Patents

Literature

135results about How to "Avoid compression deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

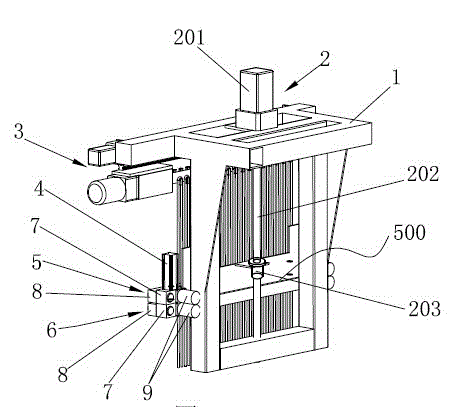

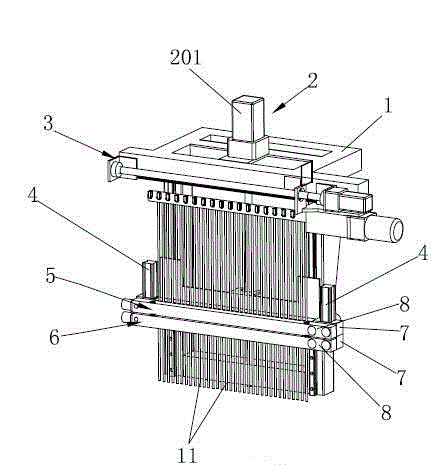

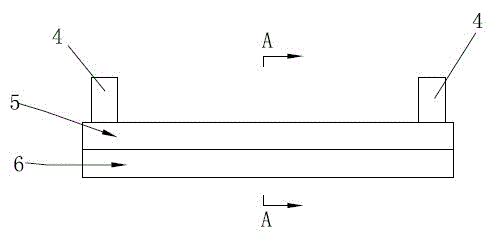

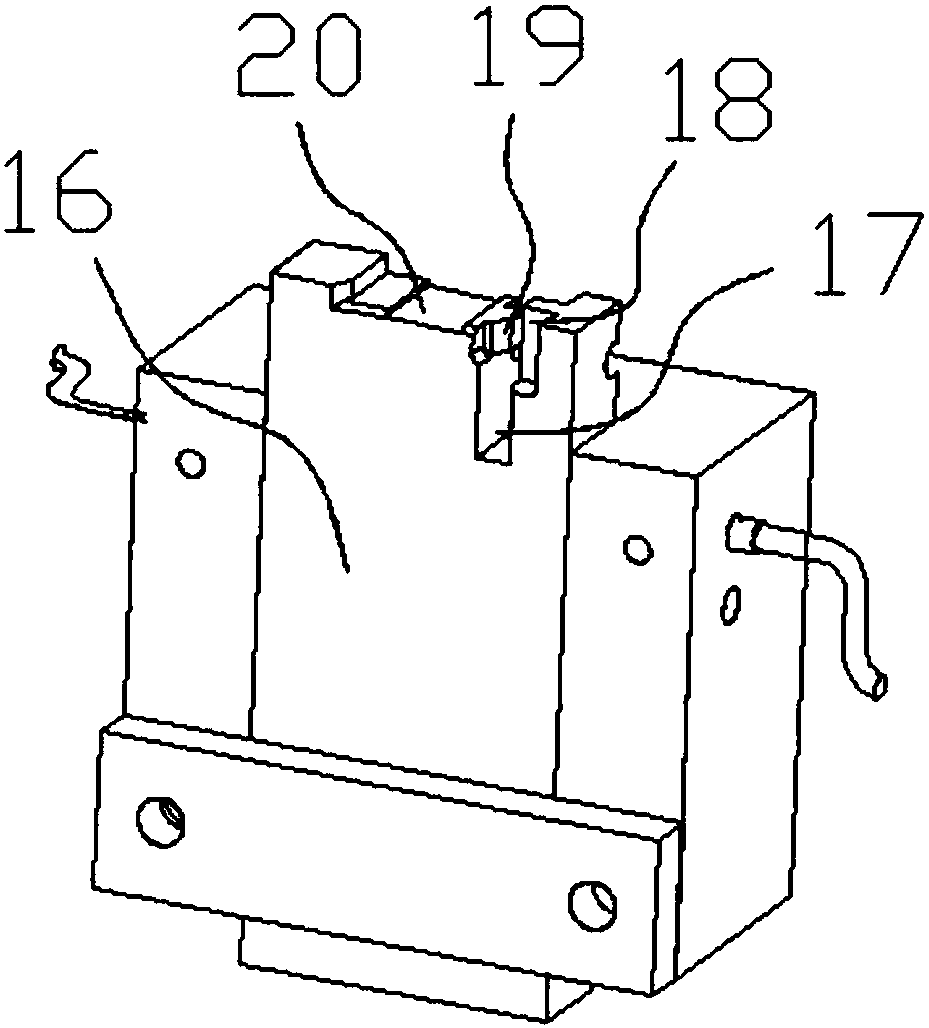

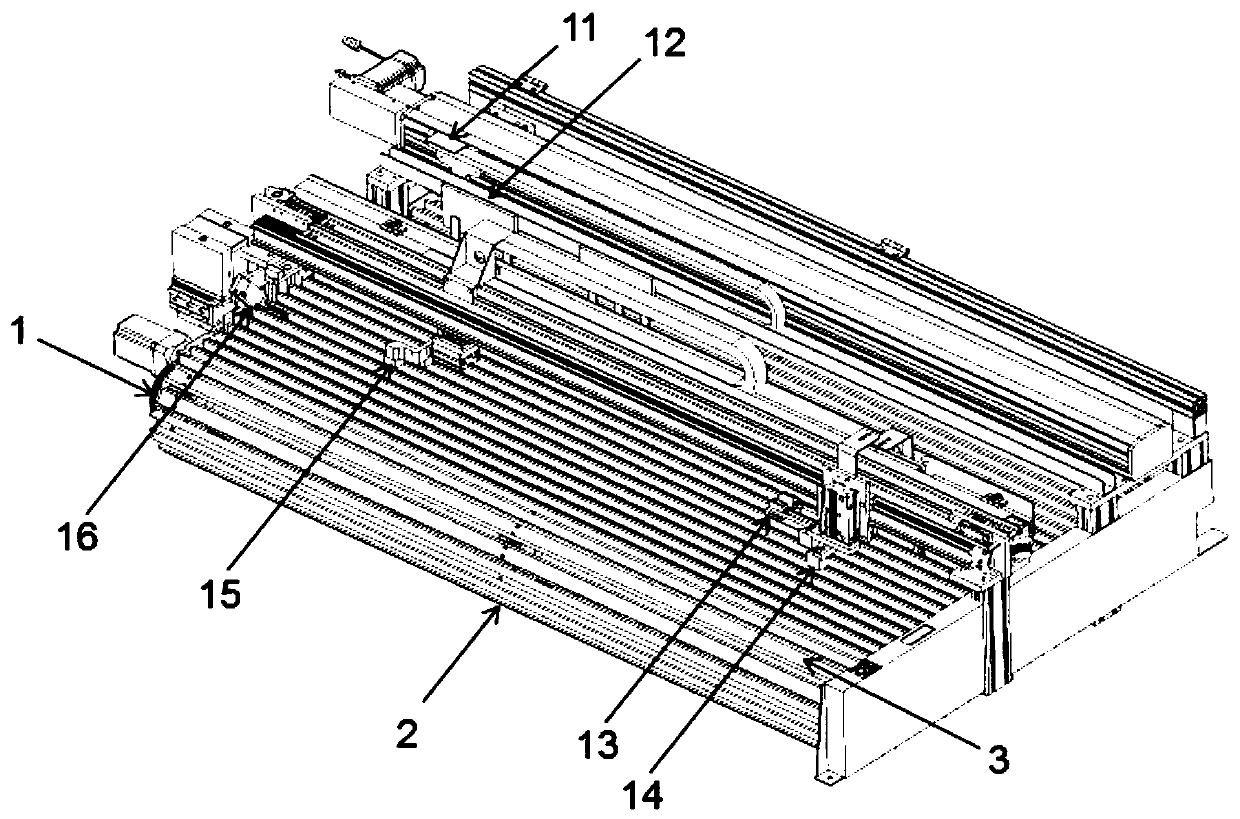

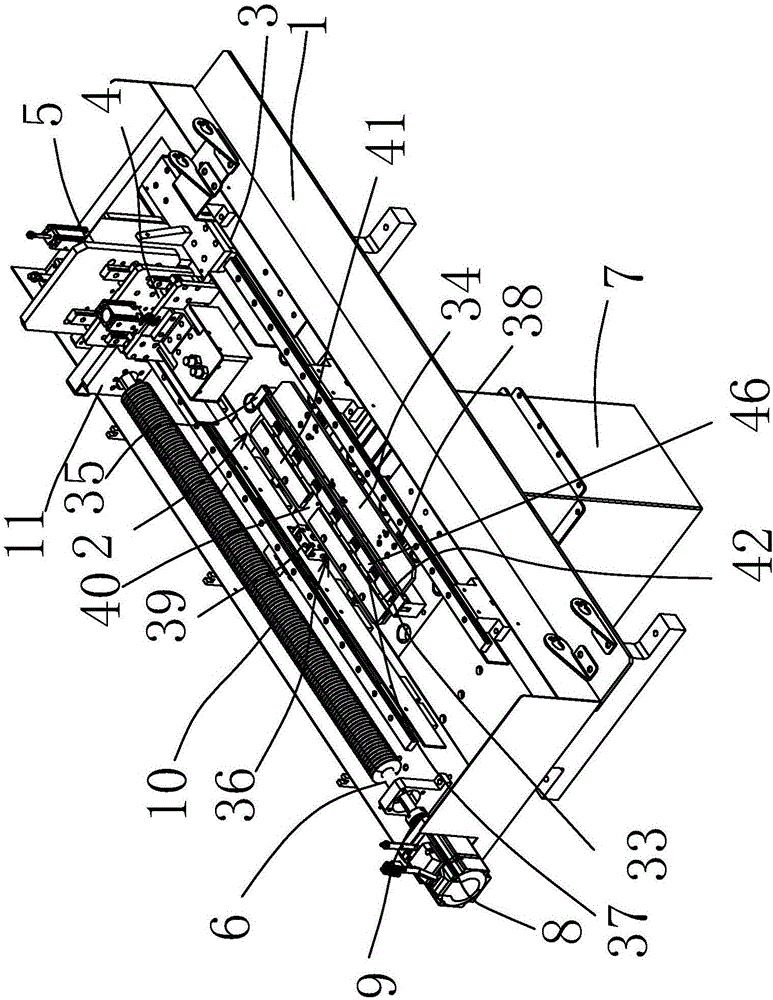

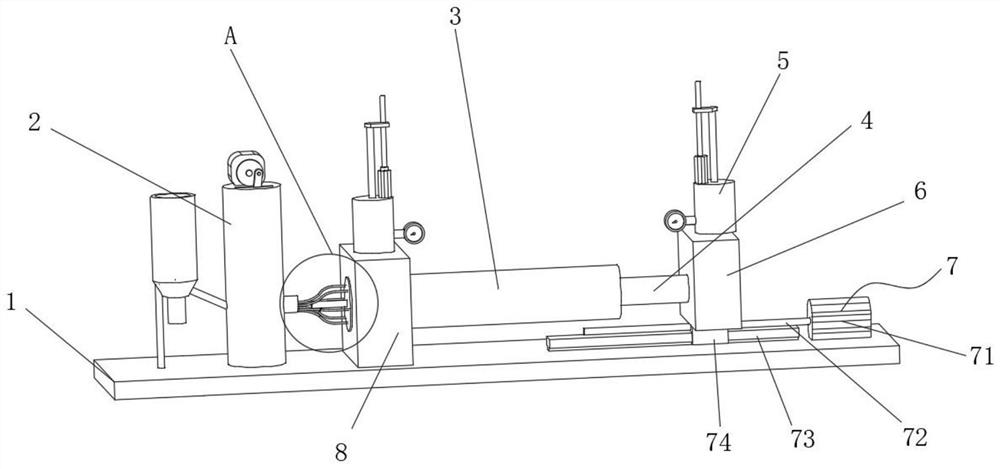

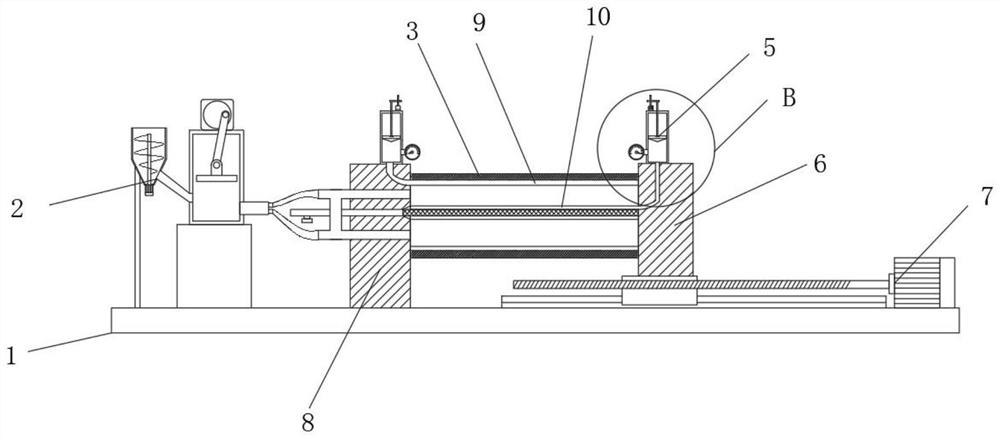

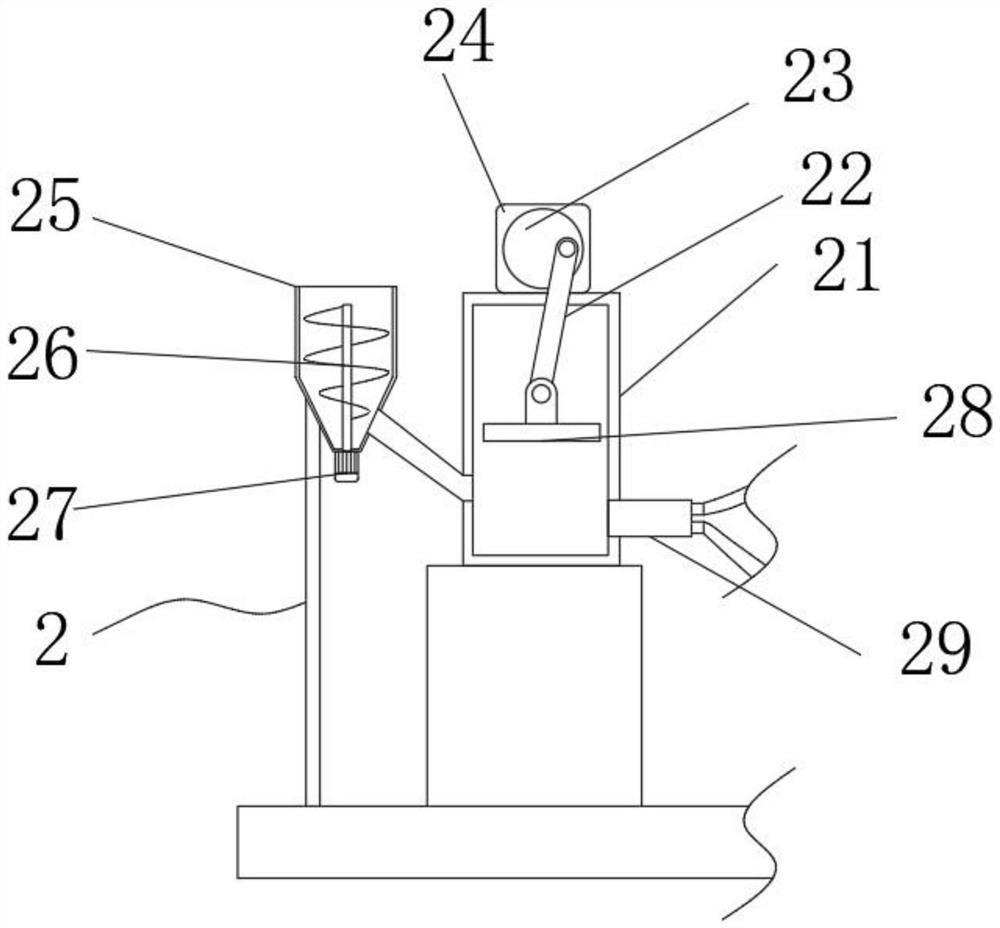

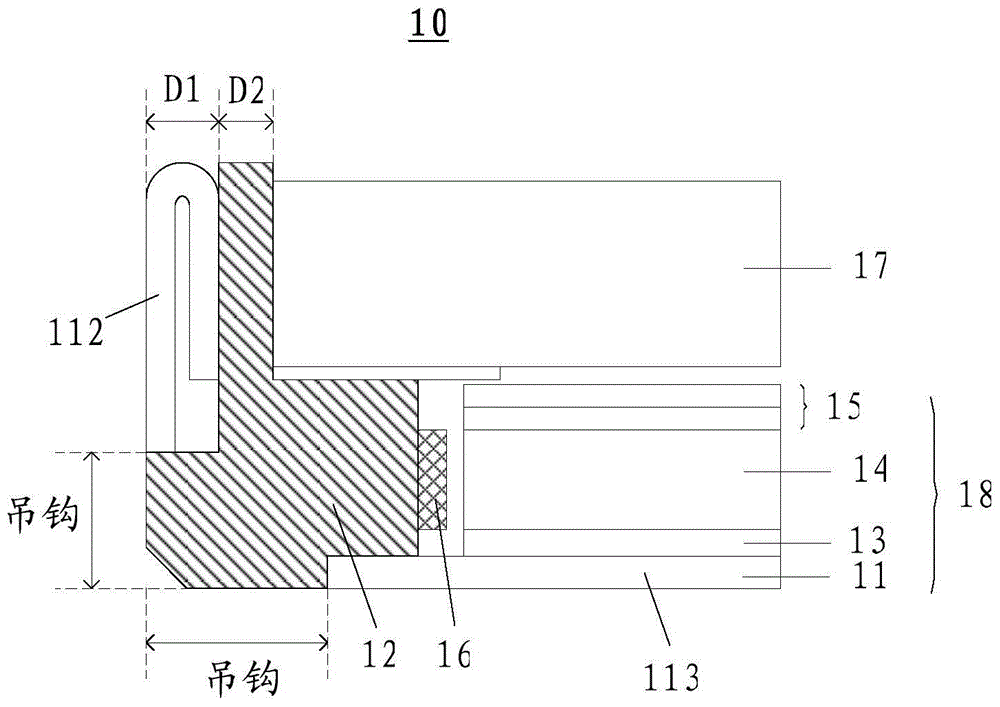

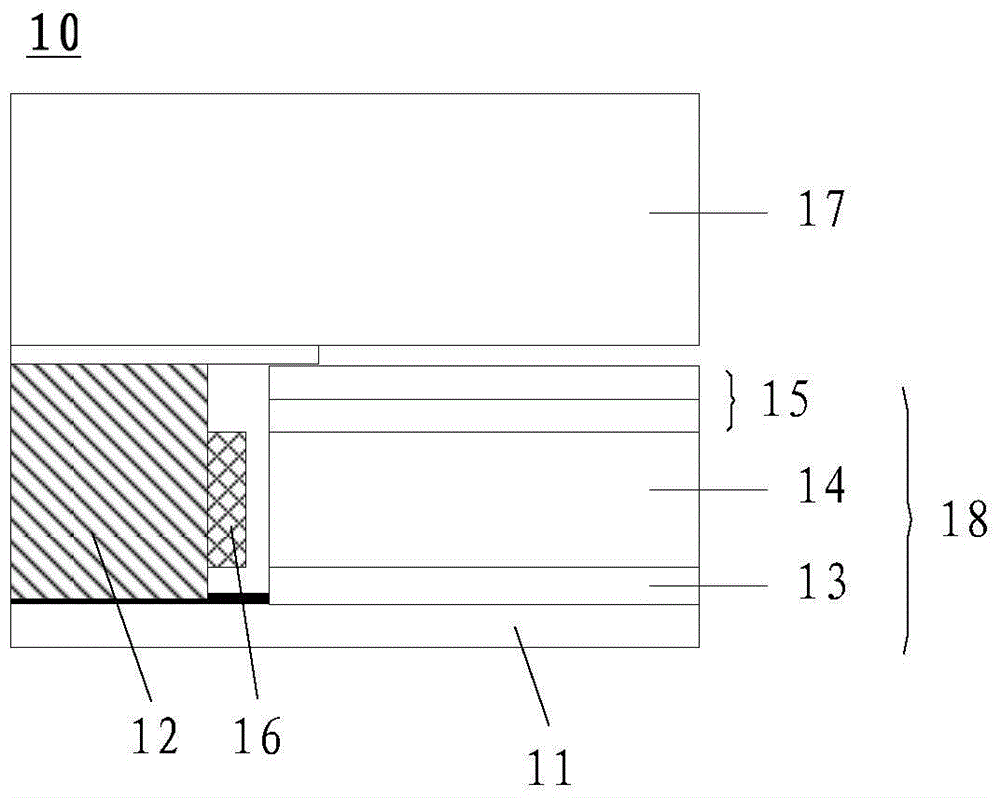

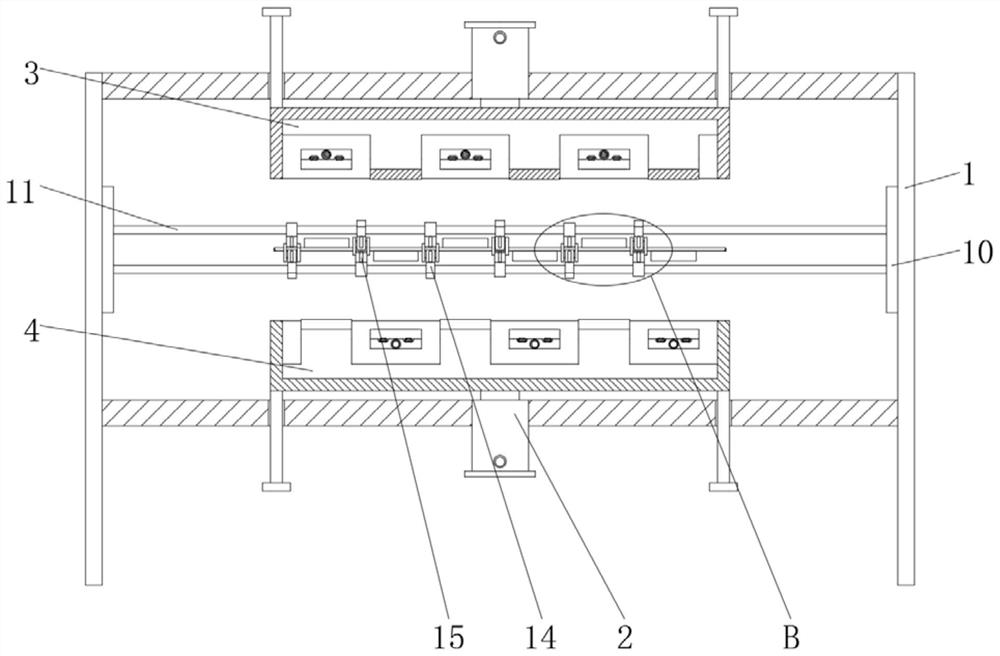

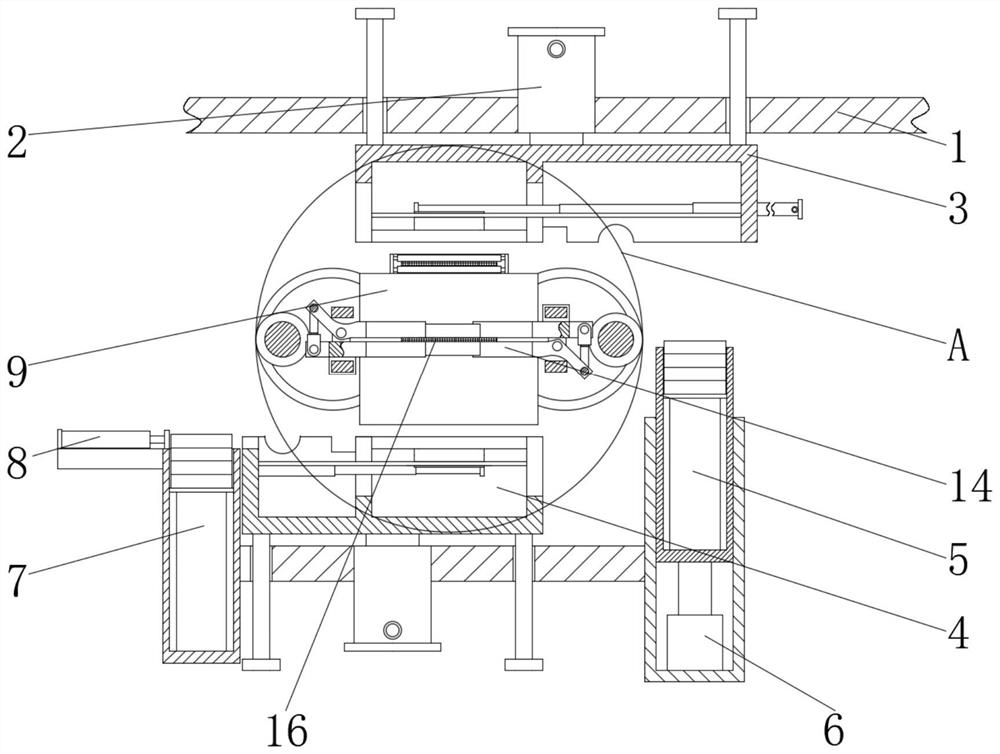

Multi-tube intensive flexible efficient automatic tube insertion process

InactiveCN102744586AReduce labor intensityAvoid compression deformationMetal working apparatusEngineeringMechanical engineering

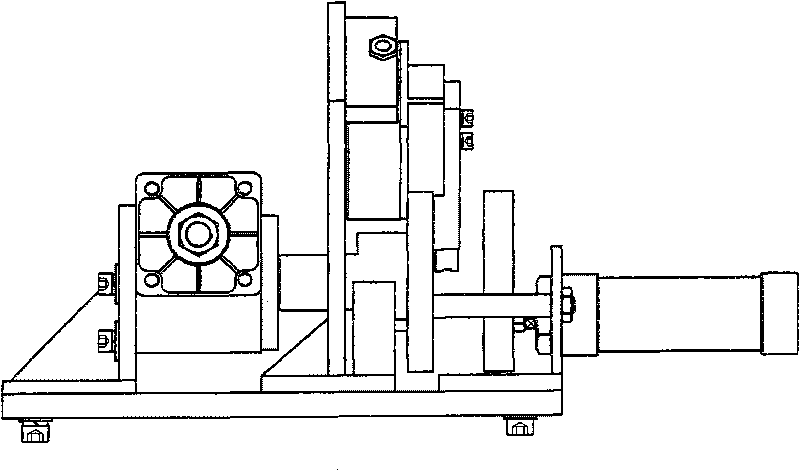

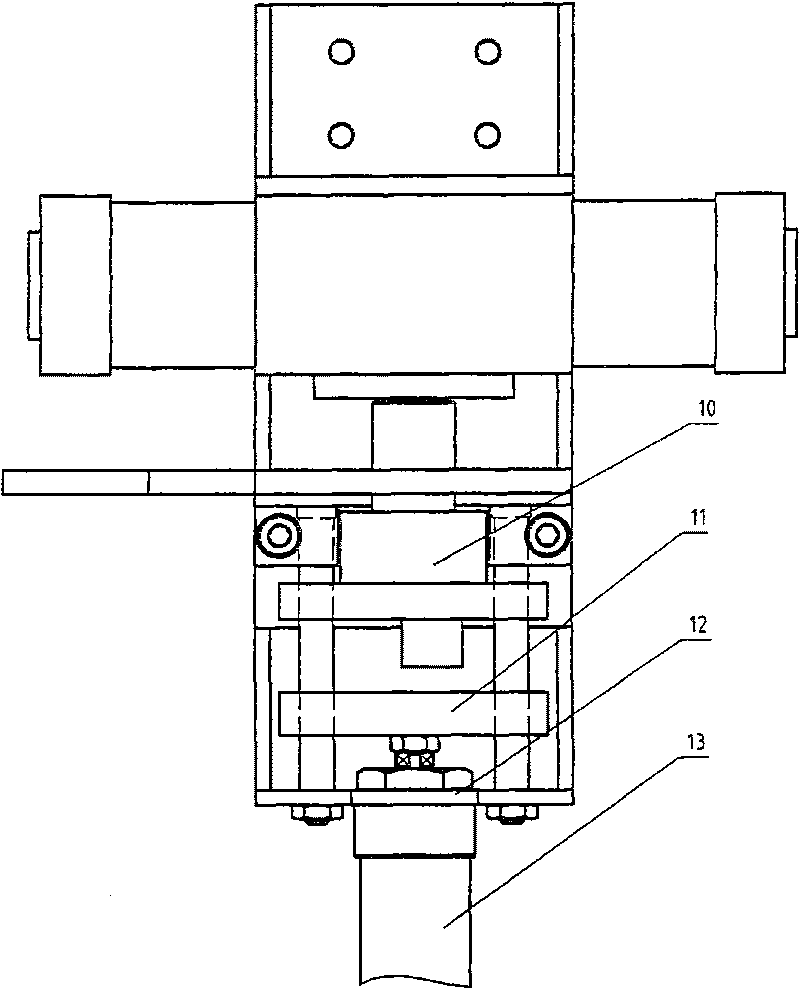

The invention relates to multi-tube intensive flexible efficient automatic tube insertion processes, adopting an automatic tube insertion machine to conduct flexible tube insertion; the automatic tube insertion machine comprises a machine frame, a hanging rod device for positioning a long U-shaped copper tube, a pinch unit, a pinch unit driving mechanism, and a working platform; the pinch unit is driven by the pinch unit driving mechanism to move up and down; the pinch unit comprises an upper pinch unit and a lower pinch unit which are arranged in parallel and driven by an upper and a lower travel mechanism to move relatively; the upper pinch unit and the lower pinch unit respectively consists of a pinch rod and a positioning pinch rod; an air bag is arranged in the pinch rod and the positioning pinch rod respectively; an open-close driving mechanism respectively drives opening and closing between the pinch rods and the positioning pinch rods of the upper pinch unit and the lower pinch unit. According to the process, automatic tube insertion is realized during heat exchanger production, the demand for labor force and production costs are reduced, the production efficiency is improved, the labor strength of workers is reduced, and an air bag is simultaneously provided in the pinch unit for flexible clamping the copper tube, thus preventing the copper tube from deformation under pressure.

