Patents

Literature

31results about How to "Realize continuous automatic processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

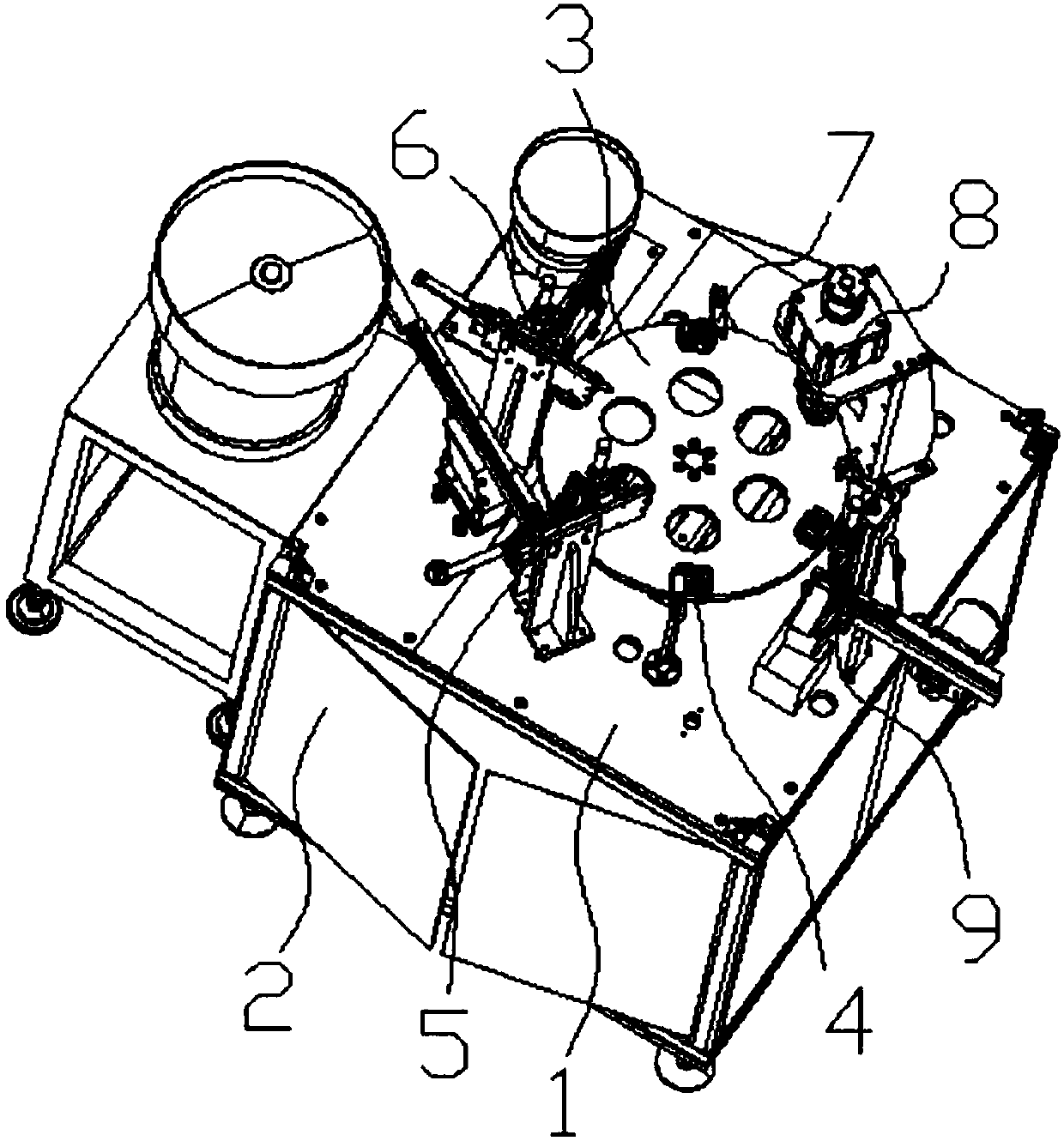

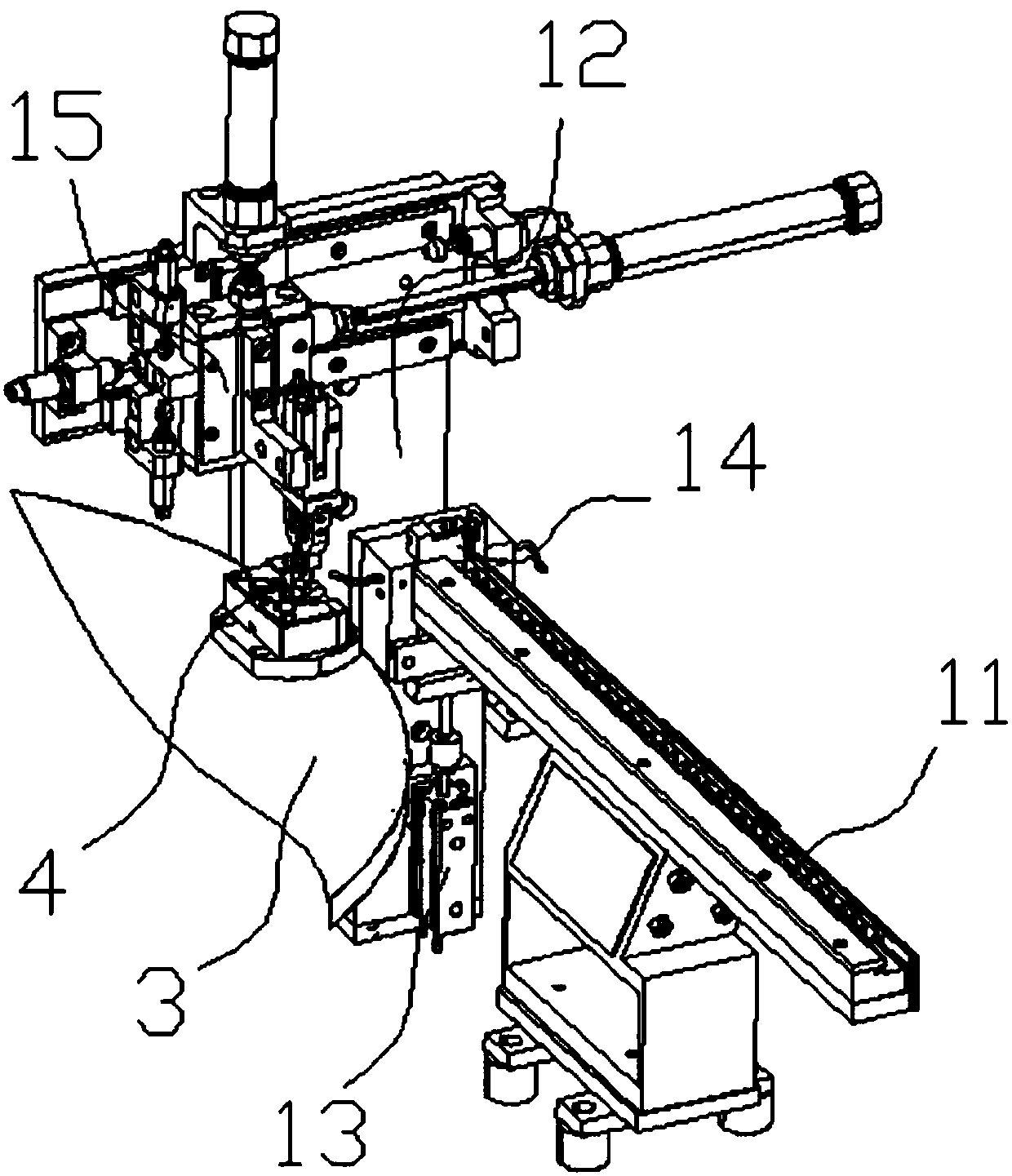

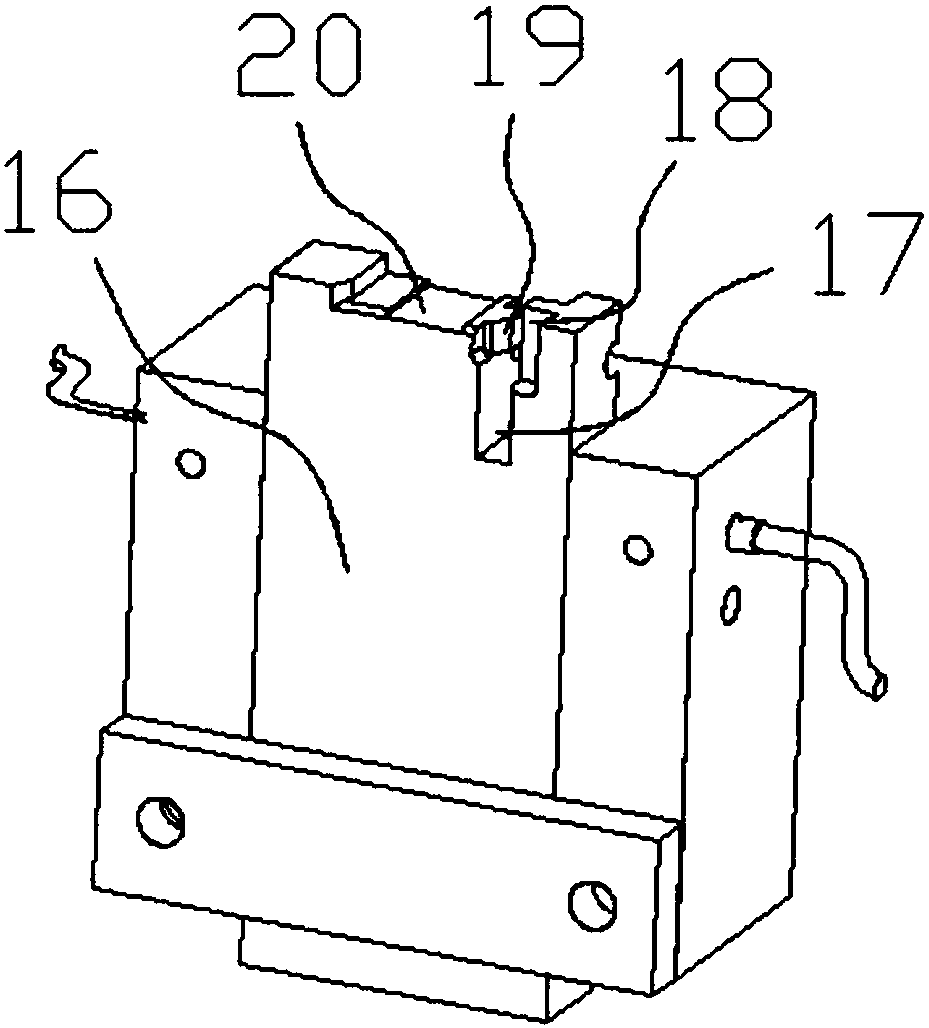

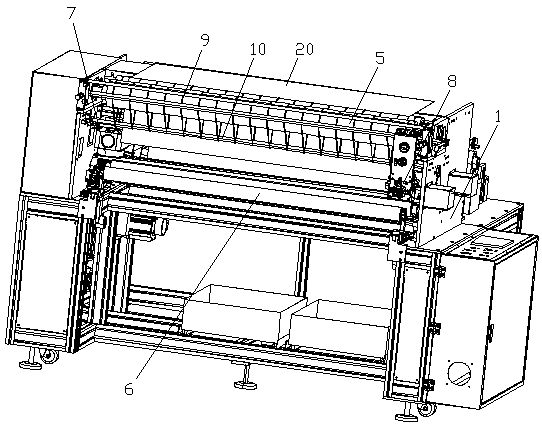

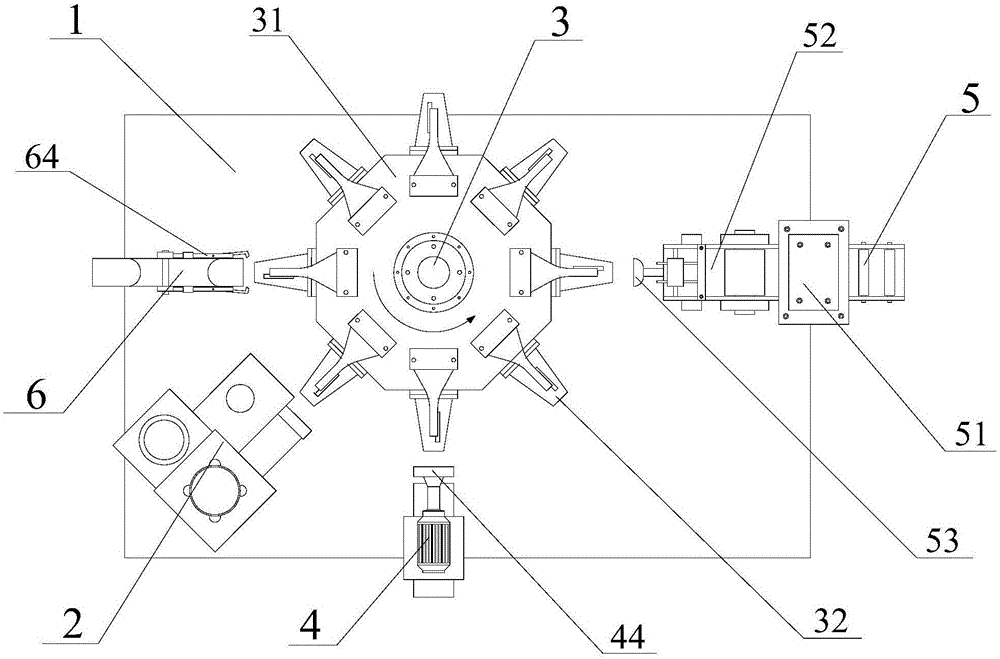

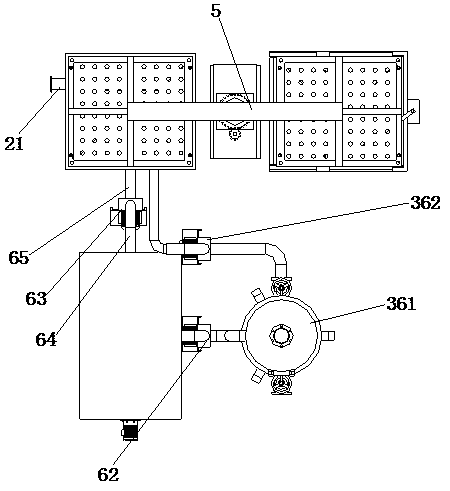

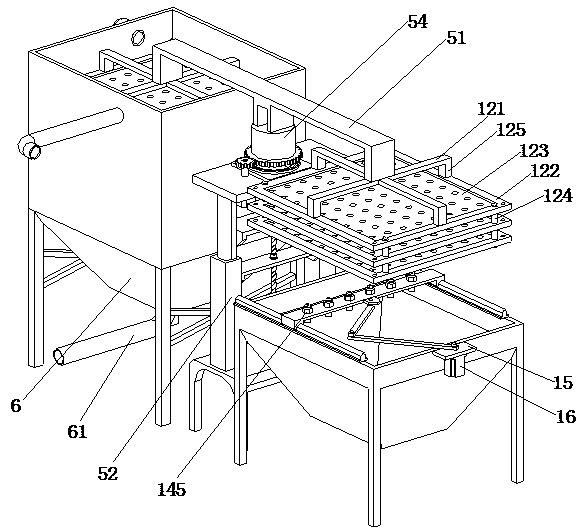

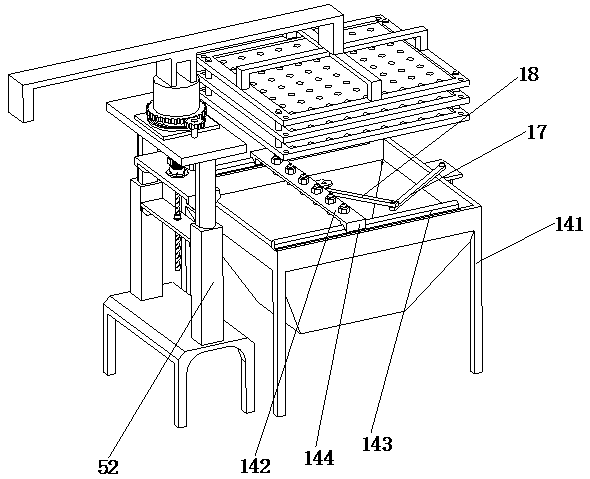

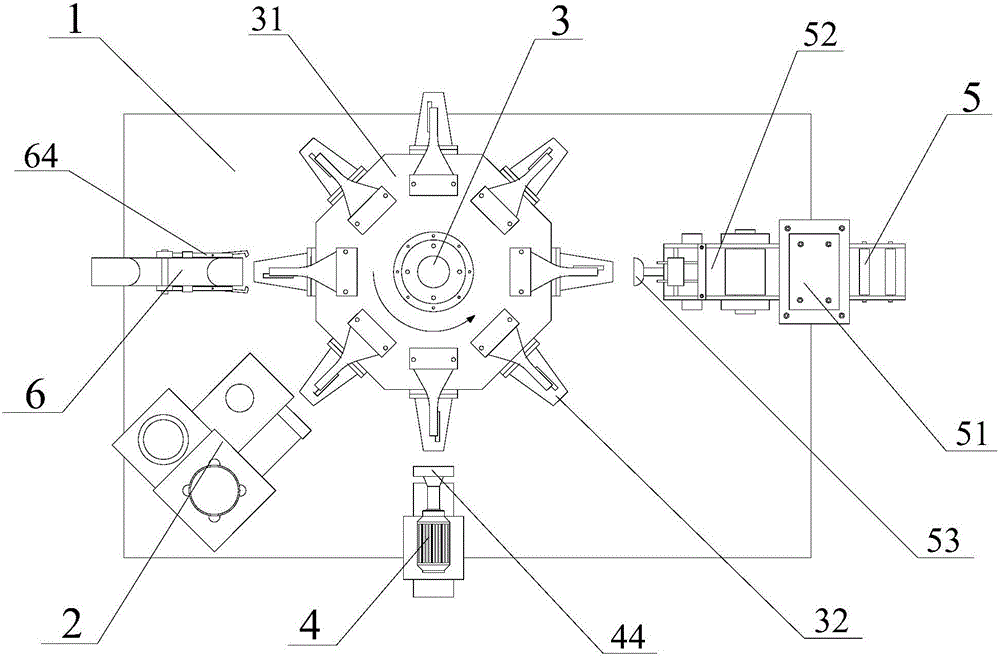

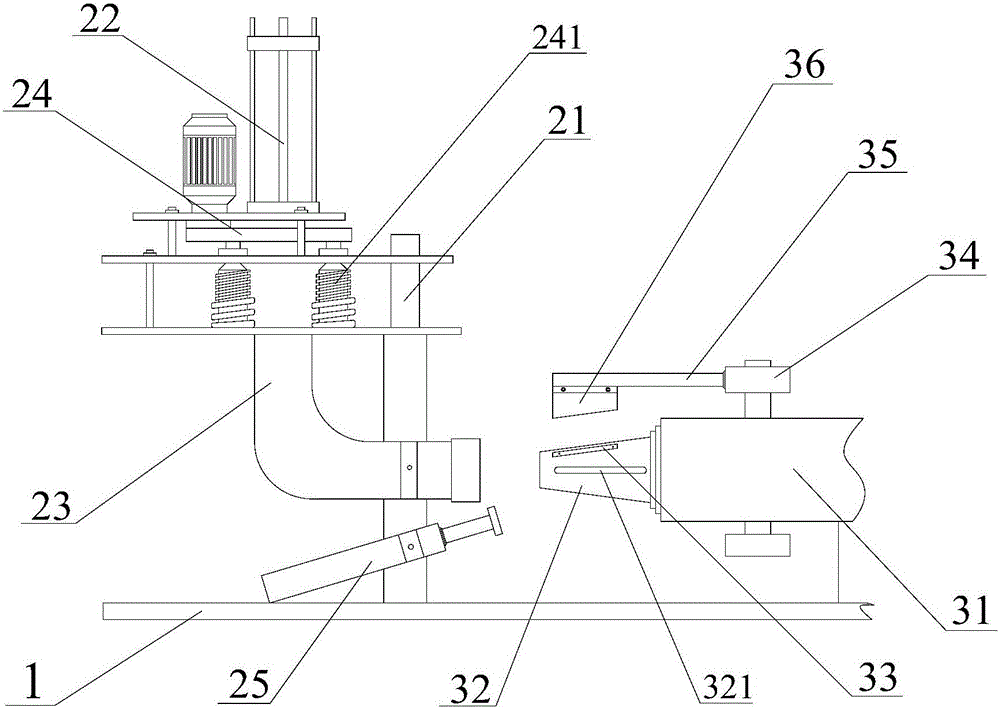

