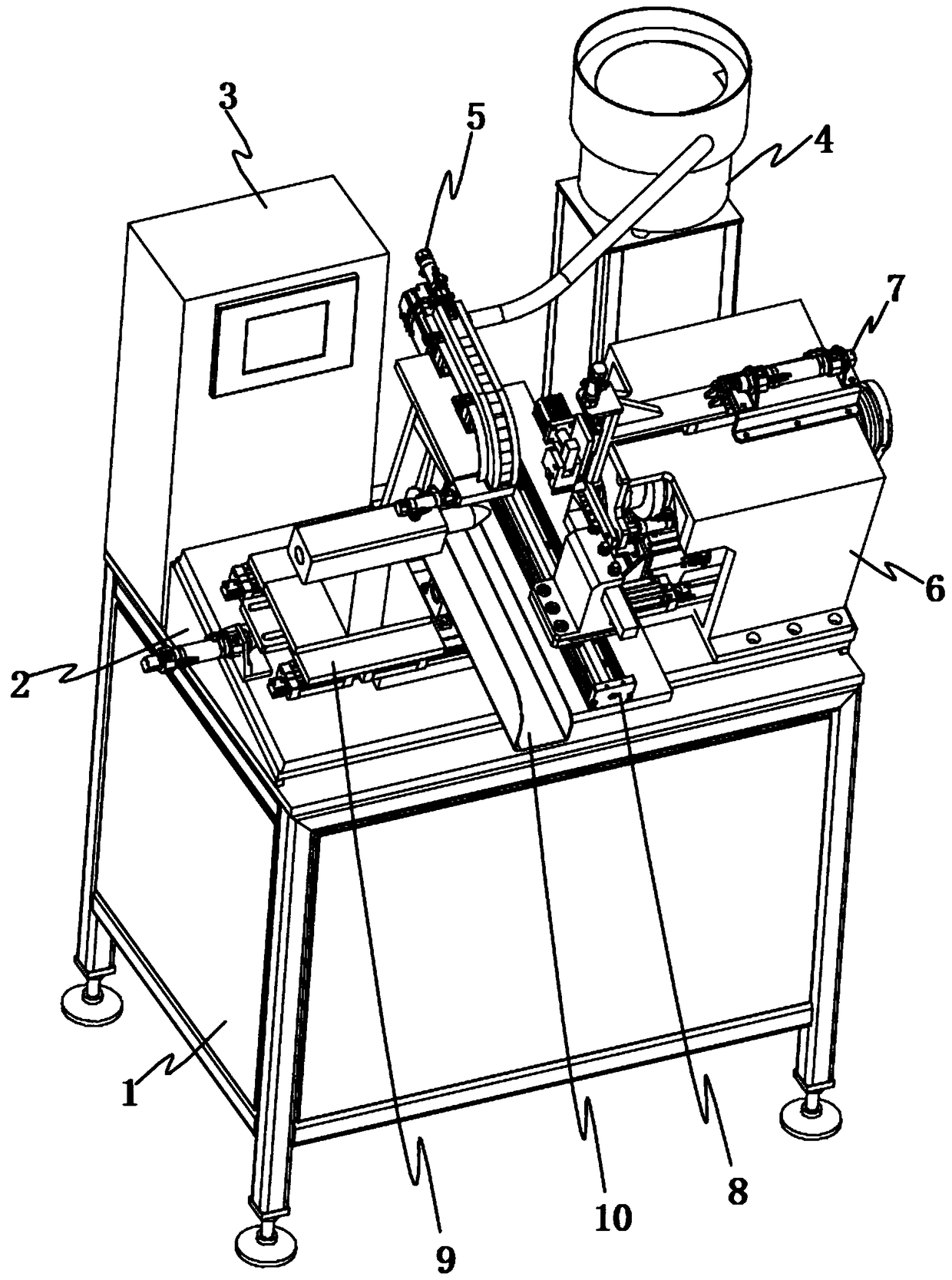

Special machine tool for square hole bearing inner ring continuous machining

A technology for bearing inner rings and special machine tools, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of difficult clamping and low processing efficiency, and achieve the effect of improving processing efficiency and ensuring surface processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

