Patents

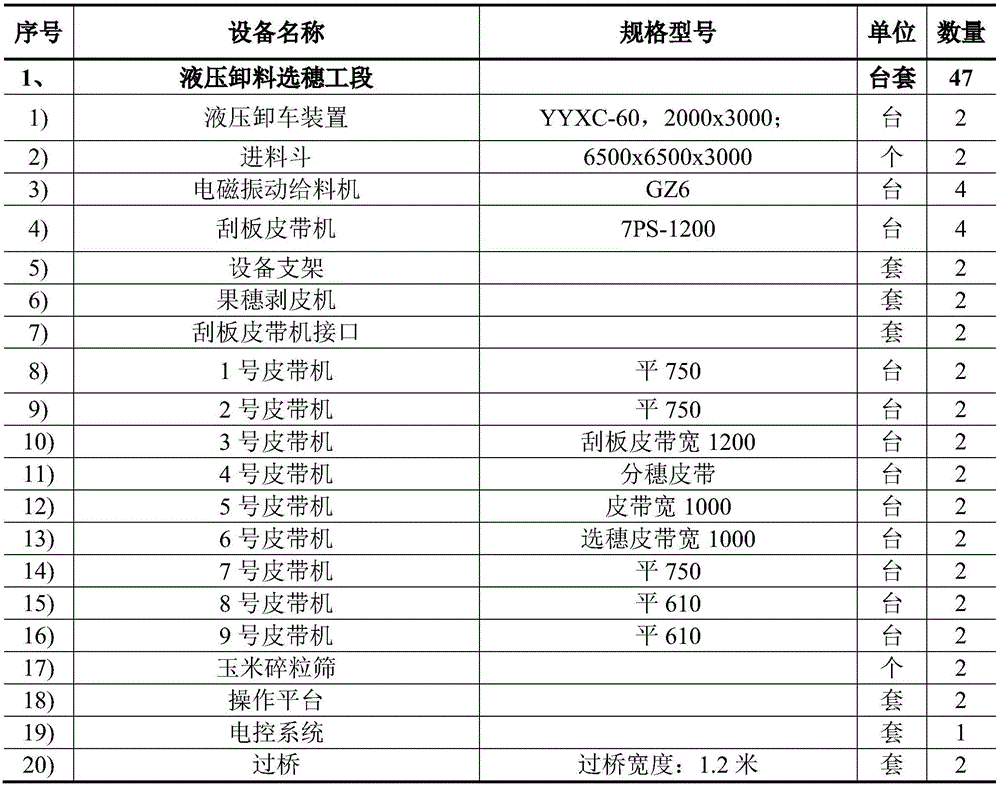

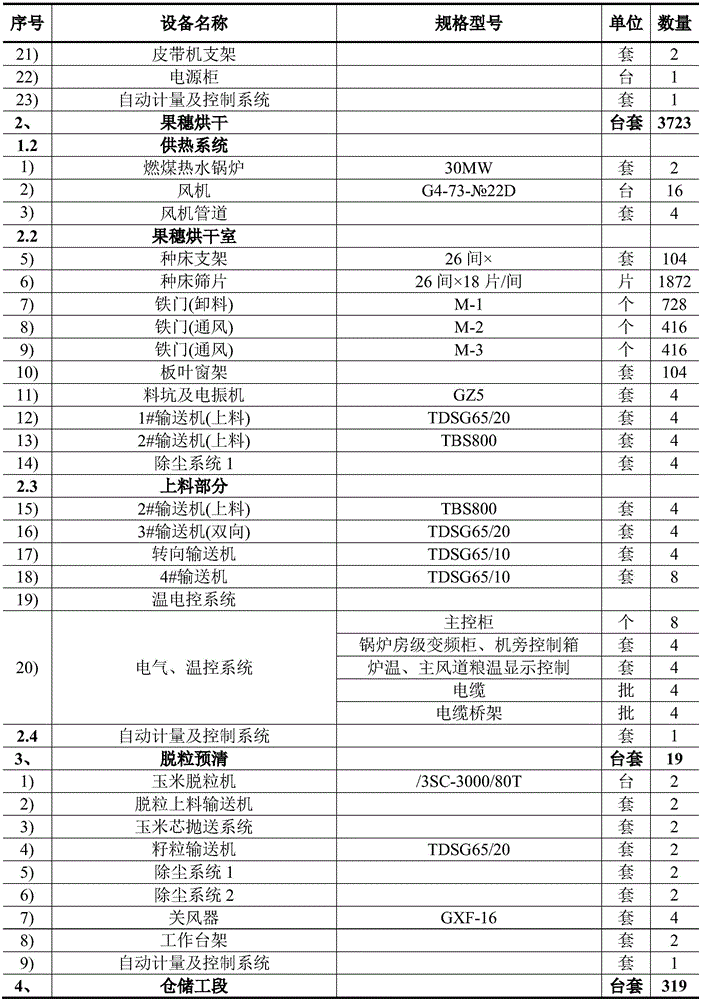

Literature

32results about How to "Solve the problem of high breakage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

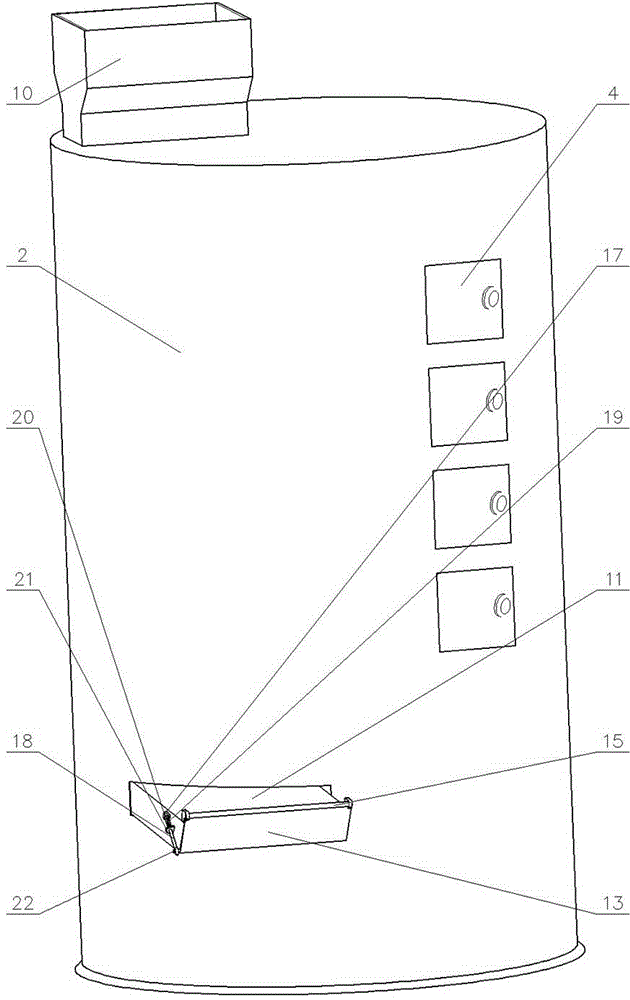

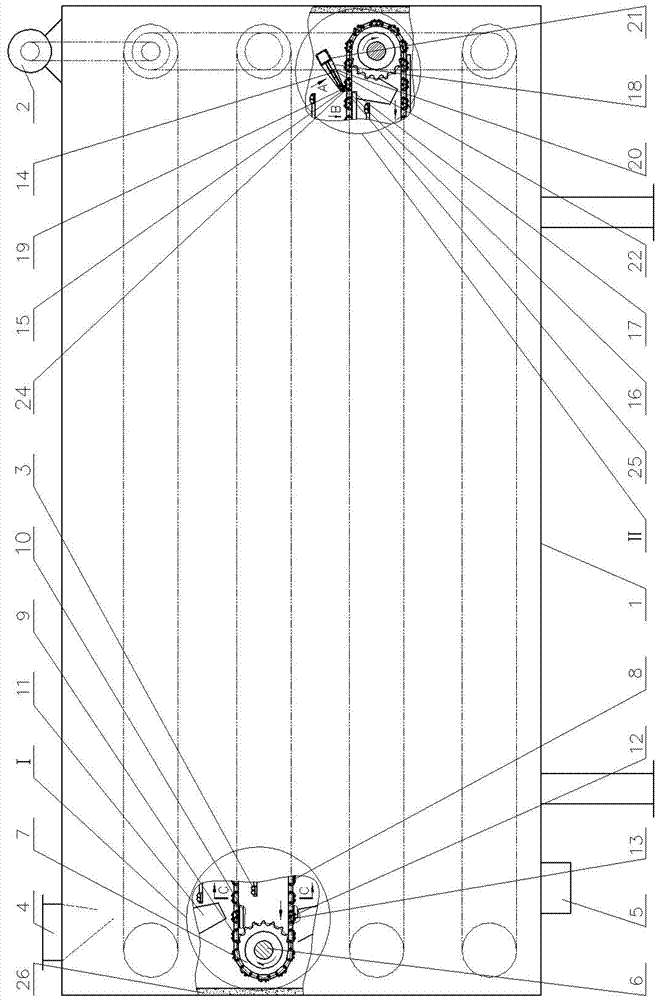

Waste heat recovering ear-corn drying machine

InactiveCN103070234AOptimized drying programKeep dryFood processingClimate change adaptationChinese charactersEngineering