Owner:WUXI G S PRECISION TOOL +1

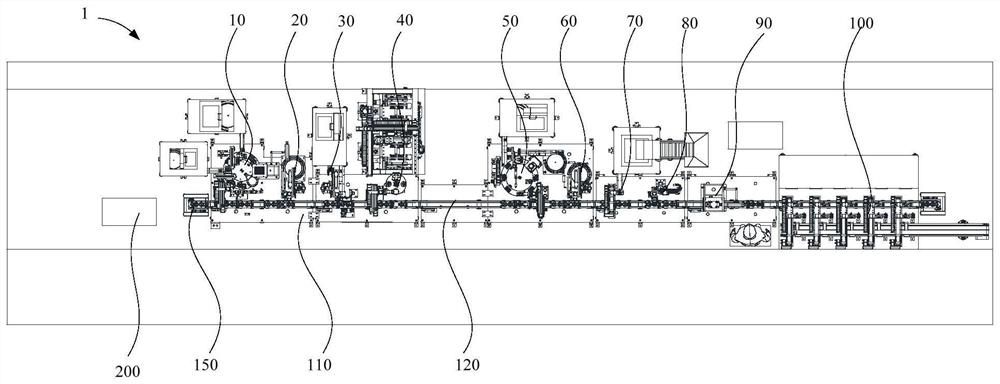

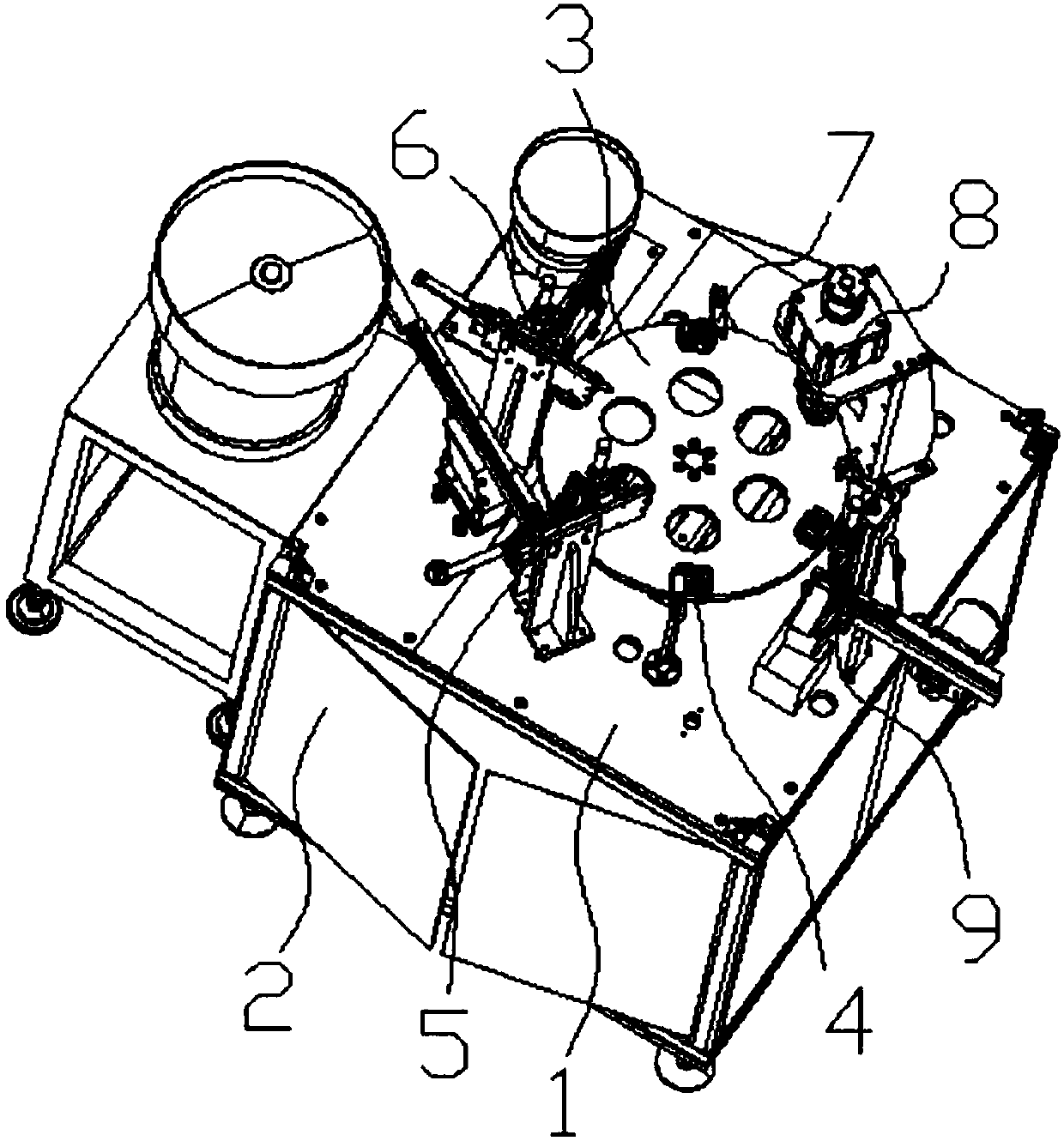

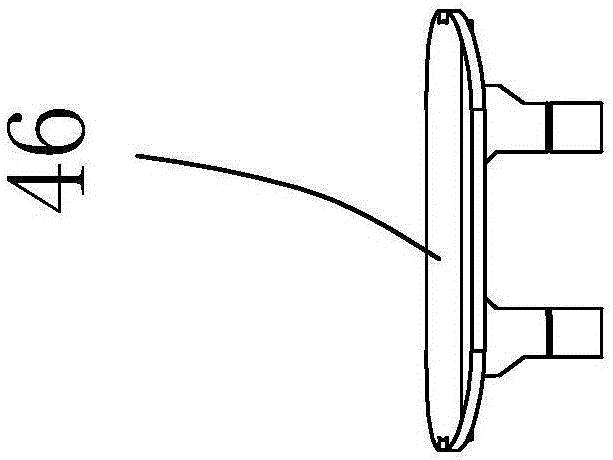

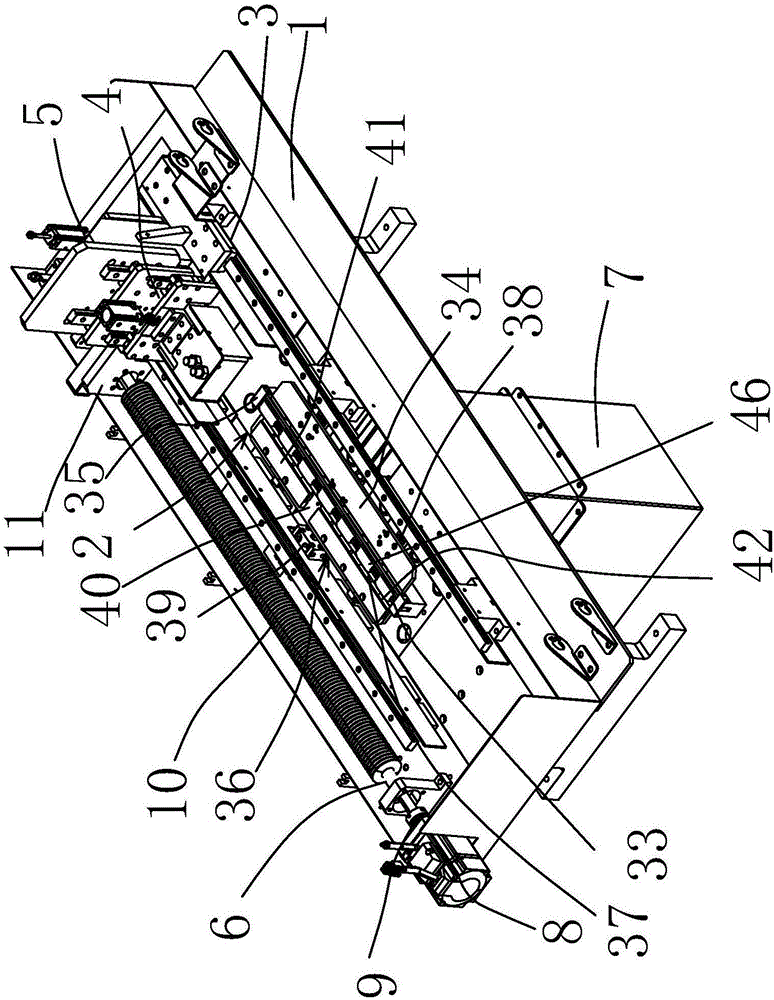

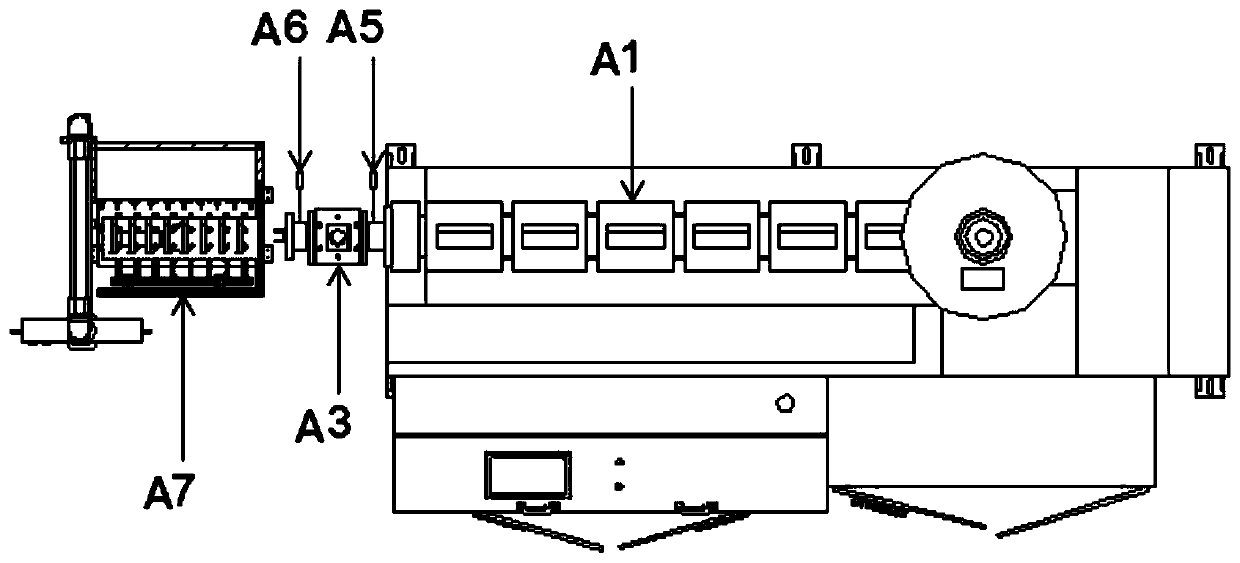

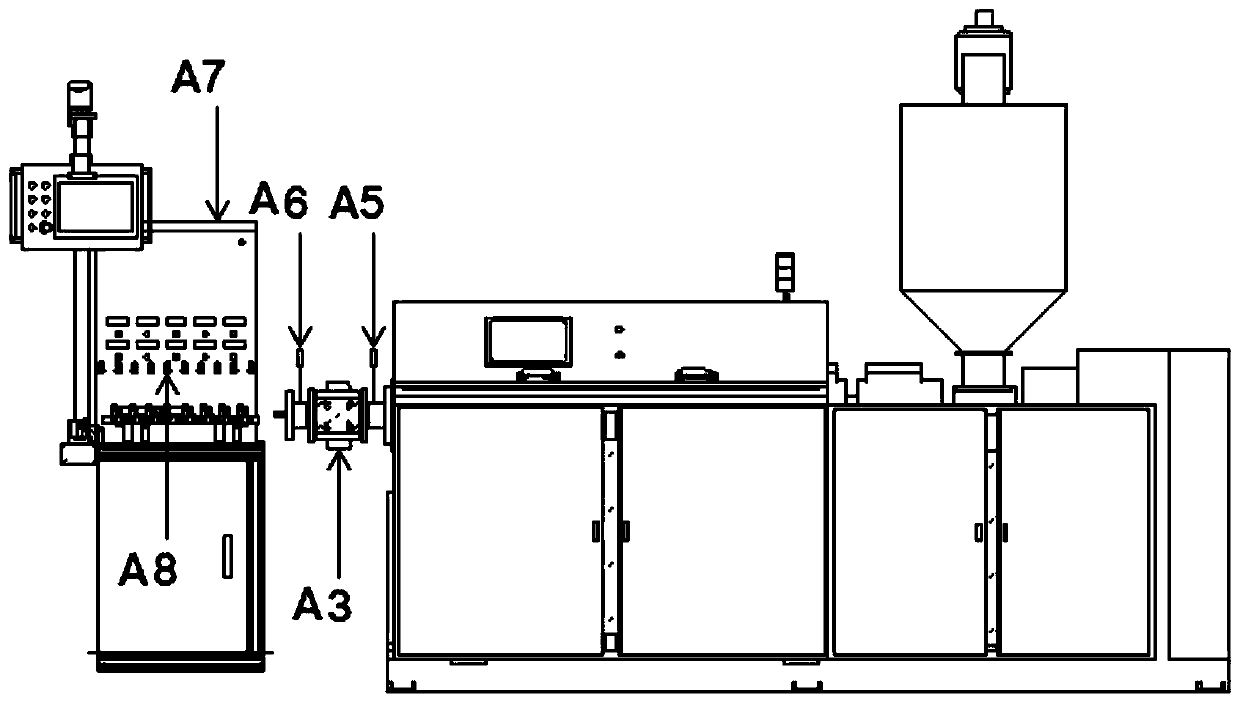

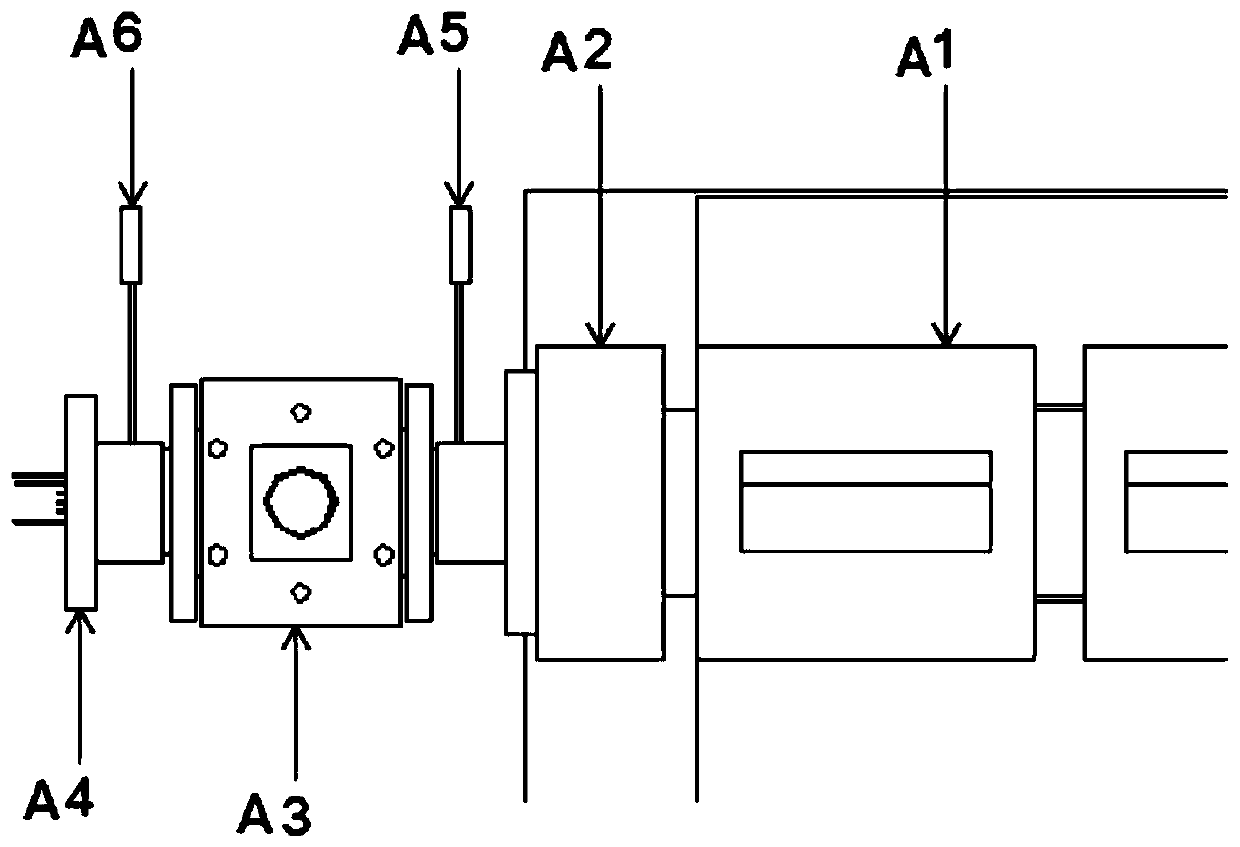

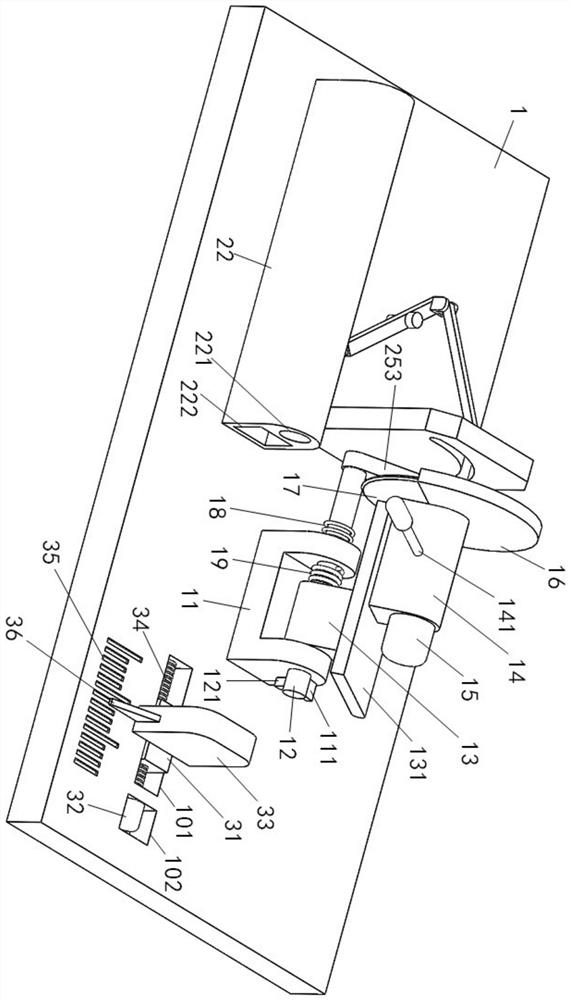

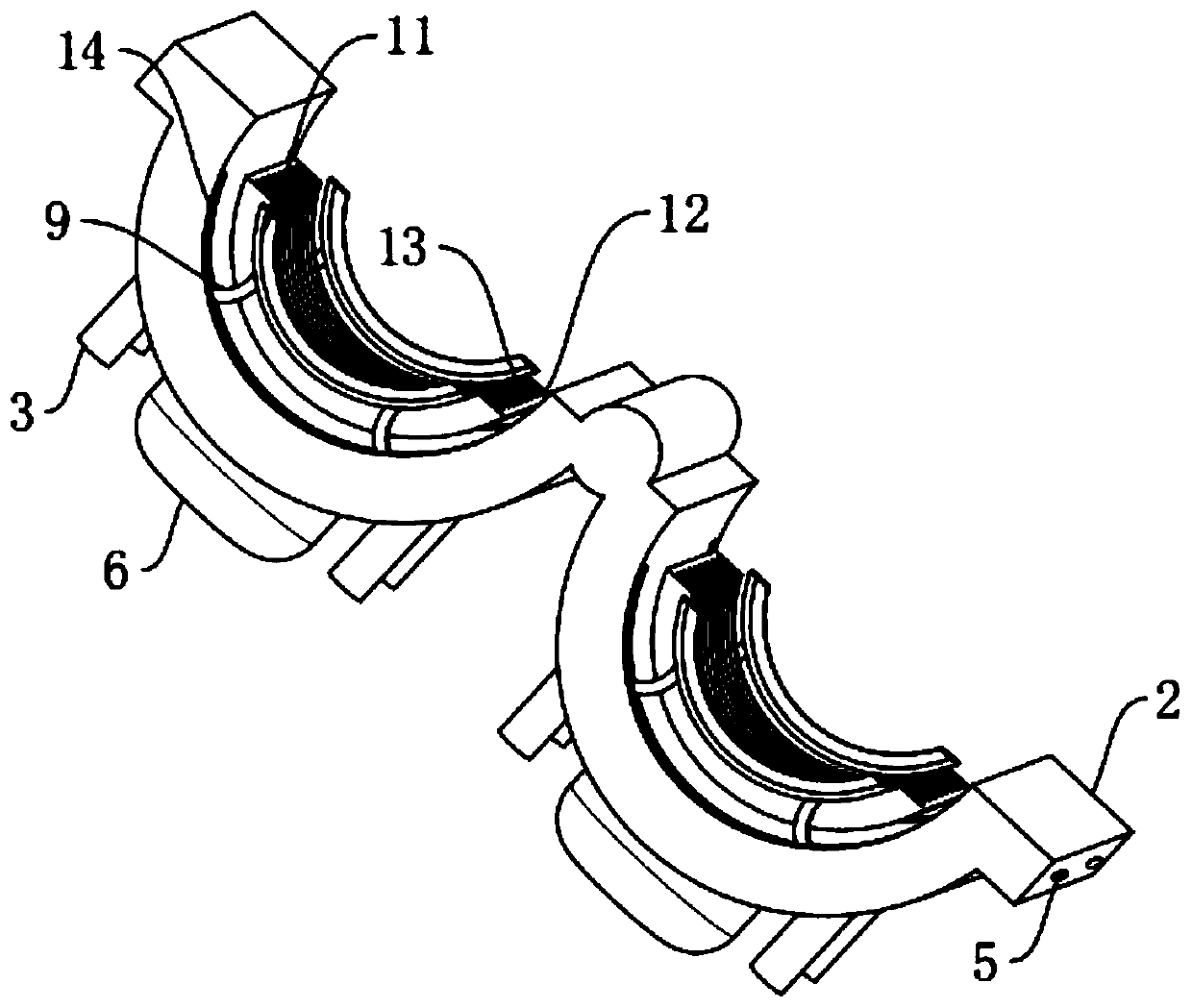

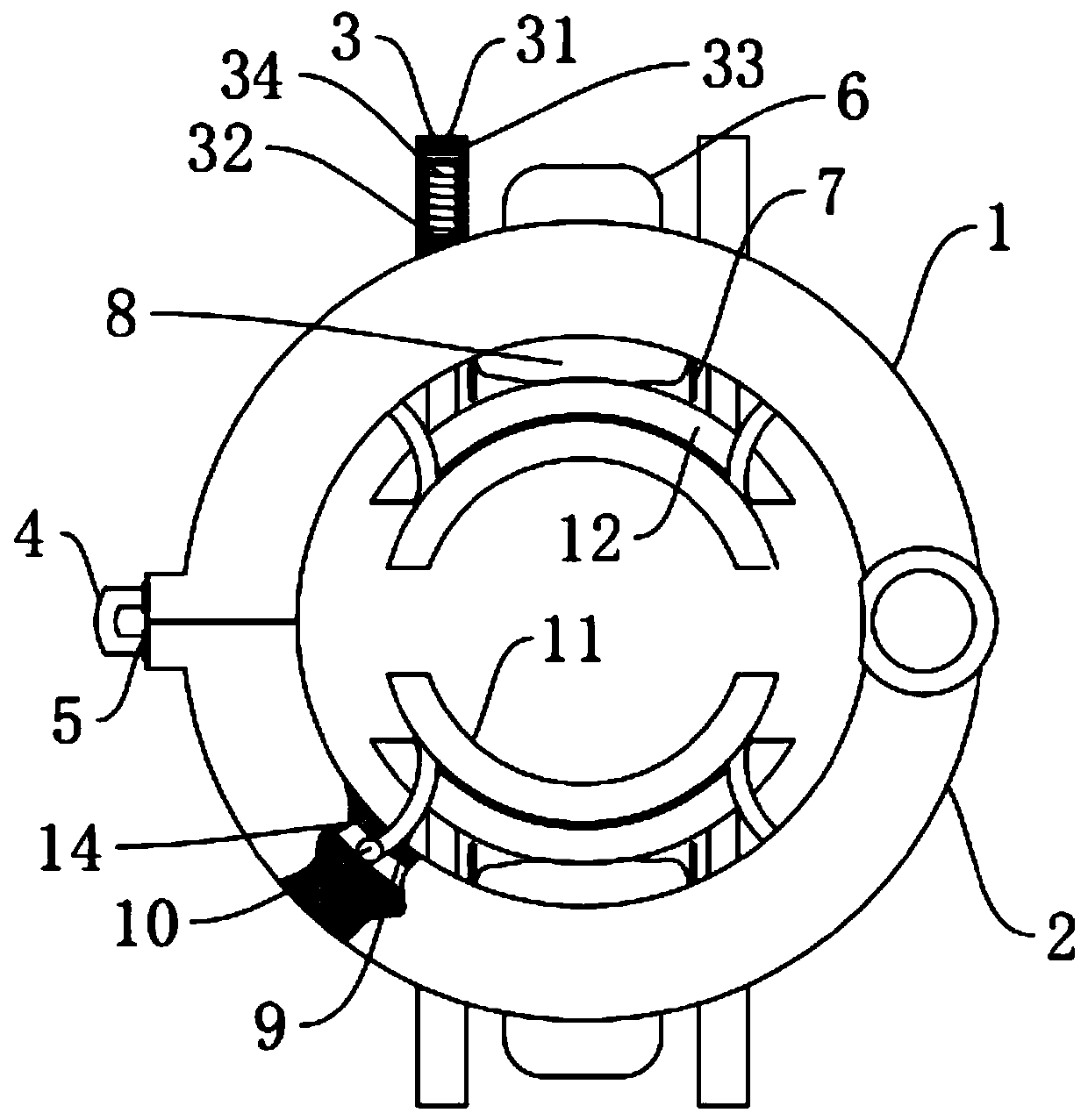

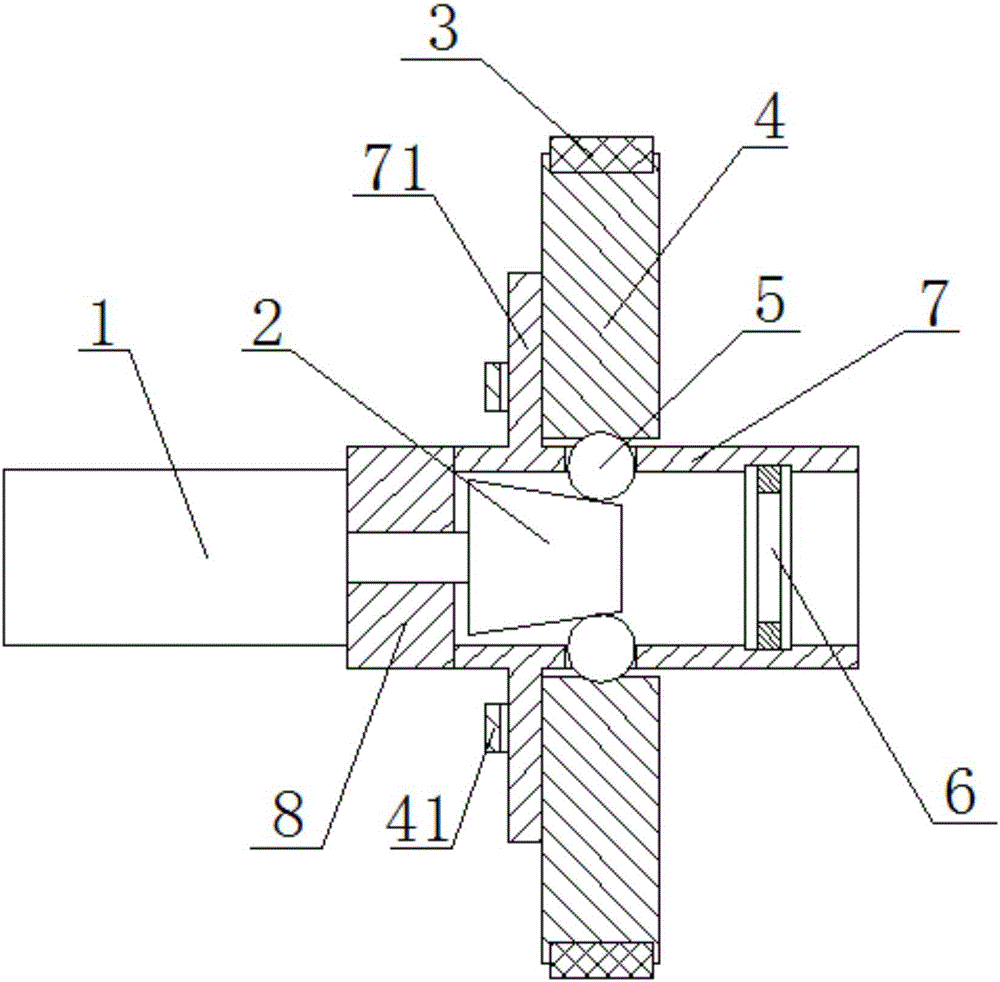

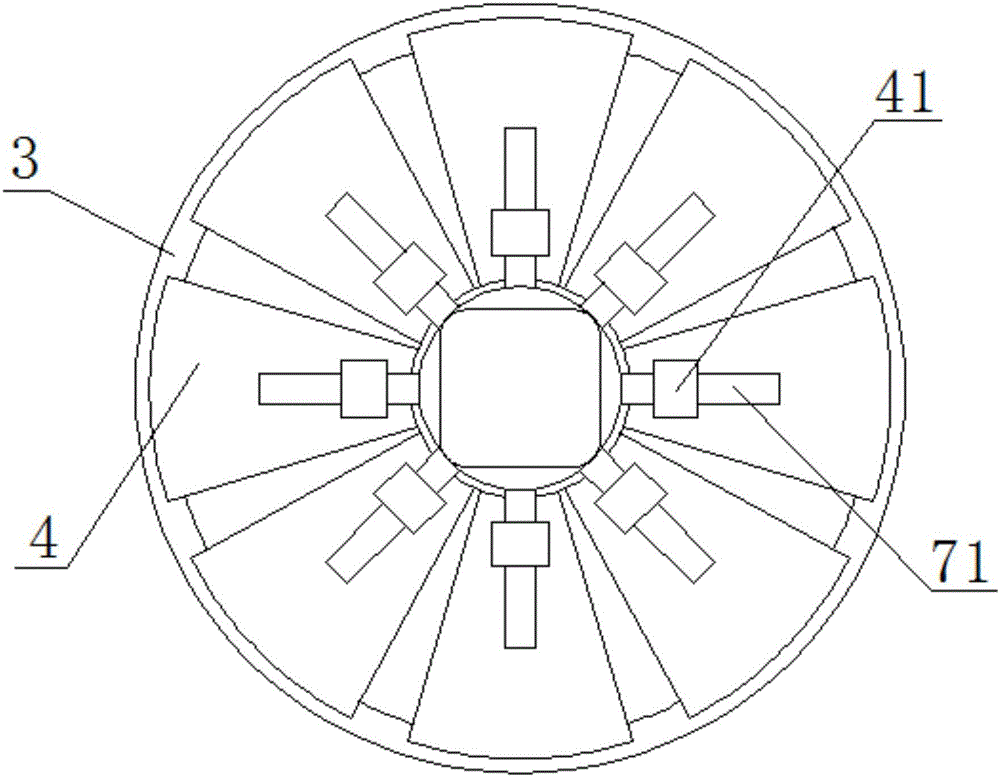

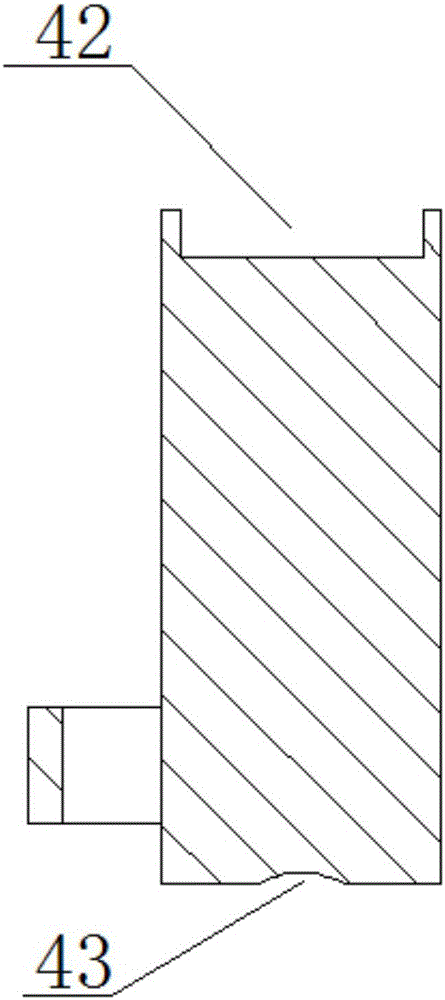

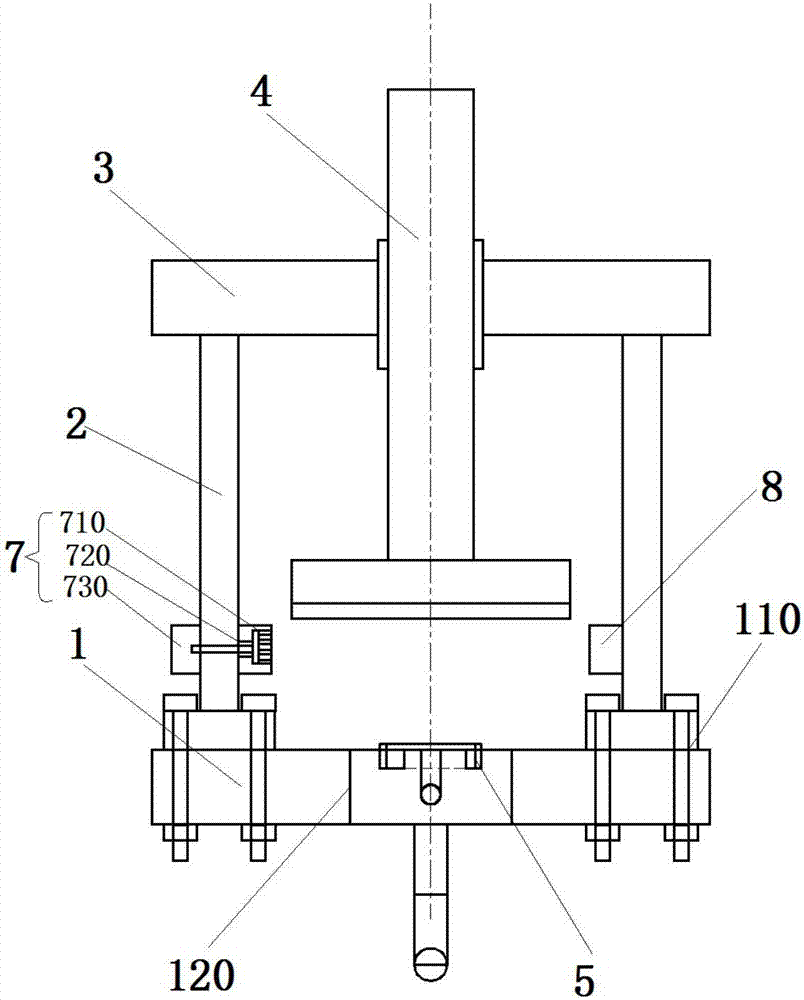

Valve body assembling system

ActiveCN112008393AImprove assembly efficiencyReduce labor costsAssembly machinesMetal working apparatusMachineReclaimer

The invention provides a valve body assembling system. The valve body assembling system comprises a first assembling station; the first assembling station comprises a first machine table, a first index plate, a taking mechanism, a riveting mechanism and a discharging mechanism; the first index plate is rotatably arranged on the first machine table, and a plurality of first jigs are arranged on thefirst index plate; the taking mechanism is arranged on the first machine table and used for placing materials into the first jigs; the riveting mechanism is arranged on the first machine table and used for riveting the materials in the first jigs to obtain a first semi-finished product material; and the discharging mechanism is arranged on the first machine table and used for taking down the first semi-finished product material and placing the first semi-finished product material onto a tool plate. According to the valve body assembling system provided by the invention, actions of assembling,feeding, discharging and the like of valve body parts are completely and automatically completed by machine equipment, the labor cost is reduced while the product assembling efficiency is improved, the actions are stable, errors are not prone to happening, the yield of a product is further increased, and the reliable guarantee is provided for normal production of other subsequent stations.

