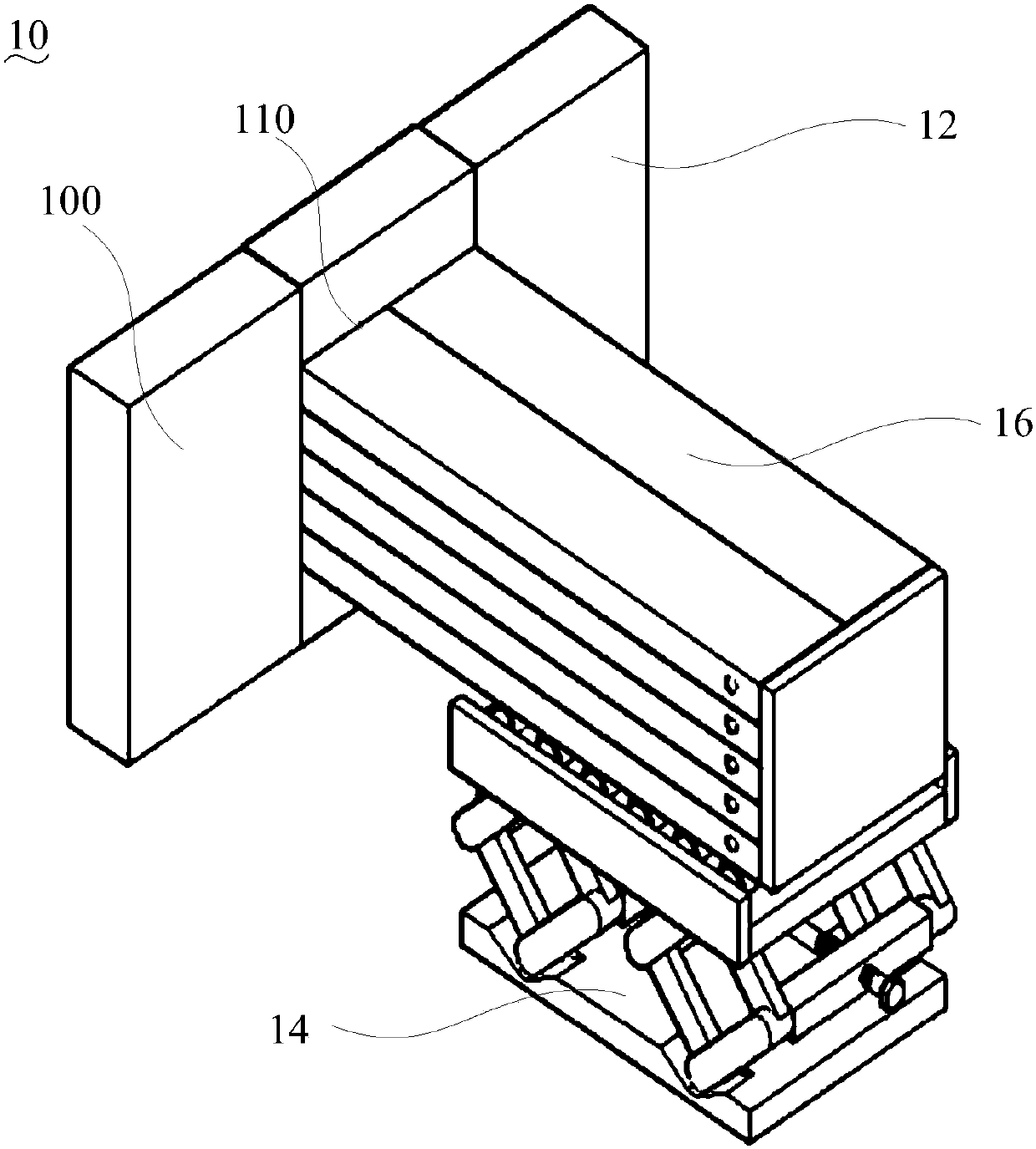

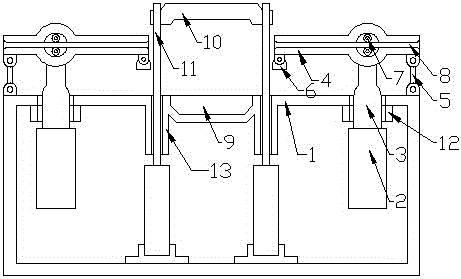

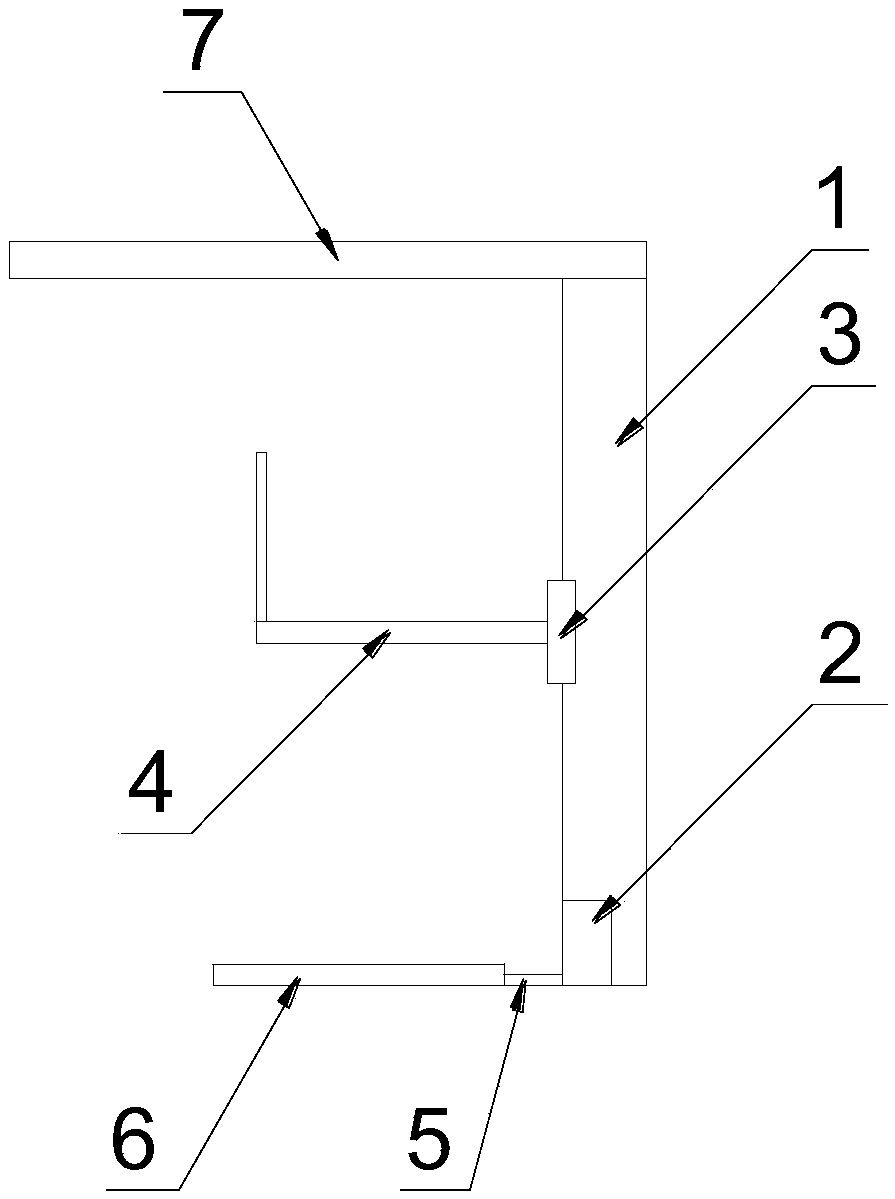

Auxiliary lead screw supporting device and processing center

The invention relates to the technical field of machine tools, and discloses an auxiliary lead screw supporting device and a processing center. The auxiliary lead screw supporting device comprises guide plates and a pair of auxiliary supporting components, the guide plates are parallel to a lead screw, the auxiliary supporting components are disposed on the guide plates on two sides of a nut and are connected by a connecting rod, each auxiliary lead screw supporting component consists of a supporting body and a supporting table, each supporting body can move along the corresponding guide plate, the bottom of each supporting table is connected with the corresponding supporting body, and the top of each supporting table is used for supporting the lead screw. In the auxiliary lead screw supporting device in an embodiment of the invention, the two auxiliary supporting components are respectively arranged below the lead screw on two sides of the nut, and are supported on the lower side of the lead screw via arc-shaped groove surfaces of the supporting tables, the hardness of each supporting table is slightly smaller than that of the lead screw, accordingly, the lead screw is supported while influences on the surface of the lead screw are reduced, and problems that the transmission precision is reduced and the service life is shortened due to the fact that the lead screw droops and vibrates are avoided.