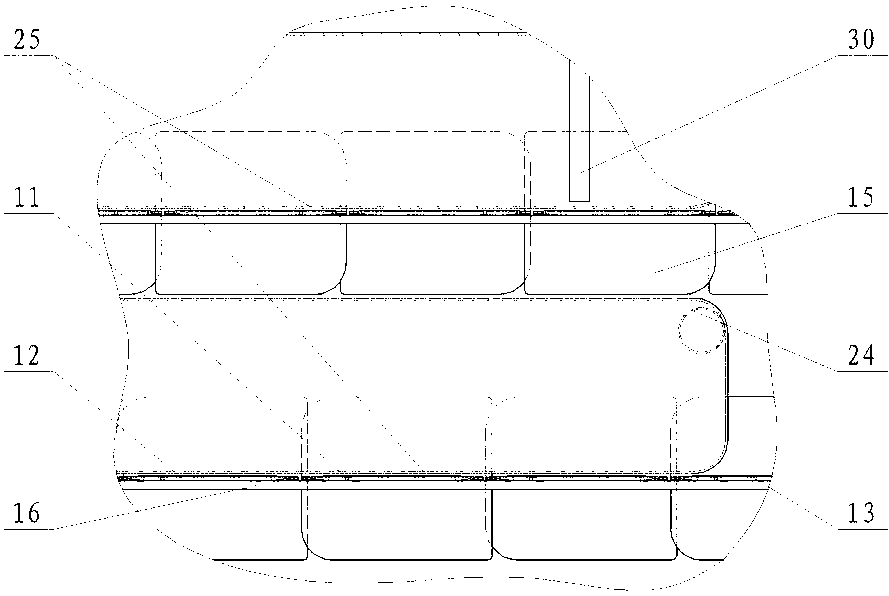

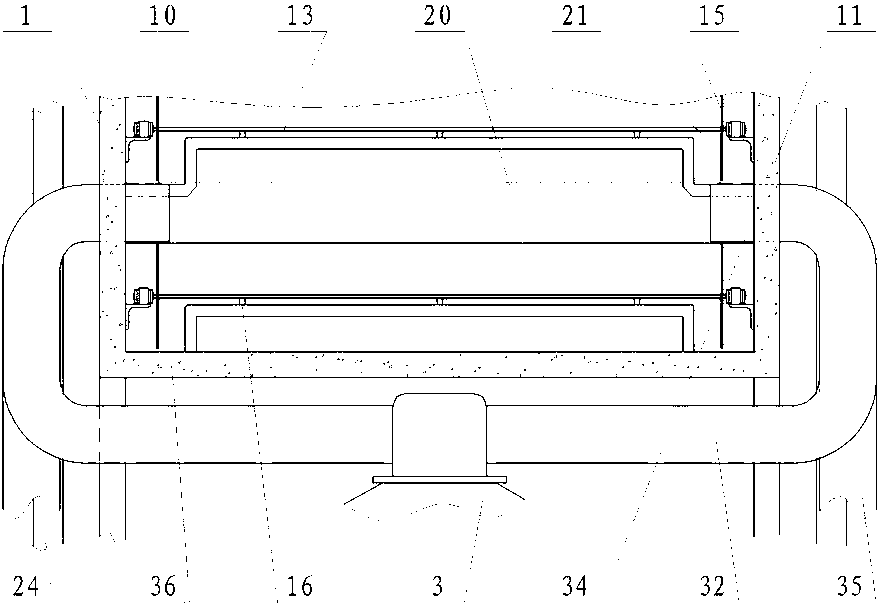

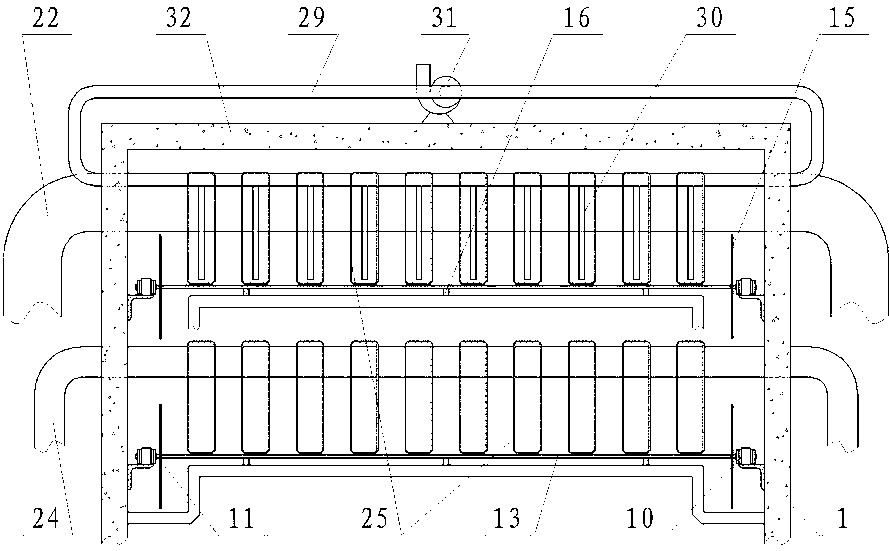

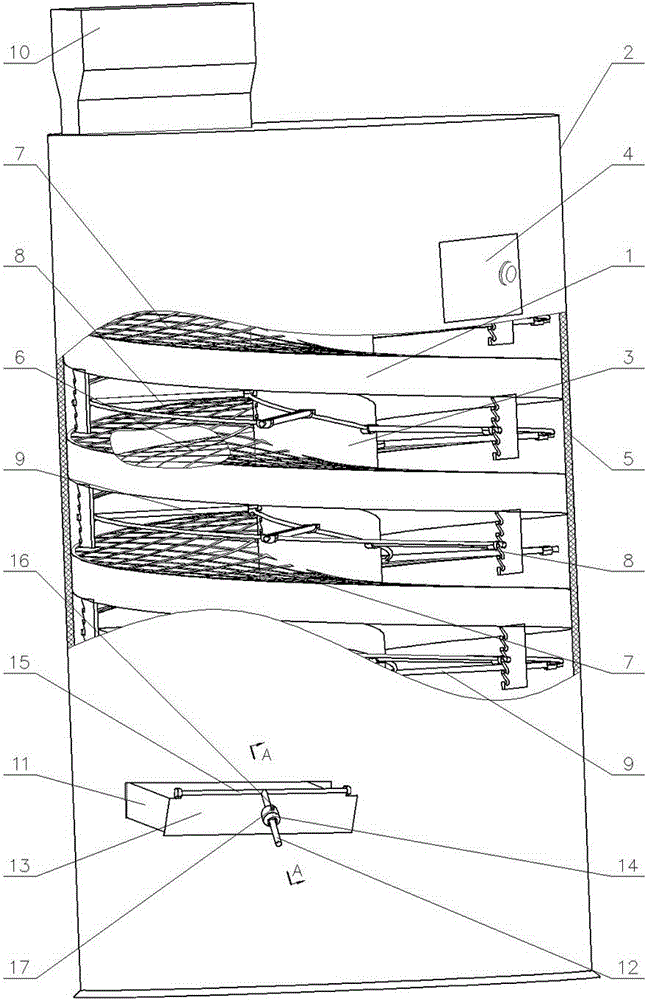

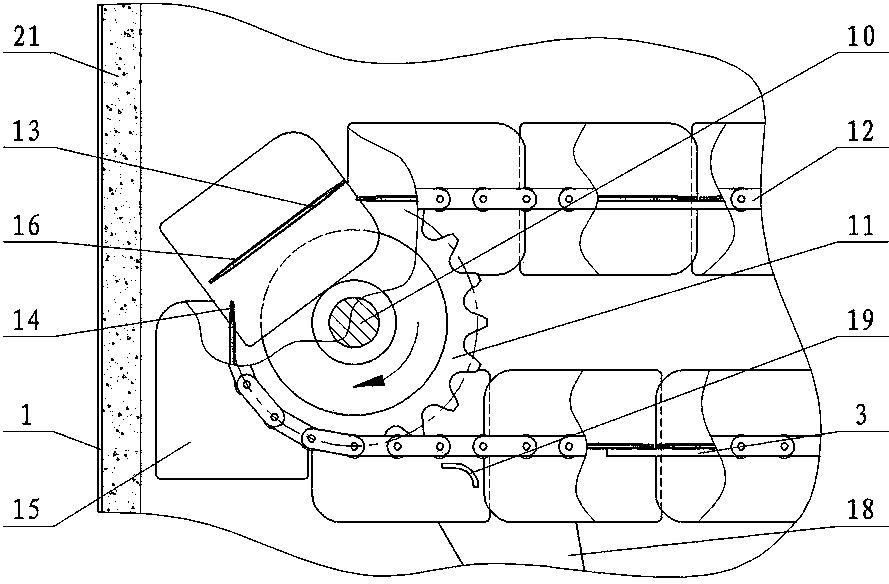

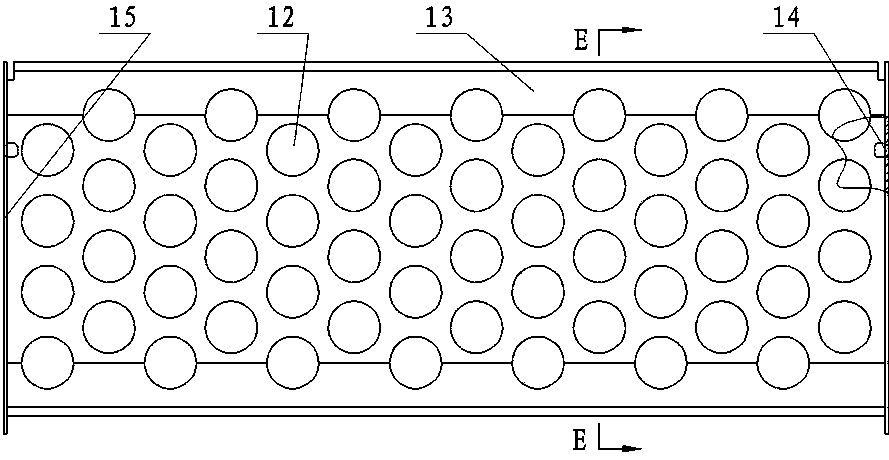

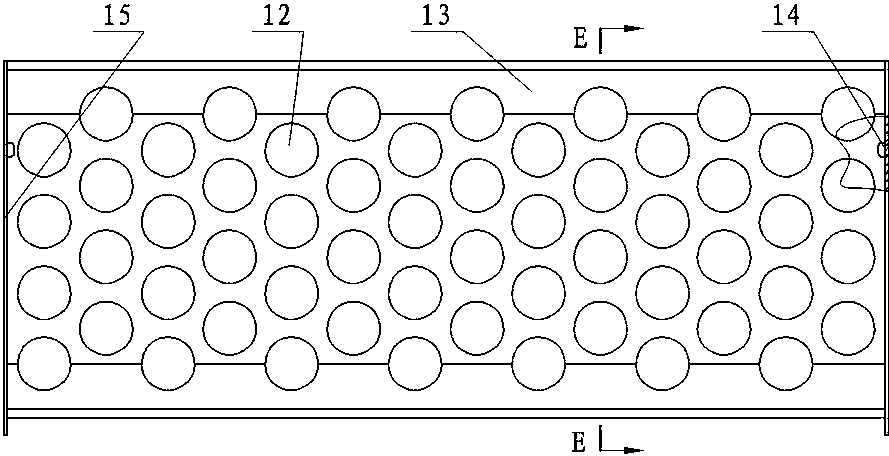

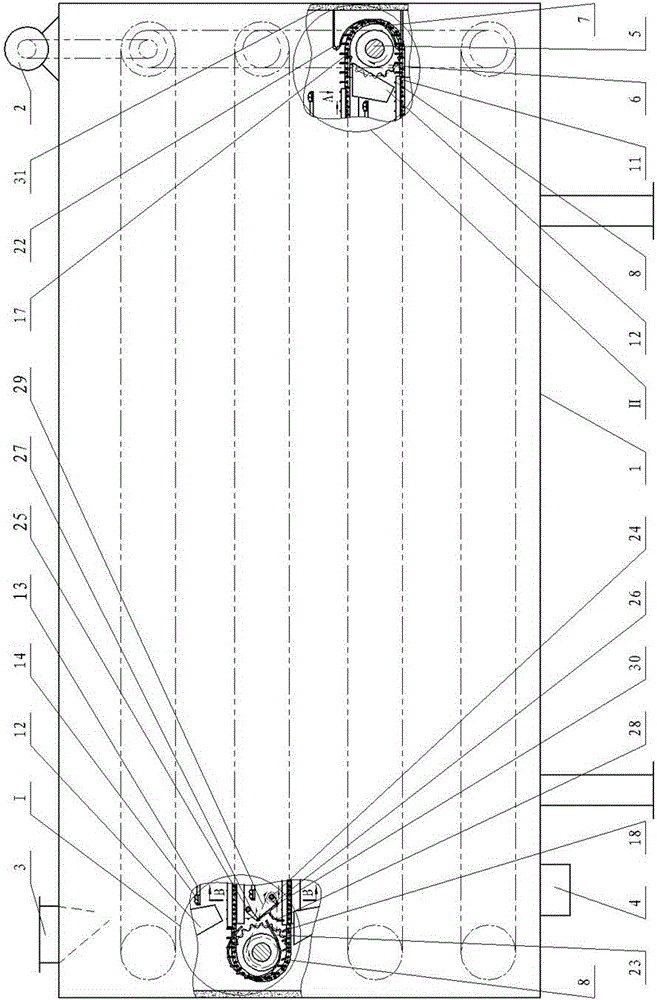

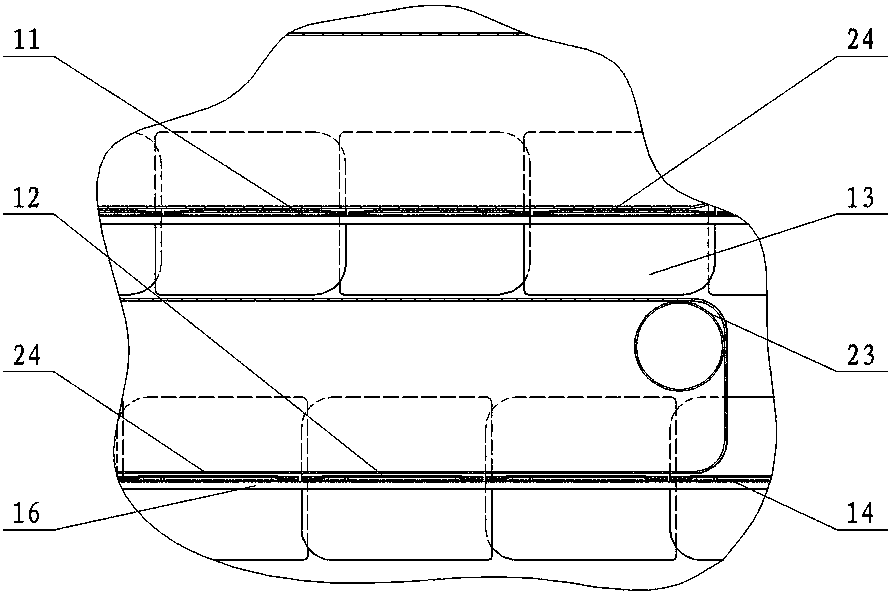

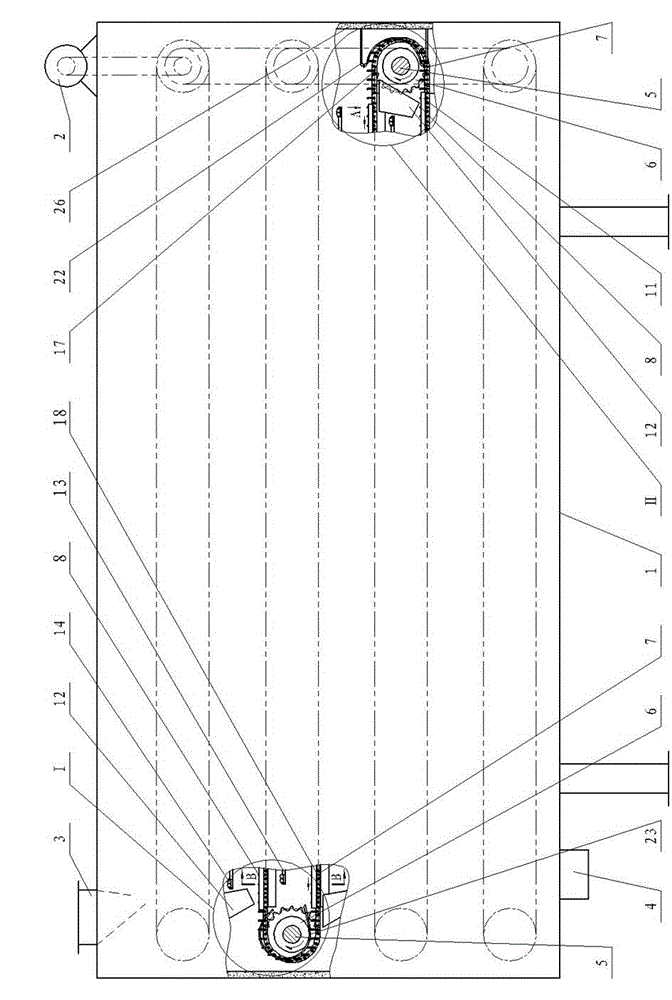

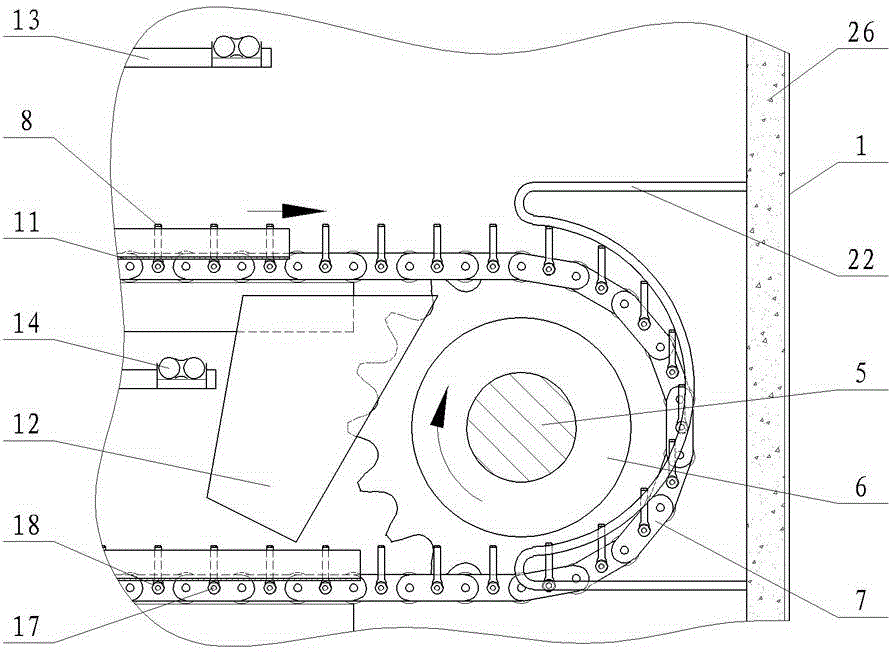

The invention provides a waste heat recovering ear-corn drying machine, which is characterized in that the chamber of the drying machine is divided into an upper area and a lower area by a partition I; the lower area is divided into three parts by partitions II; the bottom of the middle chamber is provided with an air heater with a blower; a plurality of heat exchange boxes are arranged in the upper area and are communicated with one another by annular air pipes; the heat exchange boxes on the lower part are communicated with the middle of the lower area of the chamber; the heat exchange boxes on the upper part are connected with an induced draft fan mounted at the top of the chamber; a water pump at the top of the chamber is connected with a straight pipe inserted in each heat exchange box by a water pipe which is shaped like a Chinese character 'YUE'; a plurality of conveying devices running under the driving of a driving device are arranged in the chamber; molding link plates of I and II types are hung on a pin shaft extending out of the inner side of a conveying chain at intervals and are arrayed and supported on a guide rail to form a trough material channel; a guide chute is arranged below the tail end of the channel; and a feed inlet and a discharge port are formed at the top and the bottom of the chamber respectively. The waste heat recovering ear-corn drying machine is large in moisture reducing range, good in preheating effect and reliable in working.

Owner:SHANDONG UNIV OF TECH

Water circulation pre-heating type corncob drier

InactiveCN103070235AKeep dryImprove uniformitySeed preservation by dryingWater circulationEngineering

The invention provides a water circulation pre-heating type corncob drier. The water circulation pre-heating type corncob drier is characterized in that a box is partitioned into an upper region and a lower region by a partition plate I; the lower region is partitioned into three parts by partition plates II; a water gas heater is arranged at the bottom of the middle of the box; one end of a heat exchange box above a first conveying device is communicated with the middle of the box, and the other end of the heat exchange box is connected with an induced draft fan which is arranged on the top of the box; two ends of each heat exchange box between upper and lower groove-shaped material channels of the first conveying device are connected with the water gas heater through a circulating water pump; a condensing water pump which is arranged on the top of the box is connected with a straight water pipe which is inserted into each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device to rotate are arranged in the box; a first moulding chain plate and a second moulding chain plate are suspended on a pin shaft of a chain extending inwards at intervals and supported on a guide rail to form a groove-shaped material channel; a material guide groove is formed below the tail end of the channel; a charging hole is formed on the top of the box; and a discharging hole is formed at the bottom of the box. The water circulation pre-heating type corncob drier is good in preheating and drying effect, and reliable in operation.

Owner:SHANDONG UNIV OF TECH

Cooling discharge type corncob drying machine

InactiveCN103070236AReduce the temperatureGuaranteed temperatureSeed preservation by dryingWater pipeCondensate pump

The invention provides a cooling discharge type corncob drying machine. The cooling discharge type corncob drying machine is characterized in that the inner part of a box is divided into an upper region and a lower region by a separator plate I; the lower region is divided into three parts by a separator plate II; the separator plate I and separator plates III and IV located at the lower part of the box form a cooling region; a water heater is arranged at the bottom of the middle box; the cooling region is connected with the air inlet of the water heater by a blower; the air outlet of the water heater is connected with the middle part of the box; one end of each heat exchange box at the uppermost part in the box is communicated with the middle part of the box, and the other end of the heat exchange box is connected with an induced draft fan; two ends of each heat exchange box in the lower place are connected with the water heater by a circulating water pump; a condensate water pump is connected with straight water pipes in each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device are arranged in the box; each forming chain plate is supported on a guide rail to form a groove-shaped material channel; a guide chute is arranged under the tail end of the channel; a feed port is formed in the top part of the box; and a discharge port is formed in the bottom of the box. The cooling discharge type corncob drying machine is good in drying effect and low in energy consumption, and corncobs can be packaged directly after being dried by the drying machine.

Owner:SHANDONG UNIV OF TECH

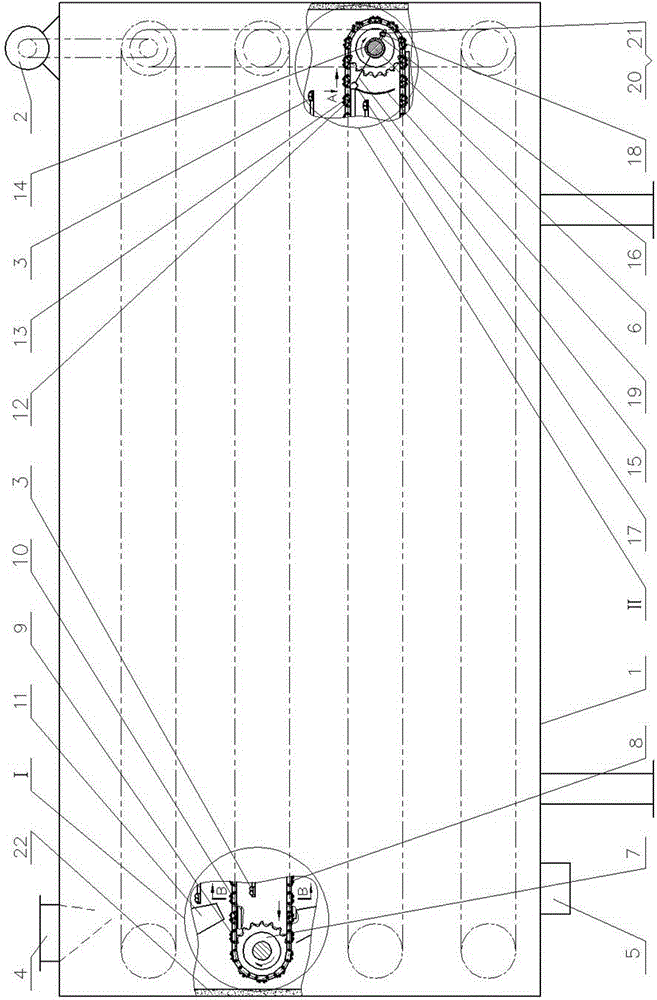

Continuous type infrared corncob drying machine

InactiveCN103081991ASolve the problem of high breakage rateImprove heat transfer efficiencyFood processingSeed preservation by dryingInfraredEngineering

