Glass melting furnace system and electrode brick supporting device thereof

A technology for supporting devices and electrodes, applied in glass furnace equipment, glass manufacturing equipment, furnace types, etc., can solve the problems of damage to electrode bricks, large propulsion resistance, affecting the safe and normal operation of melting furnaces, etc., to avoid damage to electrode bricks, reduce The effect of propulsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The glass melting furnace system and its electrode brick supporting device will be further described below in conjunction with the accompanying drawings and specific embodiments.

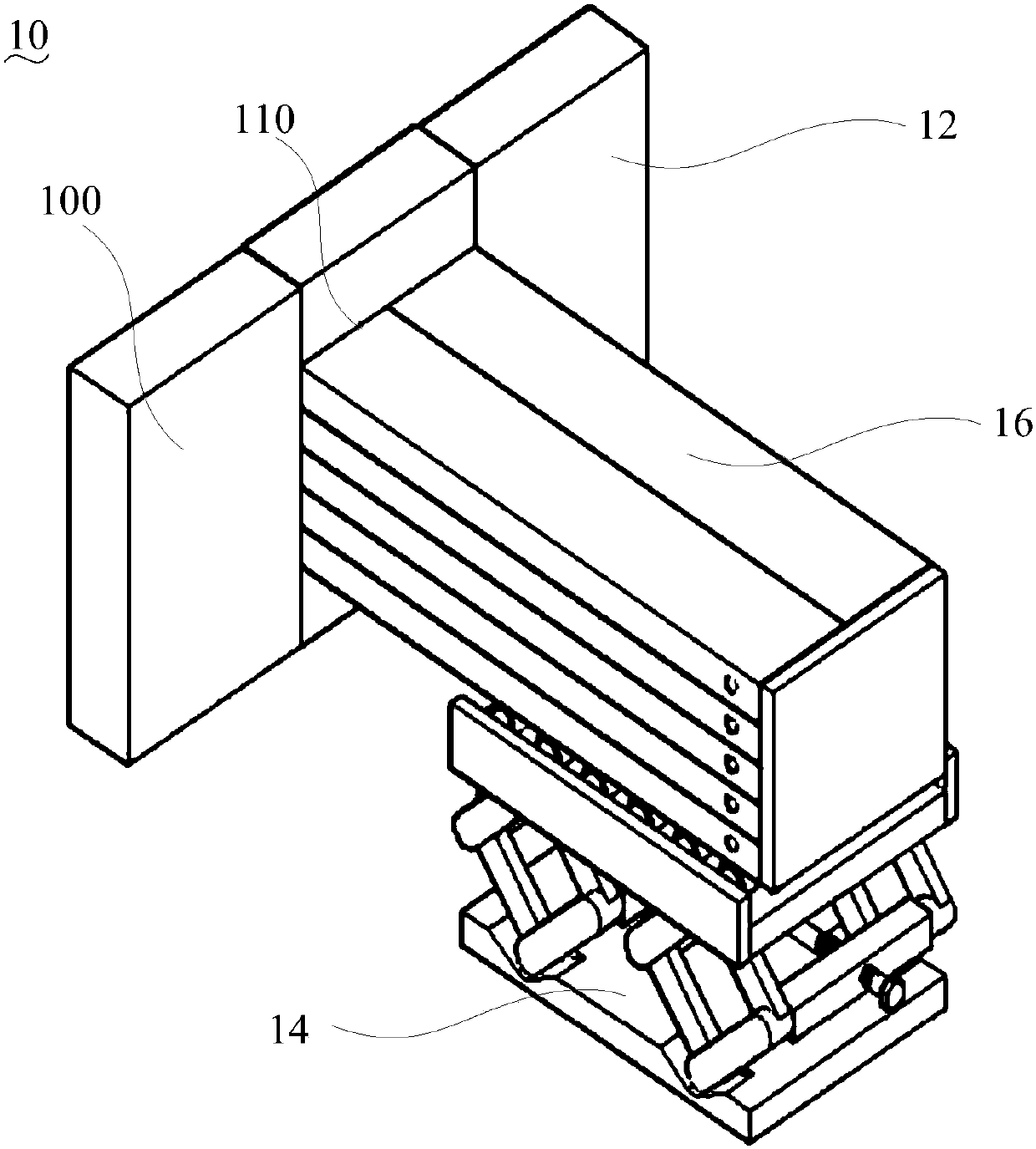

[0021] Such as figure 1 and figure 2 As shown, a glass melting furnace system 10 of an embodiment includes a melting furnace pool 12 , an electrode brick supporting device 14 and an electrode brick 16 .