Owner:KUKA ROBOTICS GUANGDONG CO LTD

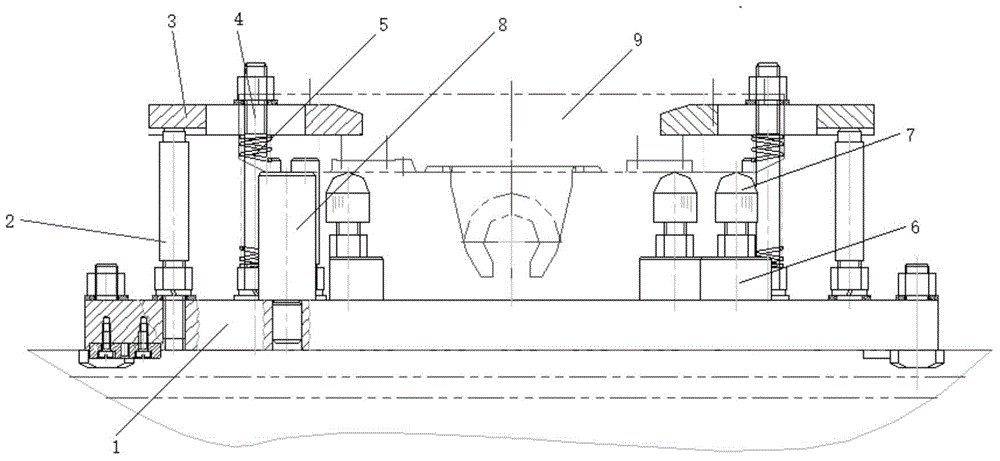

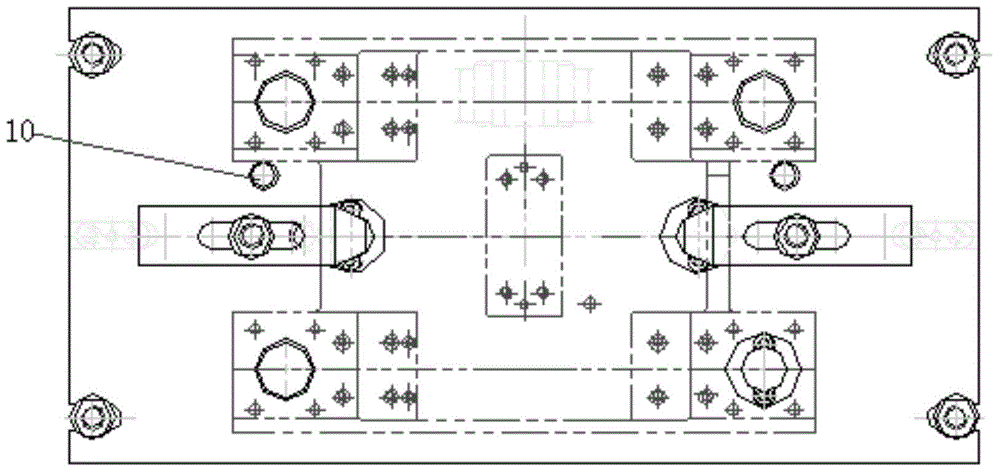

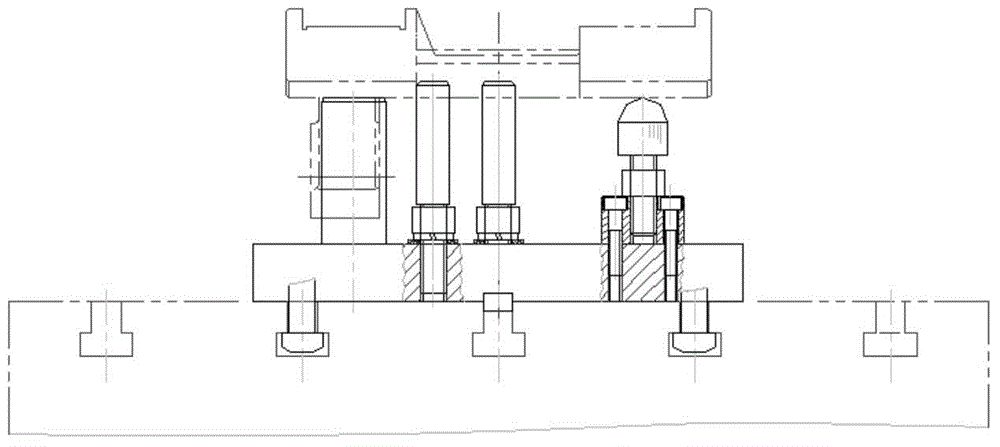

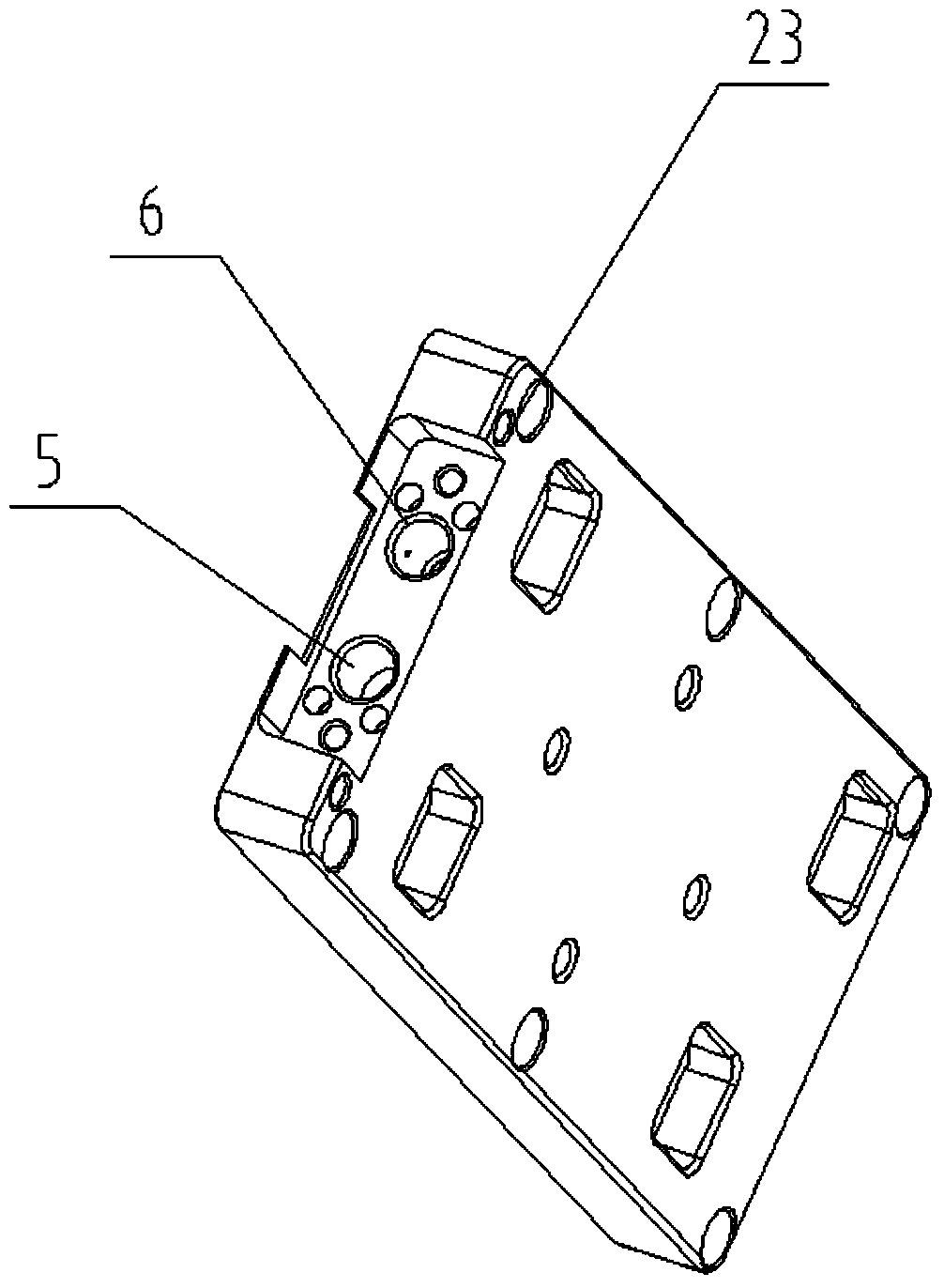

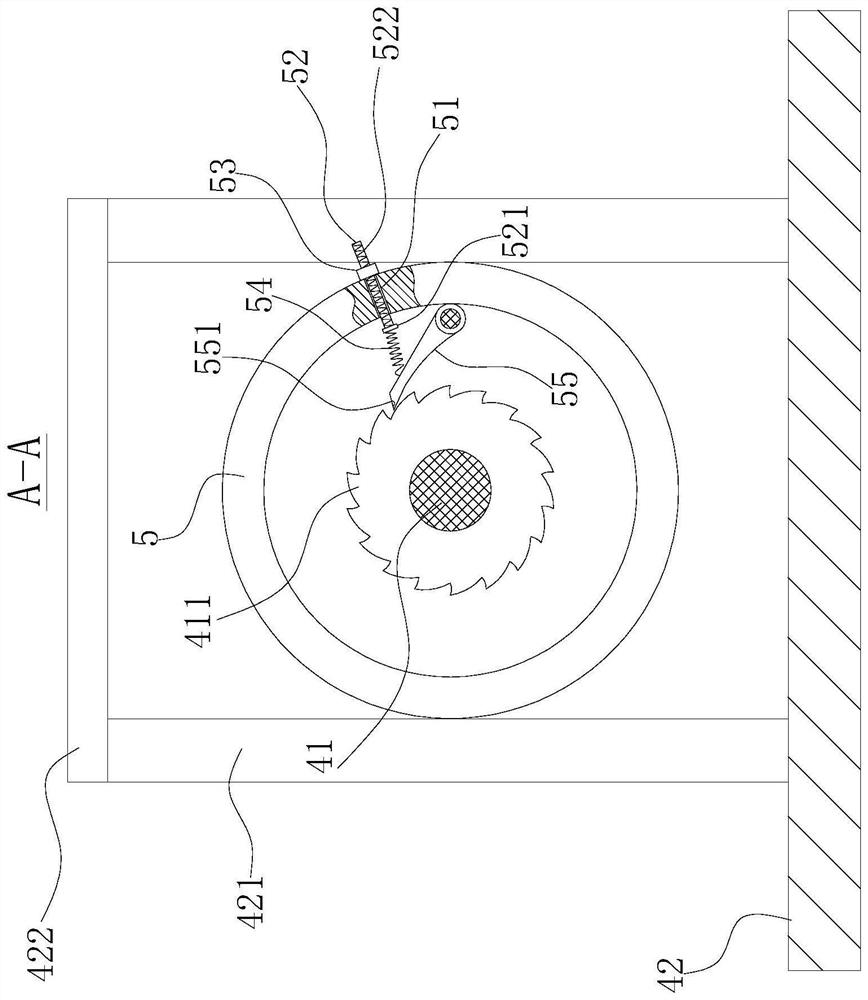

Milling clamp for plane of sliding saddle

InactiveCN105729164ANot easy to looseClamp firmlyPositioning apparatusMetal-working holdersMachine partsEngineering

The invention discloses a milling clamp for a plane of a sliding saddle and belongs to the technical field of machine tool clamp design. The milling clamp comprises a bottom plate, pressing plate supporting rods, pressing plates, studs, compression springs, movable supporting seats, movable ball head supports, a workpiece supporting rod, a workpiece and locating pins. The bottom plate is horizontally arranged. The bottom of each pressing plate supporting rod is provided with a thread. The two pressing plate supporting rods are screwed in the bottom plate, wherein one of the pressing plate supporting rods is arranged on the left, and the other pressing plate supporting rod is arranged on the right. The pressing plates are fixed to the pressing plate supporting rods. The pressing plates are pressed through cooperation of the studs and nuts. The workpiece supporting rod is arranged on the upper surface of the bottom plate, and therefore the workpiece is placed on the workpiece supporting rod and is located through the locating pins. The designed milling clamp for the plane of the sliding saddle is easy to manufacture and convenient to use, and a machined part is large in shape; a manner of combining fixed supporting and floating supporting is adopted, so that pressing deformation can be prevented, and the machining precision is ensured; and rod portions of the studs are sleeved with the compression springs, so that after the pressing plates are used for pressing the workpiece, the workpiece is not likely to be loosened, clamping is reliable, and the positions of the pressing plates are adjusted conveniently.