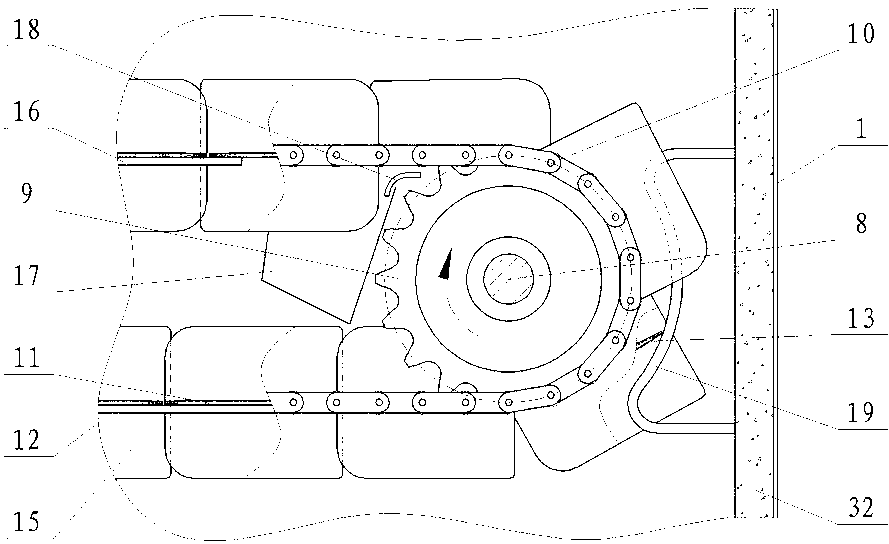

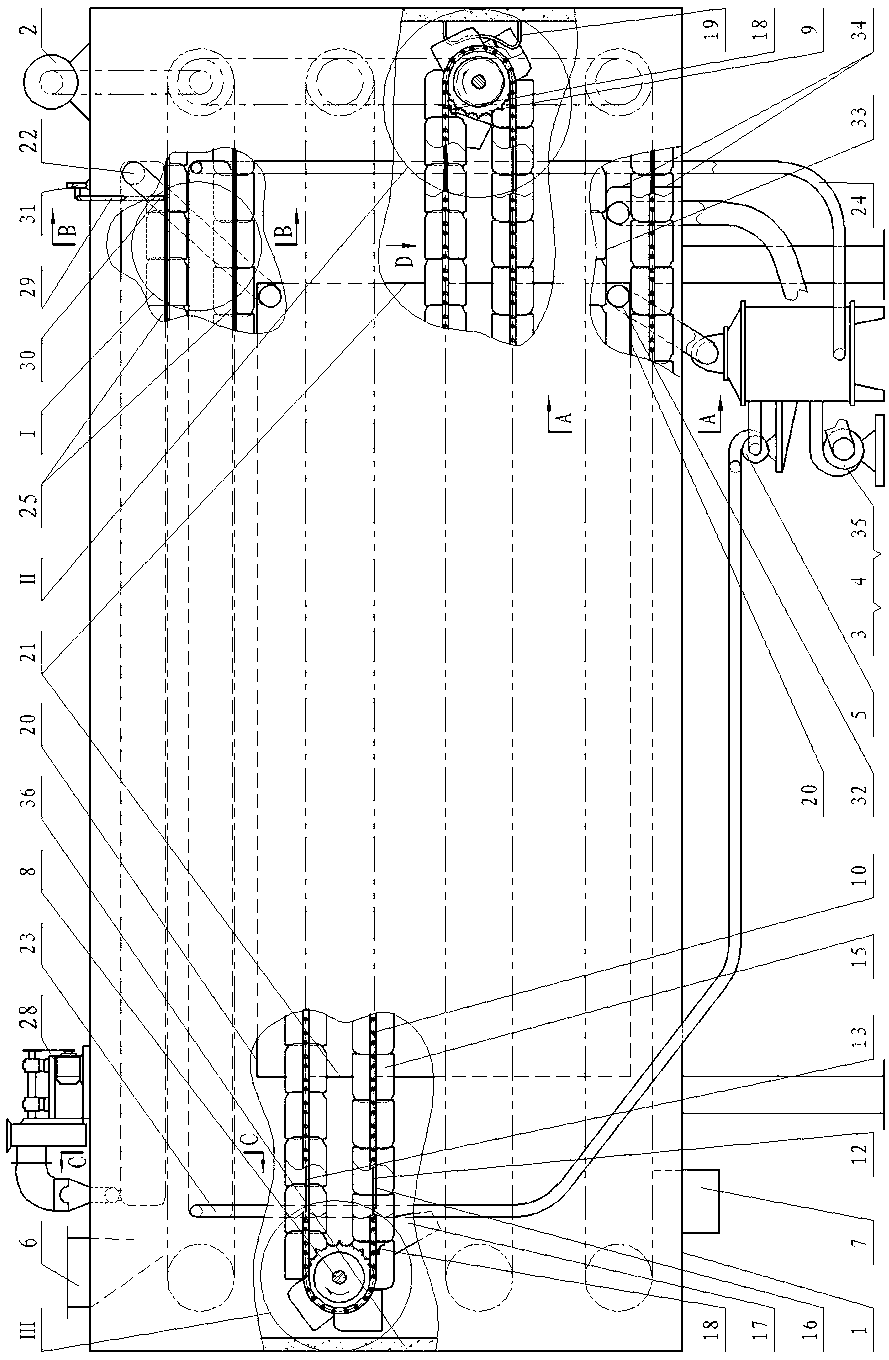

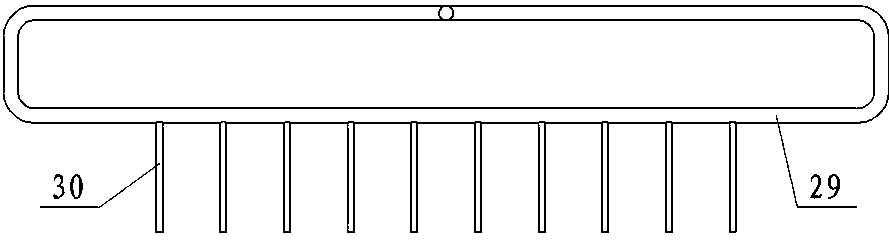

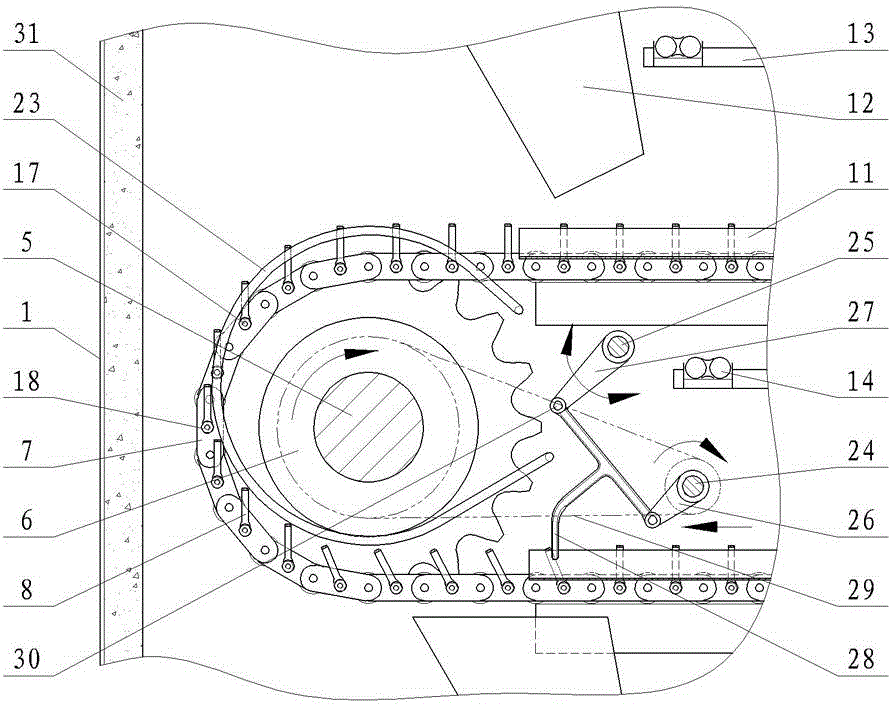

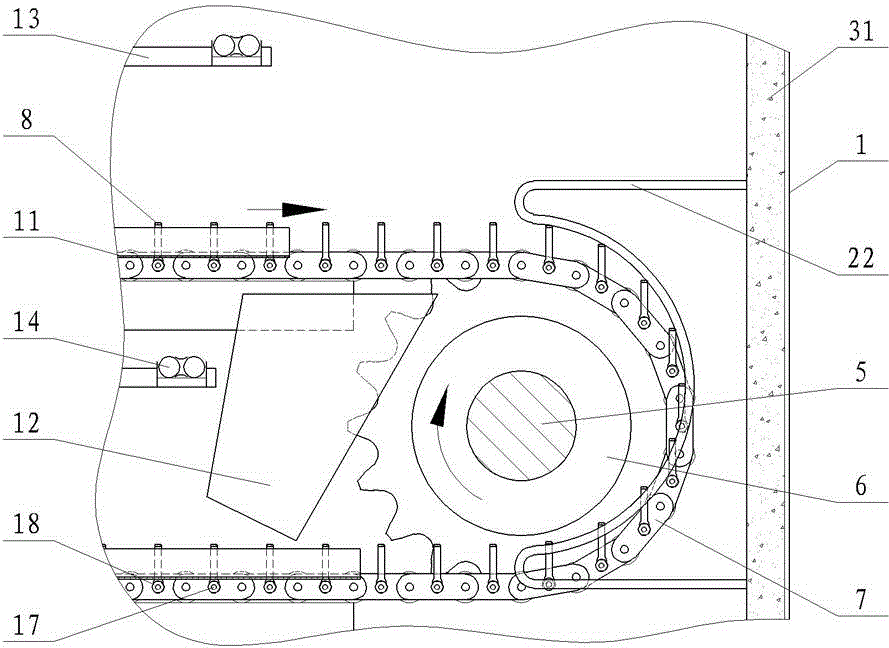

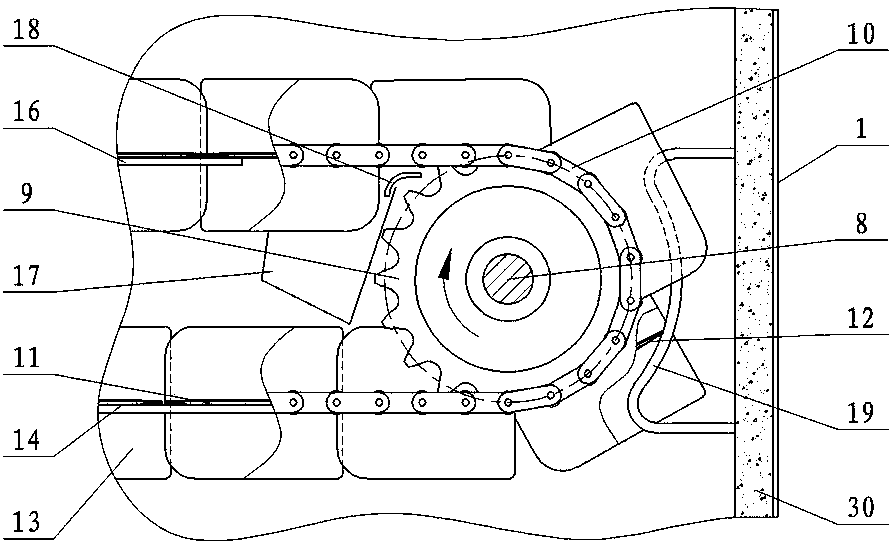

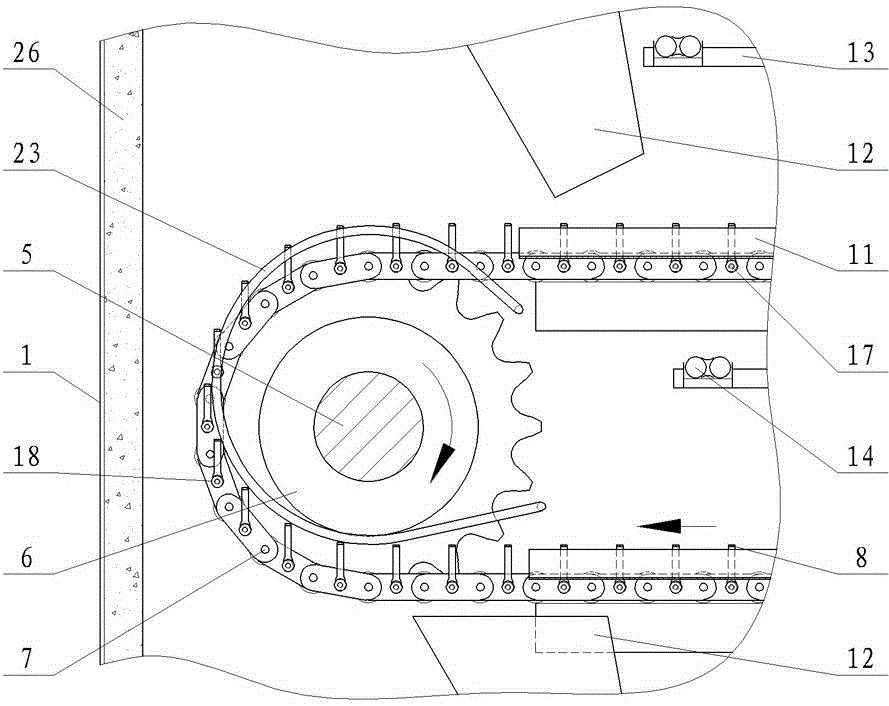

The invention provides a continuous type infrared corncob drying machine which is characterized in that a box body is internally provided with a plurality of conveying devices driven by a transmission device to run, wherein I type and II type material pulling rods with two different lengths are fixedly arranged between two chains of the same conveying device at an interval; parts of each conveying device, which correspond to upper and lower sections of horizontal sections of the chains, are respectively provided with material supporting plates; material guide grooves are arranged below the tail ends of the material supporting plates; radiation devices are arranged above the material supporting plates; radiation racks of the radiation devices are suspended on the box body; the two ends of an infrared radiation element which downwards radiates infrared rays in a single direction are mounted on the radiation racks; and a feeding opening is arranged on the top of the box body, and a discharging opening is formed at the bottom of the box body. The continuous type infrared corncob drying machine disclosed by the invention has the advantages of high heat transferring efficiency, low energy consumption and good drying uniformity.

