Production device for pressing, curing and linking neodymium-iron-boron magnet containing heavy rare earth

A production device, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems affecting the quality of materials, uneven force on the die head, and inability to clean the die holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

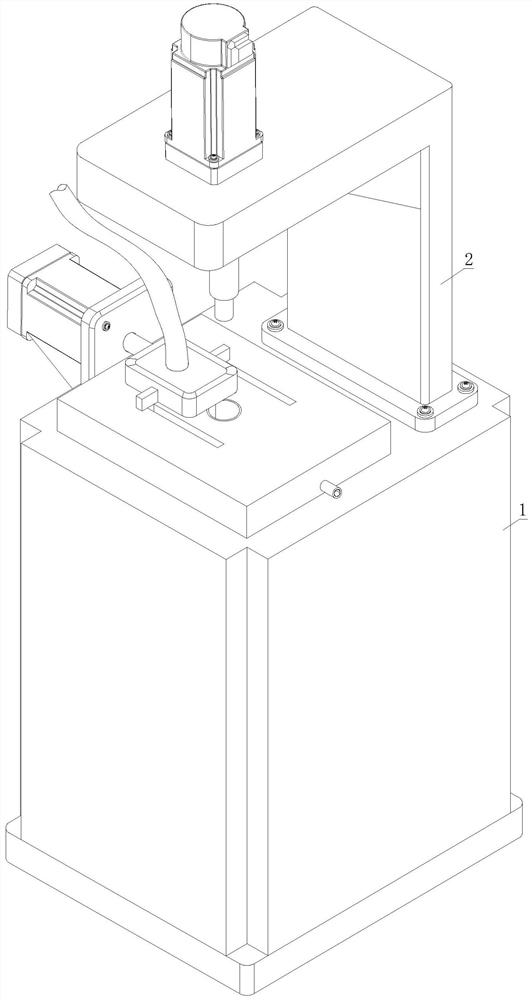

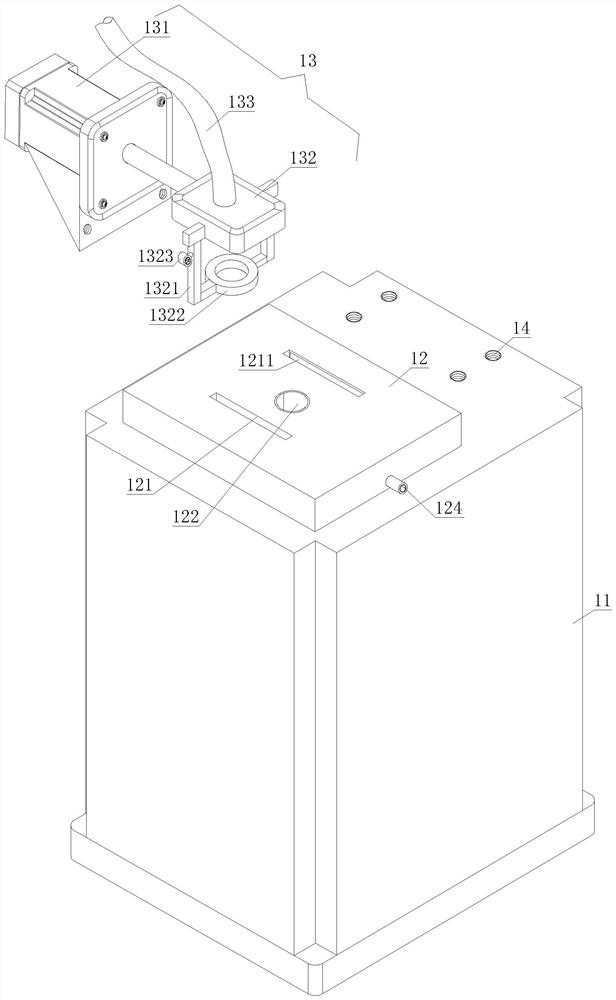

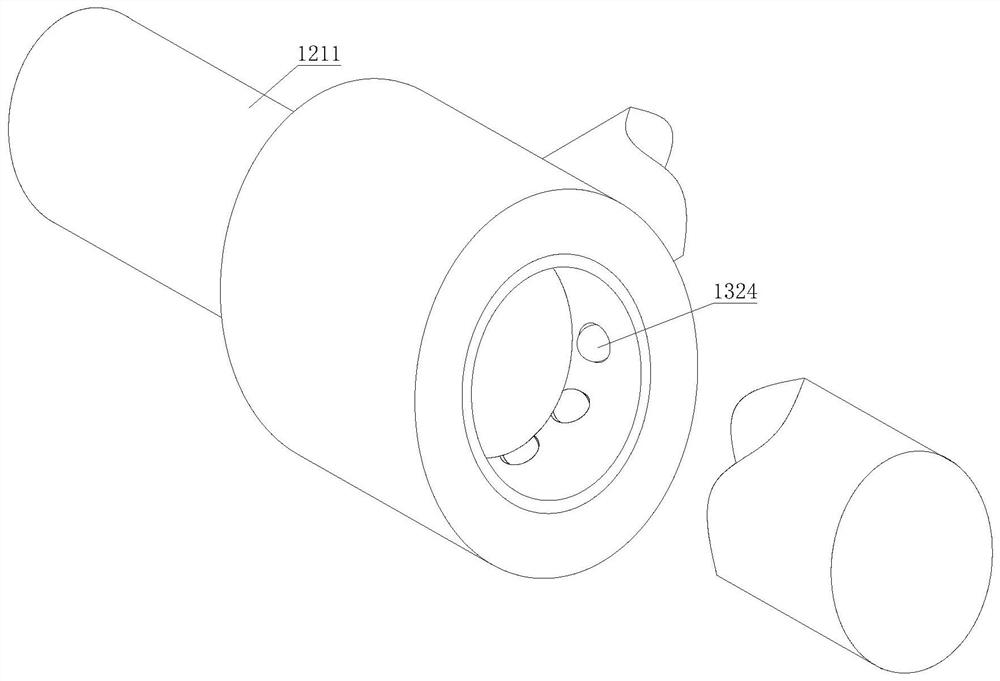

[0034] see figure 1 with 10, a production device for pressing and solidifying NdFeB magnets containing heavy rare earths, comprising a pressing table 1 and a pressing device 2, the pressing device 2 is installed on one side of the upper end of the pressing table 1, and the pressing table 1 includes a supporting table 11, Bottom membrane plate 12, feeding mechanism 13 and threaded hole 14, bottom membrane plate 12 is installed on the upper end of support platform 11, and one end side of bottom membrane plate 12 is equipped with feeding mechanism 13, and the upper end side of support platform 11 is provided with four A threaded hole 14, the inner cavity of the threaded hole 14 is threadedly connected with a press-down device 2; The upper end is equipped with a right angle frame 22, the upper end of the right angle frame 22 is equipped with a first hydraulic cylinder 23, the lower end of the first hydraulic cylinder 23 is equipped with a telescopic rod 24, and the lower end of t...

Embodiment 2

[0038] see figure 1 with 10 , a production device for pressing and solidifying NdFeB magnets containing heavy rare earths, comprising a pressing table 1 and a pressing device 2, the pressing device 2 is installed on one side of the upper end of the pressing table 1, and the pressing table 1 includes a supporting table 11, Bottom membrane plate 12, feeding mechanism 13 and threaded hole 14, bottom membrane plate 12 is installed on the upper end of support platform 11, and one end side of bottom membrane plate 12 is equipped with feeding mechanism 13, and the upper end side of support platform 11 is provided with four A threaded hole 14, the inner cavity of the threaded hole 14 is threadedly connected with a press-down device 2; The upper end is equipped with a right angle frame 22, the upper end of the right angle frame 22 is equipped with a first hydraulic cylinder 23, the lower end of the first hydraulic cylinder 23 is equipped with a telescopic rod 24, and the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com