Single-column pier beam bridge and reinforcing and reconstructing method thereof

A single-column, bridge pier technology, used in bridge reinforcement, bridges, bridge parts, etc., can solve problems such as high cost, inability to quickly transform, and difficult to transform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

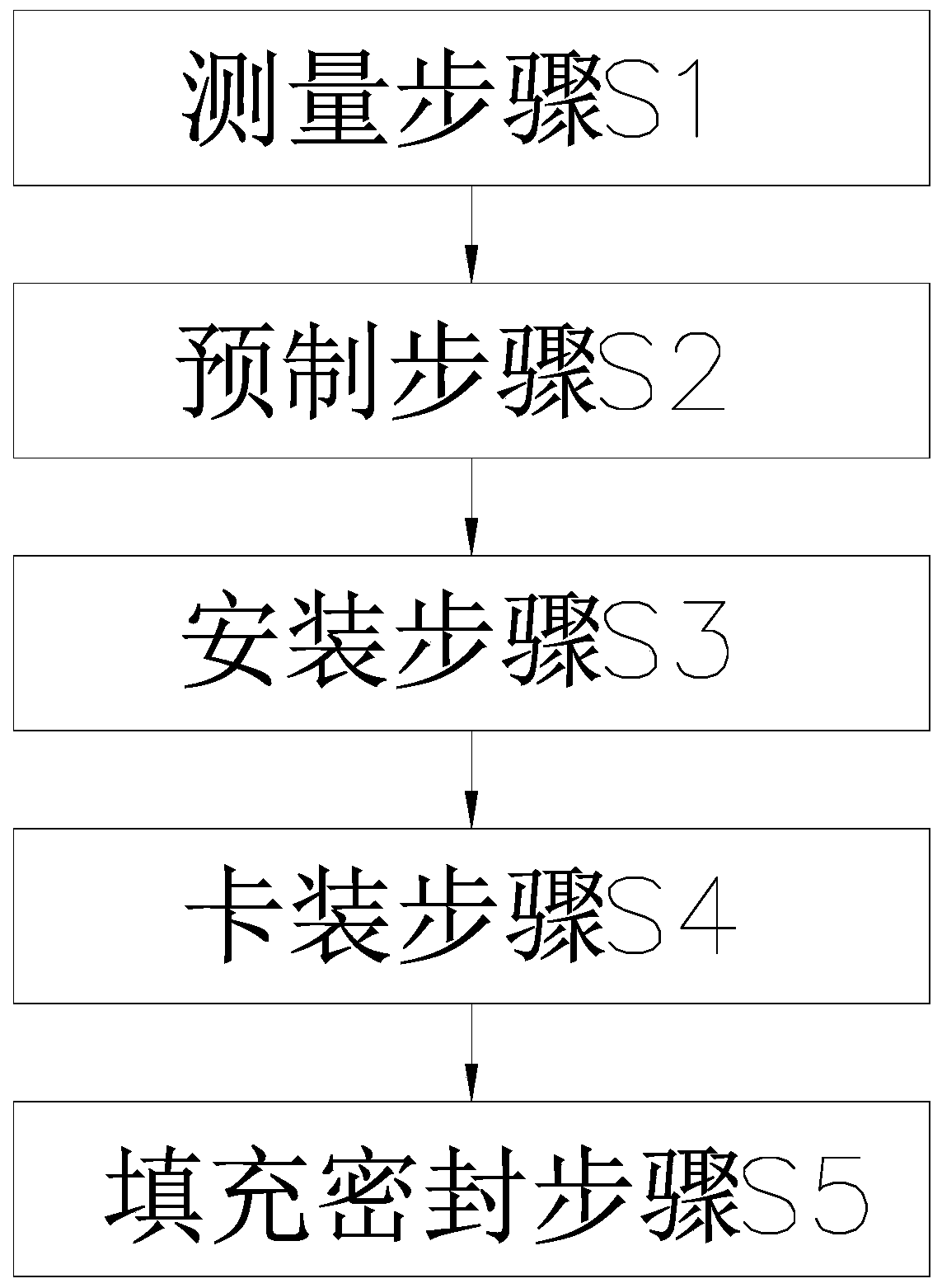

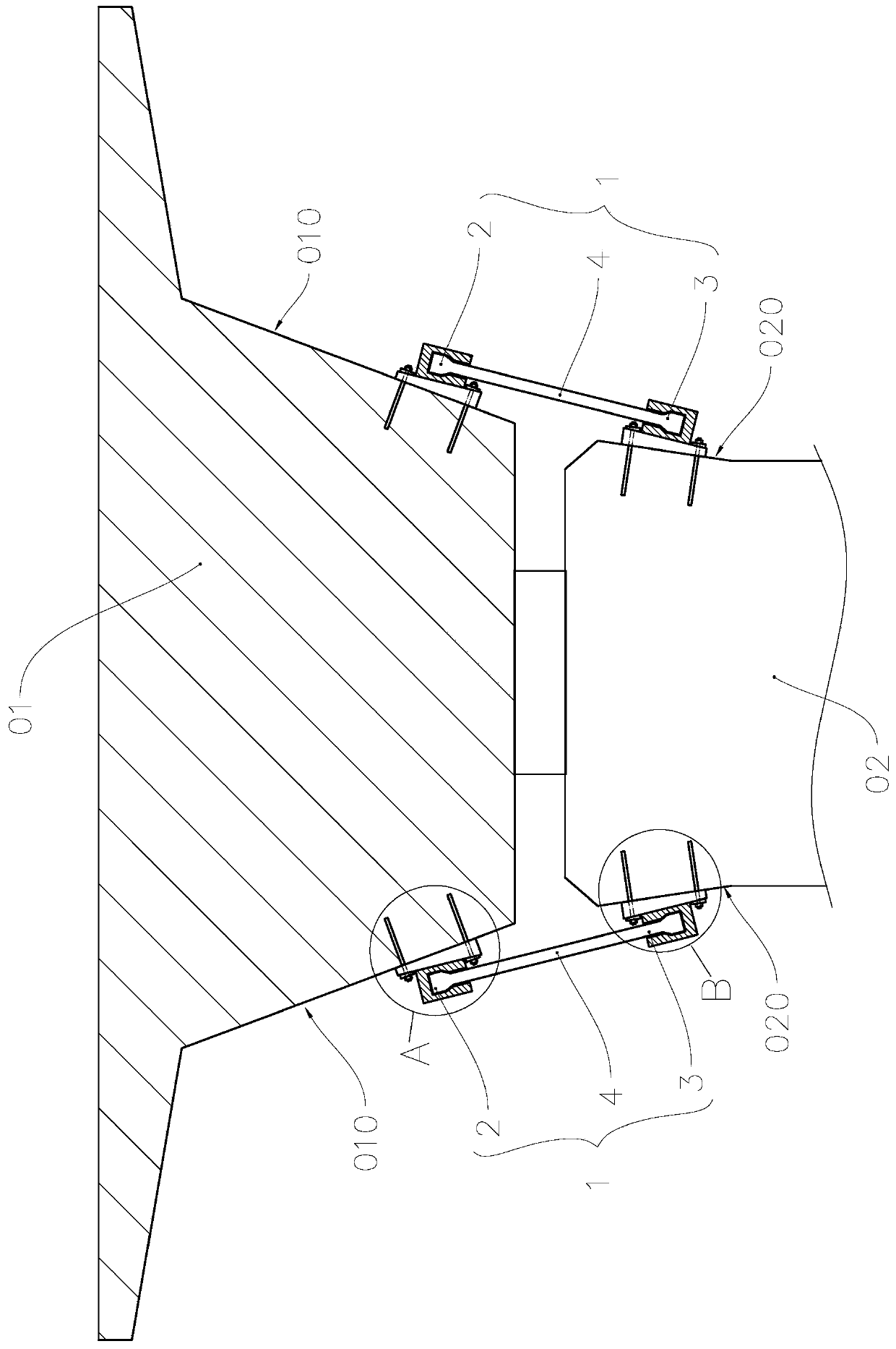

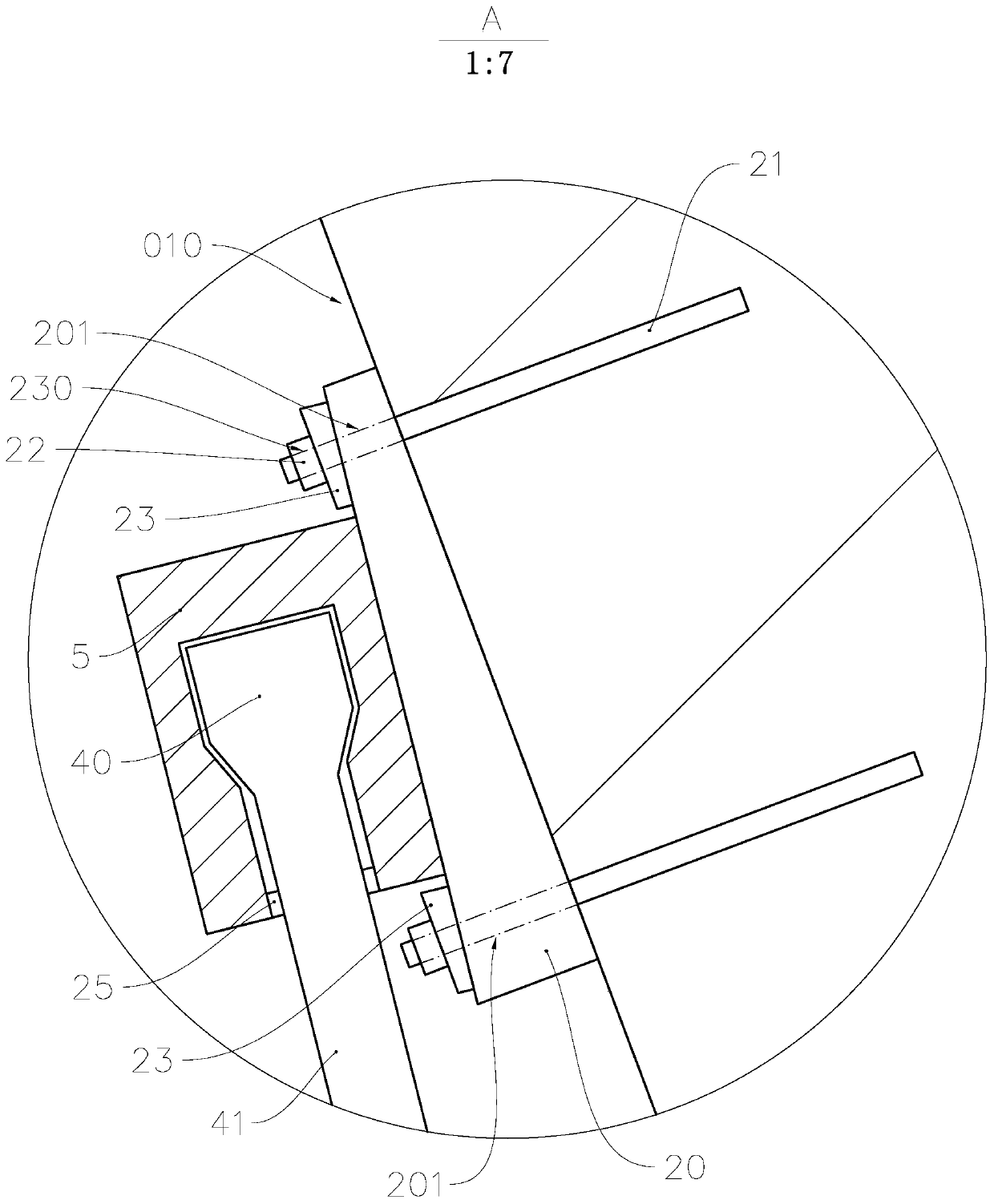

[0042] see Figure 1 to Figure 12 , the reinforcement and transformation method of the present invention is aimed at the existing single-column pier-beam bridge that has been constructed, and specifically adopts the anti-overturning device newly designed by the applicant to carry out reinforcement and transformation. Such as figure 2 As shown, the constructed single-column