Owner:SHANDONG UNIV OF TECH

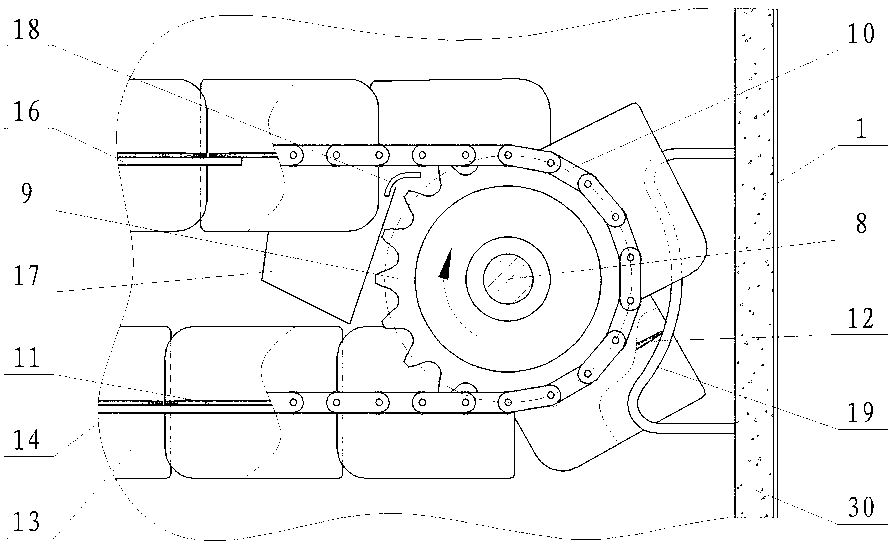

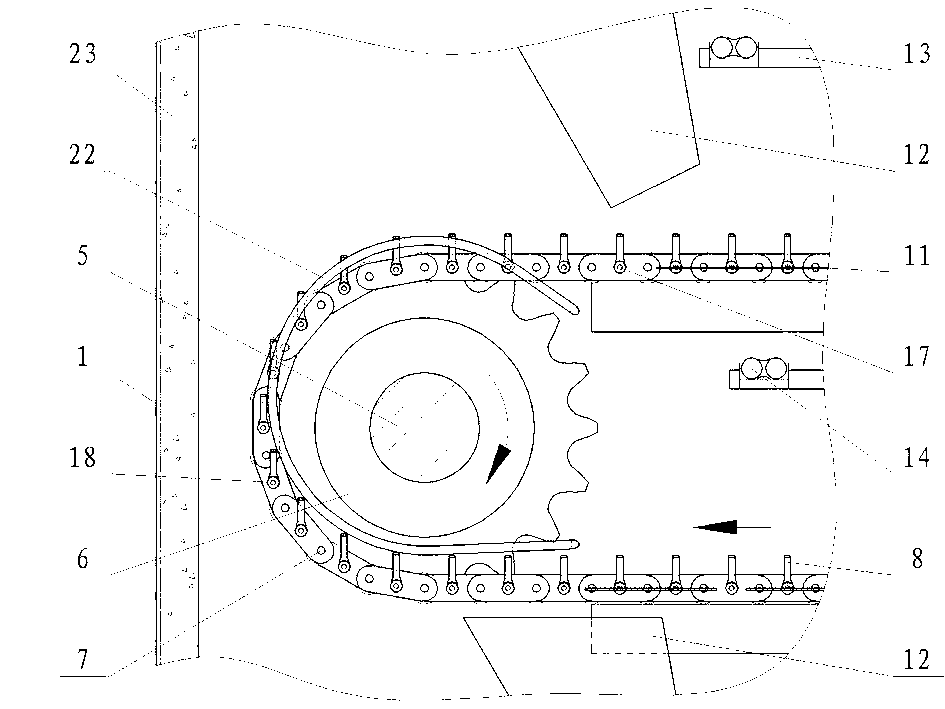

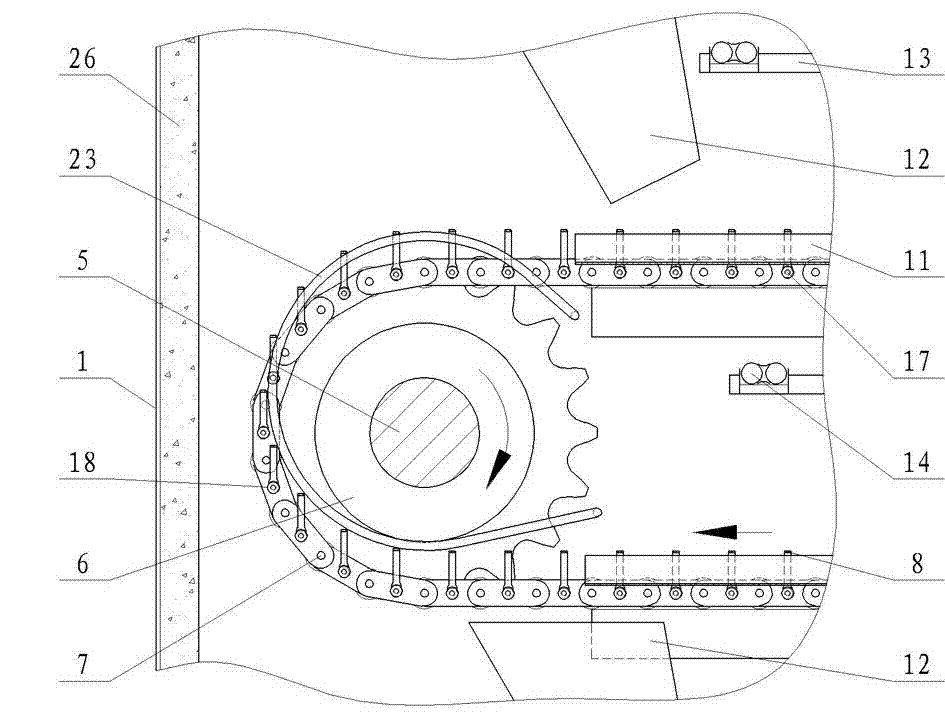

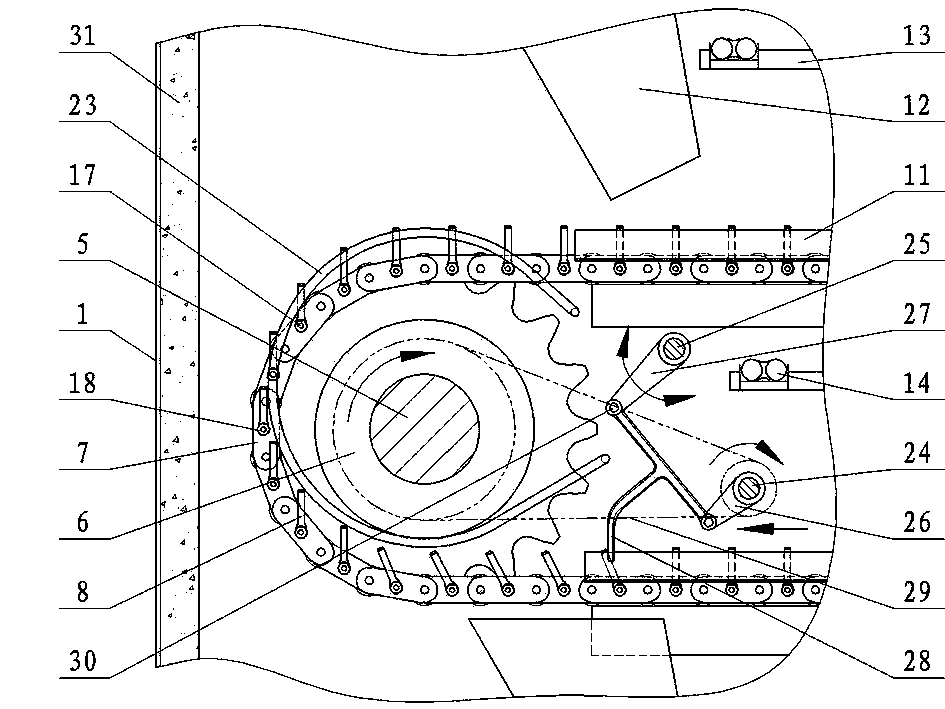

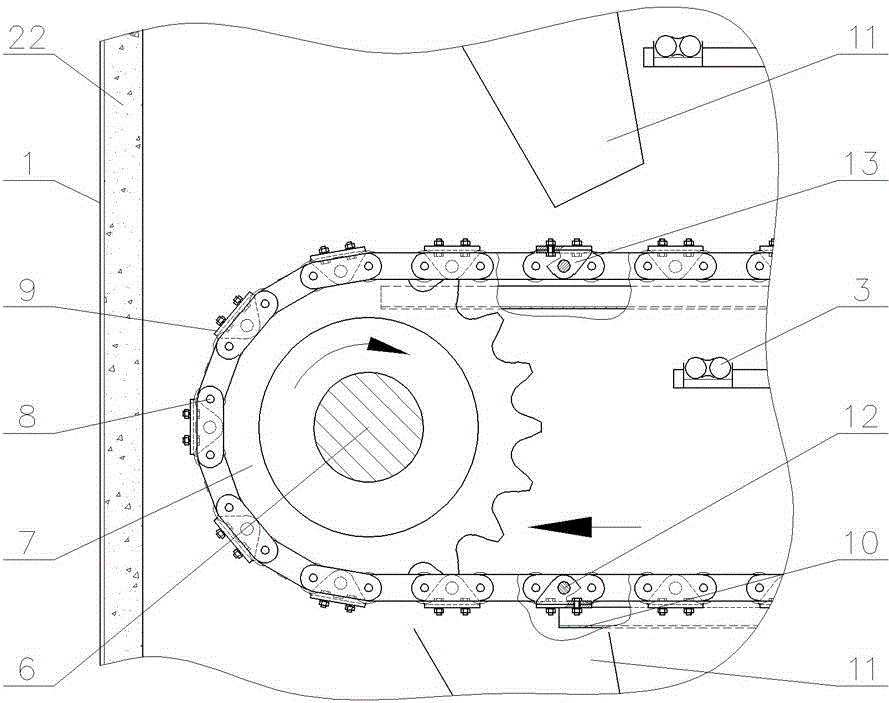

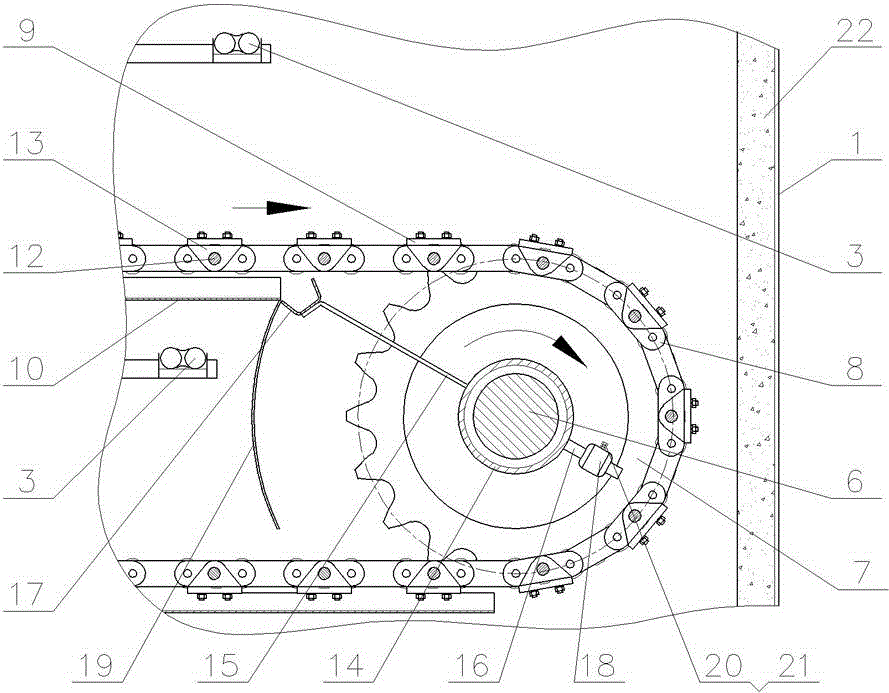

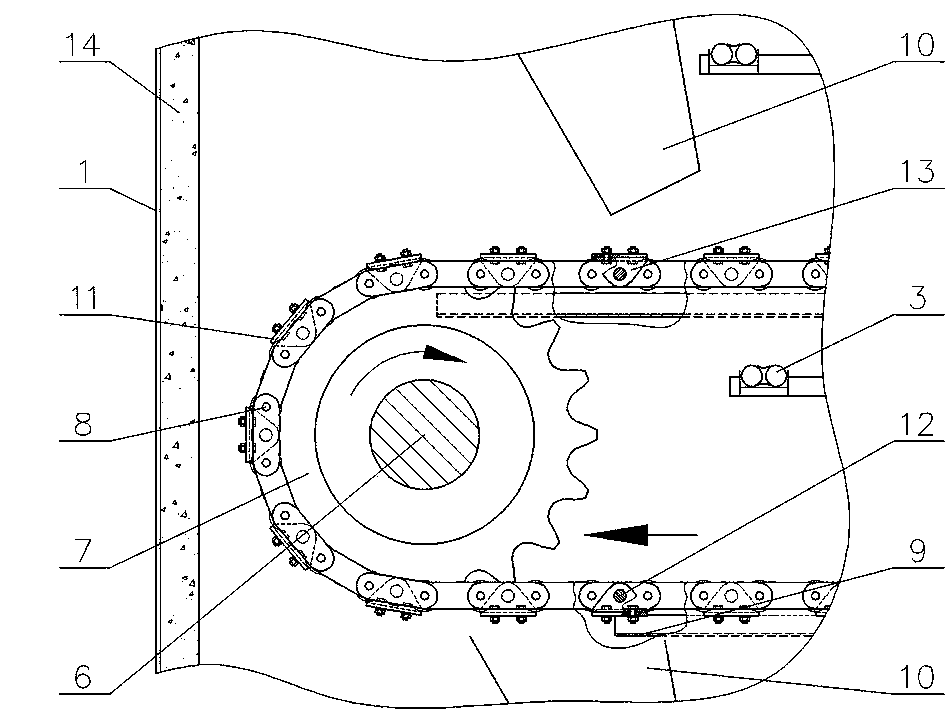

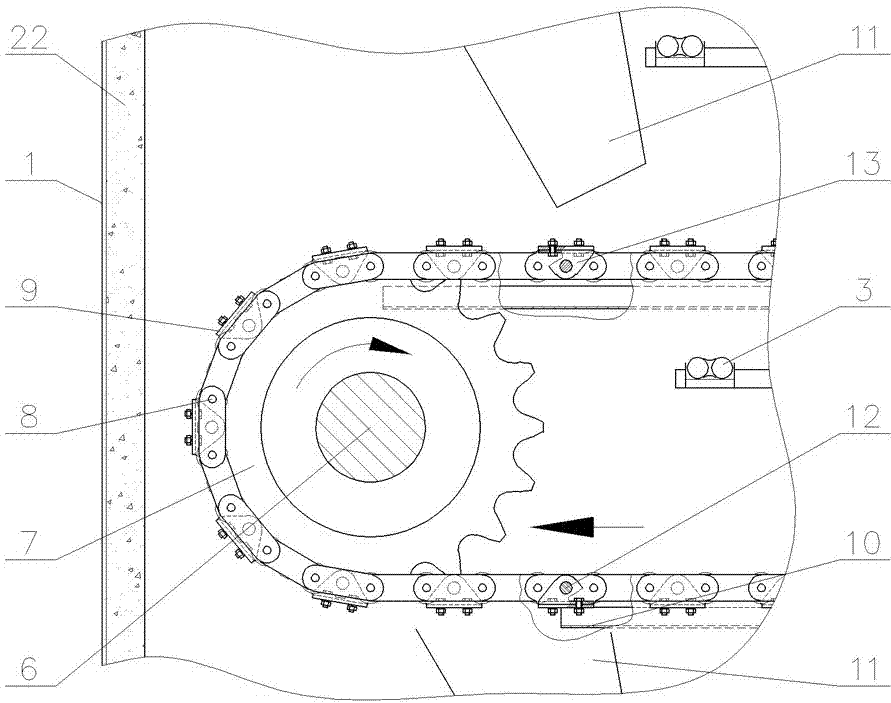

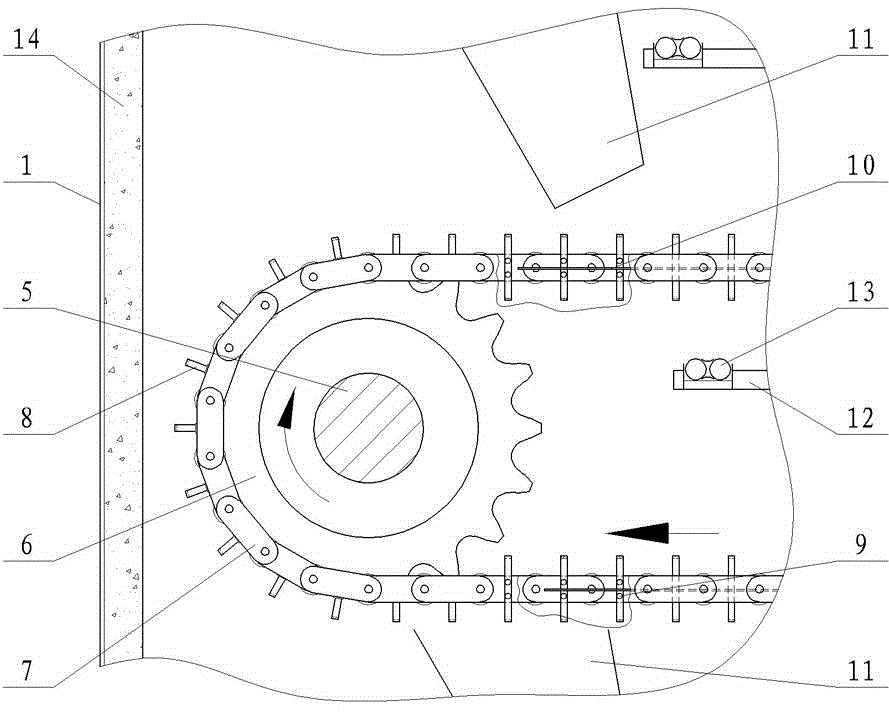

Rotating rod type infrared corncob drier

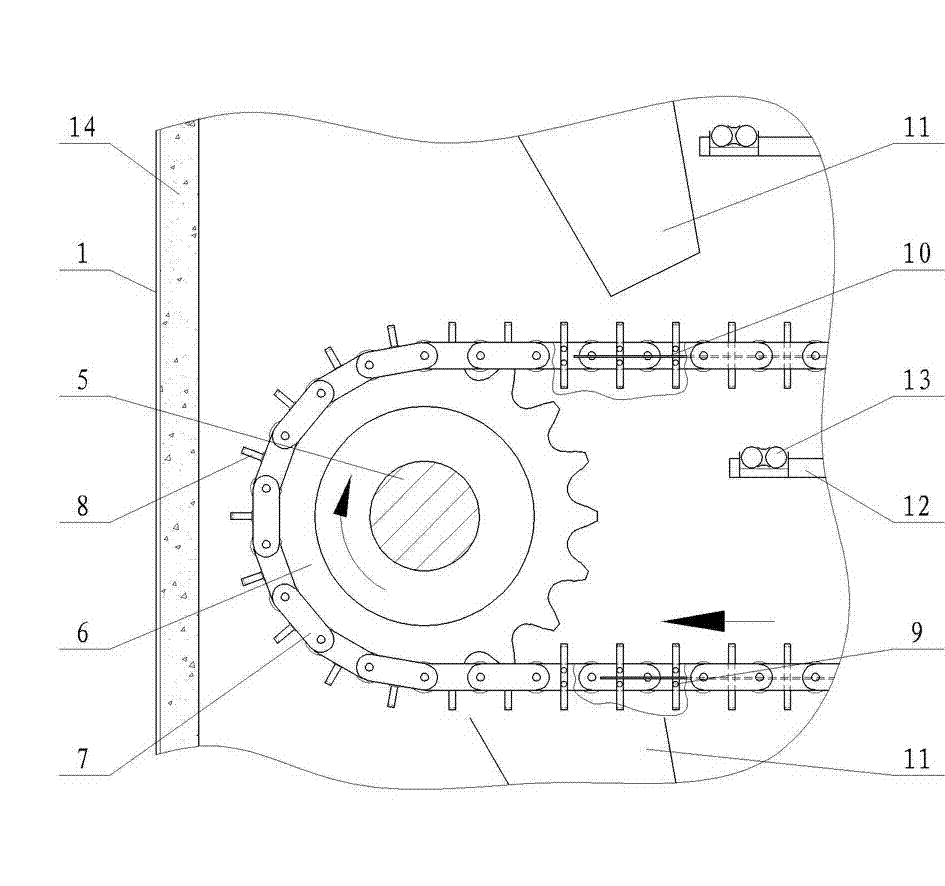

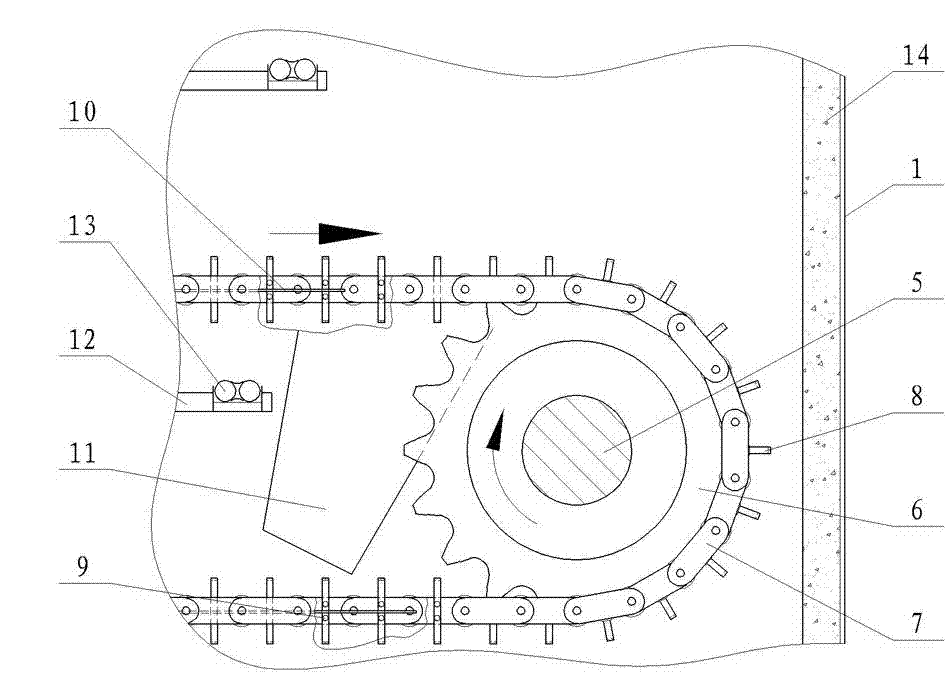

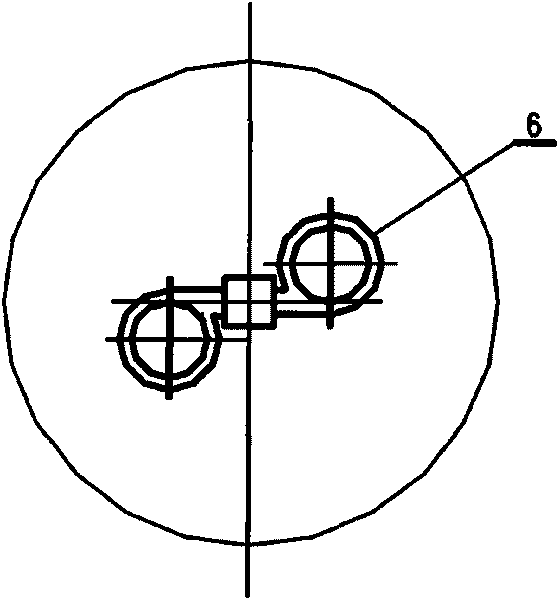

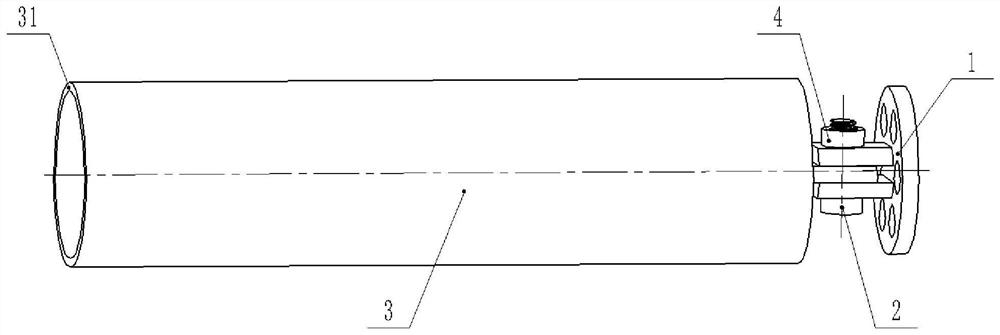

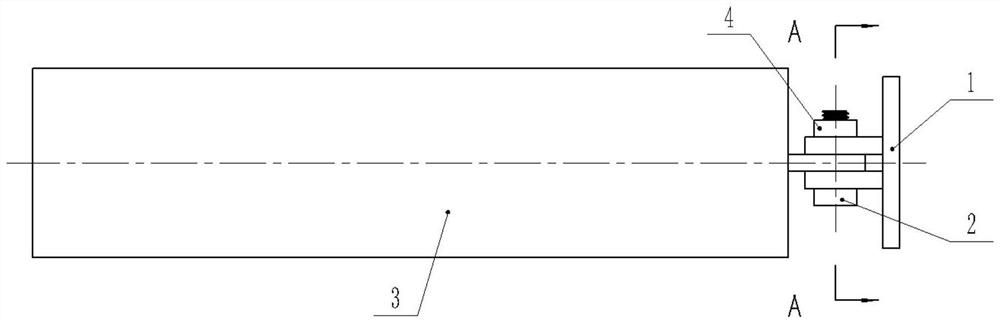

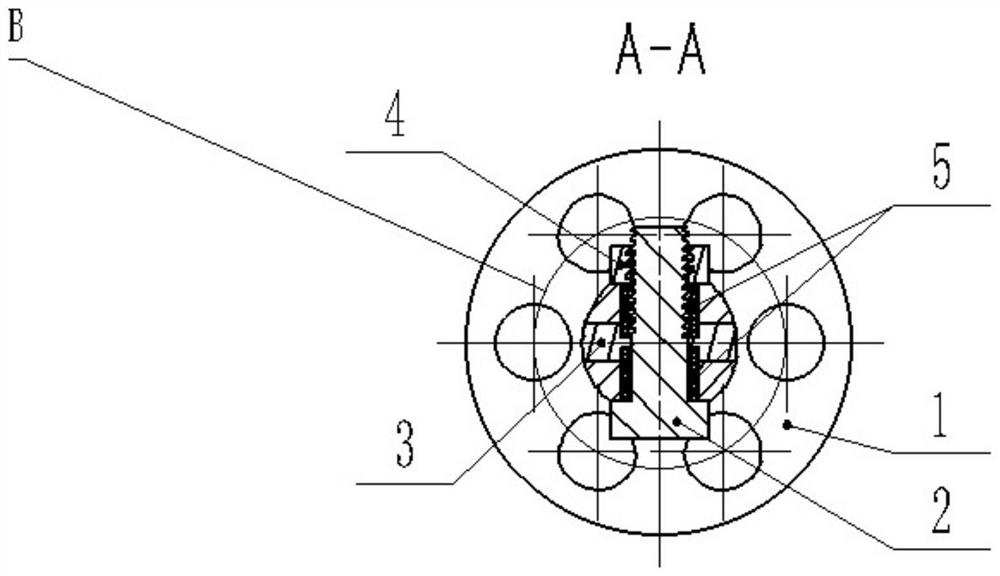

InactiveCN103070458ASolve the problem of high breakage rateImprove heat transfer efficiencyFood processingSeed preservation by dryingInfraredAngular velocity

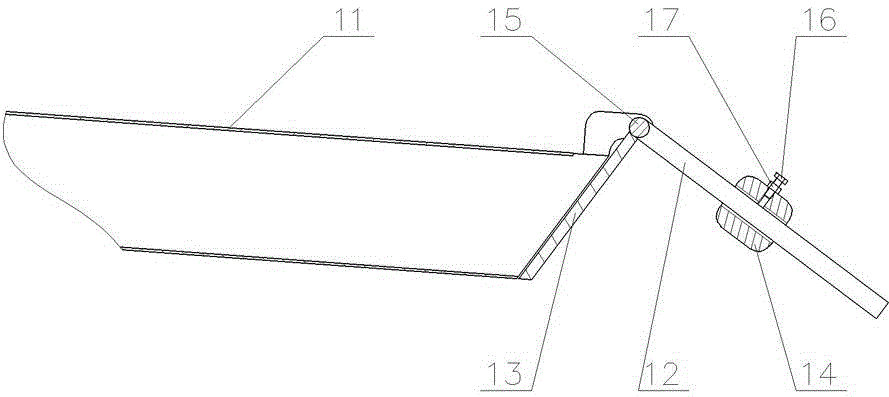

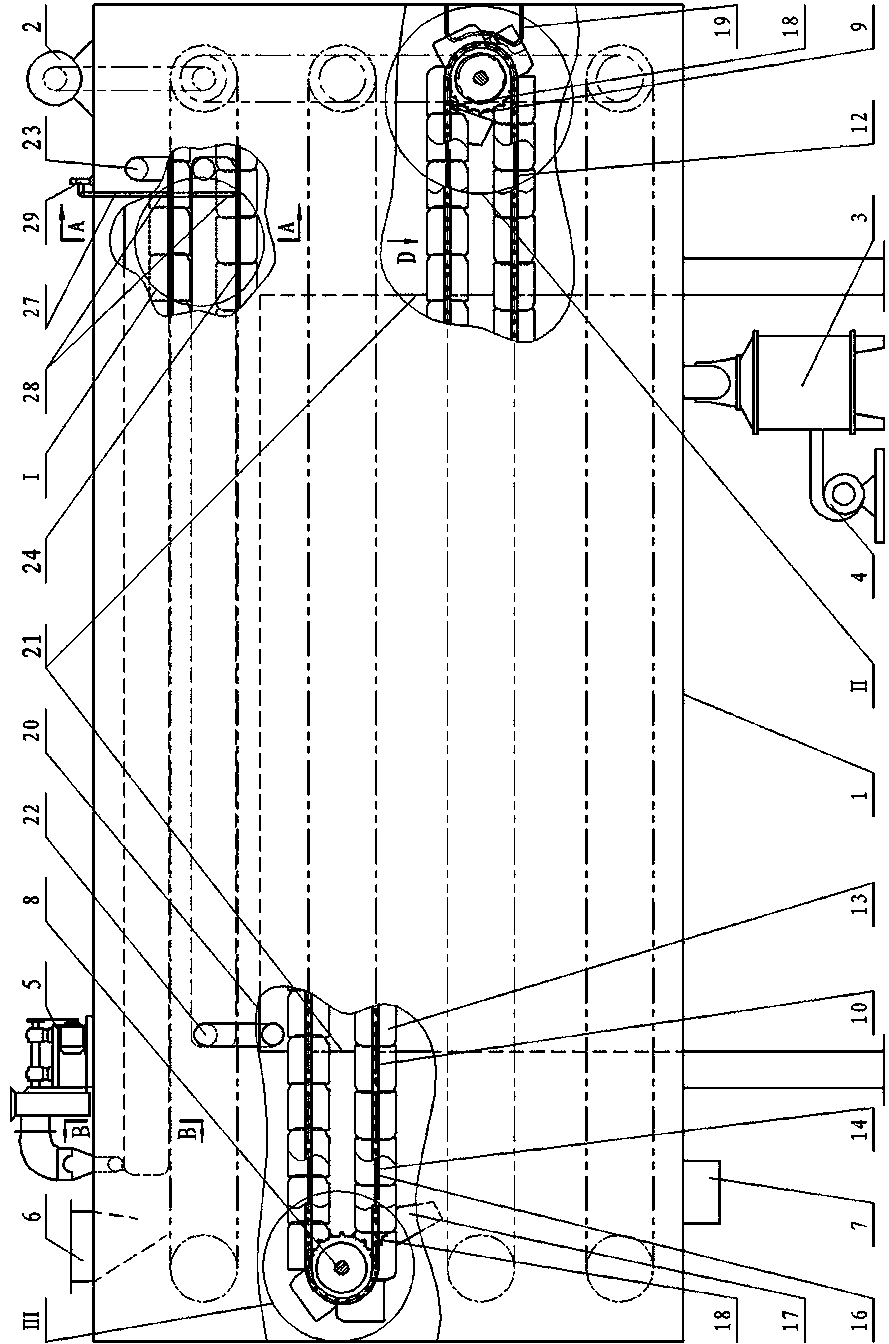

The invention provides a rotating rod type infrared corncob drier. The rotating rod type infrared corncob drier is characterized in that a plurality of conveying devices which are driven by a driving device to convey are arranged in a box body; one end of a bolt is screwed into a screw hole of a chain node on the inner side of a chain; the two ends of a material shifting rod are hollowly sleeved on the middle part of the bolt; a limit ring of which a deep concave hole contain steel balls keeps the steel balls to face the material shifting rod; the steel balls fall into a shallow concave hole of the material shifting rod and are loaded into the middle part of the bolt; each conveying device is respectively provided with material supporting plates corresponding to an upper horizontal section and a lower horizontal section of the chain; a material guide groove is formed below the tail ends of the material supporting plates; a radiating device which downwards radiates infrared ray in one direction is arranged above the material supporting plates; limit rods are arranged at the two ends of each conveying device, so that when the material shifting rod moves to a chain wheel to reverse, on one hand, the material shifting rod co-rotates along the chain wheel, on the other hand, the material shifting rod reversely rotates around the bolt at the speed equal to the co-rotation angular velocity; a material inlet is formed in the top of the box body; and a material outlet is formed in the bottom of the box body. The rotating rod type infrared corncob drier is high in heat transfer efficiency, good in drying uniformity, reasonable in structure, convenient to use and practical.

Owner:SHANDONG UNIV OF TECH

Frozen dumpling modifying agent, preparation method thereof and application

InactiveCN101744021AImprove dough sticking rollerImprove sticking phenomenonDough treatmentPre-baking dough treatmentFreeze thawingEnzyme

The invention belongs to the technical field of frozen dumpling processing by additives, in particular to a frozen dumpling modifying agent, a preparation method thereof and application. The frozen dumpling modifying agent is prepared from the following components in percentage by weight via mixing: 35 to 42 parts of active soybean meal, 25 to 38 parts of konjaku flour, 5 parts of complex enzyme, 8 to 12 parts of carrageenin and 10 to 20 parts of modified starch. The modifying agent can adapt to the process requirements of the mechanized production of the frozen dumplings, improve the quality of finished products of the frozen dumplings, effectively improve the mechanical stirring resistance degree of the flour dough of the frozen dumplings, reduce the roll adhesion phenomenon of cheeks during the mechanized production, can simultaneously improve the boil resistance performance, the smooth performance and the freeze-thaw stability of the frozen dumplings, and improve the external appearance and the mouth feeling of the frozen dumplings.