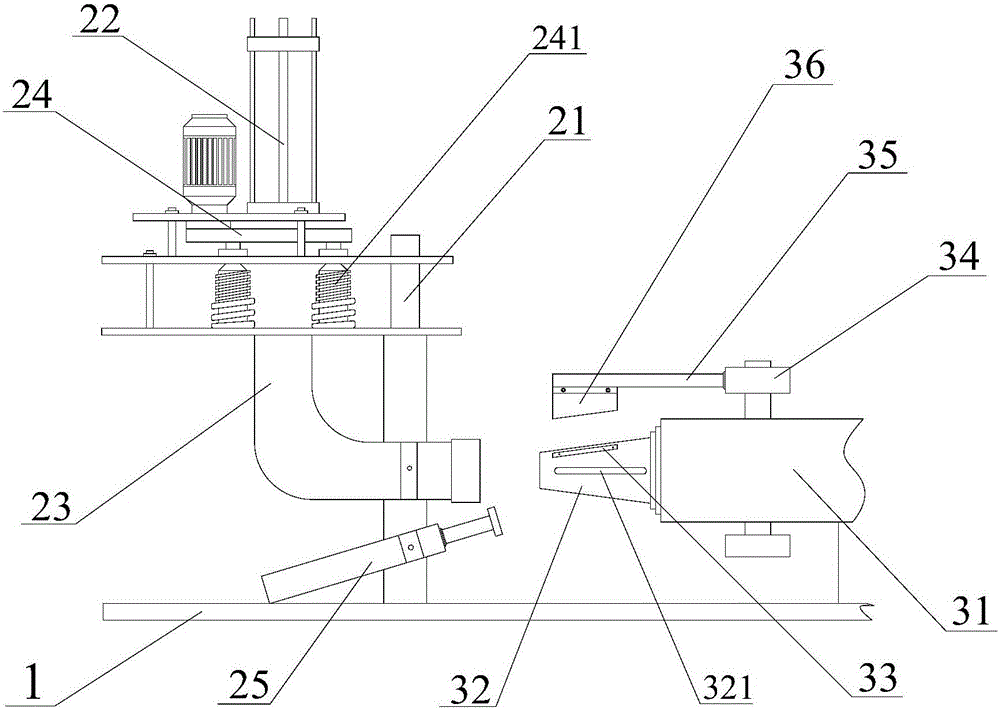

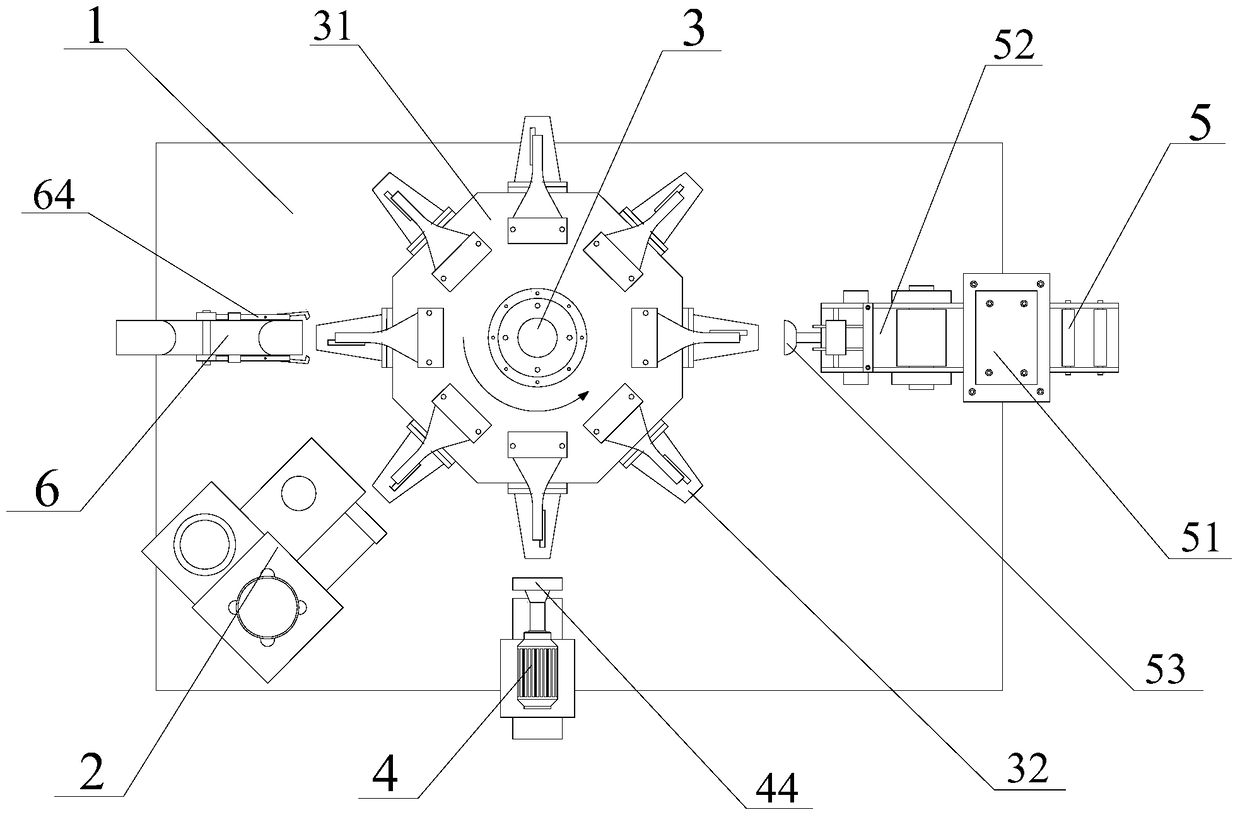

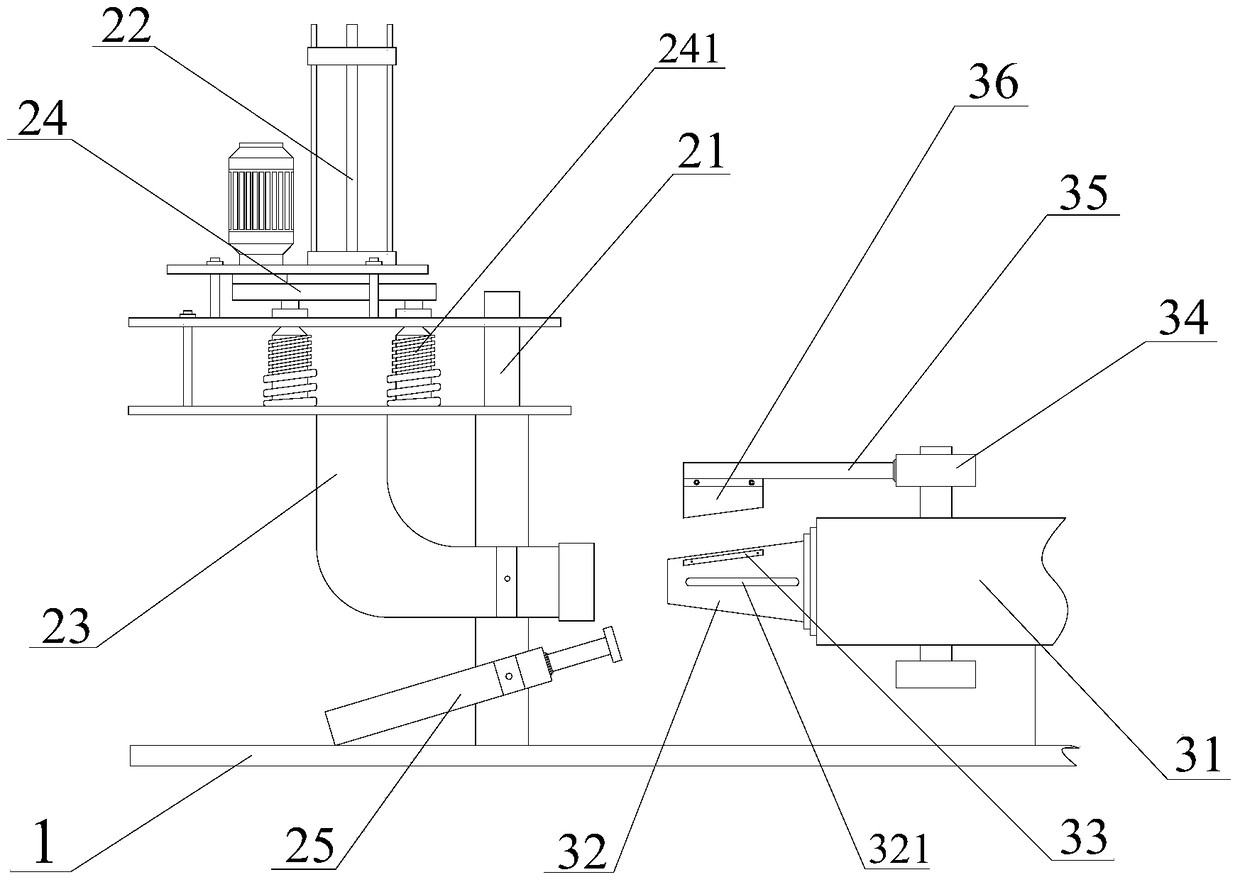

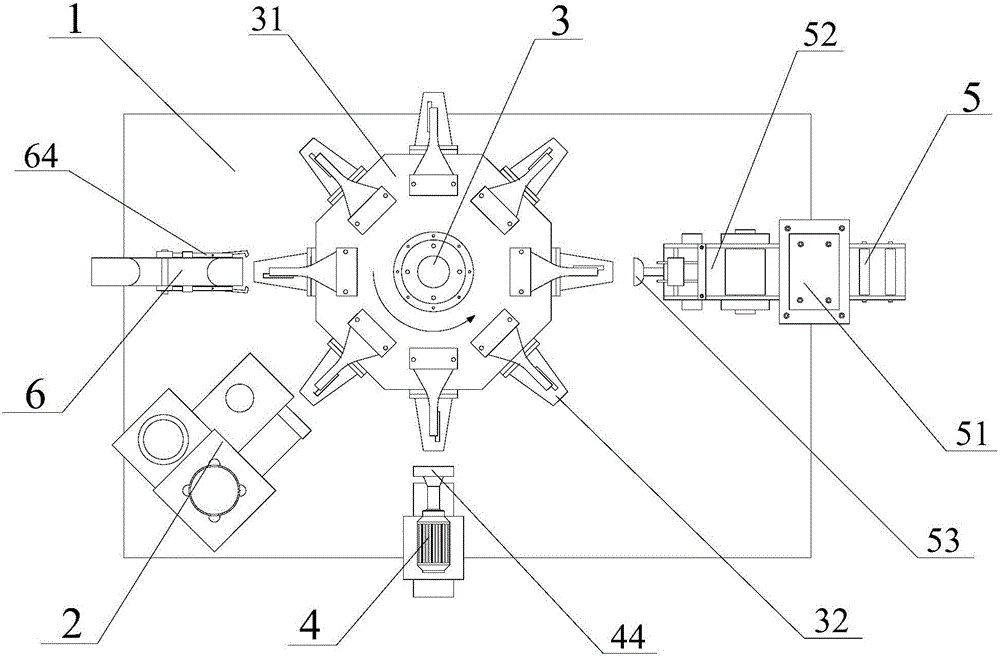

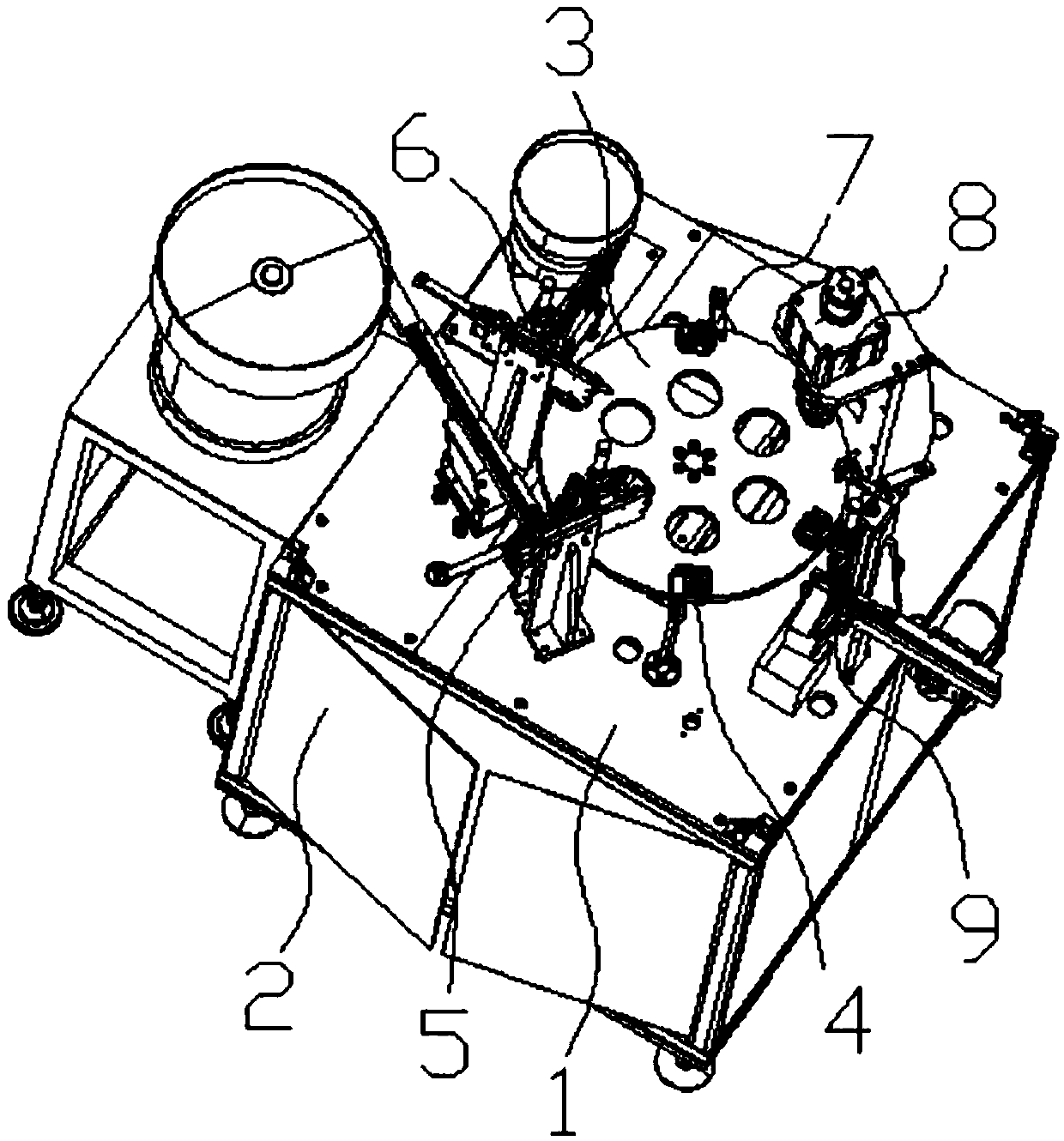

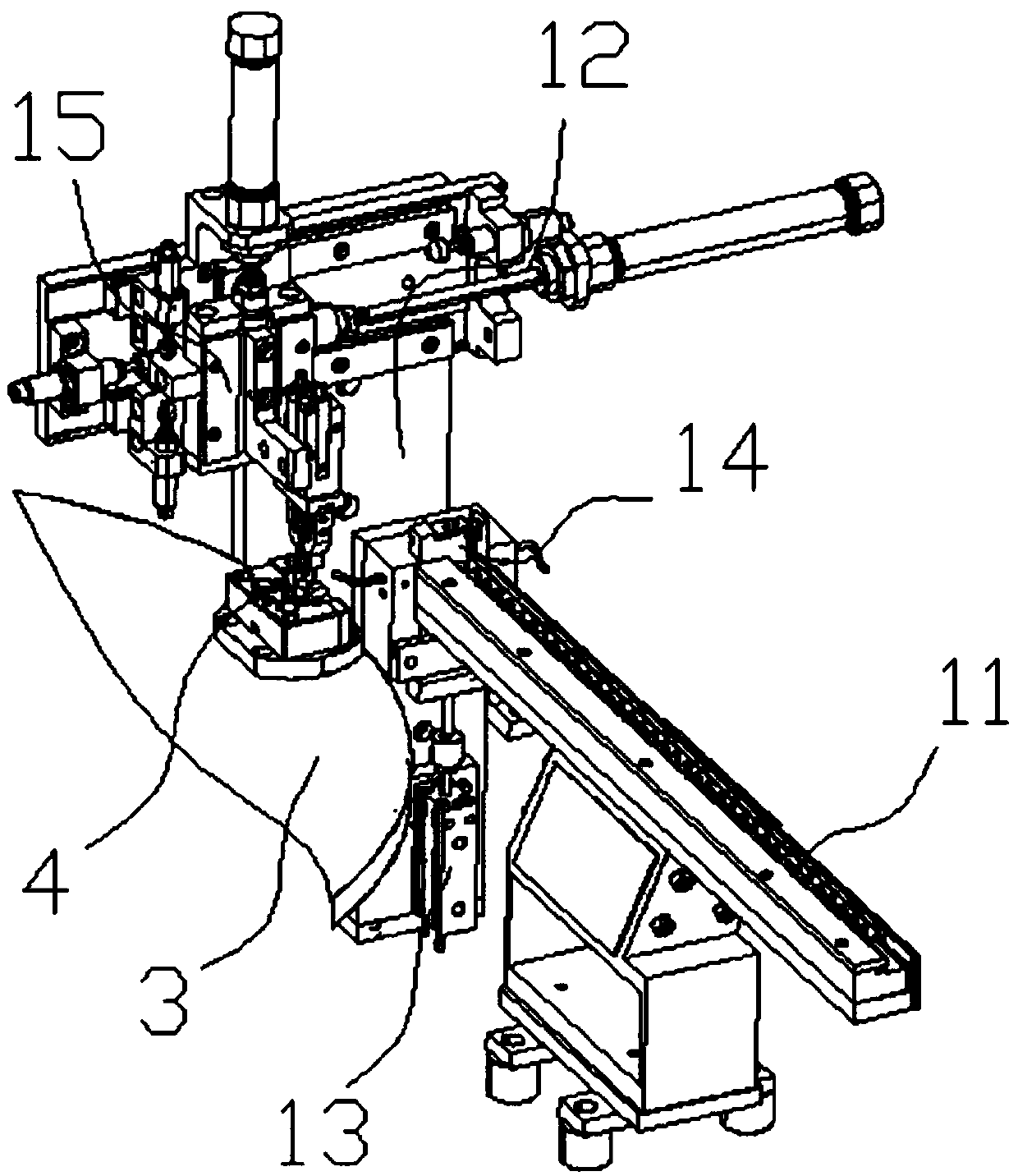

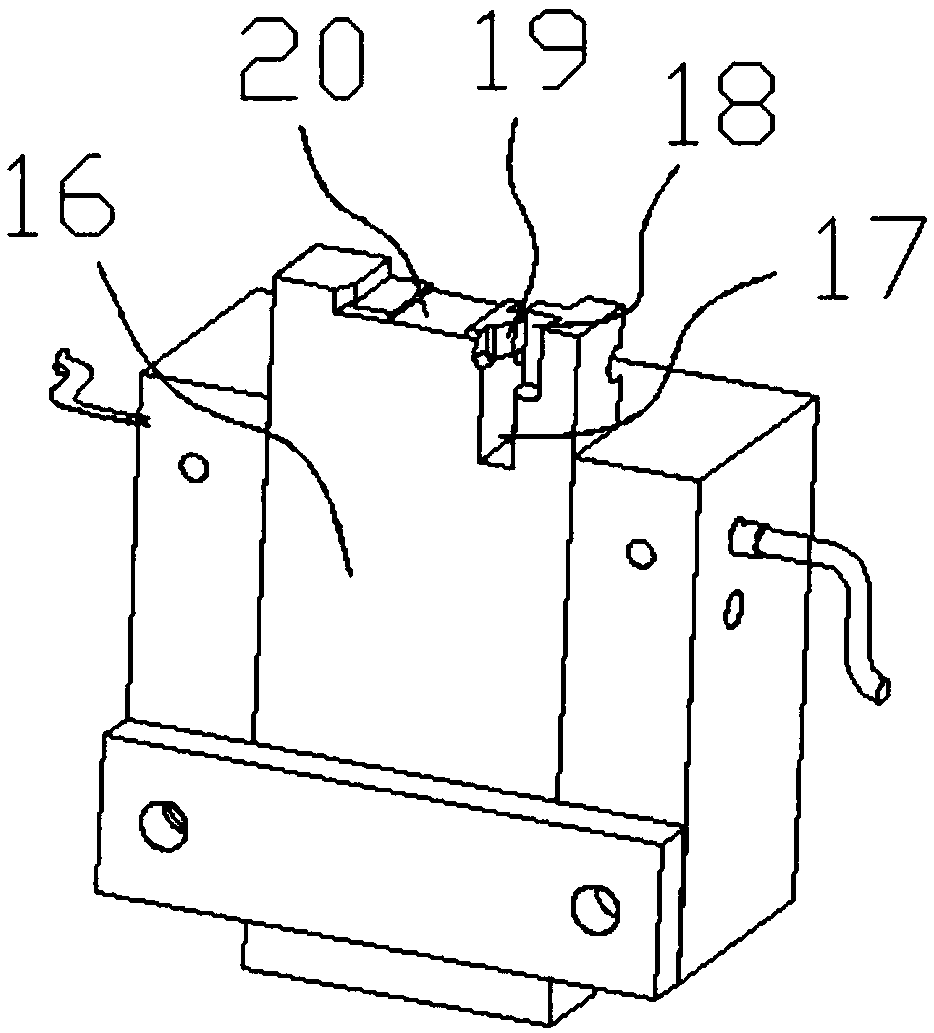

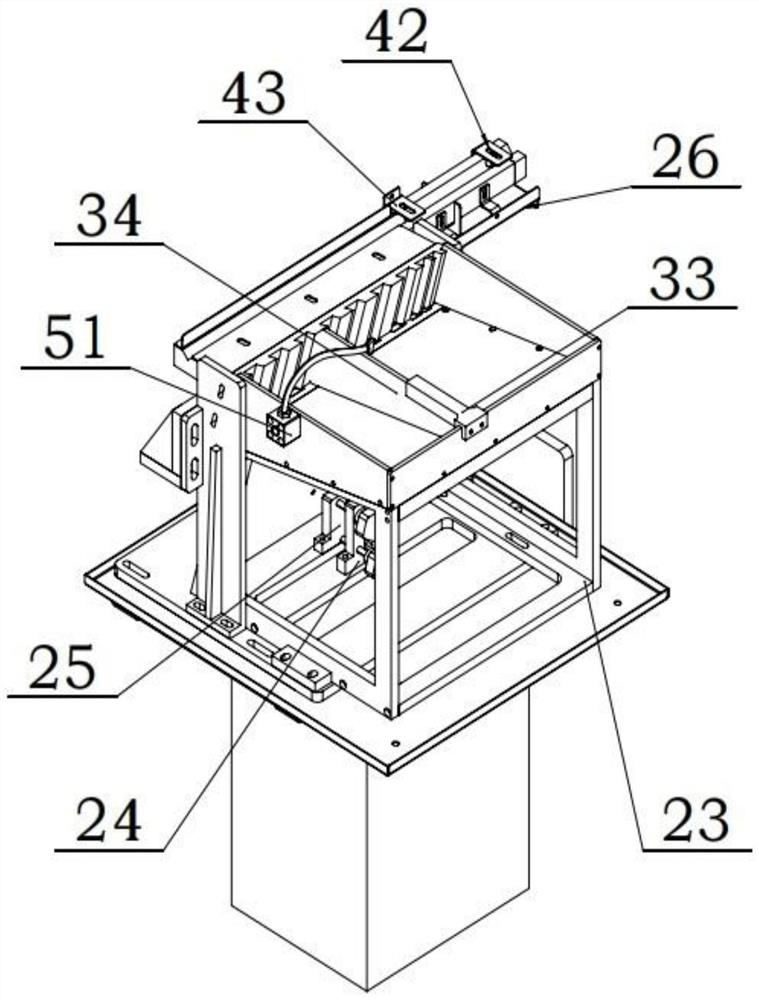

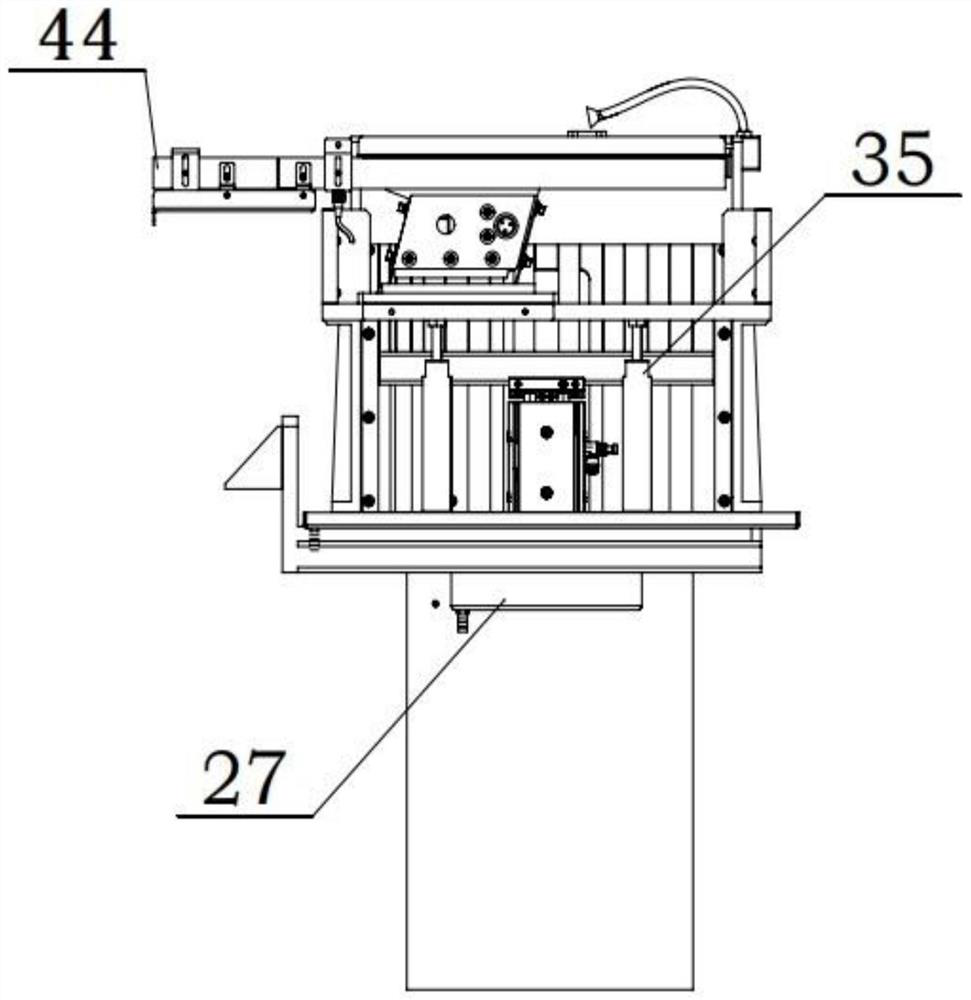

Continuous automatic assembly machine of lug plate elastic piece

ActiveCN107553107AGuaranteed accuracyAvoid elastic deformationMetal working apparatusDistribution controlButt joint