Owner:SANY GRP

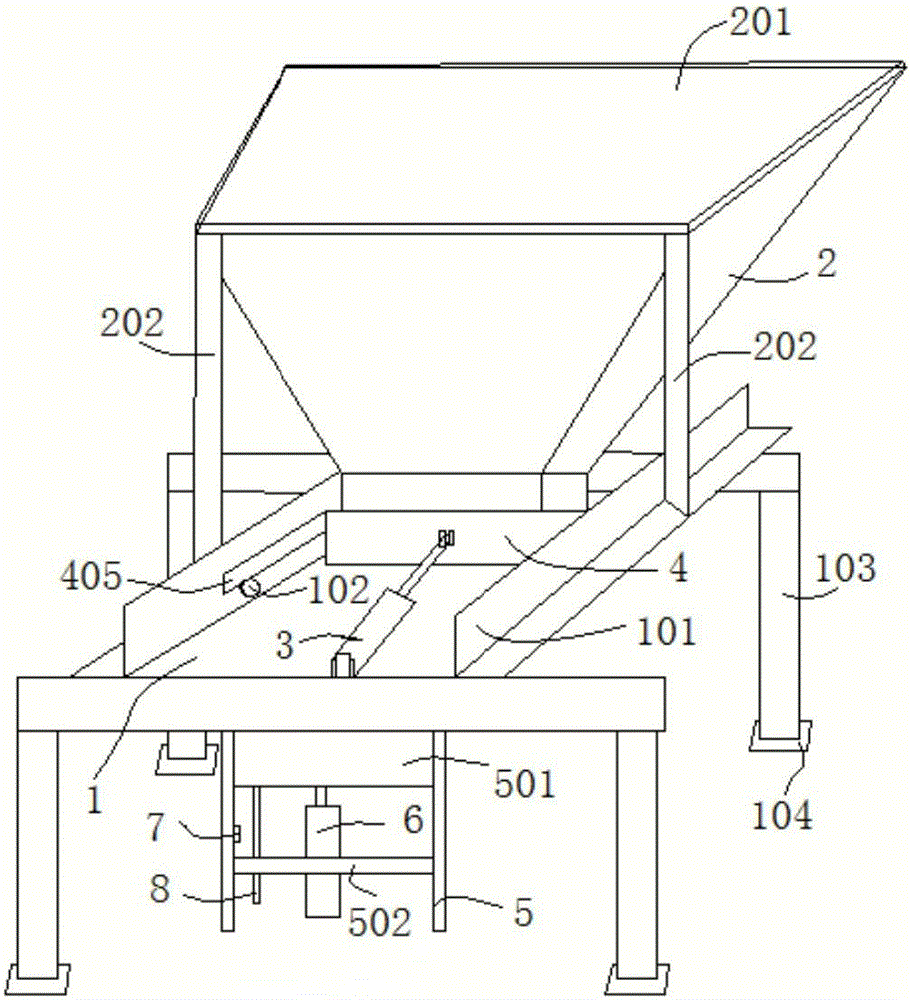

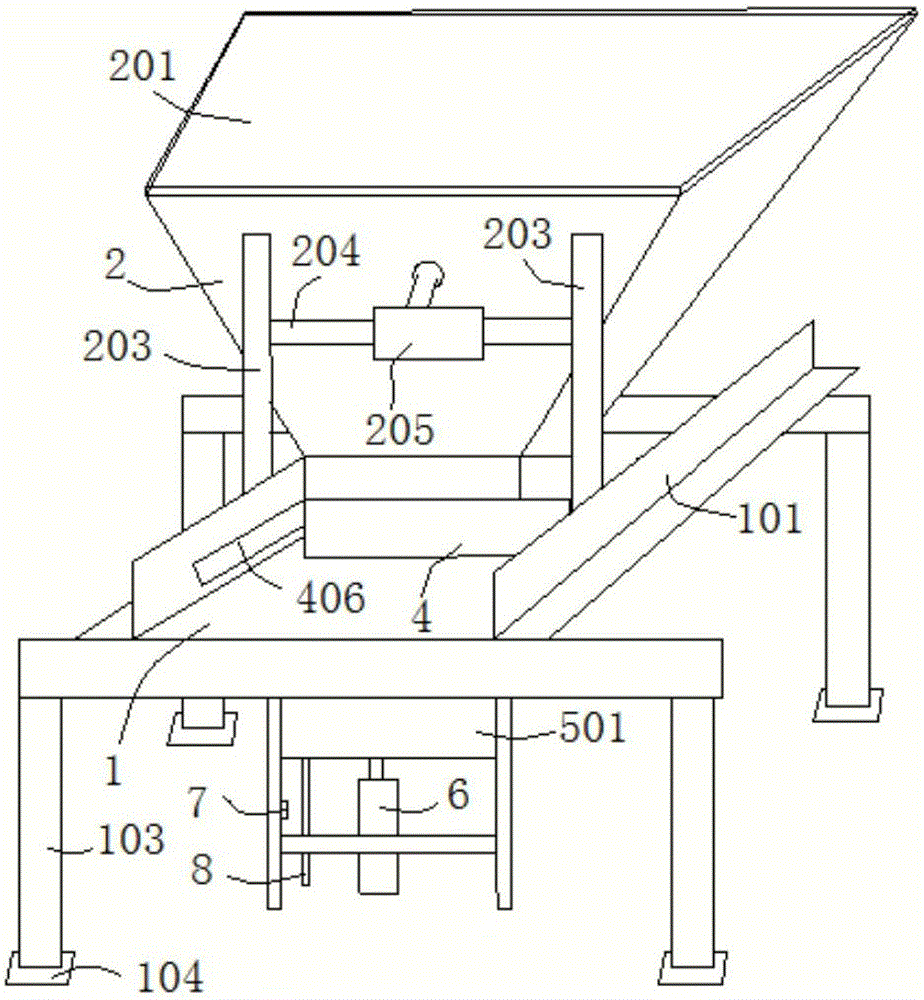

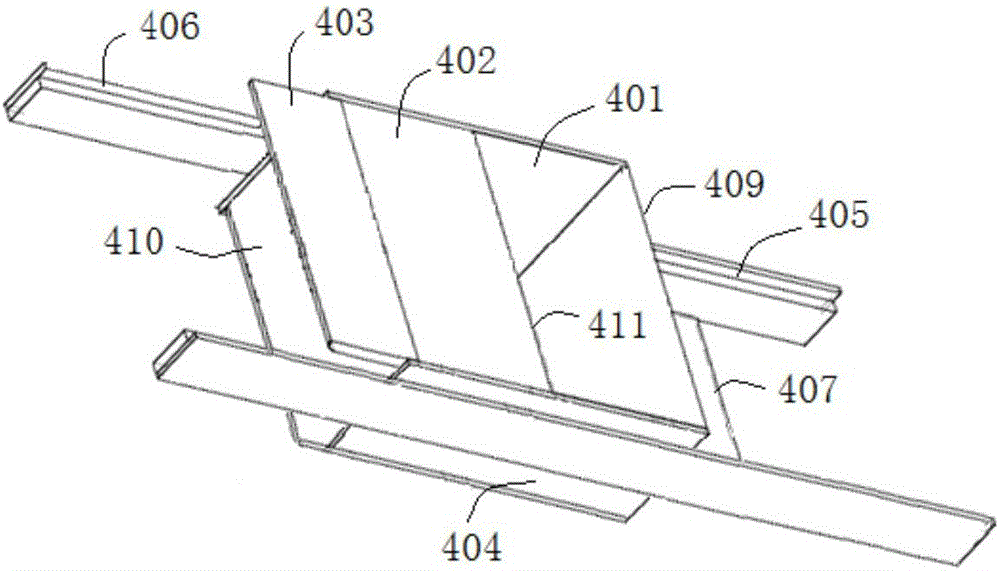

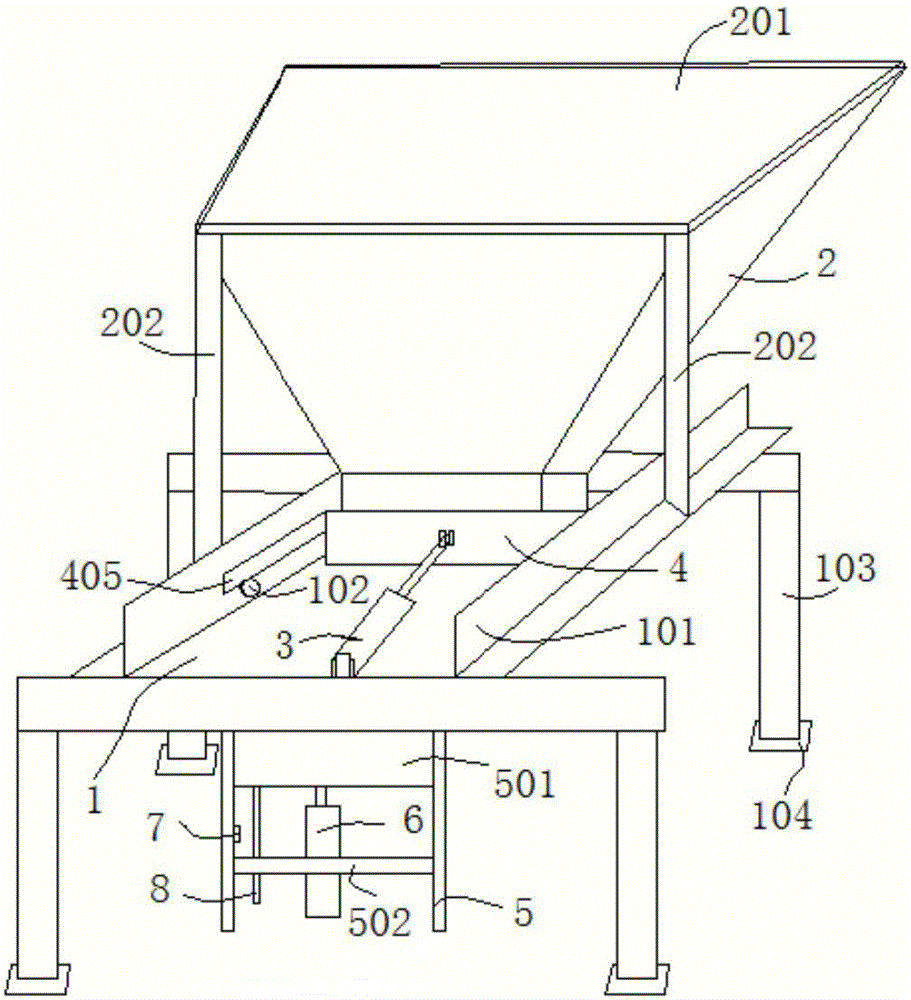

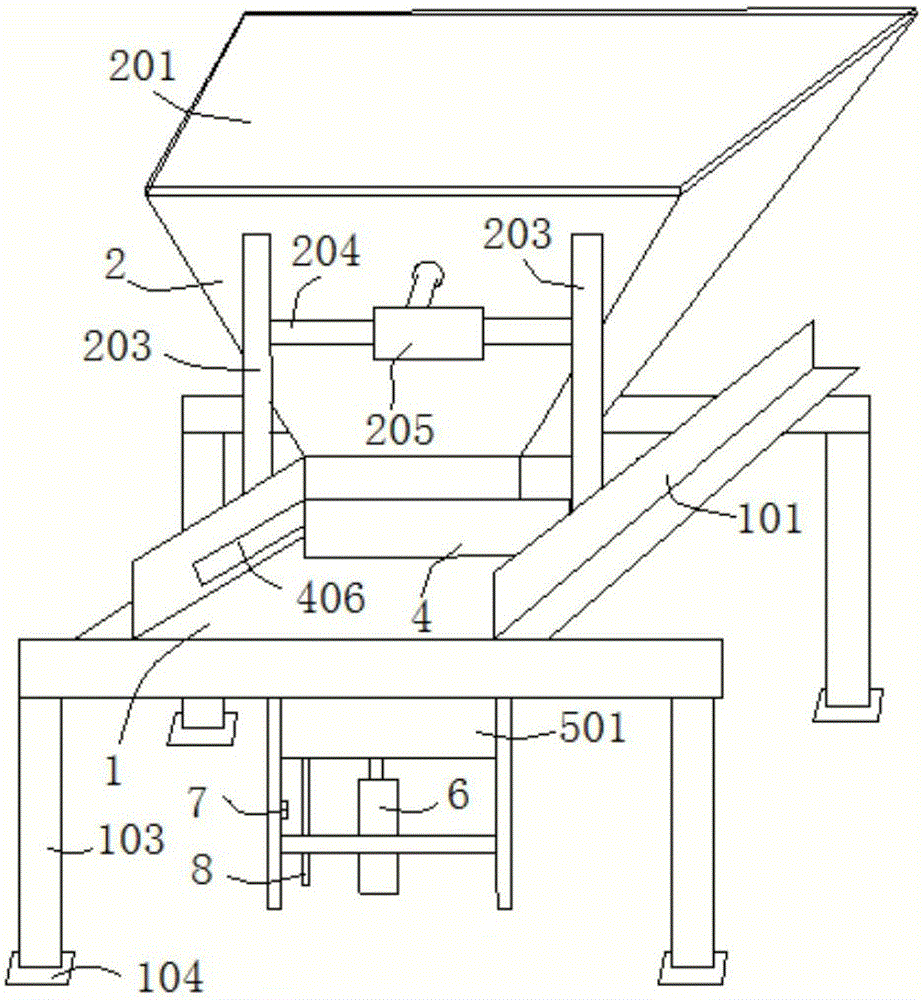

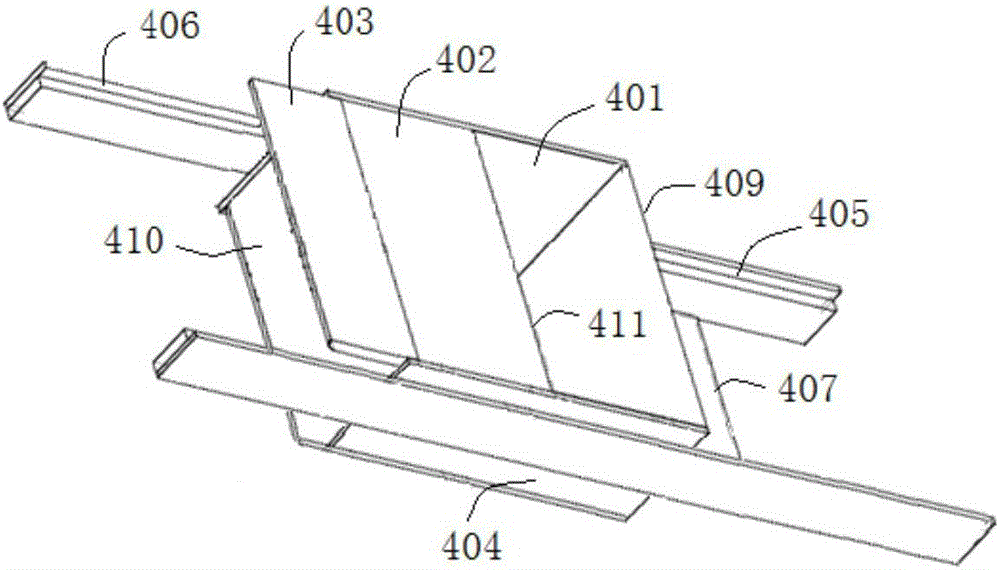

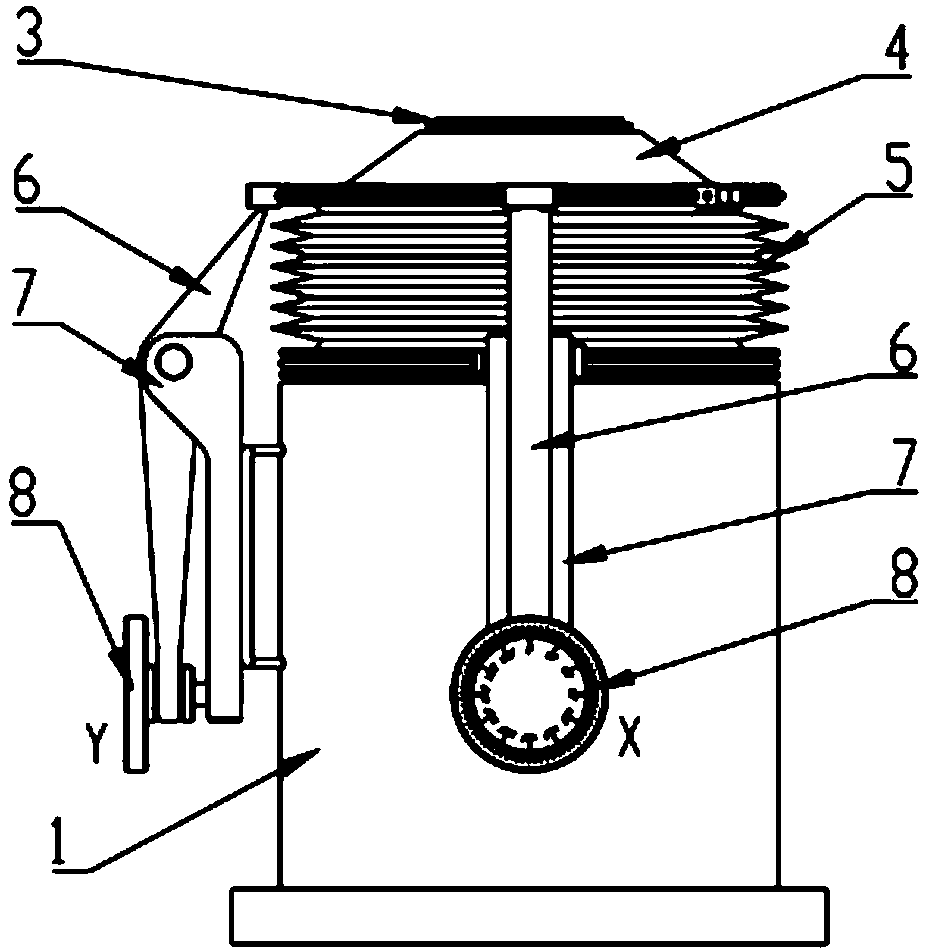

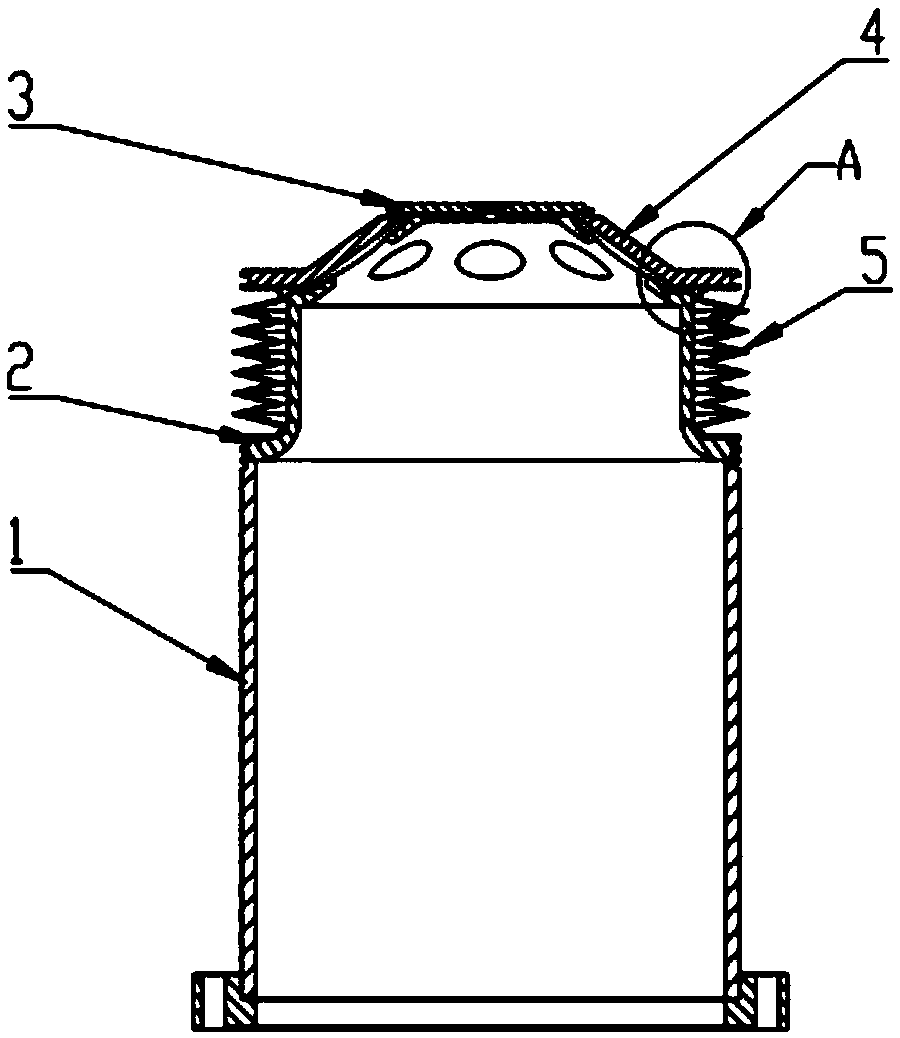

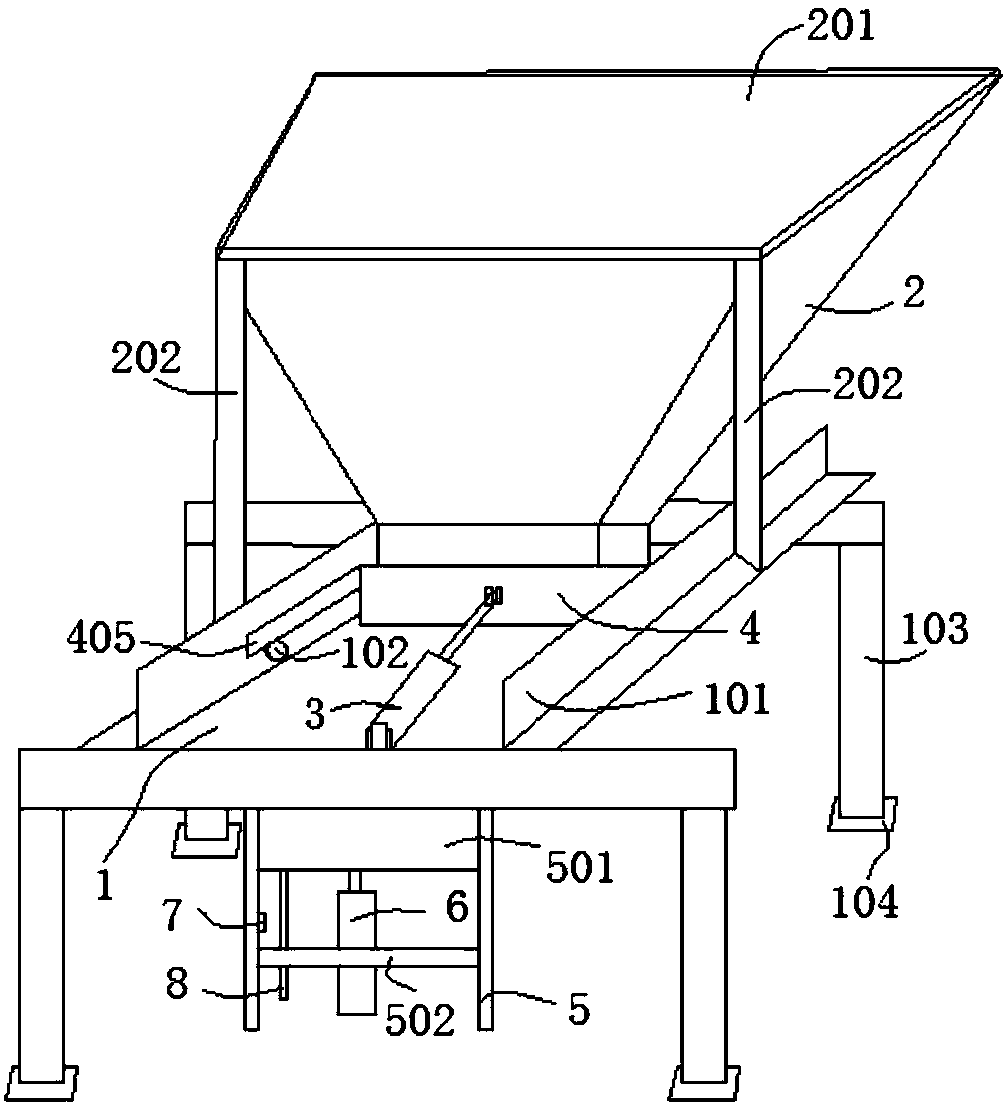

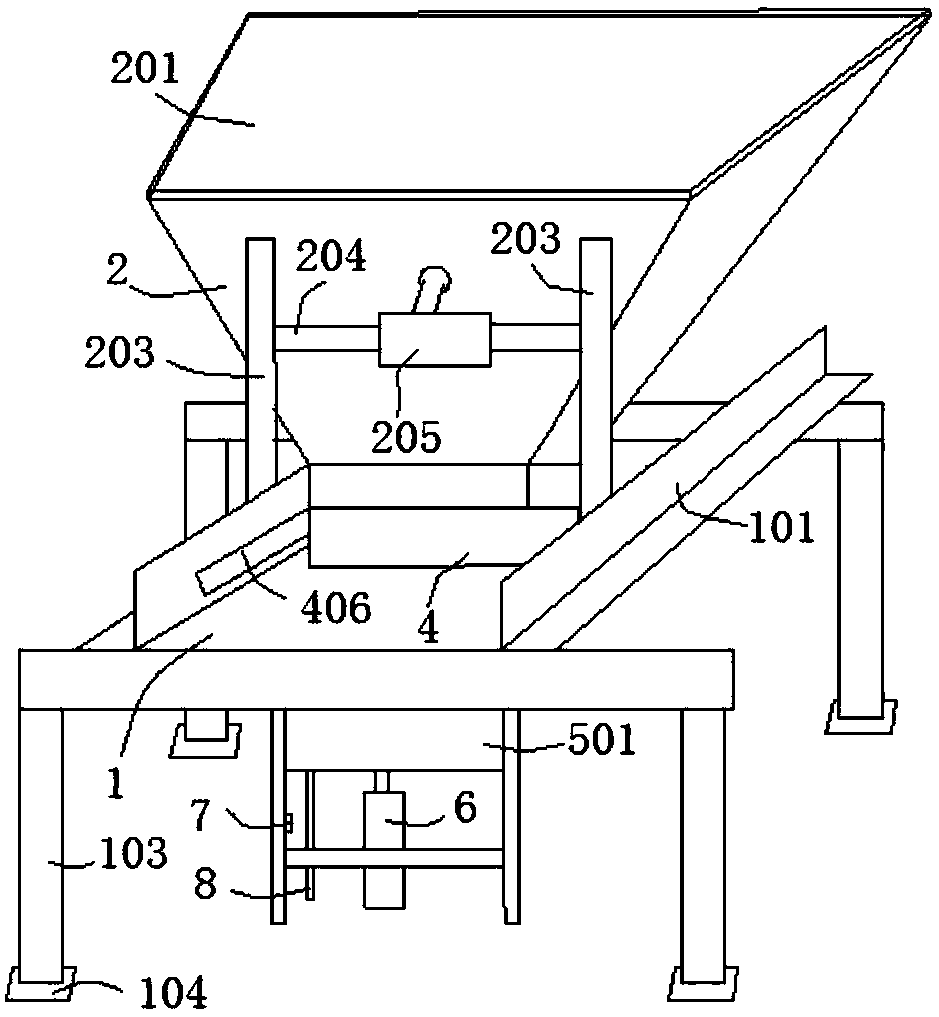

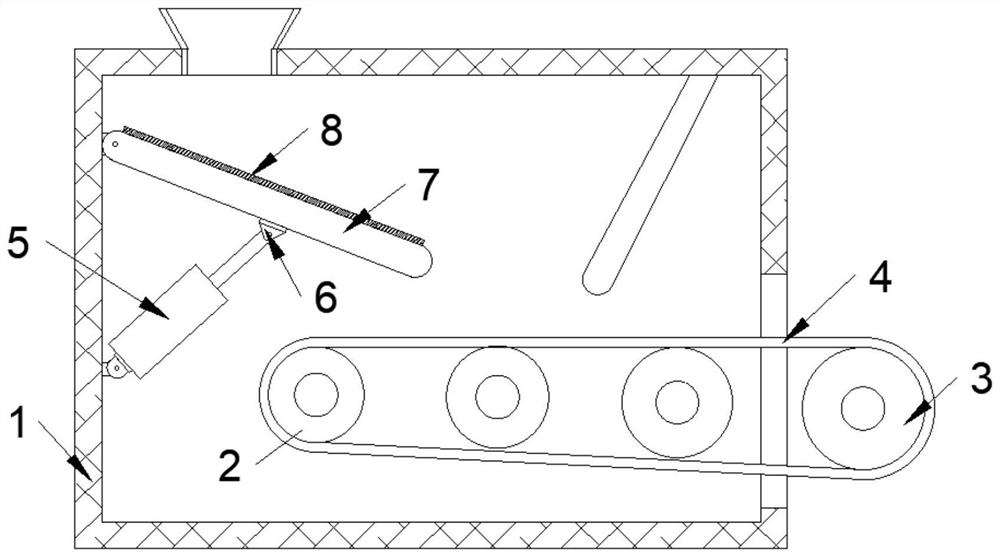

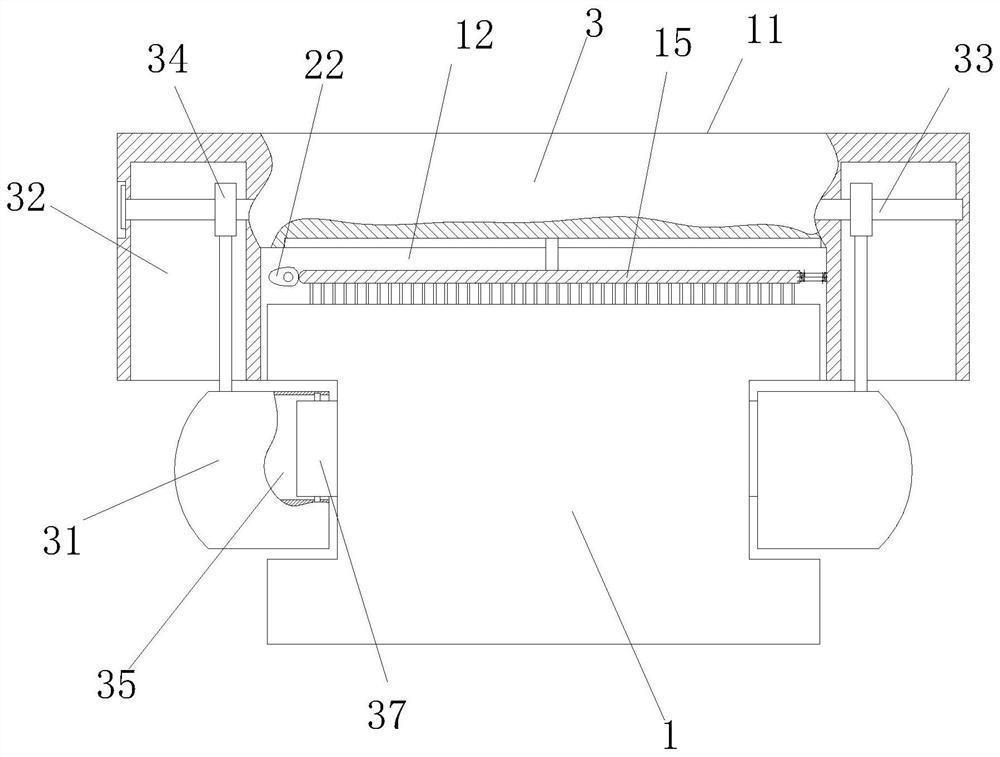

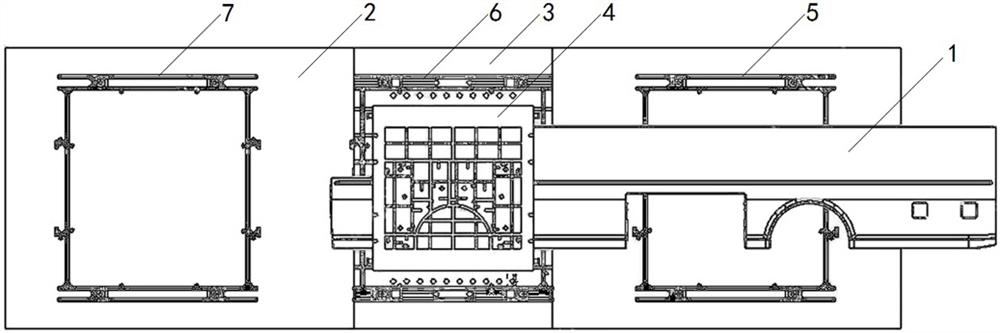

Automatic forming device for producing baking-free bricks

ActiveCN106313297AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

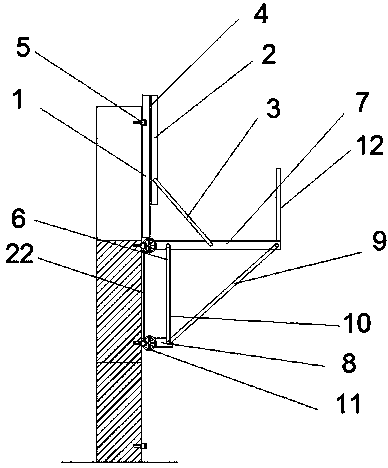

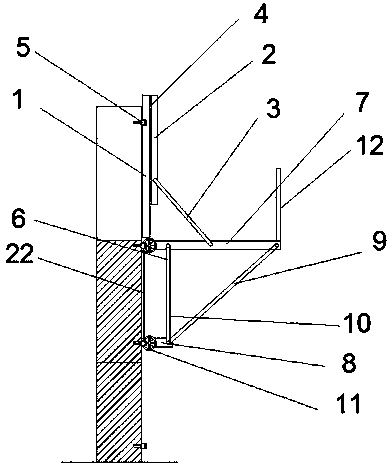

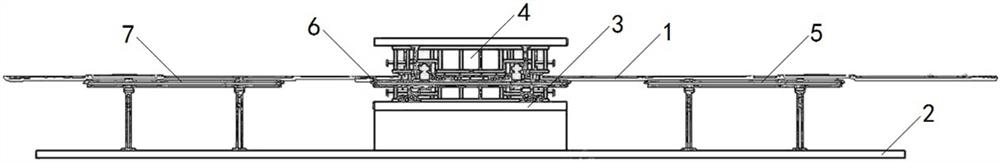

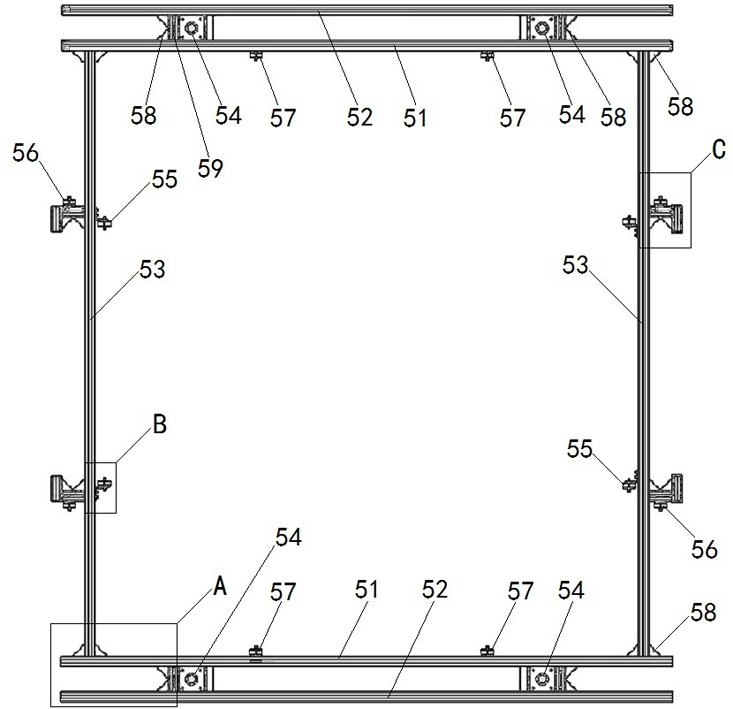

Large-formwork lifting-type construction method of shear wall and cylinder concrete structure

InactiveCN108331334AEasy to fixImprove the strength of the fixed connectionForms/shuttering/falseworksScaffold accessoriesSupporting systemRebar

The invention discloses a large-formwork lifting-type construction method of a shear wall and a cylinder concrete structure. The large-formwork lifting-type construction method comprises the followingsteps that (1) a tower crane is arranged and mounted; (2) a large-formwork face plate is manufactured through veneers, vertical back arris are manufactured through square timbers, transverse back arris are manufactured through 8# channel steel, and reinforcing is conducted through split bolts; (3) an embedded part used for a next layer of wall surface is mounted in the to-be-poured concrete wall,and a large formwork as well as the face plate, the vertical back arris and the transverse back arris of a supporting system of the large formwork are dismantled; (4) concrete pouring and curing areconducted, a movable tripod platform is upwards pushed into the embedded part of the poured wall surface and fixed, the large formwork as well as the face plate, the vertical back arris and the transverse back arris of the supporting system of the large formwork are mounted on a next to-be-poured upper layer concrete wall layer surface, steel bars of a next more upper layer wall surface are mounted, and the concrete wall surface is poured; and (5) circulating is conducted on the basis till construction of wall concrete is completed. The movable tripod platform is adopted for integral-type moving, the tripod platform does not need to be repeatedly set up, and manpower is greatly saved accordingly.