Owner:河南兴泰科技实业有限公司

Method for fermenting old leaves of Kongfu black tea

InactiveCN102246867APromote redistributionSatisfy reassignmentPre-extraction tea treatmentBlack teasHorticulture

The invention discloses a method for fermenting old leaves of Kongfu black tea, which comprises the steps of: taking middle and small-leaf dark brownish green, i.e. one bud has 3-4 leaves; thinly tedding the dark brownish green in an environment with a temperature of 20-30 DEG C and humidity of 70-90%, wherein 2-3 times of flipping is carried out during the process of tedding; fully filling withered leaves in a rolling bucket, rolling at a revolution speed of 35-45 r / min for 50-60 minutes without pressing, then lightly pressing to 1 / 4-1 / 3 of the rolling bucket, and alternating for 10-20 minutes, wherein the time for whole rolling is 75-100 minutes until 85-95% of the rolled leaves become orange and yellow, and the rope-forming rate is 80-90%; and putting the rolled leaves in a fermenting disc, wherein the thickness of piled leaves is 10-12 cm, the environment has a temperature of 20-30 DEG C and humidity of 90-95%, 3-6 times of flipping is carried out during the process until 90-95% of the rolled leaves become yellowish red, have brightly colored luster, and are fragrant and sweet or fruity. The method for fermenting the old leaves of the Kongfu black tea lowers breaking and crushing rate and improves completeness of bud leaves, and the even fermentation is guaranteed.

Owner:GUIYANG CHUNQIU INDAL

Infrared corncob drying machine of limiting sleeve

InactiveCN103081993ASolve the problem of high breakage rateReduce hindranceFood processingSeed preservation by dryingInfraredSide chain

The invention provides an infrared corncob drying machine of a limiting sleeve. The infrared corncob drying machine is characterized in that a box body is internally provided with a plurality of conveying devices driven by a transmission device to run; one end of a stud is screwed into a screw hole of an inner side chain section of a chain; the two ends of material pulling rods are hollowly sleeved in the middle of the stud; a limiting sleeve provided with a spring and steel balls in a blind hole is fixed in the middle of the stud so that the two steel balls fall into spherical concave pits of the material pulling rods; parts of each conveying device, which correspond to upper and lower sections of a horizontal section of a chain, are respectively provided with material conveying grooves; material guide grooves are arranged below the material conveying grooves; radiation devices which downwards radiate infrared rays in a single direction are arranged above the material conveying grooves; circular-arc-shaped limiting rods I and II are respectively arranged at the two ends of each conveying device so that when each material pulling rod is operated to the chain to change the direction, on one hand, the material pulling rods rotate along chain wheels, and on the other hand, the material pulling rods do reversed autorotation with the same co-rotation angle speed around the stud; and a feeding opening is arranged on the top of the box body, and a discharging opening is formed at the bottom of the box body. The infrared corncob drying machine disclosed by the invention has the advantages of high heat transferring efficiency, low energy consumption, accurate position and reliable work.