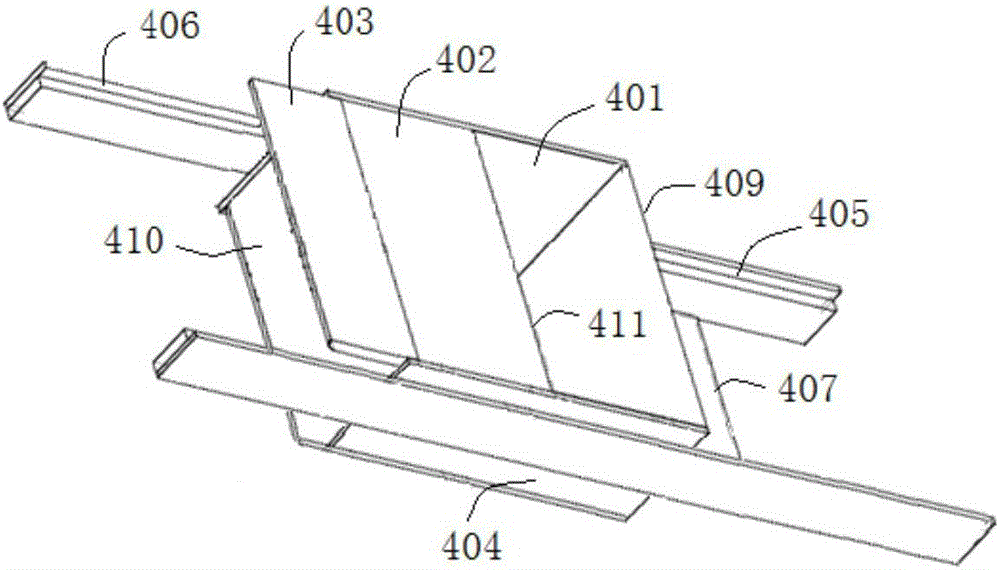

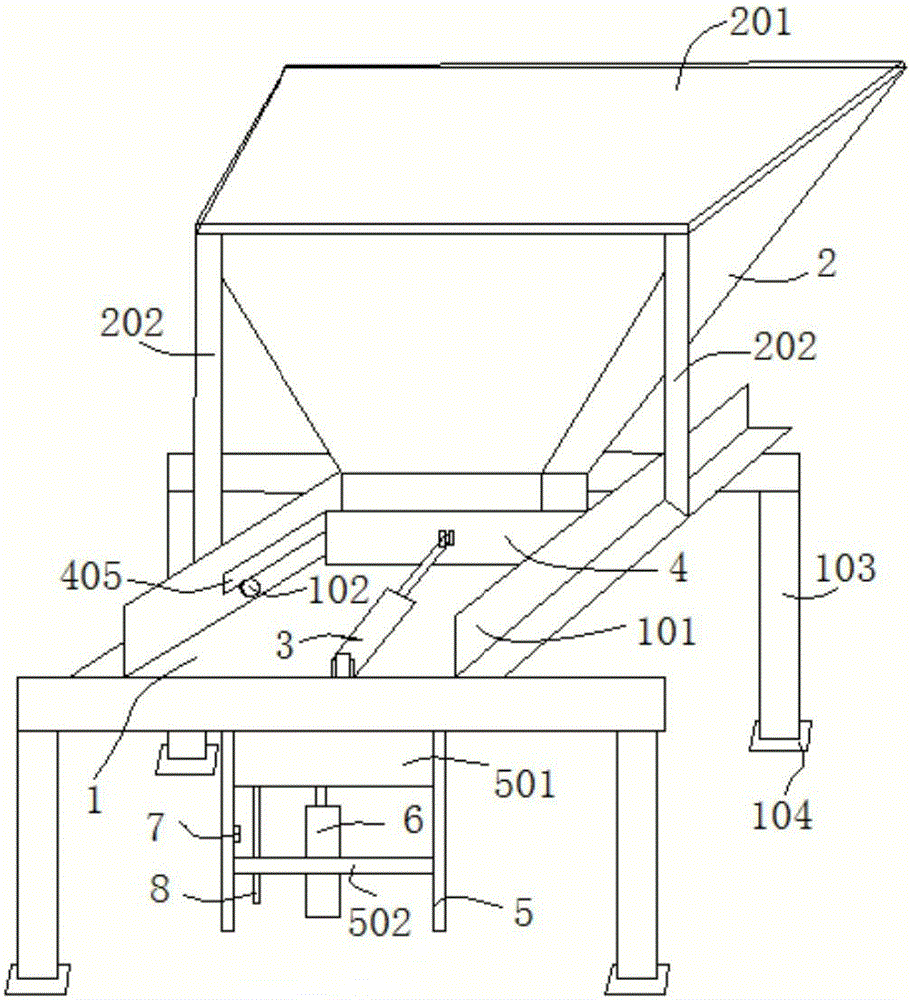

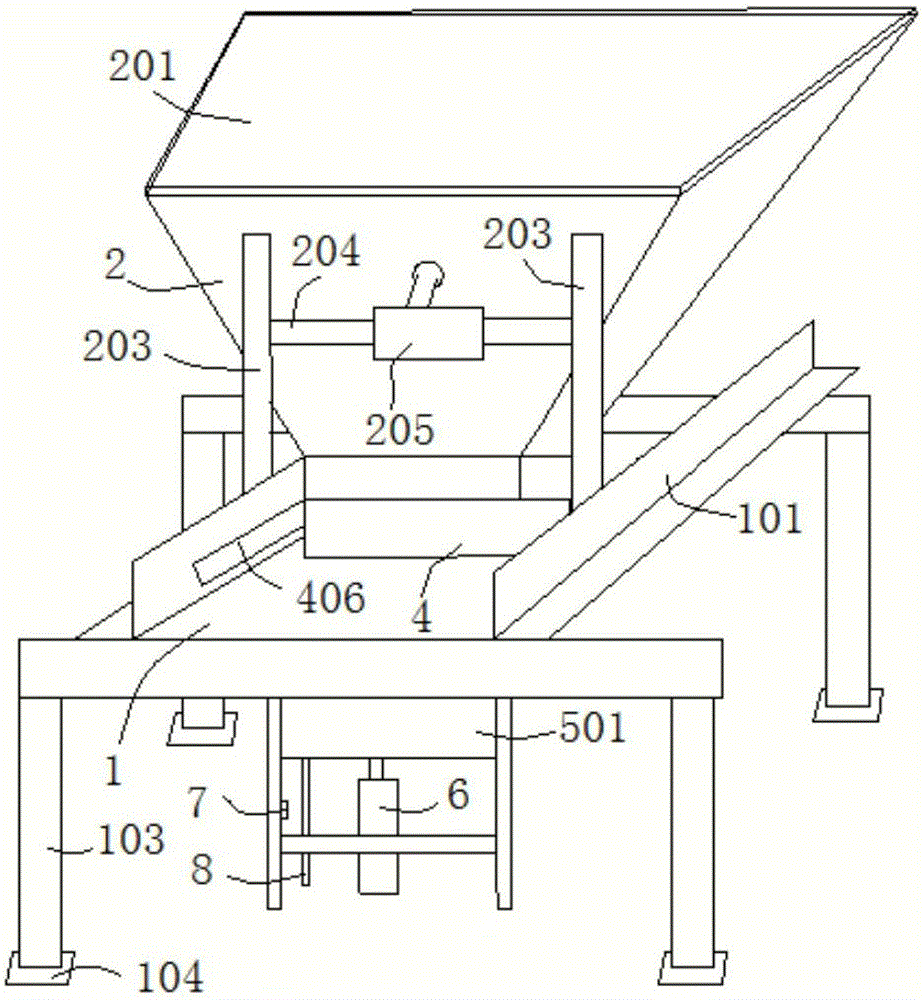

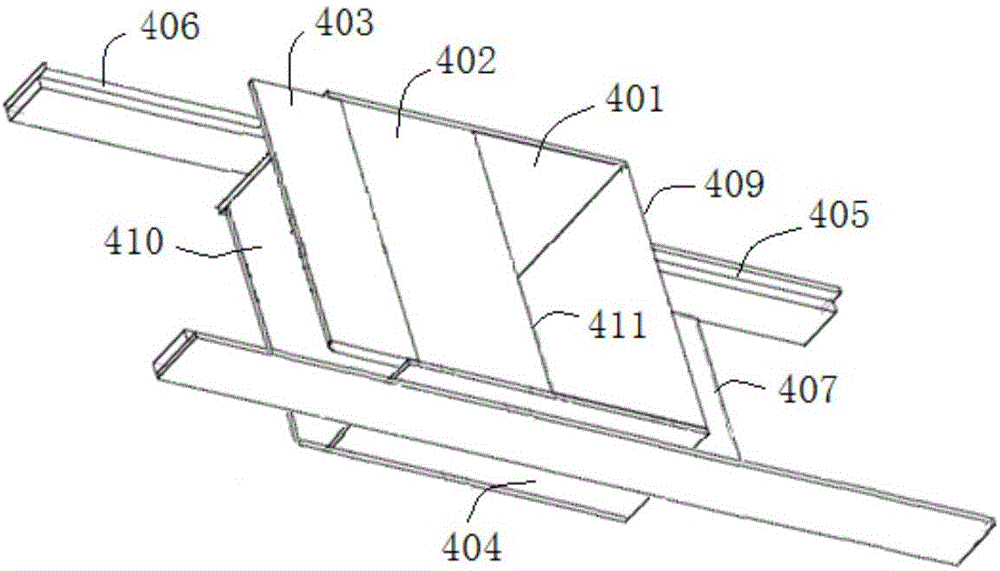

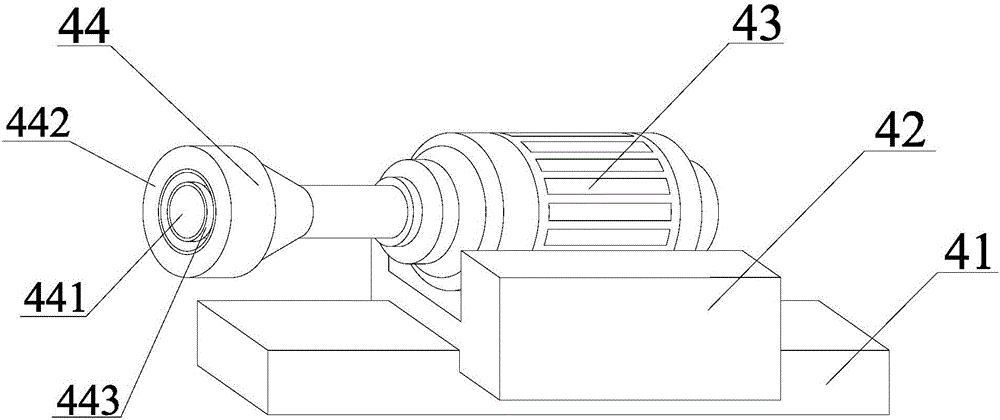

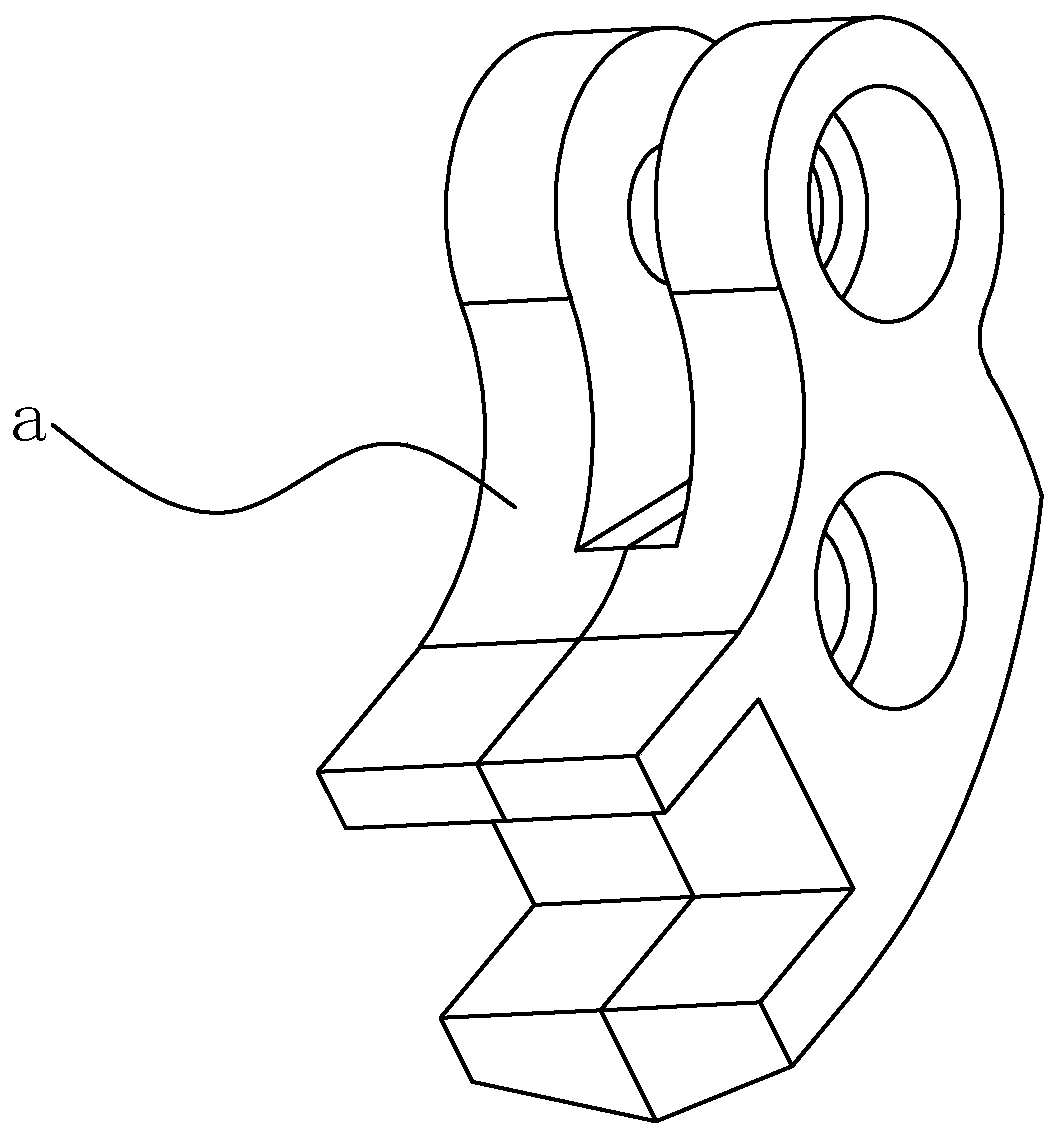

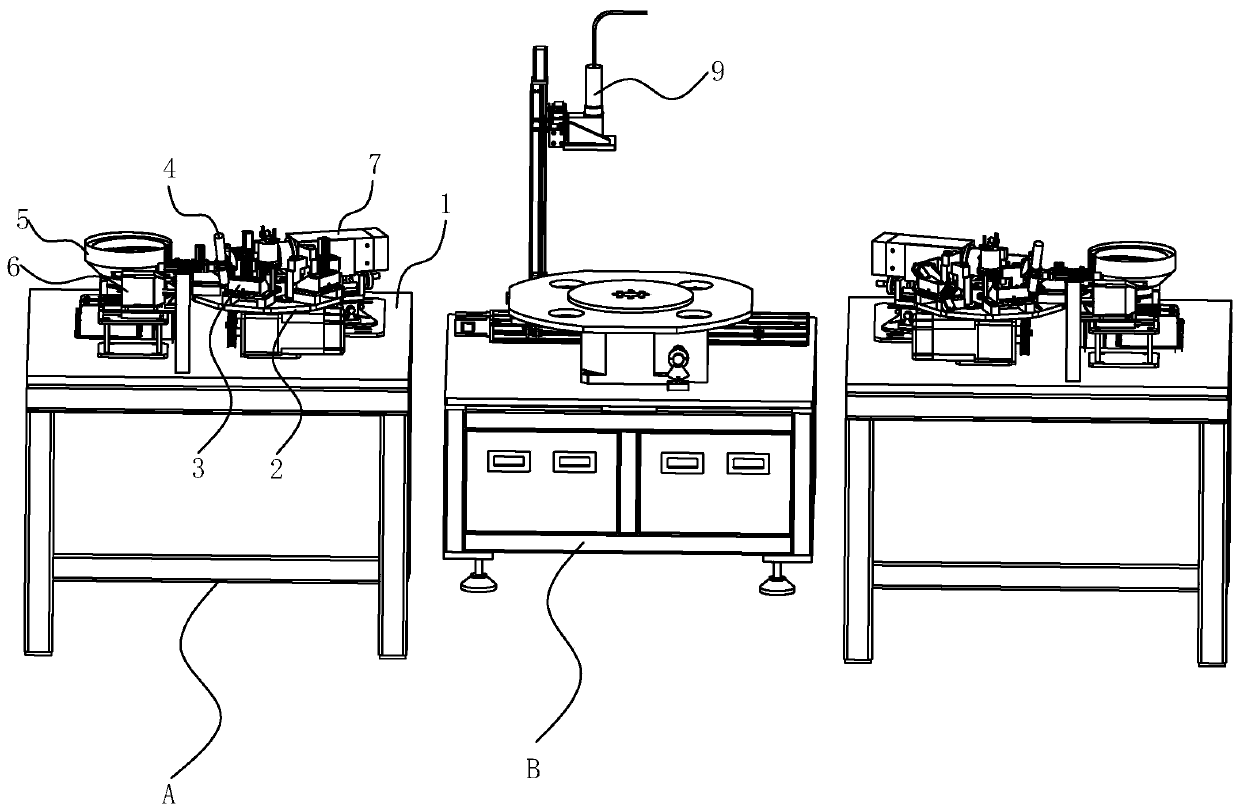

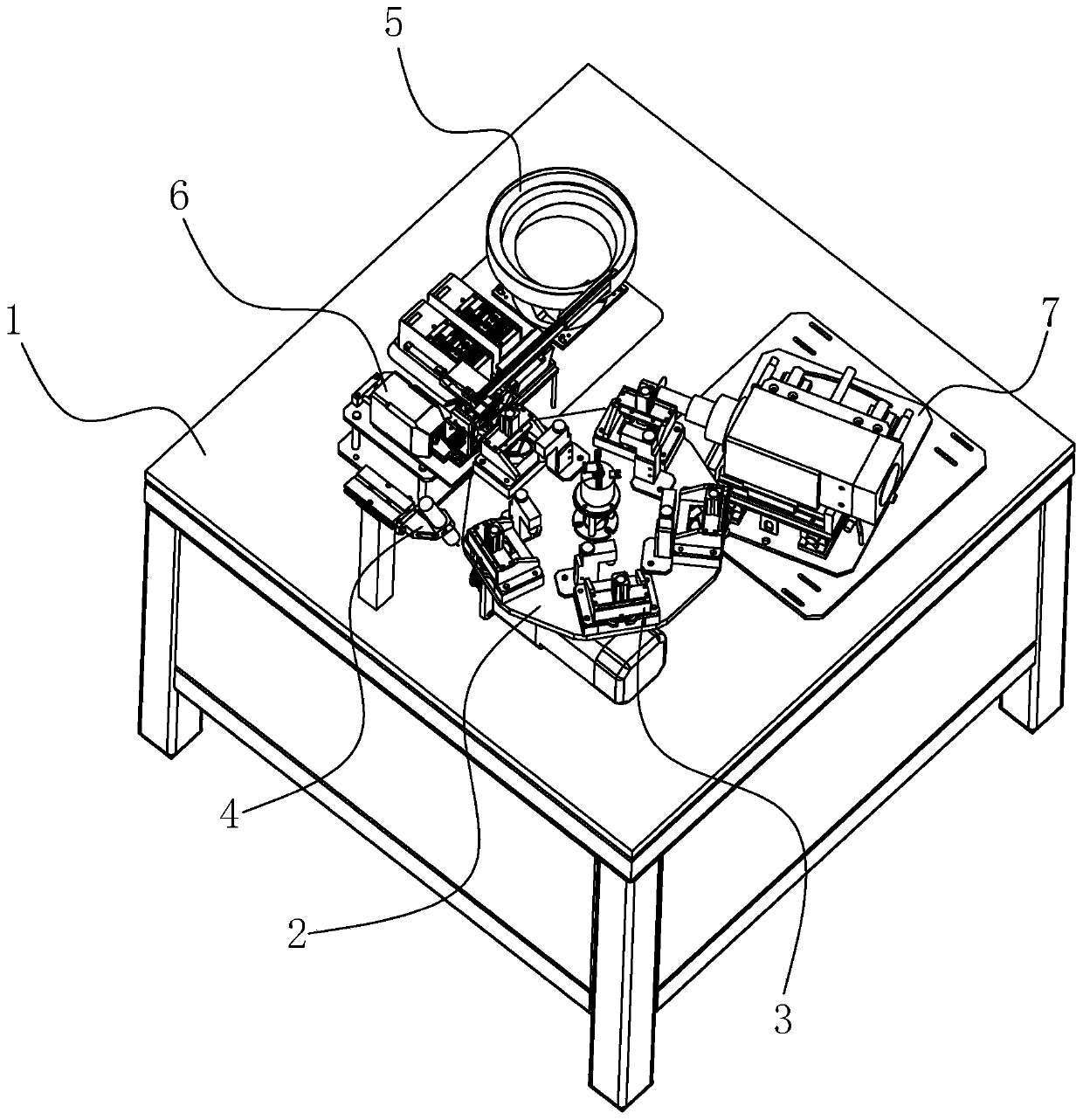

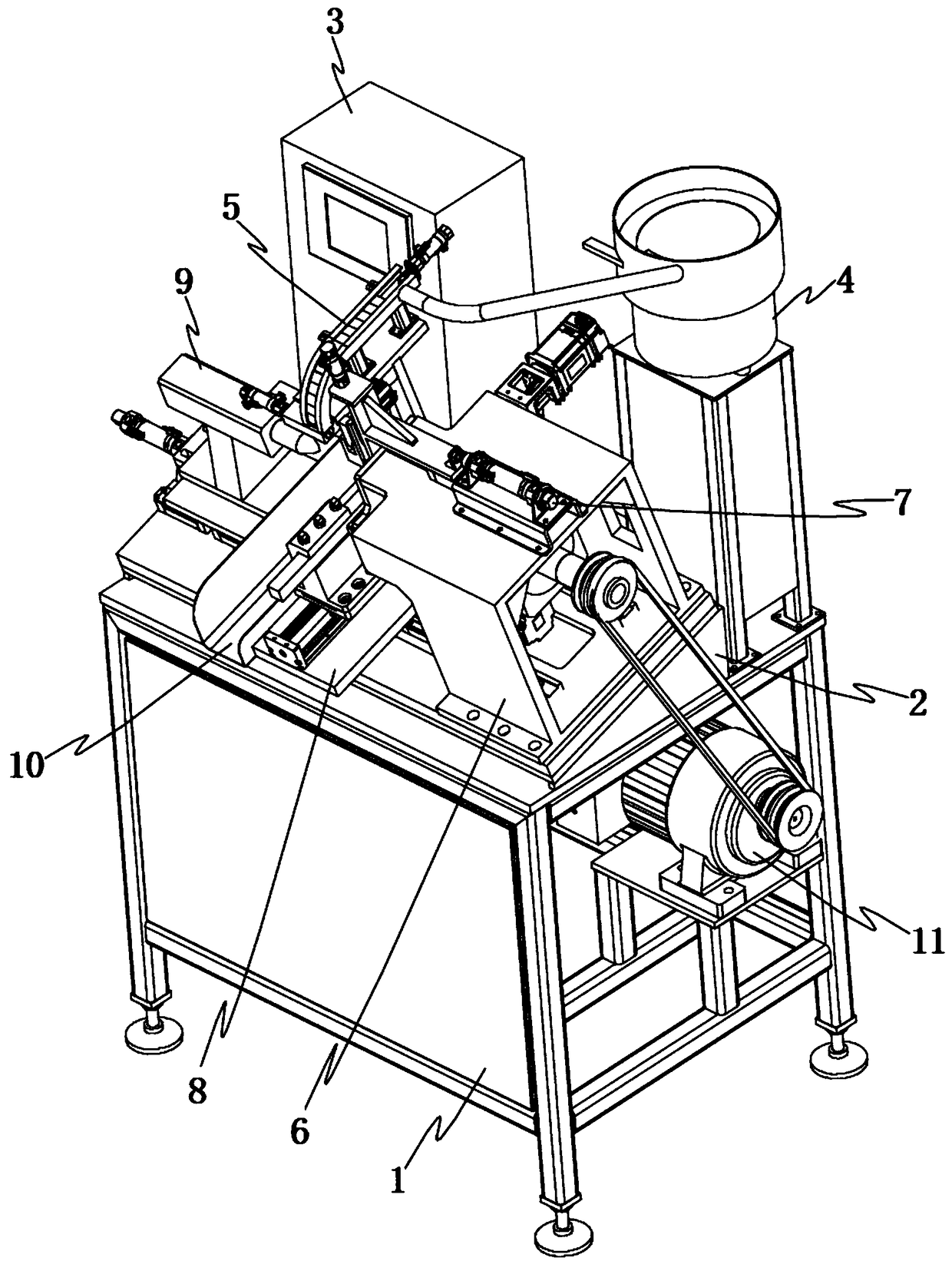

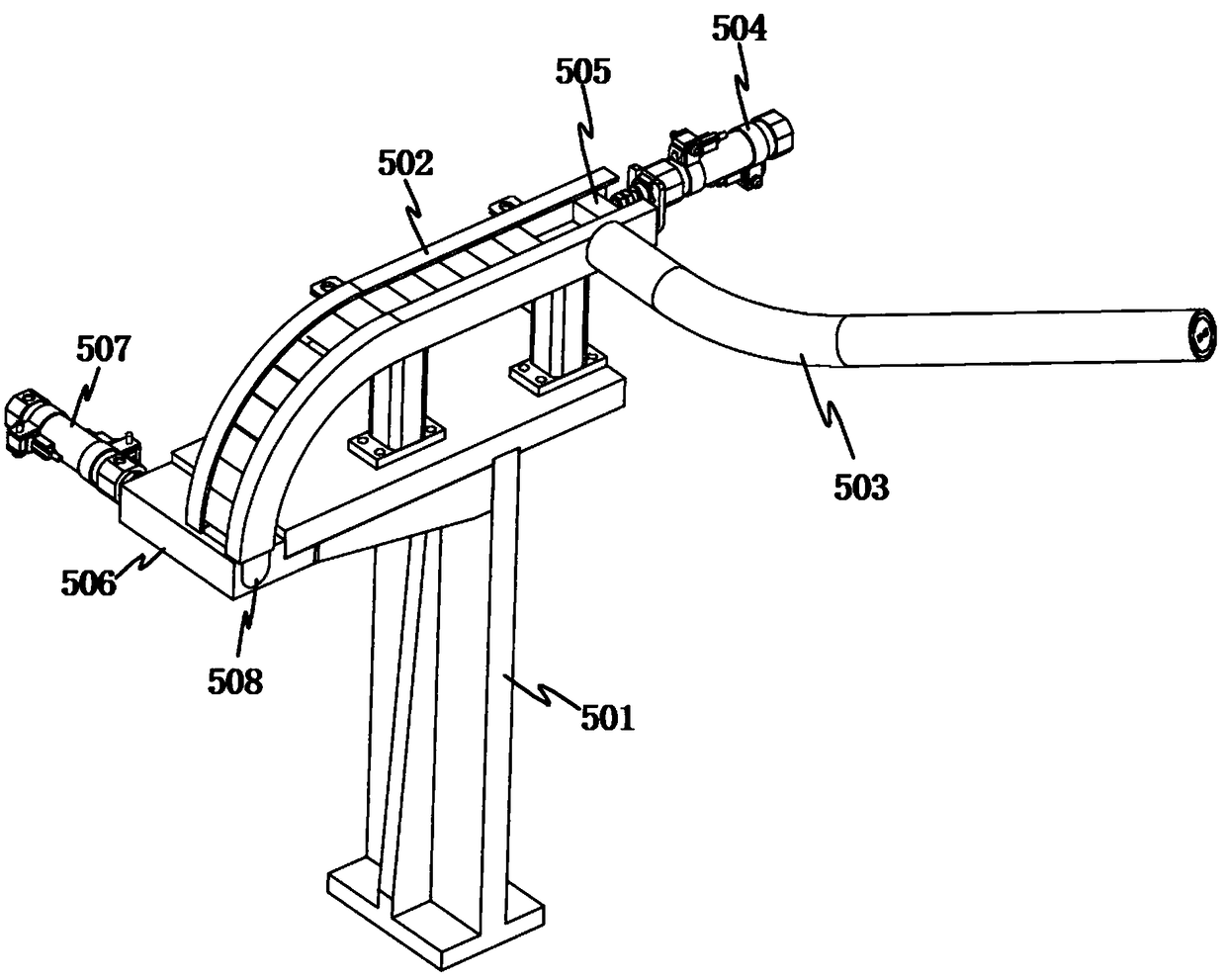

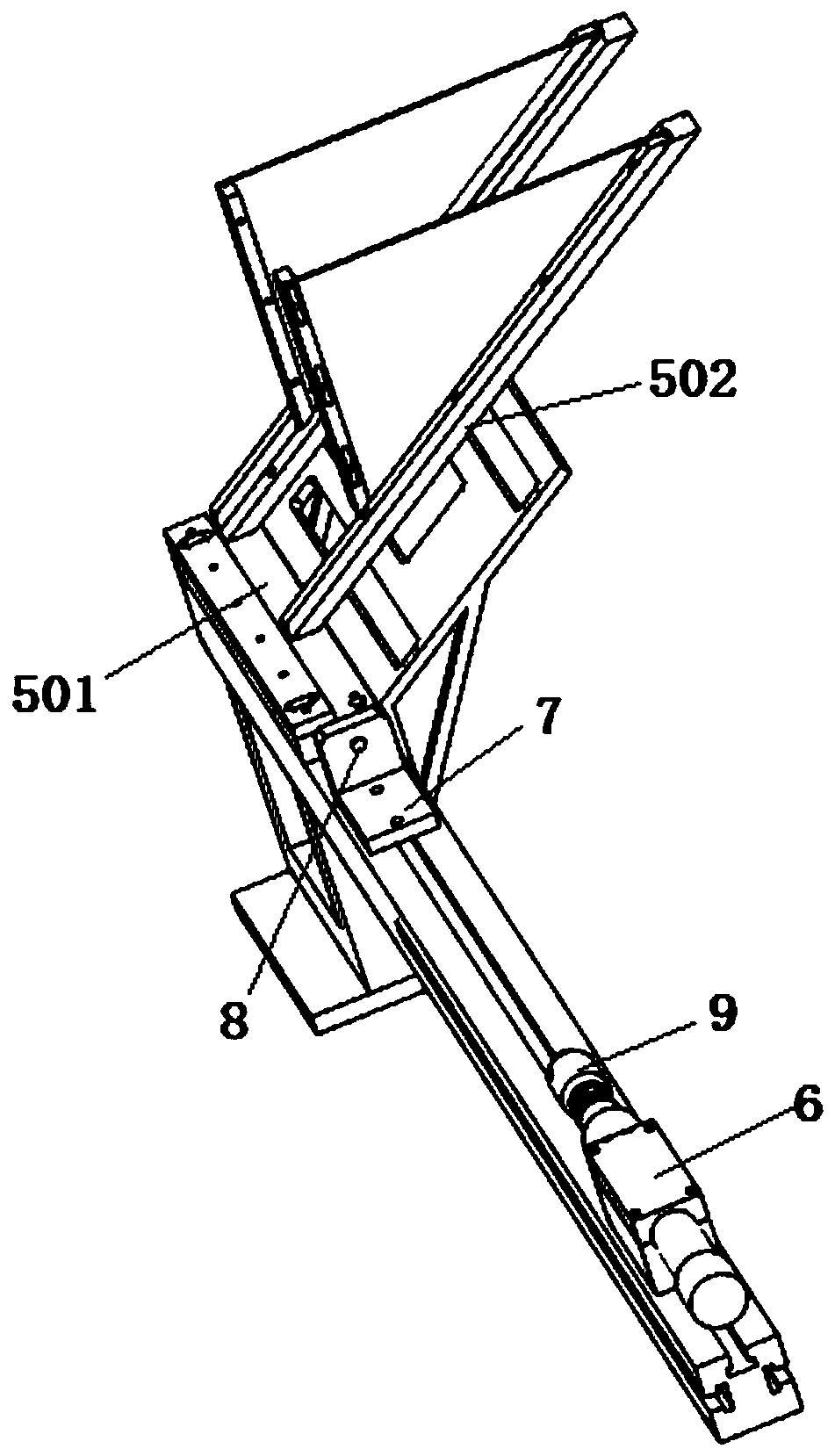

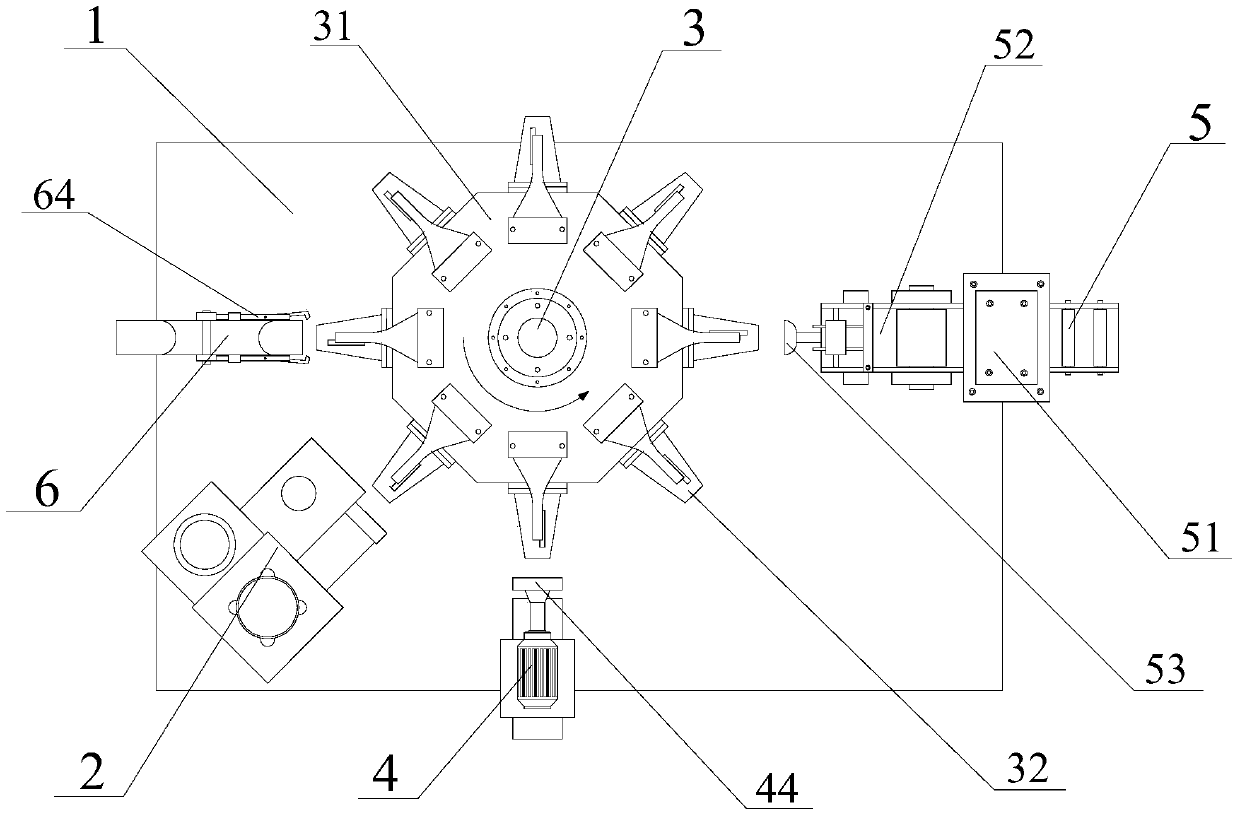

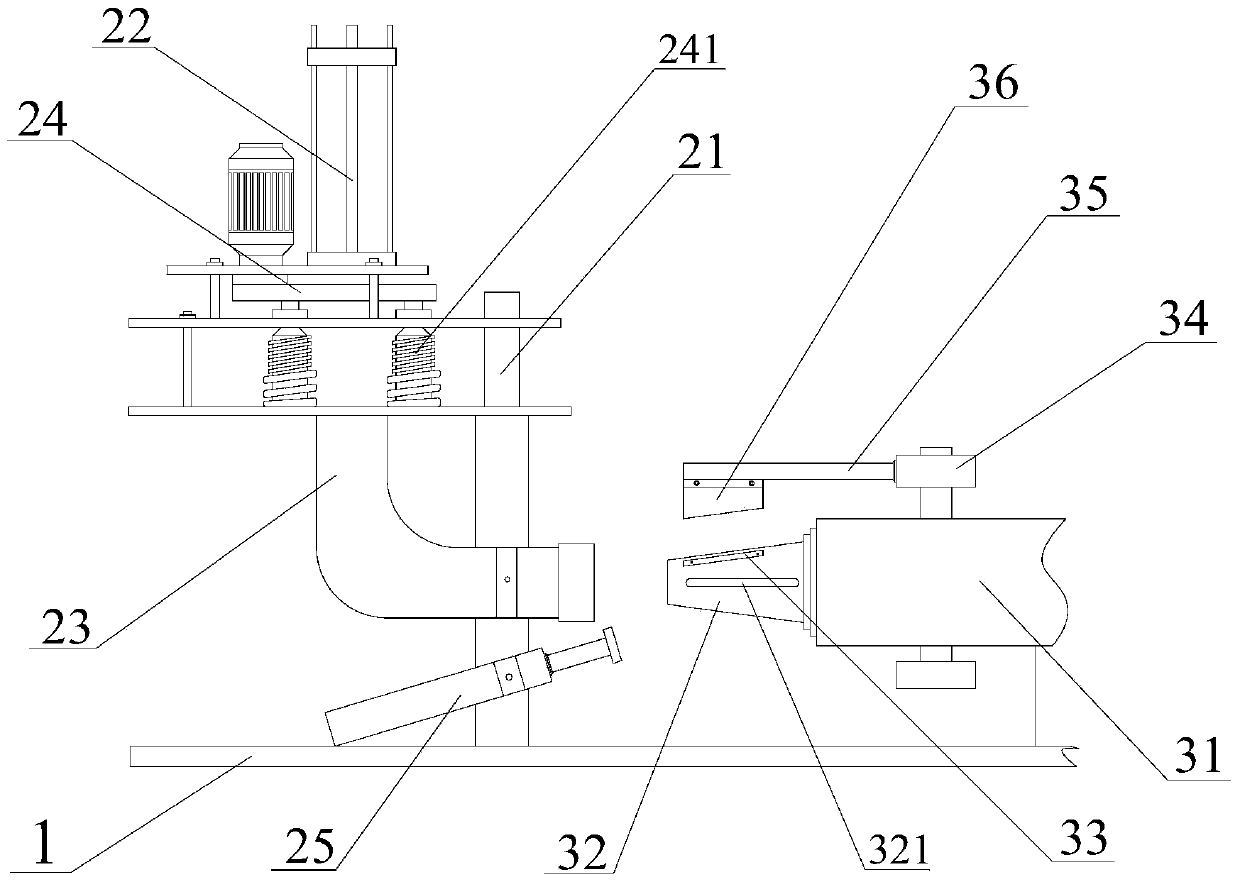

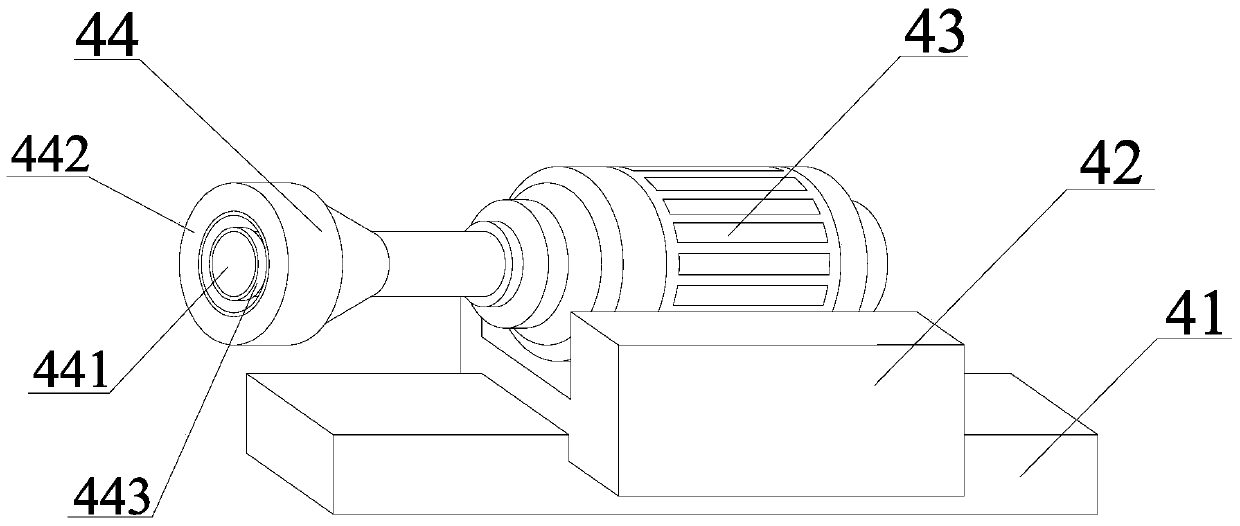

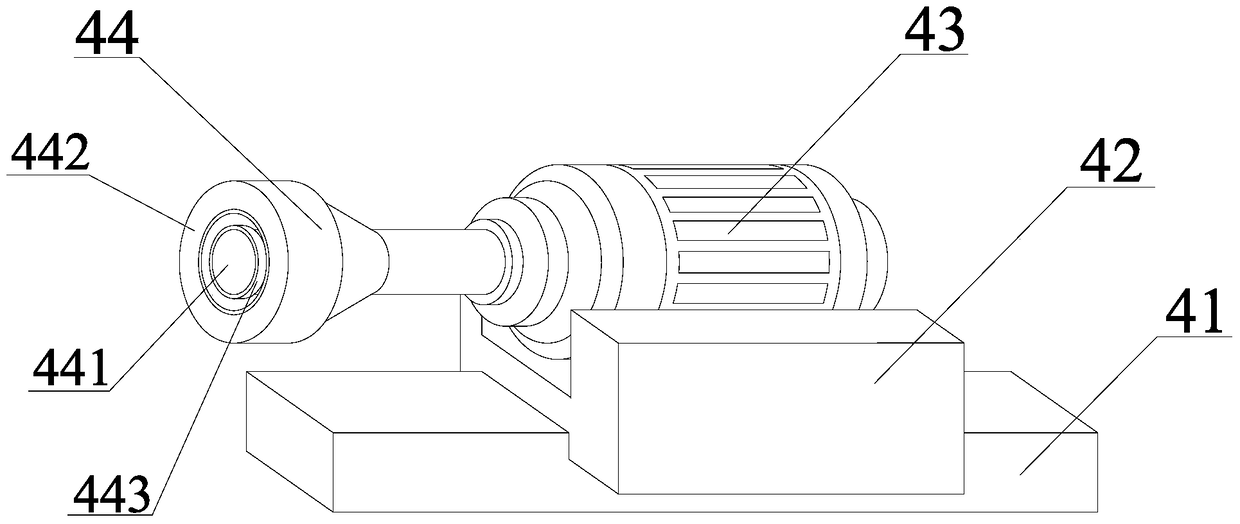

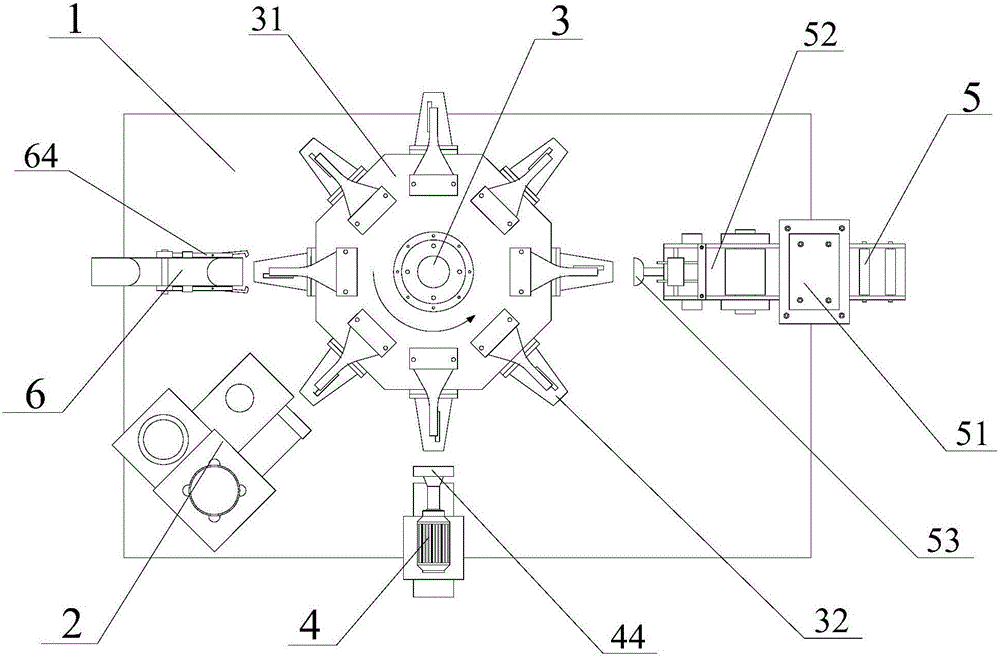

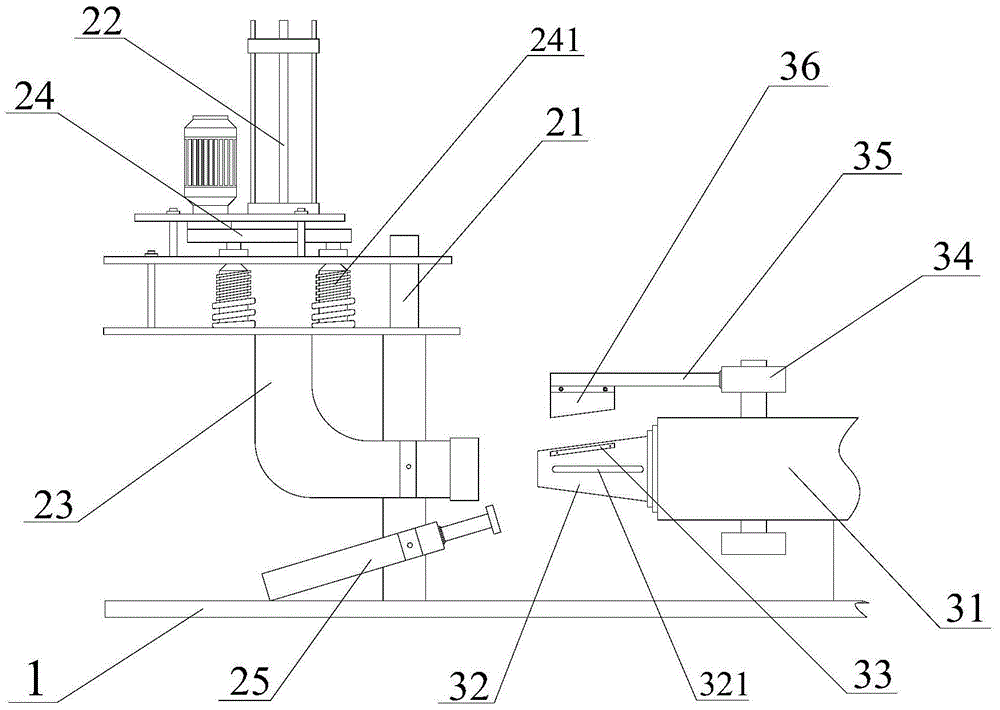

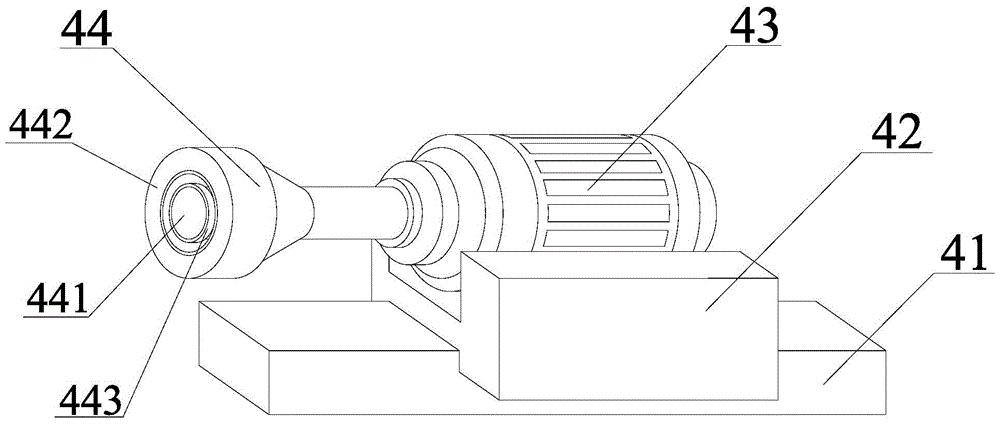

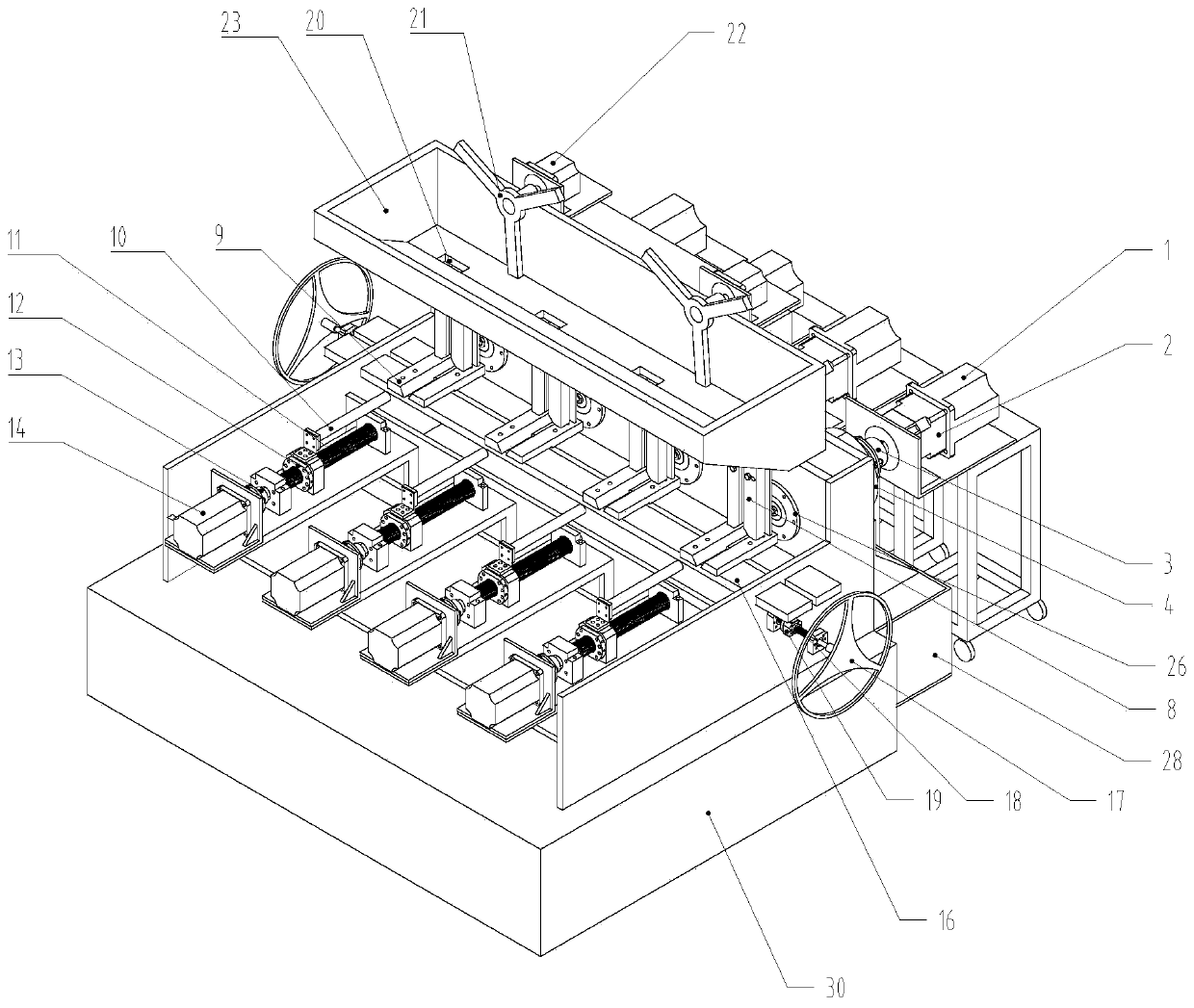

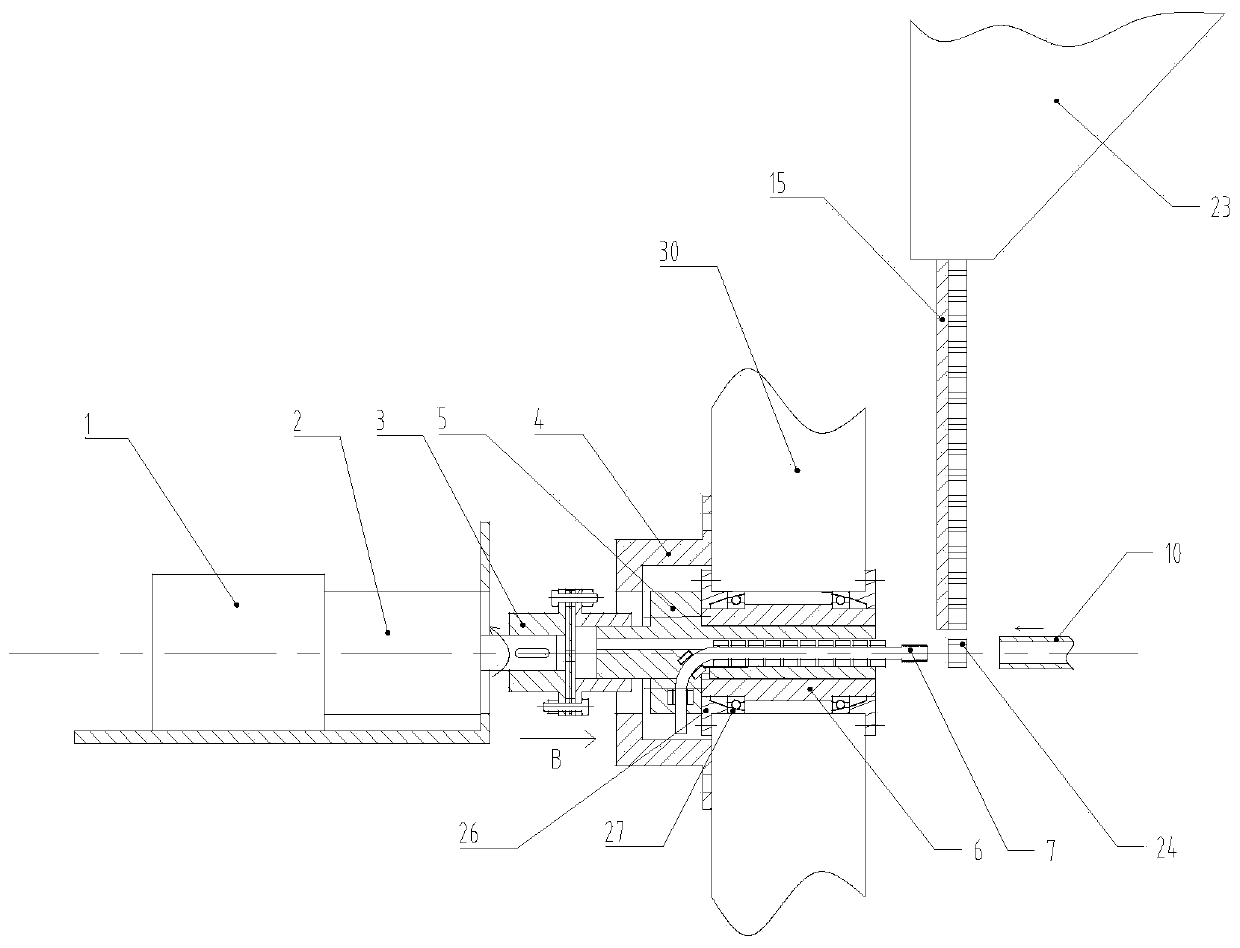

The invention relates to a continuous automatic assembly machine of a lug plate elastic piece. The continuous automatic assembly machine comprises a rack, a power distribution control box, a rotary disc and carriers. A lug plate feeding mechanism, an elastic piece feeding mechanism, a press-fitting mechanism and a discharging mechanism are arranged on the rack. Each carrier comprises a carried material mounting seat embedded into the rotary disc. A carried material seat lifting block penetrating the rotary disc is arranged in each carried material mounting seat. A vertical carried material seat composite spring is arranged between each carried material seat lifting block and the lower portion of the corresponding carried material mounting seat. A carried material seat cooperating with a product is arranged above each carried material seat lifting block. A press-fitting device comprises a press-down device cooperating with the products on the carriers and a carried material seat jackingdevice which is located below the press-down device and cooperates with the carried material seat lifting blocks. According to the continuous automatic assembly machine, the carried material seat lifting blocks and the press-down device can be in butt joint precisely, meanwhile, pressing assembly of a lock piece and a lug plate can be achieved, it can be ensured that the press-down portion is a flat plate between two elastic piece mounting columns, the press-fitting precision is ensured, elastic deformation of the elastic pieces is avoided, and meanwhile continuous automatic machining is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