pier-beam bridge includes a pier 02 and a main girder 01 supported on the pier 02, and a set of anti-overturning devices 1 are arranged on both sides of the pier 02.

[0043] Such as Figure 2 to Figure 12 As shown, each set of anti-overturning device 1 includes an upper tie rod slot assembly 2 for fixing on the side part 010 of the main girder, a lower bar slot assembly 3 for fixing on the side part 020 of the pier, and two ends All of them are tie rods 4 that hold the ends; in this embodiment, the number of tie rods 4 is more than two, specifically three, and the tie rods 4 are flat plate structures. T...

Embodiment 2

[0069] As an illustration of Embodiment 2 of the present invention, only the difference from Embodiment 1 above will be improved, that is, the structure of the water-stop rubber strip will be improved.

[0070] see Figure 13 , in this embodiment, the structure of the water-stop rubber strip 35 arranged on the lower rod slot assembly 3 is taken as an example for illustration. The water-stop rubber strip 35 includes a sealing plug body 350 for inserting into the gap between the pull rod 4 and the notch wall of the notch 60 of the pull rod slot 6 on the wedge-shaped motherboard 30, and a sealing plug body 350 for fixing. Outer connection part 351; On this outer connection part 351, be provided with installation through hole 352; Cooperate, and the water-stop rubber strip 35 is detachably fixed on the draw bar slot 6, thereby improving its fixing firmness on the draw bar slot 6. In this embodiment, the outlets of the groove cavity 61 are sealed by the cover plate, the water-sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com