Owner:SHANDONG UNIV OF TECH

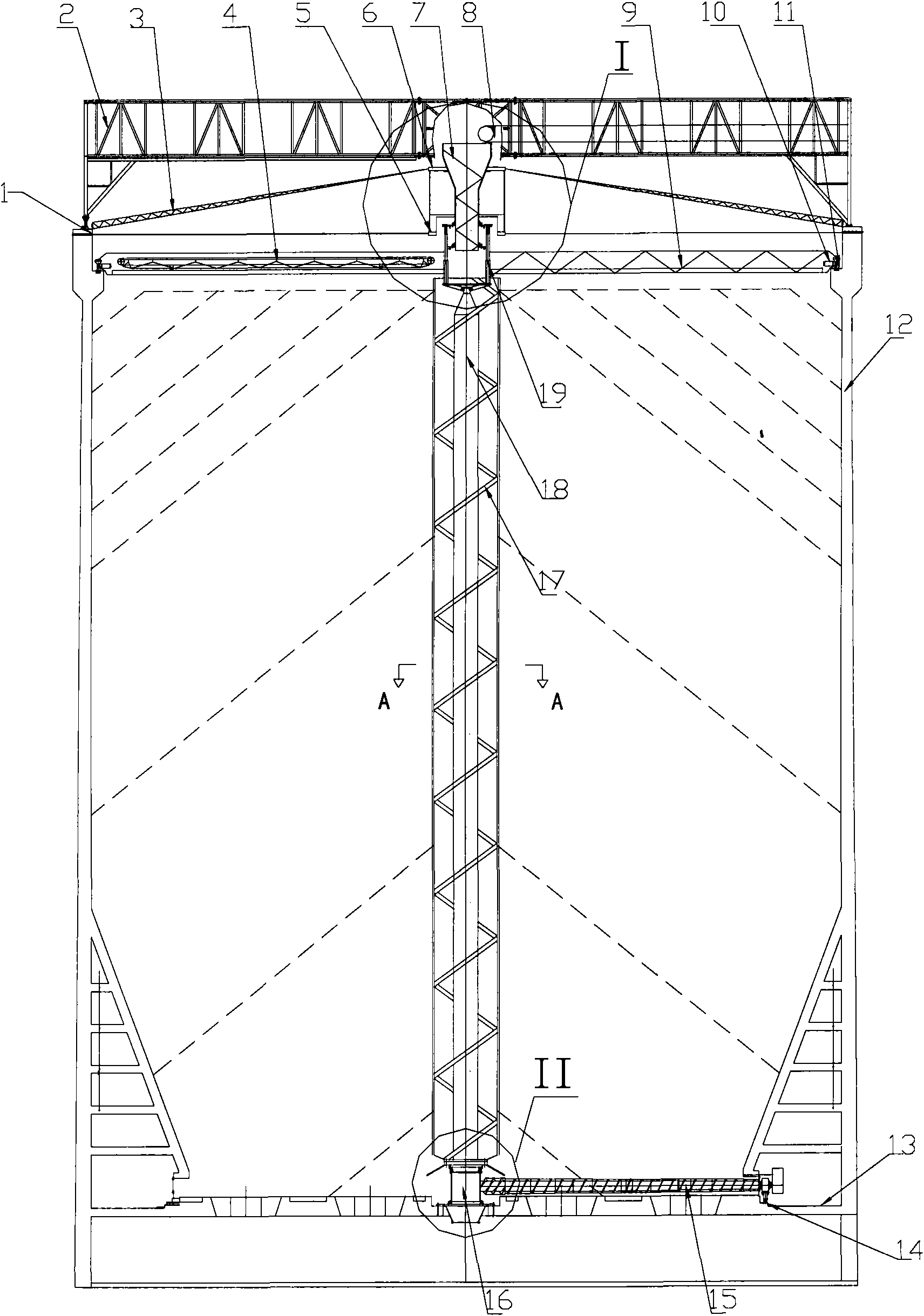

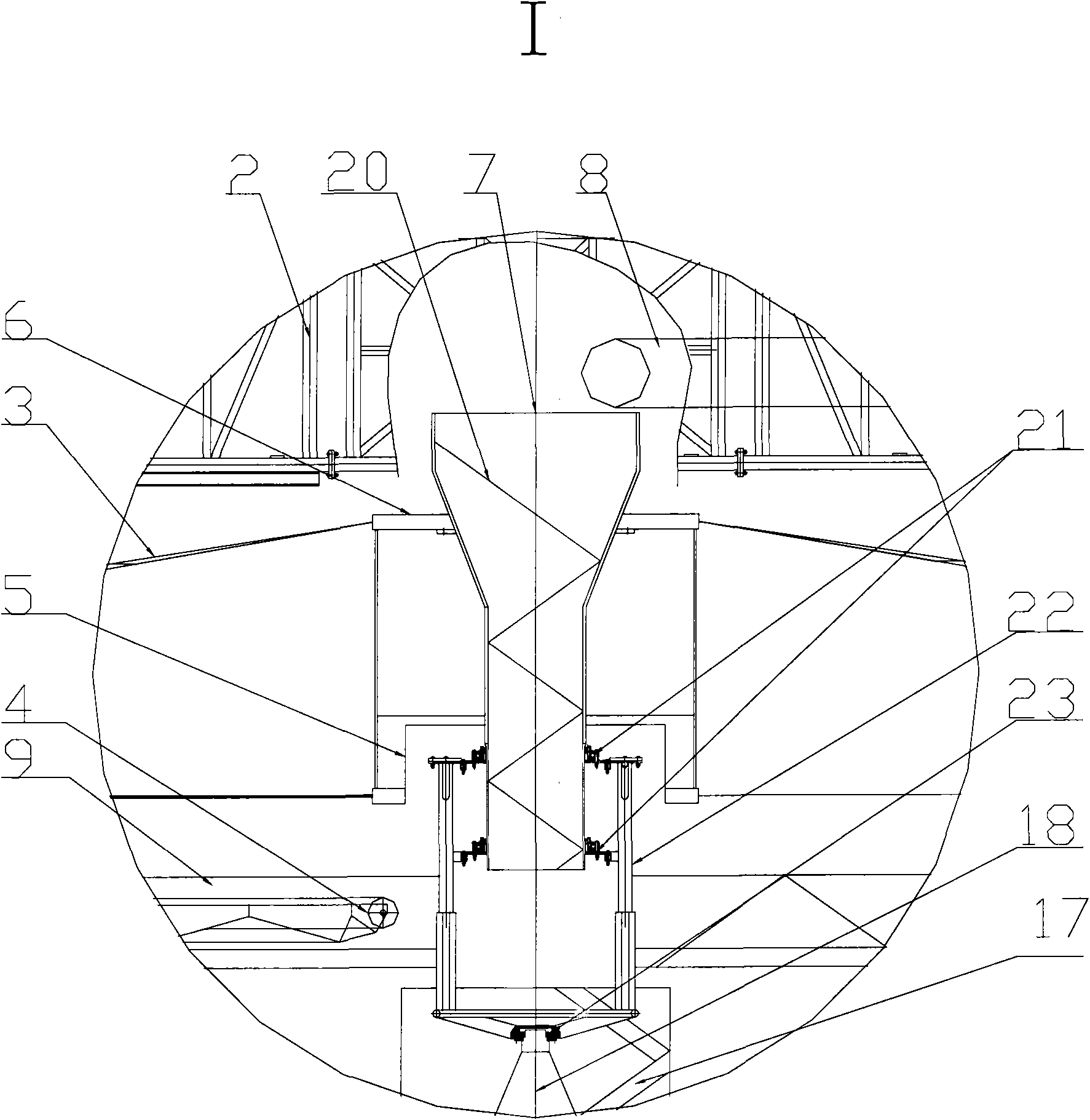

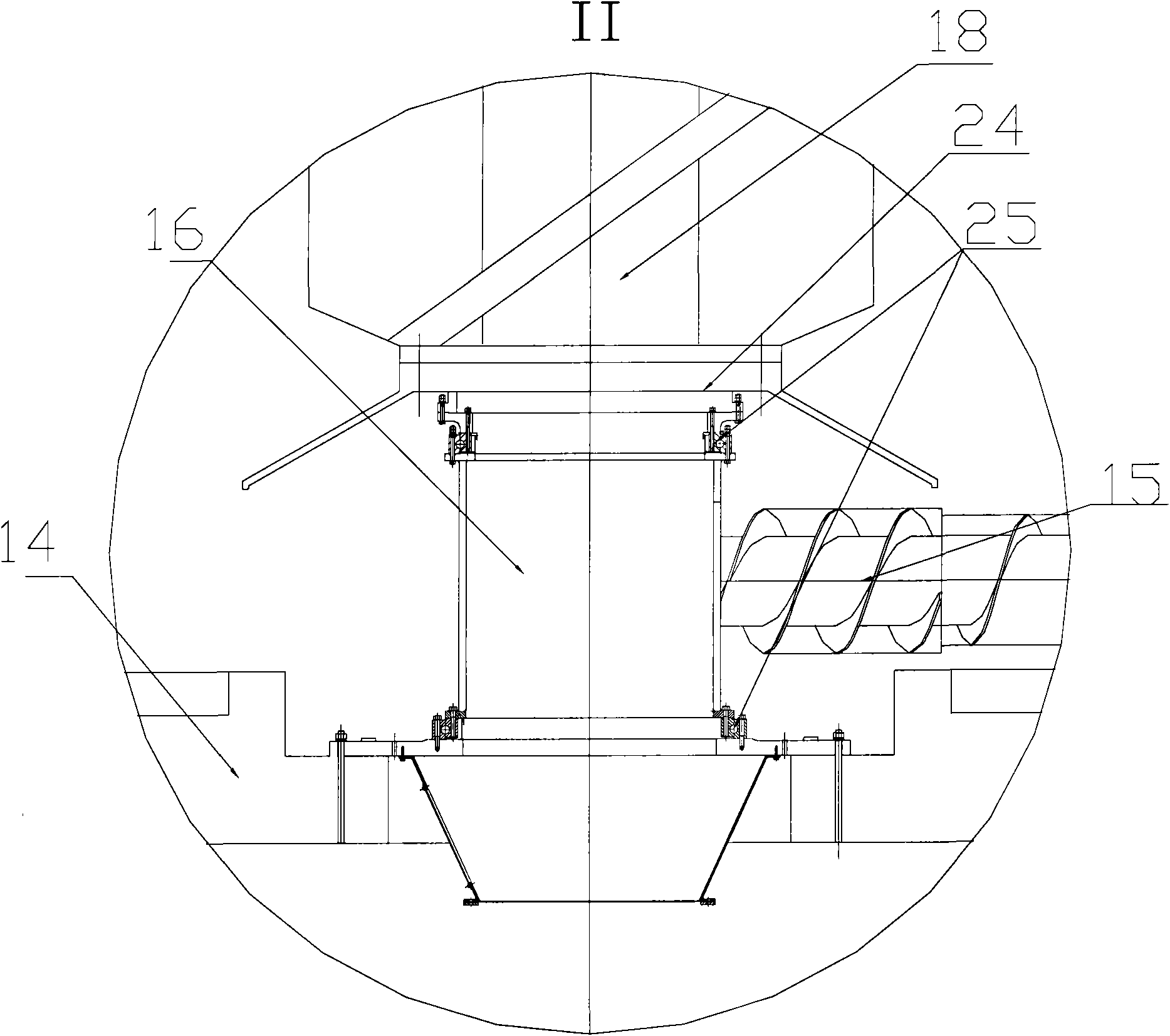

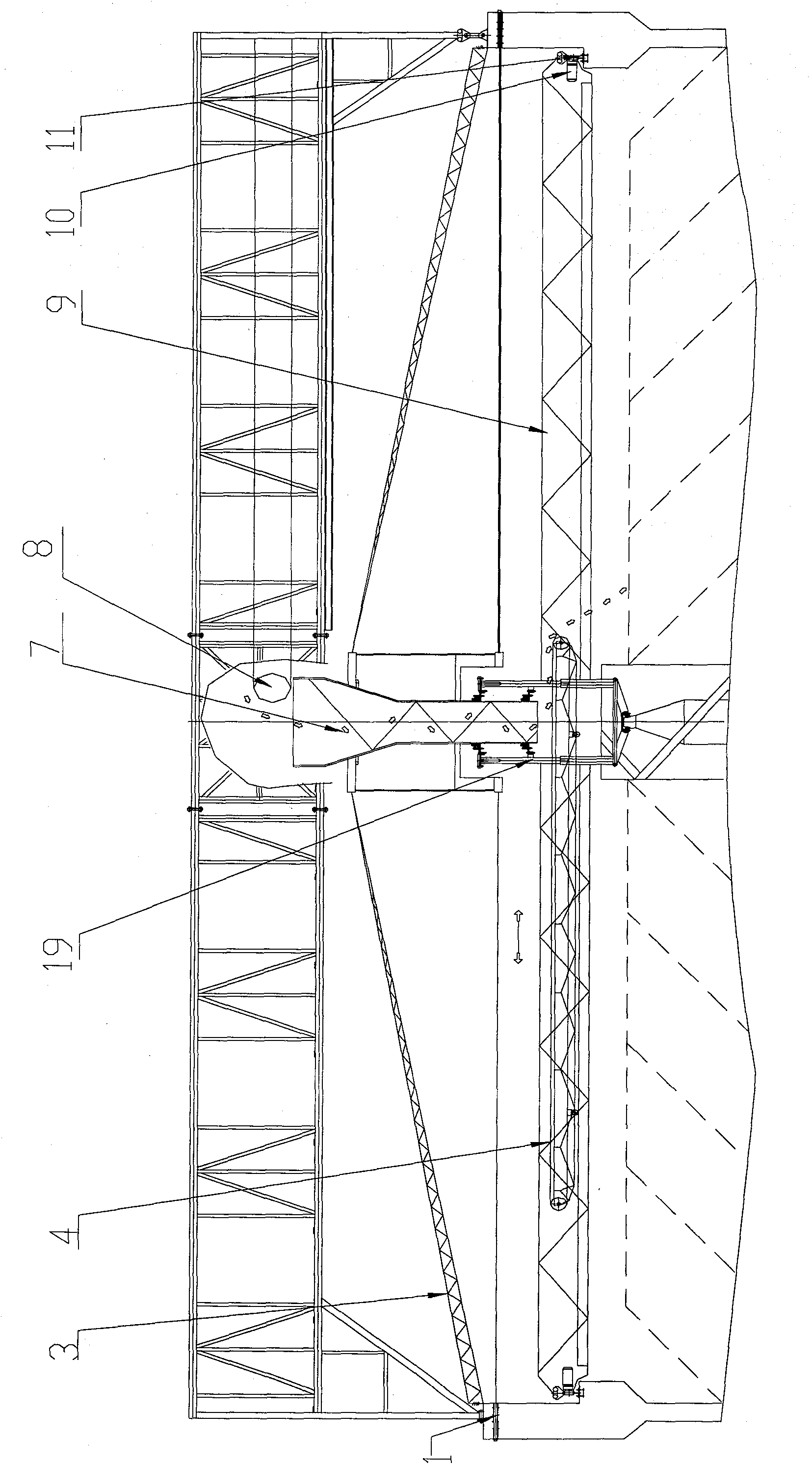

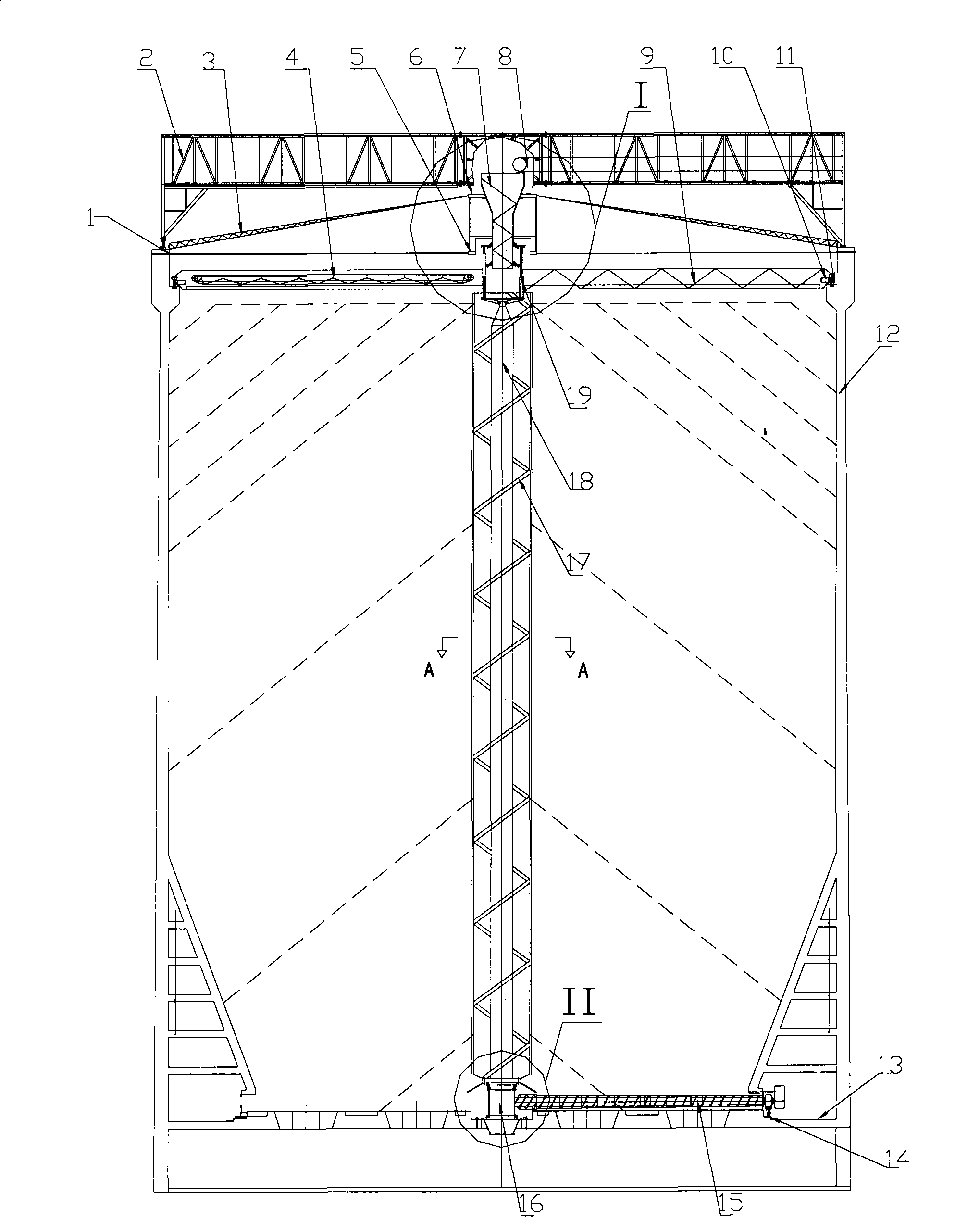

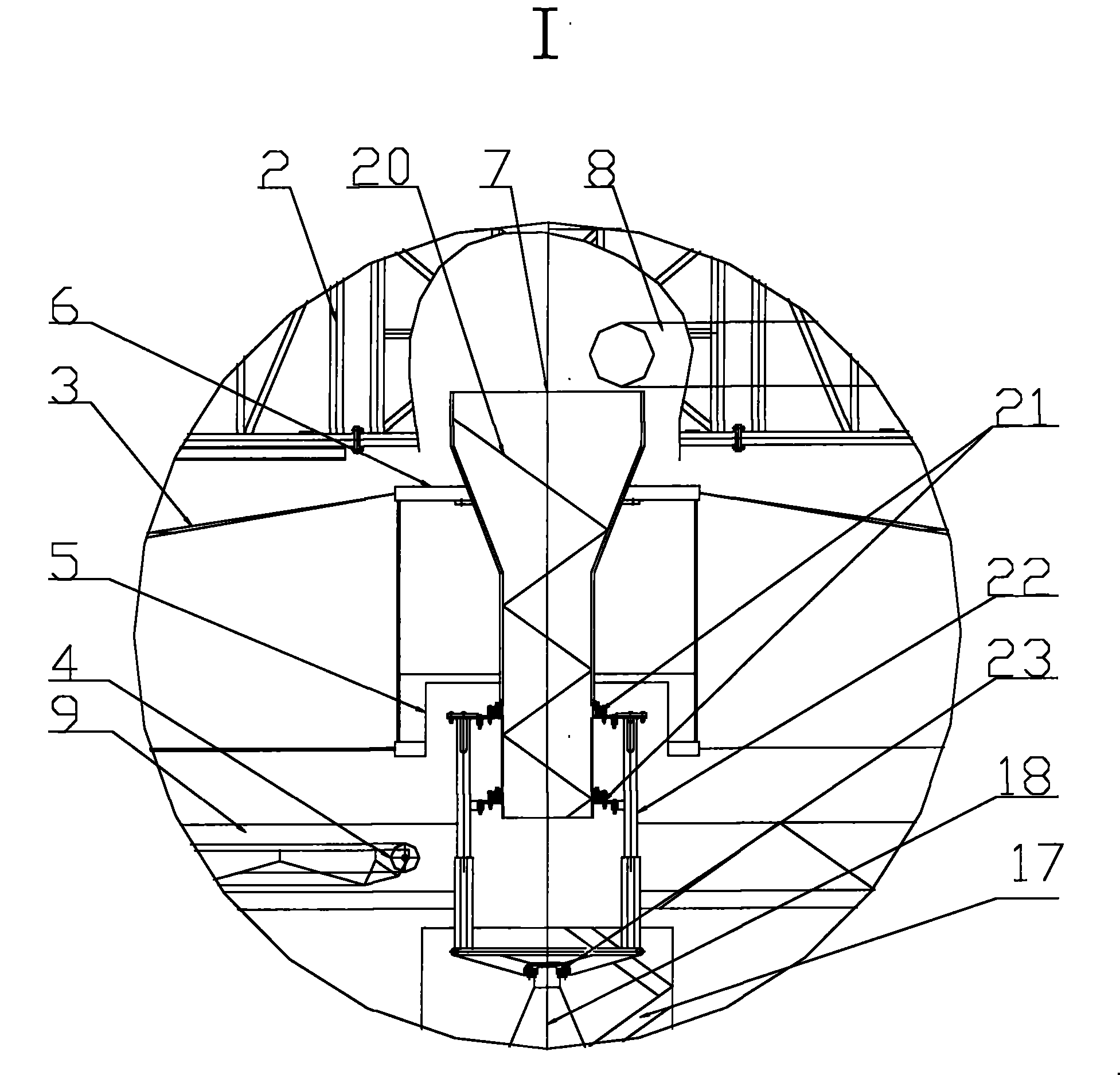

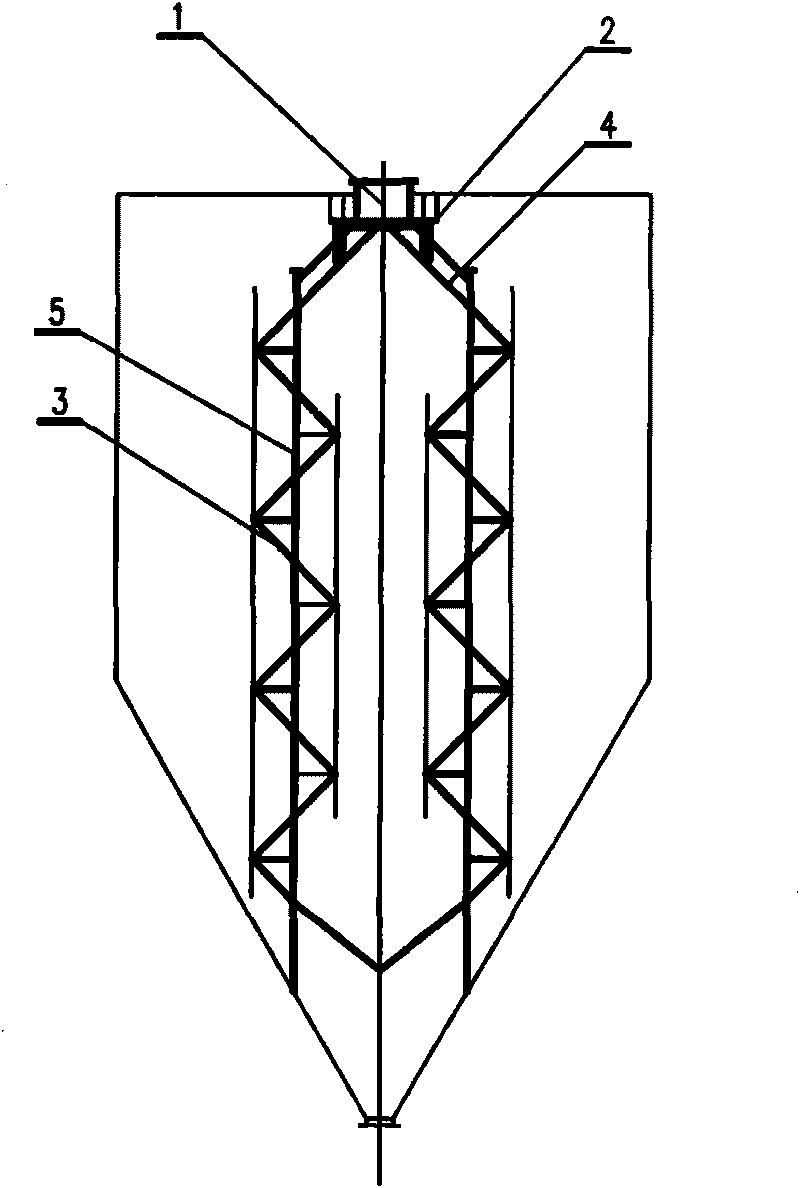

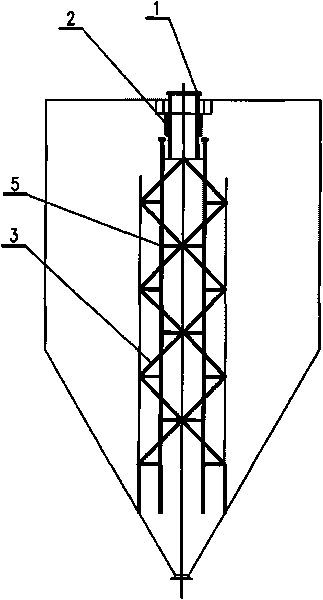

Buffer breakage-proof flat bottom silo

InactiveCN101613022AFlexible adjustmentAvoid deformationLarge containersLoading/unloadingFree fallingEngineering

The invention relates to a buffer breakage-proof flat bottom silo, wherein, a central blanking barrel and a central column which are connected through a rigid mechanism are fixed in the center of the silo; an internal screw downspouting is arranged in the central blanking barrel and the central column is coiled with one or a plurality of screw downspoutings. In the buffer breakage-proof flat bottom silo in the invention, materials firstly pass through the internal screw downspouting, then pass through an external screw downspouting, and freely fall to the bottom part of the flat bottom silo by ensuring the minimum fall in a slipping manner, thus forming a pointed piling form with high center and low center peripheral part. When the materials account for 60% of the silo body space, a mobile distributing device is started to locate randomly, and a rotary distributing bridge does rotary movement along an annular orbit; blocky materials slip from the inner part of the silo center to the periphery of the center along the pointed piling gradient of raw materials and complete the distribution of the remaining 40% of the peripheral space of the silo. The invention effectively controls the fall of material free fall, increases blanking friction force, mitigates the impact of materials and reduces flow rate, thus being in particular applicable to the storage of blocky materials.