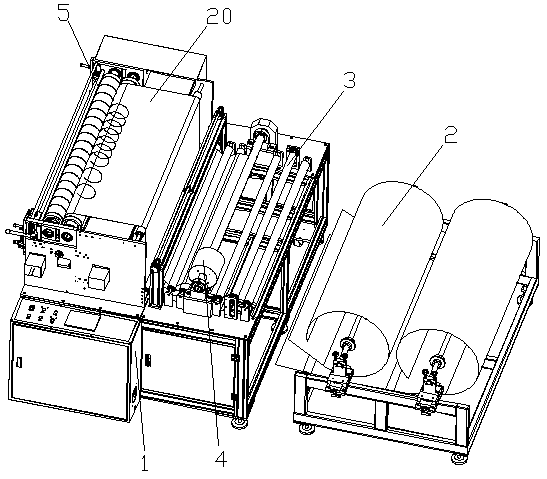

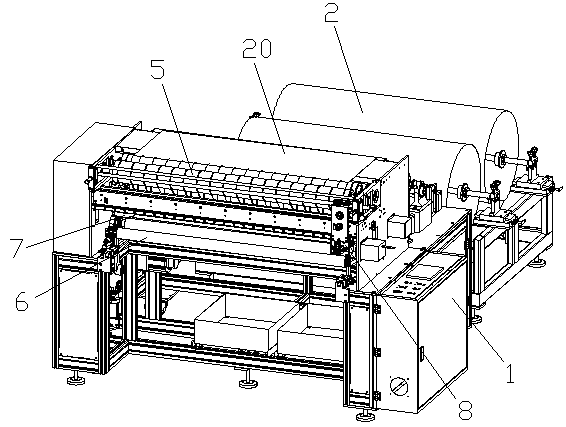

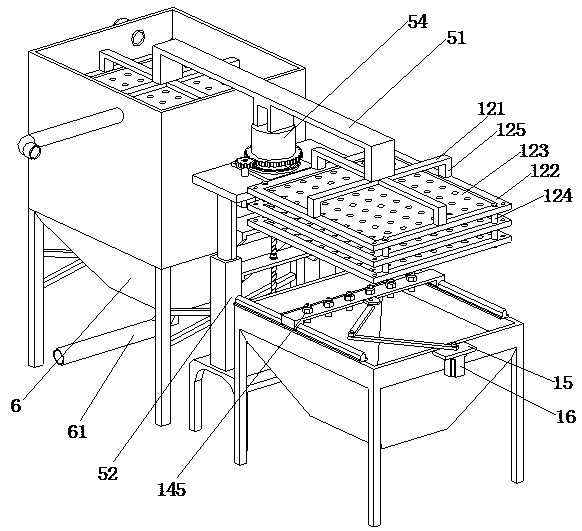

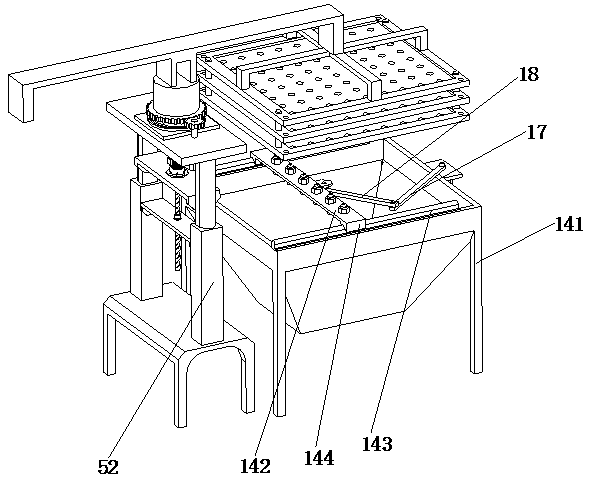

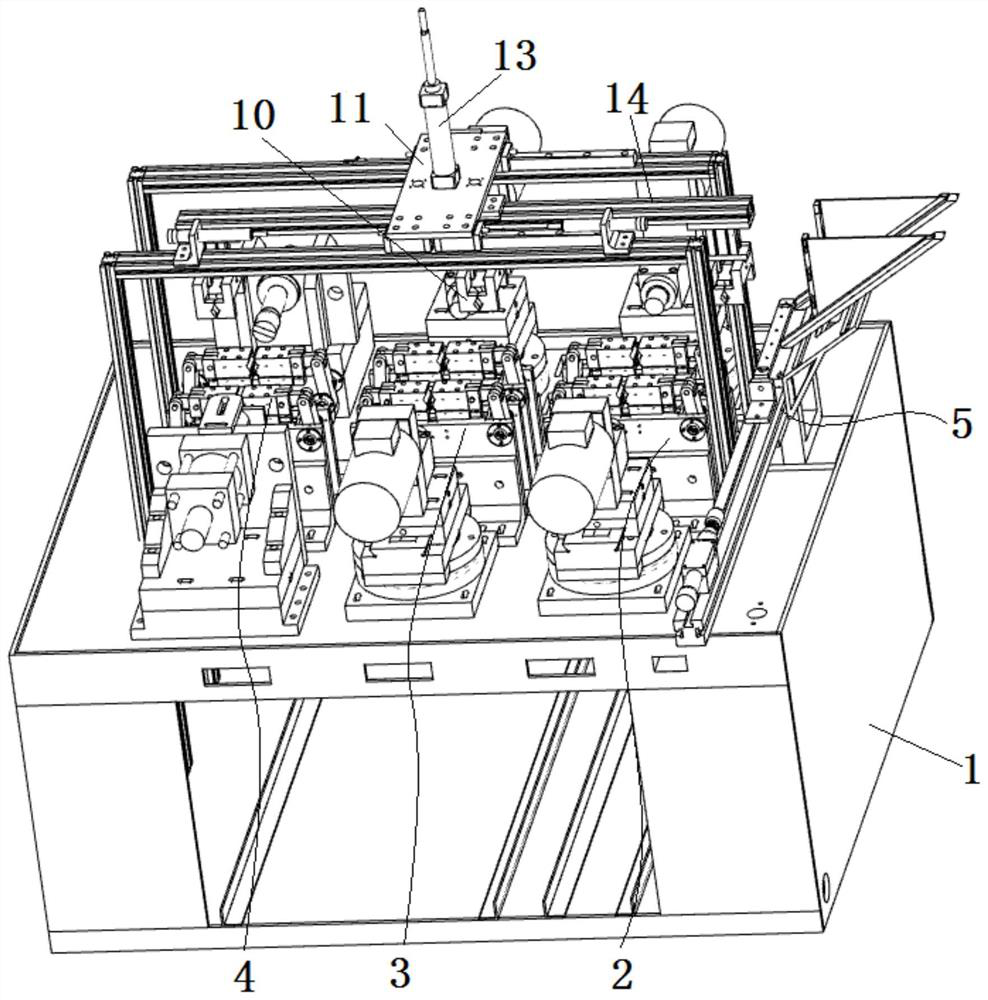

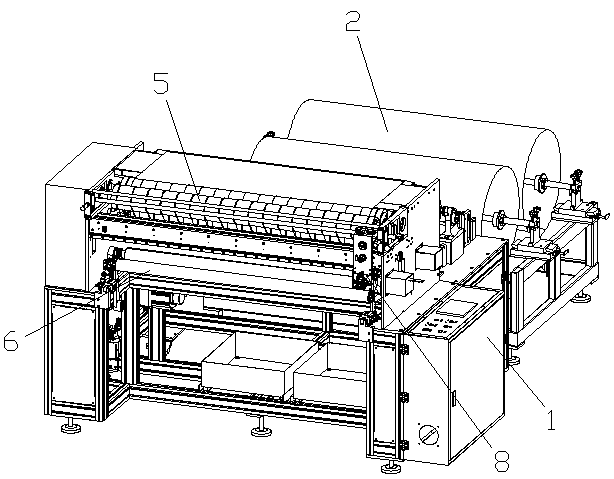

Garment pocket automatic processing integrated machine

InactiveCN109512069AEasy to operateRealize continuous automatic processingSevering textilesClothes making applicancesEngineeringAutomatic processing

Owner:DONGGUAN UNIV OF TECH +1

Method for processing paper cups with handles

ActiveCN105058864ARealize continuous automatic processingImprove work efficiencyPaper-makingBox making operationsPulp and paper industryManipulator

The invention discloses a method for processing paper cups with handles. The method comprises the following steps: a) conveying a plurality of naked paper cups to a pasting control mechanism to finish a material conveying procedure; b) rotating the paper cups, and enabling the seam line parts of the paper cups to be positioned above paper dies and then fixed to finish the alignment limit of the paper cups; c) pushing handle paper to be above the paper cups to finish a handle paper conveying procedure; d) carrying out paper hot-pressing pasting on the paper cups and the handles, and keeping hot-pressing until arriving at the next work station to finish the pasting procedure of the handle paper; and e) utilizing a manipulator to take down the paper cups with the handles, and conveying the paper cups with the handles into a material collecting groove to finish a material collecting procedure. The method for processing the paper cups with the handles has the advantages that the continuous and automatic processing for the paper cups with the handles is realized by adopting an automatic pasting processing device with a turntable for the paper cups with the handles, the work efficiency and the product quality of the paper cup pasting processing are greatly improved, and the device is stable in structure and convenient to operate and has excellent practicability and high popularization value.