Owner:CCCC SHEC FOURTH ENG

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Lifting construction method and construction device of large formwork for shear wall tubular concrete structure

InactiveCN108252504AEasy to fixImprove the strength of the fixed connectionForms/shuttering/falseworksScaffold accessoriesSupporting systemTower crane

The invention discloses a lifting construction method and a construction device of a large formwork for a shear wall tubular concrete structure. The lifting construction method comprises the followingsteps of, (1) arranging and installing a tower crane; (2) making a large formwork panel with plywood, manufacturing a vertical backstay with square wood, manufacturing a horizontal backstay with 8 #channel steel, and using pull bolts to reinforce; (3) installing embedded parts for the wall surface of the next layer in the concrete wall to be poured, removing the large formwork and the panel, thevertical backstay and the horizontal backstay of a support system thereof; (4) pouring and curing concrete, pushing a movable tripod platform upwards into the embedded parts of the poured wall surface, and fixing the movable tripod platform; installing the large formwork and the panel, the vertical backstay and the horizontal backstay of the support system on the next upper concrete wall surfaceto be poured, and installing reinforcing steel bars of the next upper layer wall surface and pouring the concrete wall surface; and (5) repeating the cycle, until the construction of wall concrete iscompleted. The method adopts a movable tripod platform to move integrally, and greatly saves manpower.

Owner:CCCC SHEC FOURTH ENG

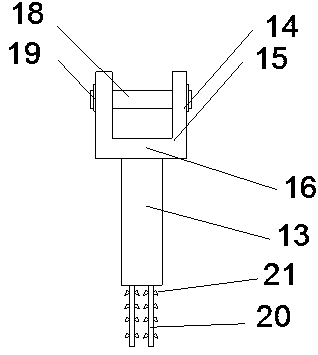

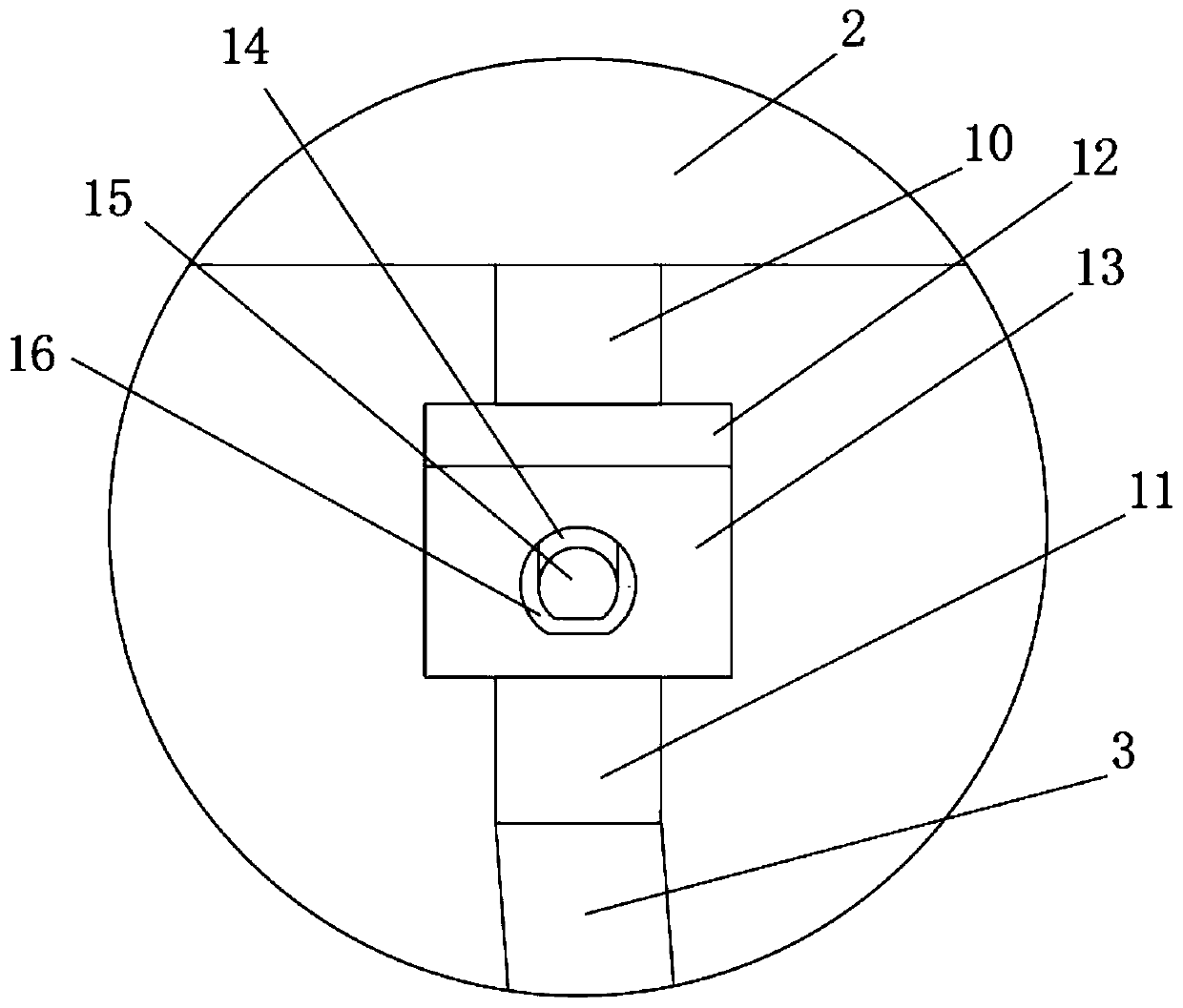

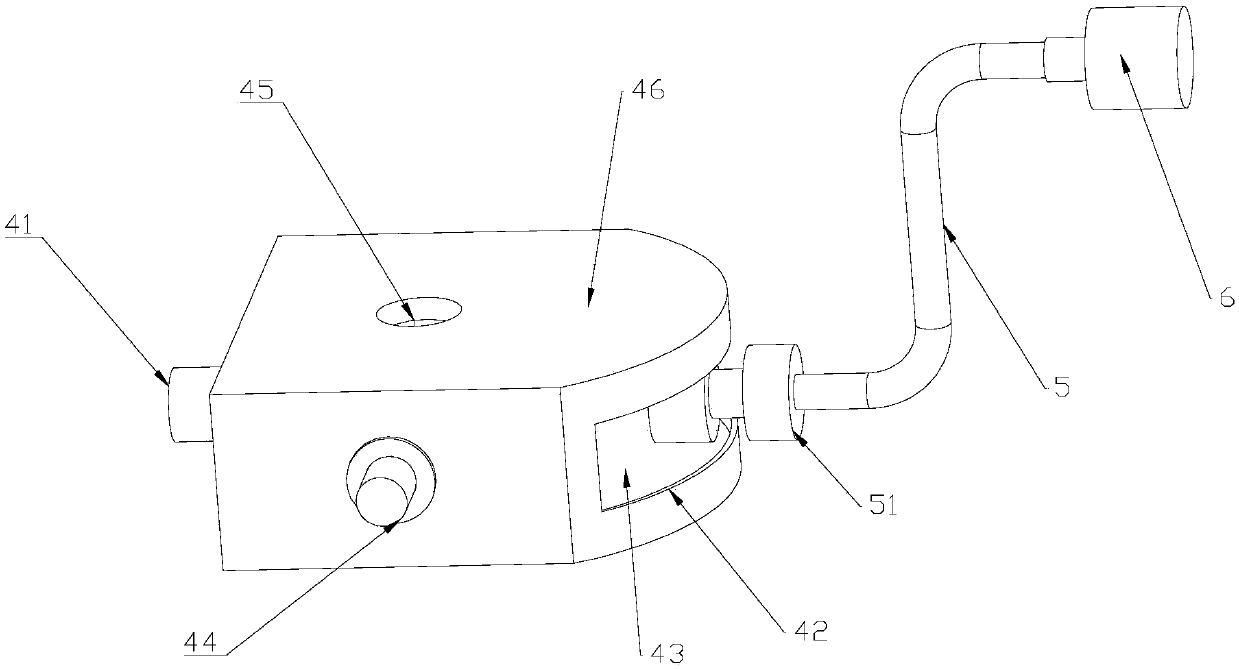

Floating target mechanism for radiation source

ActiveCN109449072AExtended service lifeAvoid target function failure problemsX-ray tube electrodesTarget surfaceEtching

The invention discloses a floating target mechanism for a radiation source. The floating target mechanism comprises a radiation source shell, a pipe shell inner cover, a floating target, a target seat, an elastic compression pipe and a driving mechanism, wherein an upper part of the target seat is hermetically connected with the floating target, a lower part of the target seat is hermetically connected with the elastic compression pipe, the target seat is arranged on the pipe shell inner cover, a lower part of the pipe shell inner cover is hermetically fixed on the radiation source shell, theelastic compression pipe sleeves the pipe shell inner cover, one end of the driving mechanism is connected with the radiation source shell, and the other end of the driving mechanism is connected withthe target seat. The floating target mechanism is applied to the radiation source, the problem of target function failure caused by target surface point etching can be effectively prevented, the service lifetime of the target is substantially prolonged, and a target assembly is not needed to be replaced within the lifetime period of the radiation source.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

