Guide rail lubricating device of turning and milling composite machine tool

A compound machine tool and lubrication device technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as reducing the service life of machine tools, crawling of machine tools, and affecting the processing accuracy of machine tools, and achieves increased cleaning. effect, ensure cleanliness, reduce the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

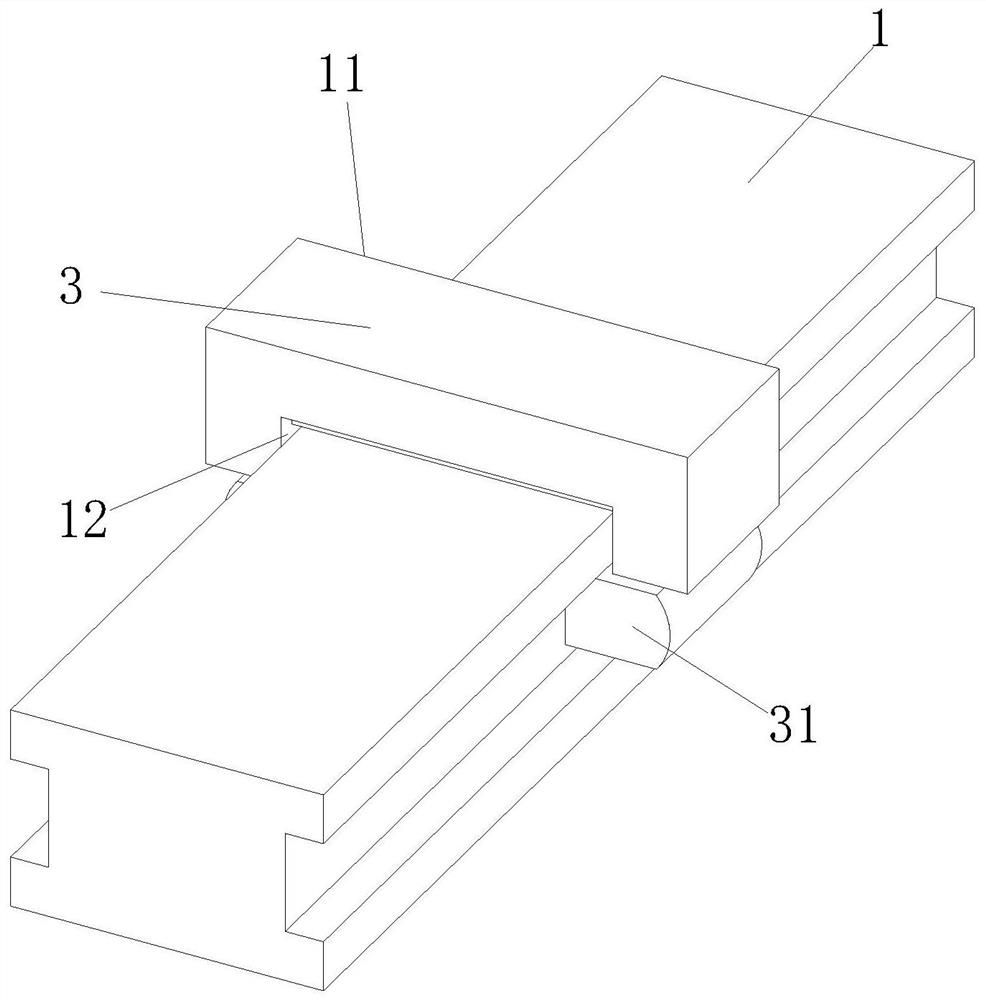

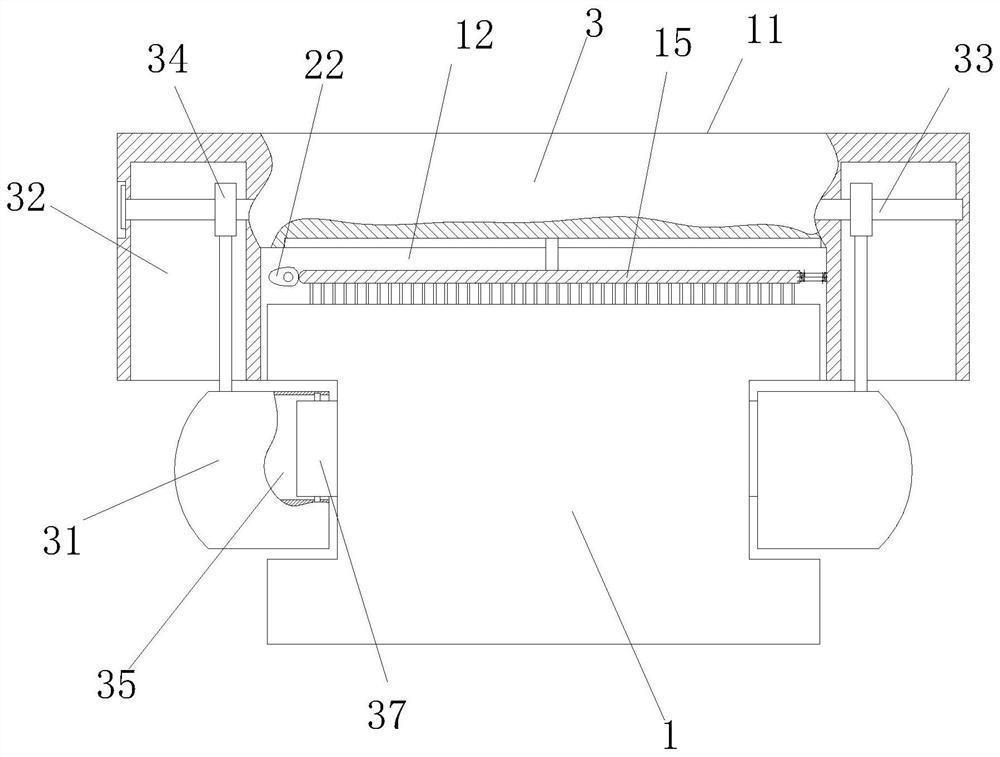

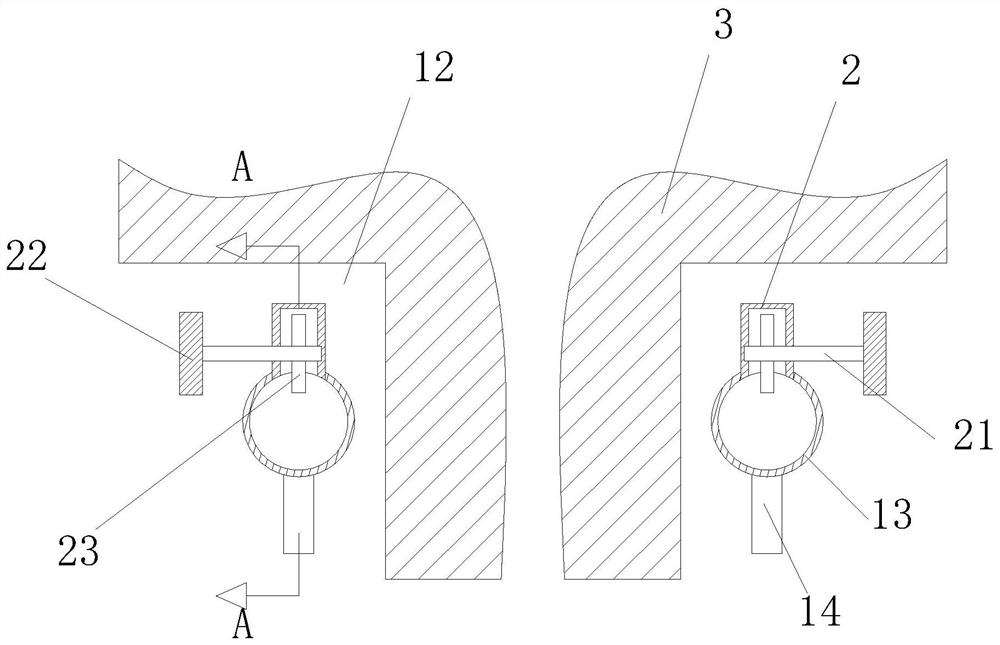

[0032] Such as Figure 1 to Figure 5 As shown, a kind of lubricating device for turning and milling compound machine tool according to the present invention includes an I-shaped slide rail 1 and a slider 11; the slider 11 is slidably connected on the I-shaped slide rail 1; the slider There are first grooves 12 on the front and rear sides of 11, and oil pipes 13 are arranged on the side walls on both sides of the first groove 12; a group of nozzles 14 are arranged at the bottom of the oil pipes 13; The sliding column is connected with a cleaning plate 15, and the bottom of the cleaning plate 15 is fixedly connected with a group of cleaning brushes; the cleaning plate 15 is located on the side where the oil pipe 13 is away from the bottom of the first groove 12; in the prior art, the When the sliding component moves on the guide rail by sliding, oil must be dripped on the guide rail after a period of time. If the oil drip is not timely, the machine tool will crawl, which will se...

Embodiment 2

[0039] see Figure 6-Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, a baffle 6 is fixed at the position of the groove bottom of the first groove 12 relative to the cleaning wheel 45, and the baffle 6 and the cleaning wheel 45 The upper cleaning brushes are in contact with each other; during work, when the cleaning wheel 45 rotates, the cleaning brushes on the cleaning wheels 45 and the baffle plate 6 collide with each other, and the collision of the cleaning brushes can realize self-cleaning of the cleaning brushes, ensuring that the cleaning brushes The cleanliness of the brush itself reduces the adhesion of impurities in the cleaning brush and increases the cleaning effect of the cleaning brush.

[0040] A first magnetic strip 61 is fixedly attached to the side wall of the baffle plate 6 close to the cleaning wheel 45; a group of arc grooves 62 are provided on the side wall of the annular air chamber 54 close to the center line of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com