Owner:ANHUI CHIZHOU HOUSEHOLD MACHINE TOOL

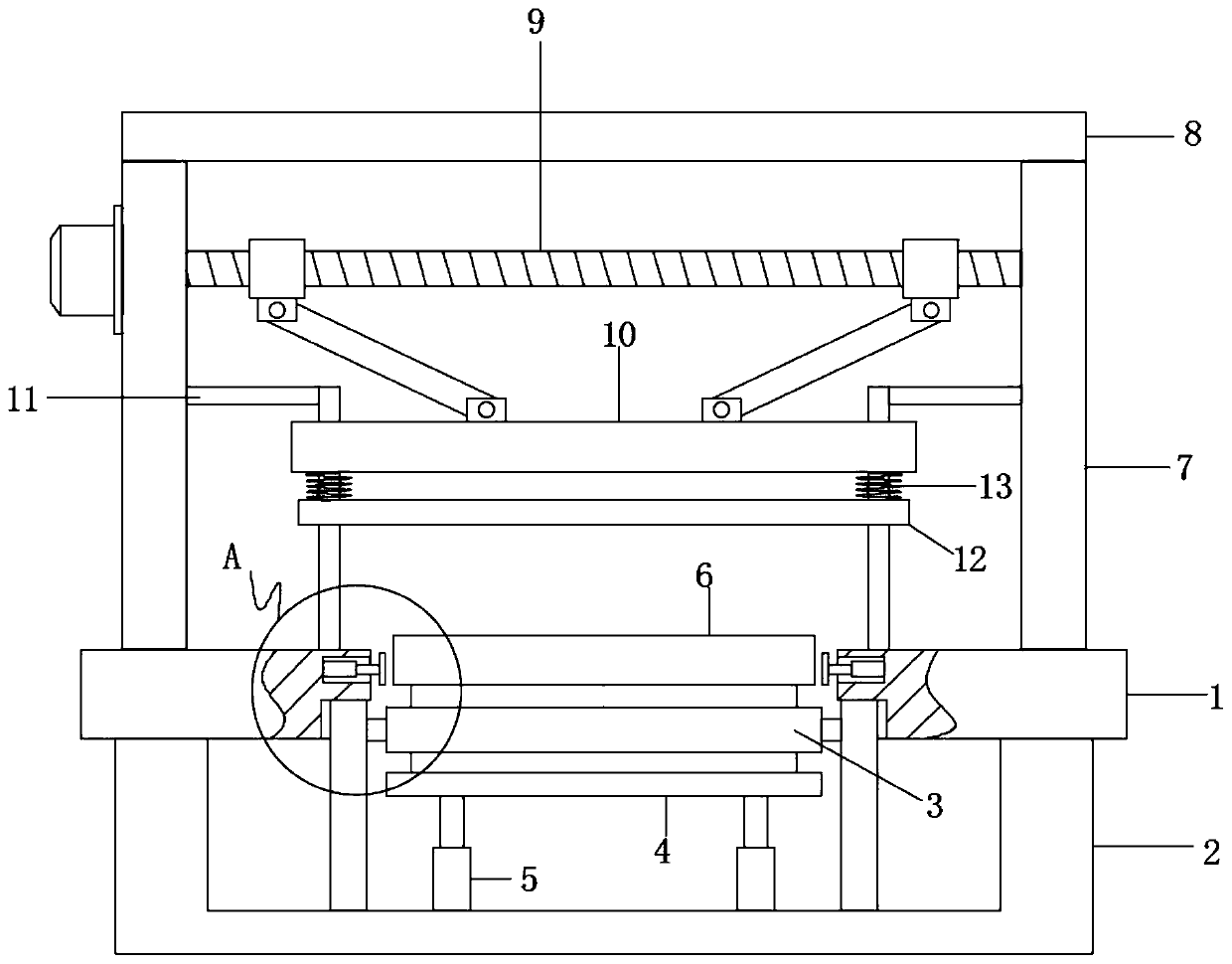

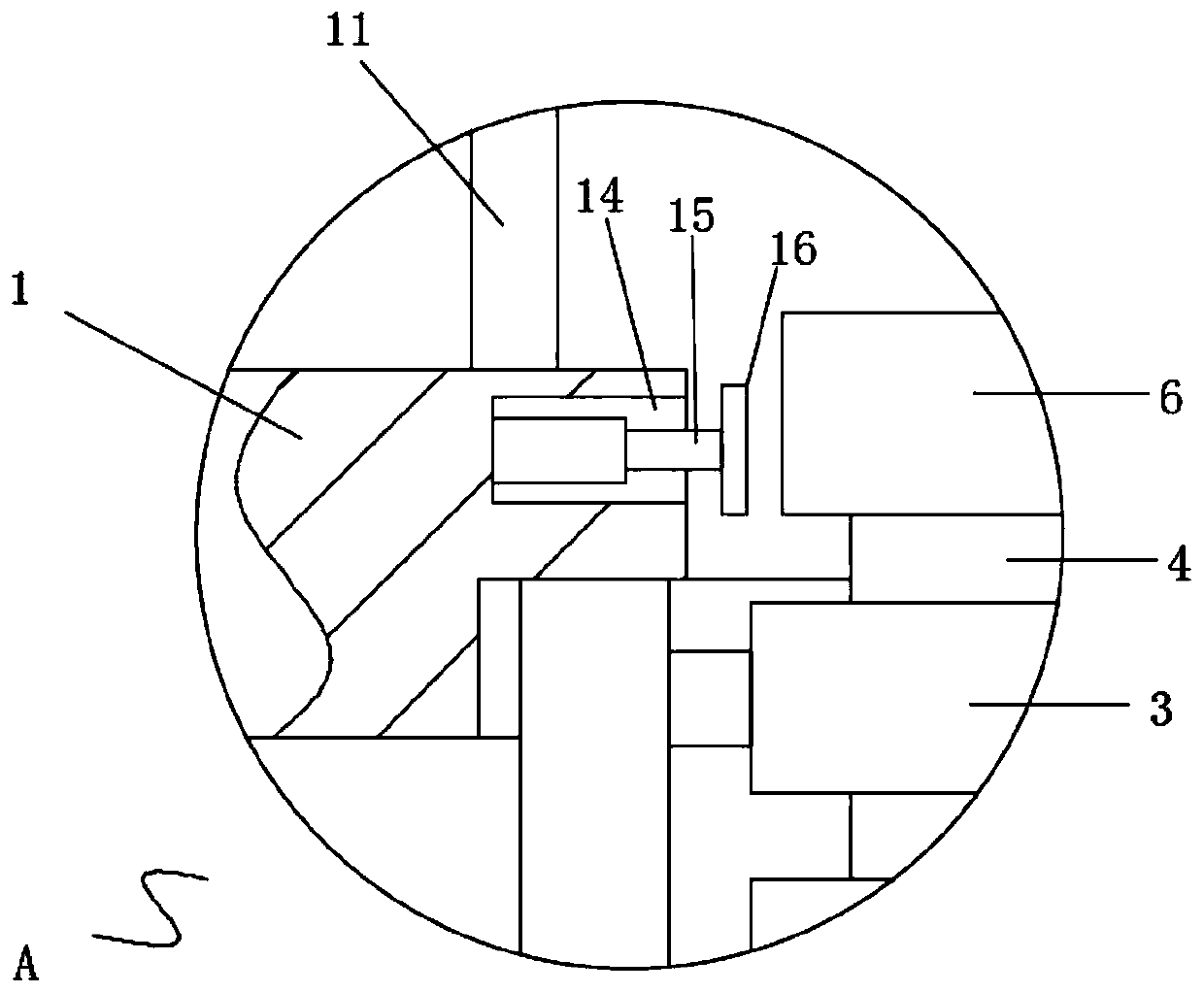

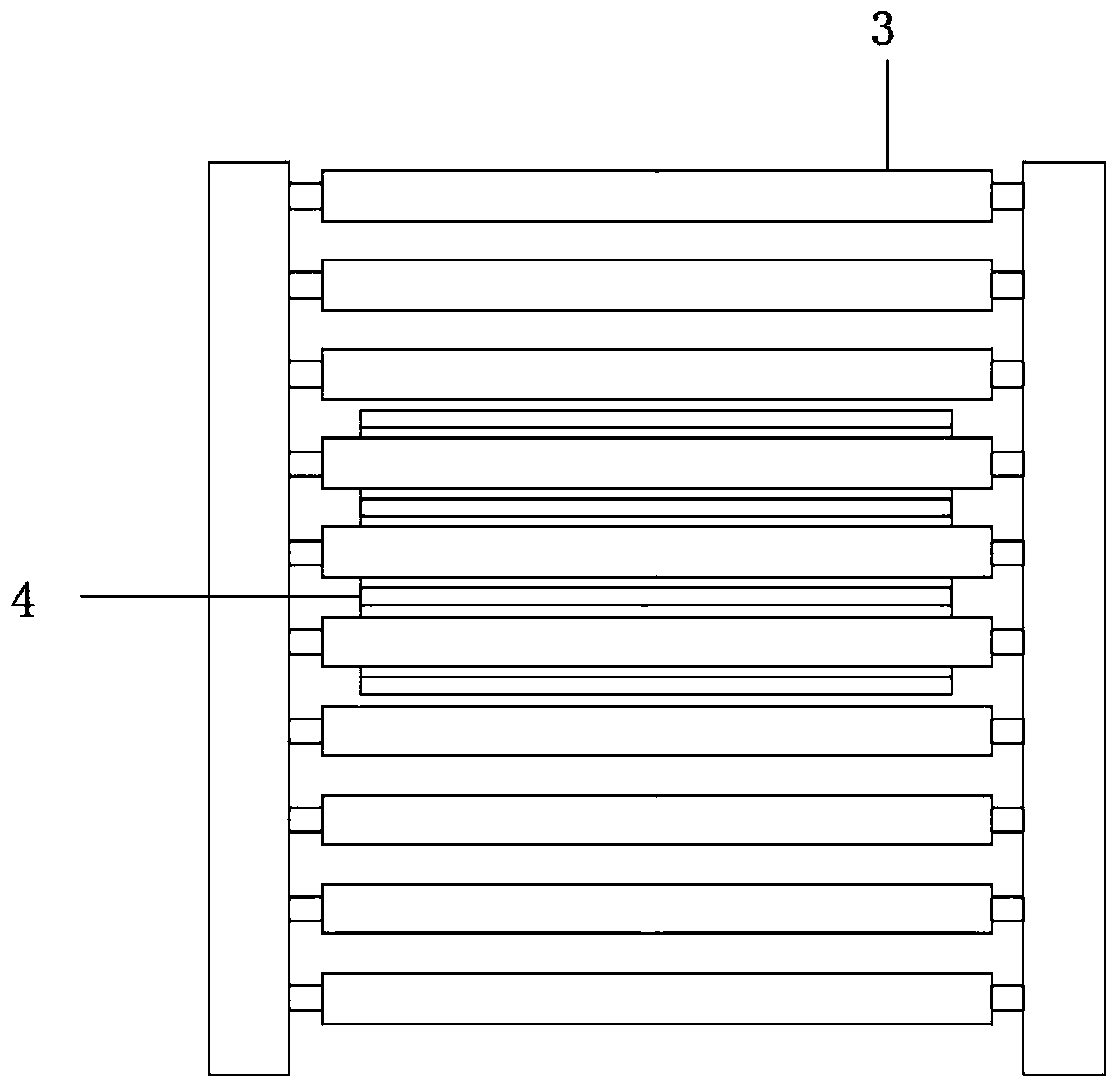

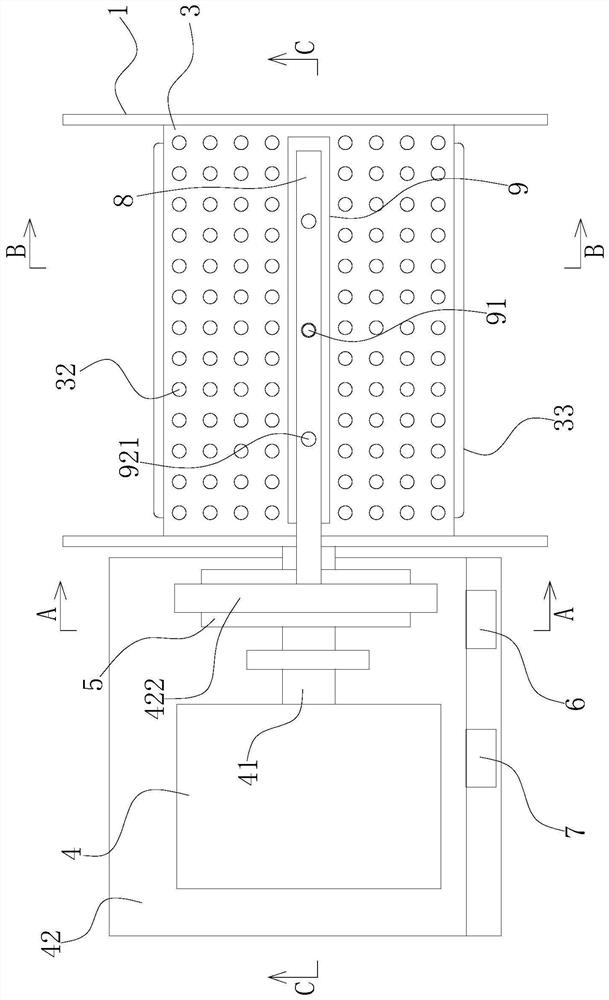

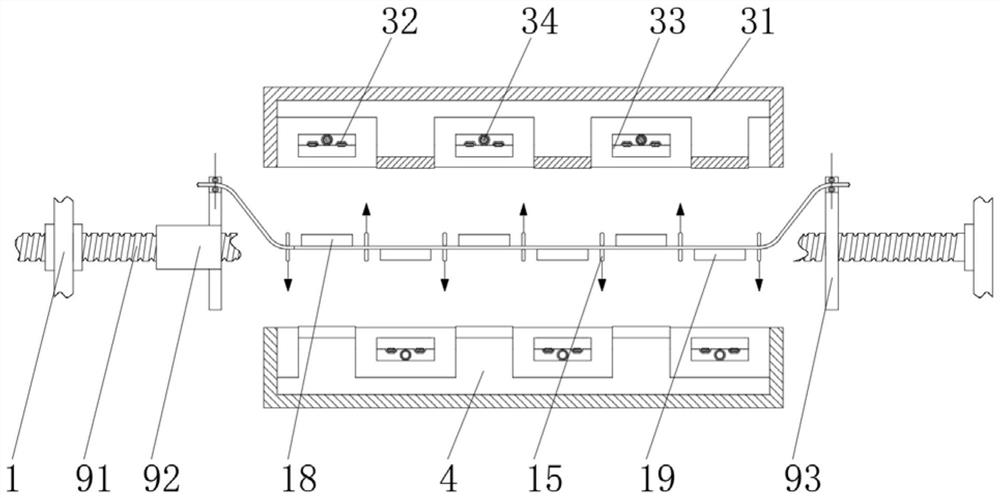

Solid wood composite floor pre-pressing device

InactiveCN110640852AImprove buffering effectAvoid compression deformationPlywood pressesVeneer pressesSolid woodStructural engineering

The invention discloses a solid wood composite floor pre-pressing device, and belongs to the technical field of board production equipment. The device comprises a workbench, wherein a support is arranged at the bottom end of the workbench, the middle of the workbench is provided with an broken opening, a conveying roller is arranged in the broken opening of the workbench, a spacing supporting plate is arranged on the lower side of the conveying roller, and a lifting push rod is arranged at the bottom end of the spacing supporting plate. The device can be directly applied to a composite board processing assembly line, in use, a board is conveyed into the broken opening of the workbench through the conveying roller, the lifting push rod pushes the spacing supporting plate upwards to push thecomposite board upwards, then a clamping push rod clamps the composite board, and then a lifting mechanism is started, so that the pre-pressing operation on the composite board can be completed. According to the device, the practicability and applicability are remarkably improved compared with the prior art, a movable transverse plate, a buffer spring and a pressing plate are arranged and connected, so that the board pre-pressing process has good buffering performance, and the problem of board pressing deformation can be effectively avoided.

Owner:安徽可尔海思新材料科技有限公司

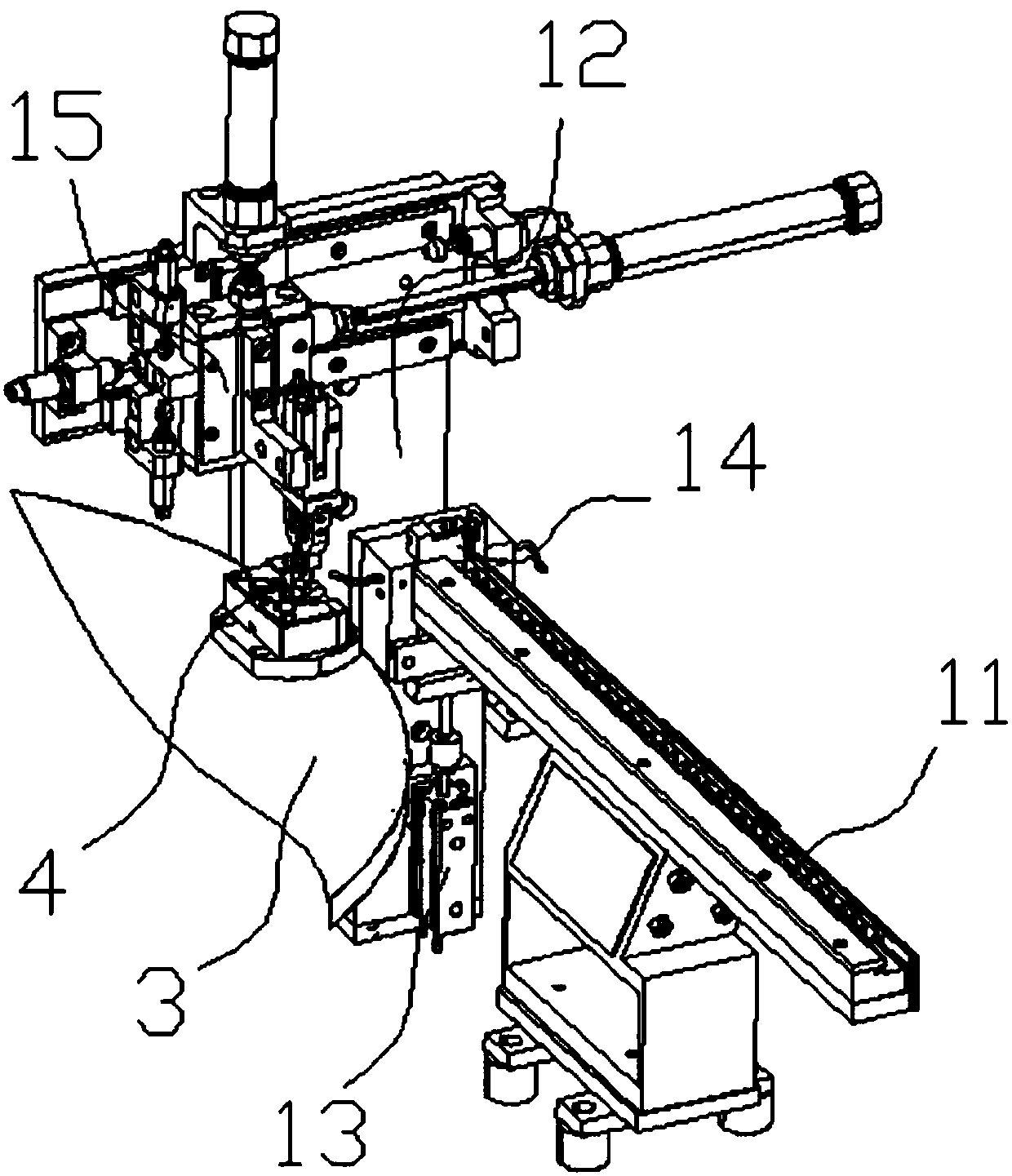

Continuous automatic assembly machine of lug plate elastic piece

ActiveCN107553107AGuaranteed accuracyAvoid elastic deformationMetal working apparatusDistribution controlButt joint

The invention relates to a continuous automatic assembly machine of a lug plate elastic piece. The continuous automatic assembly machine comprises a rack, a power distribution control box, a rotary disc and carriers. A lug plate feeding mechanism, an elastic piece feeding mechanism, a press-fitting mechanism and a discharging mechanism are arranged on the rack. Each carrier comprises a carried material mounting seat embedded into the rotary disc. A carried material seat lifting block penetrating the rotary disc is arranged in each carried material mounting seat. A vertical carried material seat composite spring is arranged between each carried material seat lifting block and the lower portion of the corresponding carried material mounting seat. A carried material seat cooperating with a product is arranged above each carried material seat lifting block. A press-fitting device comprises a press-down device cooperating with the products on the carriers and a carried material seat jackingdevice which is located below the press-down device and cooperates with the carried material seat lifting blocks. According to the continuous automatic assembly machine, the carried material seat lifting blocks and the press-down device can be in butt joint precisely, meanwhile, pressing assembly of a lock piece and a lug plate can be achieved, it can be ensured that the press-down portion is a flat plate between two elastic piece mounting columns, the press-fitting precision is ensured, elastic deformation of the elastic pieces is avoided, and meanwhile continuous automatic machining is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

Wire drawing tool for baggage rack cover plate

ActiveCN106670908AImprove efficiencyEven by forceGrinding work supportsPlane surface grinding machinesCleansers skinEngineering

The invention belongs to the technical field of automobile part manufacturing tools and provides a wire drawing tool for a baggage rack cover plate. The wire drawing tool comprises a main rack part, a wire drawing device, a gripping device, an automatic product feed device and an automatic finished product discharge device. The wire drawing tool has the advantages that the wire drawing tool is convenient to use, reliable in quality and high in efficiency; by adoption of a cylinder floating mechanism, stress is uniform during wire drawing, and the quality can still be ensured under the condition of abrasion of a wire drawing brush; manual wiping is avoided through an automatic cleaning device; particles are prevented from causing wire drawing disorder through a cleanser washing device; by adoption of an automatic blowing device, a cleanser is directly blow-dried, and manual wipe-drying is avoided; the cleanser is prevented from splashing outside through a baffle combined device; floating pressing is adopted by a clamp part, and a product is prevented from being pressed and deforming; and by adoption of a servo motor, the accuracy of wire drawing positions is ensured, using malfunction is avoided to the greatest extent, the product is uniformly stressed, and the efficiency of wire drawing is greatly improved.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

Composite sling for hot press plate translation lifting and turn over and its use method

InactiveCN1785778AAvoid compression deformationGuaranteed process requirementsLoad-engaging elementsRigid frameHot press

The present invention relates to a plates hoisting equipment, in particular, it relates to combined hoisting equipment for horizontally-hoisting and turning hot-pressed plate and its application method. Said invention is characterized by changing the original flexible steel wire rope hoisting method into the invented rigid frame structure hoisting method. The invented hoisting equipment mainly includes the following several portions: curved board, cross-beam, horizontal hoisting plate, hoisting hooks, turning-hoisting plate and channel steel. Besides, said invention also provides the concrete steps of its application method.

Owner:SHANGHAI WOOD-BASED PANEL MASCH CO LTD

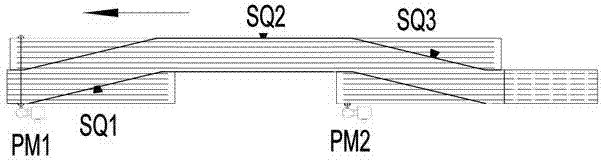

Entire-line non-pressure conveying method for bottle belts

ActiveCN103569631AAvoid compression deformationIncreased speed control flexibilityControl devices for conveyorsMotor driveEngineering

The invention discloses an entire-line non-pressure conveying method for bottle belts. Sensors SQ1,SQ2 and SQ3 for detecting bottles are arranged at the bottom of an arch falling position, at the top of an arch top position and at the top of an arch camber position of a section of arch-shaped conveyer belt in a conveyer line respectively, signals of the three sensors are connected into a drive controller, and the drive controller drives the arch-shaped conveyer belt to start, stop, accelerate and decelerate in a variable frequency control manner and correspondingly outputs speeds of a motor driving the section of the conveyer belt at the arch falling tail end of the arch-shaped conveyer belt according to detection results of each sensor and based on the speed of a previous section of conveyer belt. Compared with a traditional constant-high-speed conveying method, the entire-line non-pressure conveying method has the obvious benefits as follows: the variable frequency control is adopted, and multi-point bottle inspection and entire-line tracking are performed on the conveyer line, so that the control flexibility of the speed of conveyer belt for different bottle quantities is greatly improved, the deformation of bottles caused by pressure is effectively prevented, the conveying energy consumption is reduced, and the service life of mechanical equipment is prolonged.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

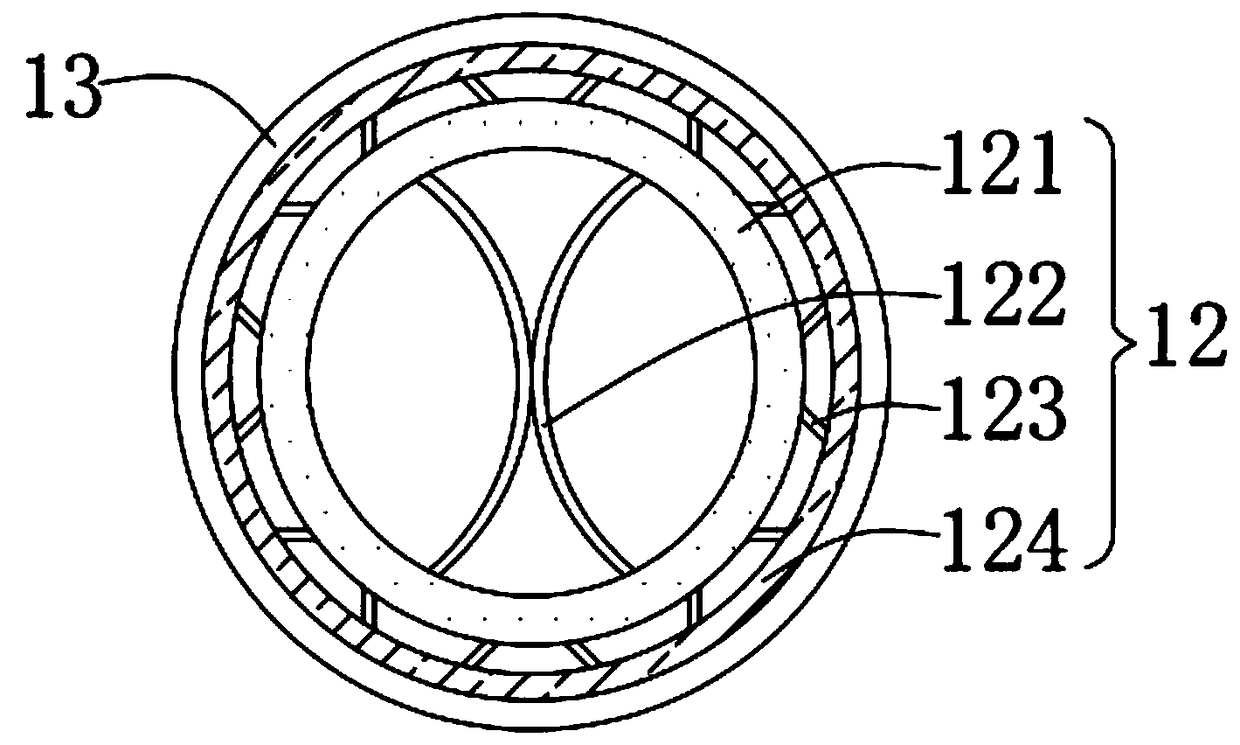

PVC pipe fitting

ActiveCN109058610AAvoid damageExtend your lifePipe elementsPipe connection arrangementsGround contactPipe fitting

The invention relates to the technical field of pipes, in particular to a PVC pipe fitting, which comprises a PVC pipe, a connecting rod, a first protrusion, a first fixture block, a pipe body, an inner pipe body, an arc-shaped piece, a reinforcing rib, an outer pipe body, a wear-resistant piece, a connector, a first fixing component, a second fixing component, a locking belt, a clamping plate, aspring, a steel ball, a groove, a locking block, a connecting component, an outer casing, a second protrusion, an inner flow tube and a second clamping block. According to the wear-resistant piece ina special structure with a fixed outer part of the PVC pipe, the pip bodies can be avoided from touching with the ground when the PVC pipe is used and the pipe bodies are prevented from damage of friction; meanwhile, the pipe body adopts a dual-layer structure, and the reinforcing rib is added in the middle with high strength; when in use, the whole body is supported by the inner arc-shaped piece,thereby effectively avoiding the pipe body from compressive deformation; the connector in a special structure is used to enable the PVC pipe be inserted; a manner of locking of the locking belt is added besides a mutual cooperation manner so as to improve the connection firmness and connection sealing performance.

Owner:湖南省星晖科技有限公司

Vacuum loading device

ActiveCN104308606ARealize processingEasy to usePositioning apparatusMetal-working holdersProduct gasMechanical engineering

The invention discloses a vacuum loading device. The vacuum loading device is characterized in that a loading device body comprises a top and a main board; a top cover can detachably cover one side of the main board by a sealing manner; a closed vacuum maintaining cavity is formed between the top cover and the main board; a vacuum loading port and a vacuum releasing port are respectively formed in the sidewall of the vacuum maintaining cavity; an one-way valve through while the air flows from the vacuum maintaining cavity is arranged in the vacuum loading port; a sealing plug for sealing the vacuum releasing port is arranged in the vacuum releasing port; the side of the top cover, back to the main board is the outer side, and the side of the top cover, toward the main board is the inner side; a plurality of inwards concave cavities which are matched with an actuation product are formed in the outer side surface of the top cover; a sealing strip is arranged like a loop on the side edges of the inwards concave cavity; air holes which are communicated with the vacuum maintaining cavity are arranged in the bottom surfaces of all the inwards concave cavities. According to the vacuum loading device, the loading device body enables fixed positioning of the product without any compressing force, and thus the product is avoided being pressed and deformed; in addition, a processing device is not provided with a vacuum generation device, so that the normal processing of high-precision and small-size processing devices is realized.

Owner:昆山冠品优精密机械有限公司

Door gasket processing and production assembly line

ActiveCN111515700AExtrusion stabilityReduce adverse effectsConveyorsFluid pressure measurement by electric/magnetic elementsProduction lineAssembly line

The invention discloses a door gasket processing and production assembly line which comprises an extrusion molding mechanism, a metering transmission mechanism, a cutting device, an automatic magneticstrip penetrating and distributing production line, a full-automatic welding production line and a control device in sequential connection. The defect that an extruding amount of a screw extruder inthe prior art is unstable is overcome, and adverse effects on molding of door gaskets are reduced to the maximum extent; the defect that molding sizes of door gaskets fluctuate due to the difference of transmission speeds of an upper synchronous belt and a lower synchronous belt of a metering transmission mechanism in the prior art is also overcome, and the extrusion deformation of the door gaskets and the fluctuation of the molding sizes of the door gaskets are avoided; the defect that production efficiency of the door gaskets drops due to collecting and stacking of the cut-off door gaskets and use of steering engines in the prior art is overcome, and production efficiency of the door gaskets is improved; and through several automatic processes of automatic mold entering, positioning, transferring, welding, piece picking and the like, the full-automatic production of the door gaskets of refrigerators from semi-finished products to finished products is realized.

Owner:ANHUI HIGASKET PLASTICS CO LTD

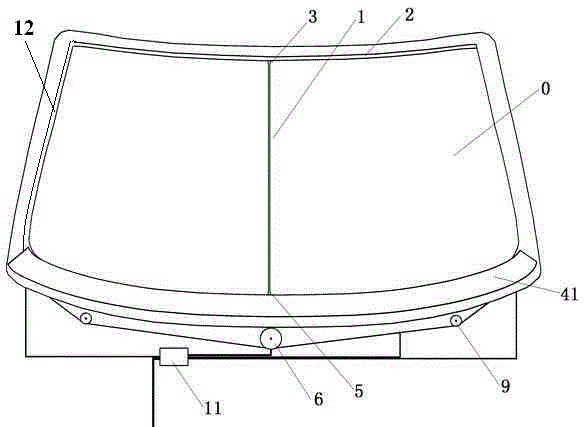

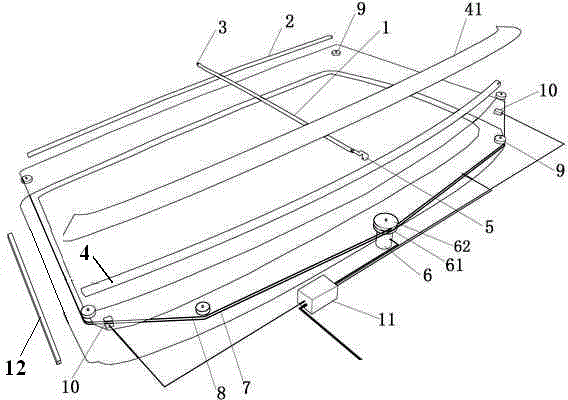

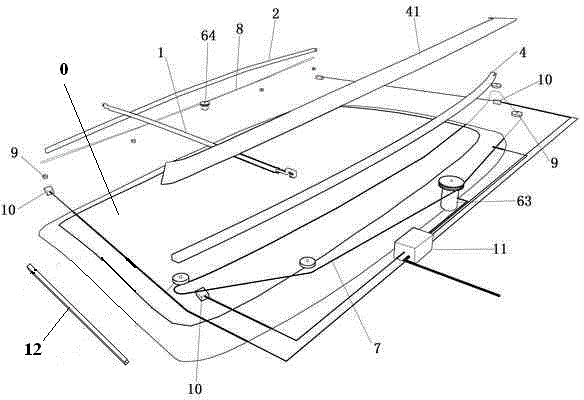

Transversely-wiping type windscreen wiper

The invention provides a transversely-wiping type windscreen wiper and relates to a device for removing dirt such as rain, snow and dust obstructing the view of a user on a windscreen. According to the transversely-wiping type windscreen wiper, a dead corner of wiping and sweeping is avoided and the phenomenon that rainwater follows the wiper is effectively avoided. The transversely-wiping type windscreen wiper comprises a windscreen wiper blade vertically arranged on the surface of a windscreen and making contact with the windscreen, an upper sliding rail and a lower sliding rail. The upper end of the windscreen wiper blade is connected with an upper sliding block arranged on the upper sliding rail and the lower end of the windscreen wiper is connected with a lower sliding block arranged on the lower sliding rail. The transversely-wiping type windscreen wiper is characterized in that the upper sliding rail and the lower sliding rail are respectively a groove-shaped sliding rail, a barrier is arranged in each groove-shaped sliding rail in the length direction of the sliding rail, each groove-shaped sliding rail is divided into an inner groove and an outer groove through one barrier, the middle of each inner groove and the middle of the corresponding outer groove are communicated, at least two idler wheels are arranged in the grooves in the length direction of the sliding rails, and a wheel shaft of each idler wheel is parallel to the corresponding barrier.

Owner:SHENZHEN JIAHUI SCI & TECH IND CO LTD

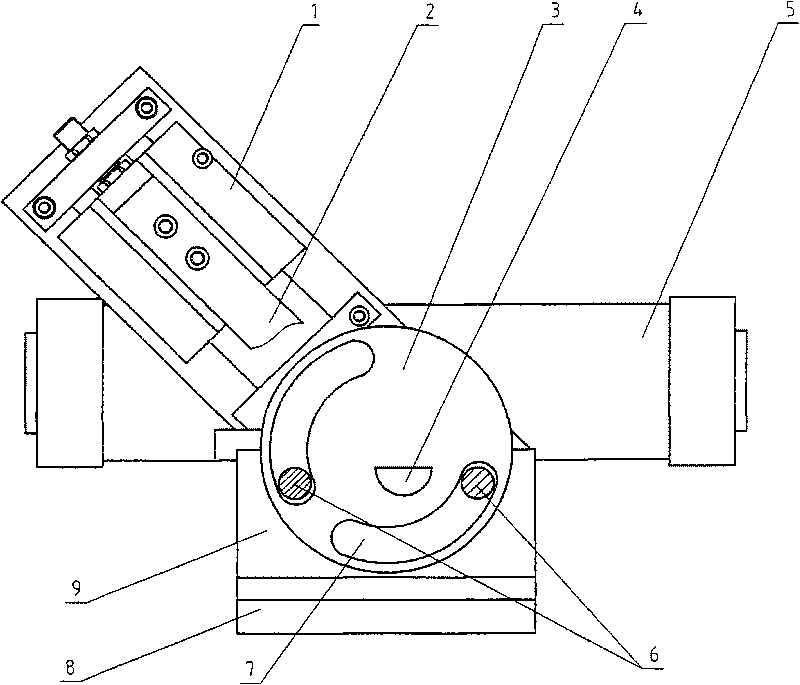

Metal spacer bender bending device

The invention discloses a metal spacer bender bending device. The bending device comprises a turntable, a locking block, a rotary cylinder, a fixing block, guiding shafts, a pressure plate, a pressing air cylinder and a baseplate, wherein the fixing block is used to fix one end of the guiding shaft, the pressing air cylinder is fixed on the base of the pressing air cylinder, the guiding shaft is connected between the fixing block and the base of the pressing air cylinder, an arc groove is arranged on the turntable corresponding to the guiding shaft; another cantilever type guiding shaft is connected on the base of the pressing air cylinder, one end of the cantilever type guiding shaft is fixed on the base of the pressing air cylinder, the other end is close to the surface of the turntable, the position of the turntable corresponding to the cantilever type guiding shaft is complanate so that no groove is needed to be arranged on the turntable, and the pressing part of the turntable and the pressure plate are both smooth planes so as to avoid that the spacers deform when being pressed at the positions; and the widths of the metal spacing frames are ensured to be equal, the bending parts are smooth and flat, and the bending effect can reach the specified requirements and the use requirements.