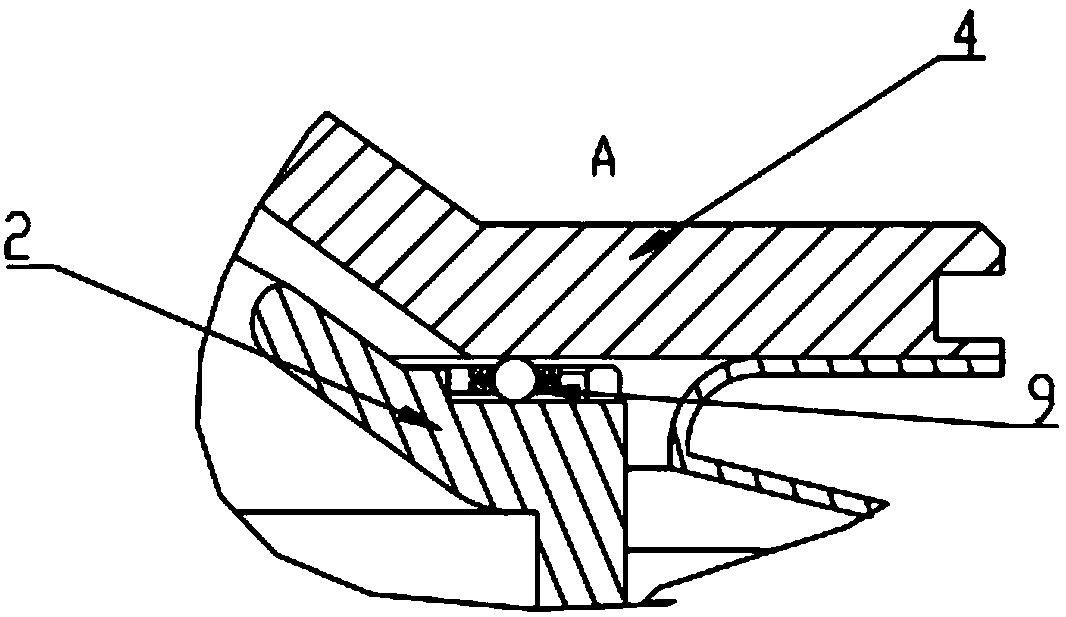

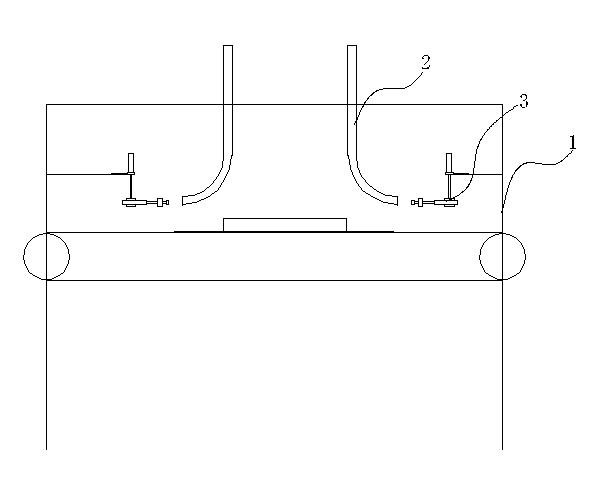

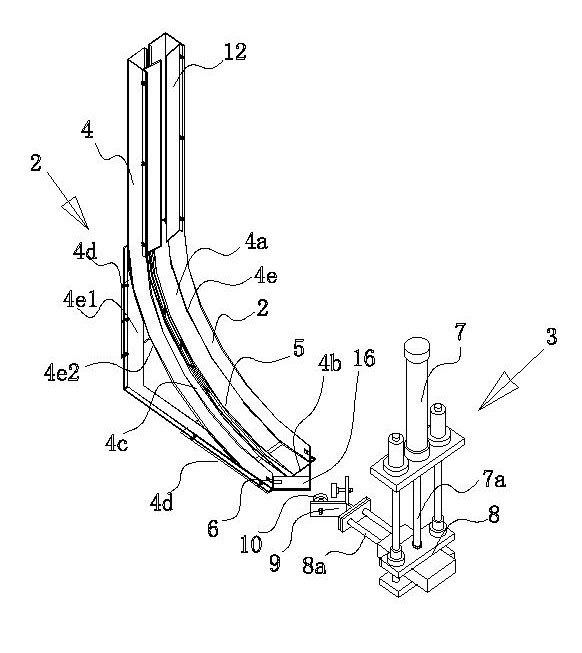

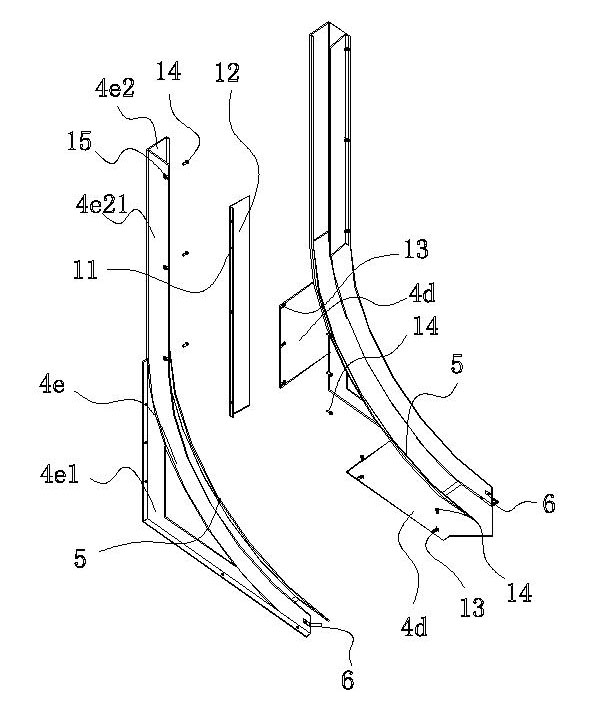

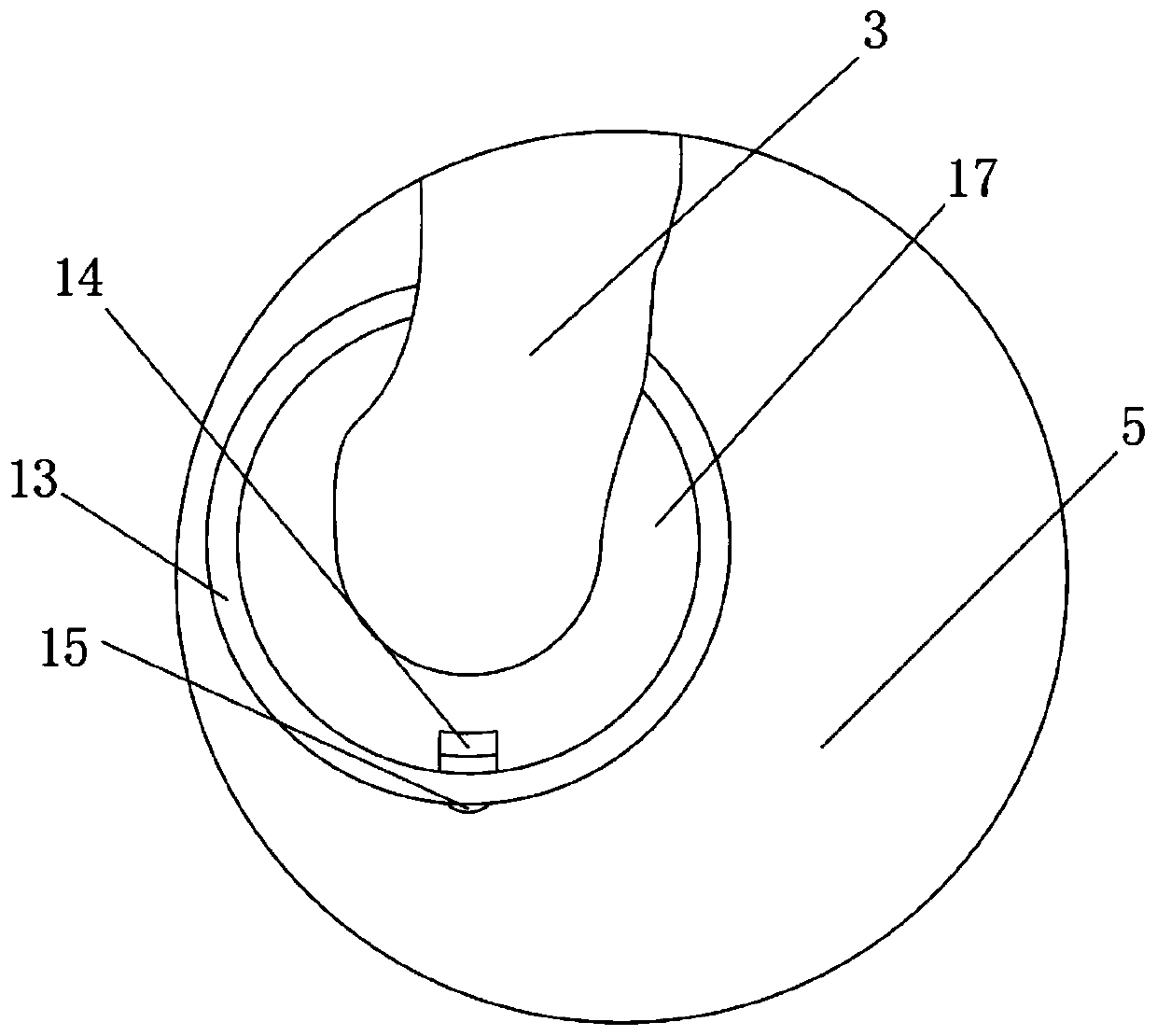

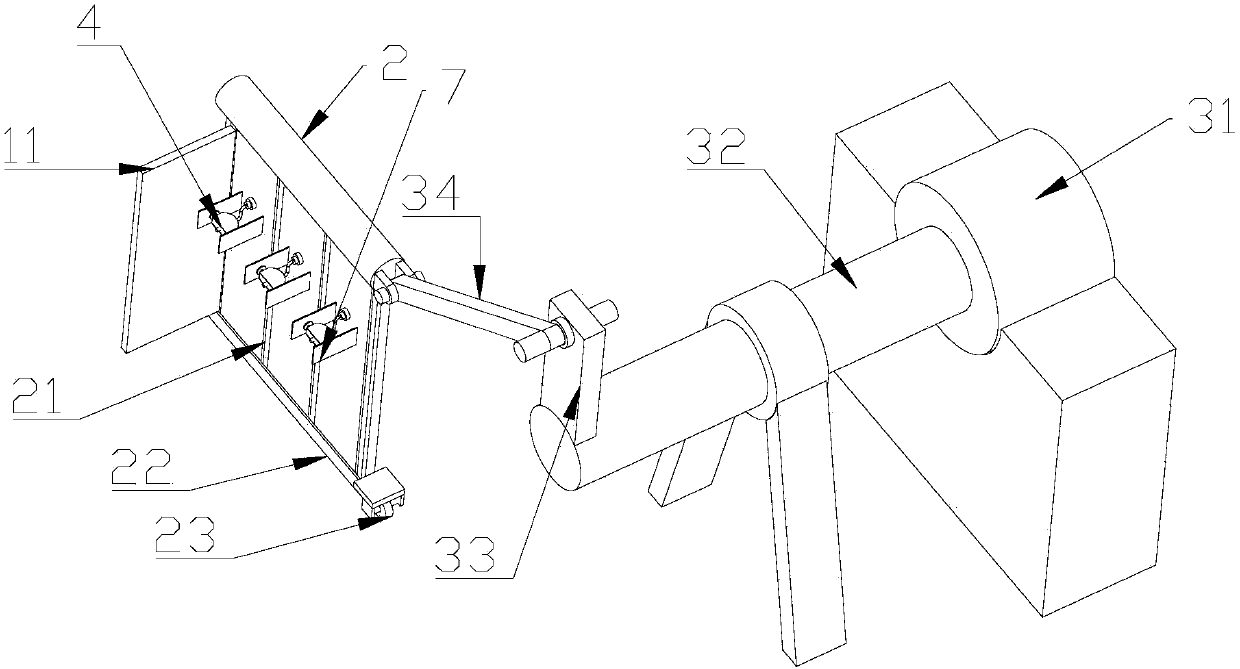

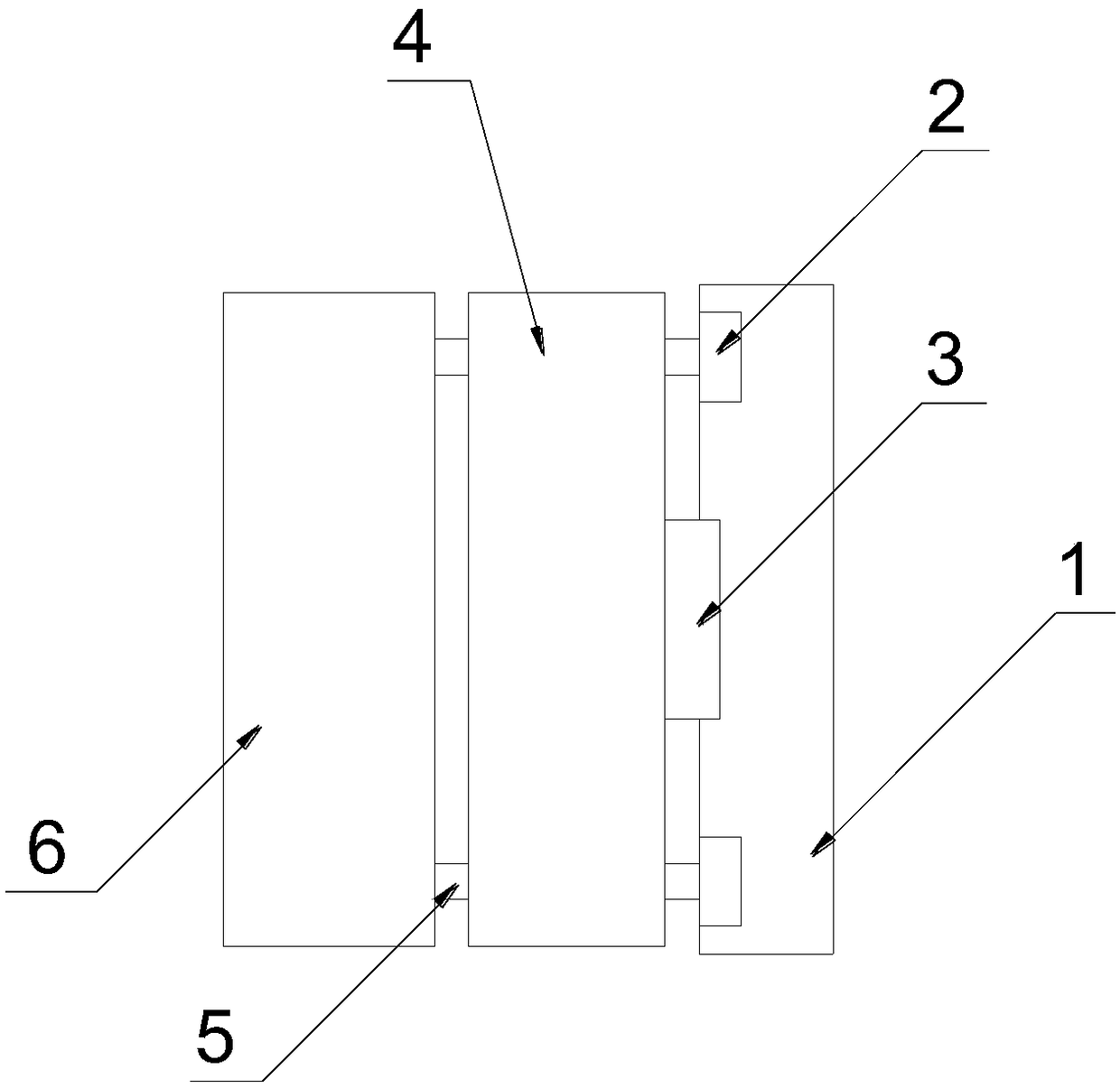

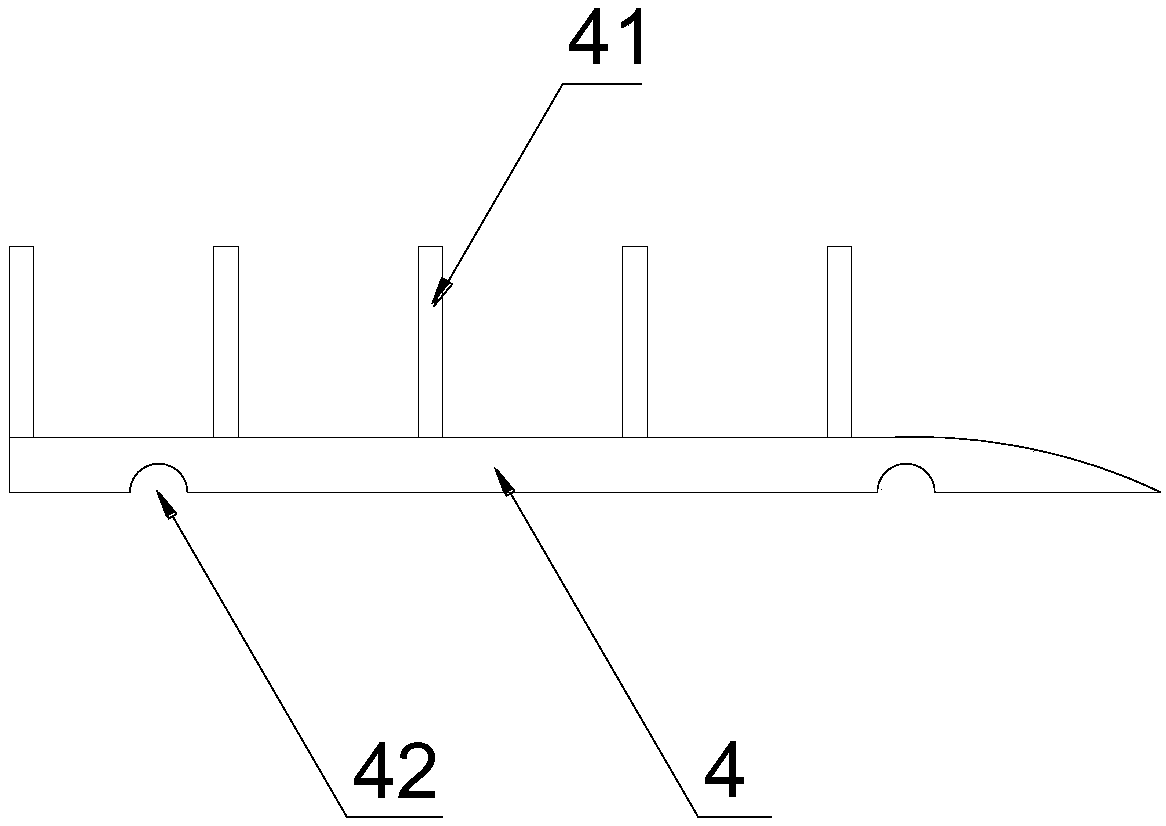

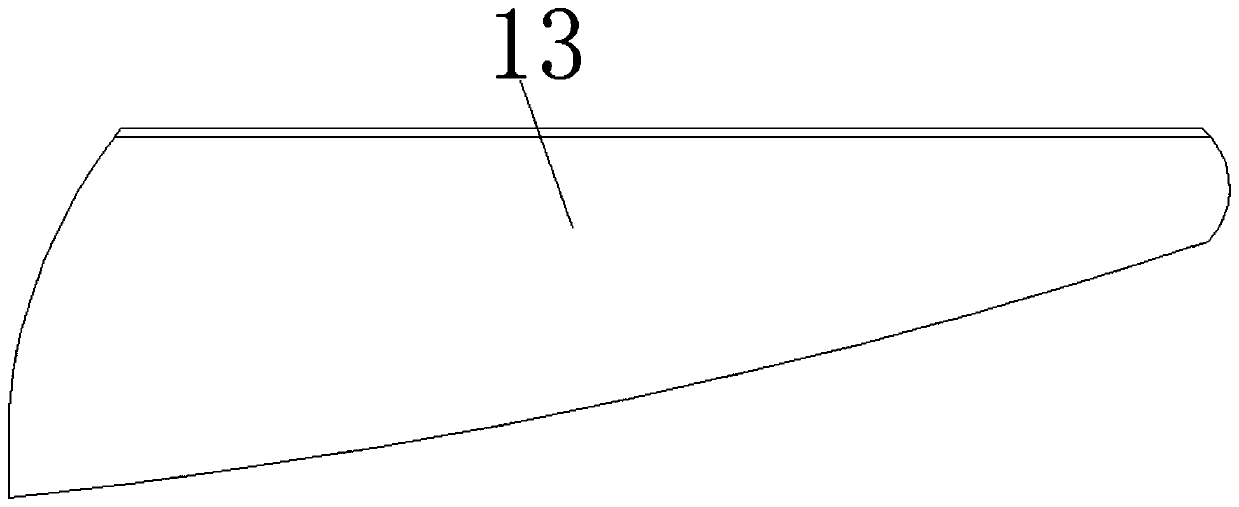

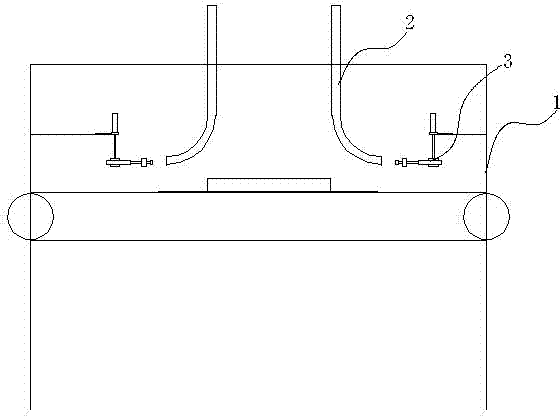

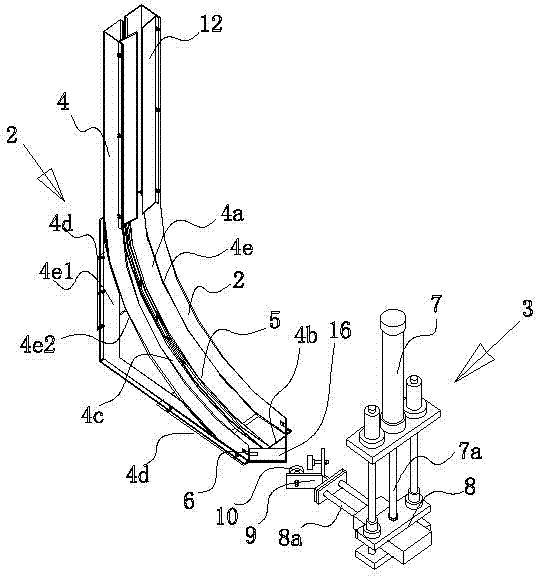

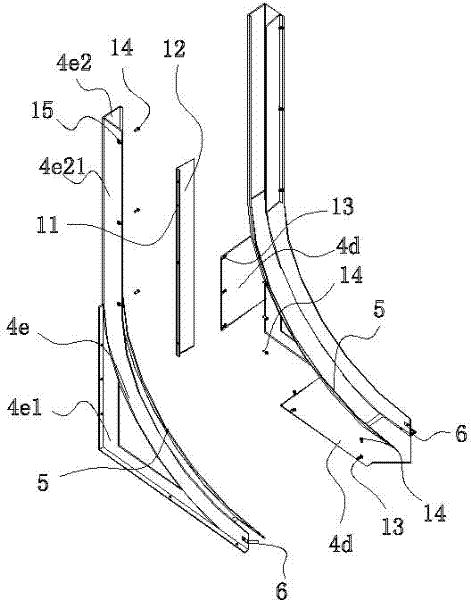

Cornerite mounting method and device used on ceramic tile packaging machine

InactiveCN102126572AReduce moving frictionEasy to moveShock-sensitive articlesCeramic tilesPackaging machine

The invention relates to a cornerite mounting method and device used on a ceramic tile packaging machine. The device comprises a rack, an arc-shaped cornerite cabin which is arranged on the rack and is distributed in a quadrangle shape, a cornerite sucking and conveying mechanism arranged on the rack and is characterized in that the arc-shaped cornerite cabin comprises an arc-shaped cabin body provided with a horizontal open opening, more than two raised rails arranged on the bottom surface of the arc-shaped cabin body and shrapnel arranged at the two sides of the horizontal open opening; and the cornerite sucking and conveying mechanism comprises a vertical moving mechanism arranged on the rack, a horizontal moving mechanism arranged on a moving driving rod of the vertical moving mechanism, a right angle type buckling sucker seat arranged on a horizontal moving driving rod of the horizontal moving mechanism and suckers respectively arranged at the inner sides of the two sides of the right angle type sucker seat. Compared with the prior art, the cornerite mounting method and device provided by the invention have the advantages that the moving frictional force of the cornerite in the arc-shaped cornerite cabin is small, the cornerite moves smoothly in the arc-shaped cornerite cabin and the cornerite can be smoothly taken out from the arc-shaped cornerite cabin one by one.

Owner:佛山市金皇化工陶瓷有限公司

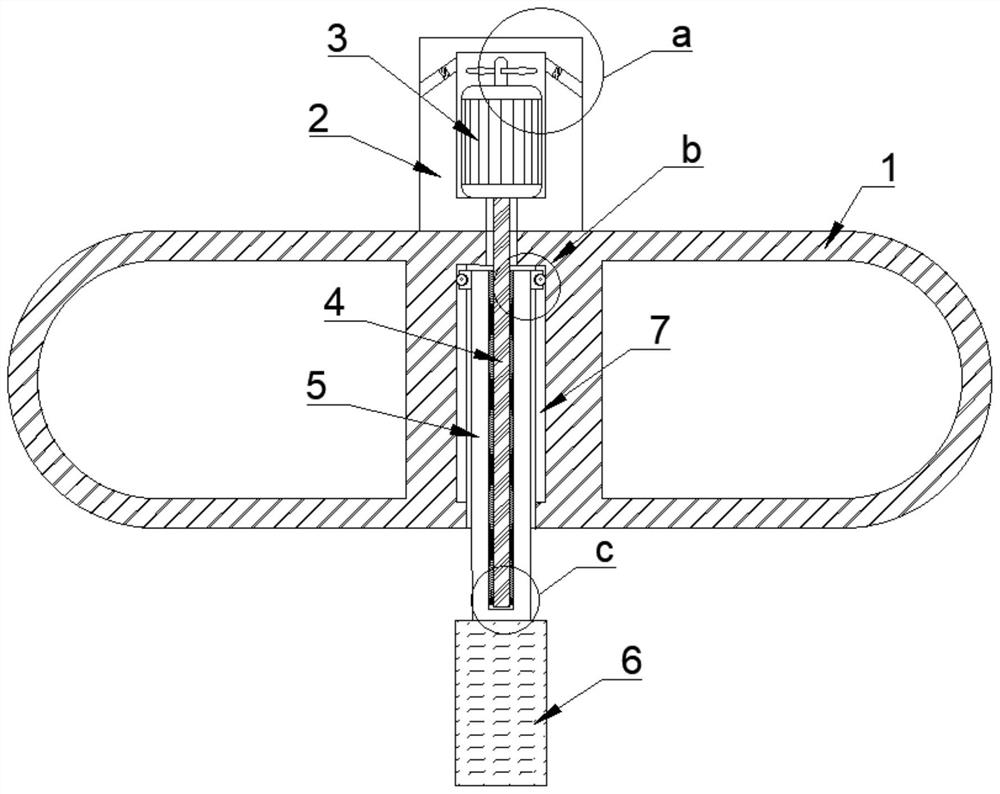

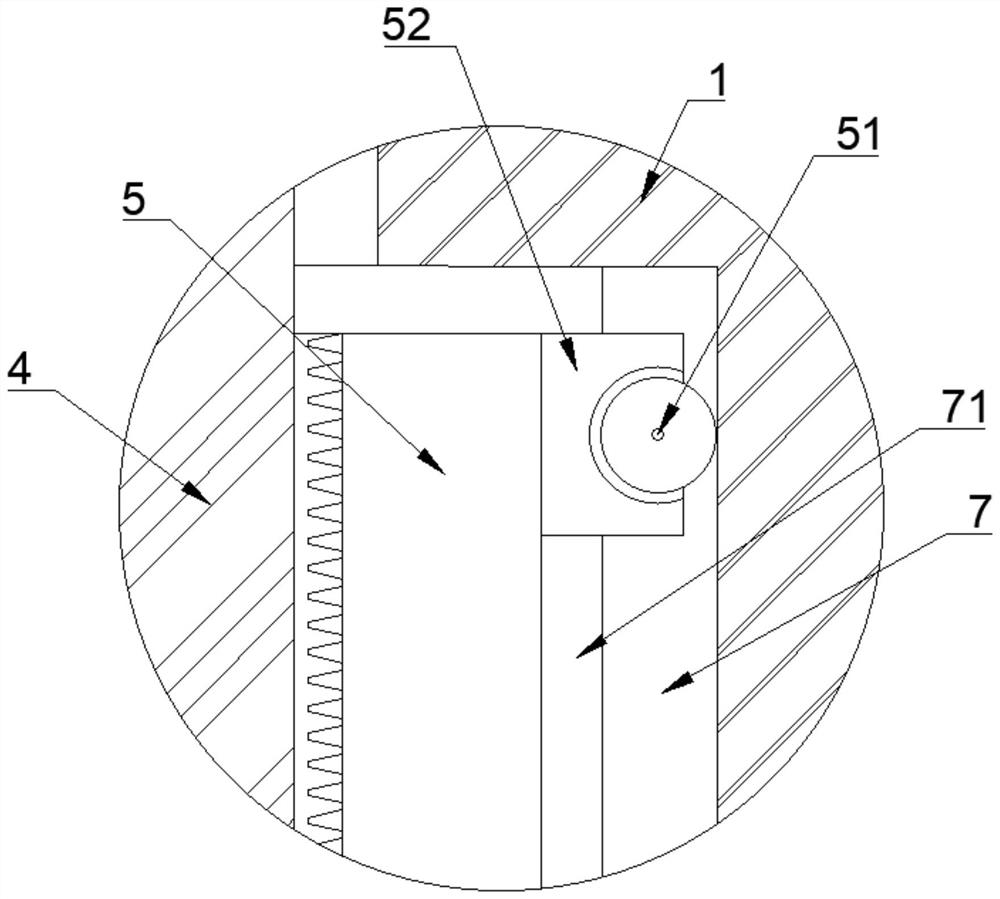

Floating island device for water ecological environment detection

PendingCN112644642AEasy to detectReduce moving frictionWaterborne vesselsTesting waterRotational axisEcological environment

The invention discloses a floating island device for water ecological environment detection. The floating island device comprises a floating body and an equipment mounting box, the equipment mounting box is fixedly mounted at the top end of the floating body, a motor is fixedly connected into the equipment mounting box, the bottom end of the motor is rotatably connected with a rotating shaft, and a mounting groove is formed in the middle of the interior of the floating body; a lifting rod is mounted in the mounting groove, the rotating shaft penetrates through the equipment mounting box and the floating body, the bottom end of the rotating shaft extends into the lifting rod, an internal thread is arranged on the inner wall of the lifting rod, an external thread matched with the internal thread is arranged at the bottom end of the outer side of the rotating shaft, and a guide groove is formed in the inner wall of the mounting groove; and a guide block is mounted on the outer edge of the top end of the lifting rod. The lifting rod is additionally arranged at the bottom end of the rotating shaft, so that the moving friction force between the guide block and the guide groove is reduced, the lifting rod can move up and down more smoothly, the blockage phenomenon is avoided, the lifting rod drives the detection head to enter a deeper water area, and the floating island device can conveniently detect water bodies with different depths.

Owner:刘志宏

Forming process for automobile high-strength plate chassis part

InactiveCN108941502AImprove extraction speedShorten the timeFoundry mouldsFoundry coresVacuum dryingThree dimensional model

The invention discloses a forming process for an automobile high-strength plate chassis part. The forming process comprises the following steps of: S1, manufacturing a hub mould: designing the hub mould according to a three-dimensional model, processing blank to form the hub mould, uniformly coating zinc stearate powder on the surface of the hub mould, and sintering the hub mould; S2, weighing rubraw materials in parts by weight; S3, mixing the hub raw materials; S4, forming a hub; and S5, performing surface treatment on the hub: soaking and passivating the hub with zinc plating liquid, vacuum-drying the electrostatic-sprayed hub and performing baking varnish processing. The forming process can improve operation efficiency of hub forming processing, shortens rub forming time, reduces hubprocessing production cost, and meets batch production requirements of the hub; and mixed processing is selected for the hub materials, so that hardness, rigidity, impact resistance and tensile strength of the formed hub are improved, the using performance of the hub is improved, and the usage period of the hub is prolonged.