Owner:朱耀平

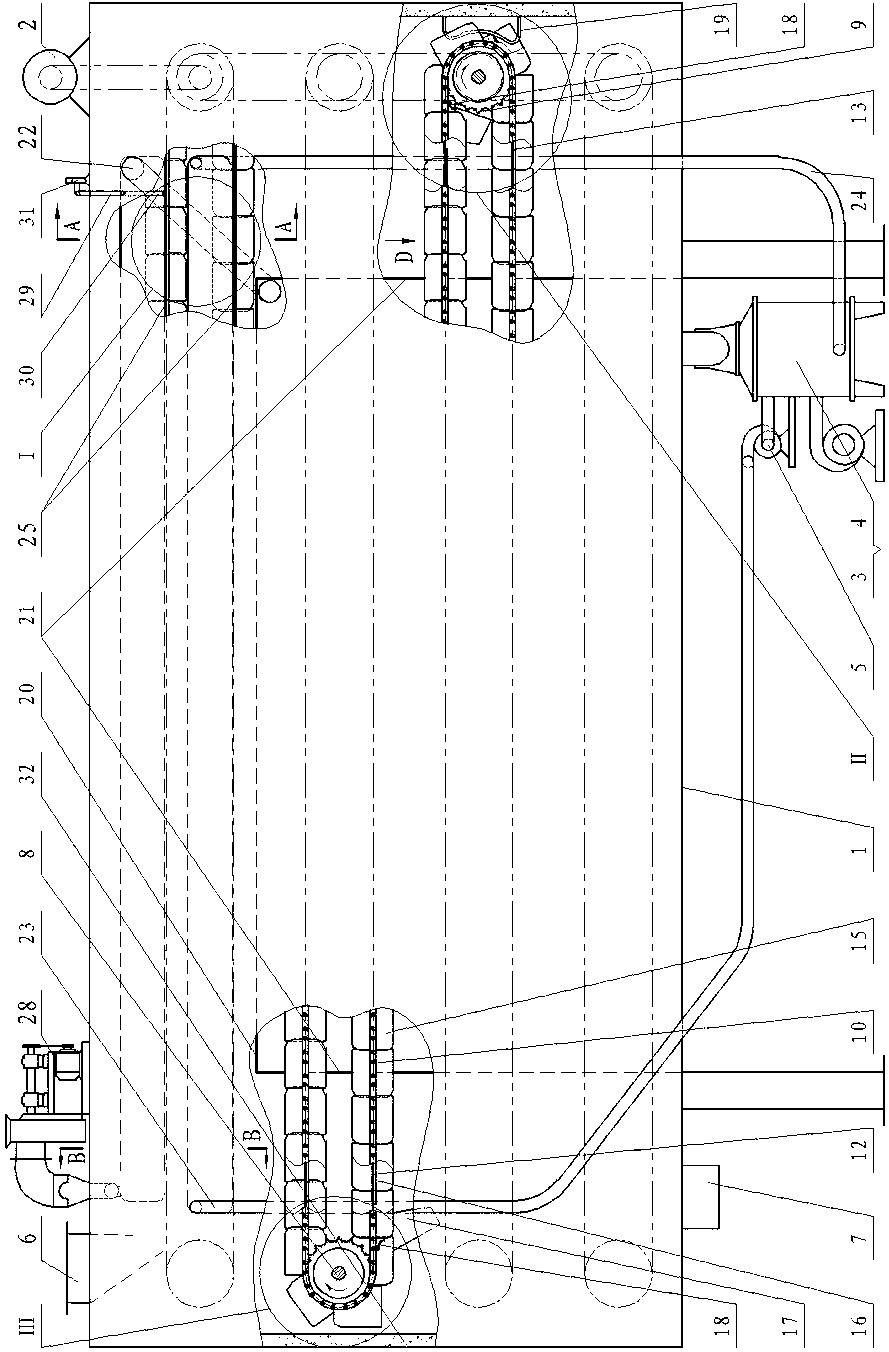

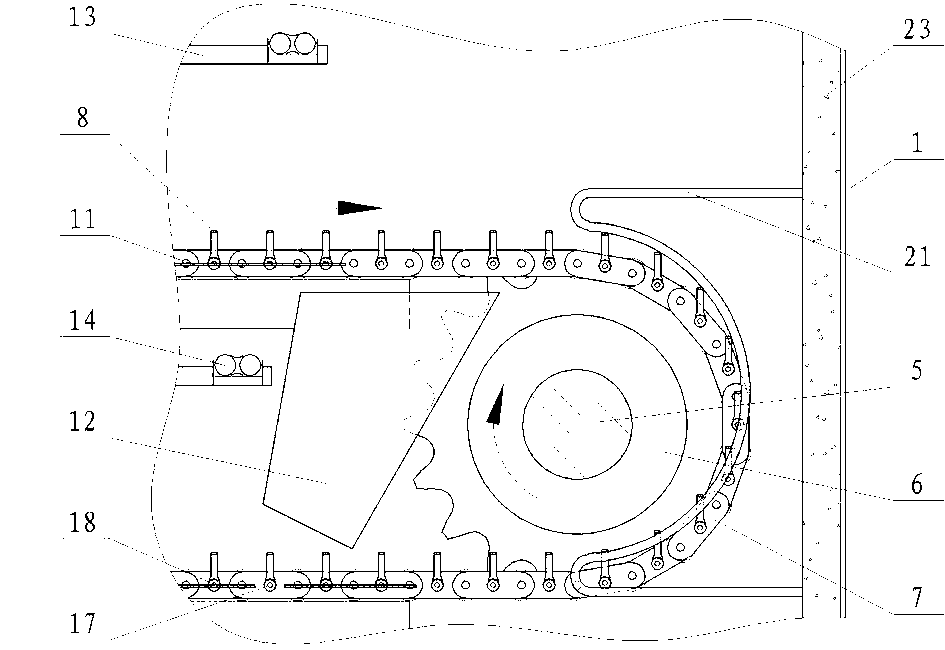

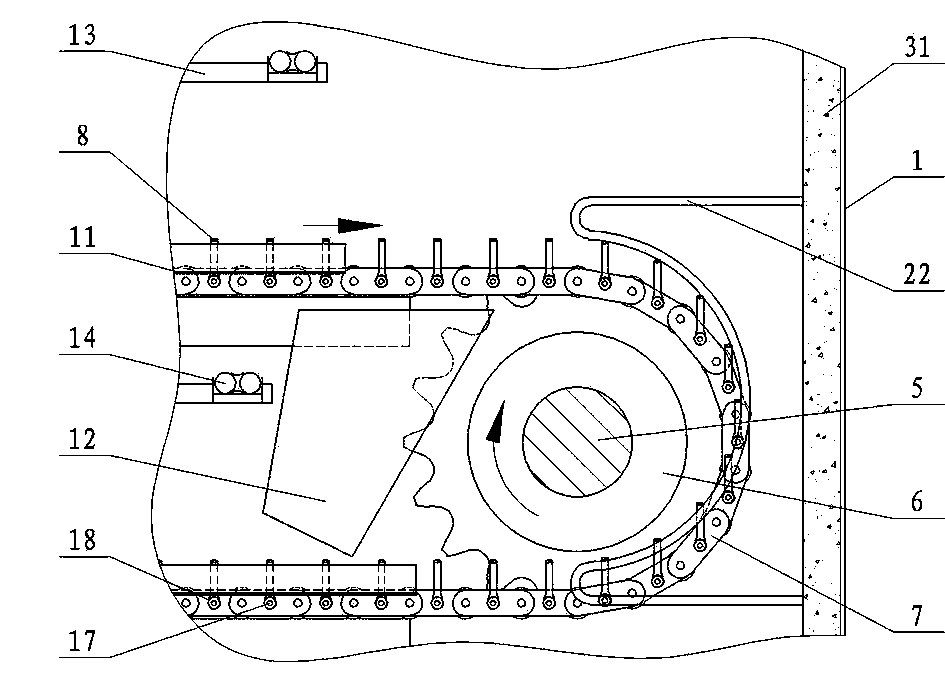

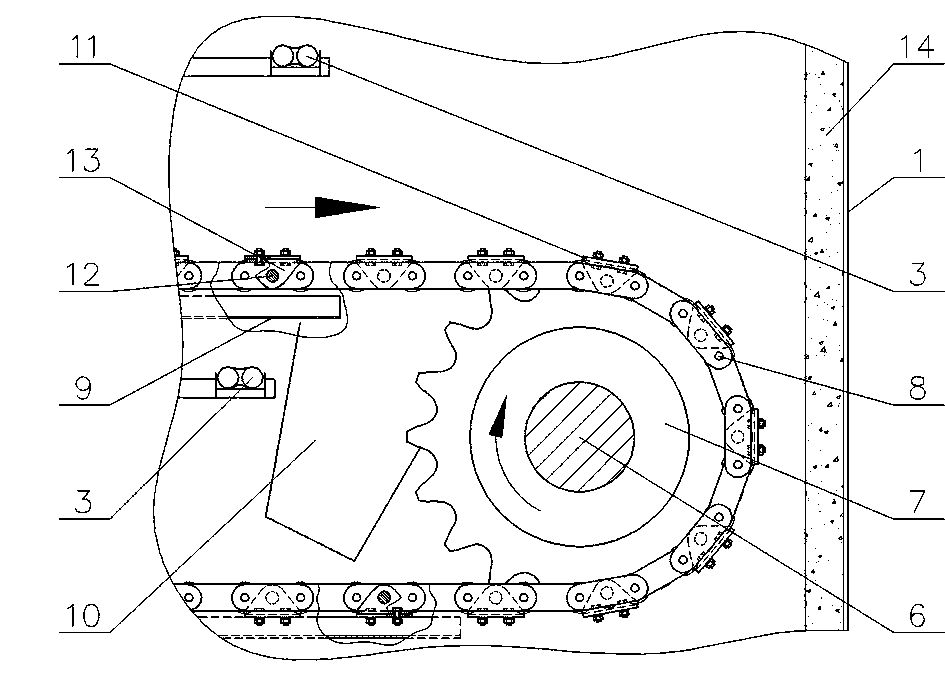

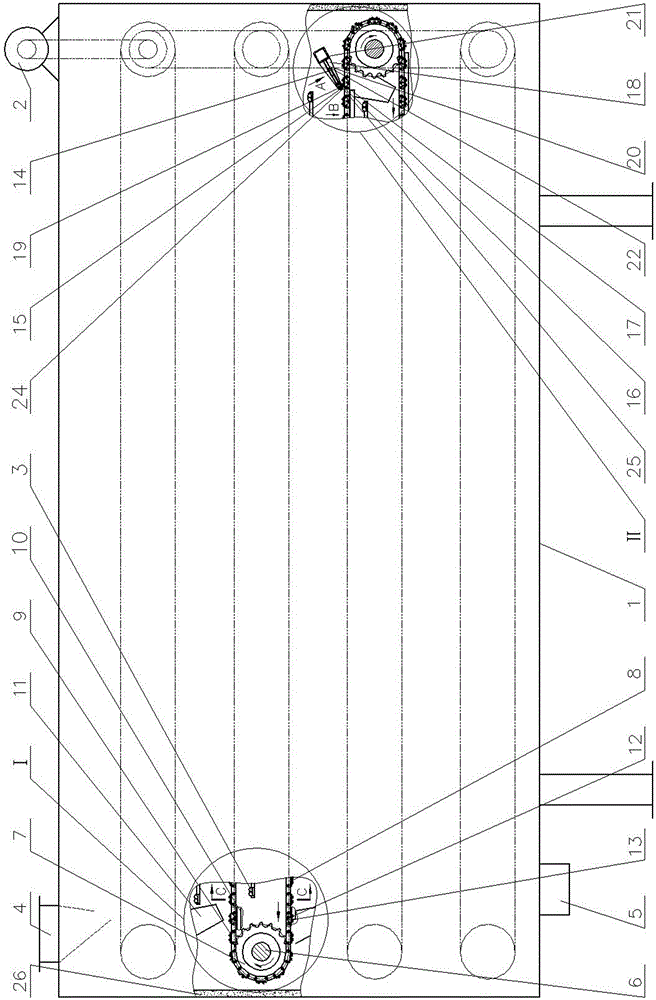

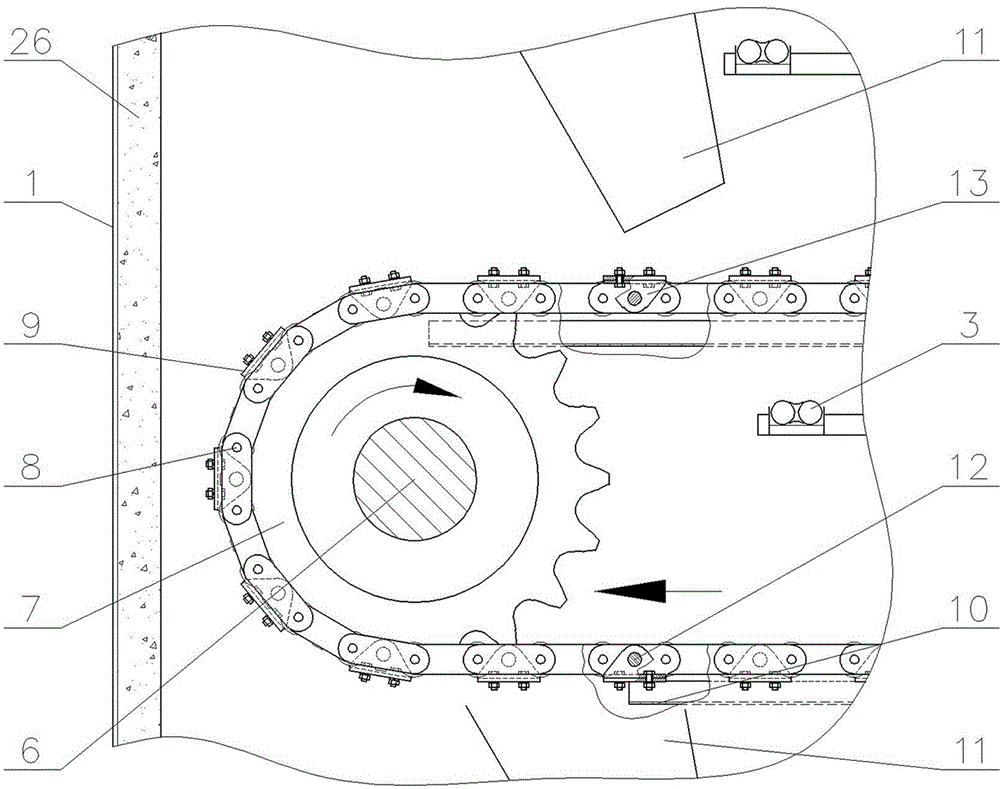

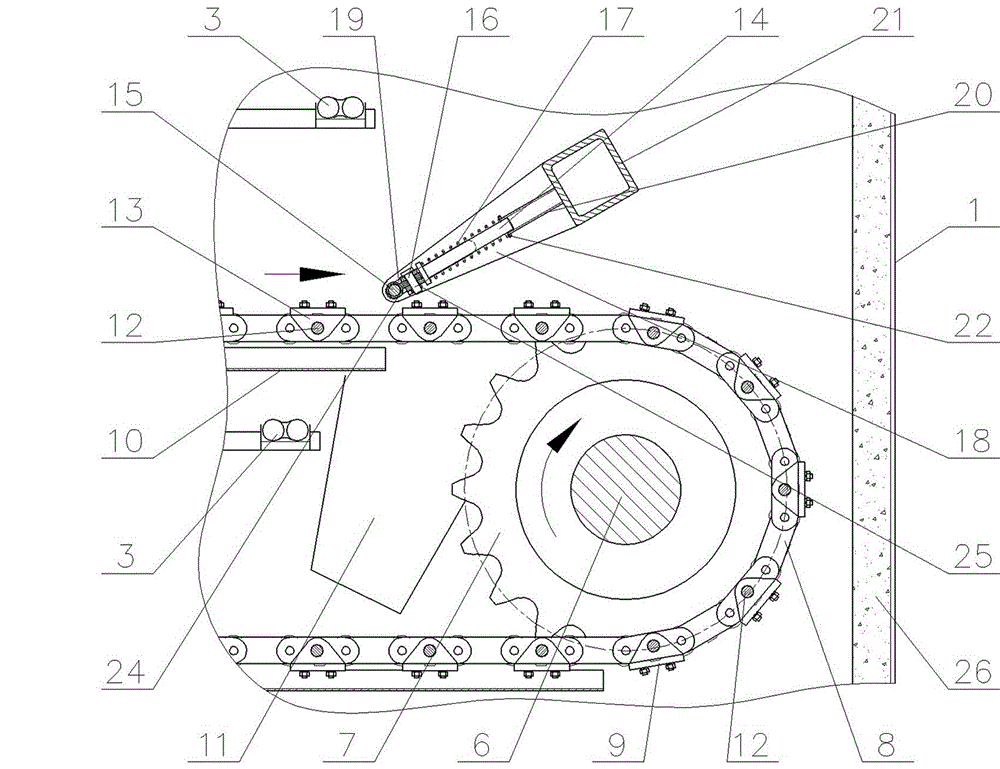

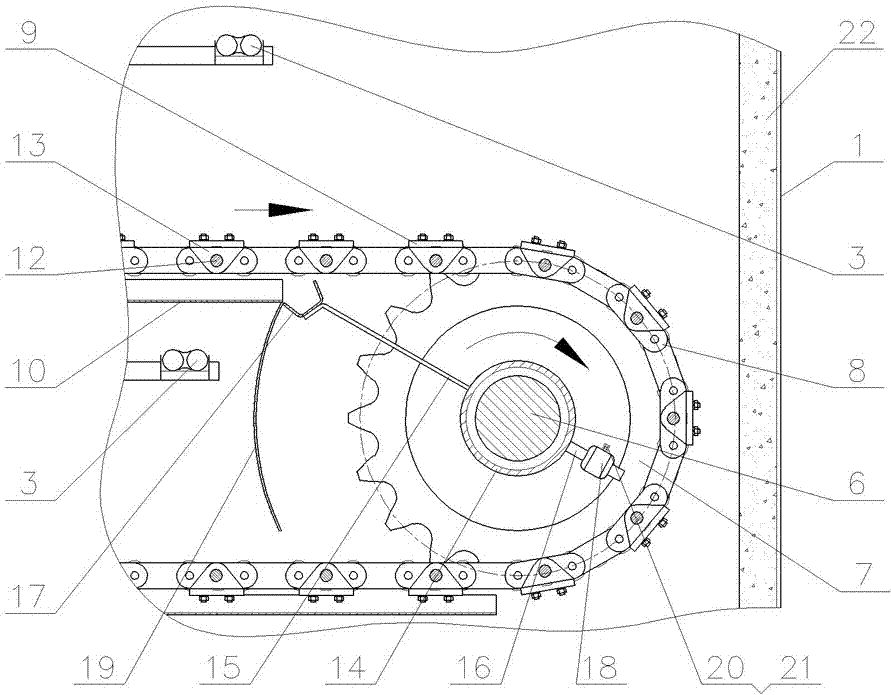

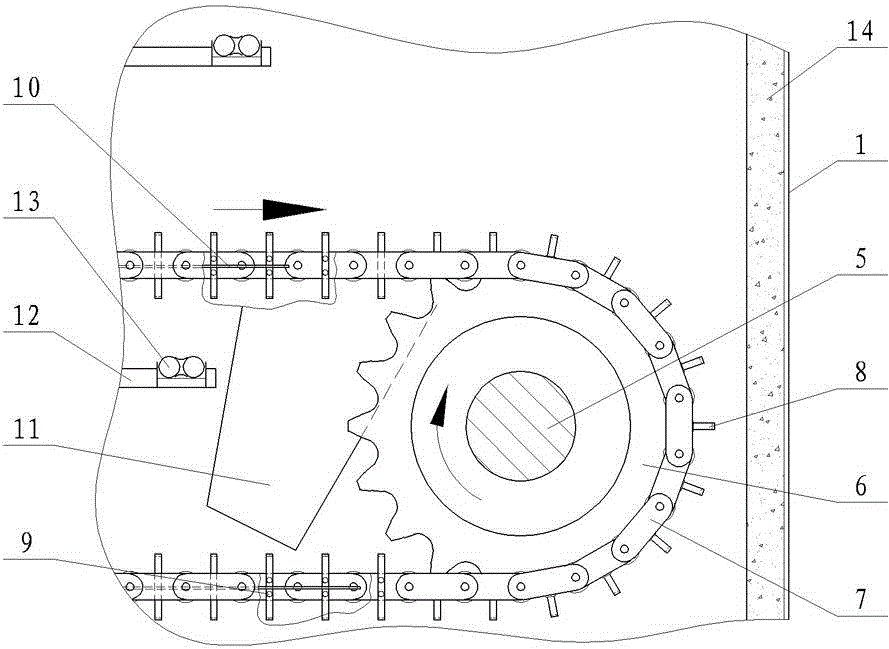

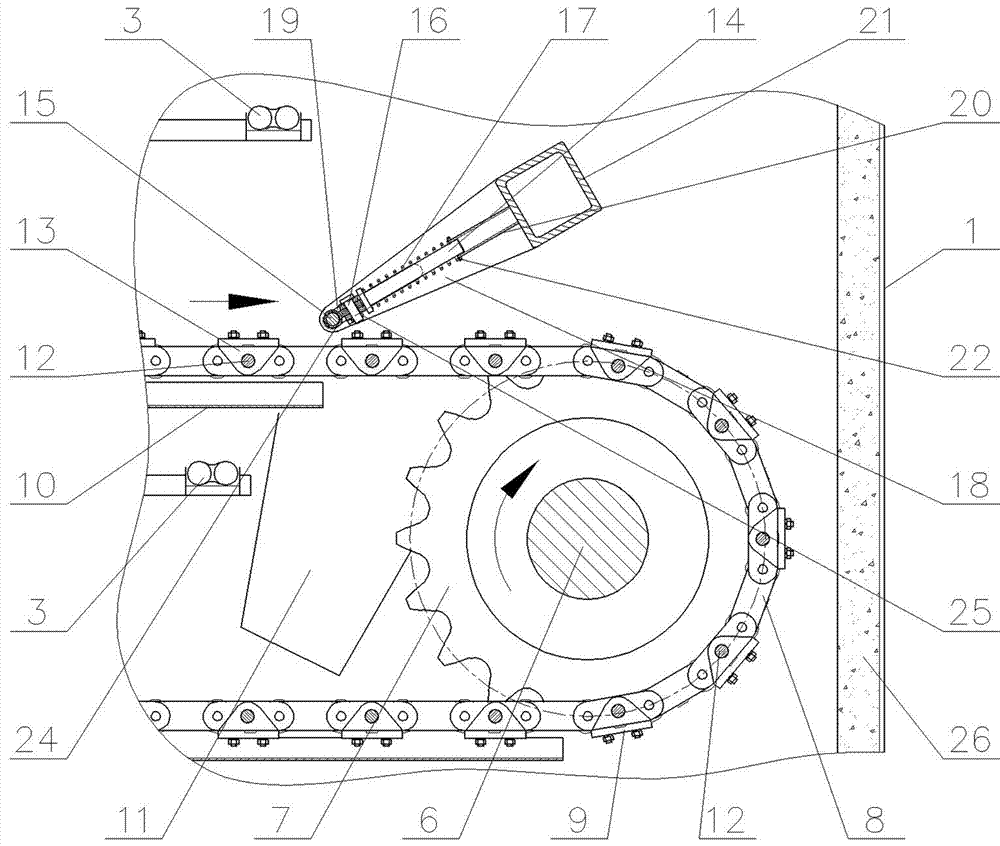

Infrared corn cob drying machine with shifting mechanisms

InactiveCN103843884ASolve the problem of high breakage rateSolve the rotation problemDrying solid materials with heatFood processingHeat transfer efficiencySteel ball

The invention provides an infrared corn cob drying machine with shifting mechanisms, which is characterized in that a box is internally provided with a plurality of conveying devices driven to run by a drive device I, one end of a stud is screwed into a screw hole in a chain link on the inner side of a chain, two ends of a shifting lever are idly arranged in the middle of the stud in a sleeving manner, a blind hole is internally provided with a spring and a steel ball stop collar which are fixed in the middle of the stud, two steel balls fall into a spherical pit of the shifting lever, each conveying device is provided with chute feeders respectively corresponding to an upper horizontal section and a lower horizontal section of the chain, a guide chute is arranged below the tail end of the chute feeder, a radiation appliance is arranged above the chute feeder, two ends of each conveying device are respectively provided with a limiting rod I and a limiting rod II, and a shifting mechanism is arranged at each chain wheel below a feed opening, so as to force each shifting lever to do reverse autorotation with speed equal to that of a corotation angle around the stud while corotating along with the chain wheel when travelling to the chain wheel for reversing; the feed opening is formed in the top of the box, and a discharge opening is formed in the bottom of the box. The infrared corn cob drying machine is high in heat transfer efficiency, low in energy consumption, reasonable in structure and reliable to work.

Owner:SHANDONG UNIV OF TECH

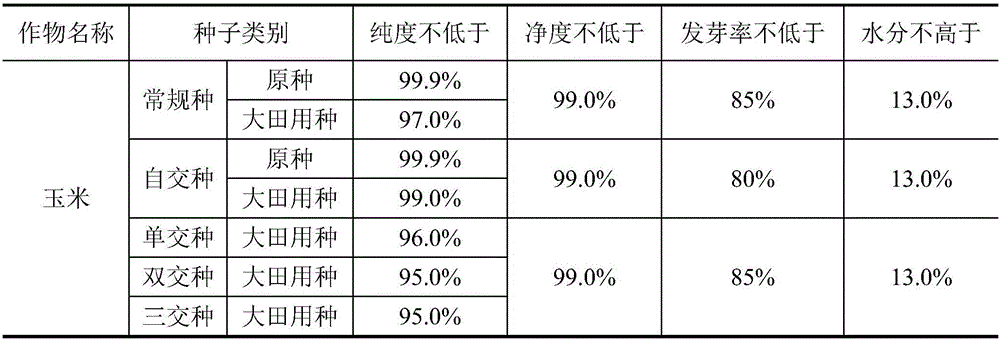

Processing method of high-quality corn seed

InactiveCN105830579ARaise the level of developmentEnsure food securityDrying solid materials with heatThreshersNatural disasterAgriculture

The fine-quality corn seed processing method of the present invention relates to a method for treating seeds before sowing, in particular to a processing method for corn seeds. The purpose is to provide a high-quality corn seed processing method with simple operation, high efficiency and low seed breakage rate. The fine-quality corn seed processing method of the present invention comprises: ear selection, ear drying, threshing, cleaning and grading, coating and packaging. The fine-quality corn seed processing method of the present invention solves the problems of weak resistance to natural disasters and susceptibility to freezing damage of corn seeds, reduces the broken rate of seeds, and reduces environmental pollution during processing. The invention is used in the field of agricultural planting.

Owner:RES INST OF GANSU DUNHUANG SEED CO LTD

Technology for preparing high efficiency biomass fuel which is formed after charred

InactiveCN103509621ASolve the complete process technologyAchieve self-sufficiencyBiofuelsSolid fuelsCombustionCarbonization

The invention relates to a technology for preparing a high efficiency biomass fuel which is formed after charred, and relates to biomass carbonization and formation, and energy fields. The preparation technology comprises: 1. crushing and charring the biomass firstly; 2. after coarsely crushing the biomass waste by a shredder and finely crushing the biomass waste by a three-rotor hammer planer, removing ferruginous metals, and then removing heavy pollutants such as sand and stones which do not accord with production of the biomass fuel by pneumatic separation; 3. charring the materials satisfying specification in a charring device; 4. burning volatile gases and the biomass waste generated in the charring process in a combustion furnace, sending a high temperature gas into the charring device by a blower fan so as to provide heat demand for drying and material carbonization in the production process; 5. finely crushing or grinding the biomass again after charred, and then cooling; and 6. sending the charred finely particles into a granulator for granulation and formation. The technology implements continuous automation production of biomass formation, fuel carbonization and granulation formation.

Owner:北京泛欧瑞得科技有限公司

Spiral slideway infrared corncob drying machine

InactiveCN104472679AReduce energy consumptionImprove the quality of infrared dryingFood processingSeed preservation by dryingEngineeringScrew thread

The invention provides a spiral slideway infrared corncob drying machine which is characterized in that: the box wall internal surface is provided with a spiral slideway with concave and convex patterns, a mesh protection cover is arranged above the upper surface of a spiral slideway and along the spiral slideway, a radiation device with adjustable height is arranged at a position above the mesh protection cover near the lower surface o the spiral slideway and along the spiral slideway, the top of the box body is provided with a feed inlet located at the start end of the spiral slideway, the bottom of the box body is provided with a material outlet located at the terminalend of the spiral slideway, the material outlet is provided with a speed control device, both ends of a pin shaft I which is at the middle part of the speed control device and is fixedly connected with the a baffle are supported on two side walls, the center of the length direction of the pin shaft I is provided with an adjusting rod stretching out along the direction vertical to the axis of the pin shaft I, an adjusting block provided with a light hole sleeves the adjusting rod by the light hole, and an extension-in end of a screw with a nut is then screwed in a threaded hole orthogonal to the axis of the light hole. The spiral slideway infrared corncob drying machine has the advantages of high drying efficiency, low energy consumption, simple structure and reliable work.

Owner:SHANDONG UNIV OF TECH

Turnover-falling infrared corncob drying machine

InactiveCN104686649AImprove heat transfer efficiencyStrong penetrating powerSeed preservation by dryingEngineeringMechanical engineering

The invention provides a turnover-falling infrared corncob drying machine. The turnover-falling infrared corncob drying machine is characterized in that a plurality of conveying devices driven by a transmission to run are arranged in a box, a plurality of setting rods are fixed on bent plates, correspondingly extending inwards, of two chains of the same conveying device by use of two joints at the end portions, carrying grooves are formed under the horizontal sections of the upper and lower sections of each conveying device corresponding to the chains, respectively, a falling device is arranged under the tail end of the carrying groove of the upper section, a supporting rod and an adjusting rod are fixed on the two sides of the outer circle of a supporting sleeve sleeving a shaft, respectively, a bearing groove located at the tail end of the carrying groove in a non-working state is fixed at the outer end of the supporting rod, the lower end of a baffle plate of which the circular arc center is located in the axis of the supporting sleeve is located under the tail end of the carrying groove, an adjusting block is locked to the adjusting rod by use of a screw and a nut, a guide groove is formed under the tail end of the carrying groove of the lower section, a radiation device is arranged above the carrying groove, and a feeding hole is formed in the top of the box, while a discharge hole is formed in the bottom of the box. The turnover-falling infrared corncob drying machine is high in drying efficiency, good in drying uniformity, simple in structure, and reliable in working.