Owner:侯可斌

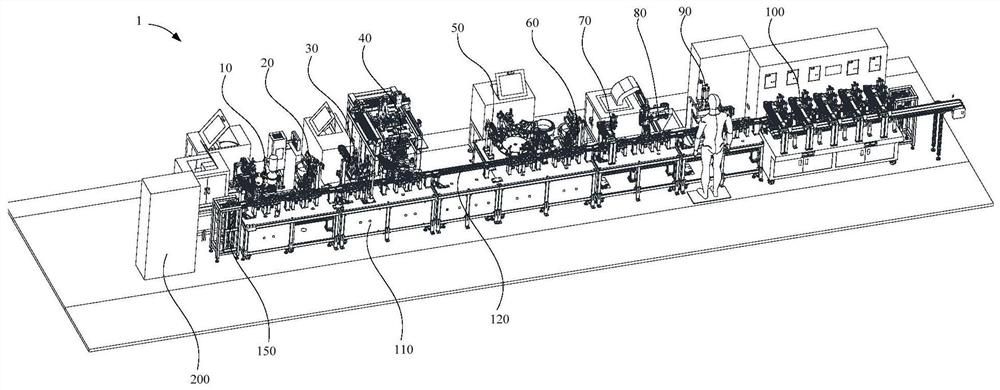

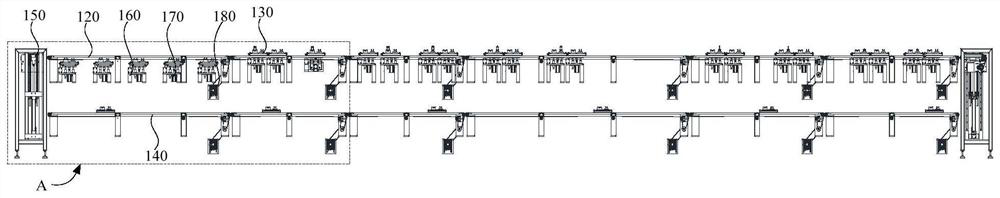

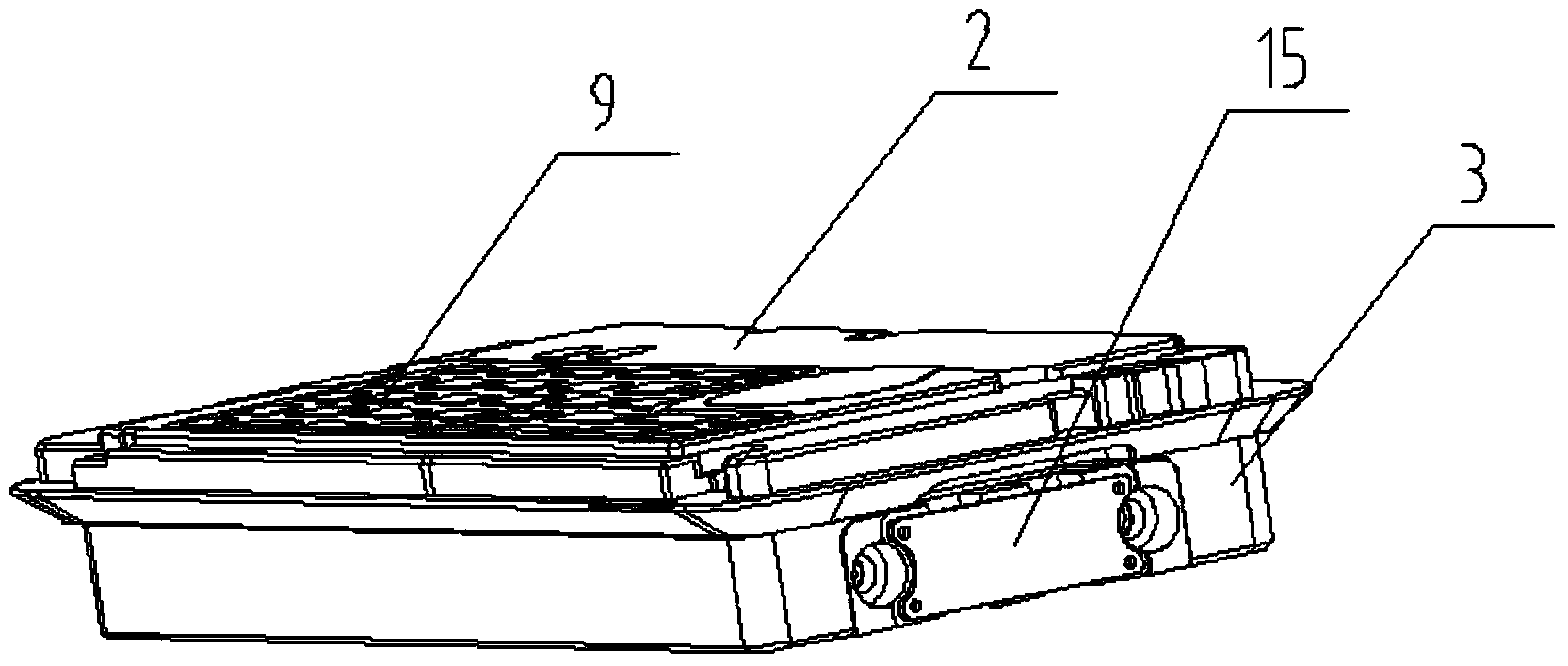

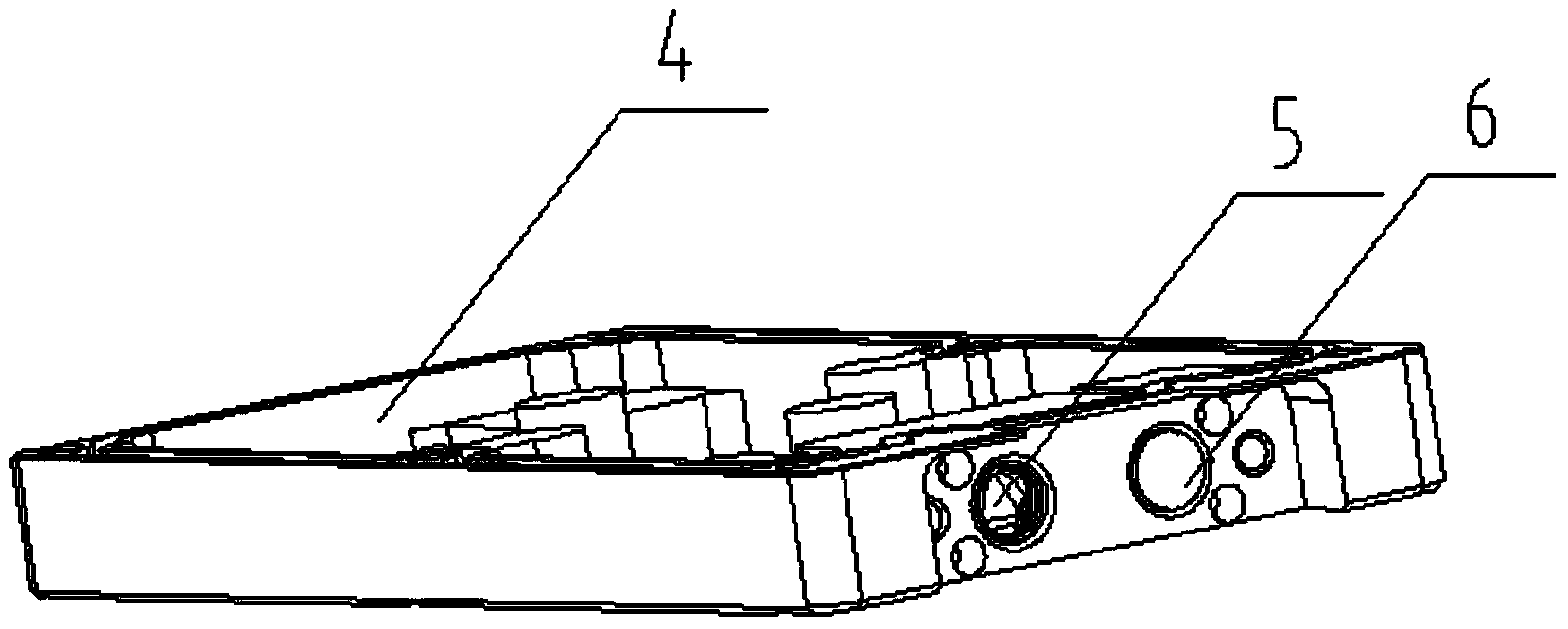

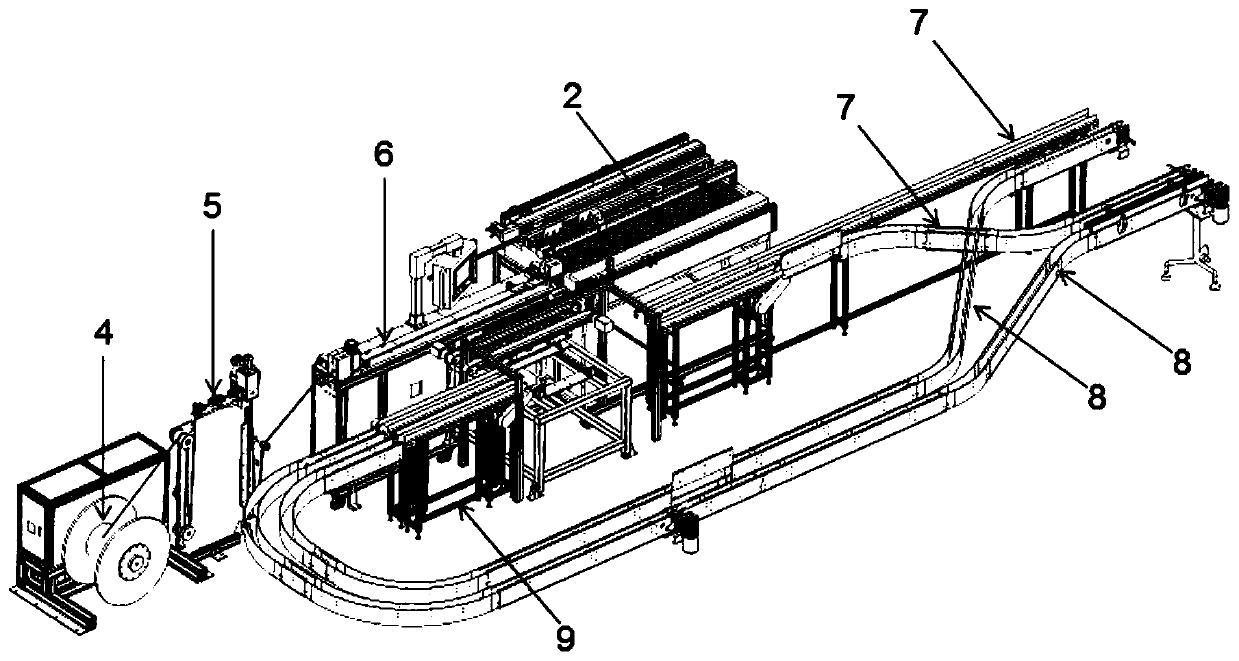

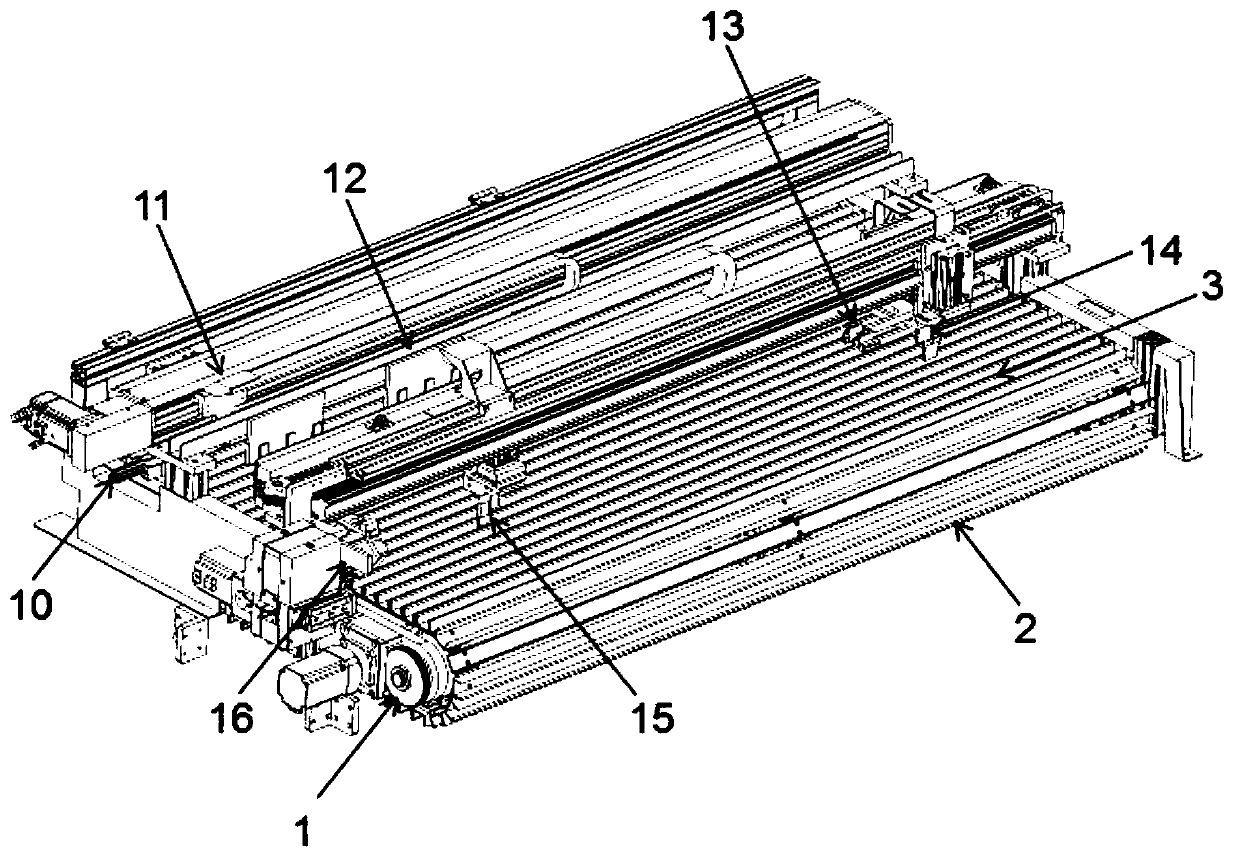

Automatic magnet penetrating and distributing production line for door seal

ActiveCN110921208AIncrease productivityAvoid compression deformationFilament handlingConveyor partsProduction linePull force

The invention relates to the technical field of door seal production, and discloses an automatic magnet penetrating and distributing production line for a door seal. The production line comprises a conveying belt; a transferring aluminum rail which is arranged on the surface of the conveying belt, wherein a plurality of storage positions used for storing the door seal are arranged on the transferring aluminum rail; a feeding device which comprises a winding drum used for storing a magnetic strip and a first driving motor used for driving the winding drum to rotate; a buffer device which is used for reducing the tension borne by the magnetic strip; a conveying channel, wherein the tail end of the conveying channel is aligned with the cavity of the door seal strip to be subjected to magneticpenetration; at least one first line body; at least one second line body, wherein the flow direction of the starting point of the second line body is opposite to the flow direction of the starting point of the first line body, and the flow direction of the end point of the second line body is the same as the flow direction of the end point of the first line body; and a distribution device which is used for clamping the at least two door seals from the storage positions and distributing the door seals to the first line body and the second line body.

Owner:ANHUI HIGASKET PLASTICS CO LTD

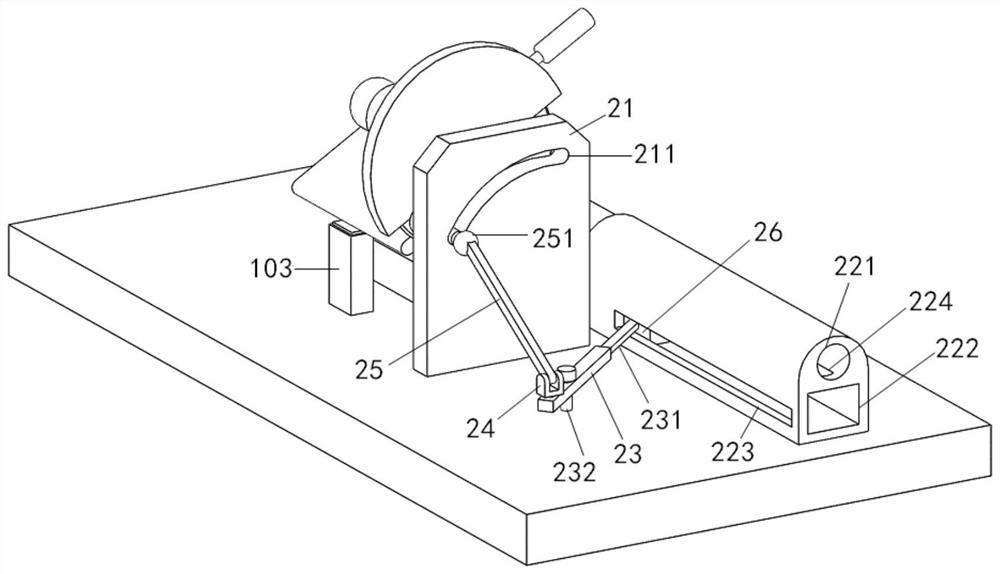

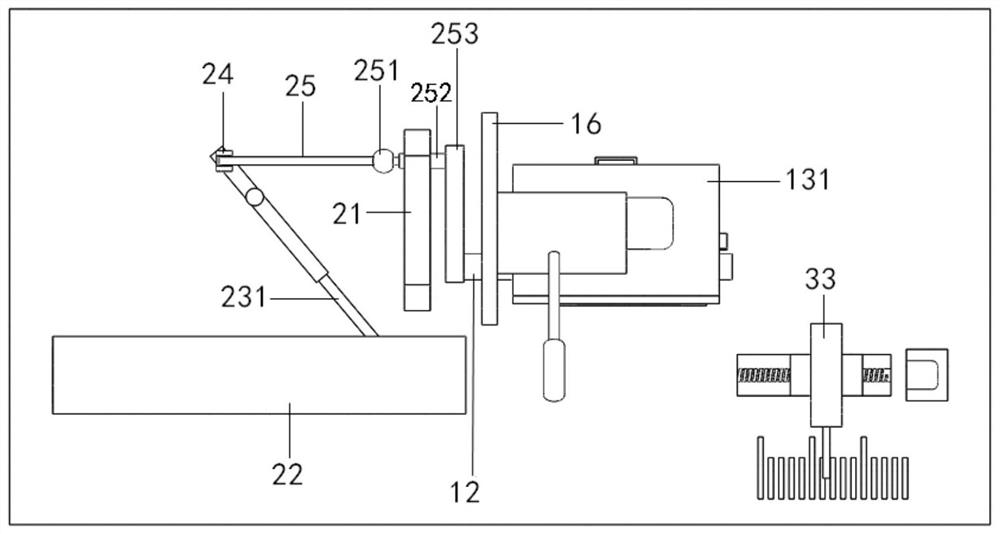

Stainless steel pipe cutting machine capable of automatically feeding and assisting in pressing after cutting

ActiveCN111730126AHigh degree of automationImprove cutting efficiencyTube shearing machinesMetal working apparatusKnife bladesManufacturing engineering

The invention discloses a stainless steel pipe cutting machine capable of automatically feeding and assisting in pressing after cutting. The stainless steel pipe cutting machine is characterized in that an automatic feeding base is arranged on the left side of a cutting blade, a feeding frame is arranged in the automatic feeding base in a sliding mode, the feeding frame is connected with a rotating center shaft in a rotating base through a connecting rod mechanism, and a vacuum suction cup and a pressing block are arranged on the feeding frame; when the cutting blade approaches a stainless steel pipe, the pressing block ascends and abuts against the outer circle wall of the stainless steel pipe, when the cutting blade cuts the stainless steel pipe, the pressing block stops ascending, and when the cutting blade finishes cutting reset, the vacuum suction cup adsorbs and drives the stainless steel pipe to move. The stainless steel pipe cutting machine has the advantages that by arrangingthe connecting rod mechanism, the feeding frame can drive the stainless steel pipe to conduct automatic feeding after the cutting machine completes cutting, in addition, the pressing block can automatically rise and press against the bottom of the stainless steel pipe when the cutting machine conducts cutting, the stainless steel pipe is fixed, the automation degree is high, and the cutting efficiency and quality are greatly improved.

Owner:永康市明科自动化设备有限公司

Positioning protection structure for tail row corrugated pipe

The invention discloses a positioning protection structure for a tail row corrugated pipe. The positioning protection structure comprises an upper supporting arc plate and a lower supporting arc plate, wherein the inner side walls of the upper supporting arc plate and the lower supporting arc plate are each provided with a sliding slot, a slide bar is slidably mounted on the inner side of each sliding slot, and the slide bars are fixedly connected to arc-shaped clamping blocks through metal elastic pieces; the right sides of the upper support arc plate and the lower support arc plate are rotatably connected, air bags are pasted to the middle portions of the inner sides of the upper support arc plate and the lower support arc plate, the air bags communicate with a micro air pump through connecting pipes, the other sides of the air bags are connected with clamping plates in an adhered manner, and the upper ends of the clamping plates are fixedly connected with reset mechanisms. The positioning protection structure is simple in structure, the protective effect on the appearance surface is achieved while the corrugated pipe is positioned, the situation that the corrugated pipe is subjected to extrusion deformation in the positioning process is avoided, and the applicability to the corrugated pipe is stronger.