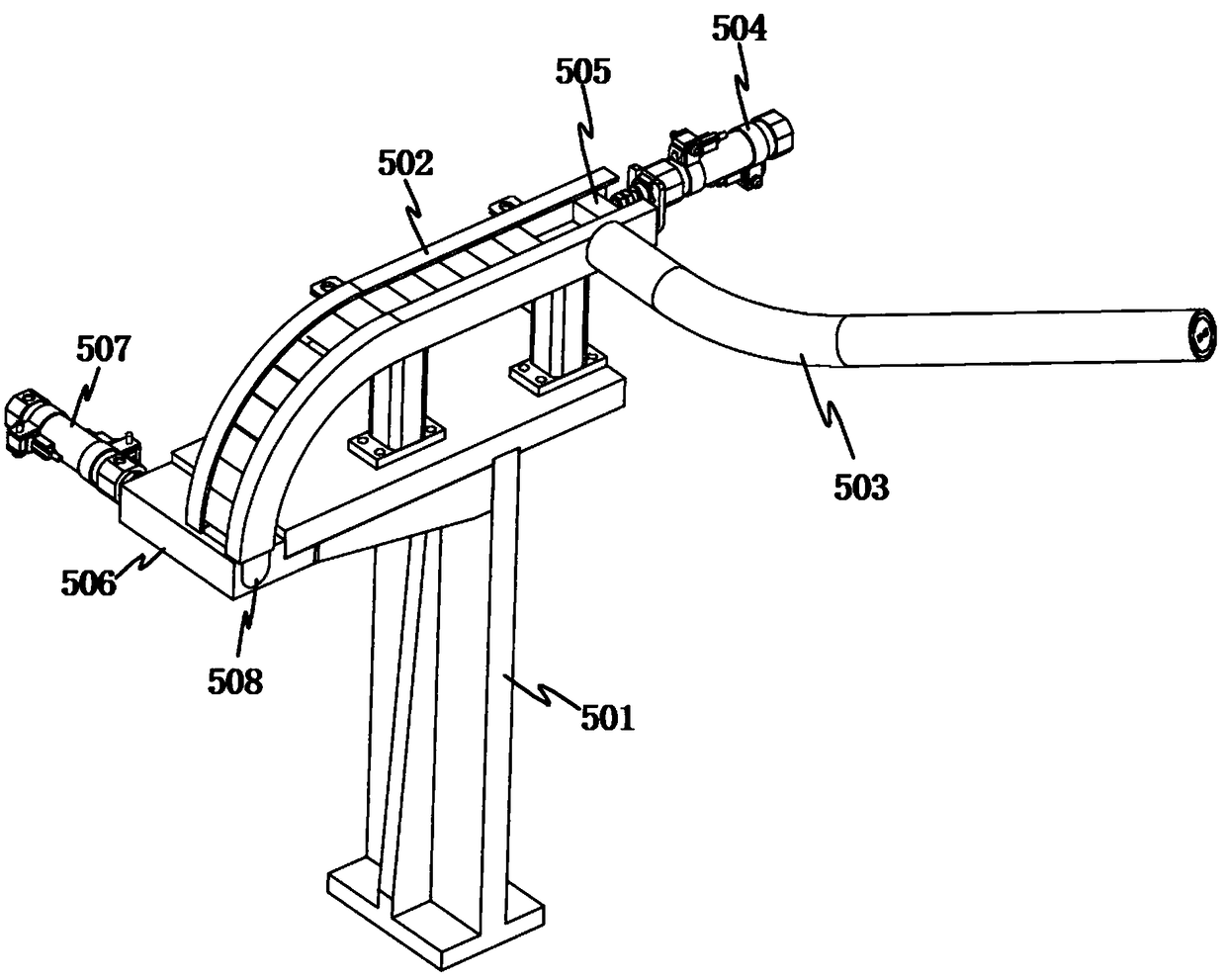

[0034] Before the equipment processes the inner rings of bearing inner rings with square holes, the inner rings of bearing inner rings with square holes in the disk are sorted one by one by the vibration output plate 4, and are input from the output port to the delivery conduit 503 of the bearing inner ring input mechanism 5, and the inner ring of the bearing is started. The input opening and closing cylinder 504 on the ring input mechanism 5 is driven by the input opening and closing cylinder 504 to drive the opening and closing groove block 505 to slide along the discharge groove 502, and open the connection port between the discharge groove 502 and the conveying conduit 503, so that the inner ring of the bearing Slide along the conveying conduit 503 into the discharge groove 502, and one by one in the discharge groove 502, and the inner ring of the bearing is discharged from the front port of the discharge groove 502 into the connecting groove 508 on the connecting block 506,...