Owner:宣城市博思特日用品有限公司

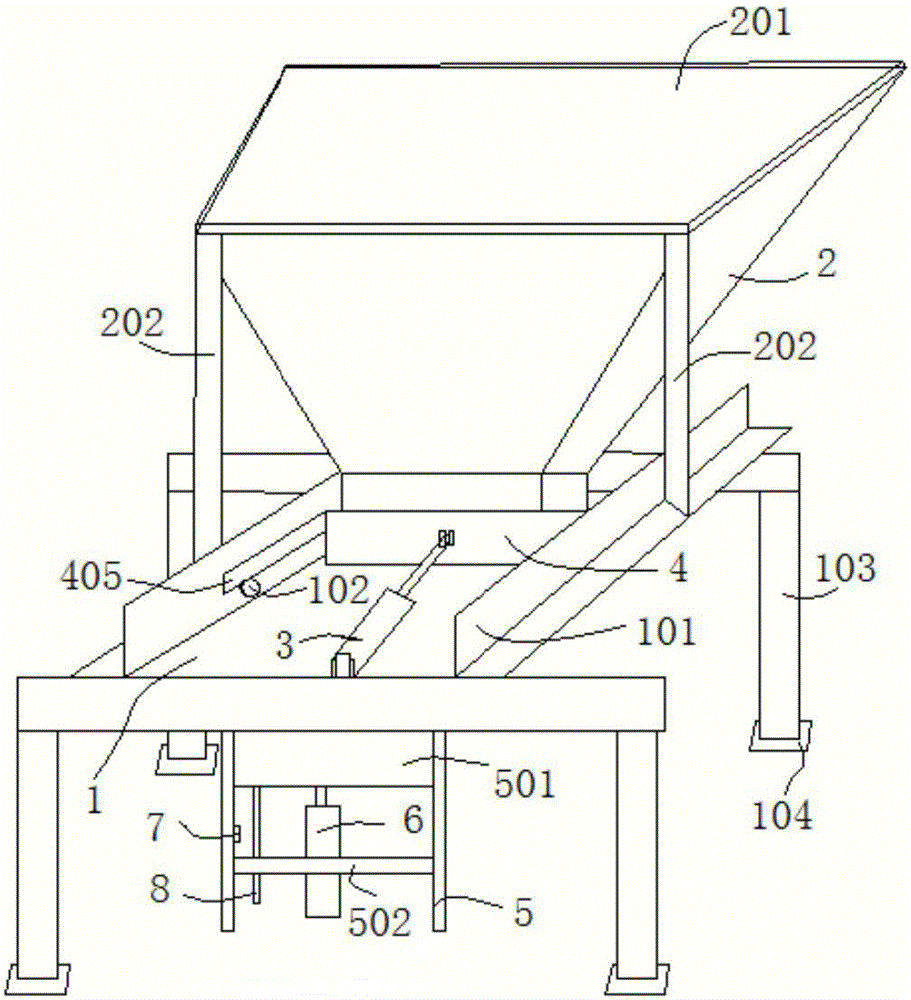

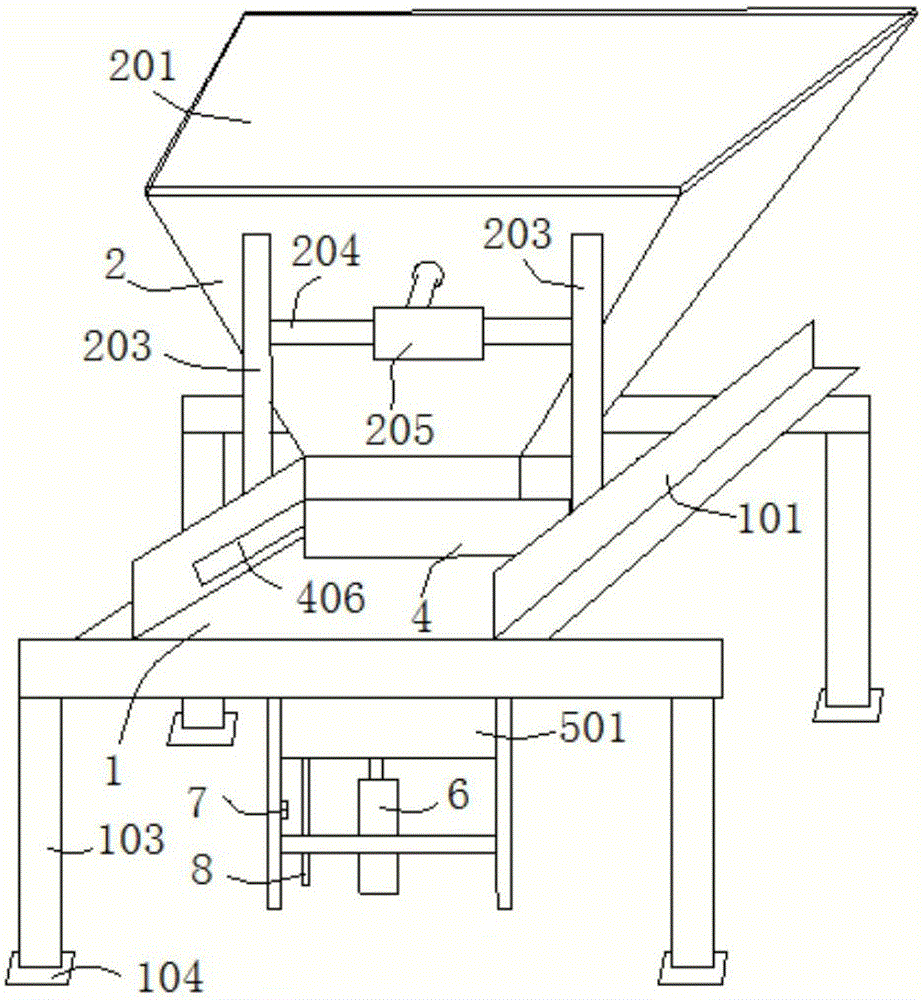

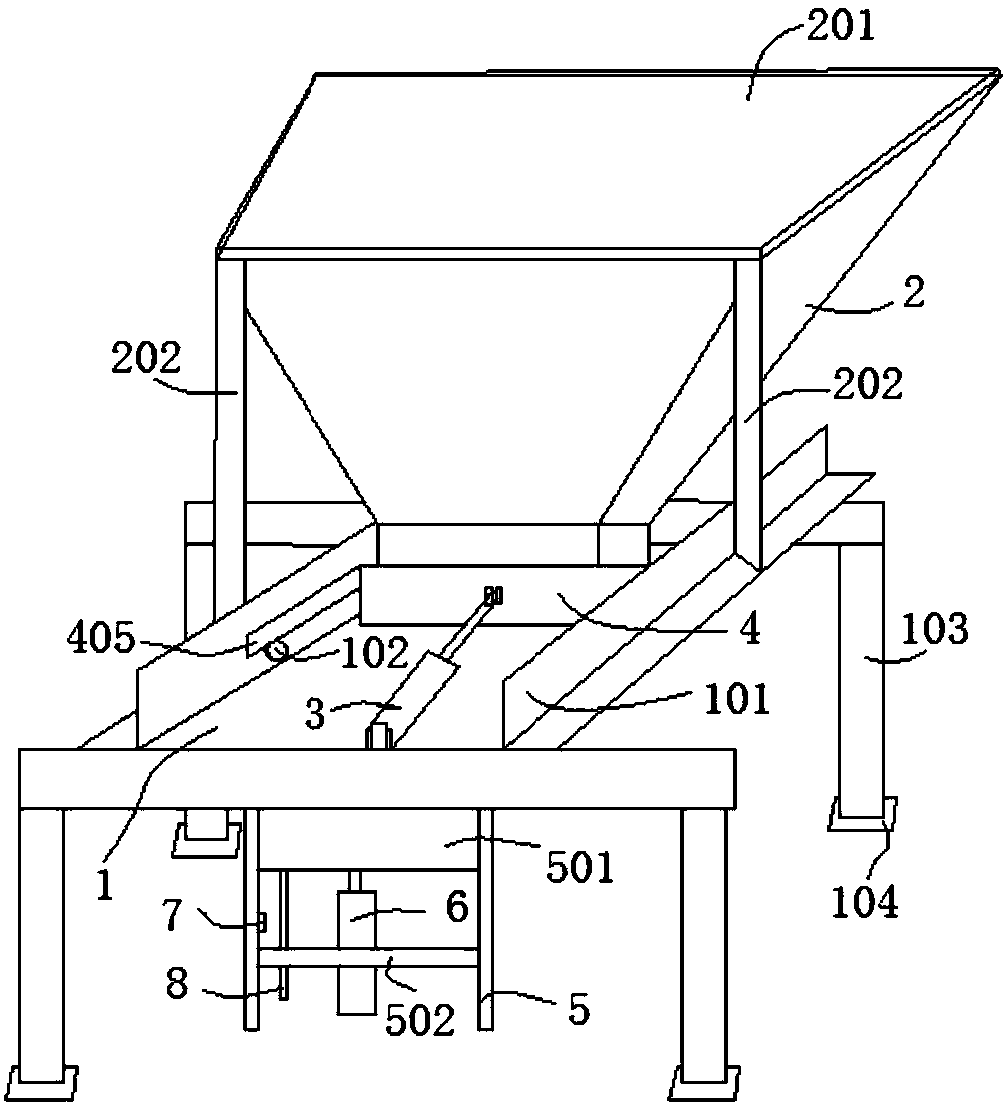

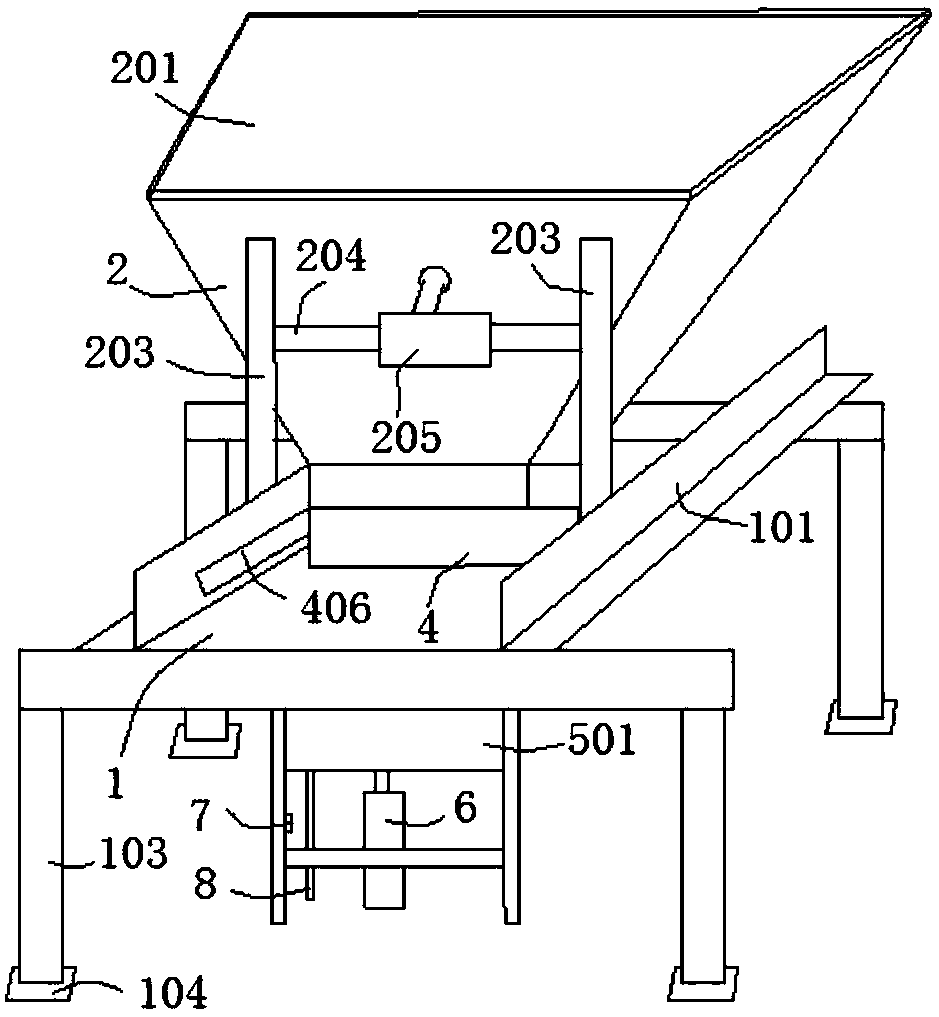

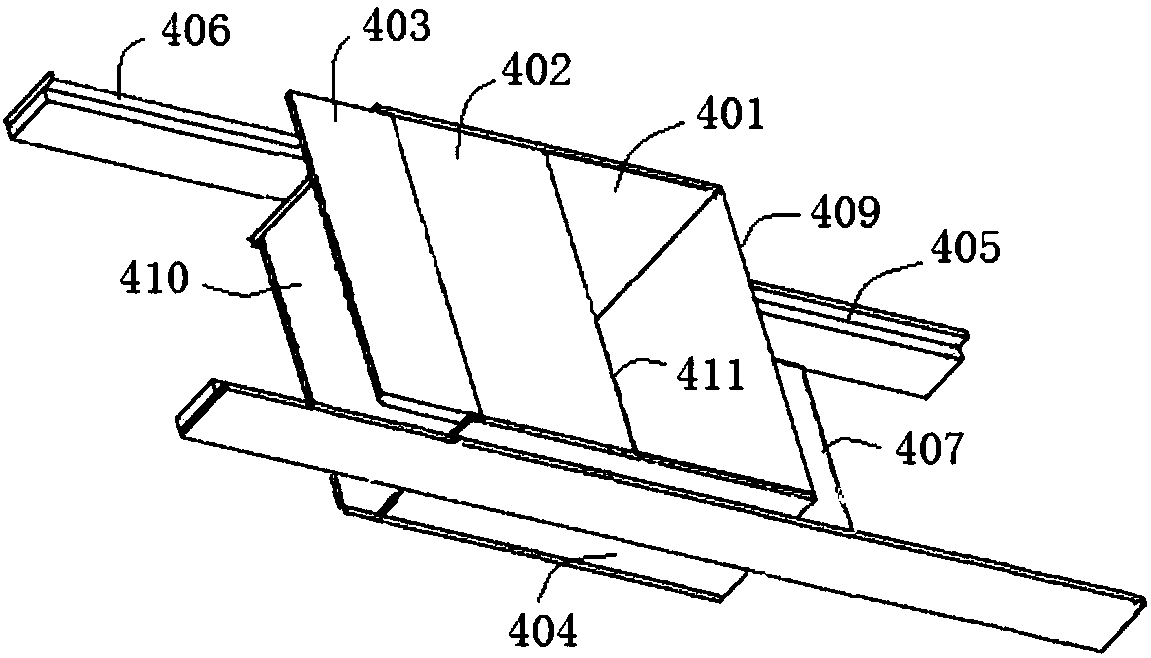

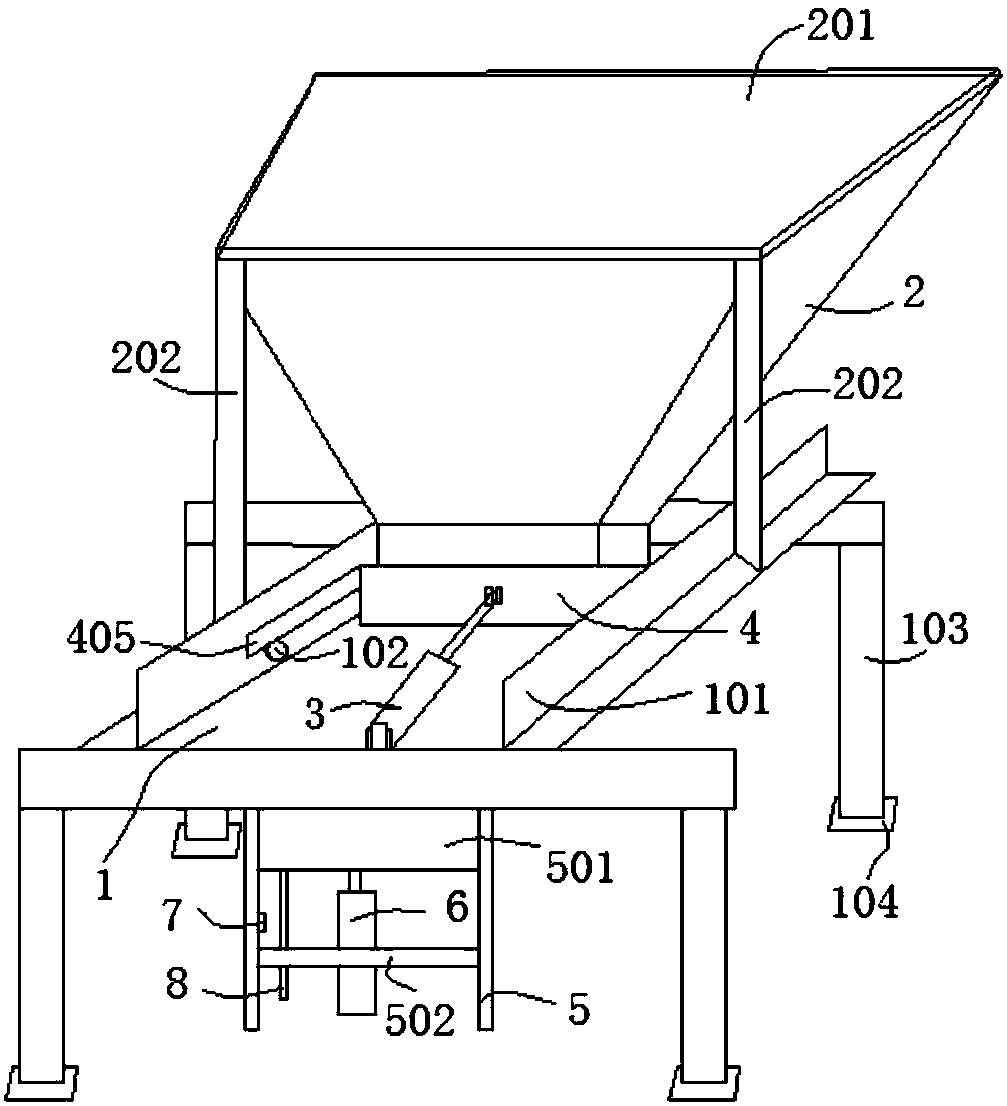

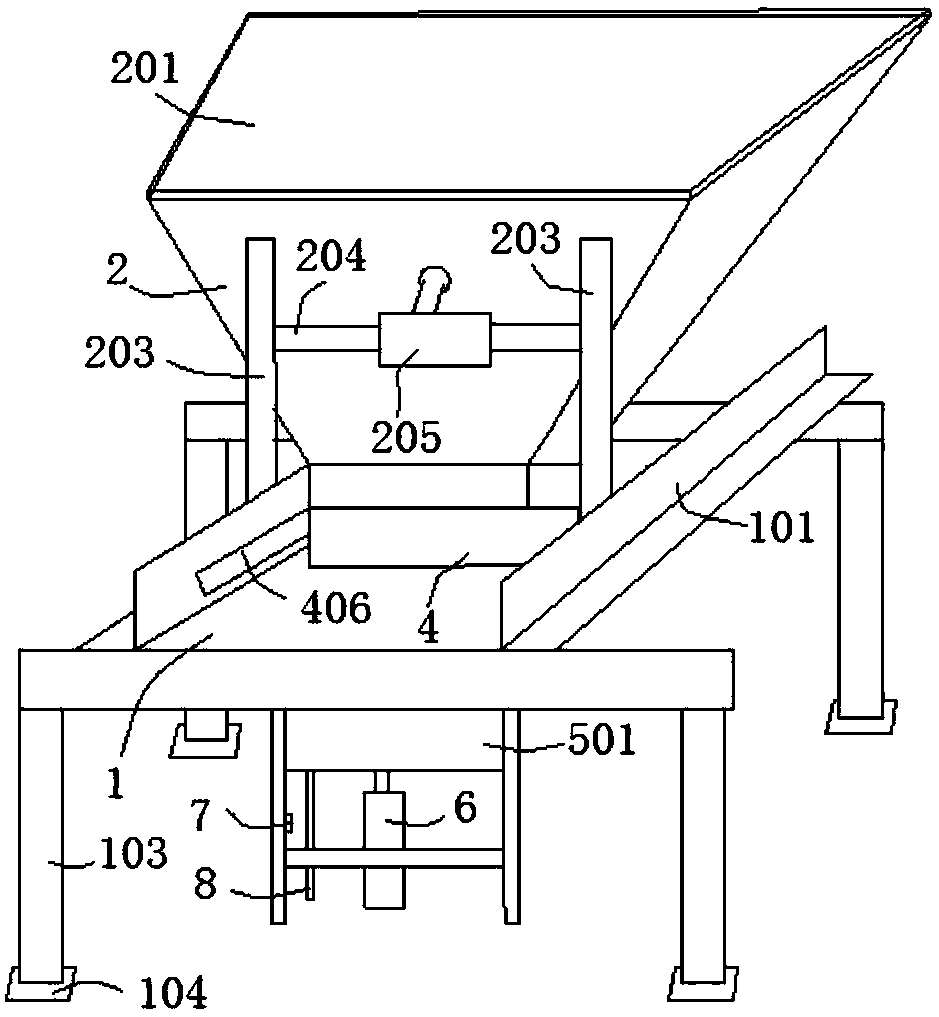

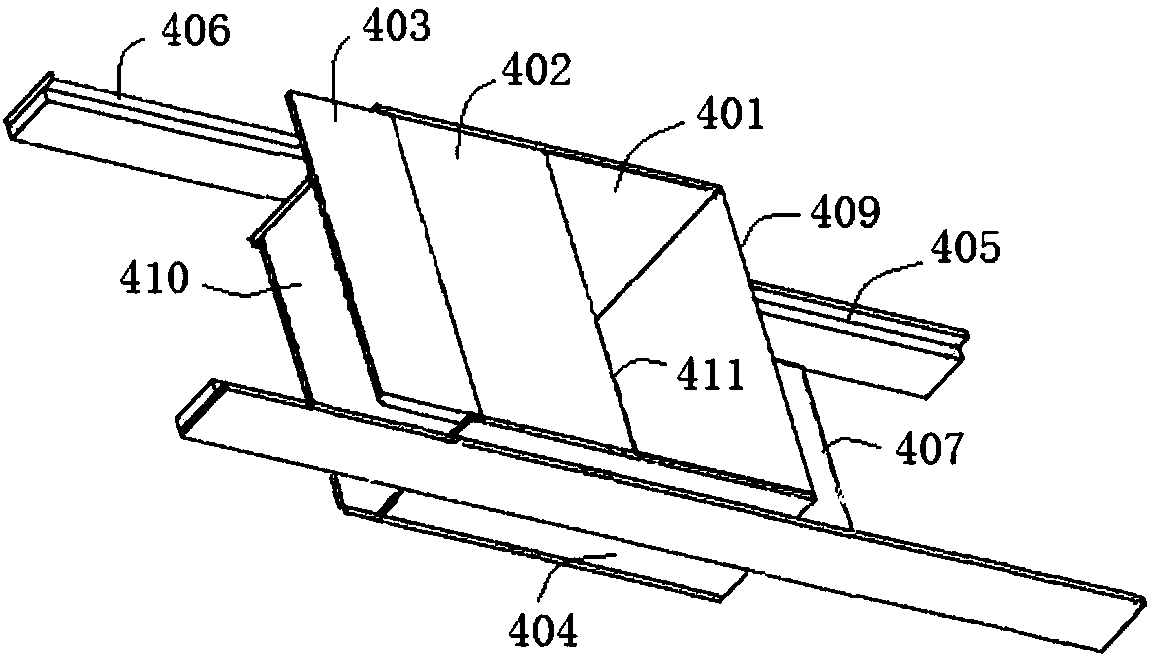

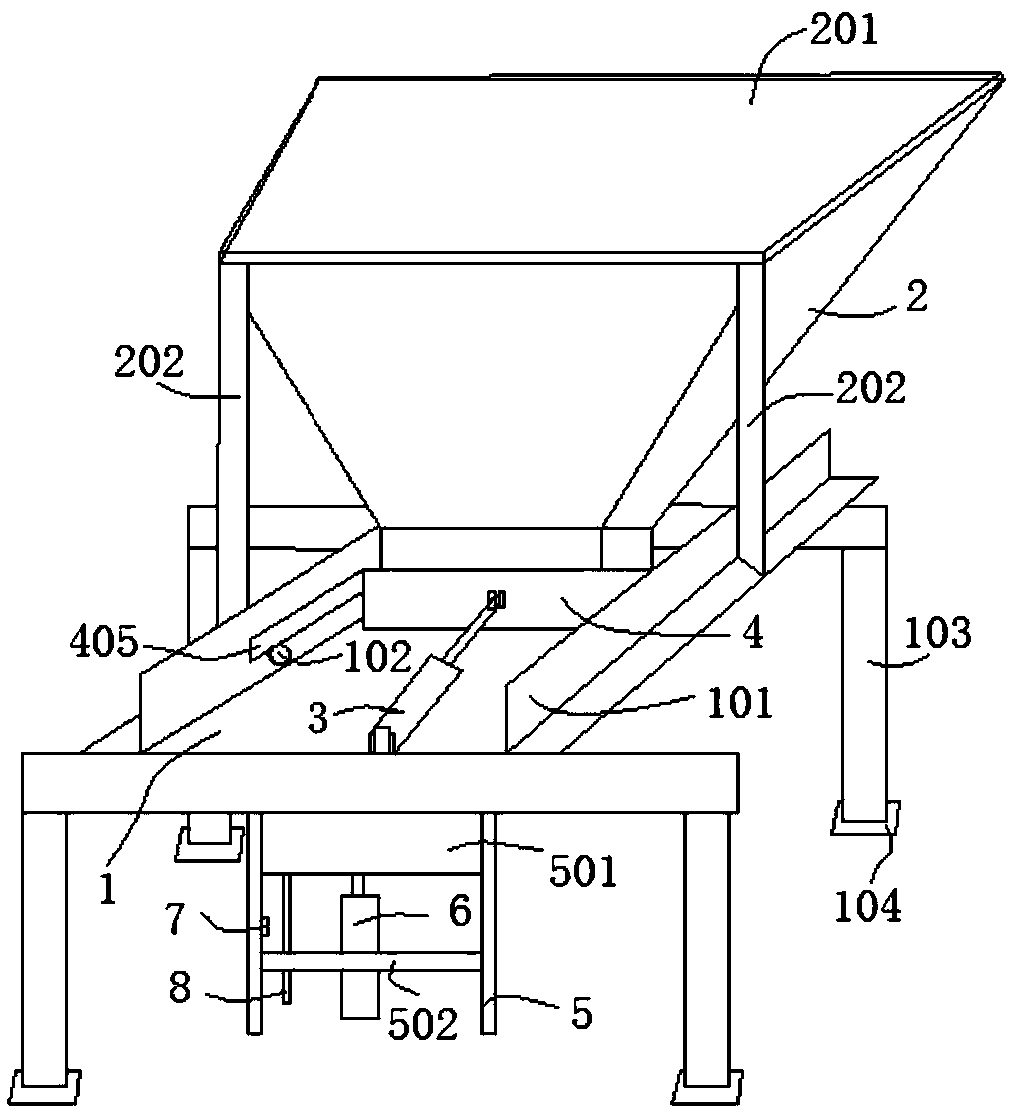

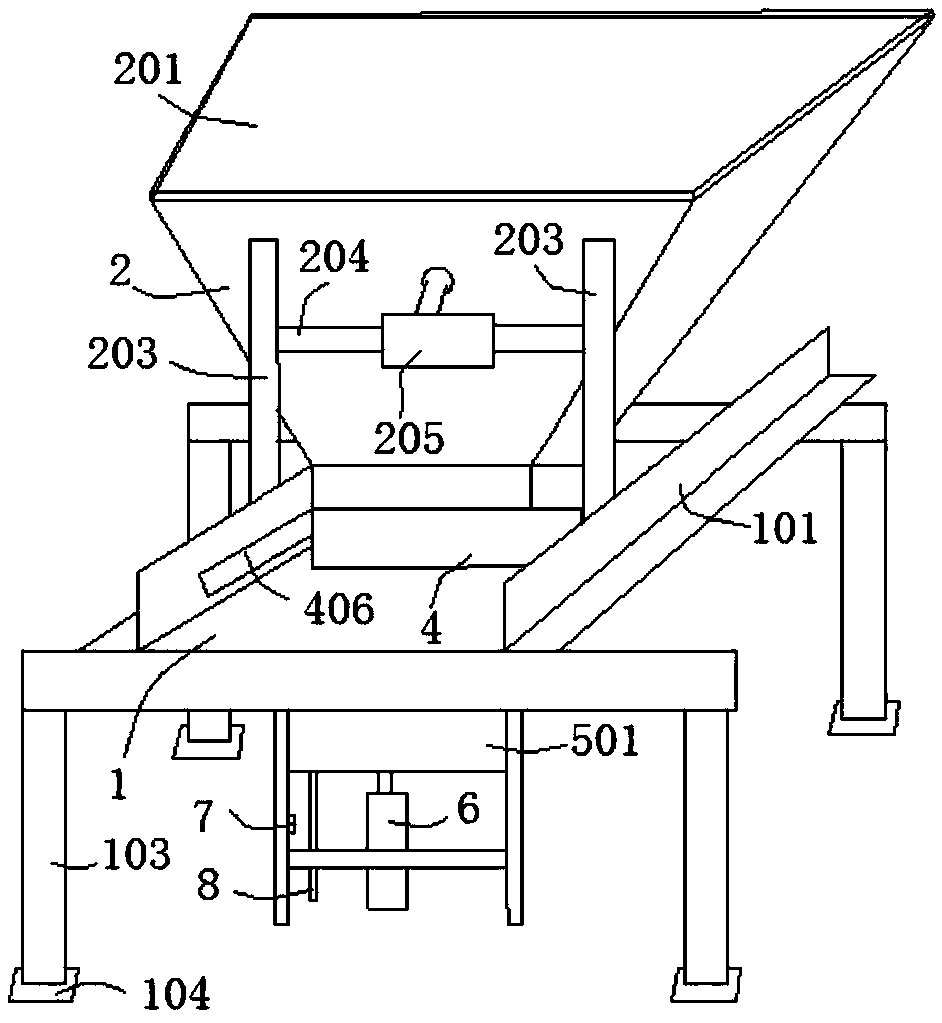

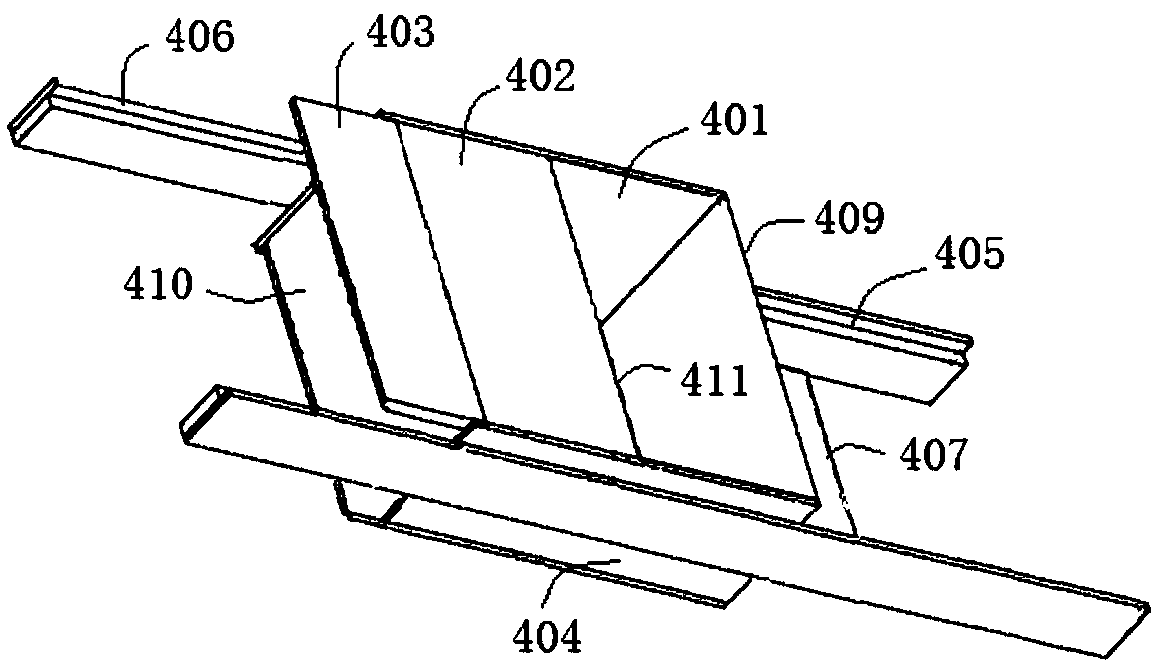

Automatic forming device for producing baking-free bricks

ActiveCN106313297AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

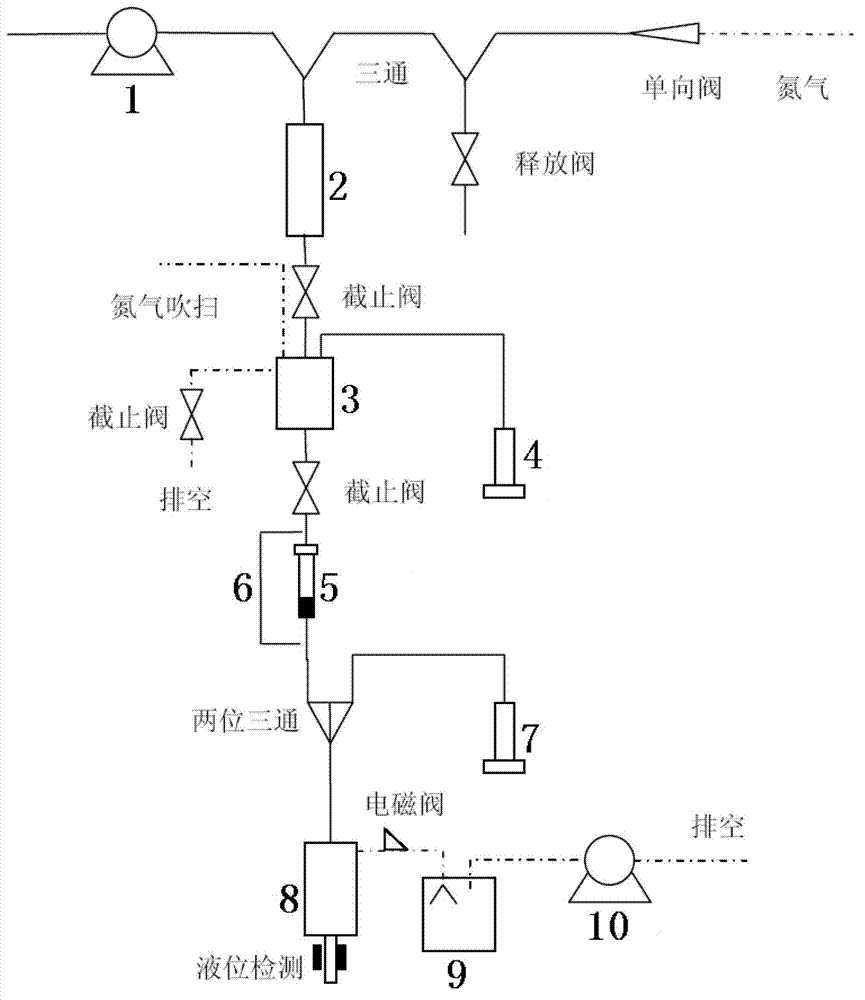

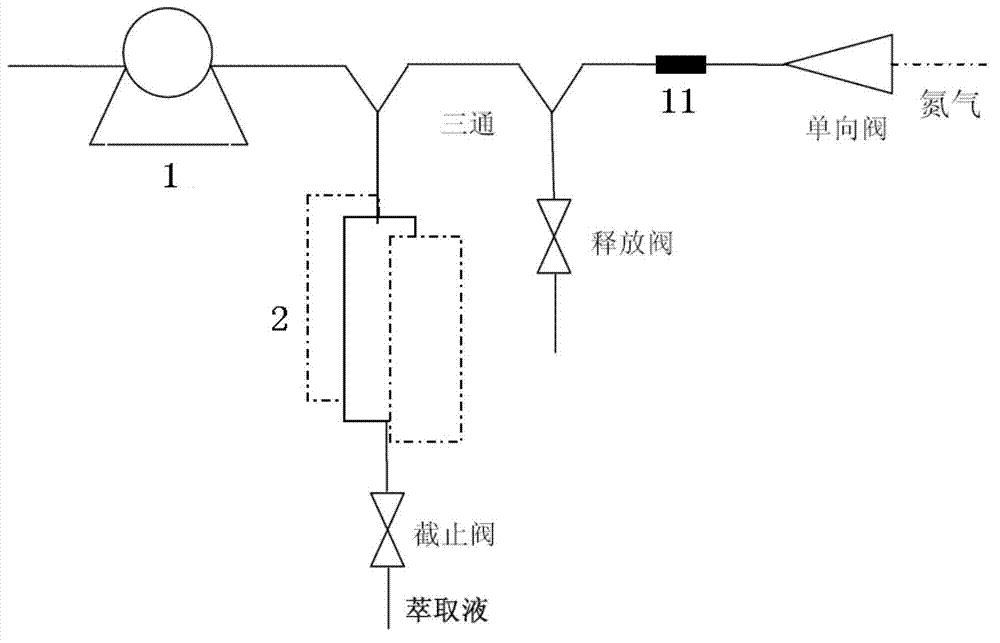

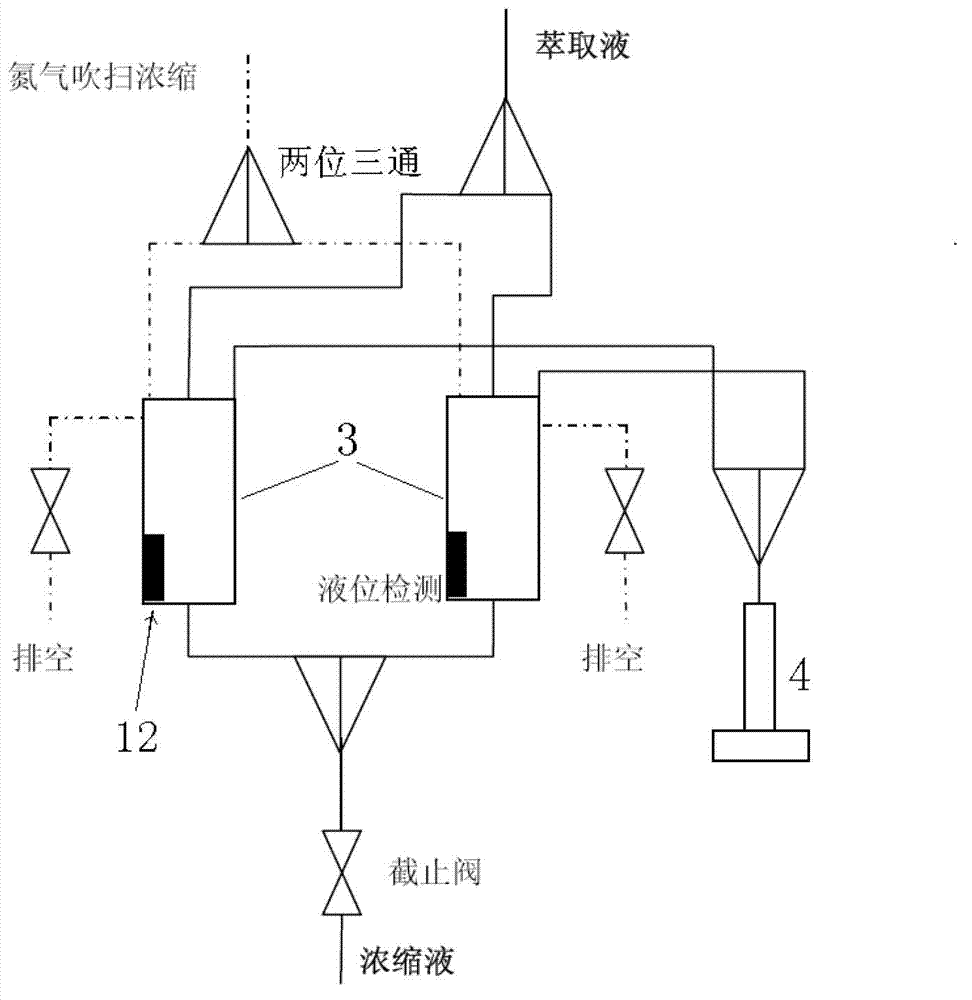

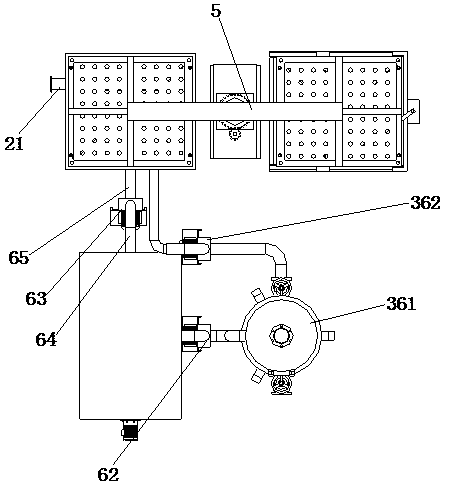

Organic pretreatment system for food samples

InactiveCN102788722ARealize continuous automatic processingRealize seamless linkPreparing sample for investigationEngineeringSolid phase extraction

The invention relates to an organic pretreatment system for food samples. The organic pretreatment system comprises an extraction module, a pre-concentration module, a purification module and a volume ensuring module. The extraction module comprises a high-pressure pump, a pressure-proof extraction and cleaning pool and a pressure and temperature control and protection valve unit and is used for extraction of the samples to obtain extract of a target compound. The pre-concentration module comprises a concentration cup, an infusion pump and a gas and liquid channel control valve unit and is used for concentration of the extract to obtain concentration liquid of the target compound. The purification module comprises an SPE (solid phase extraction) column and is used for purification of the concentration liquid to obtain purification liquid of the target compound. The volume ensuring module comprises a concentration cup, a cold trap, a vacuum pump and an infusion pump and is used for concentration and volume ensuring of the purification liquid. Under premise of guaranteeing organic pretreatment effect of the food samples, seamless connection between the samples to be detected and analyzing and detecting equipment is really achieved, unattended operation is achieved, and labor intensity of operators is reduced greatly.

Owner:BEIJING JITIAN INSTR CO LTD

Wastewater treatment equipment for aquaculture seawater

ActiveCN111217500AAchieve bactericidal effectFully absorbedSeawater treatmentWaste water treatment from animal husbandryPolycultureSewage

The invention discloses wastewater treatment equipment for aquaculture seawater. The invention relates to the technical field of wastewater treatment equipment. The equipment comprises an impurity filtering mechanism, a filtering box, a controller, a multi-stage treatment mechanism and a detection backflow mechanism, wherein the multi-stage treatment mechanism comprises an algae polyculture pond,a material mixing assembly, a sterilization assembly and a bacterium treatment cylinder, the impurity filtering mechanism comprises two multi-stage filtering parts, a position conversion assembly anda filter screen mesh dredging assembly, and the position conversion assembly comprises a mounting transverse plate, a height adjusting part and a rotating part. According to the invention, continuousautomatic treatment of aquaculture wastewater can be realized, under the action of the impurity filtering mechanism, a filter screen adhered with impurities can be replaced, meshes of the filter screen adhered with impurities can be dredged, and when the bacterium content and the nitrogen and phosphorus content do not reach the standard, a second water pump can convey sewage which does not reach the standard into the filtering box again, so that secondary purification operation on the sewage is realized.