Owner:安徽三众智能装备有限公司

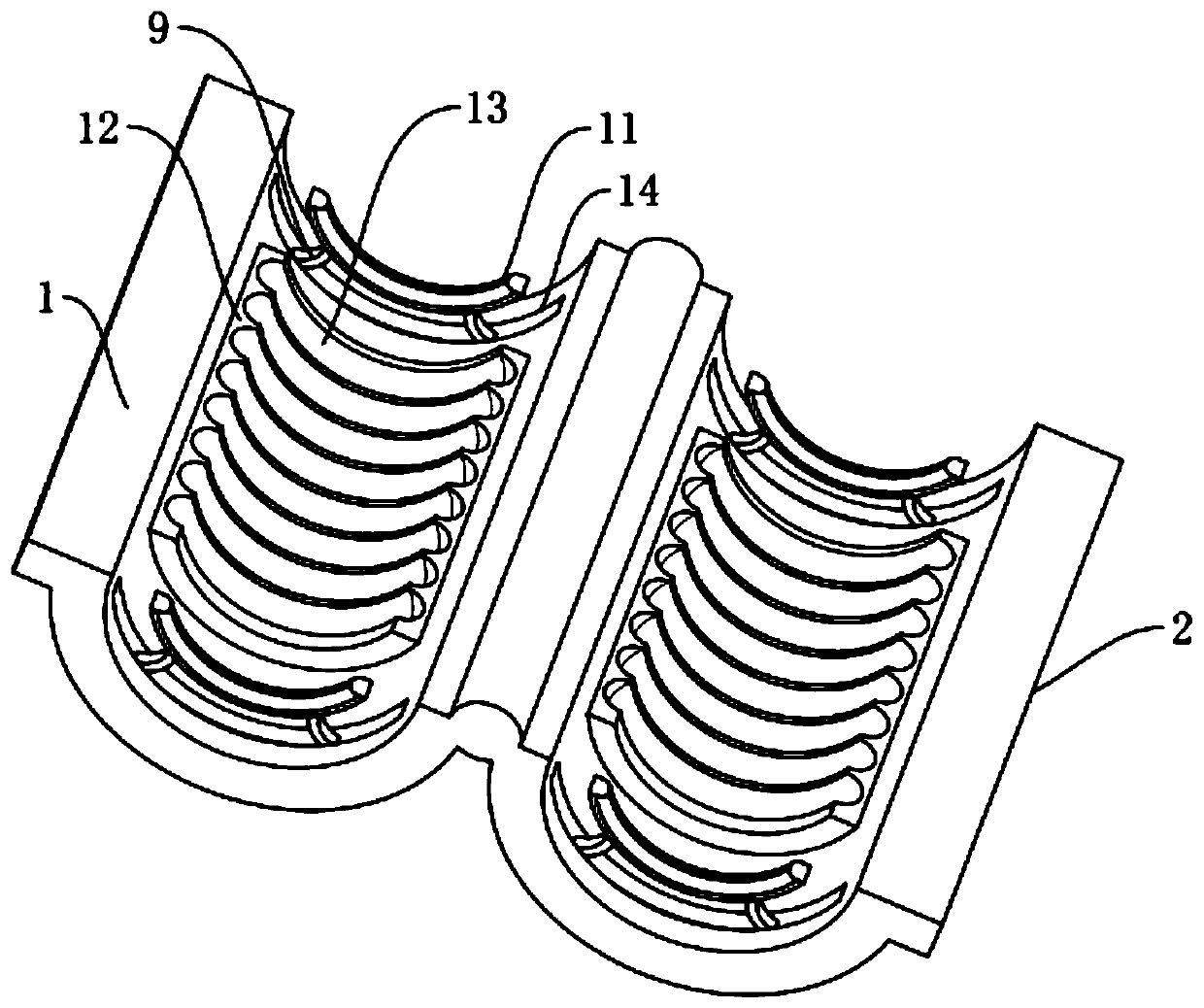

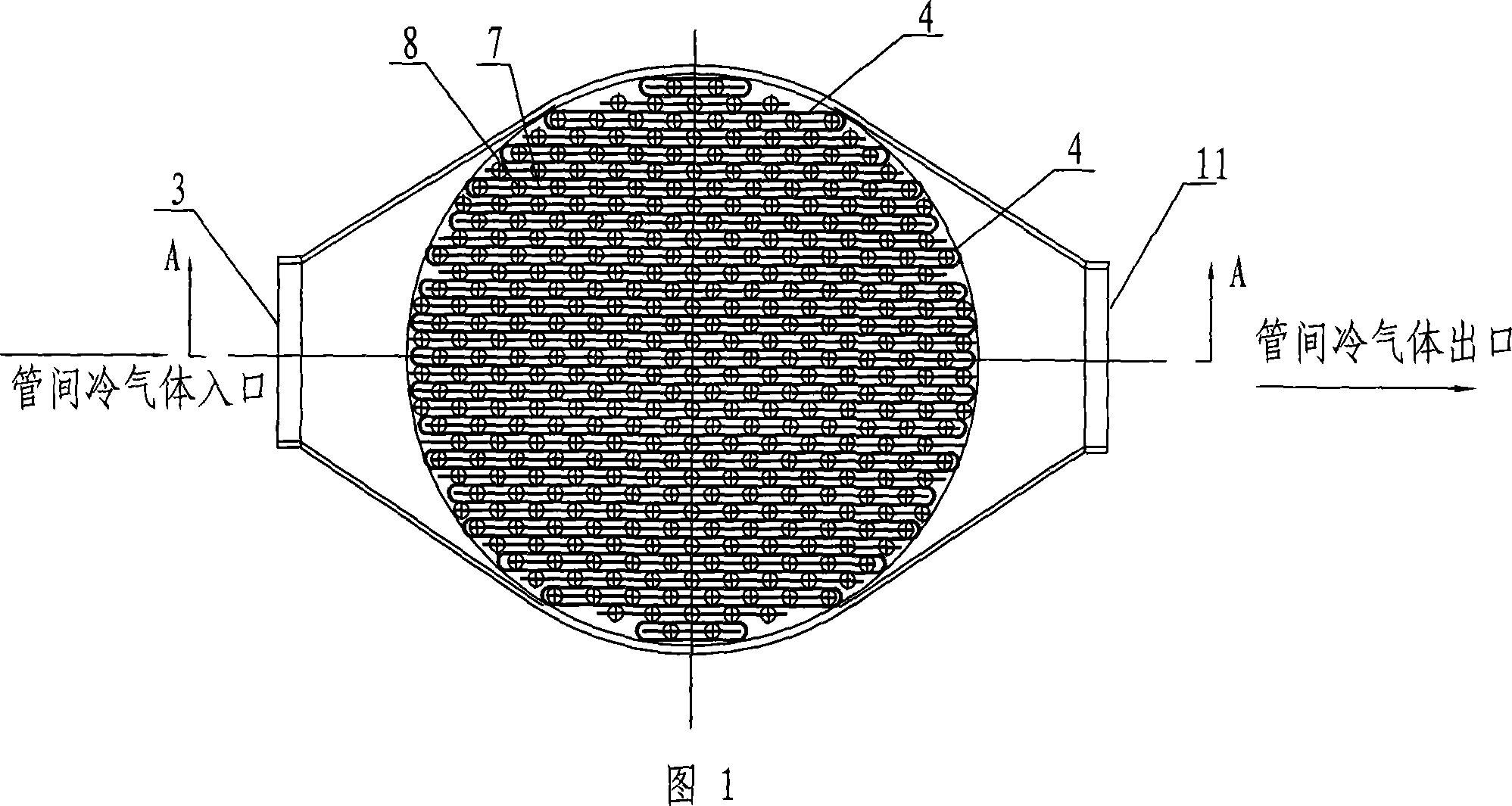

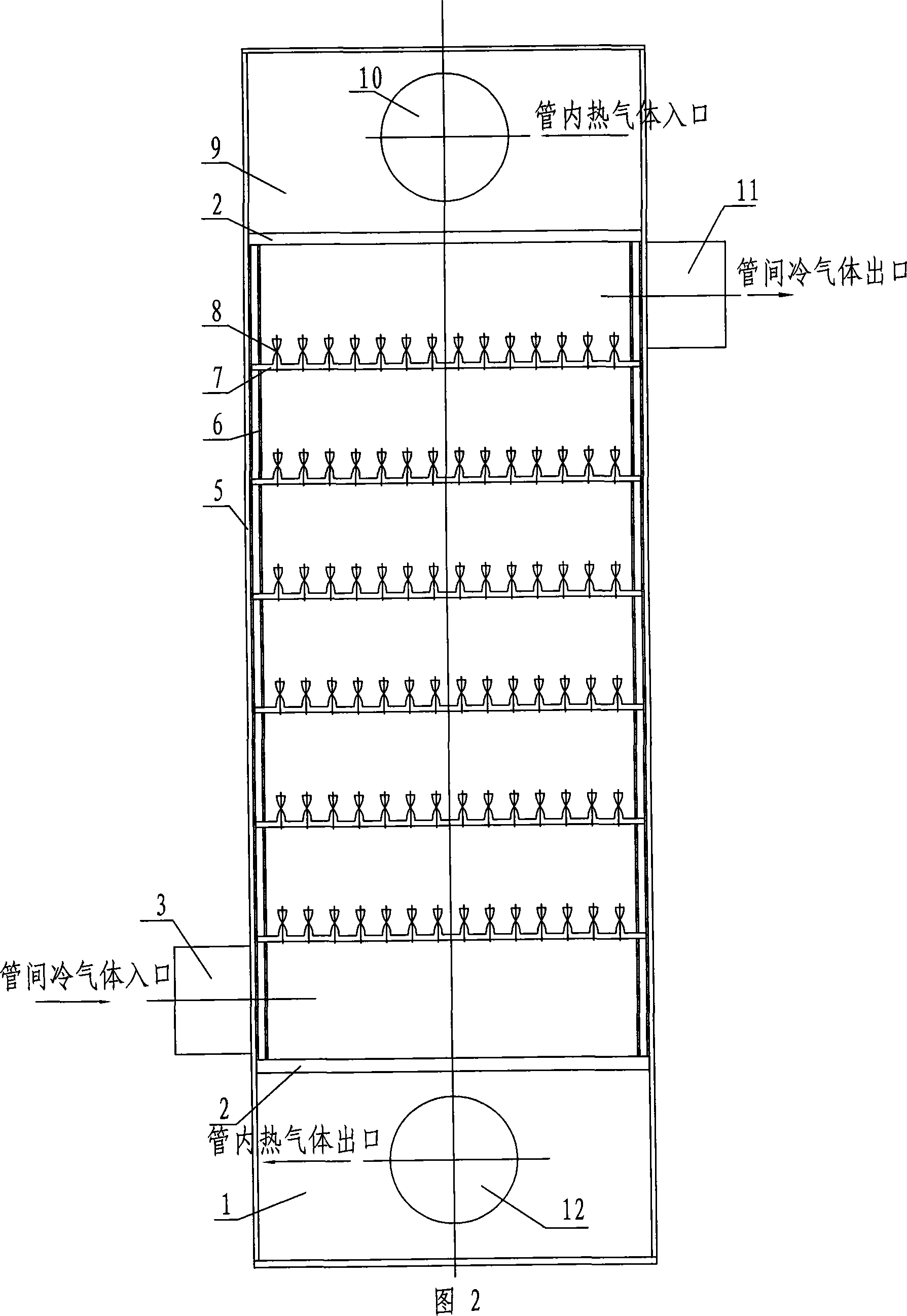

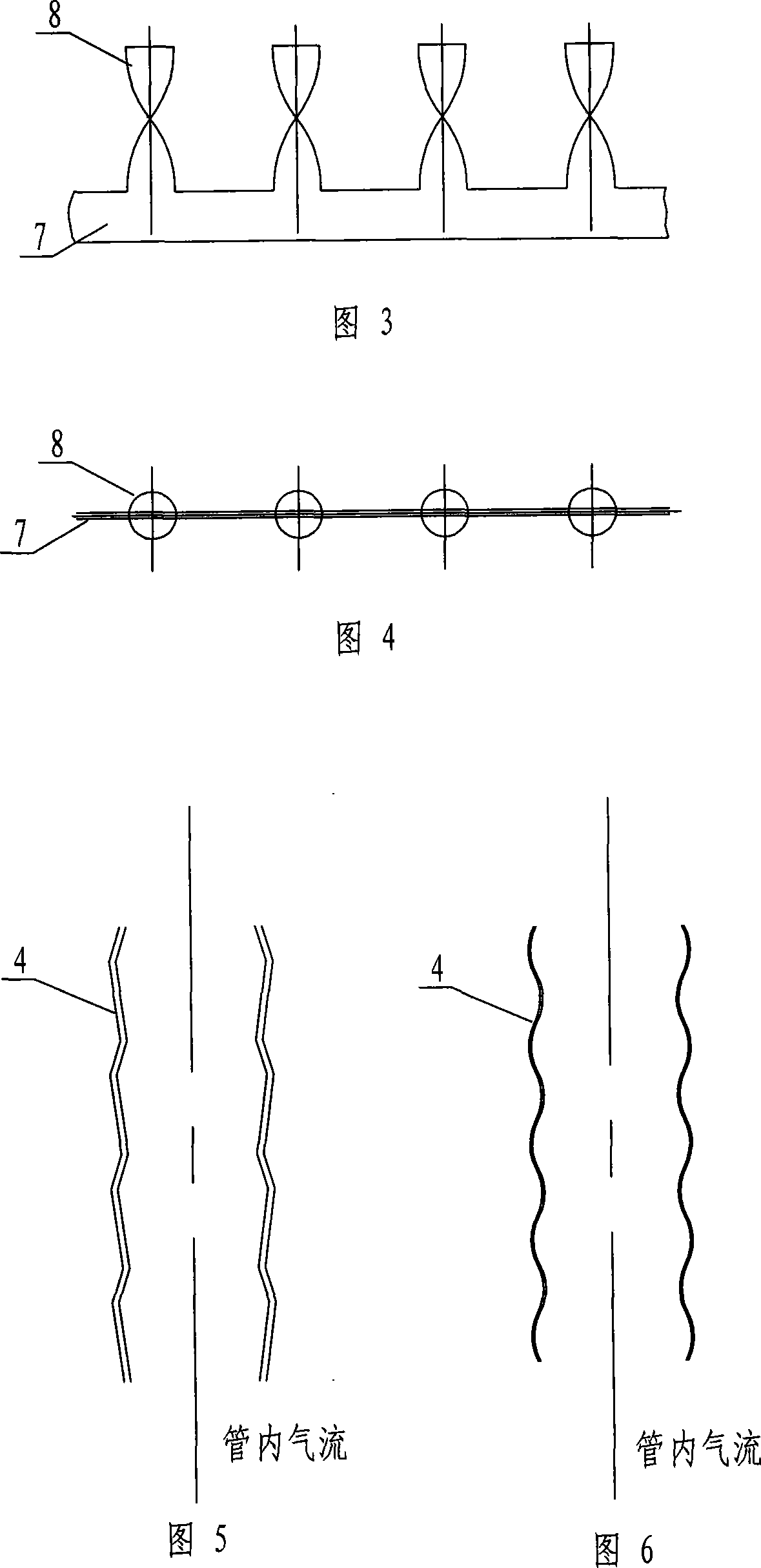

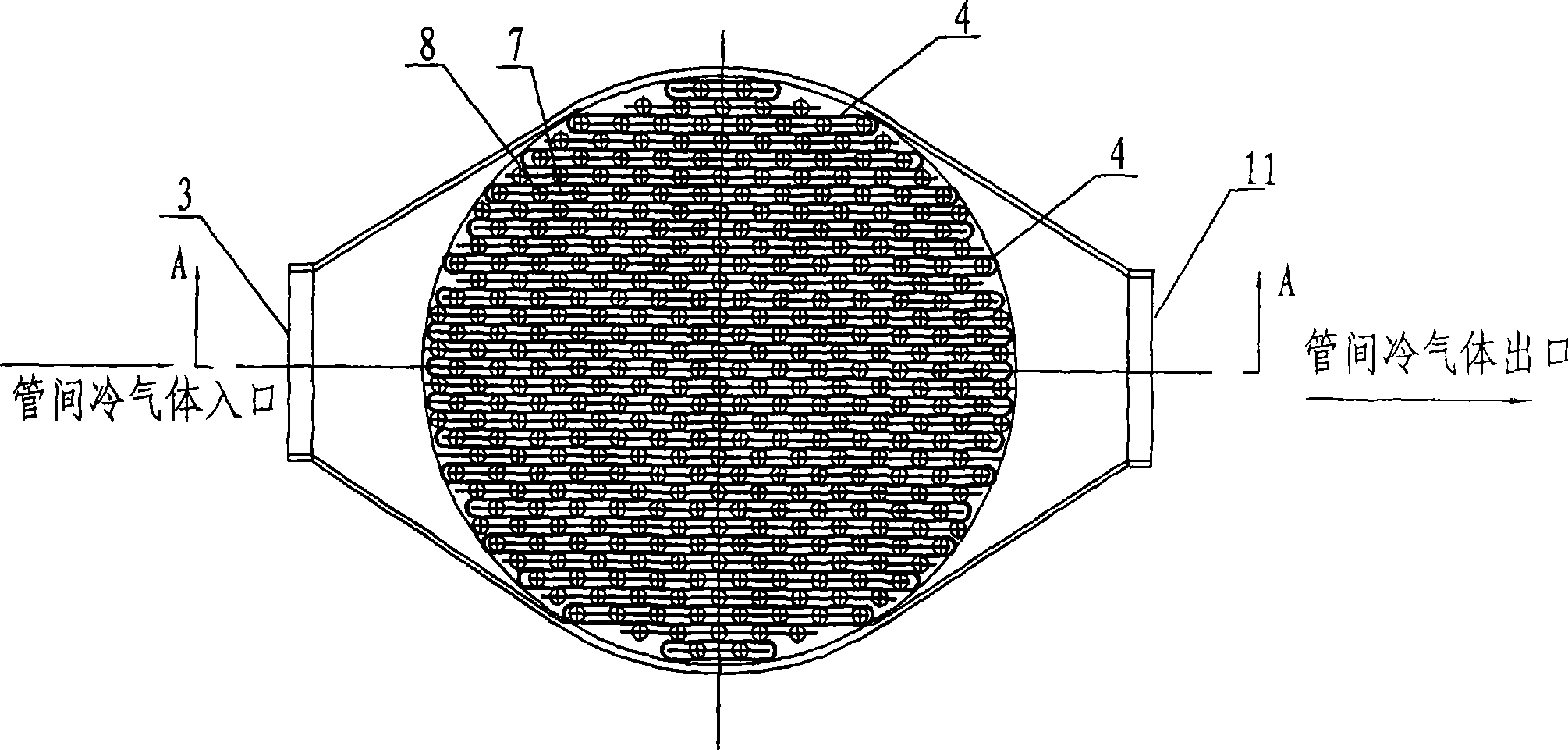

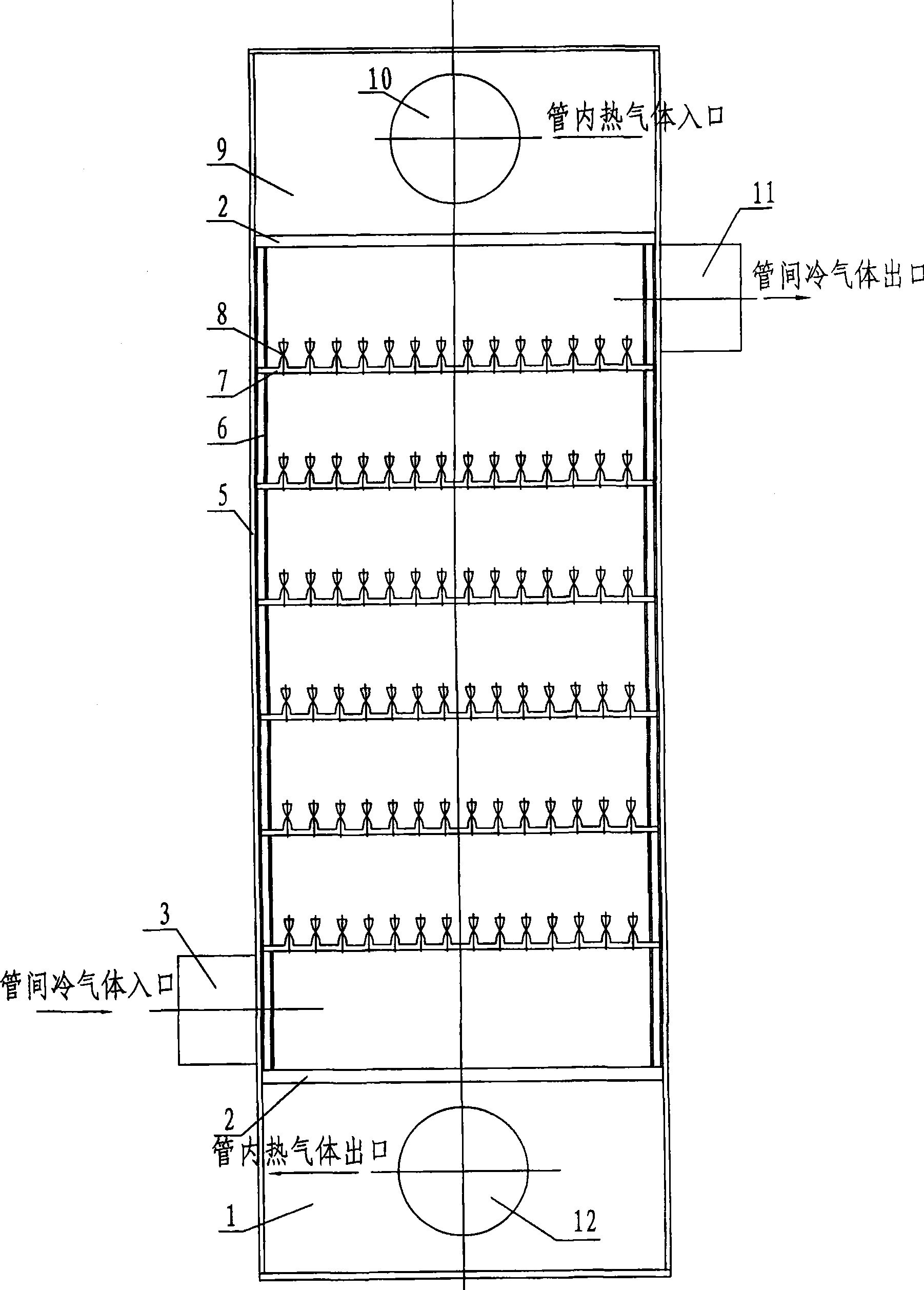

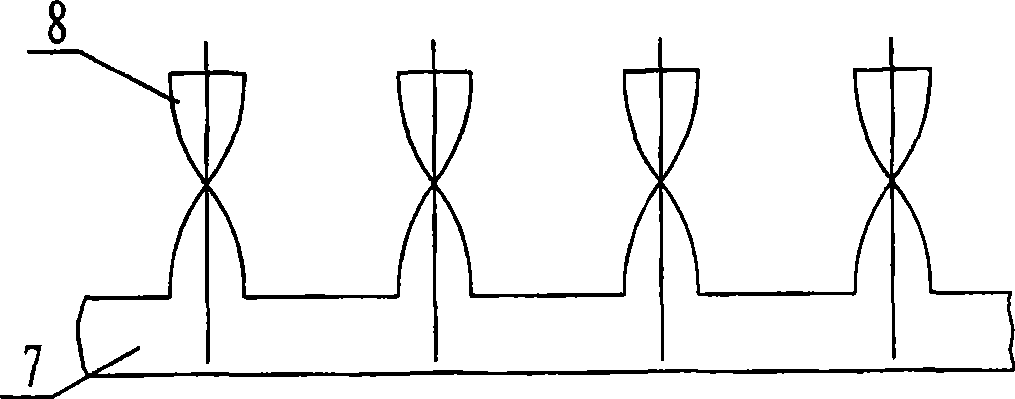

Rectangular tube bundle heat exchanger adopting swirl plate support and its intensified heat-conduction method

InactiveCN101086427AIncrease board spacingAvoid compression deformationStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

The invention discloses a rectangle tube bundle heat-exchanger supported by the vortex sheet and a strengthening heat-transfer method. The heat-exchanger comprises the following parts: a barrel body, a plurality of rectangle tube bundles, a tube plate, an up and down sub, a shell pass of the heat-exchanger, an in-out interface of the shell pass, wherein the tube inside of the rectangle tube bundle is equipped with the vortex sheets at uniform interval along the axial and transverse, the direction of the vortex sheet central line and the direction of the rectangle tube bundle central line is same, the rotating direction of the adjacent vortex sheet is different, the intertube in the rectangle tube bundle is equipped with the vortex sheets at uniform interval along the axial and transverse. The strengthening heat-transfer method improves the flowing speed of the heat-transfer boundary layer in dependence on the helical flow and the self vortex, which strengthens the convective heat transfer of the fluid. The vortex sheet provides the effective support and fixation function at the plate spacing for the rectangle tube bundle, which strengthens the heat-transfer of the rectangle tube bundle. The heat-changer can be used widely in the industry air heat-transfer.

Owner:SOUTH CHINA UNIV OF TECH

Wire drawing device of luggage rack cover plate

ActiveCN106625067AEven by forceAvoid manual dryingGrinding work supportsPlane surface grinding machinesPower componentEngineering

The invention belongs to the technical field of automobile accessory manufacturing tools and provides a wire drawing device of a luggage rack cover plate. The device comprises a bottom plate, a placement positioning assembly, a sliding rail and slider assembly, a wire drawing component, a cleaning component and a sliding power component. The bottom plate is located at the bottom, the sliding power component is arranged on one side of the bottom plate and connected with the sliding rail and slider assembly, the sliding power component drives the sliding rail and slider assembly to move, and the sliding rail and slider assembly drives the wire drawing component and the cleaning component which are combined together to move back and forth on the surface of the placed cover plate. The wire drawing device has the advantages the advantages that wire drawing stress is made uniform by using a cylinder floating mechanism, and quality can still be ensured under the condition that a wire drawing brush is abraded; by the adoption of an automatic cleaning device, manual wiping is avoided; a detergent flushing device is used, so wire drawing disorder caused by particles is avoided; an automatic air blowing device is used so that detergent can be blown dry directly, and the situation that the detergent is wiped dry manually is avoided.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

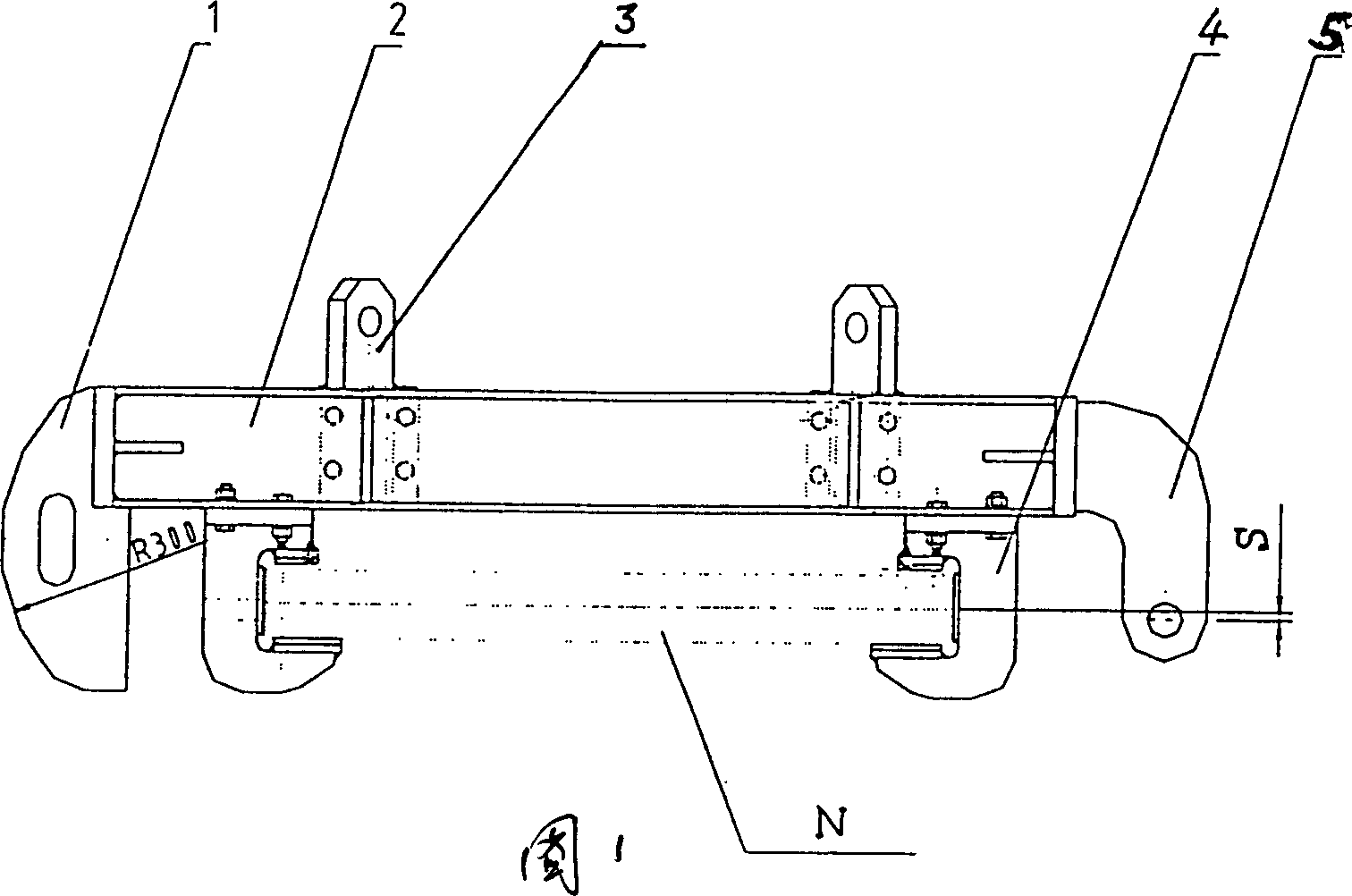

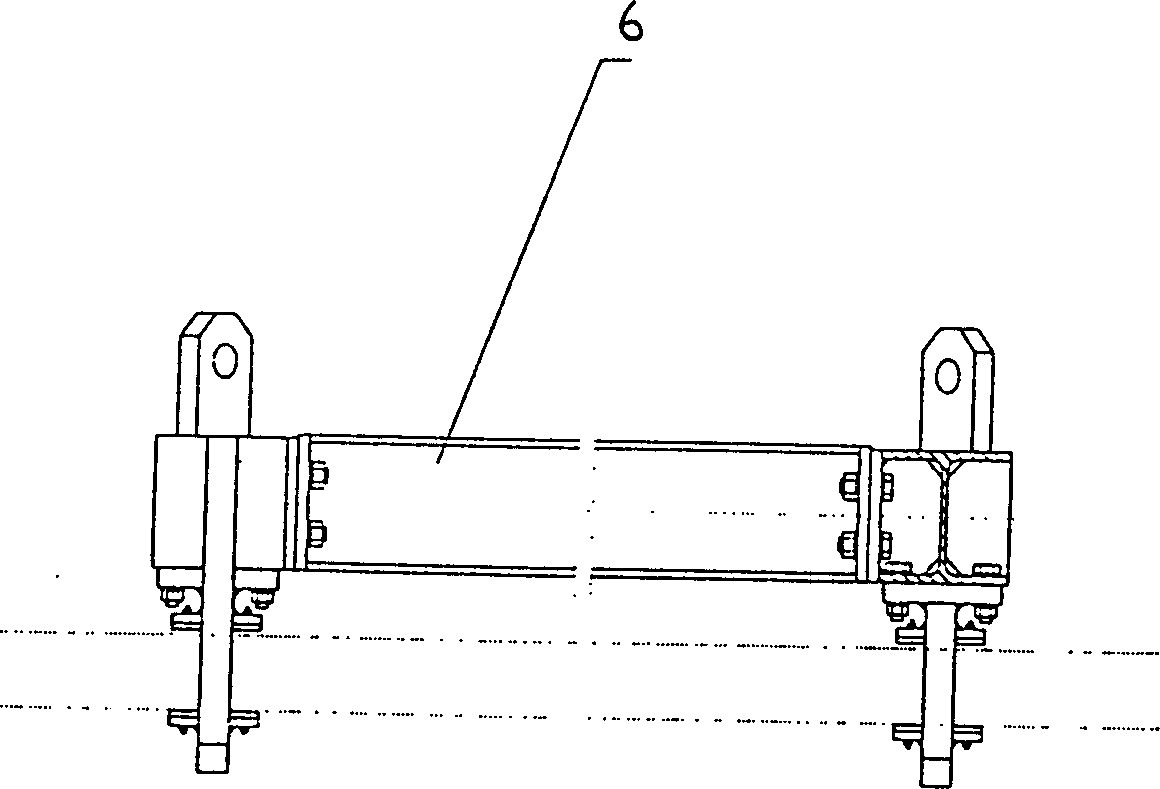

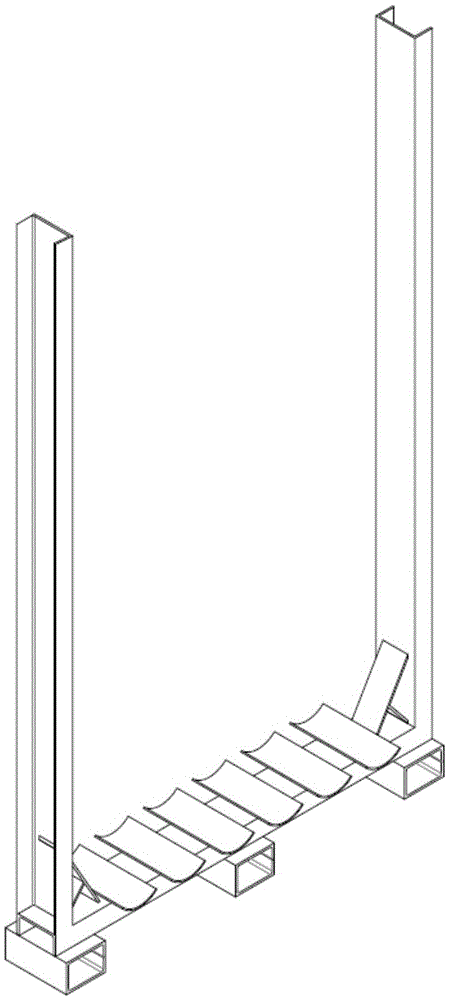

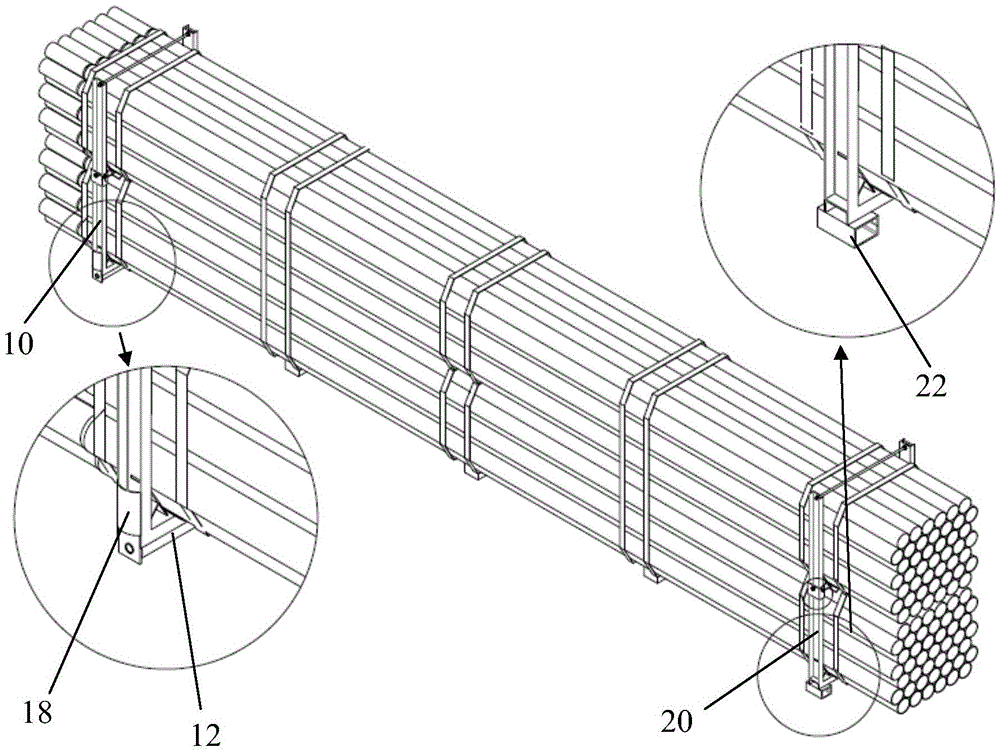

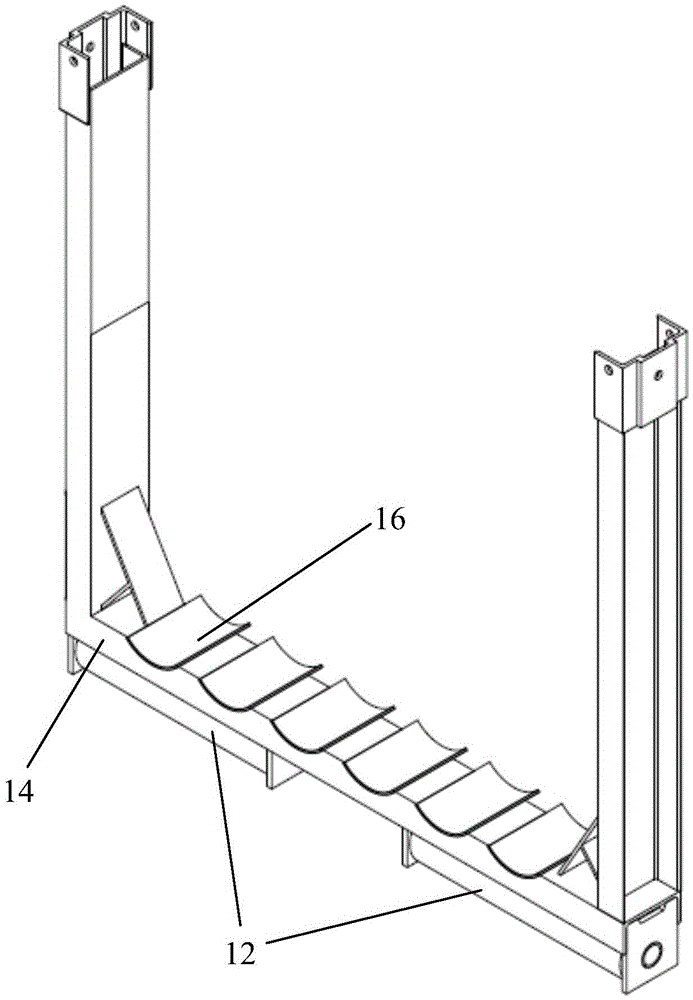

Pipe fitting packaging and fixing support assembly facilitating loading, unloading and transporting

InactiveCN105480564AGuaranteed fixed effectAvoid compression deformationExternal framesDual layerPipe fitting

The invention provides a pipe fitting packaging and fixing support assembly facilitating loading, unloading and transporting. The pipe fitting packaging and fixing support assembly comprises a front support of a U-shaped structure and a rear support of a U-shaped structure. The bottom of the front support is of a rolling wheel supporting structure. The bottom of the rear support is of a plane supporting structure. A plurality of arc-shaped structures allowing pipe fittings to be contained and located are arranged on a lower supporting cross frame of the front support and a lower supporting cross frame of the rear support. The structural form that rolling wheels are arranged at one end and a plane is arranged at the other end is adopted in the pipe fitting packaging and fixing support assembly, loading and unloading of a quite heavy pipe fitting packaging assembly can be facilitated, and meanwhile fixing of the pipe fitting packaging assembly in the transporting process can be guaranteed. A dual-layer structure is adopted, the pipe fittings at the bottom can be prevented from being pressed or deformed, and unnecessary scraping is avoided.