Owner:安徽启慧信息科技有限公司

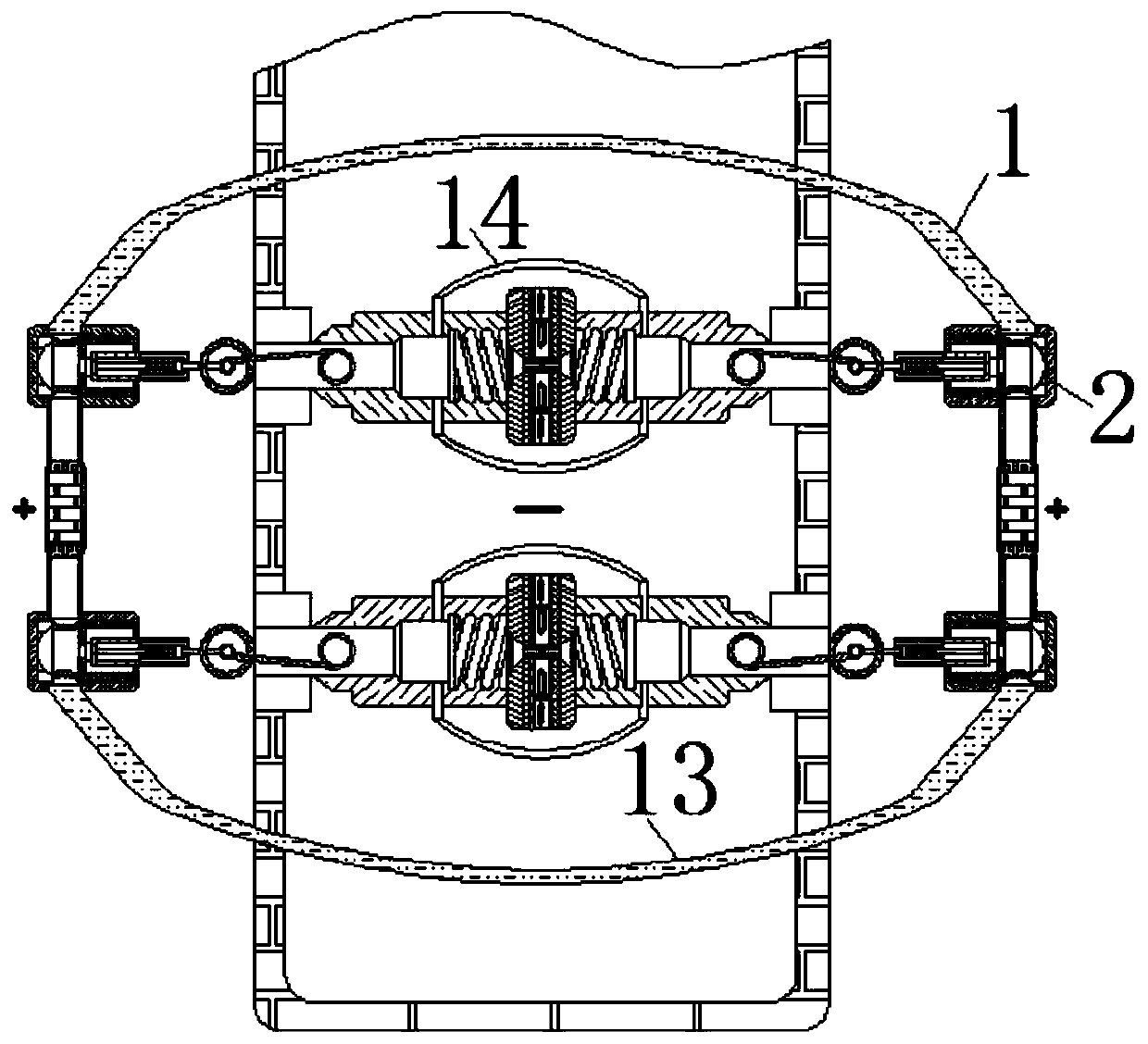

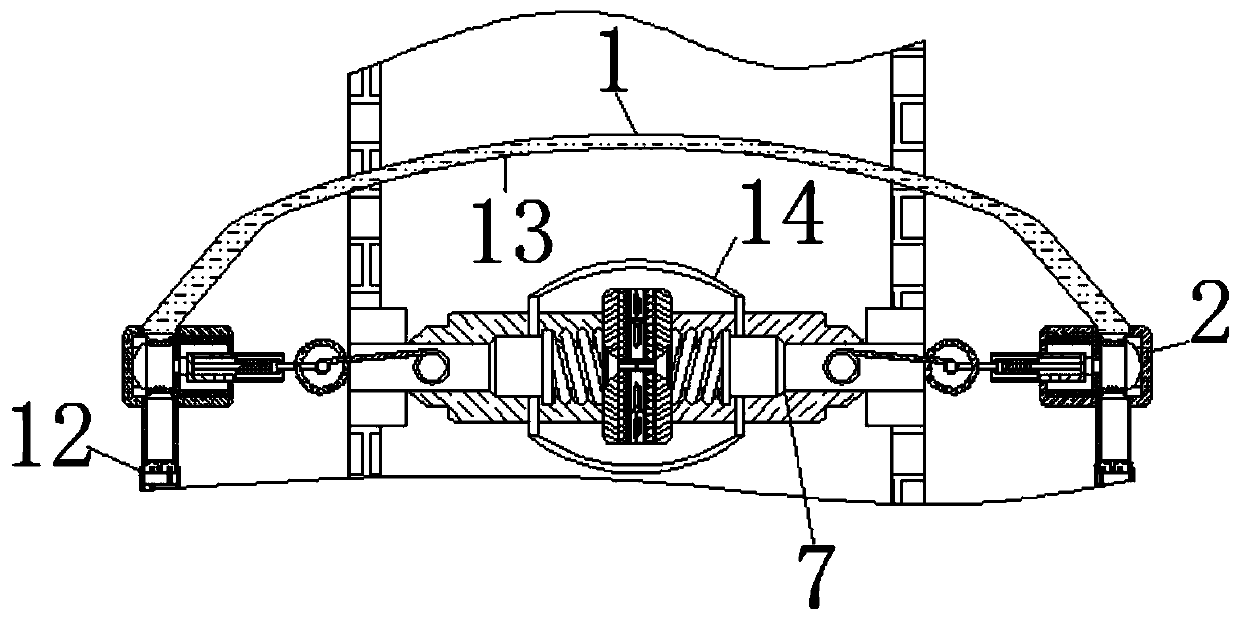

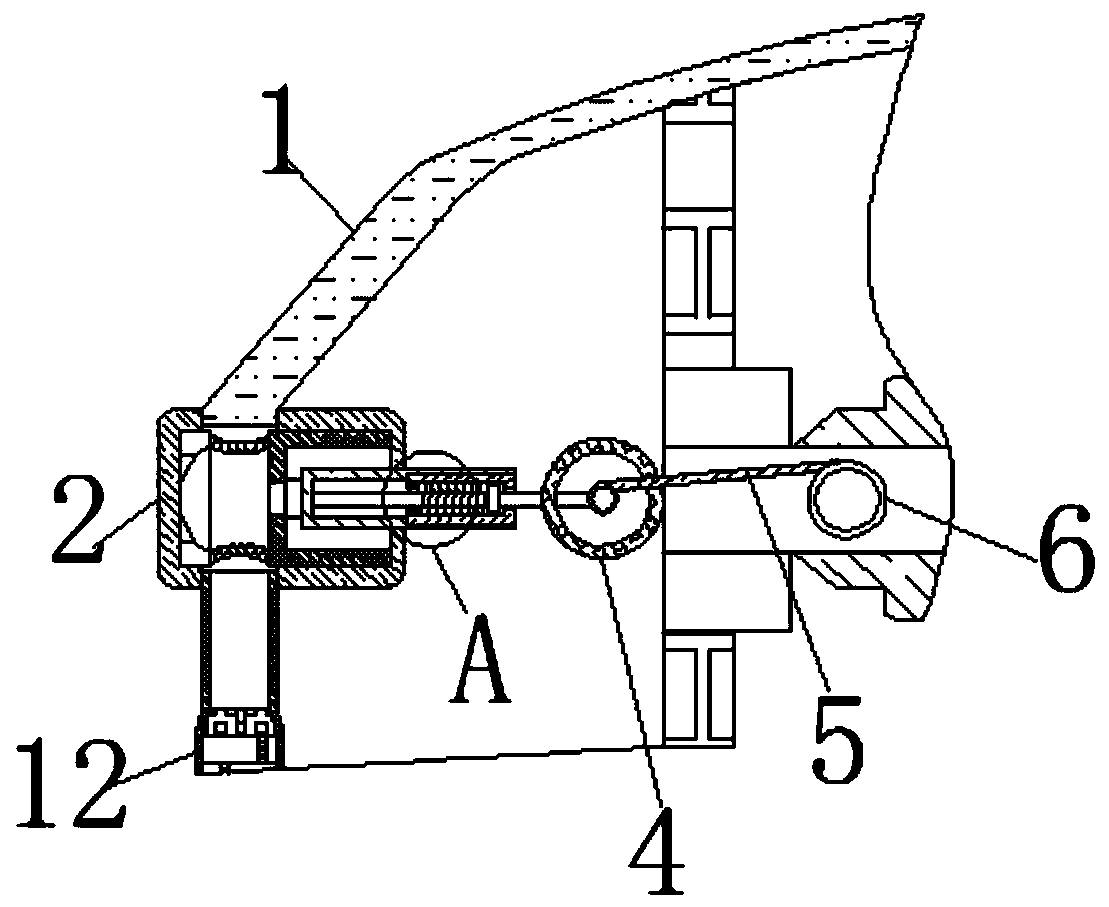

Production device for pressing, curing and linking neodymium-iron-boron magnet containing heavy rare earth

ActiveCN111834120AEven by forceQuality improvementInductances/transformers/magnets manufactureCircular discEngineering

The invention discloses a production device for pressing, curing and linking a neodymium-iron-boron magnet containing heavy rare earth. The device comprises a pressing table and a pressing device, thepressing device is mounted on one side of the upper end of the pressing table; when the air cylinder pushes the feeding bin to move at the upper end of the bottom film plate, connecting frames installed at the two ends of the feeding bin slide in inner cavities of the sliding grooves. The connecting frames move to drive the magnet to transversely move; when the magnet moves to the lower end of the vibration device; at the moment, the rotor in the power-on state can rotate, the rotor rotates to drive the disc installed at the eccentric position to rotate, the disc rotates to enable the vibration device to vibrate, vibration transmission enables the materials in the inner cavity of the film hole to be naturally laid flat under vibration, and therefore the die head is pressed downwards to bestressed evenly, and the bonding quality of the materials is improved.

Owner:BAOTOU INST MAGNETIC NEW MATERIALS CO LTD

A processing method for extruding unburned bricks

ActiveCN106626003BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

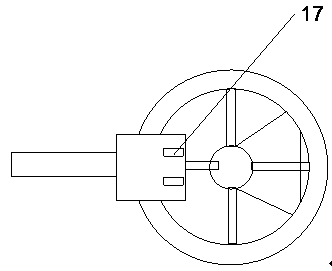

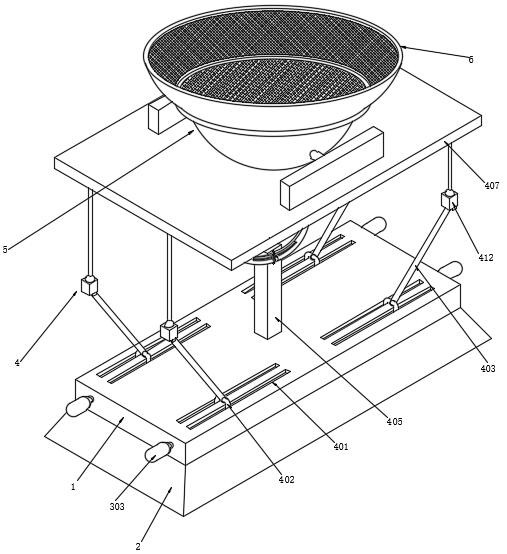

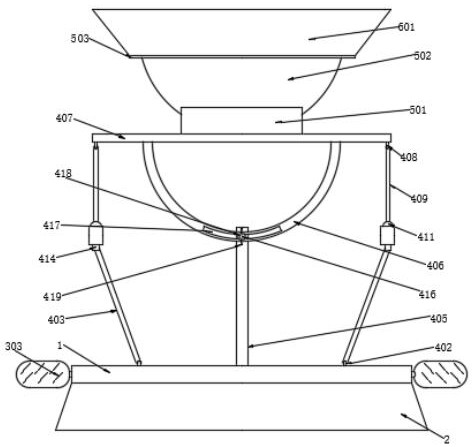

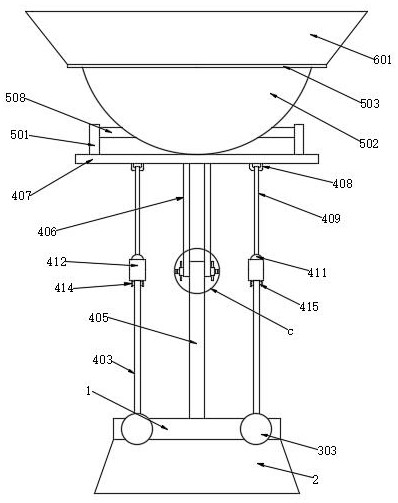

Orientation-adjustable photovoltaic module capable of automatically tracking light source

ActiveCN113325882AEasy to moveReduce moving frictionControl using feedbackEngineeringMechanical engineering

The invention discloses an orientation-adjustable photovoltaic module capable of automatically tracking a light source, which comprises a bottom plate, a transmission assembly and an adjusting assembly, the transmission assembly is fixedly mounted on the bottom plate, the adjusting assembly is fixedly connected to the transmission assembly, and when sunlight irradiates a reaction bottle on one side, gas in the reaction bottle expands after being irradiated by sunlight and enters the air bag, the volume of the air bag is expanded along with the inrush of the gas, so that the sliding block transversely moves, and as the balls roll in the rolling grooves, surface contact between the sliding block and the bottom of the movable cavity can be changed into point contact, so that the movement friction force is favorably reduced; a sliding block can move in a movable cavity more smoothly, the sliding block can enable a pull rod to pull a connecting block downwards through a first connecting rod in the moving process, so that a movable rod pulls a balance plate downwards, the balance plate inclines towards sunlight, and then a photovoltaic panel can be automatically adjusted along with the change of the illumination angle and always faces the sunlight; and the photovoltaic panel can fully receive sunlight.

Owner:骥志(江苏)新能源科技有限公司

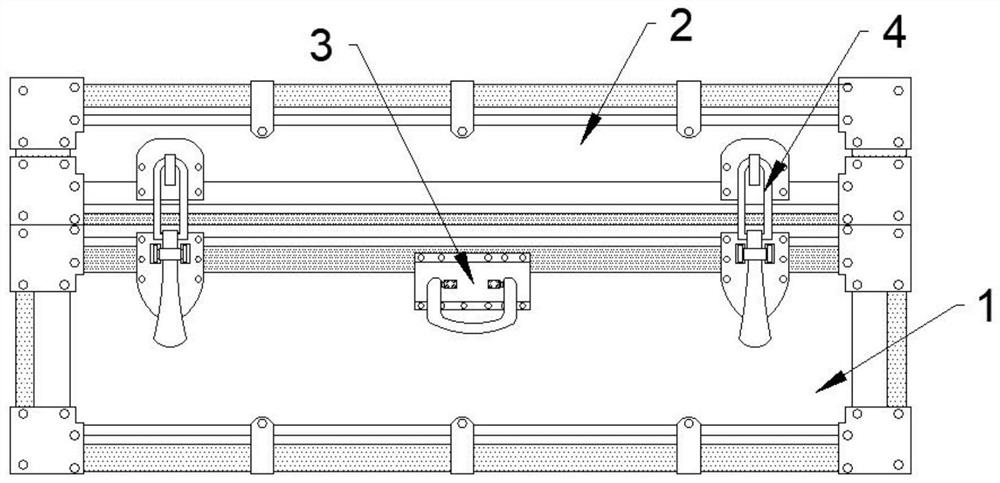

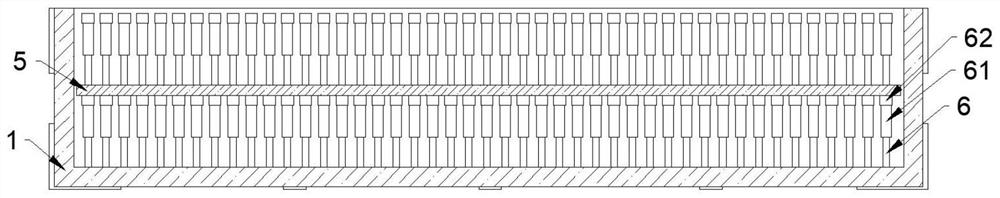

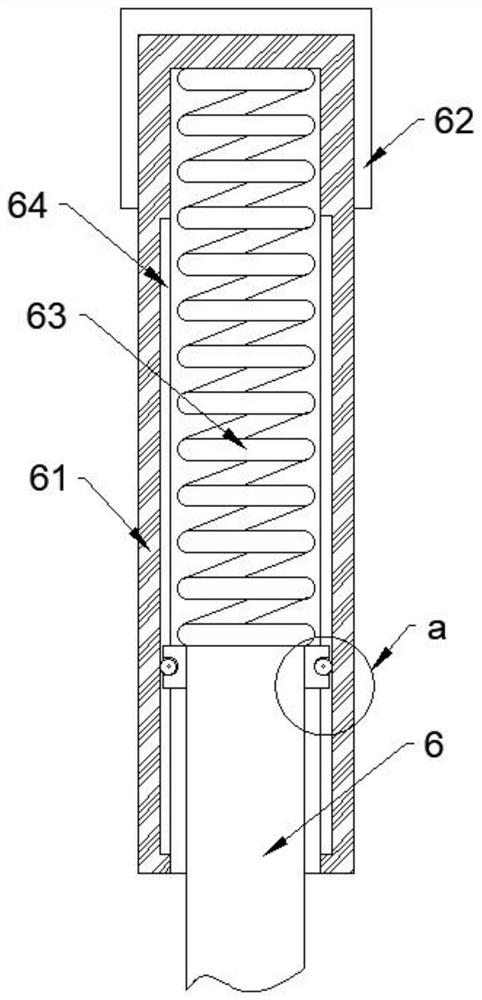

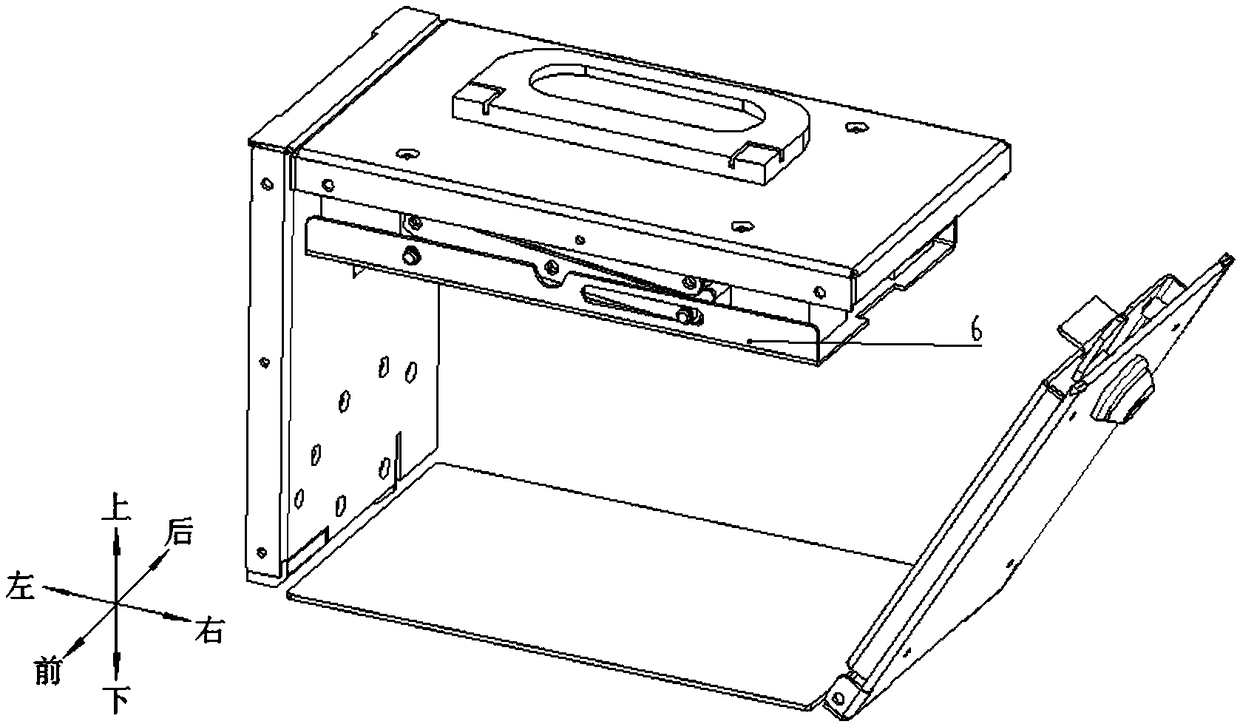

Portable safety inspection tool box

PendingCN112372611AImprove practicalityImprove the smoothness of movementWork tools storageStructural engineeringSecurity check

The invention discloses a portable safety inspection tool box. The portable safety inspection tool box comprises a lower box body, wherein a partition plate is arranged in the lower box body; fixing rods are fixedly connected to the top surface of the partition plate and the bottom surface of the interior of the lower box body; compression sleeves are arranged at the top ends of the fixing rods; springs are arranged in the compression sleeves; the top ends of the fixing rods extend into the compression sleeves and make contact with the bottom ends of the springs; and the compression sleeves are cylinders with smooth outer surfaces. According to the portable safety inspection tool box, the fixing rods are additionally arranged in the lower box body and at the top end of the partition platerespectively, electronic equipment correspondingly presses the compression sleeves through rubber sleeves according to the area of the electronic equipment, the compression sleeves compress the springs, and the electronic equipment slides downwards along the surfaces of the fixing rods, the tool box can be matched with different electronic equipment, and the practicability of the tool box is improved; and meanwhile, in the using process of the electronic equipment, dust is inevitably adsorbed, the adsorbed dust is brought into the lower box body, the compression sleeves are connected to the fixing rods in a sleeved mode, the situation that the dust enters the compression sleeves can be effectively reduced, and the moving smoothness of the compression sleeves on the fixing rods can be further improved.