Owner:SHANDONG BUSINESS INST

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

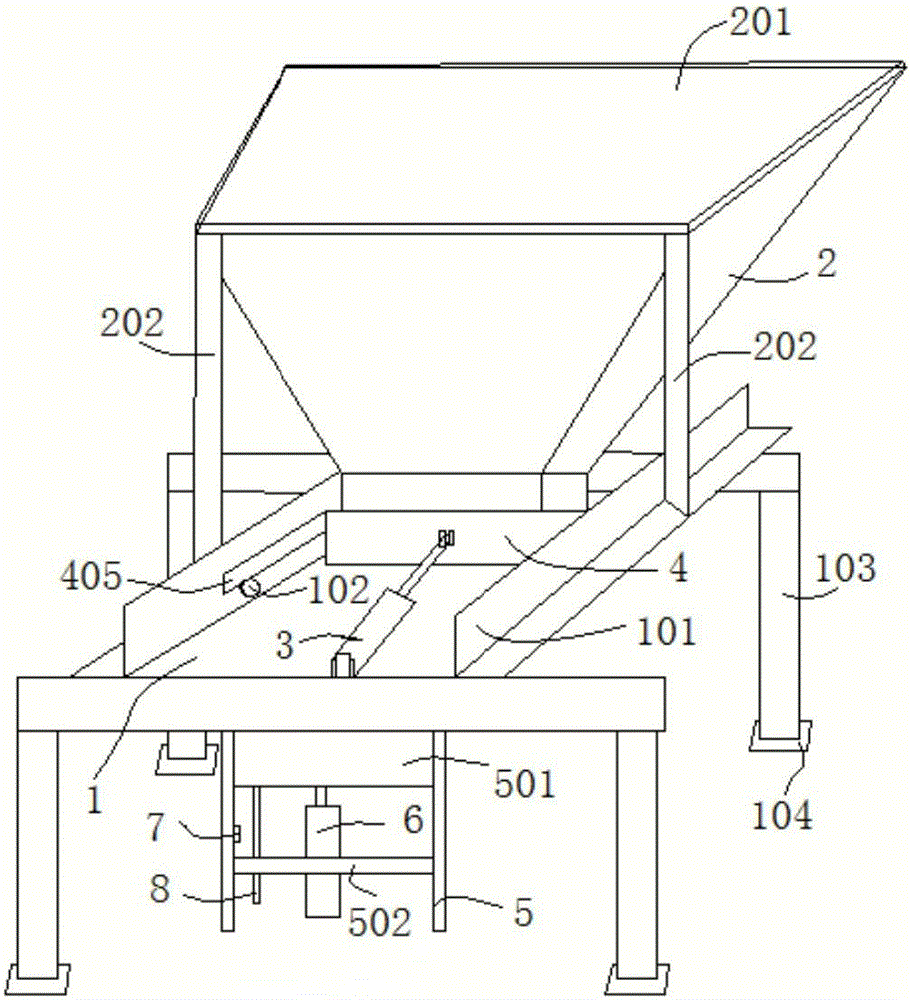

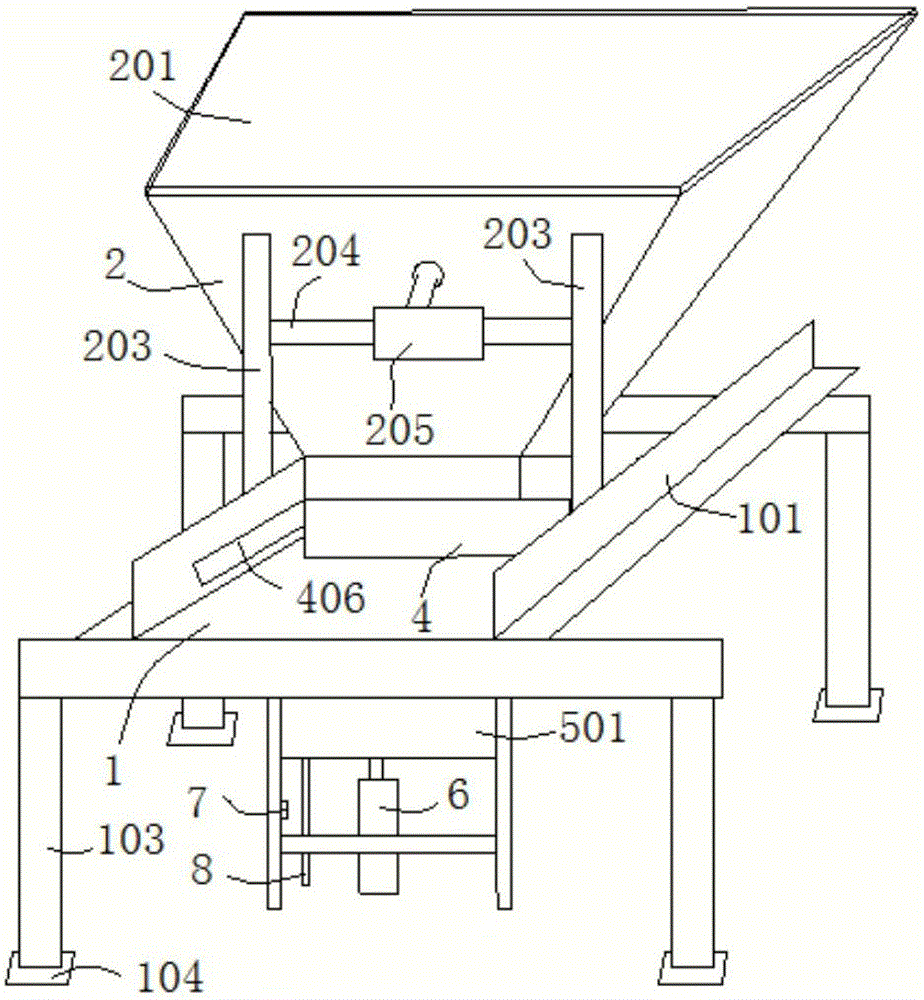

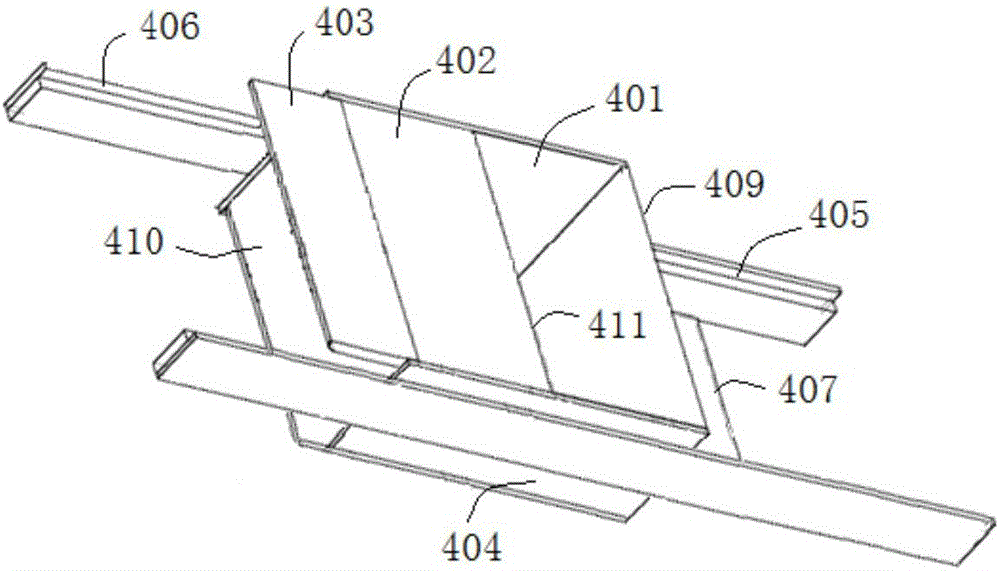

Continuous hydraulic processing system for baking-free bricks

ActiveCN106476120AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a continuous hydraulic processing system for baking-free bricks and belongs to the field of brickmaking machines. The continuous hydraulic processing system comprises a rack and a discharge hopper located above the rack, wherein a conveying mechanism for conveying brick blocks is arranged at one end of the rack; a discharge opening communicated with the bottom of the discharge hopper is formed in the rack; a forming and pushing mechanism is arranged between the rack and the discharge hopper; the forming and pushing mechanism is connected to a first hydraulic cylinder; a forming mechanism communicated with the discharge opening is arranged below the rack; the forming mechanism is connected to a second hydraulic cylinder; raw materials in the discharge hopper pass through the forming and pushing mechanism and then enter the forming mechanism; the second hydraulic cylinder extrudes the raw materials into brick blocks and push the brick blocks onto the rack; and the first hydraulic cylinder drives the forming and pushing mechanism to push the brick blocks onto the conveying mechanism for conveying. The continuous hydraulic processing system facilitates solving the problem that an existing brickmaking machine is low in continuous production degree and complex in production process, and can realize continuous extrusion forming of the brick blocks, the production efficiency is effectively improved, the production process is simple, the processing cost is low, and improvement on production benefits of an enterprise is facilitated.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

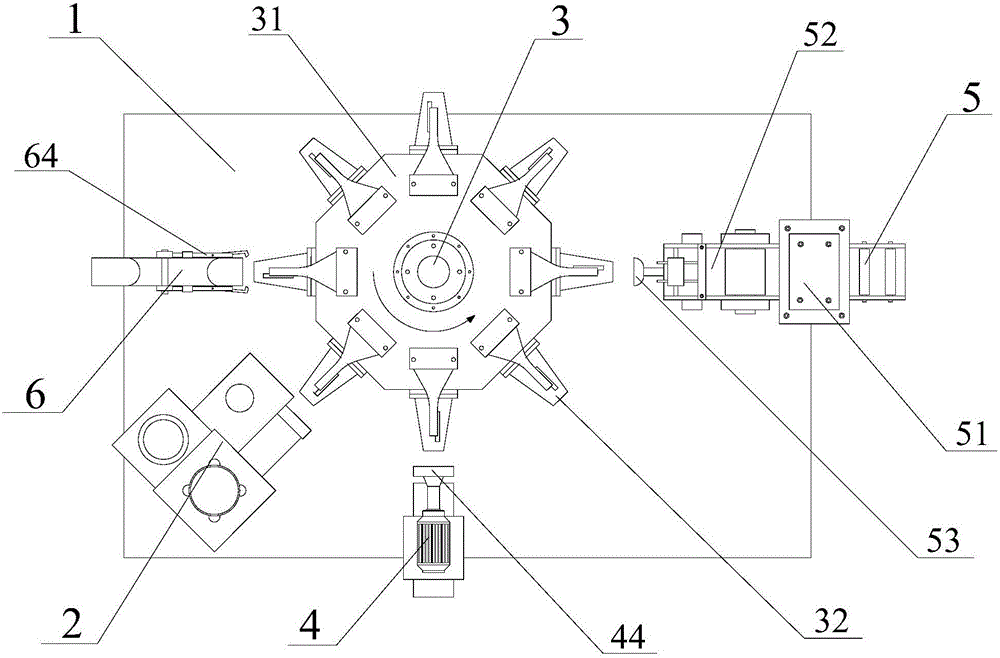

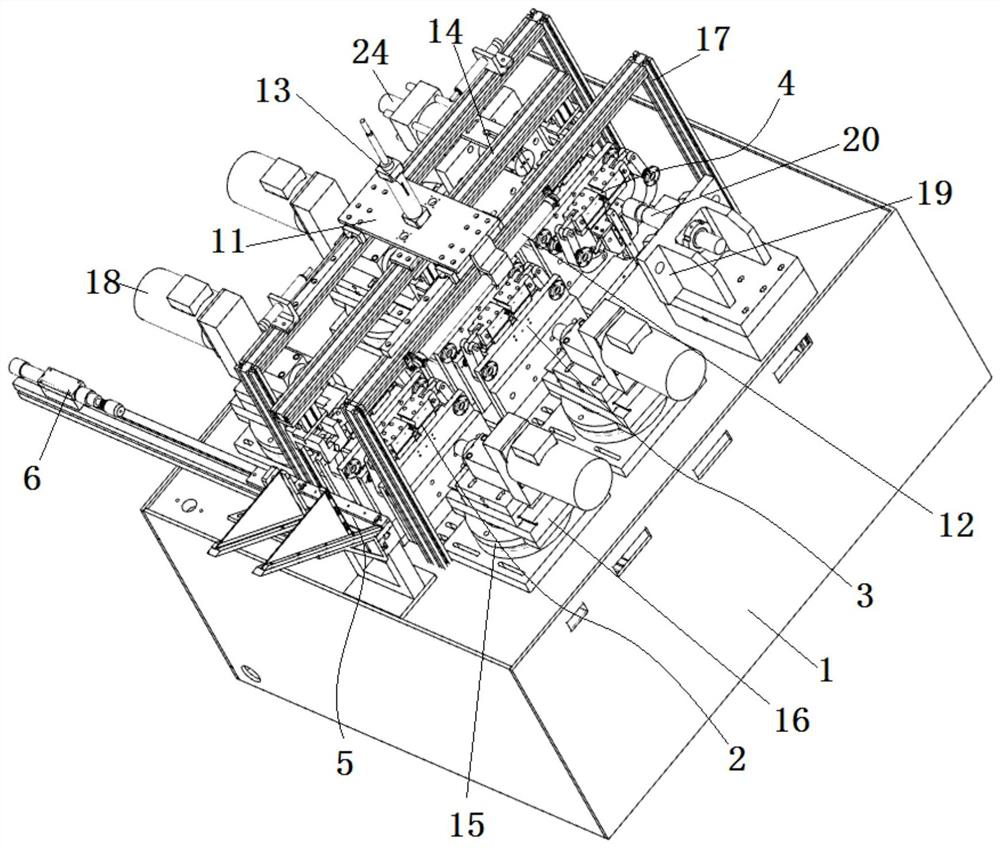

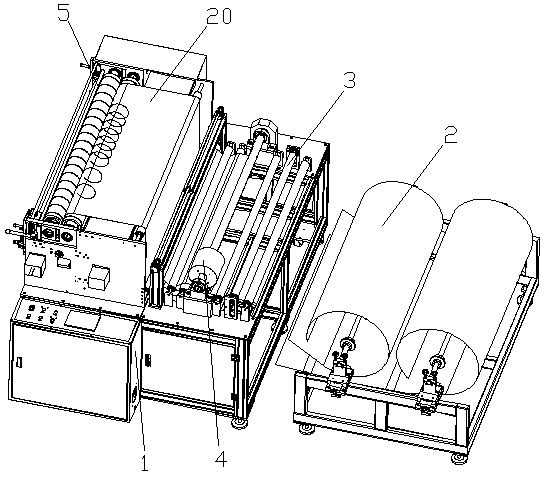

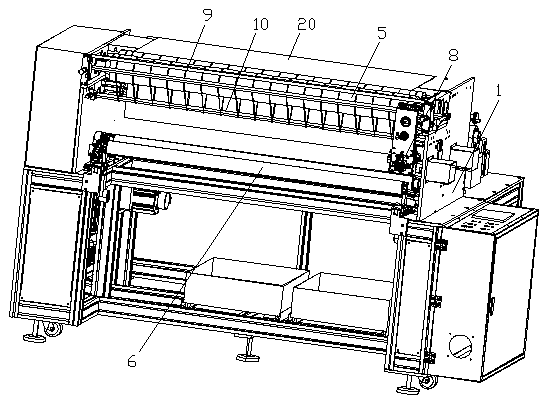

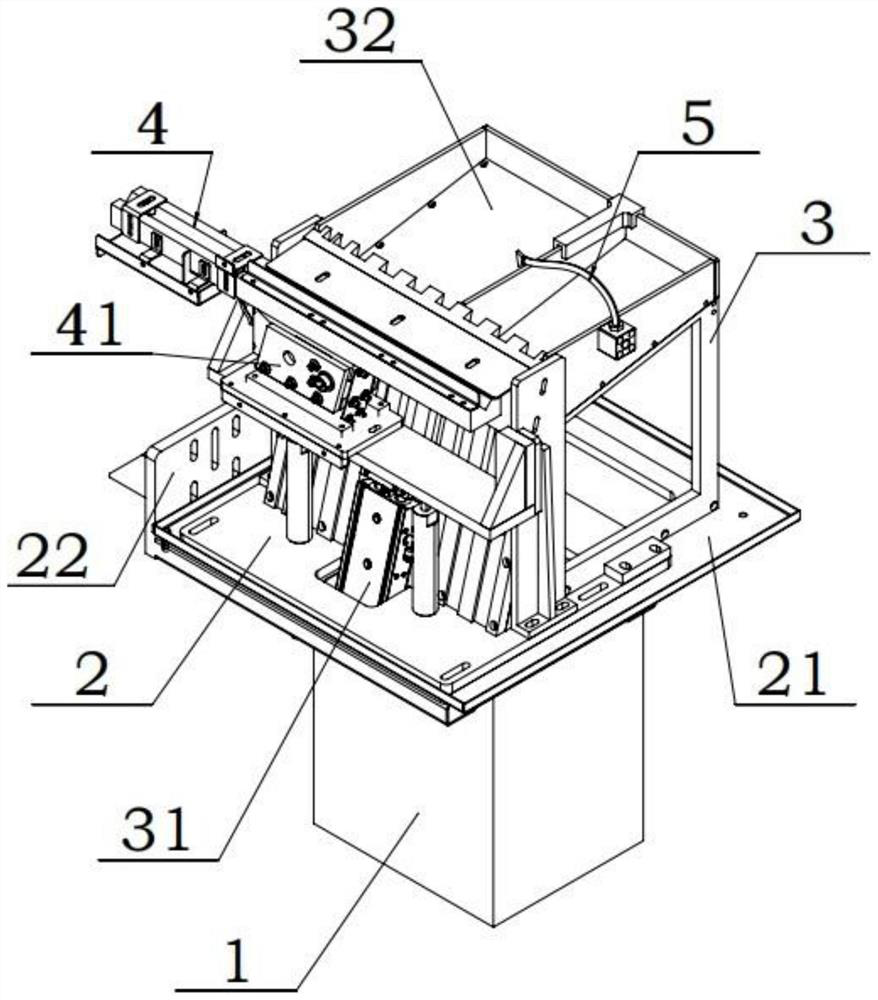

Processing device for paper cups with handles

ActiveCN105058865ARealize continuous automatic processingImprove work efficiencyBox making operationsPaper-makingPulp and paper industryPaper cup

The invention discloses a processing device for paper cups with handles. The processing device for the paper cups with the handles comprises a machine frame, a paper cup feeding control mechanism, a piece attaching control mechanism, a handle paper feeding mechanism and a cup receiving control mechanism. The paper cup feeding control mechanism, the handle paper feeding mechanism and the cup receiving control mechanism are all fixed to the machine frame. The piece attaching control mechanism is mounted at the center of the machine frame and can rotate automatically. The piece attaching control mechanism sequentially passes through the paper cup feeding control mechanism, the handle paper feeding mechanism and the cup receiving control mechanism when rotating, and circulation is formed. The processing device for the paper cups with the handles has the advantages that continuous and automatic processing of the cups with the handles is achieved through the rotation of the piece attaching control mechanism and the cooperation of the periodic operation of all the control mechanisms, and the work efficiency of paper cup piece-attaching processing and the product quality are greatly improved; the processing device is stable in structure and convenient to operate and has high practicability and high promotional value.

Owner:宣城市博思特日用品有限公司

A processing method for extruding unburned bricks

ActiveCN106626003BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Processing device with functions of aligning and limiting for paper cup with handle

ActiveCN105109106AImprove work efficiencyImprove product qualityBox making operationsPaper-makingPaper cupPulp and paper industry

The invention discloses a processing device with functions of aligning and limiting for a paper cup with a handle. The device comprises a rack, a paper cup feeding control mechanism, a sticking control mechanism, a paper cup clamping mechanism, a handle paper feeding mechanism and a cup receiving control mechanism, wherein the sticking control mechanism comprises a rotating plate and a sticking device; the rotating plate is horizontally mounted on the rack; a plurality of cup dies are arranged on the rotating plate and horizontally fixed on the circumferential surfaces of the rotating plate as well as being radially symmetrically distributed along the center of the rotating plate; the cup dies sequentially pass through the abovementioned mechanisms as the rotating plate rotates, so as to achieve the automatic sticking of the paper cup with the handle; limiting cards are mounted on the cup dies. The device has the advantages that the handles of the paper cups can be continuously stuck, so that the production efficiency can be greatly improved; in addition, handle paper can precisely cling to the paper cup, thus improving the product quality as well as prolonging the service life. The device is stable in structure, convenient to operate, outstanding in practicability, and valuable of popularization.

Owner:宣城市博思特日用品有限公司

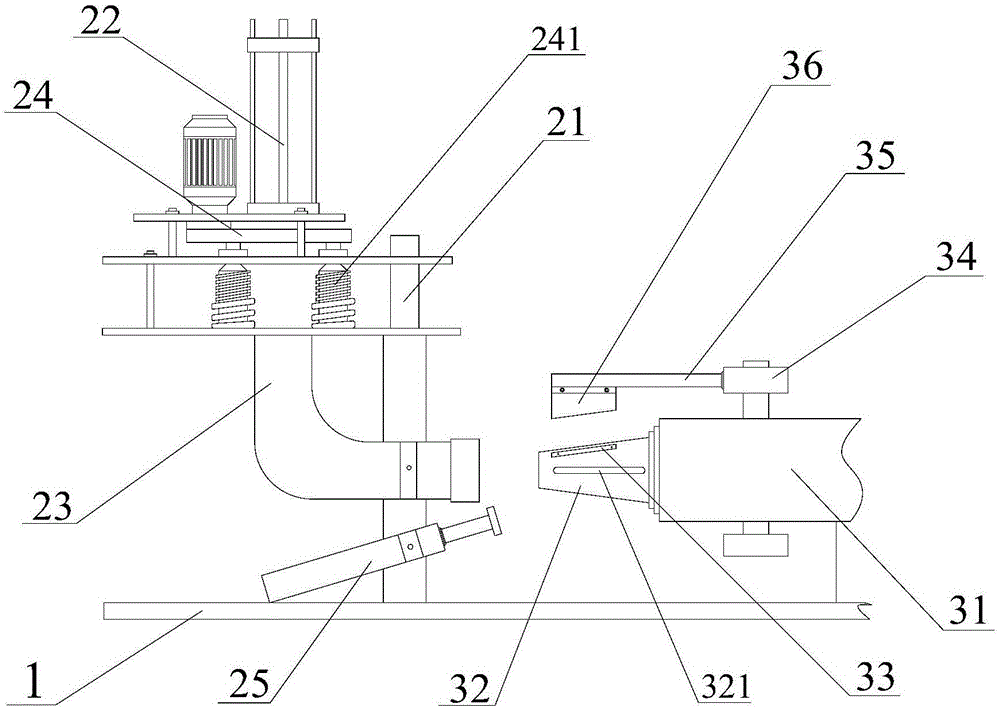

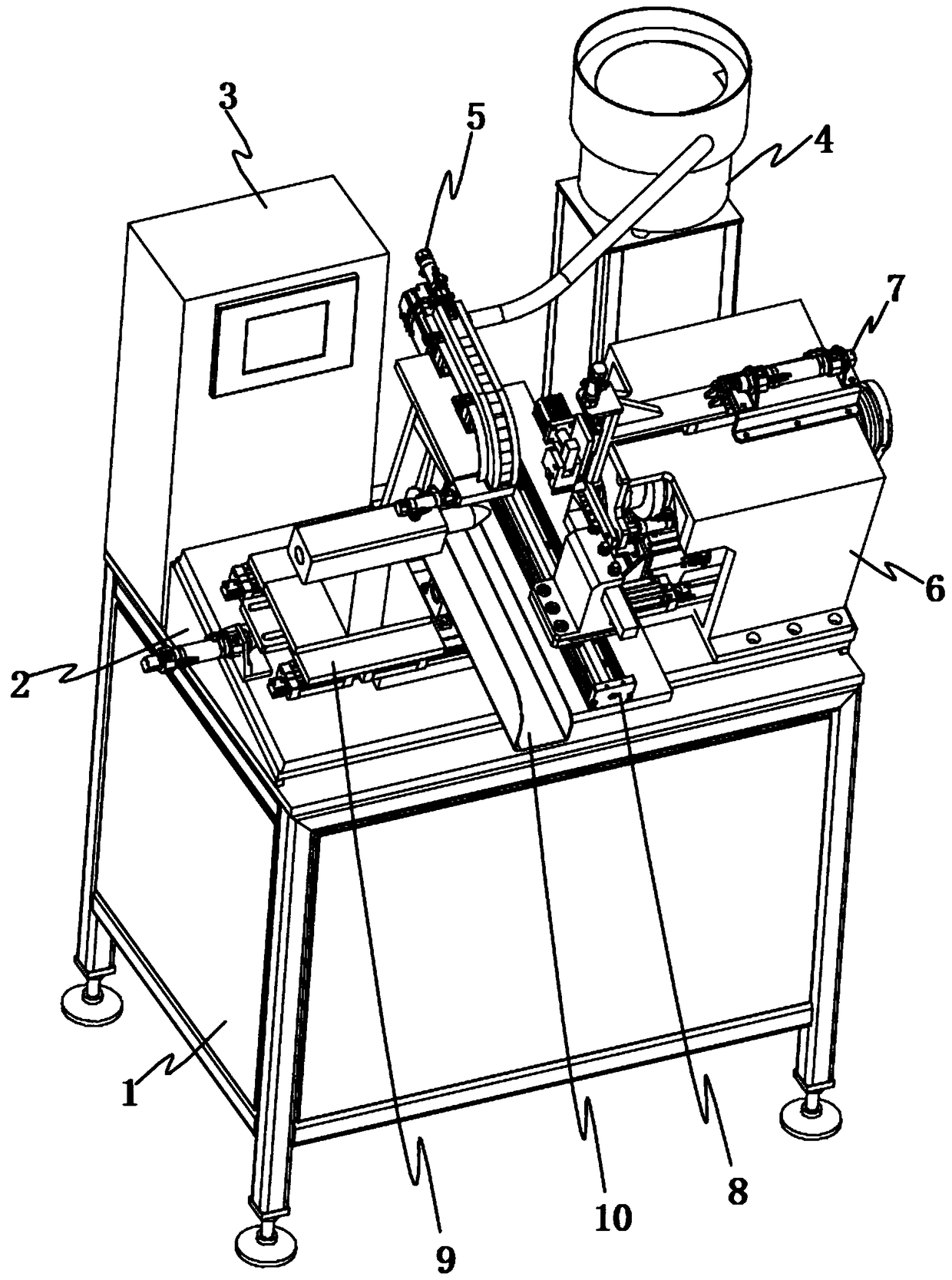

Automatic spectacle frame welding machine

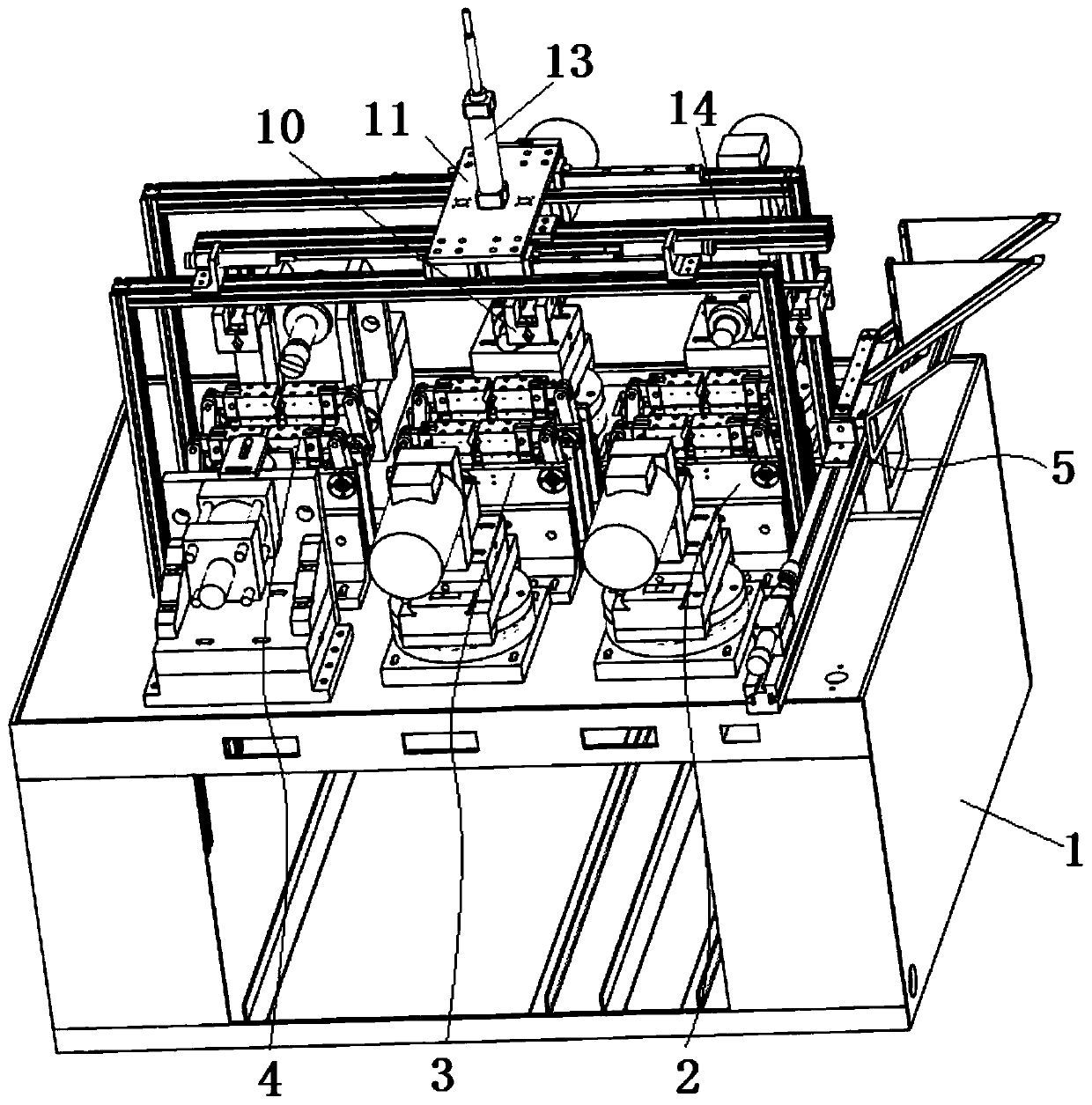

PendingCN111318804ARealize continuous automatic processingImprove processing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingAutomatic processing

The invention discloses an automatic spectacle frame welding machine. The welding machine comprises two sets of spectacle ring welding devices which are symmetrically arranged and a welding table, wherein each spectacle ring welding device comprises a machine frame, a rotary table arranged on the machine frame and a feeding assembly, and at least one set of feeding assembly is arranged on the rotary table; and each feeding assembly comprises a spectacle ring mold seat used for containing spectacle rings and a positioning device capable of fixing the spectacle rings on the spectacle ring mold seat, the spectacle ring mold seat is provided with an abutting block capable of pushing a welding portion of the spectacle ring, and each feeding assembly further comprises a spot welding assembly, avibration plate, a welding assembly, a cutting assembly and a spectacle frame mold seat. According to the automatic spectacle frame welding machine, the spectacle ring welding devices and the weldingtable are arranged, so that a plurality of procedures of spectacle frame processing can be carried out on one machine, so that continuous automatic processing of the spectacle rings and spectacle frames can be realized, and the machining efficiency is greatly improved.