Owner:SUZHOU BAOJIA NEW ENERGY TECH CO LTD

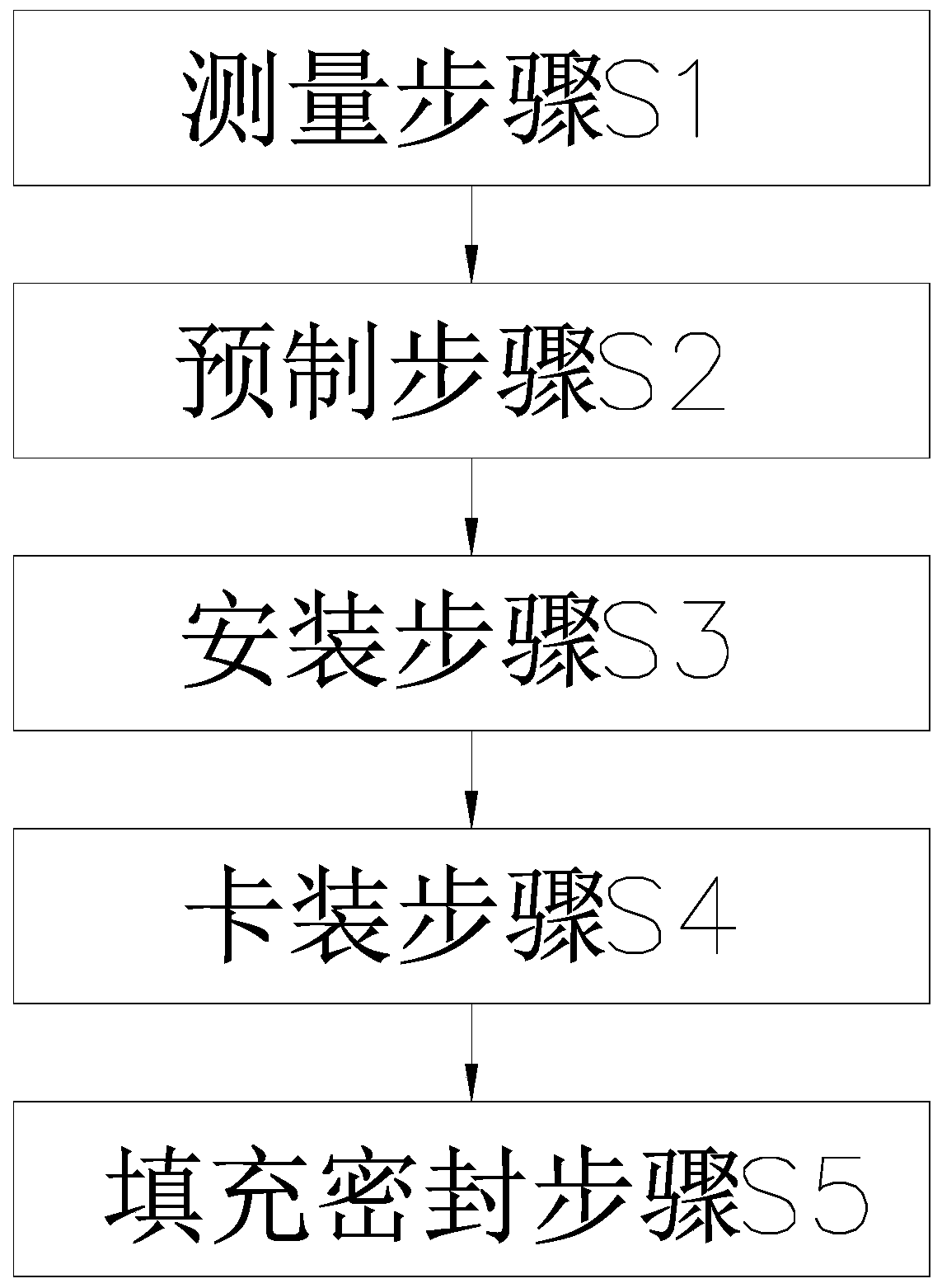

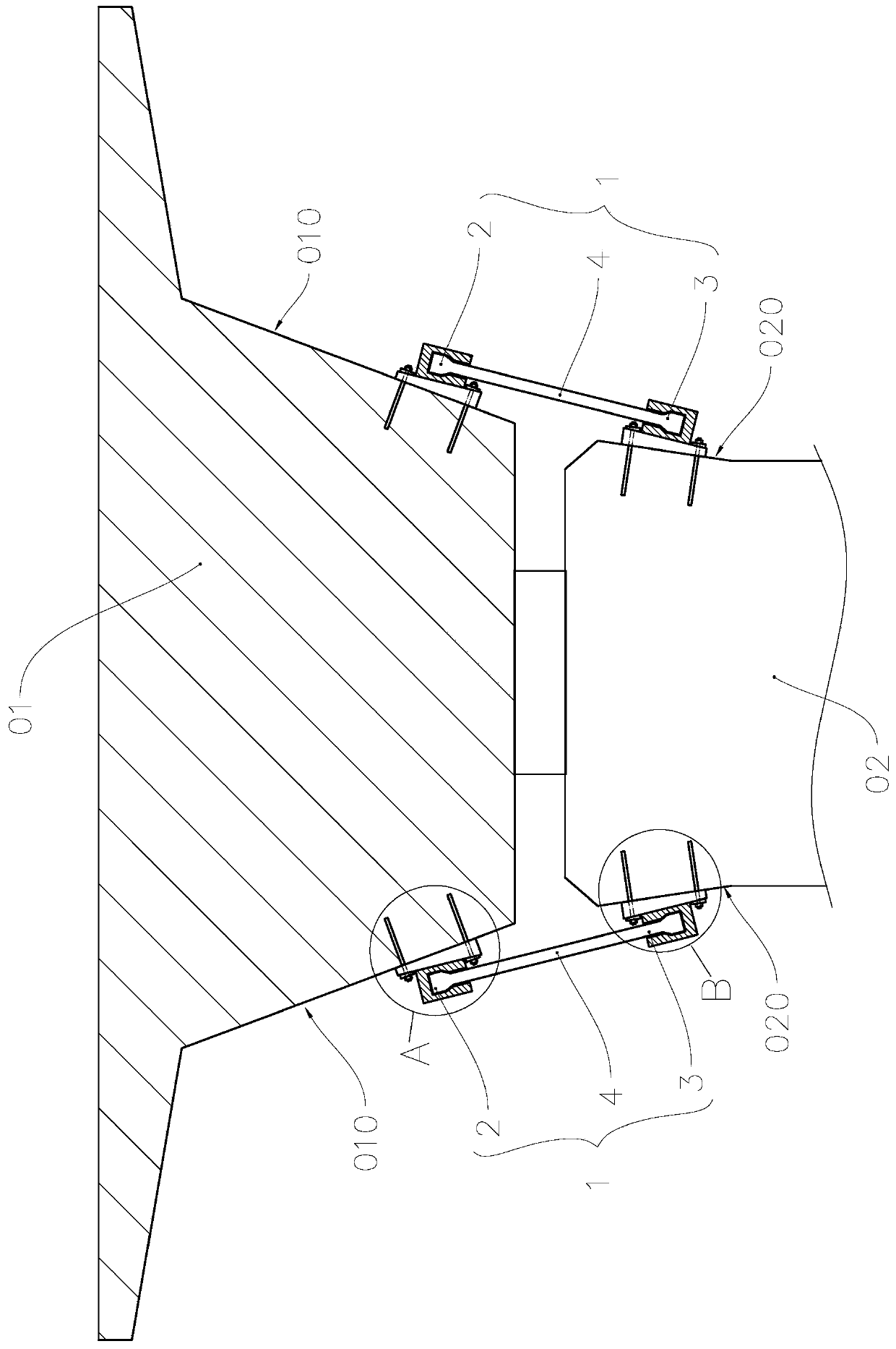

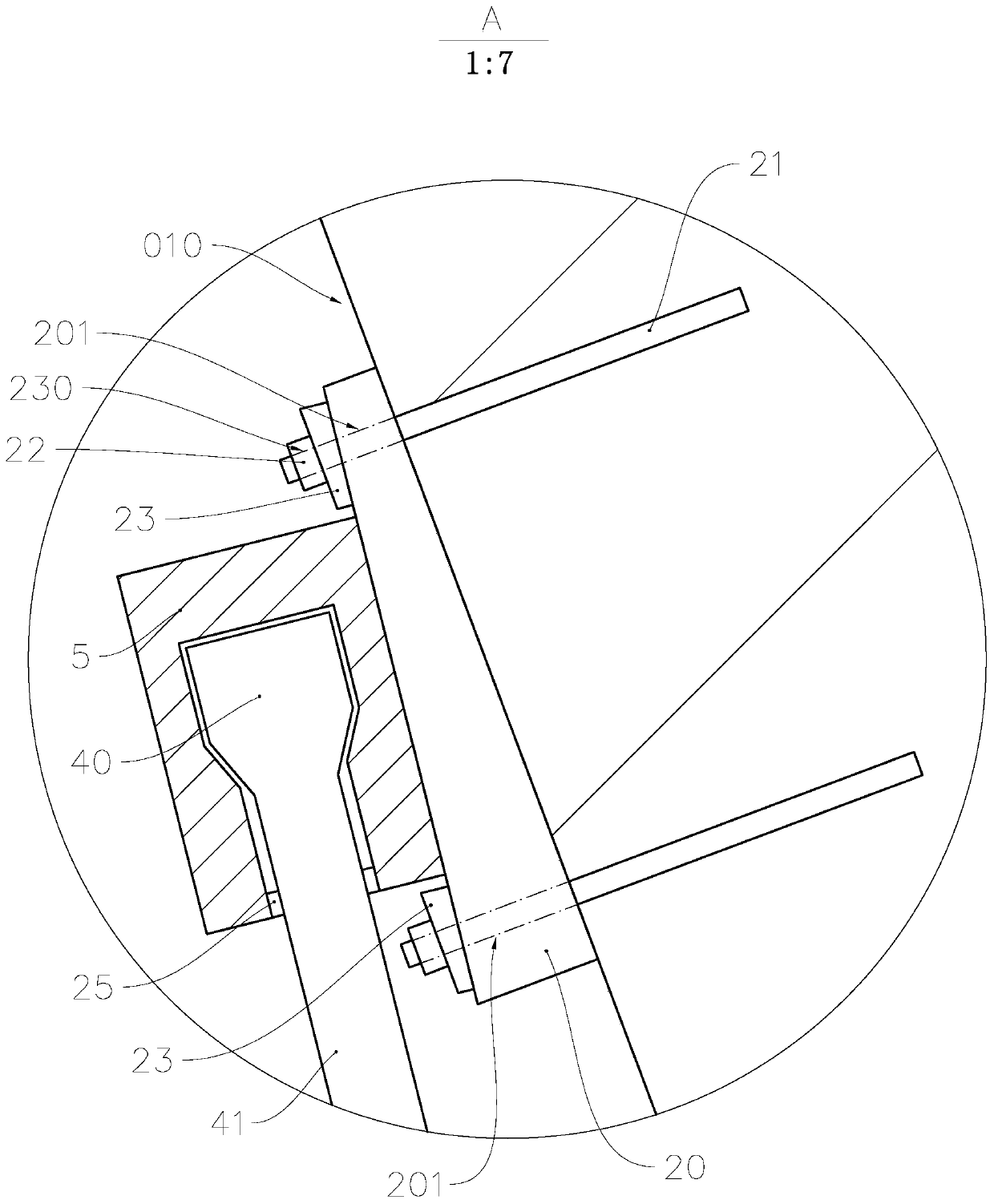

Single-column pier beam bridge and reinforcing and reconstructing method thereof

PendingCN111005308AReduce hindranceAvoid compression deformationBridge structural detailsBridge erection/assemblyPierMotherboard

The invention relates to a single-column pier beam bridge and a reinforcement and transformation method of the single-column pier beam bridge, and belongs to the technical field of bridge reinforcement and transformation. The method comprises the following steps: (1) measuring an inclination angle between a main beam side part and a pier side part; (2) prefabricating an anti-overturning device, wherein the anti-overturning device comprises a wedge-shaped mother plate, a pull rod clamping groove and a pull rod; (3) driving anchor bolts into the preset positions of the side surface parts, and fixing the upper wedge-shaped mother board and the lower wedge-shaped mother board on the corresponding side surface parts by using nuts; (4) the two expansion ends of each pull rod are clamped into thegroove cavities of the upper pull rod clamping groove and the lower pull rod clamping groove from the open ends of the clamping grooves, and movable gaps can be reserved between the two expansion ends of each pull rod and the cavity walls of the corresponding clamping groove cavity; and (5) filling a groove cavity of the pull rod clamping groove with a non-hydrophilic lubricant, and sealing the groove cavity of the pull rod clamping groove to form a sealed cavity. The reinforcement and transformation method is convenient to construct, low in cost and convenient to replace in the subsequent maintenance process, and can be widely applied to the field of bridge reinforcement and transformation.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

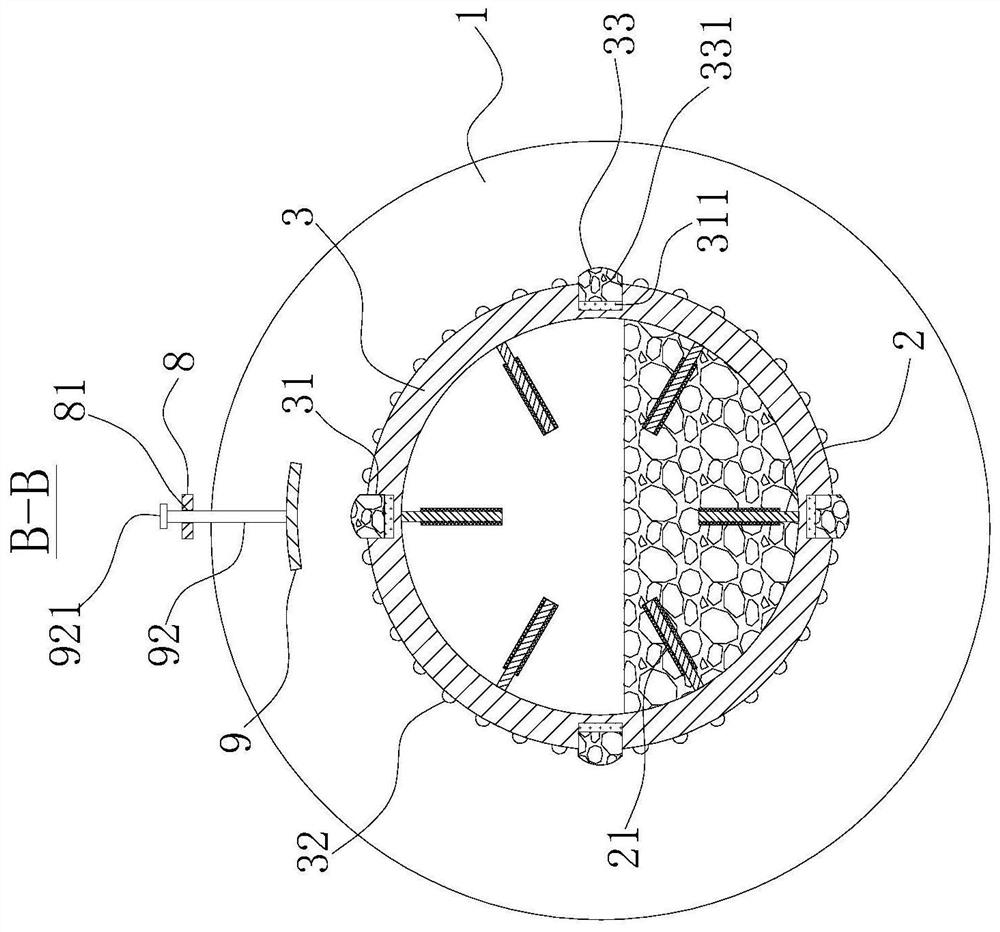

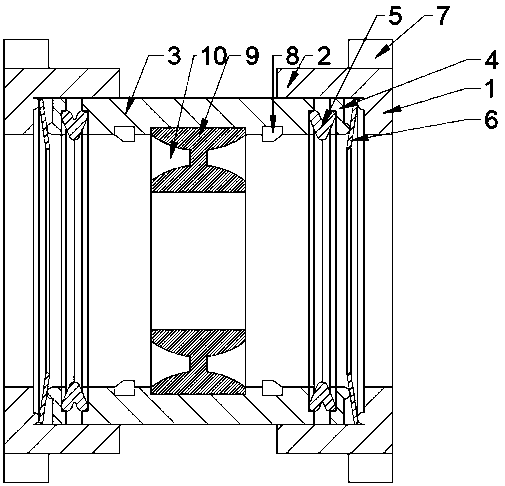

Isostatic pressing forming method and forming mold for ceramic roller bars

The invention discloses an isostatic pressing forming method and forming mold for ceramic roller bars, and relates to the field of isostatic pressing forming. The isostatic pressing forming mold comprises a bottom plate, a feeding assembly, an outer mold, an inner mold, a pressurizing assembly, a movable block, a pushing assembly, a fixed block, a first hydraulic bag, a second hydraulic bag, an exhaust pipe and feeding pipes, wherein the feeding assembly is mounted at one end of the top side of the bottom plate, the fixed block is installed on the top side of the bottom plate, the movable block is installed on the pushing assembly, and the inner mold is fixedly connected to the movable block. Through the arrangement of the feeding assembly, materials in a material hopper enter a feeding cylinder through a material guiding pipe, when a piston disc descends, the materials are discharged through discharging pipes, under the cooperation of six feeding pipes, filling of the materials can beachieved; the gap between the outer mold and an inner mold can be filled, through one-way injection material filling, gas mixing is reduced, the gas content is reduced, the compactness of blanks is improved, and through guide-in and synchronous filling of the six discharging pipes arranged in a surrounding mode, uneven material filling is avoided, and filling is more balanced.

Owner:合肥陶陶新材料科技有限公司

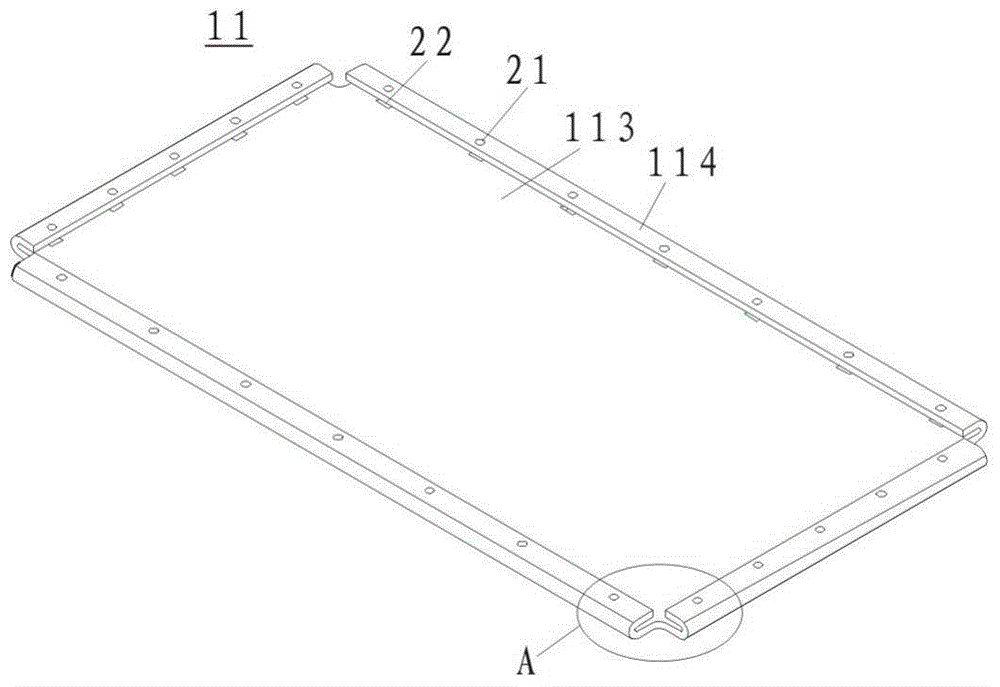

Backboard, backboard component and manufacturing method thereof as well as backlight module

ActiveCN105068319AAvoid compression deformationNot easy to fall offNon-linear opticsBackplaneEngineering

Owner:BOE TECH GRP CO LTD +1

Anti-deformation steel tube clamp

InactiveCN106271704ASimple structureEasy to useWork clamping meansPositioning apparatusEngineeringMachining process

The invention provides an anti-deformation steel tube clamp. The anti-deformation steel tube clamp comprises an electric cylinder. The electric cylinder is fixed at the left end of a centering drum, and a piston rod of the electric cylinder penetrates through an installing plate and is fixedly connected with a pushing head in the entering drum; through holes are formed in the inner side wall of the centering drum, pushing balls are installed in all the through holes, and the distance from the ball centers of the pushing balls to the right side face of the installing plate is smaller than the axial length of the pushing head; an elastic hole stopping ring is installed on the inner side wall of the centering drum, the distance from the ball centers of the pushing balls to the elastic hole stopping ring is smaller than the axial length of the pushing head; all the pushing balls correspond to all guiding rods; all sliding blocks are connected with all the guiding rods in a sliding mode, and lower ends of the sliding blocks abut against the pushing balls. According to the anti-deformation steel tube clamp, expanding supporting and clamping of the inner wall of a seamless steel tube are achieved, stress is even, it can be prevented that as a local suffers from oversize force, deformation occurs, the qualified product ratio of the seamless steel tube is effectively increased, and damage to the seamless steel tube is avoided in the transporting or processing process.

Owner:天津腾飞钢管有限公司

Electric winch with improved structure

PendingCN111847292APrevent slippingIncrease contact areaPiezoelectric/electrostriction/magnetostriction machinesWinding mechanismsElectric machineDrive motor

The invention provides an electric winch with an improved structure, and belongs to the technical field of winch devices. The electric winch with an improved structure comprises a base, a rotating shaft, a drive motor, a first round tube, a plurality of grooves and an anti-reverse mechanism. The rotating shaft is horizontally and rotatably arranged on the base through a base plate. The drive motoris fixedly arranged on the base. The drive motor is connected with the rotating shaft in a transmission mode. Both sides of the first round tube are fixedly provided with a side plate. One side plateis fixedly connected with one end of the rotating shaft. The first round tube and the rotating shaft are arranged coaxially. The outer side of the first round tube is provided with a plurality of rubber bumps. A plurality of grooves are arranged on the outer side of the first round tube along the circumferential direction. The length directions of the grooves are consistent with the length direction of the first round tube. A telescopic air bag is arranged in the grooves. The outer side of the telescopic air bag protrudes from the outer side wall of the first round tube. The telescopic air bag is filled with liquid. When the rotating shaft rotates counterclockwise, the anti-reverse mechanism can prevent the rotating shaft from rotating reversely. The electric winch can improve the anti-slide performance of a reel, and can also prevent the reel from turning over and damaging the drive motor.

Owner:ZHEJIANG OCEAN UNIV

Device for detecting air impermeability of component and detecting method thereof

InactiveCN106979845AEasy to install and testPrevent compression deformationMeasurement of fluid loss/gain rateFluid pressure control with auxillary non-electric powerOvervoltageEngineering

The invention discloses a part air tightness detection device and a detection method thereof, which sequentially comprise from bottom to top: a base plate, a support rod, an upper connecting plate, a hydraulic action rod, and a tooling mechanism; wherein, the two sides of the base plate are arranged symmetrically There is a threaded hole for installing the support rod; a through hole is processed at the center of the bottom plate; the tooling mechanism includes: a mounting slot for detecting the outer contour of the workpiece, a tooling platform, and an overvoltage protection mechanism; the center position of the tooling platform is An air inlet installation hole is provided; the upper end surface of the tooling platform is provided with a detection workpiece outer contour installation card slot installation position; the detection workpiece outer contour installation card slot passes through the detection workpiece set on the upper end surface of the tooling platform The outer contour installation card slot installation position is fixedly installed on the upper end surface of the tooling platform; the overpressure protection mechanism includes: a hydraulic rod, and a pressure regulating valve; the pressure regulating valve is used to control the bearing pressure of the hydraulic rod .

