Cornerite mounting method and device used on ceramic tile packaging machine

A packaging machine and angle wrapping technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of large slits, failures, and wrapping corners that cannot be smoothly out of the warehouse, etc., to achieve small moving friction and smooth movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

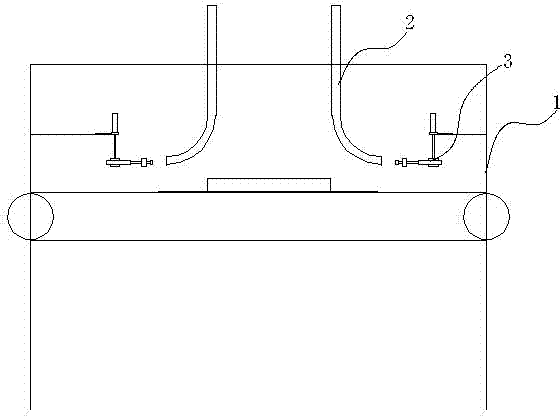

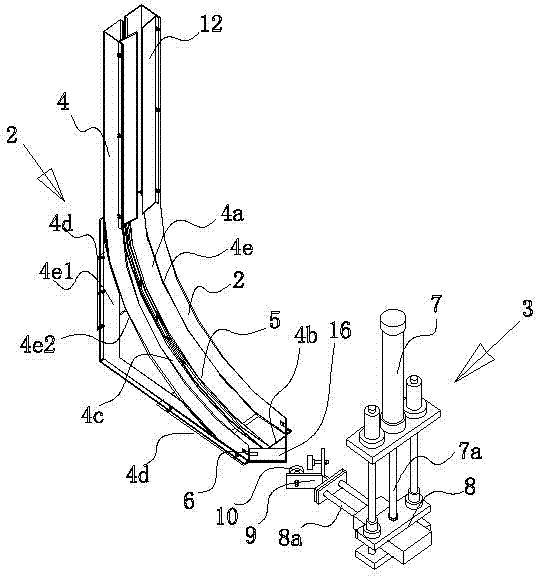

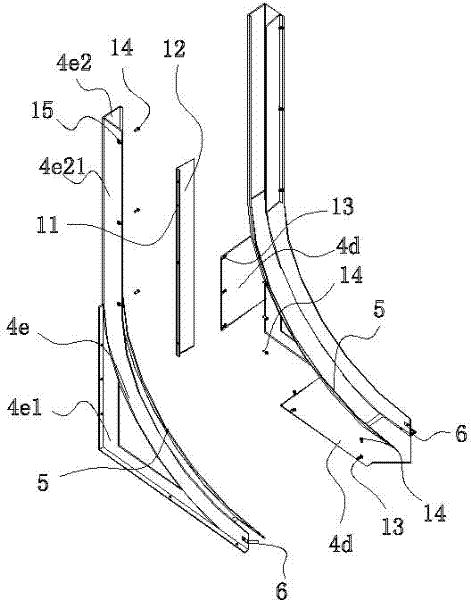

[0012] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0013] The method of wrapping the corners of the ceramic tile packaging machine of the present invention is realized in this way. A raised track is set on the bottom surface of the arc-shaped corner wrapping bin, and shrapnels are arranged on both sides of the outlet of the arc-shaped corner wrapping bin to block the exit of the arc-shaped corner wrapping bin. For the wrap angle at the outlet of the arc wrap angle warehouse, use two suction cups perpendicular to the two outer sides of the wrap angle at the outlet of the arc wrap angle warehouse to suck the two outer sides of the wrap angle at the outlet of the arc wrap angle warehouse, and move outward through the horizontal movement mechanism Move the suction cup so as to overcome the blockage of the shrapnel and remove the wrapping corner held by the suction cup, then move the wrapping corner to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com