Owner:上海清网知瑶信息科技有限公司

Buffering material receiving device for coal mine

ActiveCN112623677AReduce moving frictionEasy to moveConveyorsConveyor partsStructural engineeringProcess engineering

The invention discloses a buffering material receiving device for a coal mine. The buffering material receiving device comprises a material receiving box, a feeding port is formed in the top end of the material receiving box, a material receiving plate and a buffering air cylinder are hinged to one side of the inner wall of the material receiving box, the material receiving plate is located at the bottom end of the feeding port, the bottom end of the buffering air cylinder is located at the bottom end of the material receiving plate, connecting lugs are hinged to the top end of the material receiving plate, sliding blocks are fixedly connected to the top ends of the connecting lugs, rolling wheels are rotatably connected to the top ends of the sliding blocks, the sliding blocks matched with the sliding blocks are arranged at the bottom end of the material receiving plate, the sliding blocks are slidably connected with sliding grooves through the rolling wheels. The sliding blocks are additionally arranged at the top end of the connecting lug, the sliding grooves drive the rolling wheels to roll, meanwhile, the rolling wheels drive the sliding blocks to move downwards, the sliding blocks compress the top end of the buffer air cylinder through the connecting lugs, when materials leave the surface of the material receiving plate, the buffer air cylinder drives the material receiving plate to reset, and under the action of the sliding blocks and the sliding grooves, downward moving, resetting and moving stability of the material receiving plate is guaranteed; under the action of the rollers, the moving friction force between the sliding blocks and the sliding grooves is reduced.

Owner:甘肃华亭煤电股份有限公司华亭煤矿

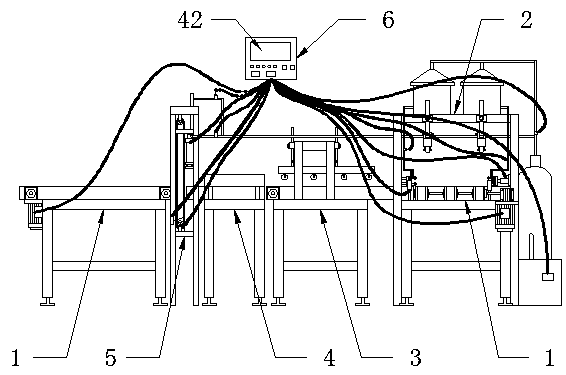

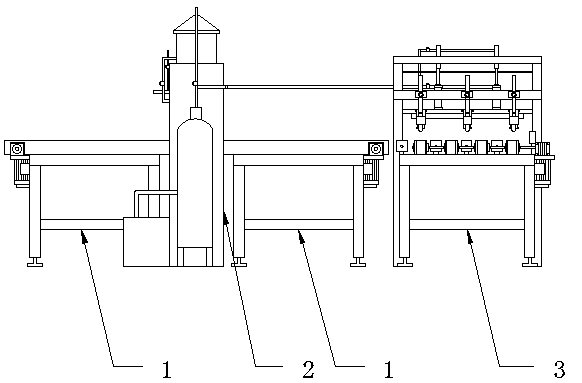

Automatic bonding cutting machine of insulation board

ActiveCN110228106AApply evenlyUniform effectMaterial gluingMetal working apparatusEngineeringAutomation

The invention discloses an automatic bonding cutting machine of an insulation board. The automatic bonding cutting machine of the insulation board comprises conveying devices, a glue spraying device,a transferring device, a bonding device, a cutting device and a control computer, wherein the conveying devices are arranged on the two sides of the glue spraying device correspondingly, one sides ofthe conveying devices are provided with the transferring device, one side of the transferring device is provided with the bonding device, the cutting device is arranged on one side of the bonding device, one conveying device is arranged on one side of the cutting device, and the conveying devices, the glue spraying device, the transferring device, the bonding device and the cutting device are connected with the control computer. Generally, the automatic bonding cutting machine has the advantages that all functions are controlled by a PLC, high automation is achieved, automatic glue spraying, automatic bonding and automatic cutting of the insulation boards with different specifications can be met, the cutting length can be controlled, and the construction requirements are met; and the problems of material waste, high construction cost and low construction efficiency caused by an existing method are effectively solved.

Owner:PUYANG HENGRUI BUILDING MATERIAL TECH CO LTD

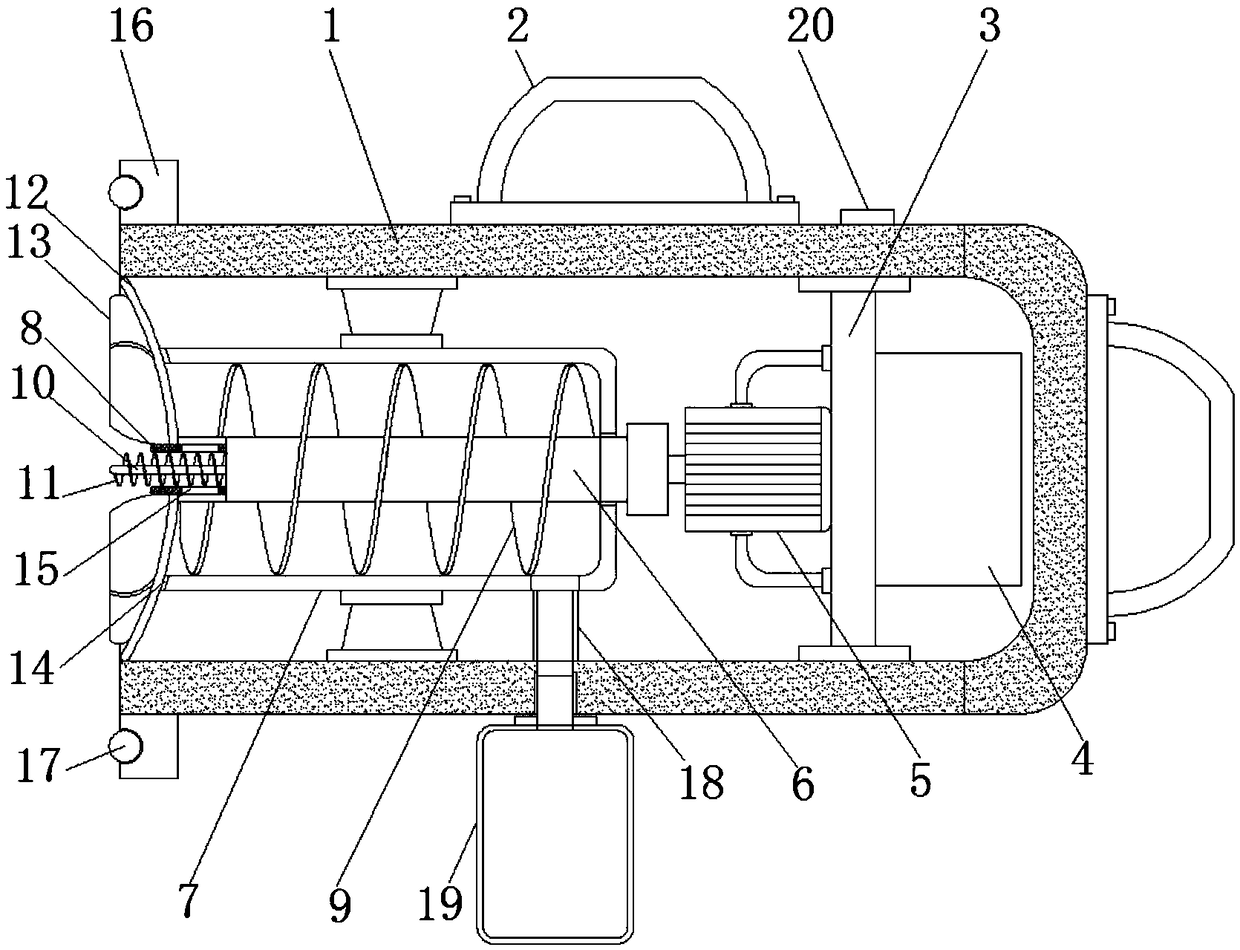

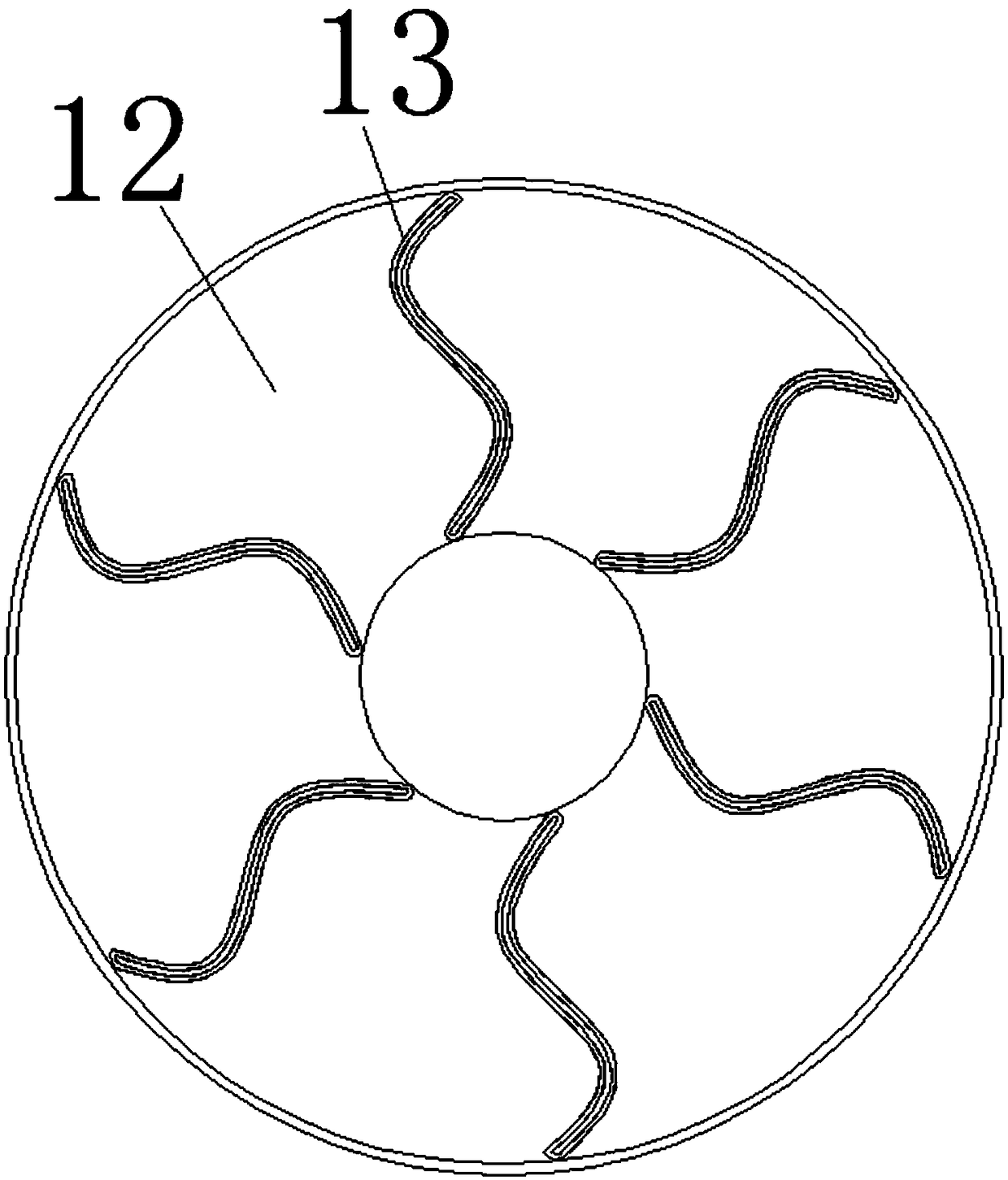

Hand-held preliminary scraping device for peeling paint off wall surface

The invention relates to the technical field of wall surface paint processing and discloses a hand-held preliminary scraping device for peeling paint off a wall surface. The device comprises a cylinder body, a right end surface and a top part of the cylinder body are fixedly connected with a hand-held handle, a mounting plate is fixedly connected between an inner top part and a bottom part of thecylinder body, a storage battery is fixedly arranged on a right side face of the mounting plate, a left side face of the mounting plate is fixedly connected to a driving motor via a fixing frame, an output shaft of the driving motor is fixedly connected with a moment rotating shaft through a shaft coupling, and an inner side of the cylinder body is fixedly connected with a discharging tube througha mounting rack; one end, positioned far away from the driving motor, the moment rotating shaft runs through a right end surface of the discharging tube and extends to an inner side of the discharging tube; one end, positioned far away from the driving motor, of the moment rotating shaft runs through a right end surface of the discharging tube and extends to the inner side of the discharging tube. Via the hand-held preliminary scraping device for peeling paint off the wall surface, paint can be prevented from splashing when being scraped; all scraped paint residues can be conveyed, eliminatedand collected; preliminary processing of the paint peeled off a wall body can be facilitated.

Owner:浙江企信检测有限公司

Electrochemical corrosion principle based steel structure equipment

ActiveCN111266980AAchieve the effect of self-cleaning rustAchieve protectionGrinding machinesSea wavesEngineering

The invention relates to the technical field of steel structure corrosion prevention in seawater, and discloses electrochemical corrosion principle based steel structure equipment. The electrochemicalcorrosion principle based steel structure equipment comprises a cover body, wherein the two side walls inside the cover body are fixedly connected to displacement slots; elastic rods are movably connected inside the displacement slots; the other ends of the elastic rods are movably connected to rollers; waterproof ropes are wound on the surfaces of the rollers; the other ends of the waterproof ropes are movably connected to wrapping posts; the lower ends of the wrapping posts are movably connected to telescopic poles; the surfaces of the telescopic poles are movably connected to springs; andthe other ends of the springs are movably connected to rust-removal wheels. While seawater rises, the cover body is pushed to move upwards, the cover body slides on the surface of a steel component, and an arc-shaped knife upwards moves in the vertical direction and also moves in the horizontal direction under influences of liquidity of seawater, so that impurities and rust on the surface of a contact position of the steel component and the arc-shaped knife are removed, and therefore, the automatic rust-removal effect is achieved through sea wave fluctuation motion.

Owner:青岛伟成达电力设备有限公司

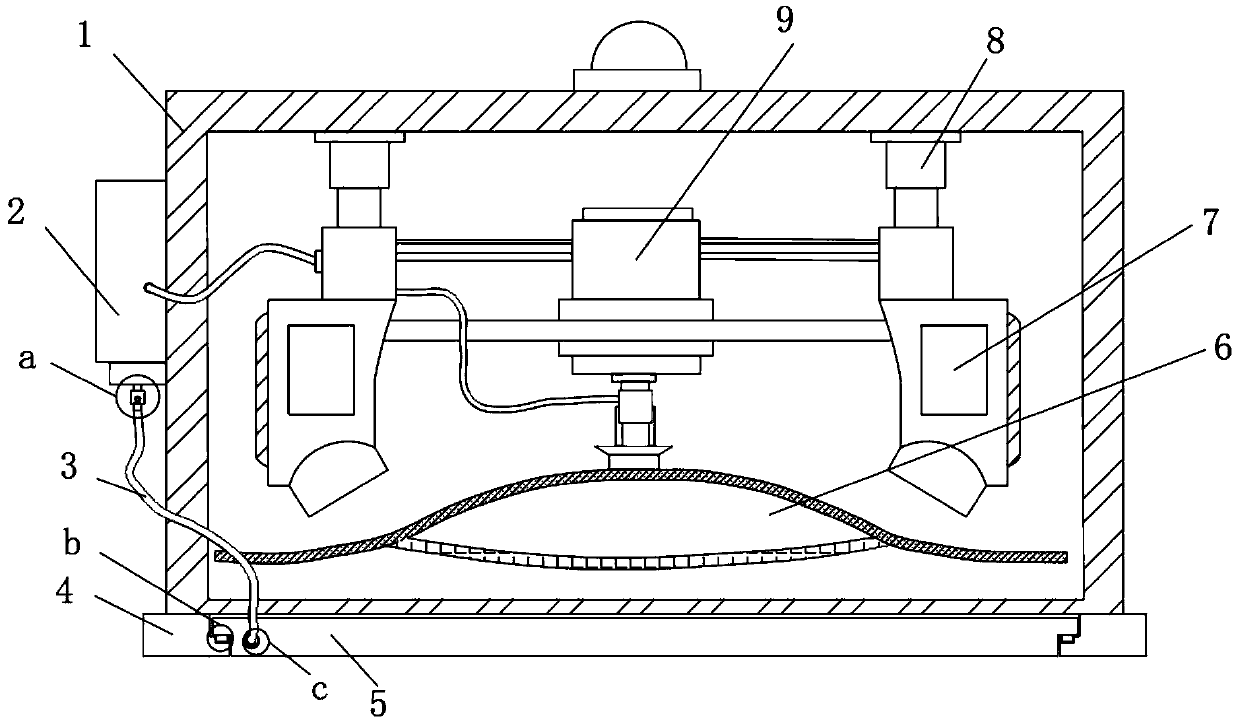

Deposit book compaction device

PendingCN108898732AEasy to put inFold out correctlyCoin/currency accepting devicesLocking mechanismEngineering

The invention relates to a deposit book compaction device. The deposit book compaction device comprises a top plate, a compaction mechanism and a locking mechanism, wherein the top plate is connectedwith the compaction mechanism; the compaction mechanism is in contact with a deposit book; the locking mechanism is connected with the compaction mechanism; when the compaction mechanism moves upwardto an extreme position, the compaction mechanism and the top plate are locked through the locking mechanism. According to the deposit book compaction device provided by the invention, the top plate isfixed on an upper top surface of a deposit book storage box, and the pressing plate moves downward due to gravity to compact the deposit book; a retractable assembly is stretched along the movement of the pressing plate and the deposit book is compacted through the pressing plate, so that the deposit book is stored in a compacted manner and the deposit book is accurately taken out; when the deposit book is put, the pressing plate is raised and a retractable assembly is compressed; when the pressing plate moves to the uppermost end, the pressing plate and the top plate are locked through the locking mechanism, and the pressing plate does not automatically fall off, so that a worker can conveniently put the deposit book.

Owner:BEIJING C&W ELECTRONICS GRP

Mechanical grinding equipment

PendingCN111469051AEasy to cleanImprove the efficiency of cleaning circulation pipesGrinding machine componentsGrinding/polishing safety devicesStructural engineeringGrinding

The invention discloses mechanical grinding equipment. The mechanical grinding equipment comprises a mounting frame, wherein a base is arranged at the bottom end of the mounting frame, a recycling boxis arranged on the inner side of the base, a filter box is arranged on one side of the mounting frame, first connecting pipes are arranged at the bottom end of the filter box and on one side of the front surface of the recycling box respectively, first fixing rings are arranged at the bottom ends of the first connecting pipes, a connecting sleeve is arranged on the outer side of the bottom end ofeach first fixing ring, fixing grooves are formed in the two ends of the outer side of each connecting sleeve and penetrate through the corresponding connecting sleeve, a second fixing ring is arranged at the bottom end of each first fixing ring, a second connecting pipe is arranged at the bottom end of each second fixing ring, a connecting strip is arranged on the outer side of the bottom end ofeach second fixing ring, a fixed head is arranged at the bottom end of the outer side of each connecting strip and located in the corresponding fixing groove; and second fixing rings are additionallyarranged at the two ends of a circulating pipe, so that workers can conveniently clean impurities in the circulating pipe, and the efficiency of cleaning the circulating pipe by the workers is improved.

