Continuous hydraulic processing system for baking-free bricks

It is a hydraulic processing and continuous technology, which is applied in the direction of forming indenters, manufacturing tools, ceramic forming machines, etc. It can solve the problems of low production level and complicated production process, achieve convenient operation, reduce processing materials, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

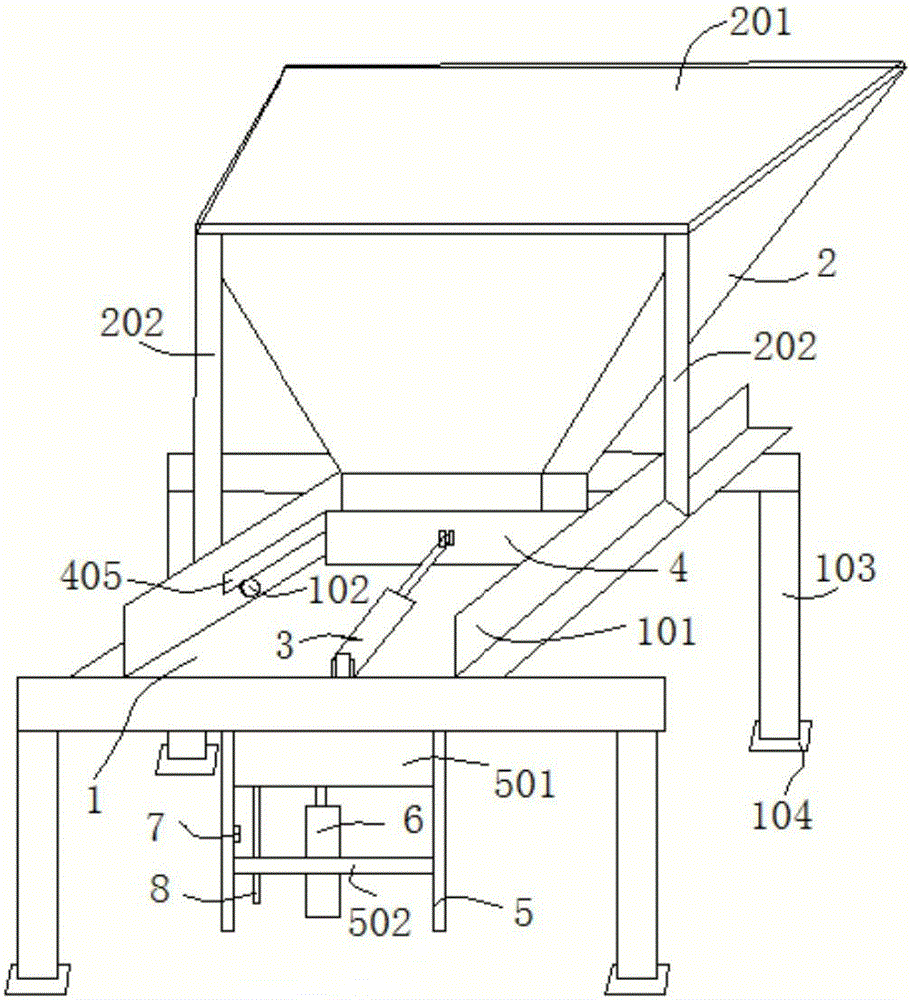

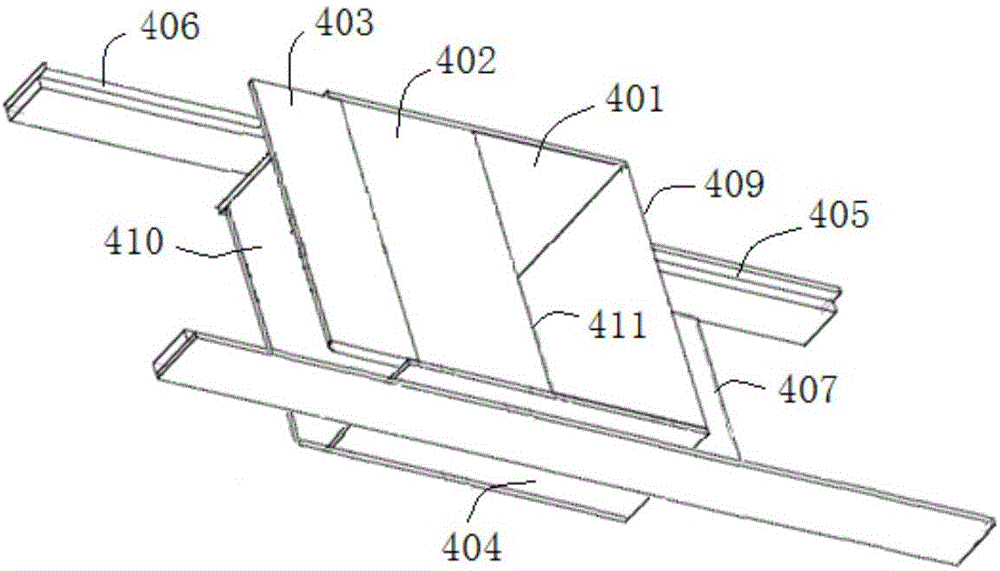

[0043] Such as Figure 1 to Figure 4 As shown, a continuous hydraulic processing system for unburned bricks in this embodiment includes a frame 1 and a falling hopper 2 located above the frame 1, wherein the frame 1 is supported by legs 103 at the four corners, and the legs The bottom of 103 is provided with a fixed plate 104, and the area of the fixed plate 104 is much larger than the cross-sectional area of the leg 103, so that the supporting contact area between the leg 103 and the ground is significantly increased, which helps to enhance the stability of the whole set of equipment. One end of the frame 1 is provided with a conveying mechanism for conveying shaped bricks, which can be conveyed by a conveying belt, and the formed bricks are directly automatically transported through the conveying mechanism. A screen 201 is provided at the opening of the top of the falling hopper 2, which is convenient for screening the brick-making raw materials added. The raw materials ...

