Lifting construction method and construction device of large formwork for shear wall tubular concrete structure

A technology of concrete structure and construction method, which is applied in the direction of formwork/formwork/work frame, house structure support, house structure support, etc., which can solve the problems of large amount of labor, etc., and achieve easy disassembly and assembly, strengthened connection strength, and convenient fixation The effect of the scroll wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

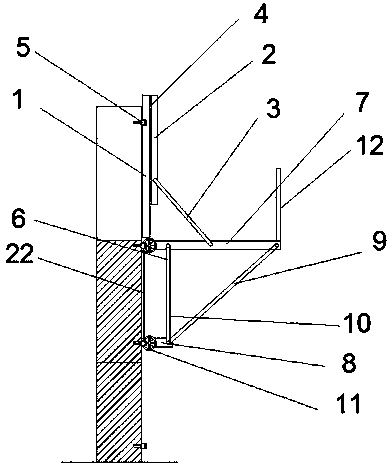

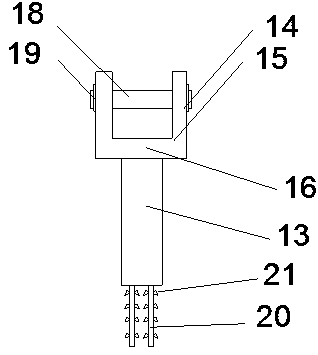

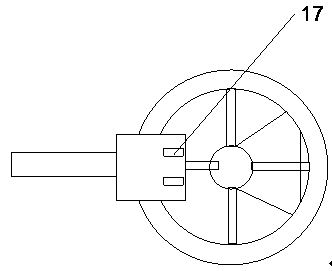

[0028] see figure 1 , figure 2 and image 3 , a construction device, including a movable triangular platform 6 and an embedded part 5 for fixing the movable triangular platform. The movable triangular platform 6 includes a horizontal support steel plate 7 , a reinforcing diagonal bar 9 and a vertical support bar 10 connected together in a right triangle. Strengthen the connection of oblique support and vertical straight bar to be provided with supporting base plate 8, be provided with roller 11 on supporting base plate and say supporting steel plate. A guardrail 12 is installed on the horizontal support steel plate; one end of the support base plate is equipped with a roller, one end of the reinforced diagonal bar is fixedly connected to one end of the horizontal support steel plate with a guard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com