Owner:南京弘晖机电制造有限公司

Guide rail lubricating device of turning and milling composite machine tool

The invention belongs to the technical field of guide rail lubricating, and particularly relates to a guide rail lubricating device of a turning and milling composite machine tool. The guide rail lubricating device comprises an I-shaped sliding rail and a sliding block. The sliding block is connected to the I-shaped sliding rail in a sliding manner. First grooves are formed in the front side and the rear side of the sliding block, and oil pipes are arranged on the side walls of the two sides of the first grooves. A group of spray heads is arranged at the bottom end of each oil pipe. The top ends of the first grooves are connected with a sweeping plate through sliding columns, and the bottom end of the sweeping plate is fixedly connected with a group of sweeping brushes. The sweeping plate is located on the sides, away from the bottoms of the first grooves, of the oil pipes. The guide rail lubricating device for the turning and milling composite machine tool is provided so as to solve the problems that when a sliding assembly in the machine tool slides to move on a guide rail, oil dripping must be carried out on a guide rail after a period of time, if oil dripping is not timely, the machine tool crawl phenomenon can be caused, the machining accuracy of the machine tool is seriously influenced, and the service life of the machine tool is shortened.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

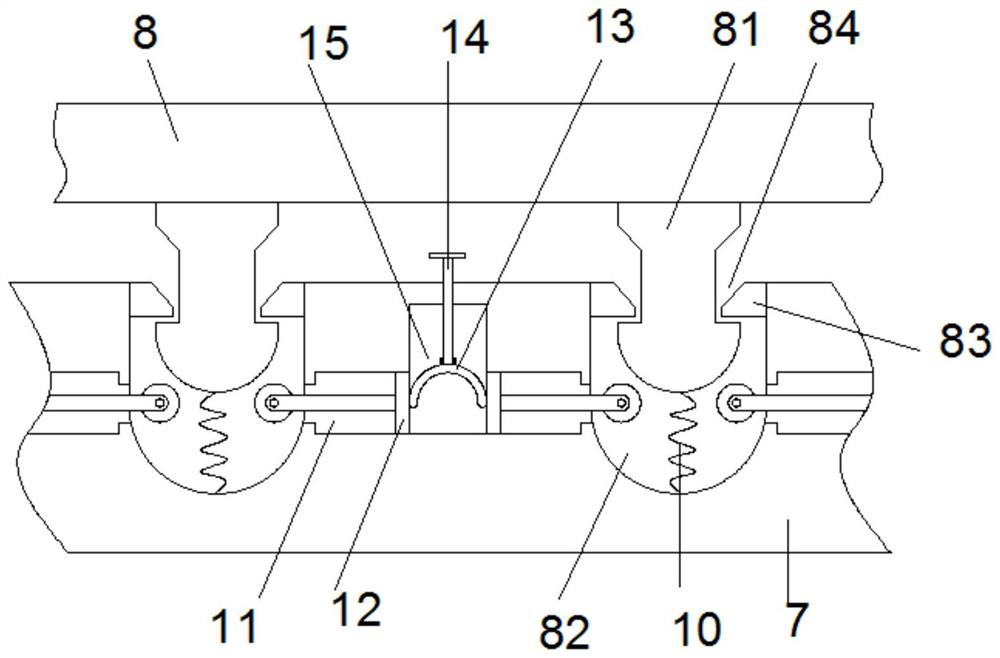

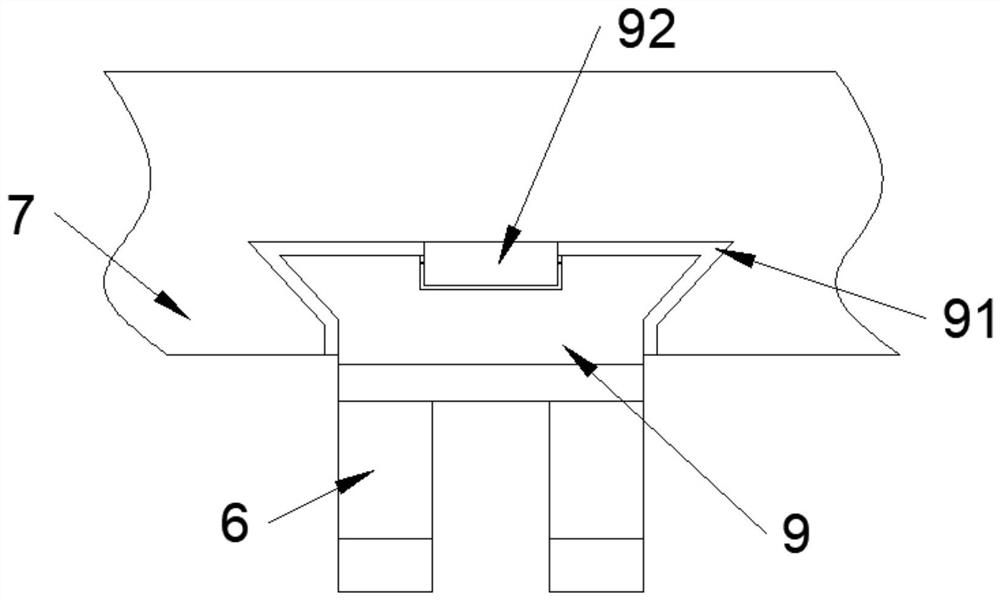

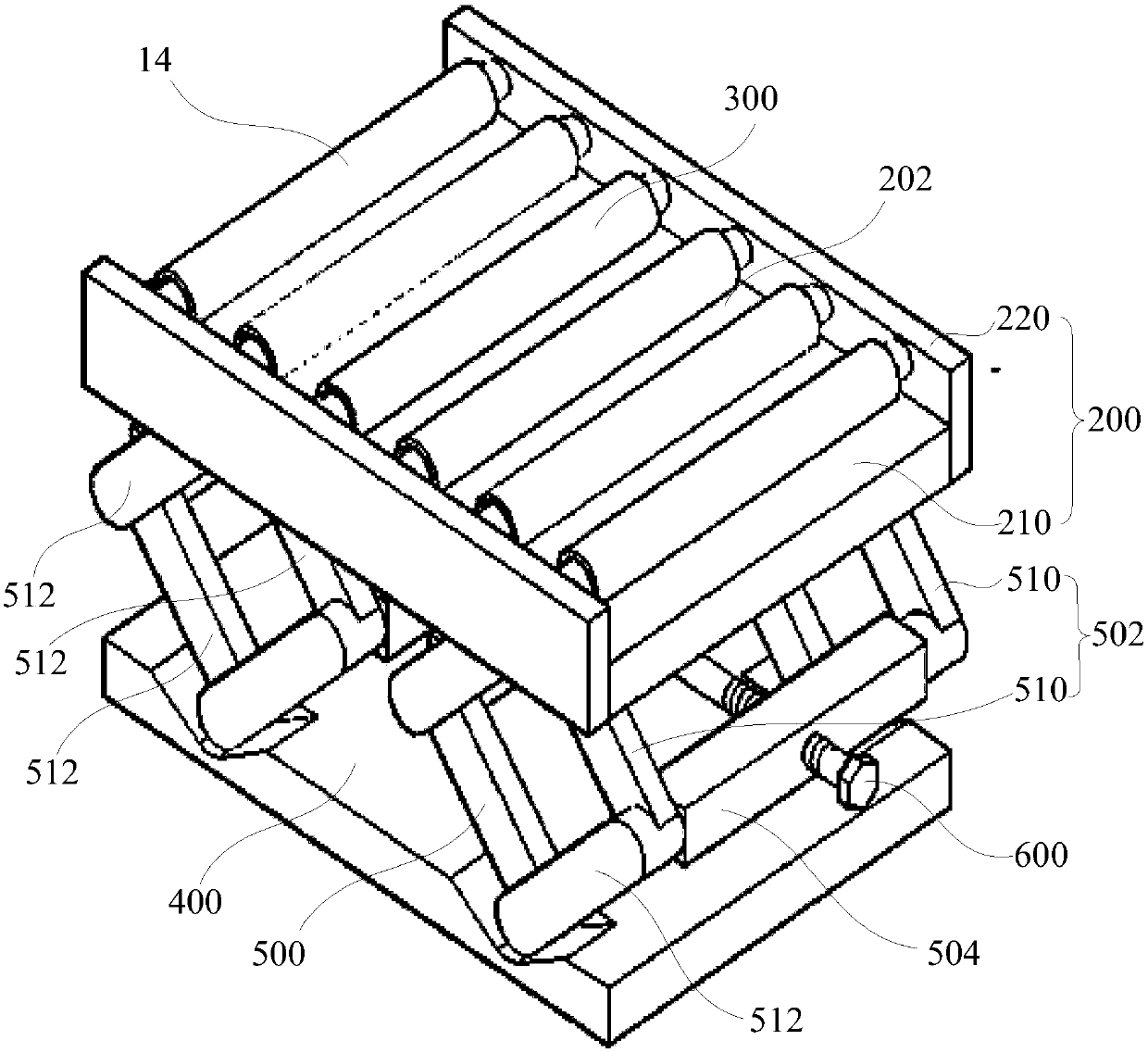

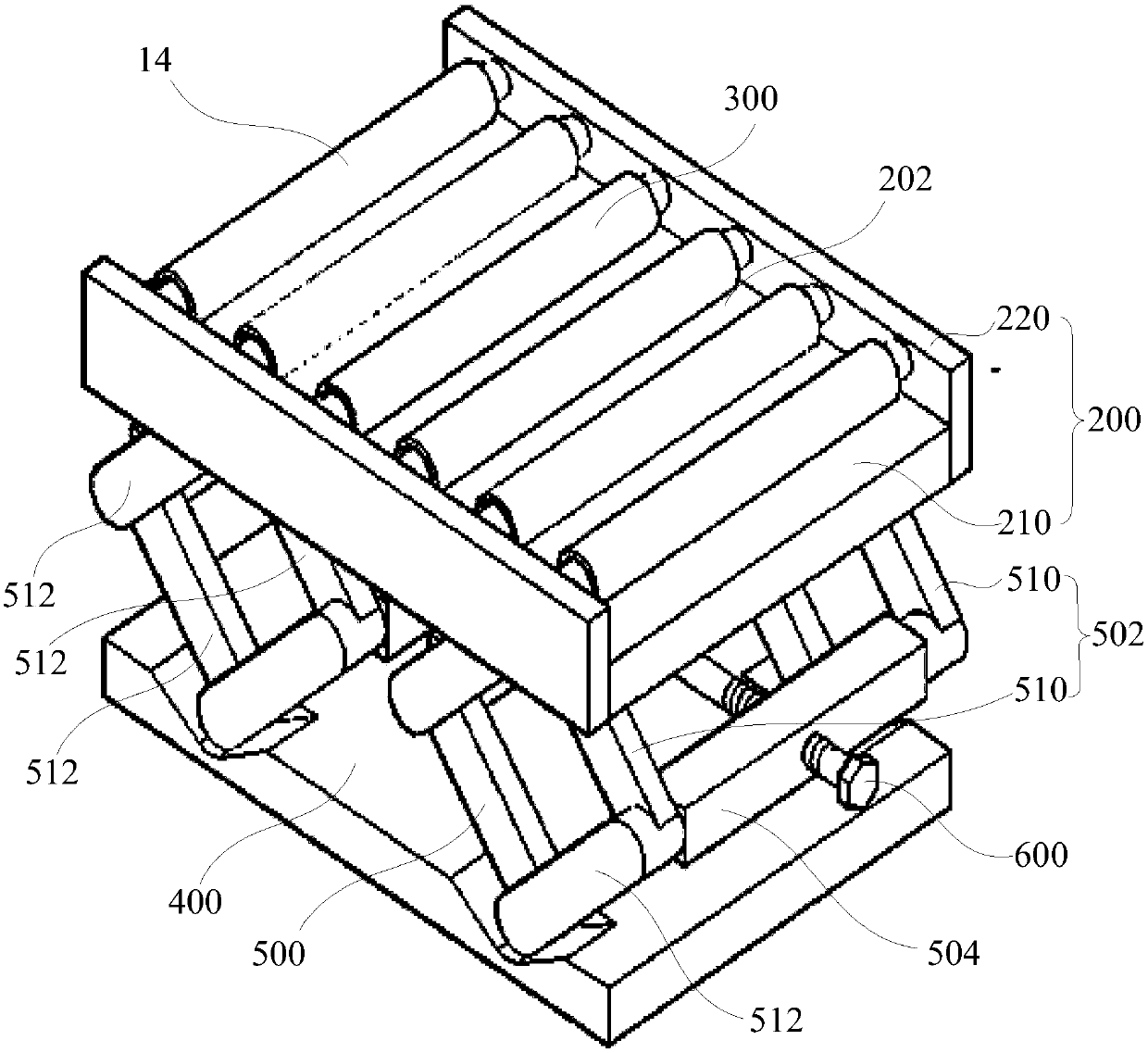

Glass melting furnace system and electrode brick supporting device thereof

InactiveCN109987821AReduce moving frictionReduce propulsion resistanceGlass furnace apparatusTank furnacesBrickRolling resistance

The invention relates to a glass melting furnace system and an electrode brick supporting device thereof. According to the electrode brick supporting device, the electrode brick supporting device is used for bearing electrode bricks, the electrode bricks can move on the electrode brick supporting device, and in the moving process, friction between the electrode bricks and the electrode brick supporting device is rolling friction. The electrode brick supporting device is used for bearing the electrode bricks, in the moving process of the electrode bricks on the electrode brick supporting device, the friction between the electrode bricks and the electrode brick supporting device is rolling friction, compared with a traditional mode that electrode bricks are supported through refractory bricks, the moving friction force of the electrode bricks on the electrode brick supporting device can be reduced, then the pushing resistance of the electrode bricks is reduced in the pushing process of the electrode bricks, and the problem that the electrode bricks are damaged or pool wall bricks move is effectively avoided.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +1

Cleaning device provided with cleaning brush and spray head bracket

InactiveCN108043792AReduce moving frictionEasy to install and disassembleMovable spraying apparatusCleaning using toolsEngineeringCombined use

The invention provides a cleaning device provided with a cleaning brush and a spray head bracket. The cleaning device comprises the cleaning brush, wherein the cleaning brush comprises a cleaning brush body, a movable frame and a brake part for driving the movable frame to move; the brake part comprises a brake motor; the brake motor is connected with a rotary shaft; the other end of the rotary shaft is perpendicularly fixed with a rotary rod; the other end of the rotary rod is hinged with a hinged rod; and the other end of the hinged rod is hinged with the movable frame. According to the cleaning device provided with the cleaning brush and the spray head bracket provided by the invention, a brush and a spray head are combined for use, so that cleaning is complete, and fin movement is reduced.

Owner:新昌县洋花园生态农业园

PP strapping machine

InactiveCN106043766ALittle change in walking pathReduce relaxation tensionWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to a PP strapping machine which comprises a workbench and a film sealing mould arranged on the middle part of the workbench, wherein axial two ends, which correspond to the film sealing mould, of the workbench are provided with PP strap guiders in a mirrored manner; each PP strap guider comprises a guide plate, wherein a flat-strap-shaped guide hole for allowing a PP strap to pass through is formed in the corresponding PP strap guider, the middle part of the guide plate is movably connected to the workbench through an air cylinder mechanism; each air cylinder mechanism comprises an air cylinder mounted in the workbench; the end part of an air cylinder rod connected in each air cylinder is rotatably connected to each guide plate; the movable axis of each air cylinder rod is perpendicular to the surface of the workbench; one side, which corresponds to the axial end part of the workbench, of each guide plate is rotatably connected to a connecting rod, and the other end of the connecting rod is fixedly connected to the axial end part of the workbench perpendicularly; the film sealing mould comprises a base mould which is in front of the workbench and an extrusion mould which is movably connected to the workbench, wherein two groups of lifting air cylinders are further arranged in the workbench; and lifting air cylinder rods of the lifting air cylinders are fixedly connected to the axial end part of the extrusion mould separately.

Owner:SUZHOU SHENGBAIWEI PACKAGE EQUIP

Novel feeding mechanism

ActiveCN113333607AReduce moving frictionReduce labor intensityMetal-working feeding devicesPositioning devicesStringerMechanical engineering

The invention provides a novel feeding mechanism. The novel feeding mechanism comprises a feeding rack; a working rack; a discharging rack; ad the three racks are sequentially arranged left and right, each rack comprises a height-adjustable supporting leg, a cross beam and a longitudinal beam, at least two longitudinal rollers are installed on each longitudinal beam, and the longitudinal rollers are installed on the longitudinal beams through an adjustable structure so that the distance can be adjusted. The novel feeding mechanism provided by the invention has high universality, height adjustment is achieved through a simple profile sleeving structure, the novel feeding mechanism can be matched with stamping dies of different heights and sizes to achieve feeding and discharging of plates, and the novel feeding mechanism is economical and practical; a working rack height adjusting mechanism can realize lifting of the plates so as to be matched with the working process of a die; and the distance between the longitudinal rollers is adjustable, and the novel feeding mechanism can adapt to feeding and discharging of plates of different widths and sizes. Therefore, one set of feeding mechanism can be suitable for the plates of different sizes and the stamping dies of different sizes, multiple sets of feeding mechanisms do not need to be arranged and frequently replaced, the tooling cost can be saved, the labor intensity of workers is reduced, and meanwhile the production efficiency can be improved.