Embodiment 2

[0053] A continuous hydraulic processing system for non-burning bricks in this embodiment has the same basic structure as in Embodiment 1. Furthermore, in this embodiment, the lower part of the bottom bracket 5 is connected with a fixed frame 502, and the second hydraulic cylinder 6 is located at the bottom. In the frame enclosed by the bracket 5 and the fixed frame 502, an adjustment mechanism for controlling the positional deviation of the second hydraulic cylinder 6 is arranged in the frame. Such as Figure 5 As shown, the bottom bracket 5 and the fixing frame 502 form a rectangular frame, and the adjustment mechanism includes adjusting screw rods 503 correspondingly arranged on the bottom brackets 5 on both sides, and fastening bolts 505 correspondingly arranged on the fixing brackets 502 on both sides. The end of the screw 503 is provided with a fastening block 504 close to the edge of the second hydraulic cylinder 6, and the side of the fastening block 504 in contact wit...

Embodiment 3

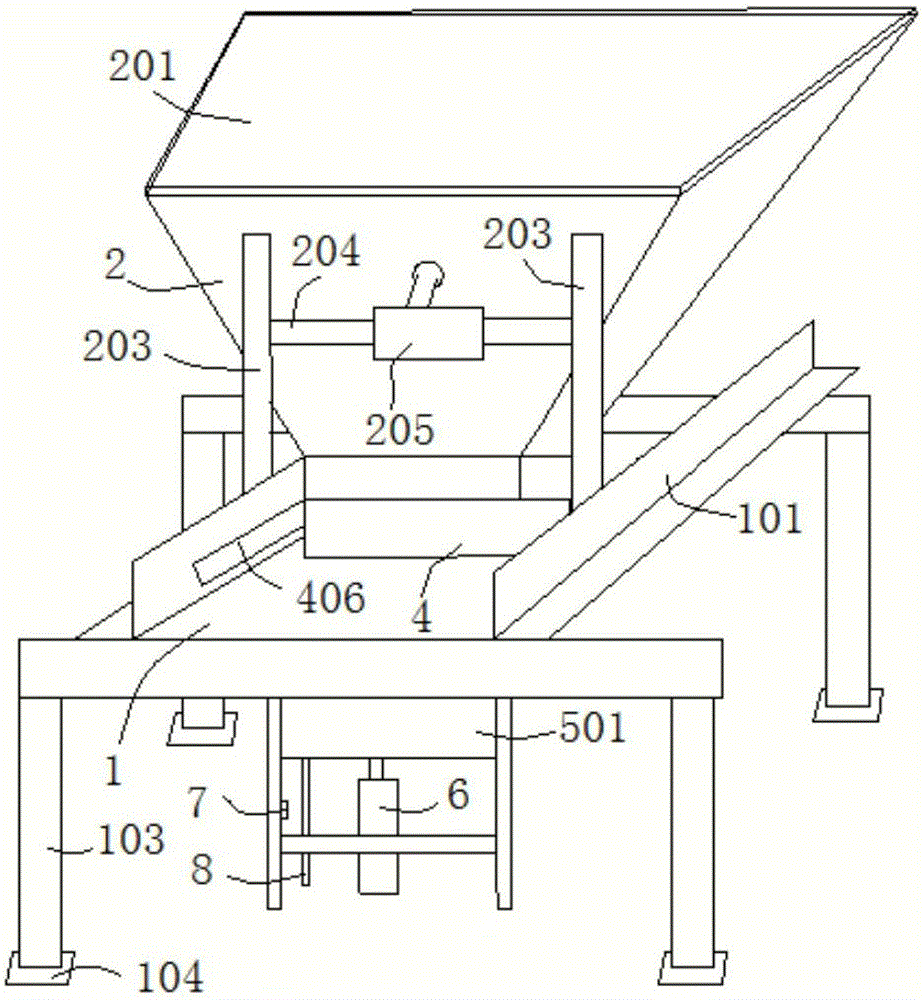

[0055] A continuous hydraulic processing system for non-burning bricks in this embodiment has the same basic structure as in Embodiment 2. Further, side fixing plates 101 are provided on both sides of the frame 1 in this embodiment to effectively strengthen the structural strength. The guide pulley 102 is installed on the side fixed plate 101, and one end of the support frame 202 is fixedly connected with the side fixed plate 101, and the other end is fixedly connected with the blanking hopper 2, as figure 1 As shown, the supporting frame 202 stably supports the dropping hopper 2 to improve its structural stability. Such as figure 2 As shown, two mounting frames 203 are fixedly connected to the side fixing plate 101, and one end of the two mounting frames 203 is fixedly connected to the blanking hopper 2 respectively, and a connecting rod 204 is arranged between the two mounting frames 203, and the vibrating device 205 is It is installed on the connecting rod 204 and effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com