Automatic bonding cutting machine of insulation board

An automatic bonding and cutting machine technology, applied in the direction of connecting components, mechanical equipment, material gluing, etc., can solve the problems of material waste, low construction efficiency and high construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

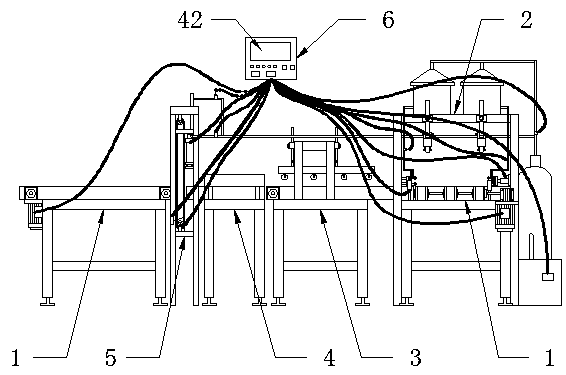

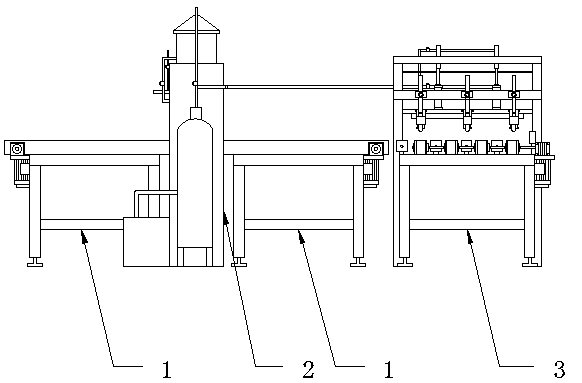

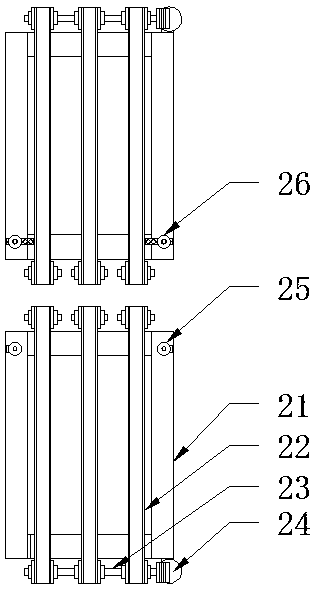

[0029] as attached Figure 1-10As shown, a thermal insulation board automatic bonding and cutting machine includes a conveying device 1, a glue spraying device 2, a transfer device 3, a bonding device 4, a cutting device 5, and a control computer 6. The two sides of the glue spraying device 2 A conveying device 1 is provided respectively, a transfer device 3 is provided on one side of the transfer device 1, a bonding device 4 is provided on one side of the transfer device 3, a cutting device 5 is provided on one side of the bonding device 4, One side of the cutting device 5 is provided with a delivery device 1, and the glue spraying device 2 includes a glue spraying bracket 7, an air compressor 8, an air storage tank 9, a glue storage tank 10, a spray gun 11, a spray gun support 12, Electric telescopic rod 13, pulley 14, pulley mount 15, one side of described glue spraying support 7 is provided with air compressor 8, air storage tank 9, and the top two ends of described sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com