Embodiment 2

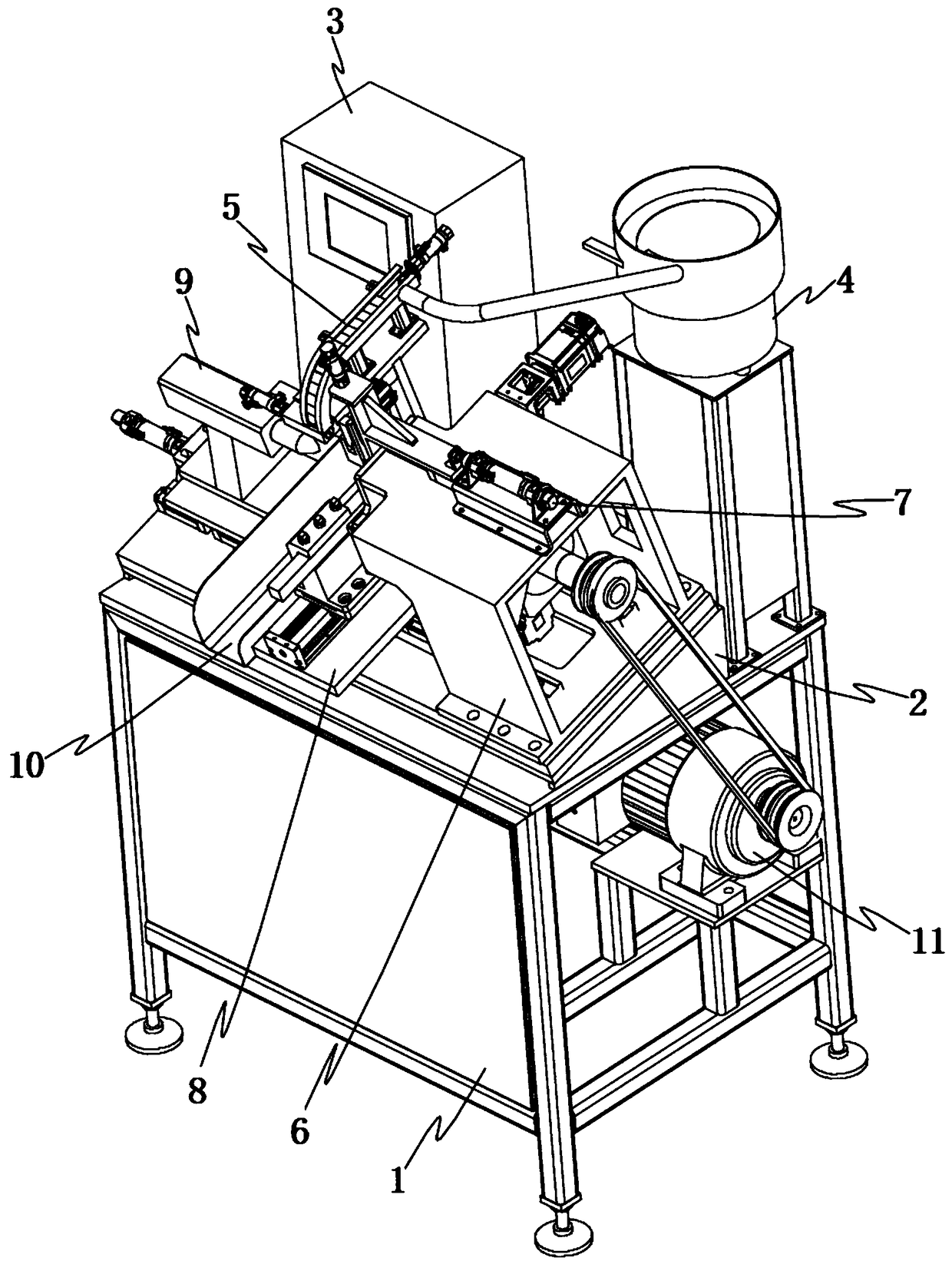

[0036] When the equipment is processing the inner ring of the square hole bearing, the rotary drive motor 11 on the chassis body 1 drives the rotary shaft 602 of the workpiece clamping rotary mechanism 6 to rotate through belt transmission, and the rotary shaft 602 drives the front clamping plate 603 and the clamping plate. The workpiece matching shaft 604 on the disc 603 and the inner ring of the square hole bearing plugged with the workpiece matching shaft 604 rotate, and then the transverse drive motor 804 of the tool displacement mechanism 8 is started, and the longitudinal displacement plate 806 is driven by the transverse drive motor 804 Move along the traversing drive screw 805, start the longitudinal drive motor 807 on the longitudinal displacement plate 806 at the same time, drive the longitudinal drive block 810 equipped with the processing tool 811 by the longitudinal drive motor 807, move along the longitudinal drive screw 808, pass Transverse driving motor 804 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com