Floor seam beautifying removing device

A technology of removing device and beautiful seam, applied in the direction of building maintenance, construction, building structure, etc., can solve the problems of slow construction speed, poor construction quality, need manual operation, etc., to achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

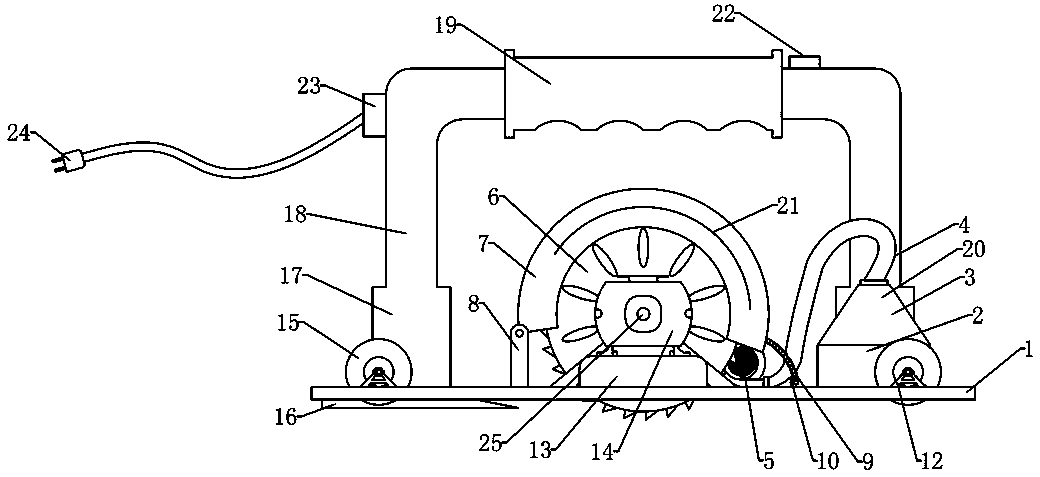

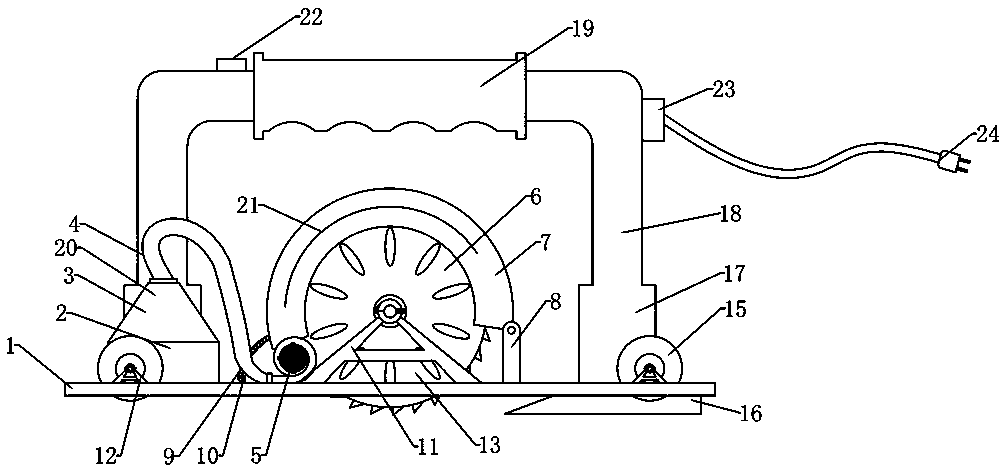

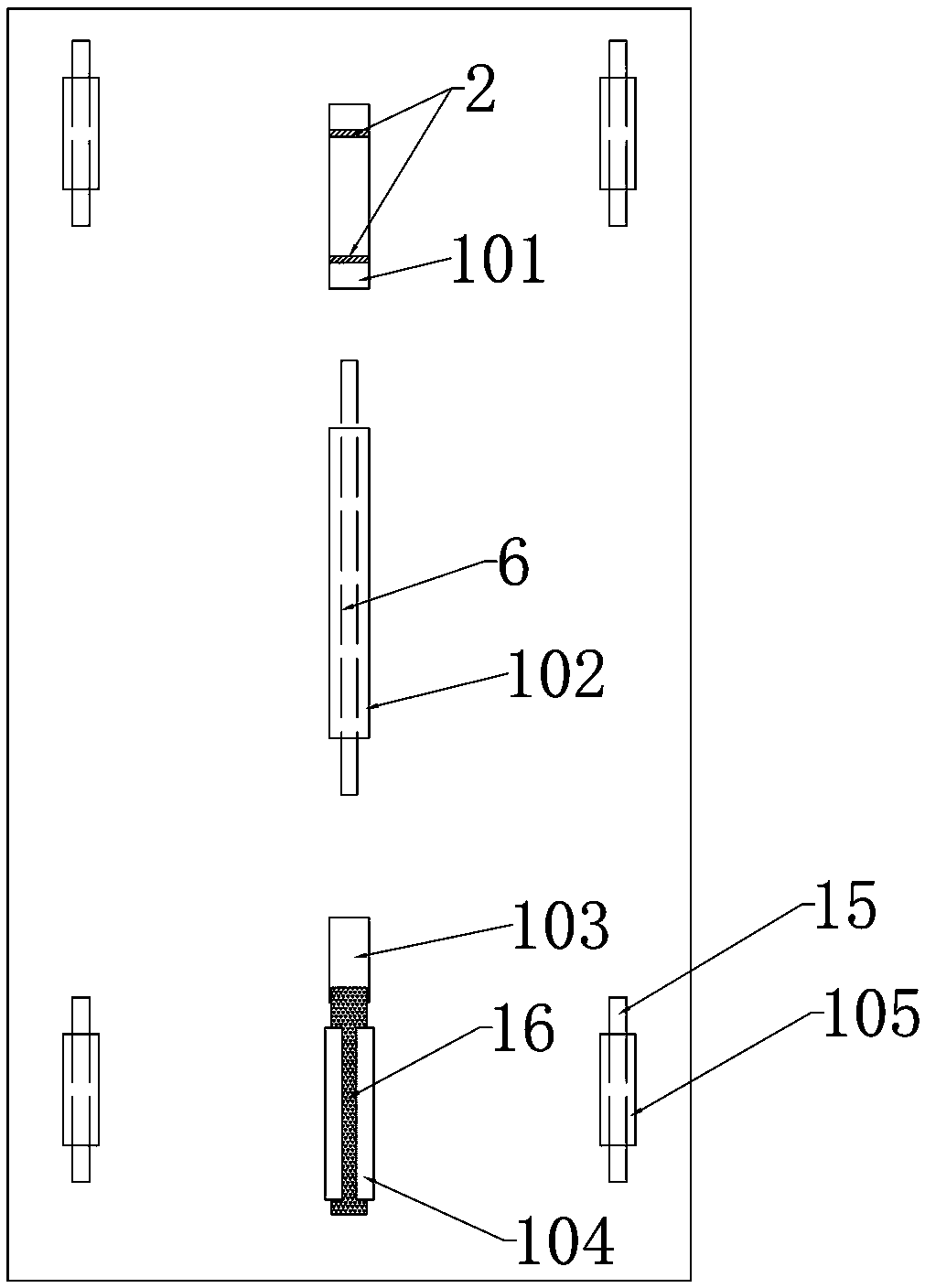

[0023] Embodiment 1: a kind of clearing device, is used for floor gap clearing operation, as Figure 1-3 As shown, the cutting mechanism 21 in the device is located in the middle of the upper side of the device carrier 1, the heating mechanism 20 is located in the front end of the upper side of the device carrier 1 to ensure that the floor gap beautifying agent is heated before cutting, and the guide rod 16 is located on the device carrier 1. The rear end of the lower side provides a precise moving direction for the device. The device carrier 1 is provided with an arc clip 104 on the lower side of the guide rod 16. The arc clip 104 is made of stainless steel, and the inner diameter of the arc clip 104 is the guide rod. 16, it is tightly welded and fixed with the top of the arc clip 104 and the bottom of the device carrier 1.

[0024] The device carrier 1 is a rectangular steel plate, and the four corners of the device carrier 1 are respectively equipped with walking aid wheels...

Embodiment 2

[0026] Embodiment 2: The content of this embodiment is the same as that of Embodiment 1 and will not be repeated. The difference from Embodiment 1 is that the cutting mechanism 21 includes a cutting wheel 6, a driving motor 14 and a transmission mechanism 25, which are located on the lower side of the cutting mechanism 21. A cutting hole 102 is arranged on the carrier plate 1 of the device, and shaft seats 11 are fixed on both sides of the cutting hole 102. The rotating shaft of the cutting wheel 6 is installed on the two shaft seats 11 through bearings, and the rotating shaft of the cutting wheel 6 communicates with the driving motor through the transmission mechanism 25 14 transmission connections, the transmission mechanism 25 is a rotating shaft transmission, the cutting wheel 6 right side is provided with a driving motor 14, the bottom of the driving motor 14 is provided with a pedestal 13, the bottom of the pedestal and the upper side of the device carrier plate 1 are tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com