Owner:郑州豫诚模具有限公司

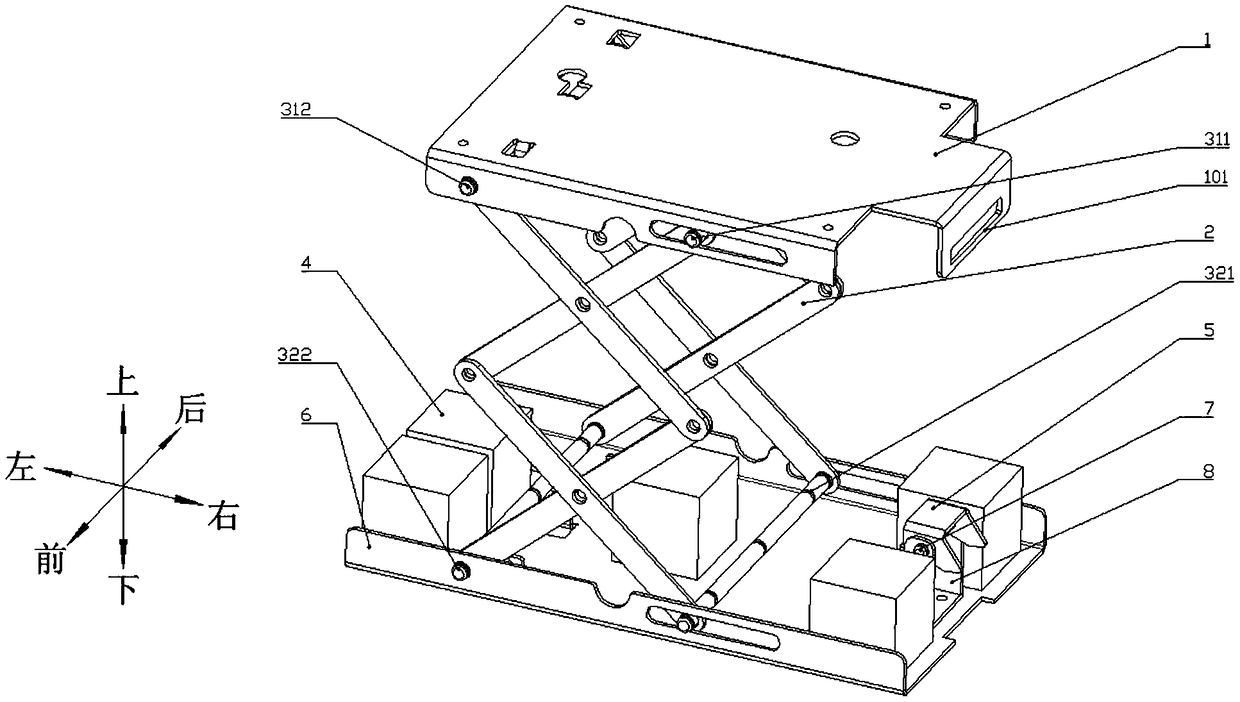

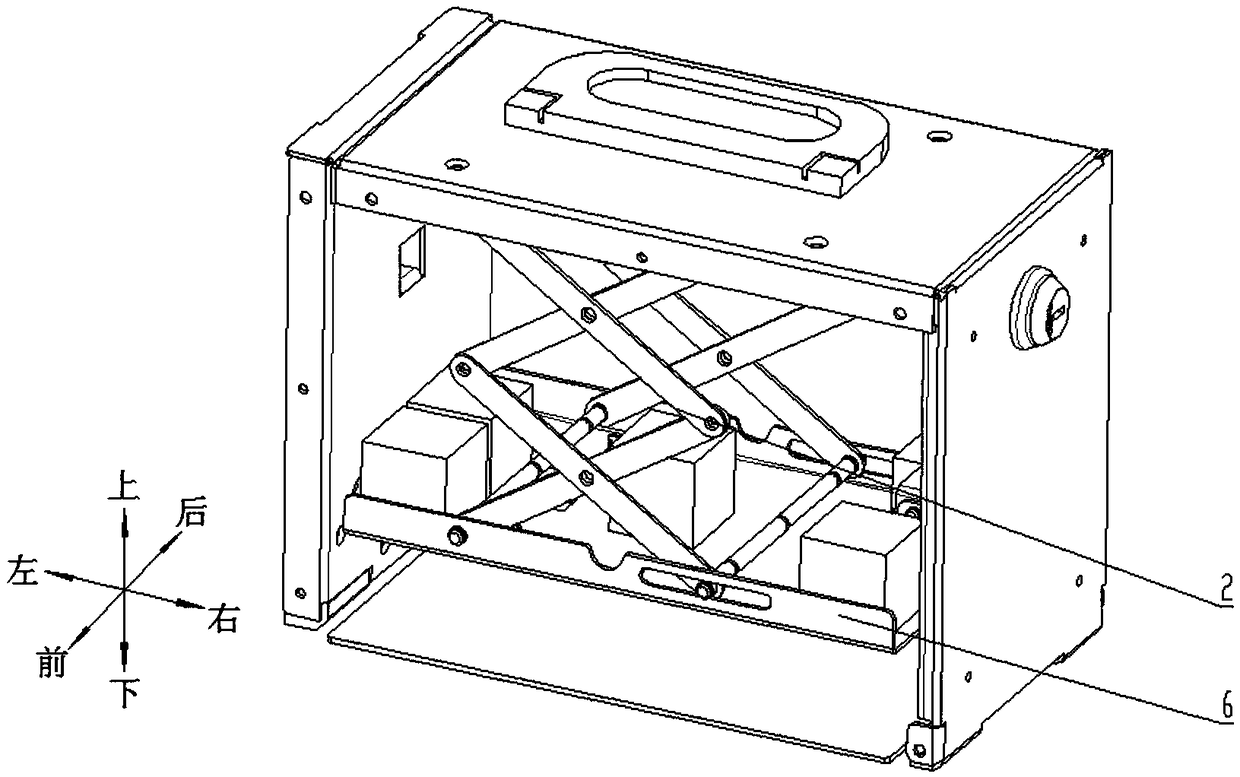

High-efficiency double-layer parking device

Owner:HEFEI SHENDIAO HOISTING MACHINERY

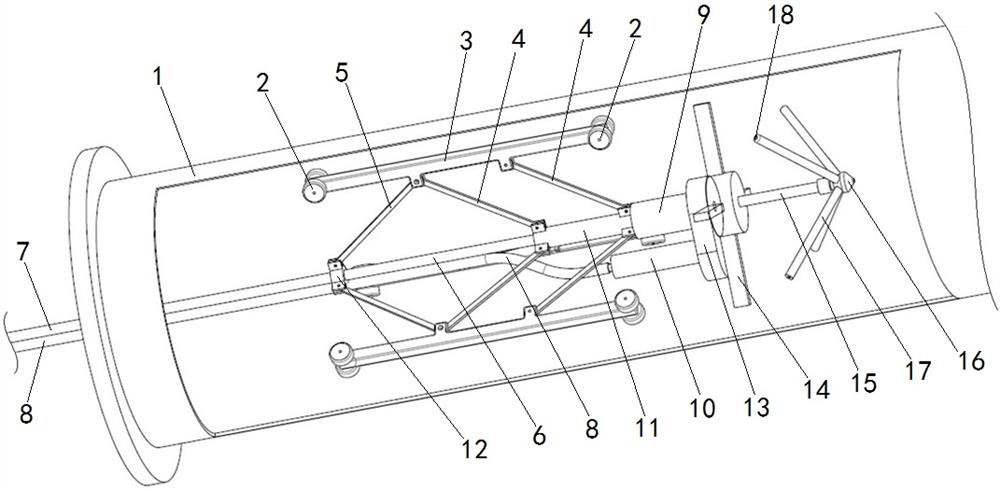

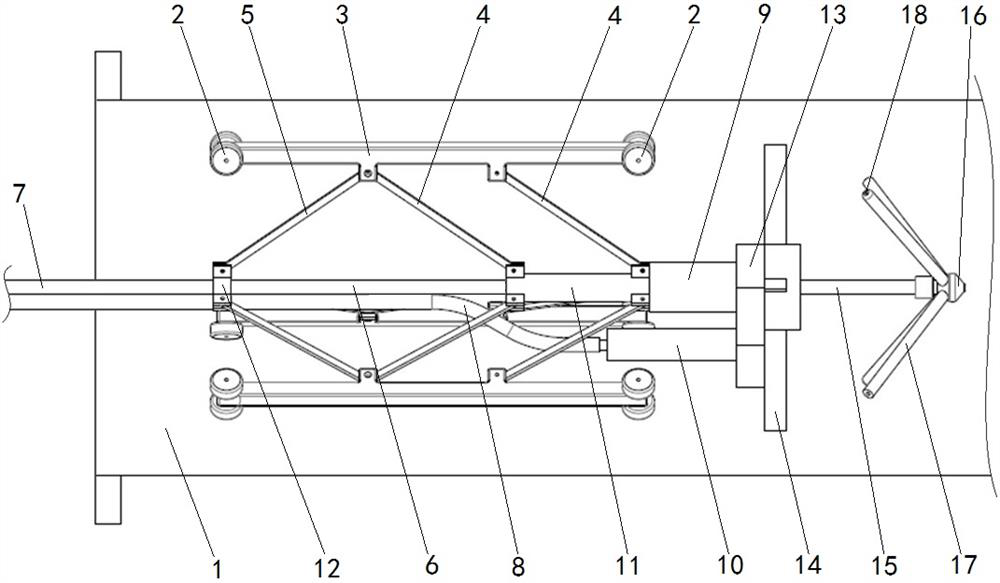

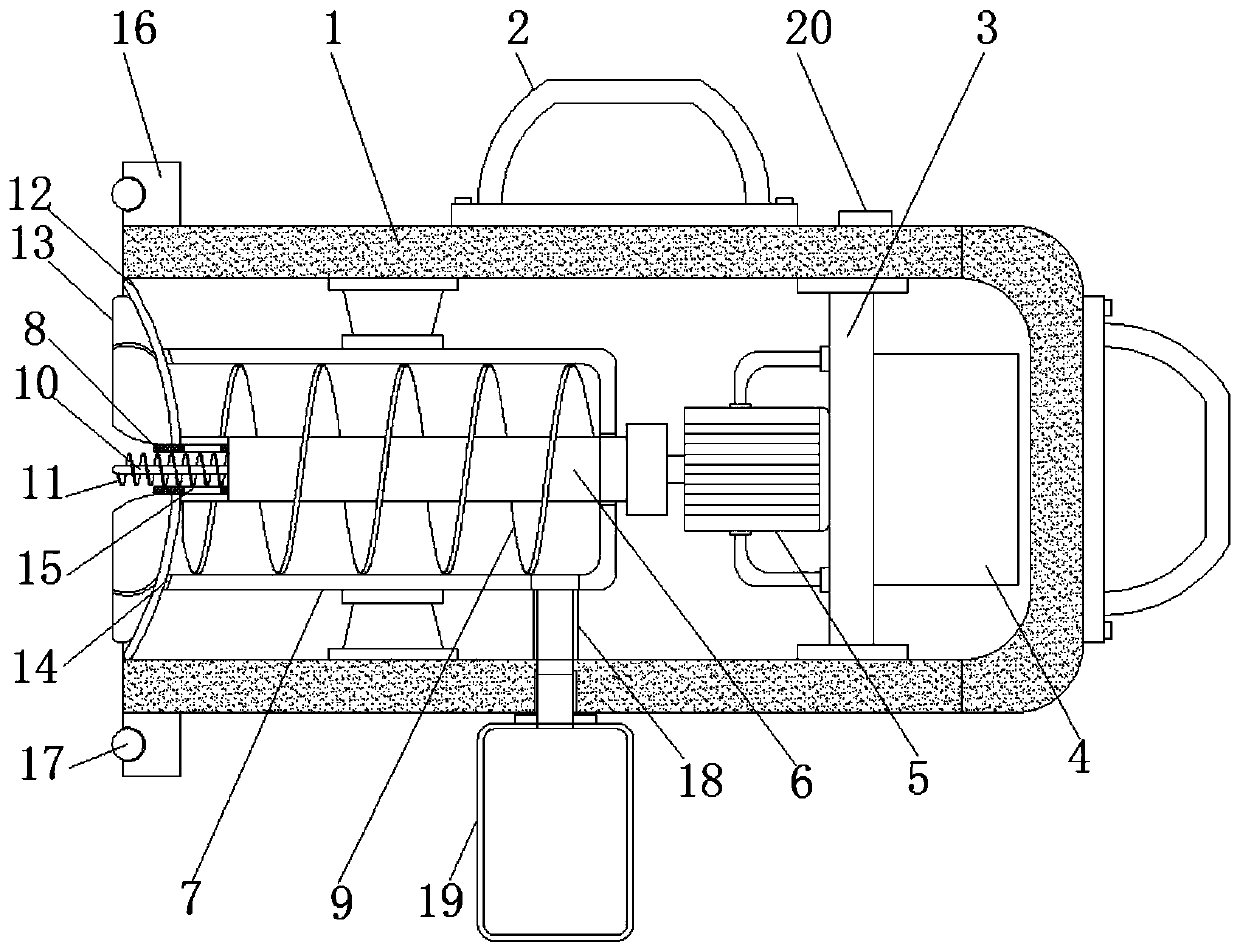

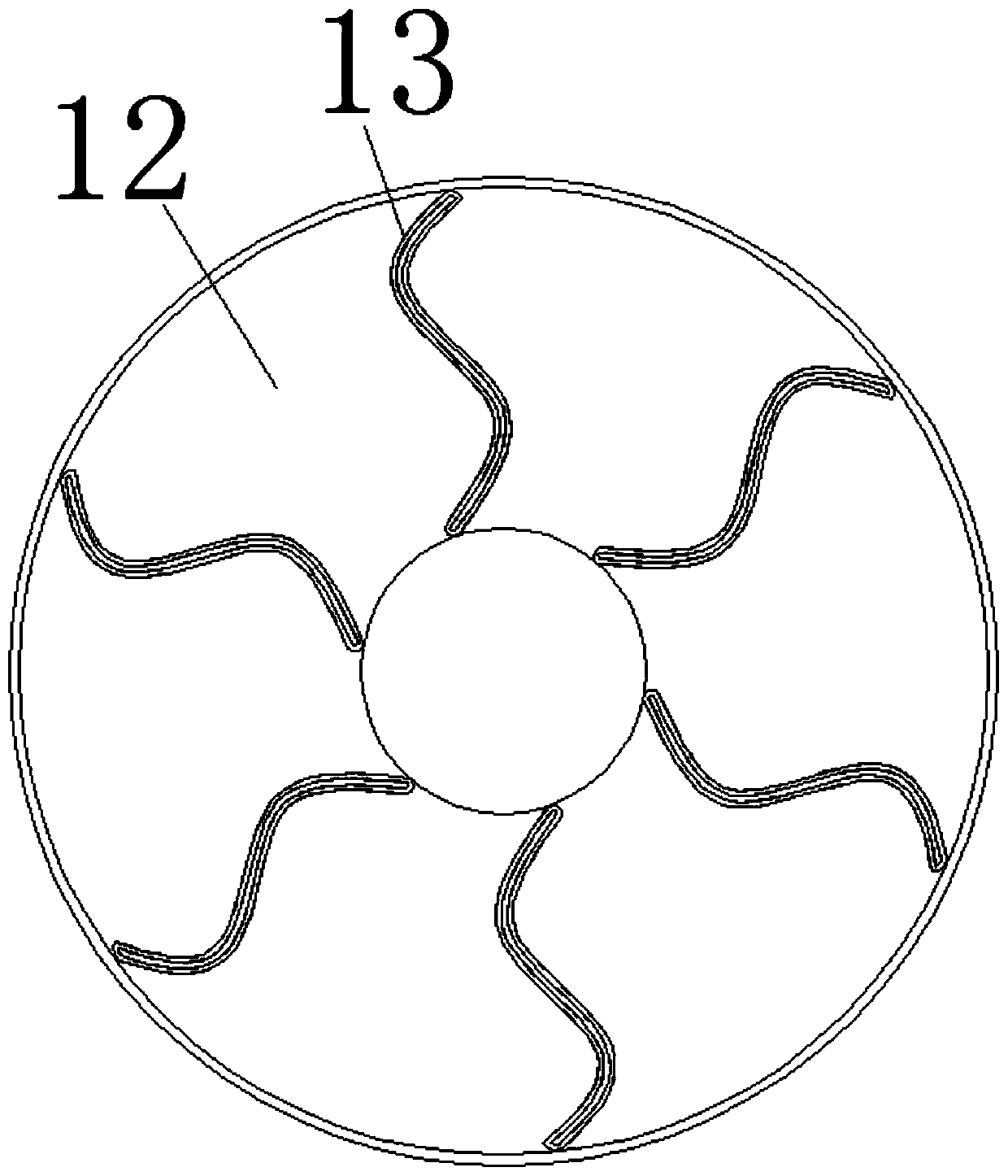

Self-walking type barrel cleaning device

PendingCN114505737ARealize by yourselfReduce moving frictionGrinding carriagesRevolution surface grinding machinesEngineeringStructural engineering

The invention provides a self-walking type barrel cleaning device which comprises a hard water pipe, a water inlet pipe, a water outlet pipe and a water outlet pipe. The supporting leg structures are fixed to the hard water pipe, and the supporting leg structures are arranged in the circumferential direction of the hard water pipe; the rolling wheels are installed on the supporting leg structures and used for making rolling contact with the inner wall of the barrel so that the cleaning device can be supported in the barrel; the water spraying pipe is gradually inclined upwards from front to back, the front end of the water spraying pipe is communicated with the front end of the hard water pipe, and a water outlet facing the inclined rear portion is formed in the rear end of the water spraying pipe, so that the water spraying pipe is subjected to forward recoil force while spraying water, and the cleaning device automatically moves forwards. A walking driving device is omitted, the washing device is driven to move automatically through recoil force borne when the water spraying pipe sprays water, external force is not needed, and the problems that in the prior art, a driving device needs to be arranged, so that the structure is complex, operation is tedious, and potential safety hazards exist are solved.

Owner:HENAN PINGGAO ELECTRIC +2

A hand-held preliminary scraping device for wall peeling paint

ActiveCN109025341BEfficient scrapingProtection against splashingBuilding repairsElectric machineCoupling

The invention relates to the technical field of wall paint treatment, and discloses a hand-held preliminary scraping device for peeling paint on the wall, which includes a cylinder body, the right end surface and the top of the cylinder body are fixedly connected with hand-held handles, and the inner top of the cylinder body is A mounting plate is fixedly connected with the bottom, the right side of the mounting plate is fixedly equipped with a battery, the left side of the mounting plate is fixedly connected with a drive motor through a fixing frame, and the output shaft of the drive motor is fixedly connected with a torque shaft through a coupling , the inner side of the cylinder is fixedly connected with the discharge pipe through the mounting frame, the torque shaft runs through the right end face of the discharge pipe at the end away from the drive motor and extends to the inner side of the discharge pipe, and the torque shaft runs through the discharge at the end far away from the drive motor right end of the tube and extends to the inside of the discharge tube. The hand-held preliminary scraping device for peeling paint on the wall prevents the scraping paint from splashing, conveys, removes and collects the scraped paint residue, and facilitates the preliminary treatment of the peeling paint on the wall.

Owner:浙江企信检测有限公司

Cornerite mounting method and device used on ceramic tile packaging machine

InactiveCN102126572BReduce moving frictionEasy to moveShock-sensitive articlesCeramic tilesPackaging machine

The invention relates to a cornerite mounting method and device used on a ceramic tile packaging machine. The device comprises a rack, an arc-shaped cornerite cabin which is arranged on the rack and is distributed in a quadrangle shape, a cornerite sucking and conveying mechanism arranged on the rack and is characterized in that the arc-shaped cornerite cabin comprises an arc-shaped cabin body provided with a horizontal open opening, more than two raised rails arranged on the bottom surface of the arc-shaped cabin body and shrapnel arranged at the two sides of the horizontal open opening; and the cornerite sucking and conveying mechanism comprises a vertical moving mechanism arranged on the rack, a horizontal moving mechanism arranged on a moving driving rod of the vertical moving mechanism, a right angle type buckling sucker seat arranged on a horizontal moving driving rod of the horizontal moving mechanism and suckers respectively arranged at the inner sides of the two sides of the right angle type sucker seat. Compared with the prior art, the cornerite mounting method and device provided by the invention have the advantages that the moving frictional force of the cornerite in the arc-shaped cornerite cabin is small, the cornerite moves smoothly in the arc-shaped cornerite cabin and the cornerite can be smoothly taken out from the arc-shaped cornerite cabin one by one.

Owner:佛山市金皇化工陶瓷有限公司

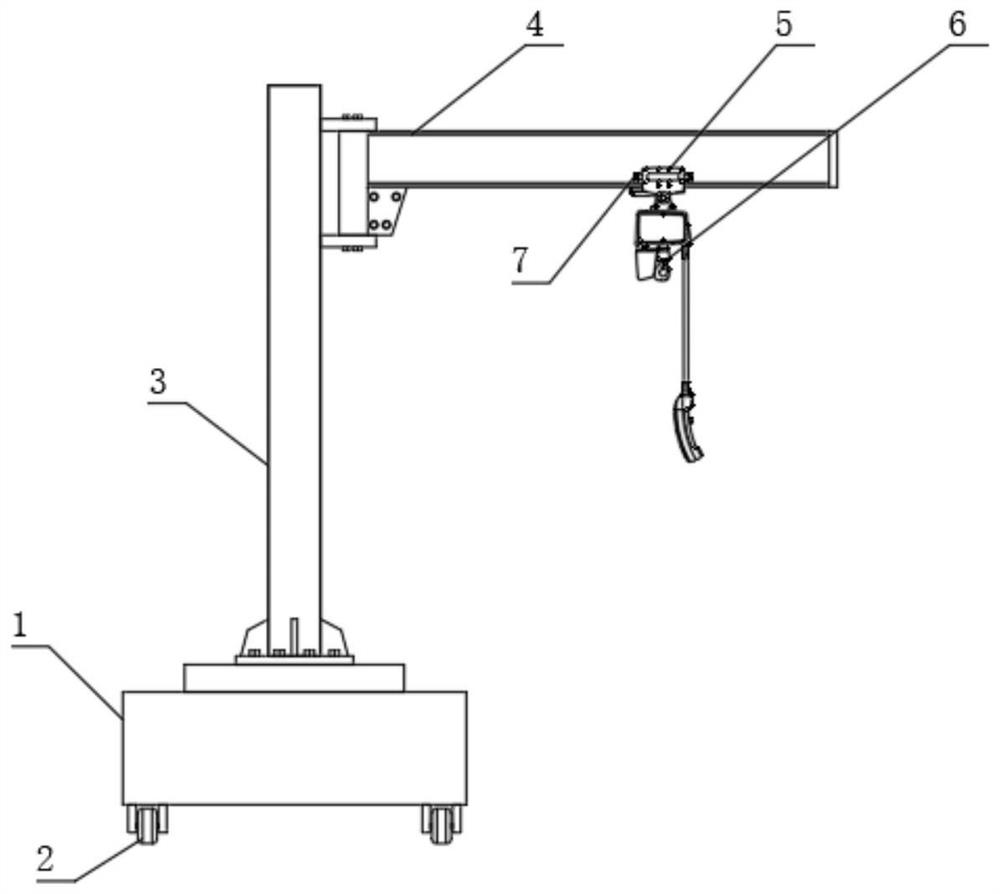

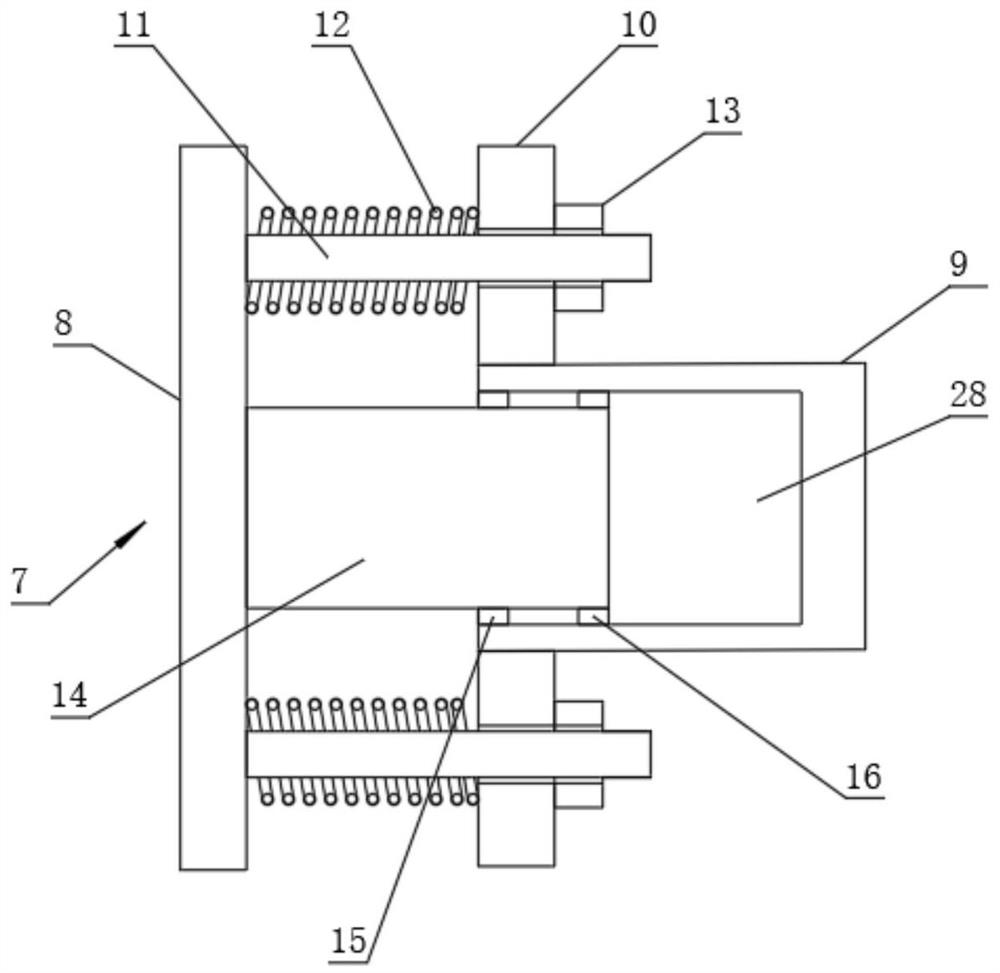

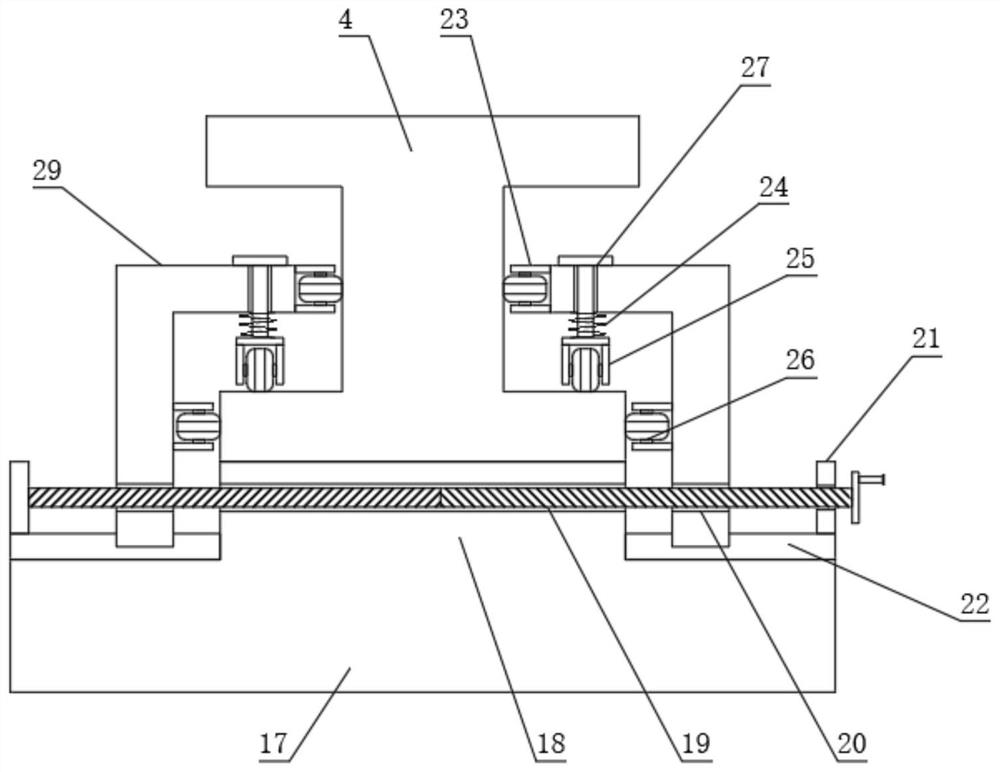

Semi-suspension type single-beam crane

Owner:常州化工设备制造安装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com