[0022] In the process of producing glass, after the glass raw material enters the melting furnace pool 12, the glass raw material is heated in the melting furnace pool 12, so that the glass raw material is melted to form glass liquid.

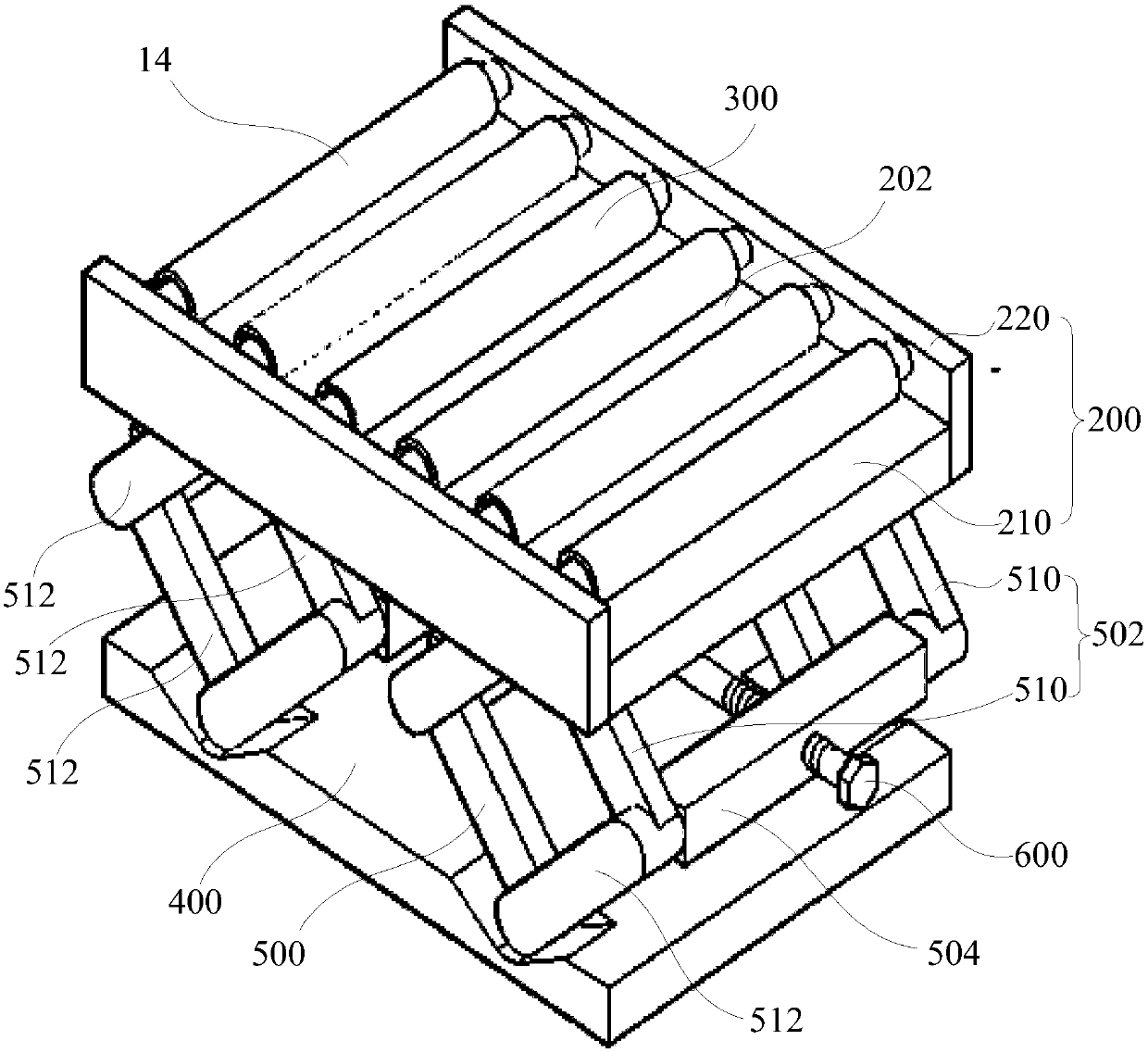

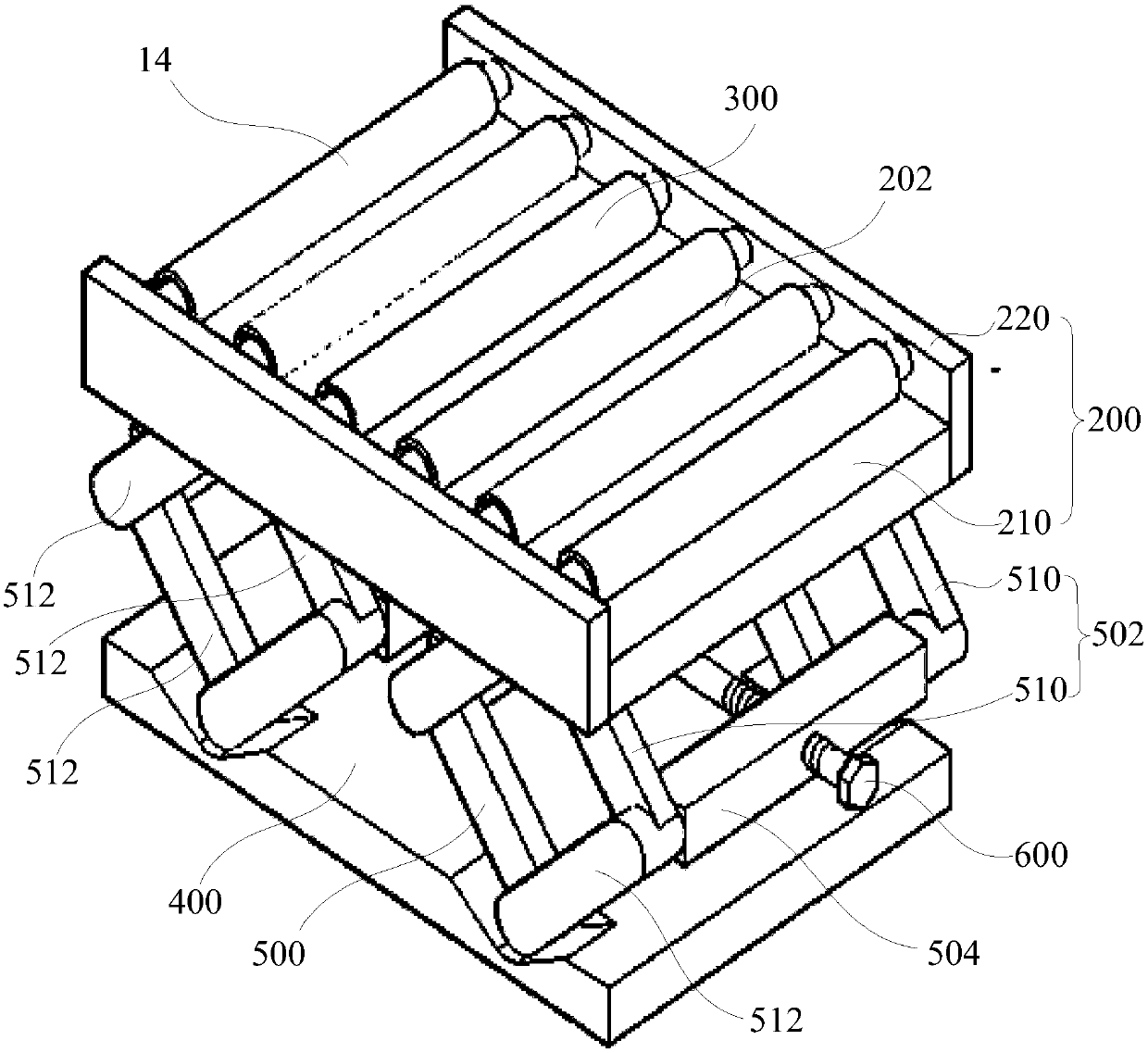

[0023] The furnace pool 12 includes pool wall bricks 100 , and the pool wall bricks 100 are provided with installation through holes 110 for installing electrode bricks 16 . Specifically, there are multiple pool wall bricks 100 , and a plurality of pool wall bricks 100 enclose to form a furnace pool 12 . The electrode brick supporting device 14 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com