Owner:温州艾特科智能科技有限公司

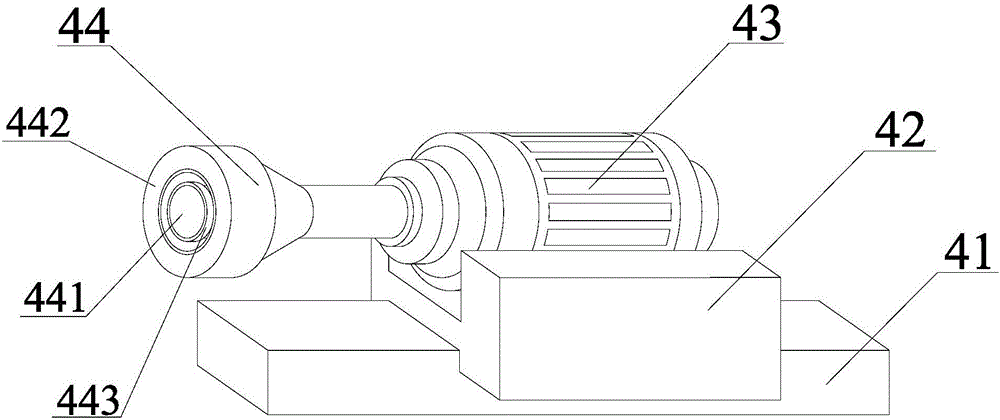

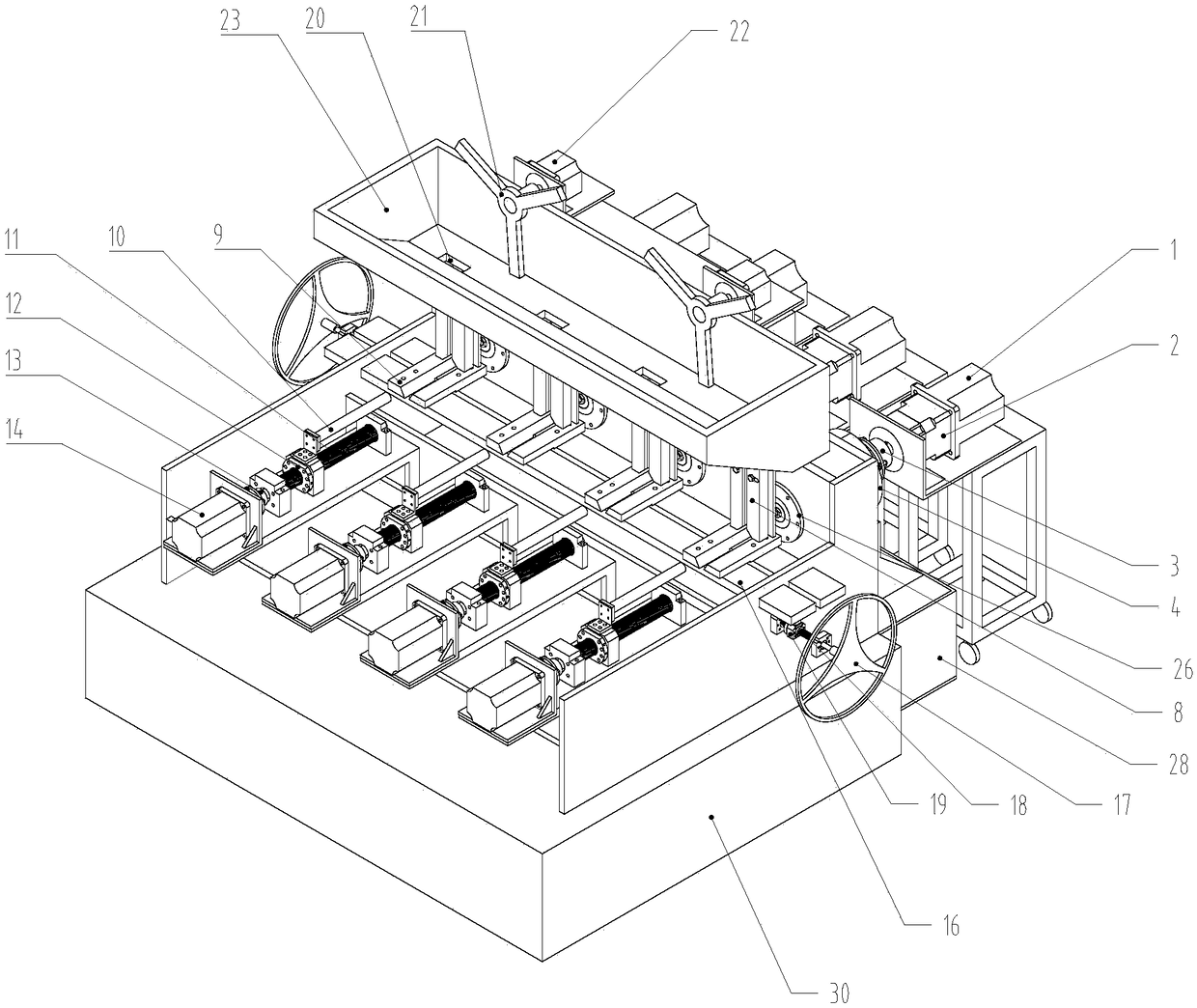

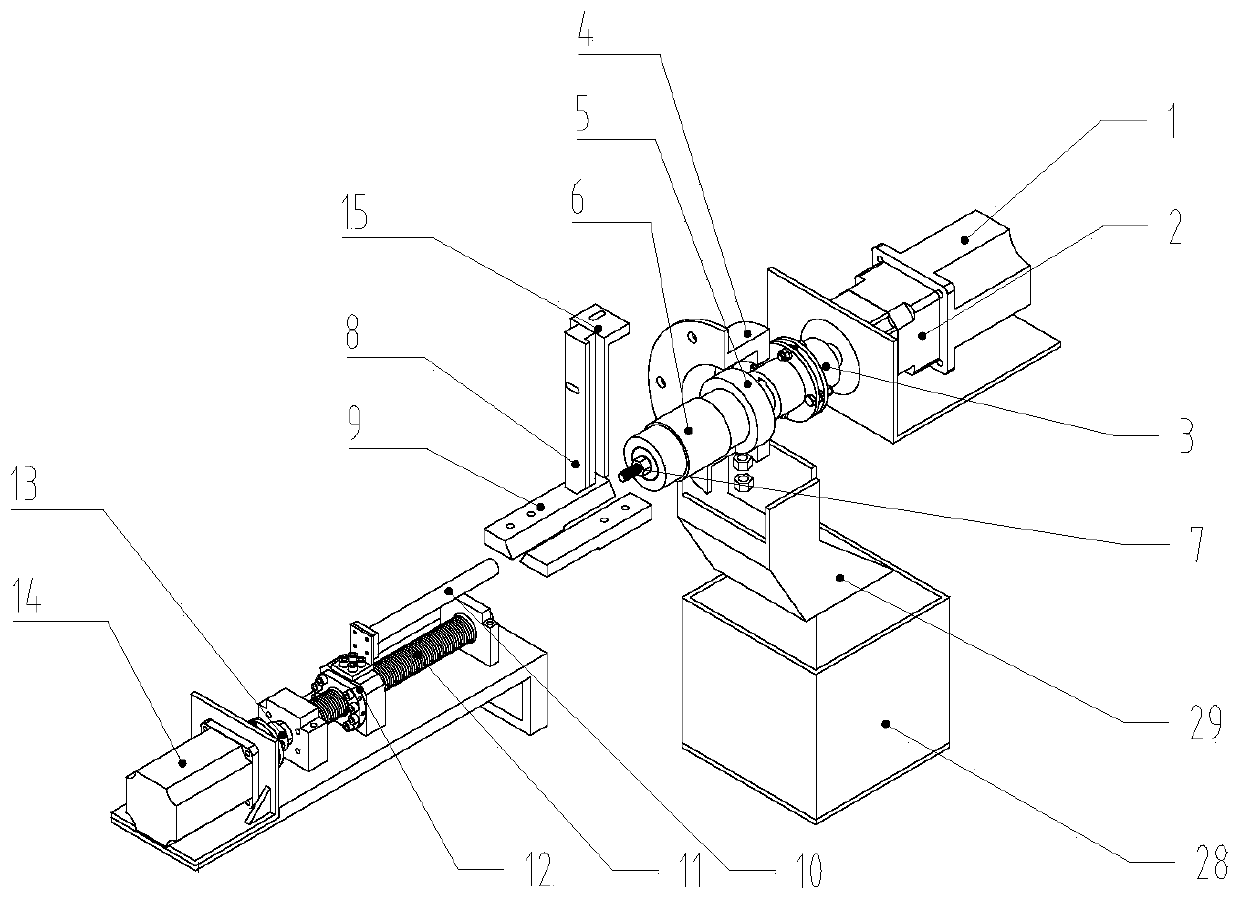

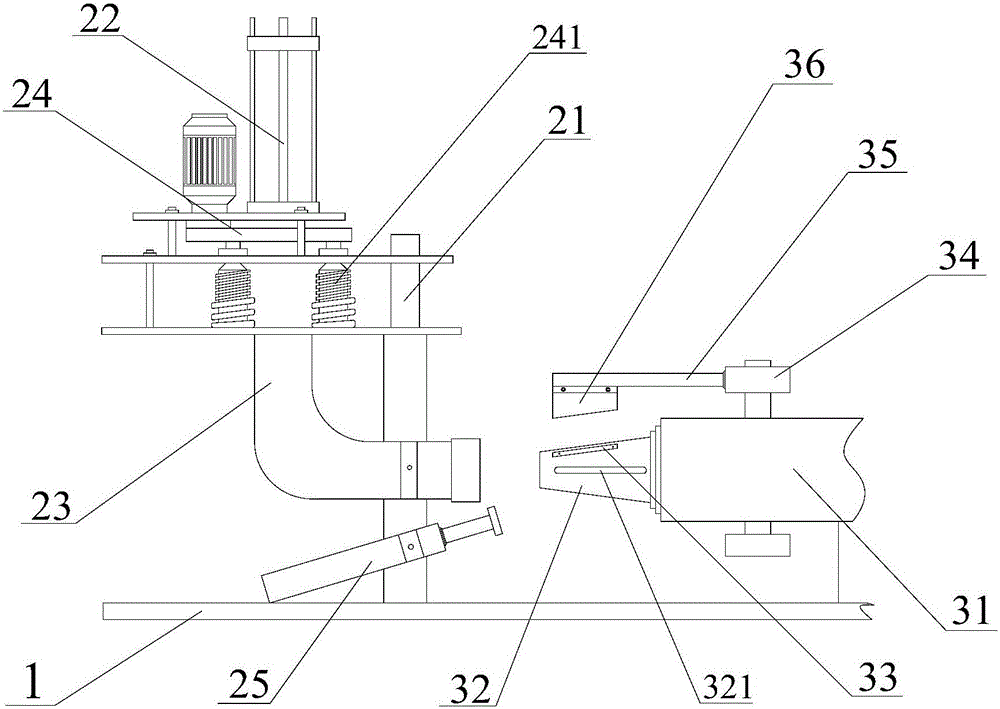

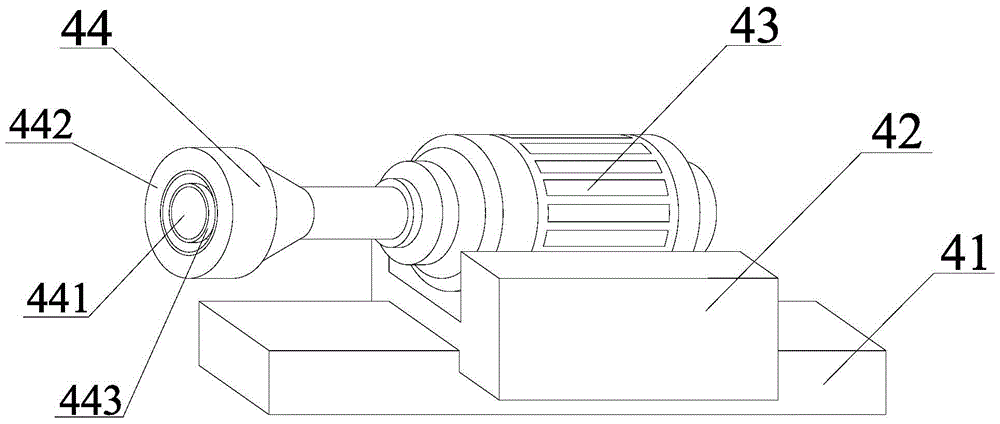

Full-automatic vibration cold extruding plastic forming device and technology for small-medium-diameter internal threads

ActiveCN108465886AAvoid excessive torqueGuaranteed tapping qualityThread cutting feeding devicesThread cutting machinesWork in processEngineering

The invention discloses a full-automatic vibration cold extruding plastic forming device and technology for small-medium-diameter internal threads. The full-automatic vibration cold extruding plasticforming device comprises extrusion taps, the extrusion taps are driven by tapping motors different in forward and reverse rotation angle to achieve vibration tapping and are installed in driving shafts, the driving shafts are installed in guide shafts, and the extrusion taps can move in the axial direction but are limited by chucks; and a semi-finished product feeding mechanism is arranged above the extrusion taps, to-be-machined nuts sequentially enter two feeding rails to be arranged under the action of stirring rods, pushing mechanisms are arranged in front of the extrusion taps, and push rods pushed by pushing motors push the to-be-machined nuts to be sleeved the extrusion taps for tapping machining. The full-automatic vibration cold extruding plastic forming device has the advantagesof being high in machining efficiency and easy to operate. The technology has the advantages that the material utilization rate is high, and the cold-extruded internal threads are high in strength andprecision and good in surface smoothness. Through the full-automatic vibration cold extruding plastic forming device and technology, automatic and efficient machining of internal threads for hexagonnuts with multiple specifications and thicknesses or parts in other shapes can be achieved.

Owner:XI AN JIAOTONG UNIV

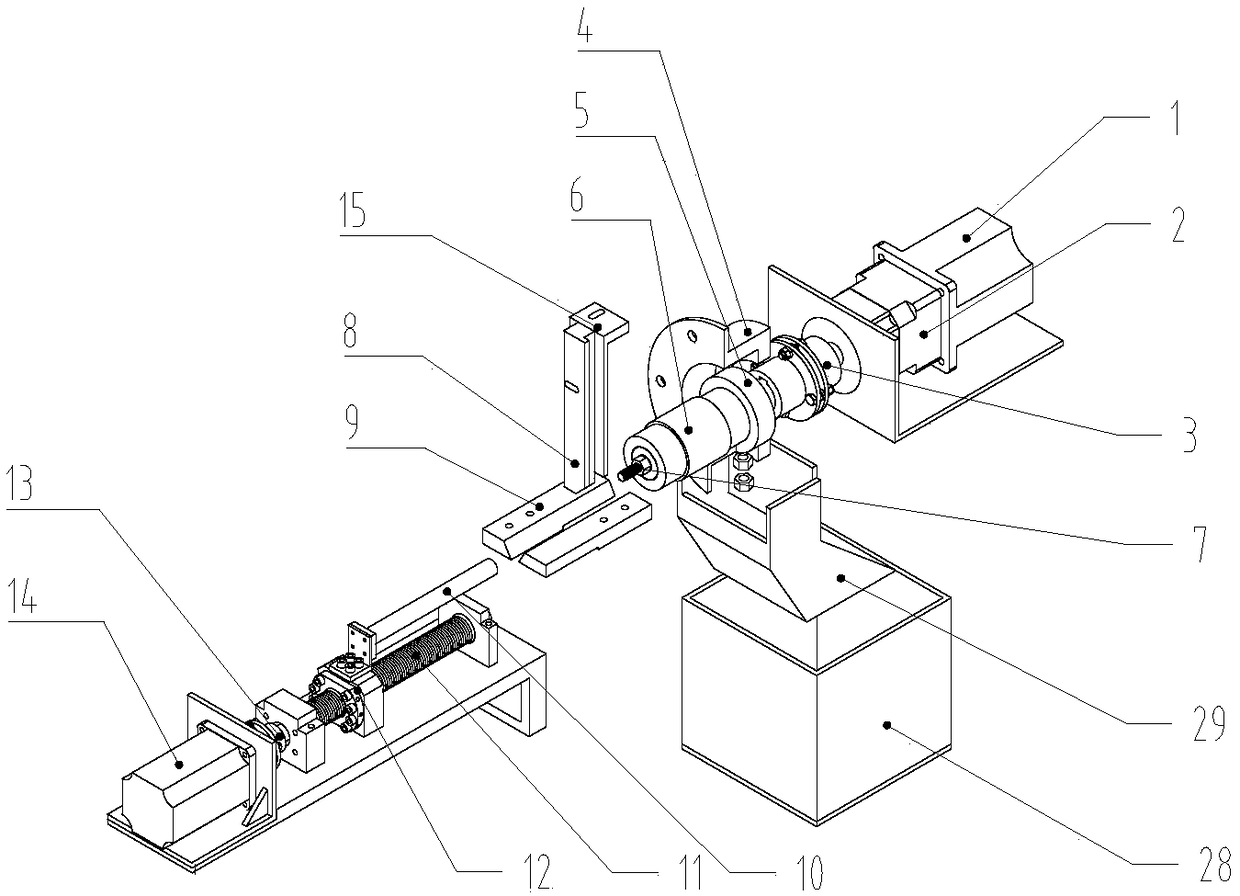

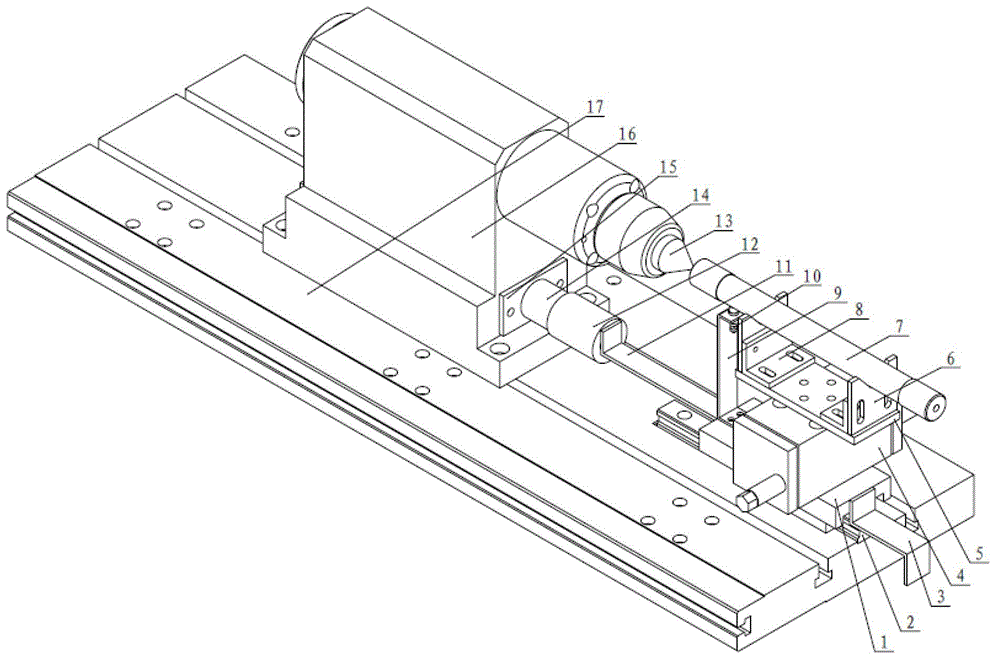

Automatic rotation part for support material

ActiveCN103317070ARealize continuous automatic processingSimple structureGear wheelsRotary stageEngineering

The invention discloses an automatic rotation part for a support material. The automatic rotation part comprises a small automatic 180-degree rotation table, a rotation table sliding saddle, a linear rail, a bracket base plate, an L-shaped bracket, a V-shaped bracket, an inductive switch support, a front limit stop block, a connection rod, a sleeve, a support cylinder, a spring, a sliding rod, a bearing, a front press cover and a rear press cover. The rotation table sliding saddle is fixed above the linear rail which is fixed on a front tailstock sliding saddle, the front limit stop block is fixed on the front side of the rotation table sliding saddle, the small automatic 180-degree rotation table is fixed above the rotation table sliding saddle, the bracket base plate is fixed on the small automatic 180-degree rotation table 4, the L-shaped bracket is fixed on the bracket base plate, the V-shaped bracket is fixed on the L-shaped bracket, the inductive switch support is mounted on the rotation table sliding saddle, an inductive switch is mounted on the inductive switch support, the connection rod is fixed between the rotation table sliding saddle and an internal sliding guide rod of the sleeve, a tailstock is mounted on a tailstock base, front and rear baffles are mounted on the tailstock base to prevent the bearing from being exposed, and the tailstock base is mounted on the front tailstock sliding saddle. By means of the automatic rotation part, automation is achieved, and a basis is provided for continuous production.

Owner:ANHUI LICHENG MACHINERY EQUIP

Continuous automatic tool machining device

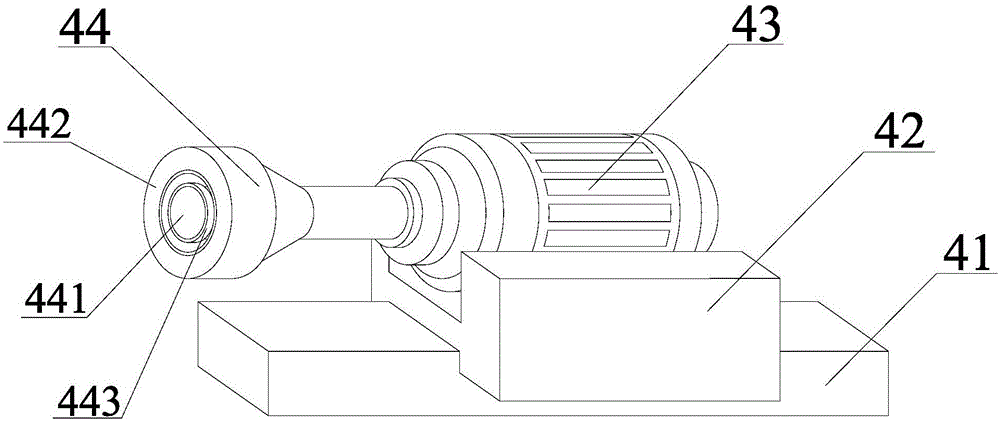

InactiveCN103128610ARealize continuous automatic processingImprove processing efficiencyOther manufacturing equipments/toolsPistonRotational axis

The invention provides a continuous automatic tool machining device which comprises an auto-clamping precision rotating shaft and a support module. The auto-clamping precision rotating shaft mounted on X-axis comprises a bar clamping module. The bar clamping module comprises a piston cavity located in a rotor adapter, the piston cavity is provided with an air guide hole and a piston post inside. The piston post is connected with a gripper handle through a precision spring. A gripper is fixed on the inner side of a round end cover. The support module mounted on X-axis comprises a Y-axial and Z-axial sliding table, a cylinder and a shaft sleeve. A parallel two-finger clamp serves as an output end of the cylinder. The gripper and the shaft sleeve are collinear and are coordinated with the parallel two-finger clamp to act. The precision rotating shaft has the function of automatic clamping. The support module and a support frame are fitted to two ends of the bar, pneumatic technology is applied, and accordingly continuous automatic machining of tools can be achieved by pre-feeding and simple adjustment. Precision is guaranteed, feeding times are decreased, automation level is increased, and machining efficiency of precision tools is increased and cost is lowered.