Owner:刘丽华

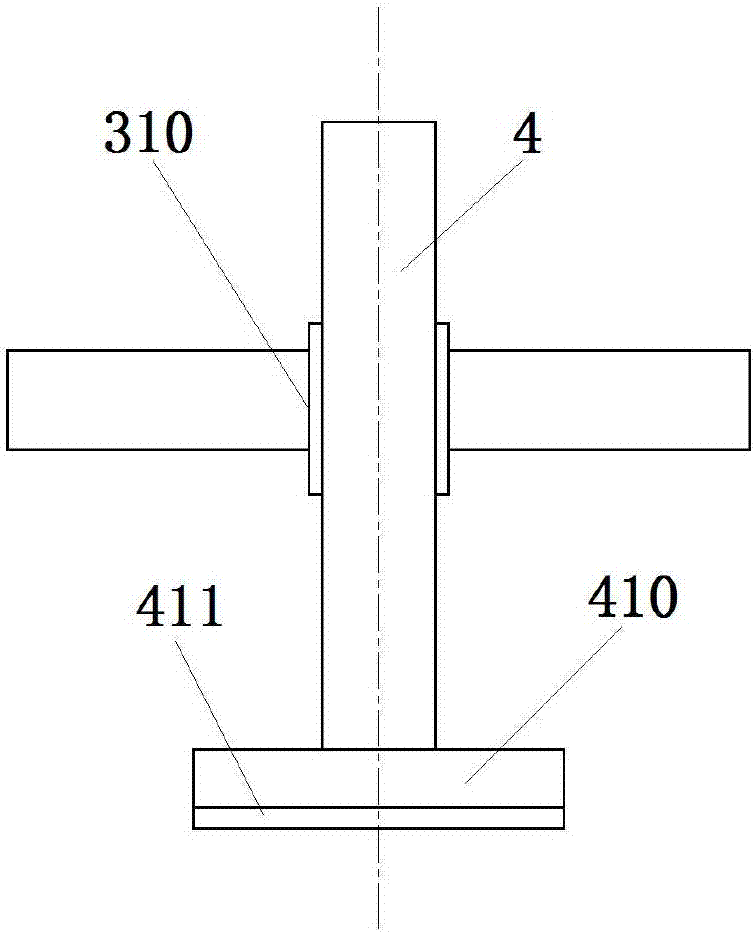

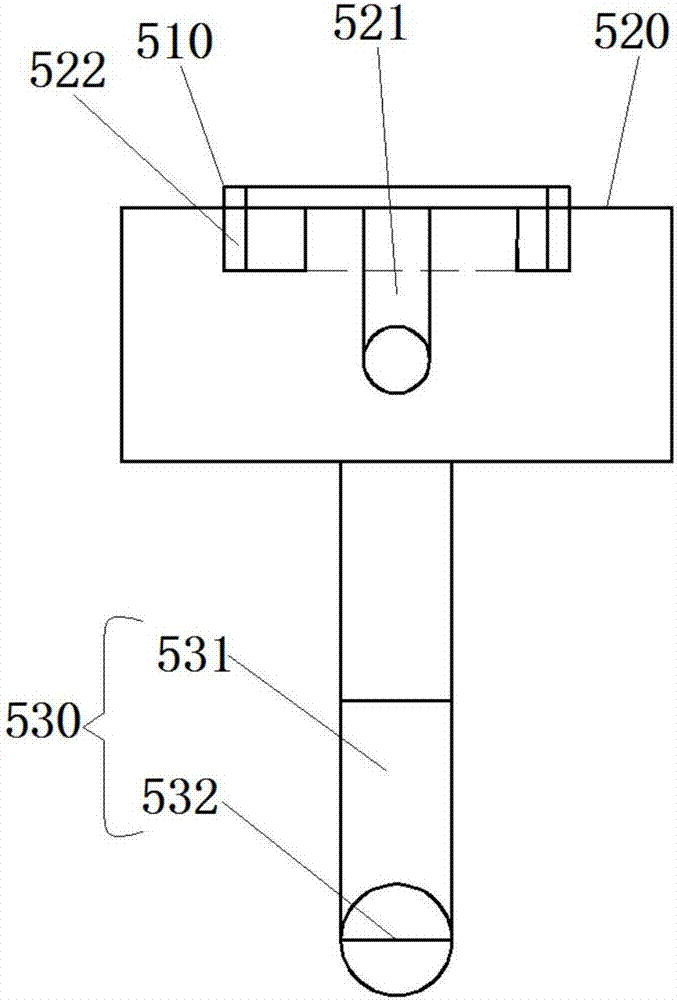

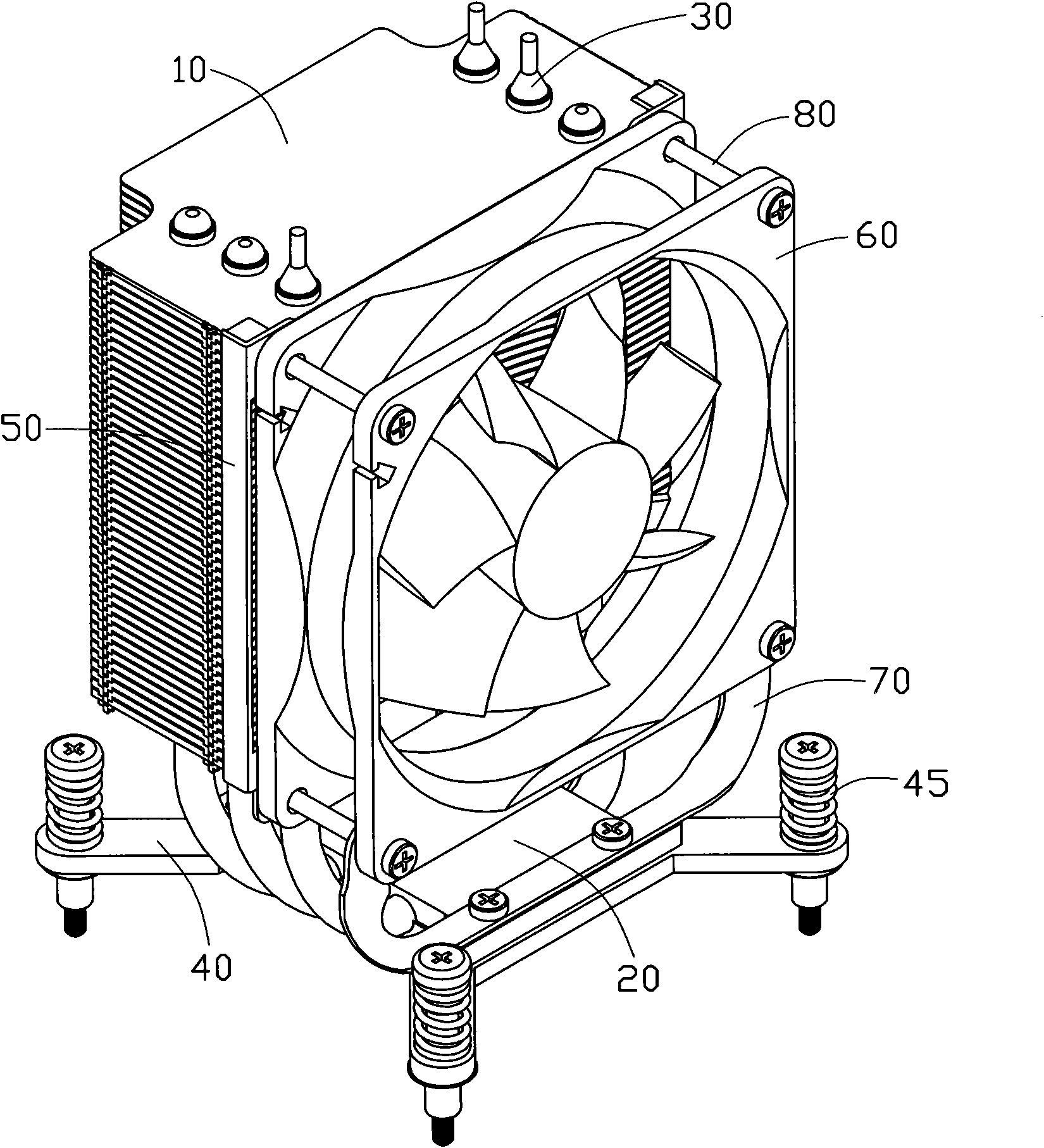

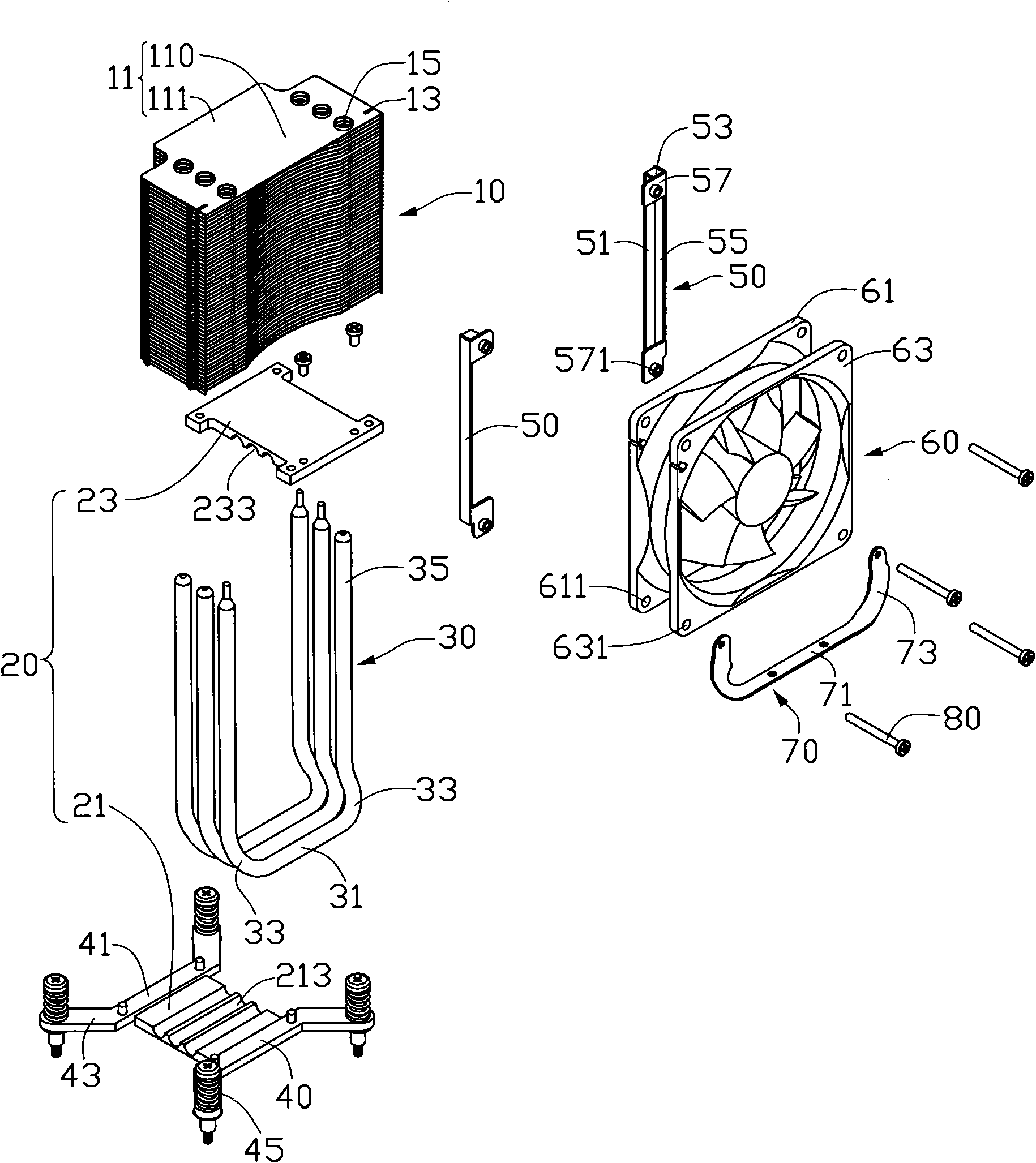

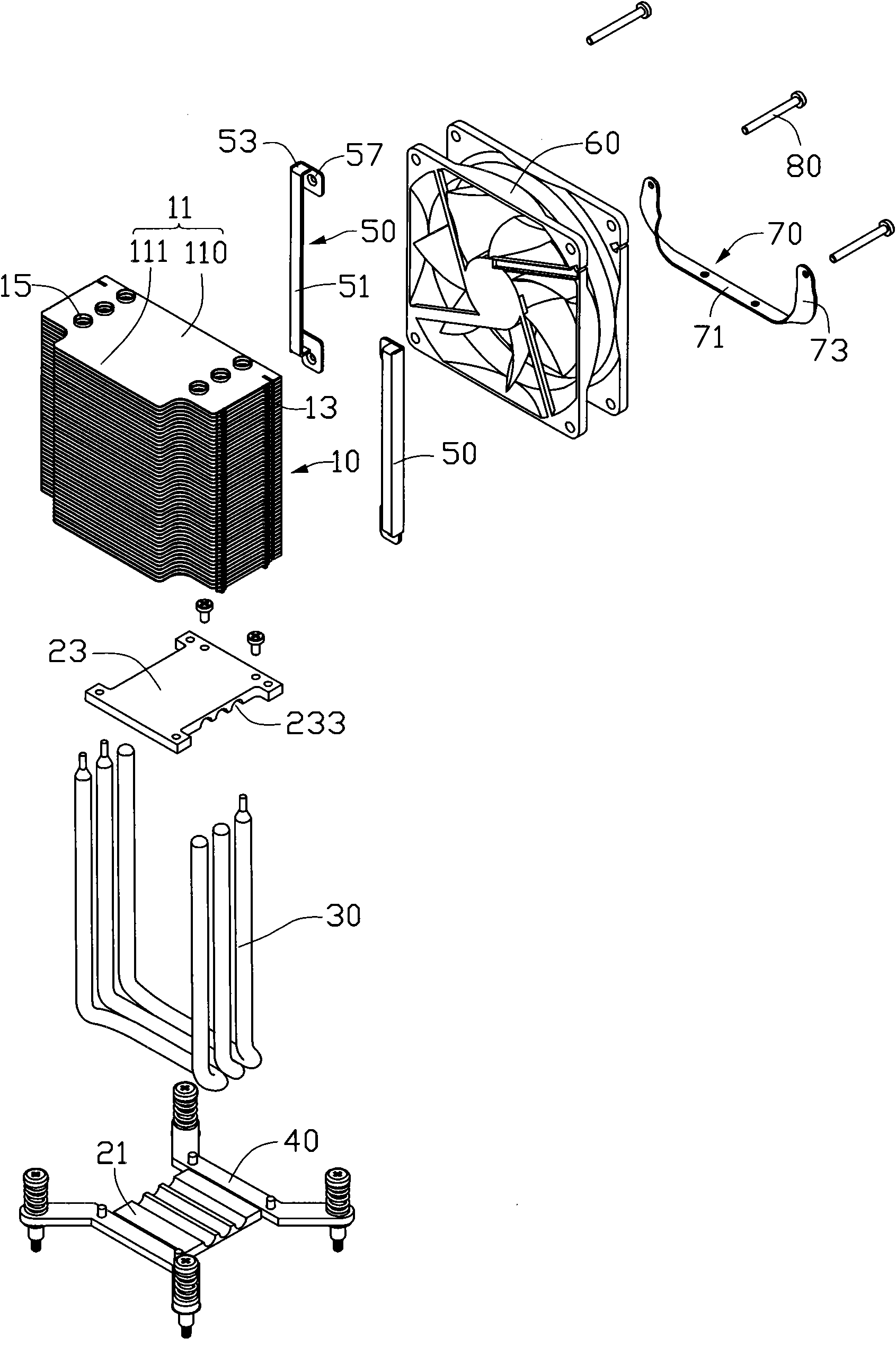

Heat radiator

InactiveCN101600322ARelieve pressureAvoid compression deformationSemiconductor/solid-state device detailsSolid-state devicesHeat sinkEngineering

The invention relates to a heat radiator for radiating the heat of an electronic component fixed on a circuit board. The heat radiator comprises a base board, a cooling fin group, a heat pipe and a fan, wherein the cooling fin group is arranged above the base board, the heat pipe is used for connecting the base board and the cooling fin group, and the fan is arranged on one side of the cooling fin group; the heat radiator also comprises a supporting frame comprising a fixing part and two supporting arms, the fixing part is fixed on the base board, the two supporting arms extend from the fixing part, and the two supporting arms are fixedly connected with the fan so as to supporting the fan. Compared with the prior art, the fan of the heat radiator is supported by the supporting frame, thereby the pressure on the heat pipe from the fan is reduced, the press deformation of the heat pipe is avoided, and the heat radiating efficiency of the heat radiator is ensured.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Rectangular tube bundle heat exchanger adopting swirl plate support and its intensified heat-conduction method

InactiveCN100498180CIncrease board spacingAvoid compression deformationStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

The invention discloses a rectangle tube bundle heat-exchanger supported by the vortex sheet and a strengthening heat-transfer method. The heat-exchanger comprises the following parts: a barrel body, a plurality of rectangle tube bundles, a tube plate, an up and down sub, a shell pass of the heat-exchanger, an in-out interface of the shell pass, wherein the tube inside of the rectangle tube bundle is equipped with the vortex sheets at uniform interval along the axial and transverse, the direction of the vortex sheet central line and the direction of the rectangle tube bundle central line is same, the rotating direction of the adjacent vortex sheet is different, the intertube in the rectangle tube bundle is equipped with the vortex sheets at uniform interval along the axial and transverse. The strengthening heat-transfer method improves the flowing speed of the heat-transfer boundary layer in dependence on the helical flow and the self vortex, which strengthens the convective heat transfer of the fluid. The vortex sheet provides the effective support and fixation function at the plate spacing for the rectangle tube bundle, which strengthens the heat-transfer of the rectangle tube bundle. The heat-changer can be used widely in the industry air heat-transfer.

Owner:SOUTH CHINA UNIV OF TECH

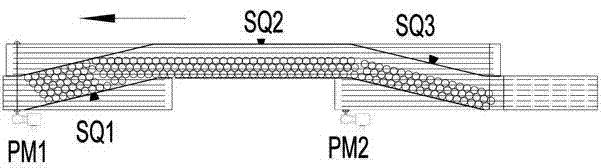

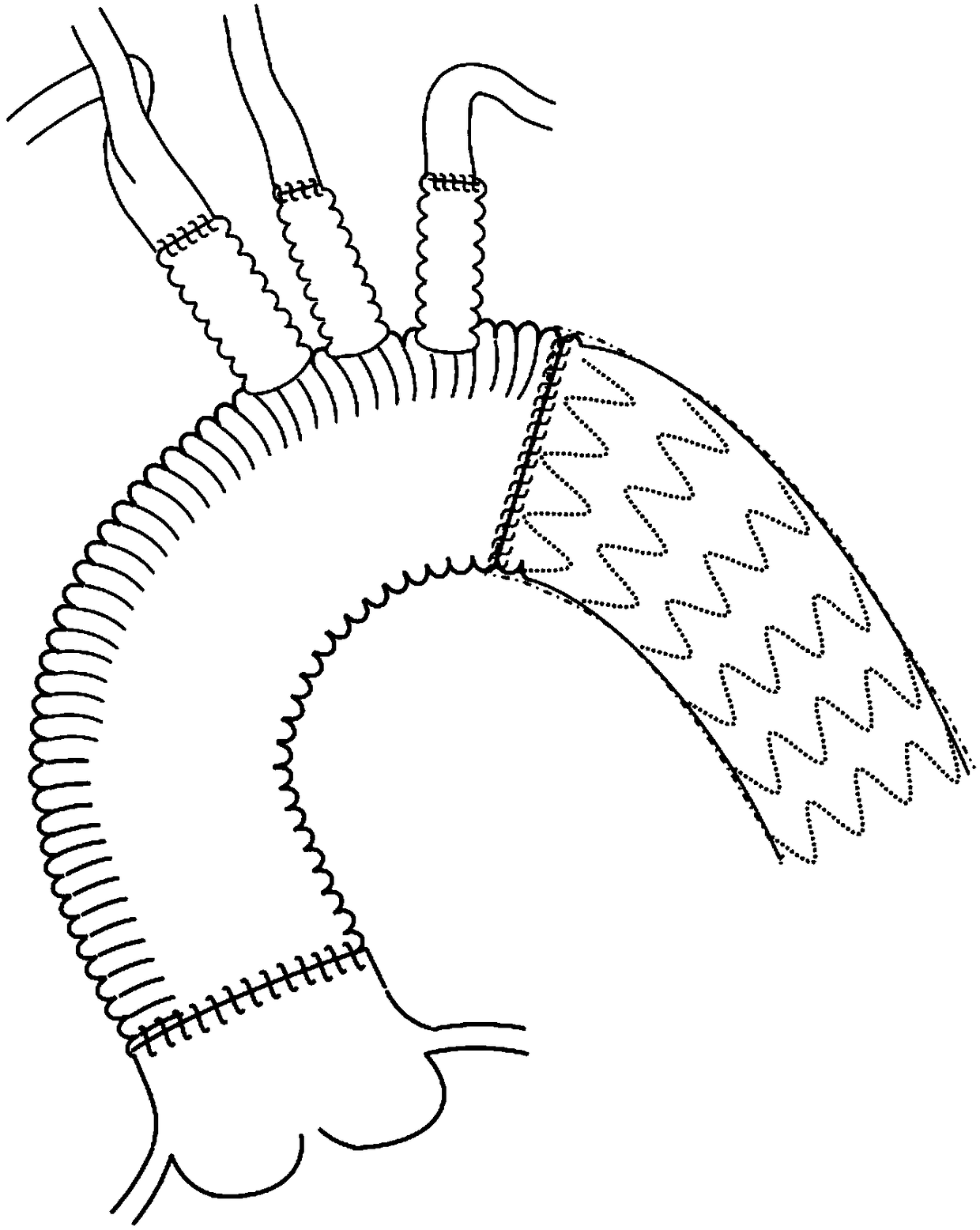

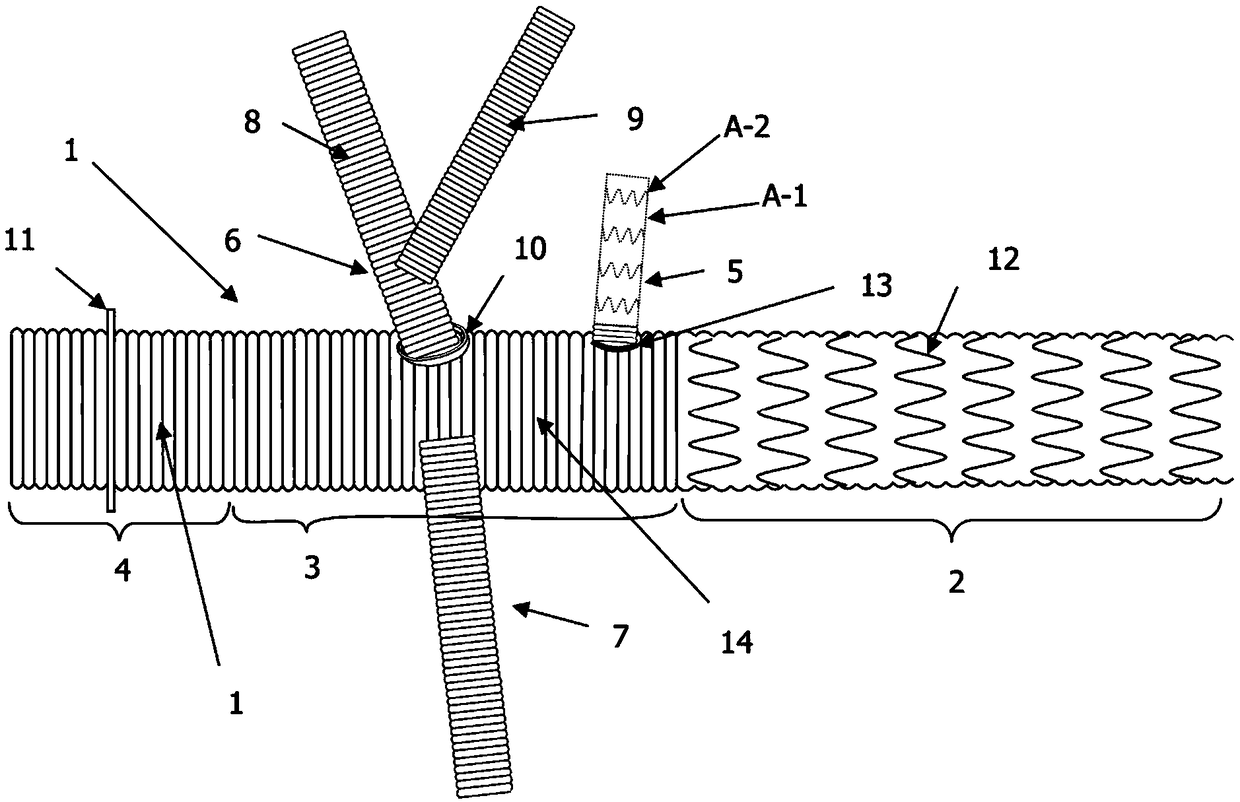

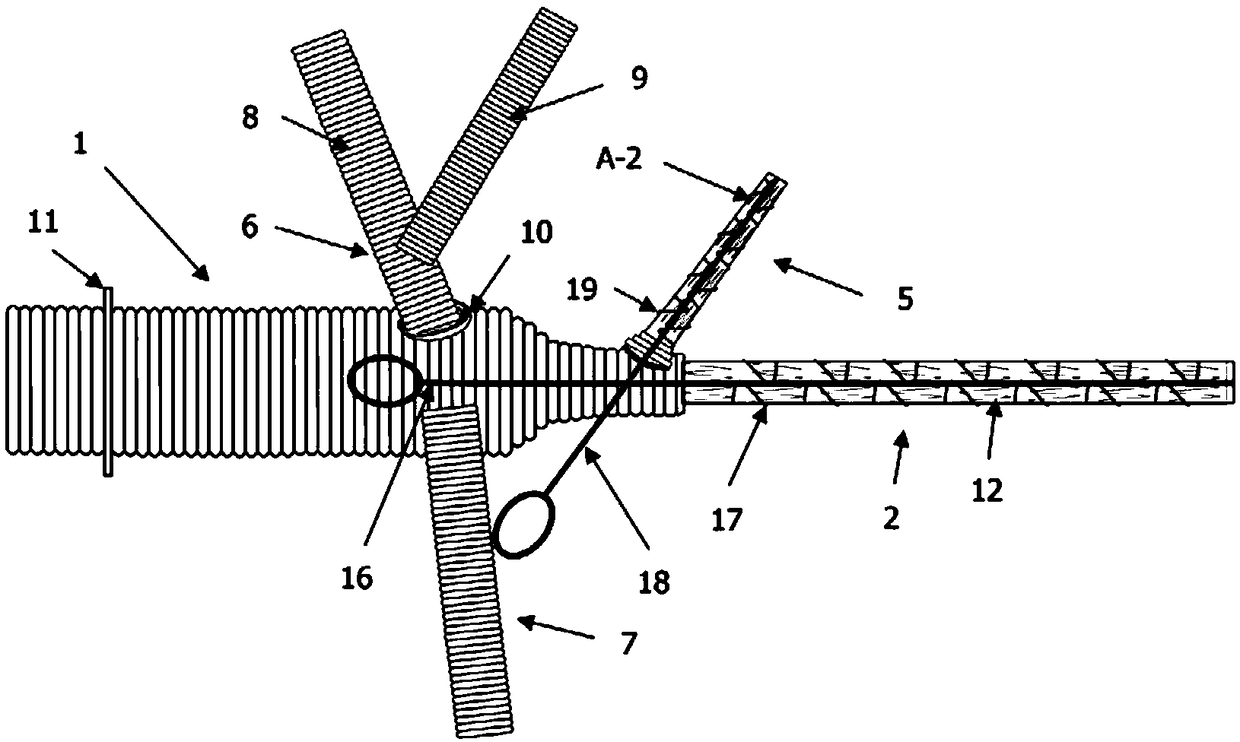

Individualized branch stent arch reconstruction artificial blood vessel

PendingCN109199634AShorten deep low temperature cycle shutdown timeAvoid matchingBlood vesselsAv graftEasy Bleeding

The invention relates to an individualized branch stent arch reconstruction artificial blood vessel, which relates to an artificial blood vessel. The invention solves the technical problems of high technical requirements, easy bleeding, difficult hemostasis, long operation time and high operation risk in the prior total arch replacement operation. The invention comprises an aortic stent vessel (1), The descending aortic stent blood vessel (2) of the aortic stent blood vessel (1) is sequentially formed into an arch aortic stent blood vessel (3) and an ascending aortic stent blood vessel (4) ina proximal direction, and a plurality of arch partial branches including a branch stent blood vessel (5) are emitted from the arch aortic stent blood vessel (3). The descending aortic stent blood vessel (2), the arch part and the ascending part of the descending aortic stent are integrally formed, and the deep hypothermia circulatory arrest time can be shortened from more than 20 minutes to less than 5 minutes without anastomosis, thereby greatly reducing the risk of spinal cord ischemia and paraplegia. The invention is used for aortic arch replacement surgery.

Owner:李杰

Lithium battery Z-shaped lamination device

InactiveCN112109955AShorten the timeReduce mistakesPrimary cell manufactureNon-aqueous electrolyte cellsPole pieceMechanical engineering

The invention relates to the technical field of lithium battery production, and discloses a lithium battery Z-shaped lamination device. The lithium battery Z-shaped lamination device comprises a fixing frame, a negative pole piece lifter, a positive pole piece lifter, an isolating membrane, a motor and an air pump; the fixing frame can be divided into three parts including a side plate, a top plate and a bottom supporting plate, and a battery negative pole piece is movably mounted in the negative pole piece lifter; and a battery positive pole piece is movably mounted to the position, the positive pole piece lifter, in the fixing frame, and a negative pole piece conveying device is movably mounted on a top plate of the fixing frame. Through arrangement of the negative pole piece conveying device and the positive pole piece conveying device, the battery negative pole piece and the battery positive pole piece which need to be laminated are quickly mounted on the isolating membrane at a time, so that the pole piece conveying time is shortened, and the laminating efficiency is improved; and meanwhile, due to synchronism of the negative pole piece conveying device and the positive pole piece conveying device, the position difference of each pole piece after installation is small, so that the error between the pole pieces is small, and the quality of battery pieces is effectively improved.

Owner:张忐忑

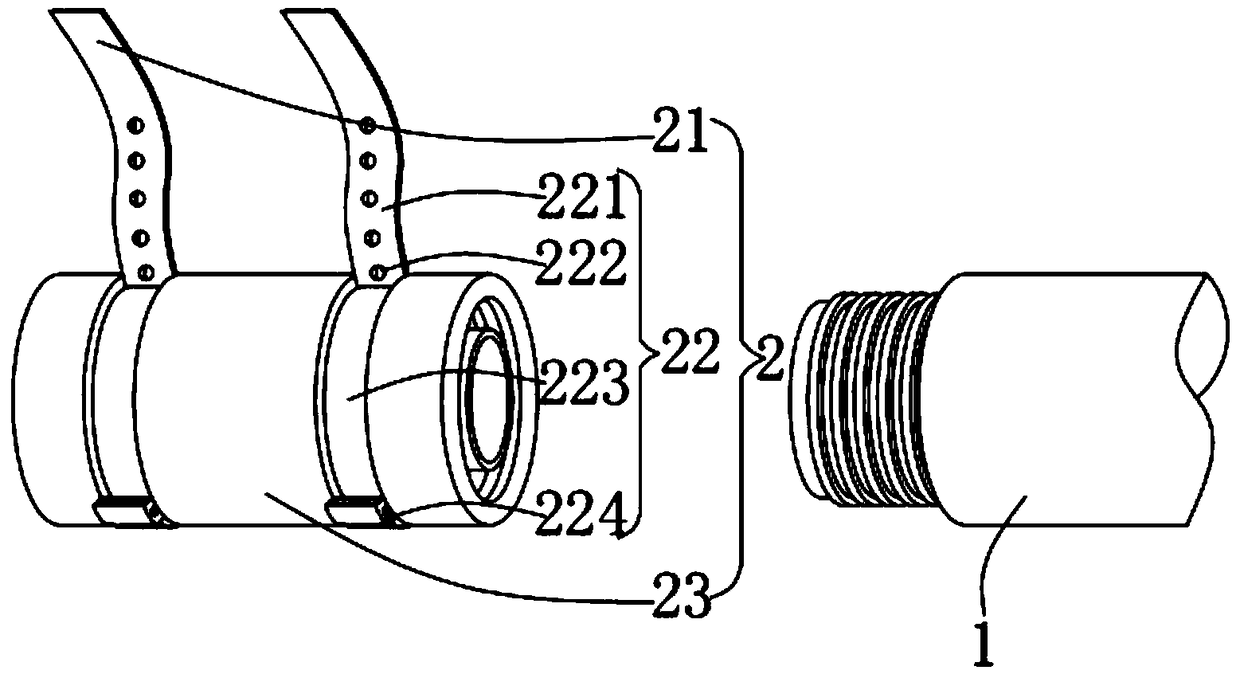

Bidirectional seal pipeline butt joint

InactiveCN107725926AAvoid compression deformationGuaranteed clamping and fixing effectSleeve/socket jointsButt joint

The invention relates to a two-way sealed pipeline butt joint, which includes a connecting cylinder, and pressing rings are symmetrically arranged on both axial sides of the connecting cylinder, and an annular connecting ring is arranged on the outer ring of the tightening ring, and the connecting ring and the outer wall of the connecting cylinder pass through Threaded fixed connection; a pipe fixing assembly and a pipe sealing assembly are arranged between the connecting cylinder and the pressing ring; the pipe sealing assembly includes a pipe wall sealing ring and a compression ring, the compression ring is slidingly connected to the inner wall of the connection ring, and the pipe wall The sealing ring is clamped between the end of the connecting cylinder and the end of the compression ring; the pipe fixing component includes a ring-shaped spring leaf, the spring leaf is a tapered structure, and an annular support protrusion is arranged on the outer edge of the pressing ring. On the inner edge of the pressing ring, there is an annular pushing protrusion, and the spring piece is clamped between the supporting protrusion and the pushing protrusion; the inner wall of the middle part of the connecting cylinder is also provided with an annular pipe end sealing ring, and the pipe Annular sealing grooves are coaxially arranged at both lateral ends of the end sealing ring.

Owner:朱毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com