Owner:KUNSHAN YUNCO PRECISION IND TECH

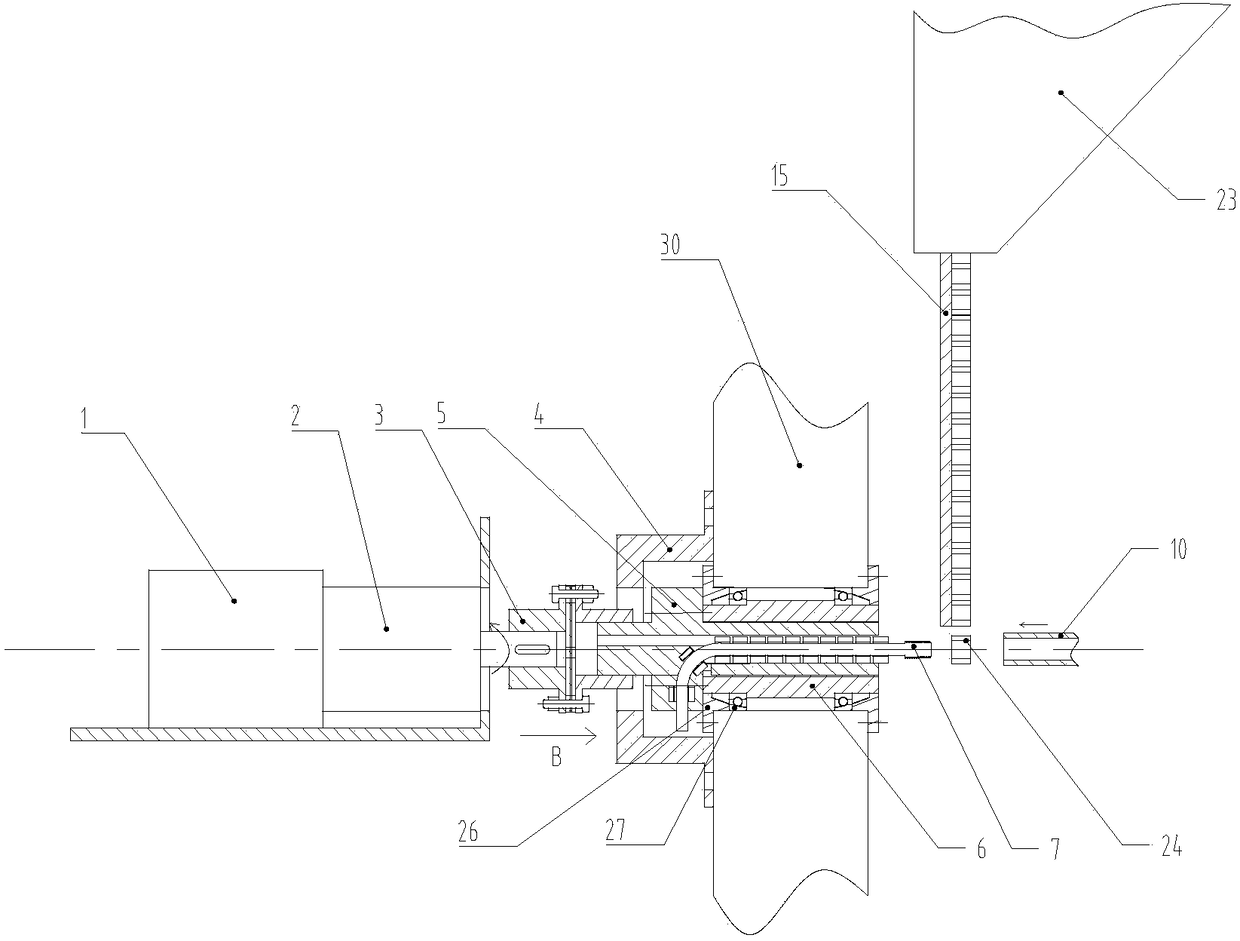

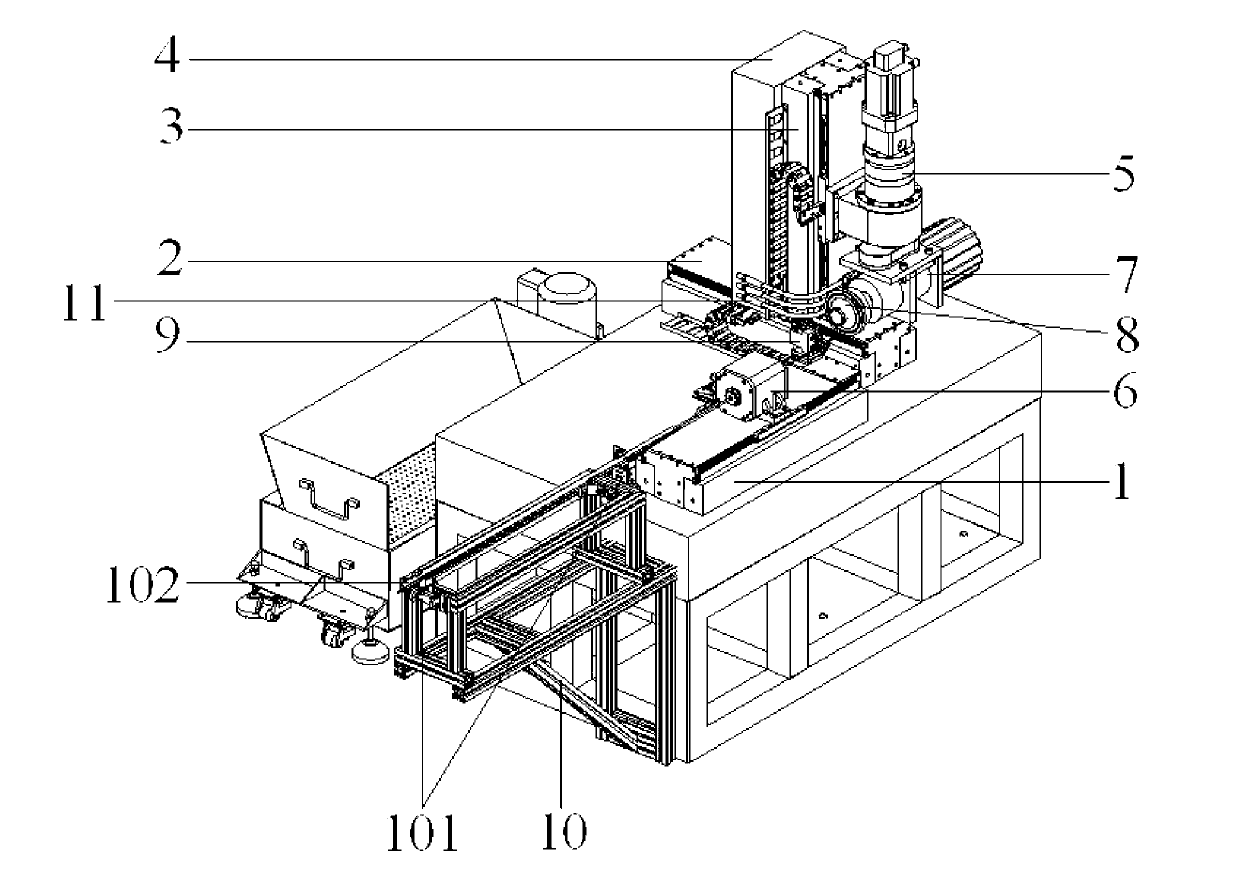

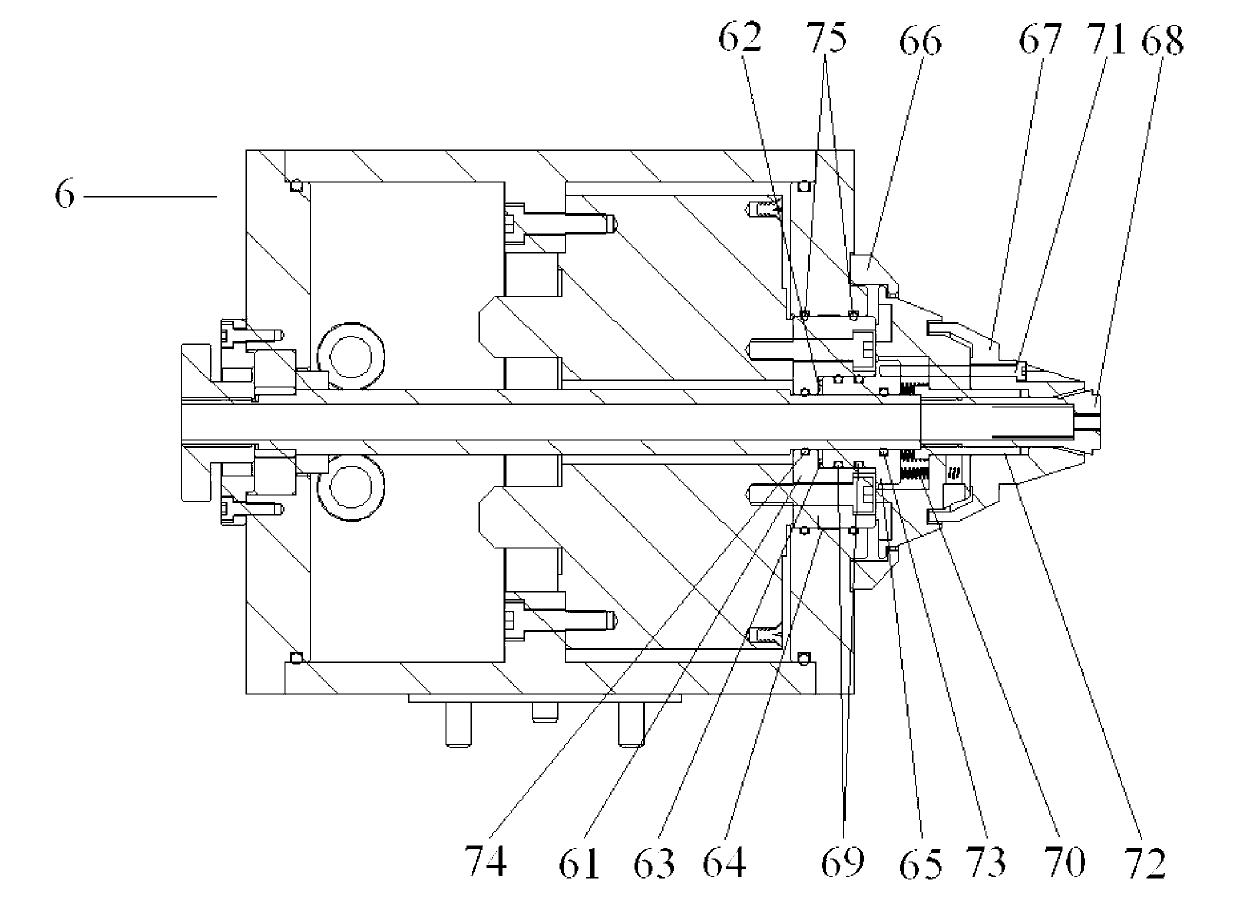

Special machine tool for square hole bearing inner ring continuous machining

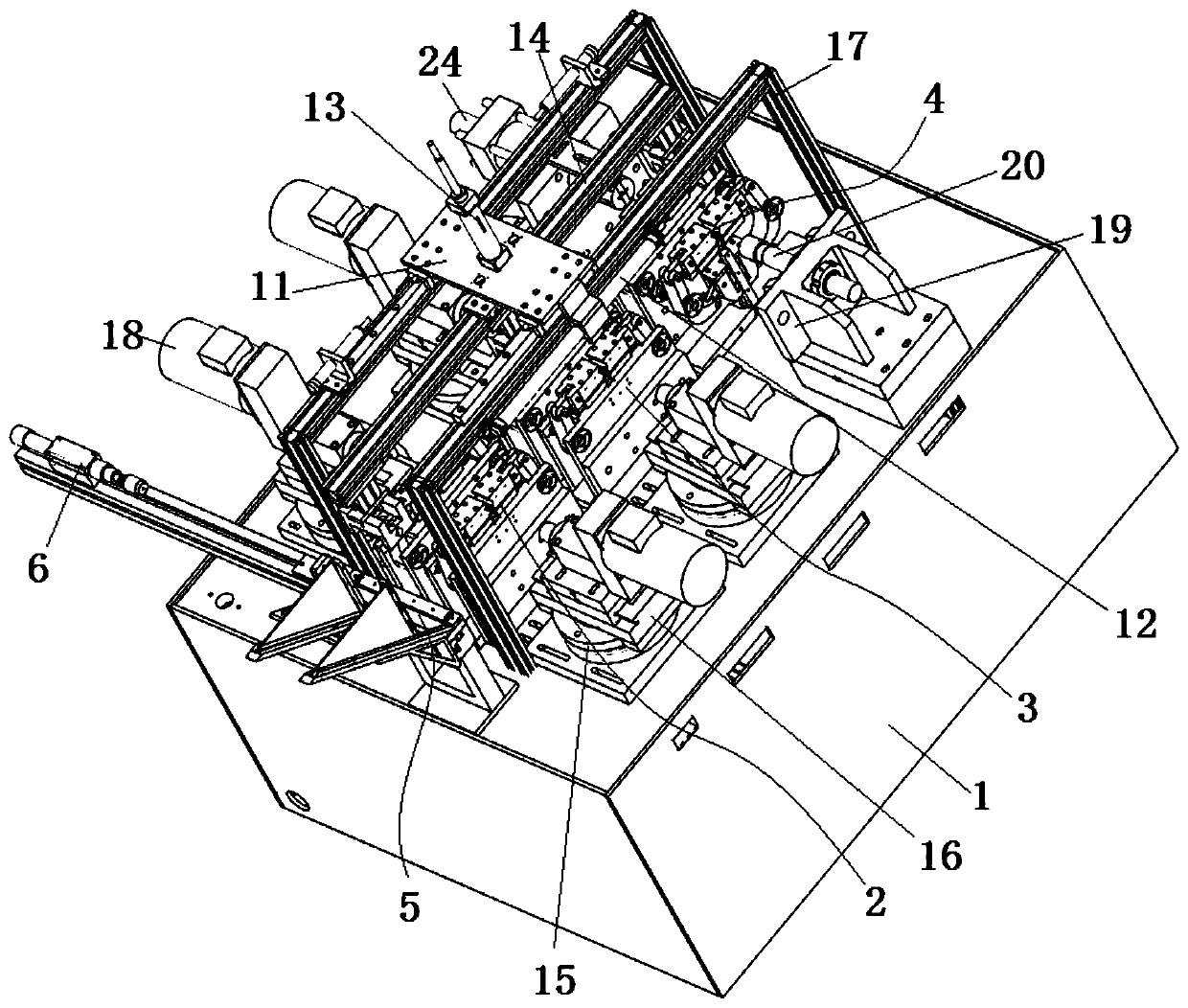

InactiveCN108890319ASolve the problems of difficult clamping and low processing efficiencyRealize continuous automatic processingLarge fixed membersPositioning apparatusElectric controlMachine tool

The invention relates to a special machine tool for square hole bearing inner ring continuous machining. The machine tool comprises a machine tool box body, an electric control cabinet is arranged onone side of the upper end surface of the machine tool box body, and a vibration output disc is arranged on the other side of the upper end surface of the machine tool box body; a triangular installingpedestal is arranged on the upper end surface of the machine tool box body, a cutter displacement mechanism and a bearing inner ring input mechanism are arranged on the triangular installing pedestal, and a workpiece clamping rotating mechanism is arranged on the portion, on one side of the cutter displacement mechanism, of the upper end surface of the triangular installing pedestal; an end surface pushing mechanism is arranged on the portion, on the other side of the cutter displacement mechanism, of the triangular installing pedestal, and a loading clamping mechanism is arranged on the topof the workpiece clamping rotating mechanism. The machine tool solves the problems that according to existing square hole bearing inner ring machining, the clamping is difficult, and the machining efficiency is low, a previous mode that a workpiece needs to be manually clamped and loaded is replaced, the continuous automatic machining for square hole inner rings is achieved, the machining efficiency is increased, and the surface machining quality is ensured.

Owner:杭州巧狮信息科技有限公司

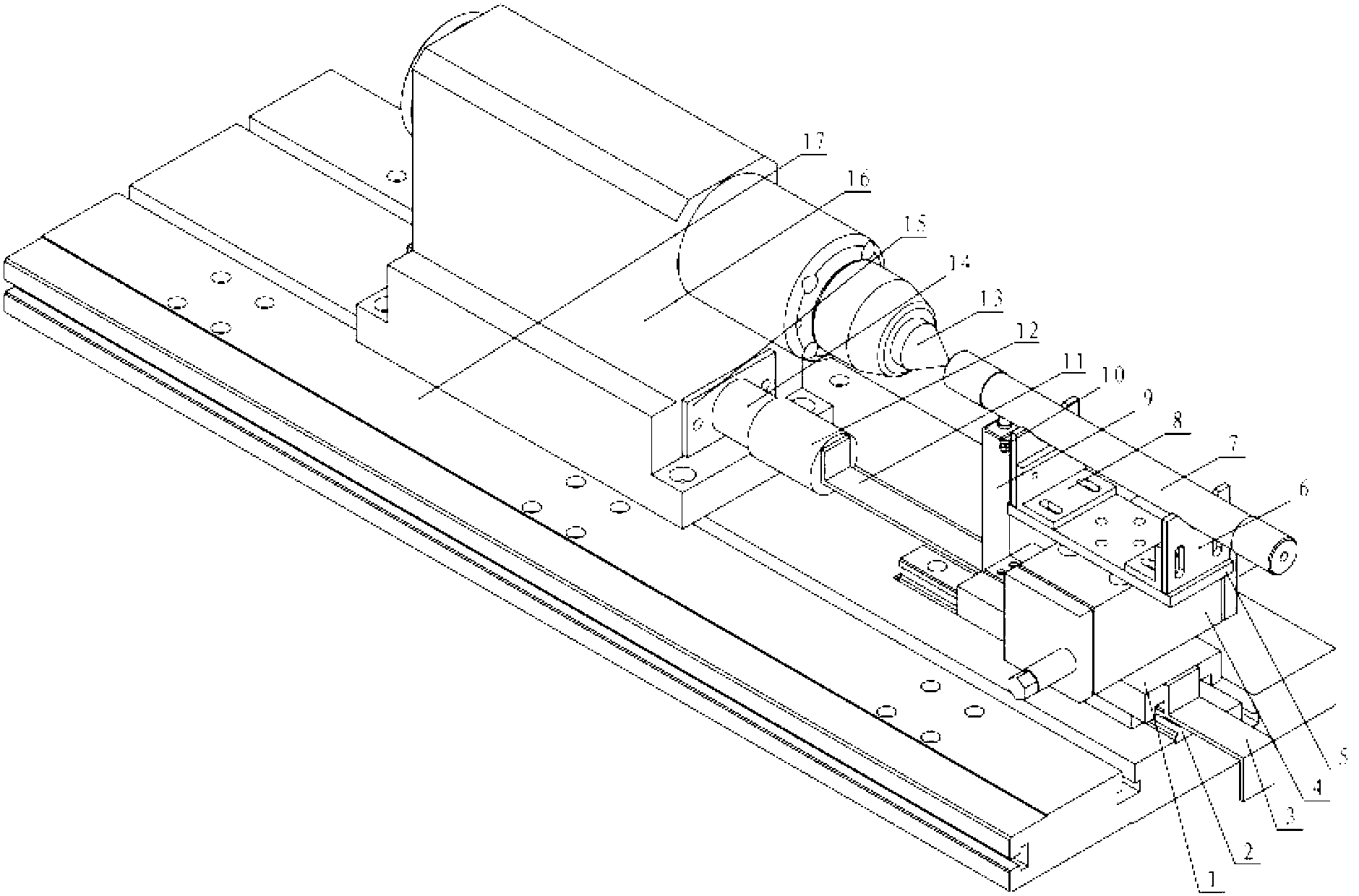

Multi-station continuous hexagonal hole machining integrated machine

ActiveCN111360544AImprove processing efficiencyRealize continuous automatic processingOther manufacturing equipments/toolsMetal working apparatusMolding machineEngineering

The invention discloses a multi-station continuous hexagonal hole machining integrated machine which comprises a worktable. A hole guiding station, a perforating station and a forming station are parallelly arranged on the worktable successively, the hole guiding station is provided with a hole guiding mechanism in a fit manner, the perforating station is provided with a perforating mechanism in afit manner, and the forming station is provided with a hole forming mechanism in a fit manner; a feeding station is arranged on one side of the hole guiding station, the feeding station is provided with a pushing mechanism in a fit manner, and the worktable is connected to a movable clamping mechanism which is slidably arranged above the hole guiding station through a supporting rack; the pushingmechanism moves a workpiece on the feeding station to a discharge end of the feeding station and the workpiece is successively moved to the hole guiding station, the perforating station and the forming station to be machined through the movable clamping mechanism. Compared with the prior art, a hexagonal hole is machined automatically, and the machining efficiency and the machining quality of theworkpiece are improved.

Owner:浙江唯沣精密机械有限公司

Handle paper cup processing device with positive rotation limit function

ActiveCN105109106BRealize continuous automatic processingPrecise positive limitPaper-makingBox making operationsEngineeringMechanical engineering

The invention discloses a handle paper cup processing device with the function of positive rotation and limit position, comprising a frame, a paper cup feeding control mechanism, a patch control mechanism, a paper cup clamping mechanism, a handle paper feeding mechanism, and a cup receiving control mechanism; The mechanism includes a rotating disk and a patch device. The rotating disk is installed horizontally on the frame. There are several cup molds on the rotating disk. The cup molds are horizontally fixed on the peripheral surface of the rotating disk, and along the rotating disk The centers are radially and symmetrically distributed. When the rotating disk rotates, the cup molds pass through the above-mentioned mechanisms in turn to complete the automatic patch processing of the handle paper cups. The cup molds are equipped with limit cards. The advantages of the present invention are: the device can not only carry out continuous automatic patch processing on the handle of the paper cup, which greatly improves the production efficiency, but also realizes the precise lamination between the handle paper and the paper cup, which improves the product quality and service life; the structure of the device is stable , Easy to operate, good practicability and promotion value.

Owner:宣城市博思特日用品有限公司

A continuous hydraulic processing system for unburned bricks

ActiveCN106476120BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a continuous hydraulic processing system for baking-free bricks and belongs to the field of brickmaking machines. The continuous hydraulic processing system comprises a rack and a discharge hopper located above the rack, wherein a conveying mechanism for conveying brick blocks is arranged at one end of the rack; a discharge opening communicated with the bottom of the discharge hopper is formed in the rack; a forming and pushing mechanism is arranged between the rack and the discharge hopper; the forming and pushing mechanism is connected to a first hydraulic cylinder; a forming mechanism communicated with the discharge opening is arranged below the rack; the forming mechanism is connected to a second hydraulic cylinder; raw materials in the discharge hopper pass through the forming and pushing mechanism and then enter the forming mechanism; the second hydraulic cylinder extrudes the raw materials into brick blocks and push the brick blocks onto the rack; and the first hydraulic cylinder drives the forming and pushing mechanism to push the brick blocks onto the conveying mechanism for conveying. The continuous hydraulic processing system facilitates solving the problem that an existing brickmaking machine is low in continuous production degree and complex in production process, and can realize continuous extrusion forming of the brick blocks, the production efficiency is effectively improved, the production process is simple, the processing cost is low, and improvement on production benefits of an enterprise is facilitated.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Wastewater treatment equipment for aquaculture seawater

ActiveCN111217500BAchieve bactericidal effectFully absorbedSeawater treatmentWaste water treatment from animal husbandryPolycultureSewage

The invention discloses wastewater treatment equipment for aquaculture seawater, relates to the technical field of wastewater treatment equipment, and includes an impurity filtering mechanism, a filtering box, a controller, a multi-stage processing mechanism, and a detection backflow mechanism. The multi-stage processing mechanism includes: The algae polyculture tank, the mixing component, the sterilization component and the bacteria treatment cylinder, the impurity filter mechanism includes two multi-stage filter components, the position conversion component and the filter mesh dredging component, the position conversion component includes the installation horizontal plate, Height adjustment part and swivel part. The present invention can realize the continuous automatic treatment of aquaculture wastewater, and can realize the replacement of the filter screen adhering impurities under the action of the impurity filtering mechanism, and can dredge the mesh holes of the adhering impurity filter screen, when the bacteria content and When the nitrogen and phosphorus content does not reach the standard, the second water pump can retransmit the sewage that has not reached the standard to the filter box to realize the secondary purification of the sewage.

Owner:SHANDONG BUSINESS INST

An automatic patch processing device for paper cups with a handle

ActiveCN105058866BRealize continuous automatic processingImprove work efficiencyPaper-makingBox making operationsAutomatic processingEngineering

The invention discloses a processing device with an automatic piece attaching function for paper cups with handles. The processing device comprises a machine frame, a paper cup feeding control mechanism, a piece attaching control mechanism, a paper cup clamping mechanism, a handle paper feeding mechanism and a cup receiving control mechanism. The piece attaching control mechanism comprises a rotary disc and a piece attaching device. The rotary disc is horizontally mounted on the machine frame. A plurality of cup moulds are arranged on the rotary disc, horizontally fixed to the circumferential surface of the rotary disc and radially and symmetrically distributed along the center of the rotary disc. When the rotary disc rotates, the cup moulds are made to pass through all the above mechanisms in sequence, so that automatic piece-attaching processing of the paper cups with the handles is completed. The processing device with the automatic piece attaching function for the paper cups with the handles has the advantages that continuous and automatic processing of the paper cups with the handles is achieved through the rotation of the rotary disc and the cooperation of the periodic operation of all the control mechanisms, and the work efficiency of paper cup piece-attaching processing and the product quality are greatly improved; the processing device is stable in structure and convenient to operate and has high practicability and high promotional value.

Owner:宣城市博思特日用品有限公司

A kind of processing method of handle paper cup

ActiveCN105058864BRealize continuous automatic processingImprove work efficiencyPaper-makingBox making operationsPulp and paper industryManipulator

The invention discloses a method for processing paper cups with handles. The method comprises the following steps: a) conveying a plurality of naked paper cups to a pasting control mechanism to finish a material conveying procedure; b) rotating the paper cups, and enabling the seam line parts of the paper cups to be positioned above paper dies and then fixed to finish the alignment limit of the paper cups; c) pushing handle paper to be above the paper cups to finish a handle paper conveying procedure; d) carrying out paper hot-pressing pasting on the paper cups and the handles, and keeping hot-pressing until arriving at the next work station to finish the pasting procedure of the handle paper; and e) utilizing a manipulator to take down the paper cups with the handles, and conveying the paper cups with the handles into a material collecting groove to finish a material collecting procedure. The method for processing the paper cups with the handles has the advantages that the continuous and automatic processing for the paper cups with the handles is realized by adopting an automatic pasting processing device with a turntable for the paper cups with the handles, the work efficiency and the product quality of the paper cup pasting processing are greatly improved, and the device is stable in structure and convenient to operate and has excellent practicability and high popularization value.

Owner:宣城市博思特日用品有限公司

Automatic rotation part for support material

ActiveCN103317070BRealize continuous automatic processingSimple structureGear wheelsRotary stageEngineering

The invention discloses an automatic rotation part for a support material. The automatic rotation part comprises a small automatic 180-degree rotation table, a rotation table sliding saddle, a linear rail, a bracket base plate, an L-shaped bracket, a V-shaped bracket, an inductive switch support, a front limit stop block, a connection rod, a sleeve, a support cylinder, a spring, a sliding rod, a bearing, a front press cover and a rear press cover. The rotation table sliding saddle is fixed above the linear rail which is fixed on a front tailstock sliding saddle, the front limit stop block is fixed on the front side of the rotation table sliding saddle, the small automatic 180-degree rotation table is fixed above the rotation table sliding saddle, the bracket base plate is fixed on the small automatic 180-degree rotation table 4, the L-shaped bracket is fixed on the bracket base plate, the V-shaped bracket is fixed on the L-shaped bracket, the inductive switch support is mounted on the rotation table sliding saddle, an inductive switch is mounted on the inductive switch support, the connection rod is fixed between the rotation table sliding saddle and an internal sliding guide rod of the sleeve, a tailstock is mounted on a tailstock base, front and rear baffles are mounted on the tailstock base to prevent the bearing from being exposed, and the tailstock base is mounted on the front tailstock sliding saddle. By means of the automatic rotation part, automation is achieved, and a basis is provided for continuous production.

Owner:ANHUI LICHENG MACHINERY EQUIP

A multi-station continuous hexagonal hole processing integrated machine

ActiveCN111360544BImprove processing efficiencyRealize continuous automatic processingOther manufacturing equipments/toolsMetal working apparatusPunchingMolding machine

The invention discloses a multi-station continuous hexagonal hole processing integrated machine, which includes a workbench, on which a hole-leading station, a punching station and a forming station are arranged side by side in sequence, and the hole-leading station is arranged in conjunction with each other. There is a hole introduction mechanism, the punching station is equipped with a punching mechanism, and the forming station is equipped with a hole forming mechanism; one side of the hole introduction station is equipped with a feeding station, and the feeding station is equipped with a pusher Mechanism, the worktable is connected with a mobile clamping mechanism slidingly arranged above the leading hole station through a support frame; the pushing mechanism moves the workpiece on the feeding station to the discharge end of the feeding station and then clamps it by moving The mechanism moves the workpiece to the hole-leading station, the punching station and the forming station in sequence for processing; compared with the prior art, the present invention forms the automatic processing of hexagonal holes and improves the processing efficiency and quality of the workpiece.

Owner:浙江唯沣精密机械有限公司

Fully automatic vibrating cold extrusion plastic forming device and process for medium and small diameter internal threads

ActiveCN108465886BExtend your lifeAvoid the disadvantage of excessive torqueThread cutting feeding devicesThread cutting machinesDrive shaftElectric machinery

The invention discloses a full-automatic vibration cold extruding plastic forming device and technology for small-medium-diameter internal threads. The full-automatic vibration cold extruding plasticforming device comprises extrusion taps, the extrusion taps are driven by tapping motors different in forward and reverse rotation angle to achieve vibration tapping and are installed in driving shafts, the driving shafts are installed in guide shafts, and the extrusion taps can move in the axial direction but are limited by chucks; and a semi-finished product feeding mechanism is arranged above the extrusion taps, to-be-machined nuts sequentially enter two feeding rails to be arranged under the action of stirring rods, pushing mechanisms are arranged in front of the extrusion taps, and push rods pushed by pushing motors push the to-be-machined nuts to be sleeved the extrusion taps for tapping machining. The full-automatic vibration cold extruding plastic forming device has the advantagesof being high in machining efficiency and easy to operate. The technology has the advantages that the material utilization rate is high, and the cold-extruded internal threads are high in strength andprecision and good in surface smoothness. Through the full-automatic vibration cold extruding plastic forming device and technology, automatic and efficient machining of internal threads for hexagonnuts with multiple specifications and thicknesses or parts in other shapes can be achieved.

Owner:XI AN JIAOTONG UNIV

Edge-sealing cutting integrated structure for double-layer fabric

InactiveCN109518449ARealize continuous automatic processingImprove processing efficiencySevering textilesEngineeringTransmission belt

The invention relates to an edge-sealing cutting integrated structure for a double-layer fabric. The mechanism comprises a rack and two fabric rolls, the rack is provided with a guiding tube, a delivery tube and a tensioning device which cooperate with the double-layer fabric, an edge pressing device is arranged on the part, between the delivery tube and the fabric rolls, of the rack, a cutting device is arranged between the delivery tube and the tensioning device, the edge pressing device comprises an edge pressing seat which is arranged on the rack, an edge pressing rotary shaft is arrangedon the edge pressing seat, edge pressing sleeves cooperating with the side edges of the double-layer fabric sleeve the two ends of the edge pressing rotary shaft, an edge pressing sewing device cooperates with the lower portions of the edge pressing sleeves, the edge pressing sewing device is a sewing device which presses the double-layer fabric through a thermal pressing manner, an edge transmission wheel is connected with the edge pressing rotary shaft, and the edge pressing sewing device is connected with the edge pressing driving component through an edge pressing transmission belt. The structure has the advantages that the edges of cloth sheets on the two fabric rolls can be pressed to the double-layer fabric, and cutting can be conducted according to a certain length through the cutting device between the tensioning device and the delivery tube.

Owner:DONGGUAN UNIV OF TECH +1

A handle paper cup processing device

ActiveCN105058865BRealize continuous automatic processingImprove work efficiencyBox making operationsPaper-makingPulp and paper industryPaper cup

Owner:宣城市博思特日用品有限公司

An automatic forming device for unburned brick production

ActiveCN106313297BAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

A continuous automatic assembly machine for ear plate shrapnel

ActiveCN107553107BGuaranteed accuracyAvoid elastic deformationMetal working apparatusDistribution controlButt joint

The invention relates to a continuous automatic assembly machine of a lug plate elastic piece. The continuous automatic assembly machine comprises a rack, a power distribution control box, a rotary disc and carriers. A lug plate feeding mechanism, an elastic piece feeding mechanism, a press-fitting mechanism and a discharging mechanism are arranged on the rack. Each carrier comprises a carried material mounting seat embedded into the rotary disc. A carried material seat lifting block penetrating the rotary disc is arranged in each carried material mounting seat. A vertical carried material seat composite spring is arranged between each carried material seat lifting block and the lower portion of the corresponding carried material mounting seat. A carried material seat cooperating with a product is arranged above each carried material seat lifting block. A press-fitting device comprises a press-down device cooperating with the products on the carriers and a carried material seat jackingdevice which is located below the press-down device and cooperates with the carried material seat lifting blocks. According to the continuous automatic assembly machine, the carried material seat lifting blocks and the press-down device can be in butt joint precisely, meanwhile, pressing assembly of a lock piece and a lug plate can be achieved, it can be ensured that the press-down portion is a flat plate between two elastic piece mounting columns, the press-fitting precision is ensured, elastic deformation of the elastic pieces is avoided, and meanwhile continuous automatic machining is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

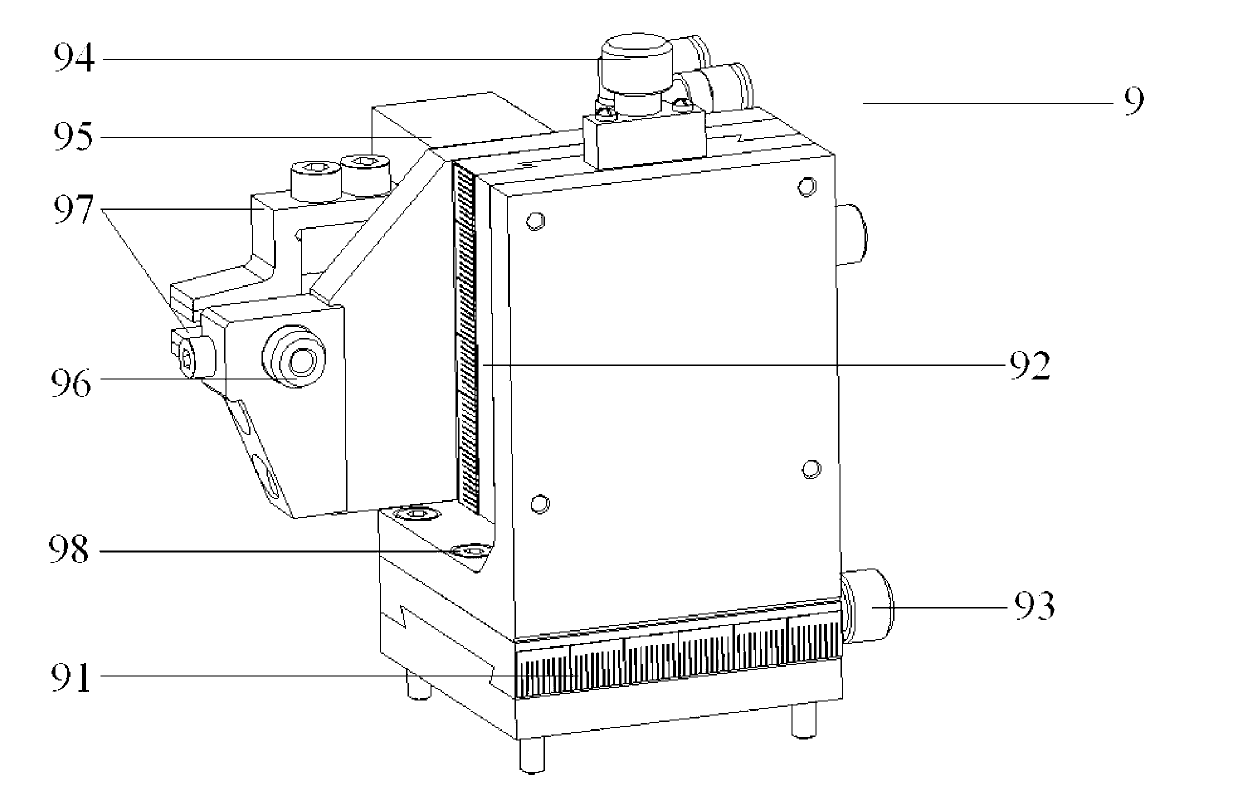

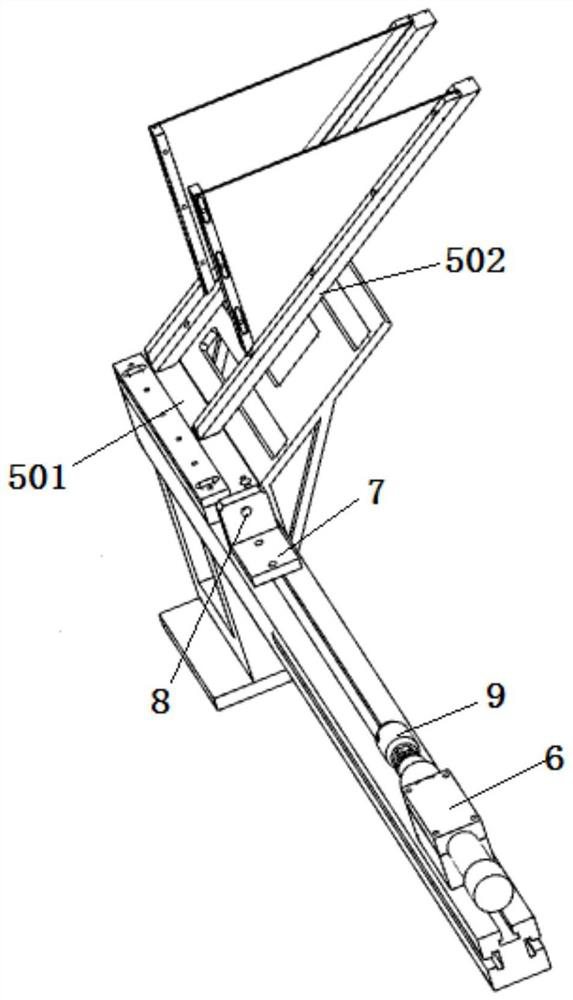

Centerless grinding automatic feeding device for extruding PCB drill points

InactiveCN113547396ARealize continuous automatic processingClosely connectedEdge grinding machinesRevolution surface grinding machinesElectrical controlMachine

The invention discloses a centerless grinding automatic feeding device for extruding PCB drill points, and relates to the technical field of feeding devices. The centerless grinding automatic feeding device comprises a linear vibration feeding mechanism connected with a centerless grinding machine through a main body connection protection mechanism and an electrical control mechanism, and the linear vibration feeding mechanism receives bars which come from a storage hopper mechanism and are sorted through a pushing sorting mechanism and feeds the sorted bars into the centerless grinding machine one by one for processing; and the electrical control mechanism is mounted at the bottom of the main body connection protection mechanism and is used for controlling the linear vibration feeding mechanism to count the bars and controlling the operation of the pushing sorting mechanism. The device can be compactly connected with existing equipment, and the installation space is reduced; and rapid, continuous and automatic machining of external circles of extrusion PCB drill point type hard alloy products, rapid switching of machining of external circles of multiple kinds of products and machining quality control of the external circles of the products can be achieved.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com