Owner:SHANDONG UNIV OF TECH

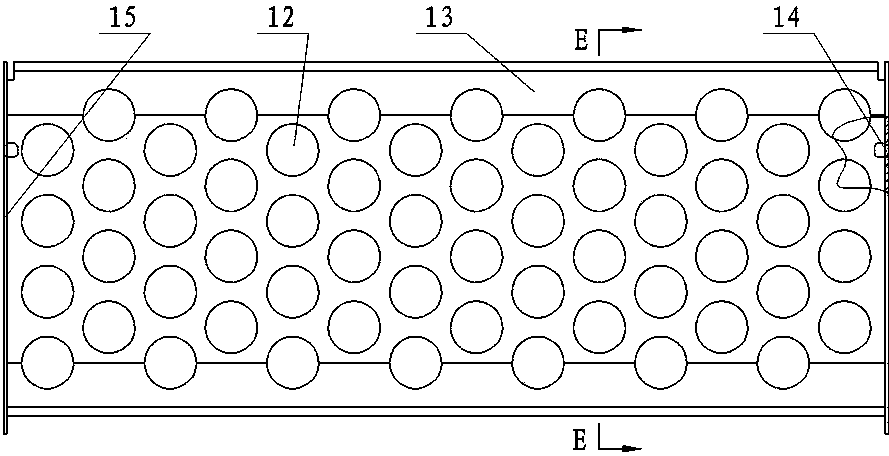

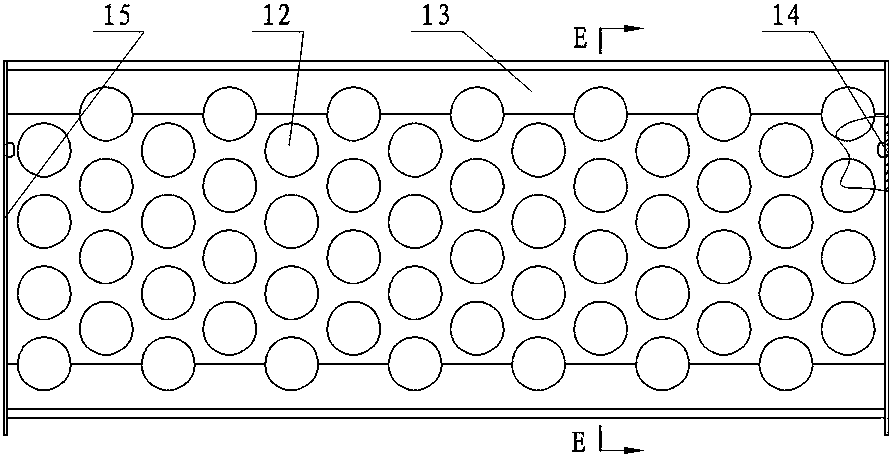

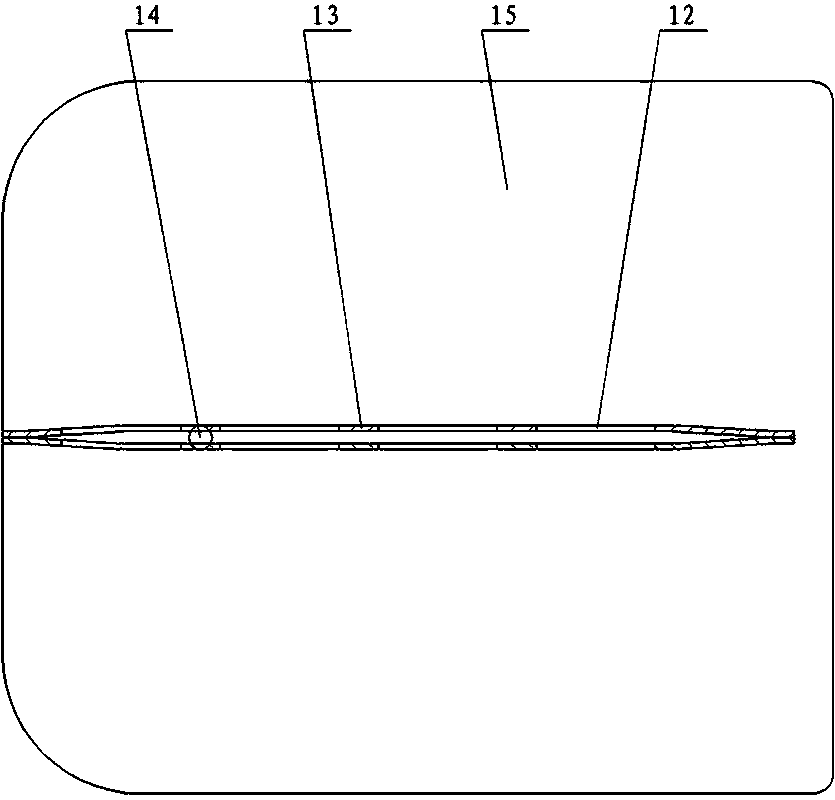

Straight-rod type infrared corncob drying machine

InactiveCN103960355ADry evenlyImprove heat transfer efficiencyFood processingSeed preservation by dryingInfraredHeat transfer efficiency

The invention provides a straight-rod type infrared corncob drying machine. The straight-rod type infrared corncob drying machine is characterized in that a plurality of conveying devices driven by a transmission device to run are arranged in a box; a plurality of shifting rods are fixed on bent plates, correspondingly stretching towards the inner side, of two chains of the same conveying device by two connectors on the ends; each conveying device is provided with supporting grooves corresponding to spaces below the upper horizontal section and the lower horizontal section of each chain, respectively; a guide groove is formed below the tail end of each supporting groove; a radiation device for radiating an infrared ray unidirectionally downwards is arranged above each support groove; a charge opening is formed in the top of the box, and a discharge hole is formed in the bottom of the box. The straight-rod type infrared corncob drying machine provided by the invention is high in heat transfer efficiency, low in energy consumption, good in drying uniformity, simple and reasonable in structure, and high in working reliability.

Owner:SHANDONG UNIV OF TECH

Buffer breakage-proof flat bottom silo

InactiveCN101613022BIncrease frictionSolve the problem of high breakage rateLarge containersLoading/unloadingFree fallingEngineering

The invention relates to a buffer breakage-proof flat bottom silo, wherein, a central blanking barrel and a central column which are connected through a rigid mechanism are fixed in the center of the silo; an internal screw downspouting is arranged in the central blanking barrel and the central column is coiled with one or a plurality of screw downspoutings. In the buffer breakage-proof flat bottom silo in the invention, materials firstly pass through the internal screw downspouting, then pass through an external screw downspouting, and freely fall to the bottom part of the flat bottom silo by ensuring the minimum fall in a slipping manner, thus forming a pointed piling form with high center and low center peripheral part. When the materials account for 60% of the silo body space, a mobile distributing device is started to locate randomly, and a rotary distributing bridge does rotary movement along an annular orbit; blocky materials slip from the inner part of the silo center to the periphery of the center along the pointed piling gradient of raw materials and complete the distribution of the remaining 40% of the peripheral space of the silo. The invention effectively controls thefall of material free fall, increases blanking friction force, mitigates the impact of materials and reduces flow rate, thus being in particular applicable to the storage of blocky materials.

Owner:朱耀平

Method and device for effectively reducing breakage rate of lime lump materials

InactiveCN101723188AReduce breakage rateSimple production processLarge containersLoading/unloadingBreakage rateSilo

The invention relates to the technical field of lime production, in particular to a method and a device for effectively reducing breakage rate of lime lump materials. The method is realized by arranging a rotating warehousing device of the lime lump materials in a silo, the lime lump materials to be warehoused are divided into a plurality of paths through the rotating warehousing device of the lime lump materials, then the lime lump materials enter into the silo through a rotating slideway and the lime lump materials are gradually paved in the silo. The device comprises a silo opening chute, a hanger and a rotating slideway, wherein the rotating slideway is connected with an outlet of the silo opening chute, and the other end of the rotating slideway is near to the outlet of the silo; and the hanger is used for suspending the rotating slideway in the silo. The rotating slideway comprises a material distributing chute, a fixed support and a rotating chute, wherein the material distributing chute is arranged at the outlet of the silo opening chute and fixed through the hanger, the rotating chute is connected with the material distributing chute, and the rotating chute is fixed in the silo through the fixed support. The method and the device for effectively reducing the breakage rate of the lime lump materials, and the rotating warehousing device of the lime lump materials is arranged in the silo, thereby effectively reducing the breakage rate of the lime lump materials and improving the finished product utilization rate of the lime lump materials.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Infrared corn cob drier capable of elastically cropping

InactiveCN104855507AEliminate the phenomenon of being stuck in the guide grooveEvenly absorbs radiant heatSeed preservation by dryingEngineeringMechanical engineering

The invention provides an infrared corn cob drier capable of elastically cropping. The infrared corn cob drier is characterized in that a plurality of conveying devices driven to rotate by a transmission device are arranged in a box body, a plurality of material shifting rods are fixed to bent boards which correspondingly and inwards extend out of two chains of the same conveying device through two connectors at end parts, material supporting grooves are respectively formed under an upper horizontal section and a lower section horizontal of the chains corresponding to each conveying device, a cropping device which is supported on the side wall of the box body through a cross beam is arranged under the tail end of the material supporting groove at the upper section, a plurality of supporting sleeves which are parallel to supporting boards are uniformly fixed between the two supporting boards which are fixed to the cross beam and are provided with a chute, rolling sleeves supported on a supporting rod can compress springs through pin shafts and telescopic rods and can slide axially along the inner holes of the supporting sleeves, material guiding grooves are formed in positions under the tail end of the material supporting groove in the lower section, and radiation devices are arranged above the material supporting grooves; a feed opening is formed in the top of the box body, and a discharge opening is formed in the bottom of the box body. The infrared corn cob drier disclosed by the invention is high in drying efficiency, is good in drying uniformity, is simple in structure and is reliable in work.

Owner:SHANDONG UNIV OF TECH

Turning and blanking infrared corn cob dryer

InactiveCN104686649BImprove heat transfer efficiencyStrong penetrating powerDrying solid materials with heatSeed preservation by dryingGear driveEngineering

The invention provides a turning and blanking infrared corn ear dryer, which is characterized in that: a plurality of conveying devices driven by a transmission device are arranged in the box, and a plurality of material shifting rods are fixed on two ends of the same conveying device through two joints at the ends. The two chains correspond to the curved plates protruding inward. Each conveying device is respectively provided with supporting troughs corresponding to the upper and lower horizontal sections of the chain. Support rods and adjustment rods are respectively fixed on both sides of the outer circle of the support sleeve on the shaft. The outer end of the support rod is fixed with a material receiving trough at the end of the support tank in the non-working state. Below the end of the support trough, the adjustment block is locked on the adjustment rod through screws and nuts, there is a material guide trough under the end of the lower support trough, a radiation device is installed above the support trough, the top of the box is equipped with a feed port, and the bottom There is a discharge port. The invention has high drying efficiency, good drying uniformity, simple structure and reliable operation.

Owner:SHANDONG UNIV OF TECH

Straight bar infrared corn cob dryer

InactiveCN103960355BDry evenlyImprove heat transfer efficiencyDrying solid materials with heatFood processingEngineeringHeat transfer efficiency

The invention provides a straight-rod type infrared corncob drying machine. The straight-rod type infrared corncob drying machine is characterized in that a plurality of conveying devices driven by a transmission device to run are arranged in a box; a plurality of shifting rods are fixed on bent plates, correspondingly stretching towards the inner side, of two chains of the same conveying device by two connectors on the ends; each conveying device is provided with supporting grooves corresponding to spaces below the upper horizontal section and the lower horizontal section of each chain, respectively; a guide groove is formed below the tail end of each supporting groove; a radiation device for radiating an infrared ray unidirectionally downwards is arranged above each support groove; a charge opening is formed in the top of the box, and a discharge hole is formed in the bottom of the box. The straight-rod type infrared corncob drying machine provided by the invention is high in heat transfer efficiency, low in energy consumption, good in drying uniformity, simple and reasonable in structure, and high in working reliability.

Owner:SHANDONG UNIV OF TECH

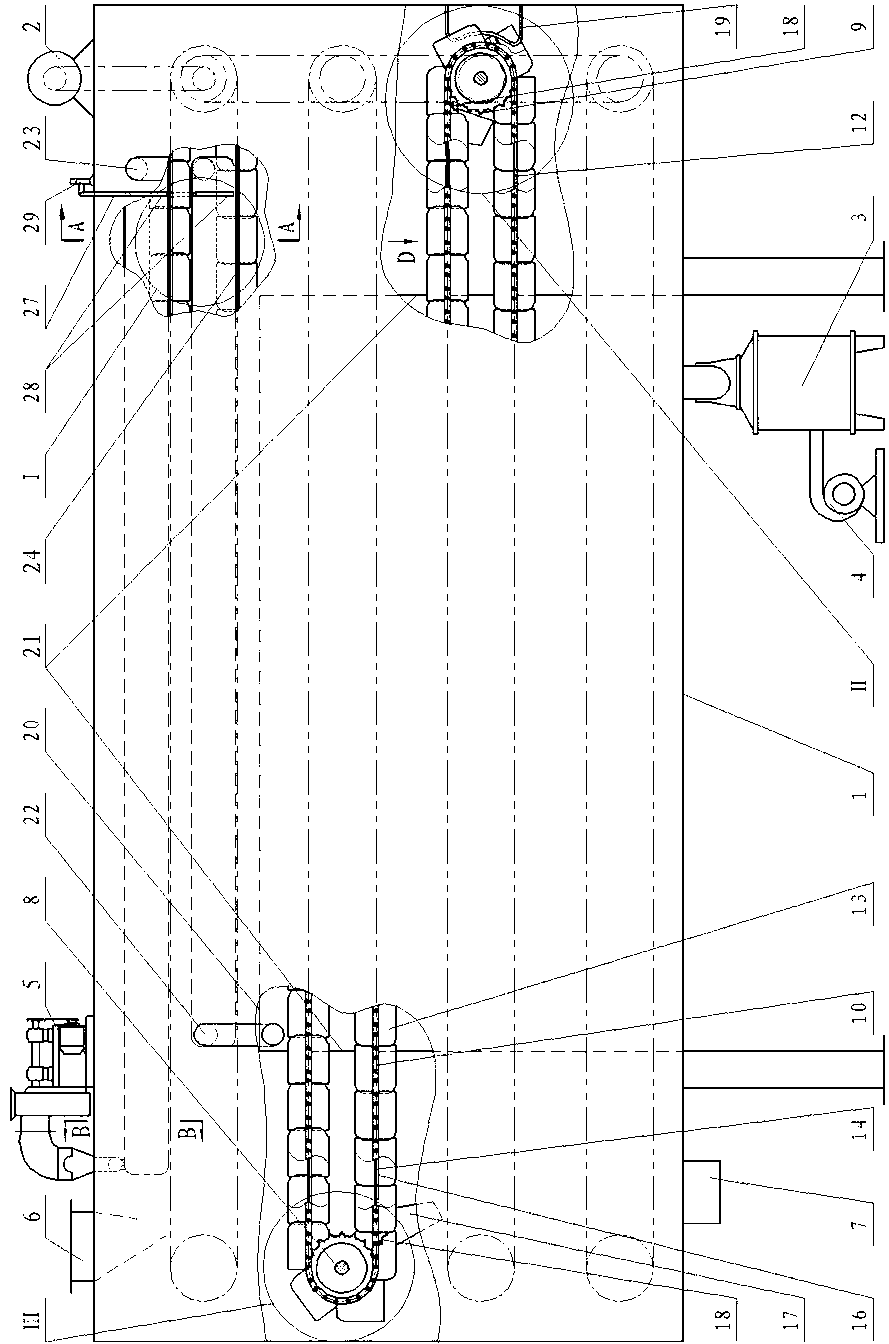

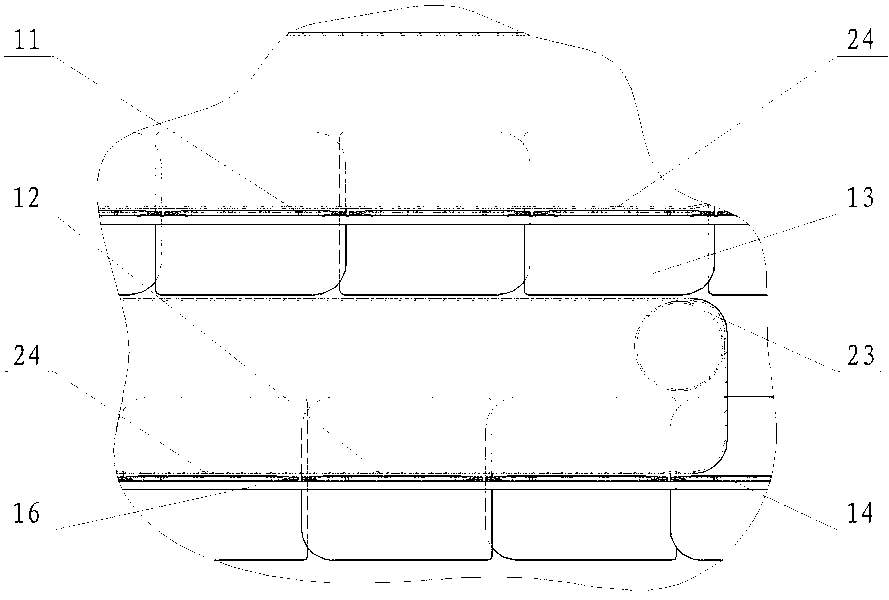

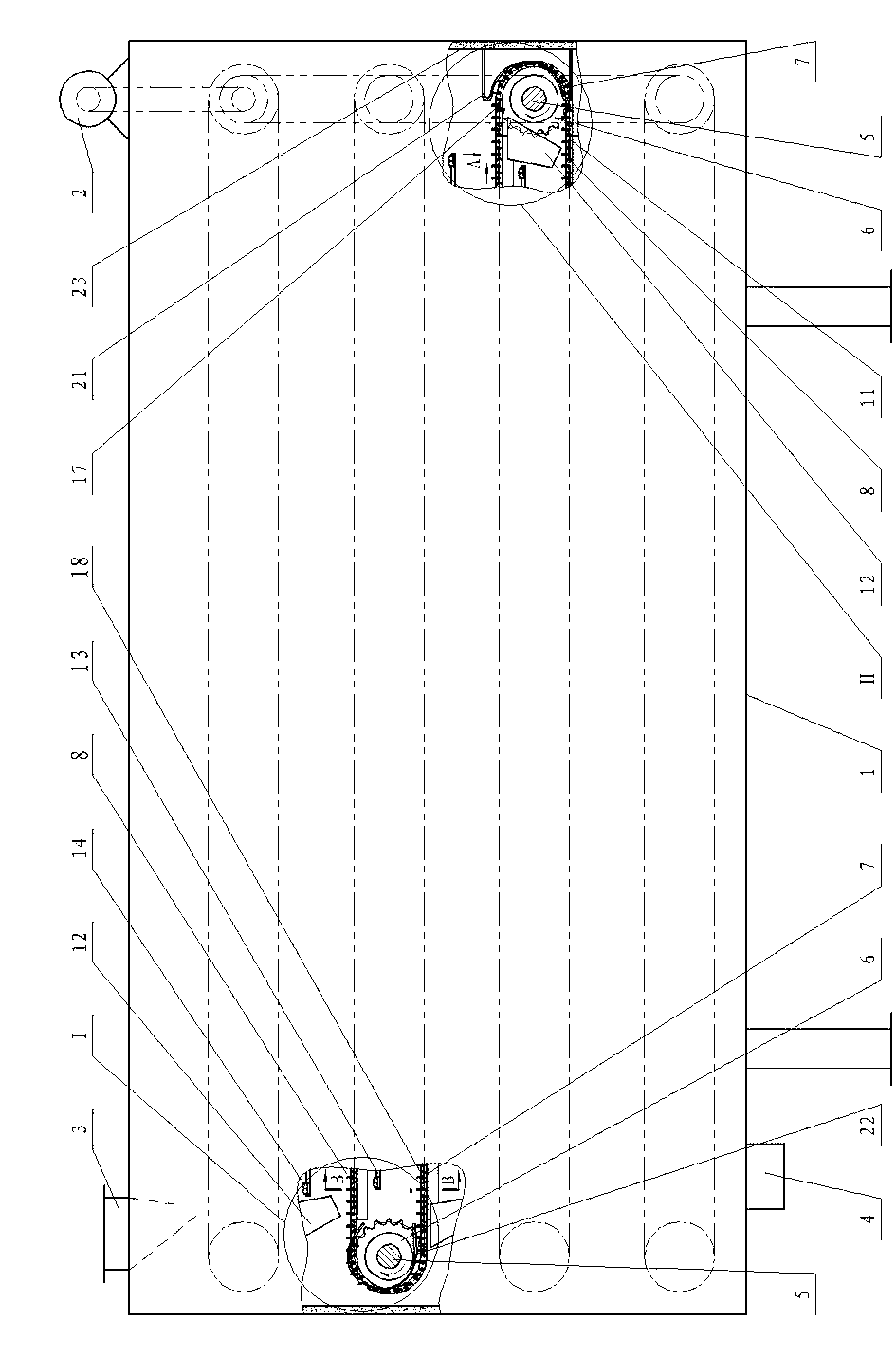

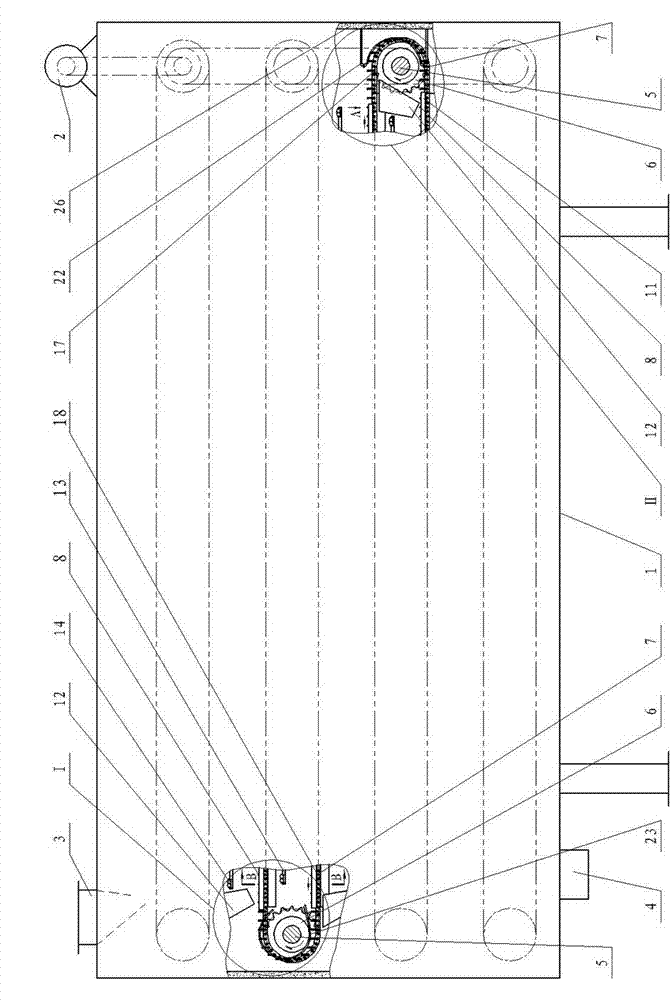

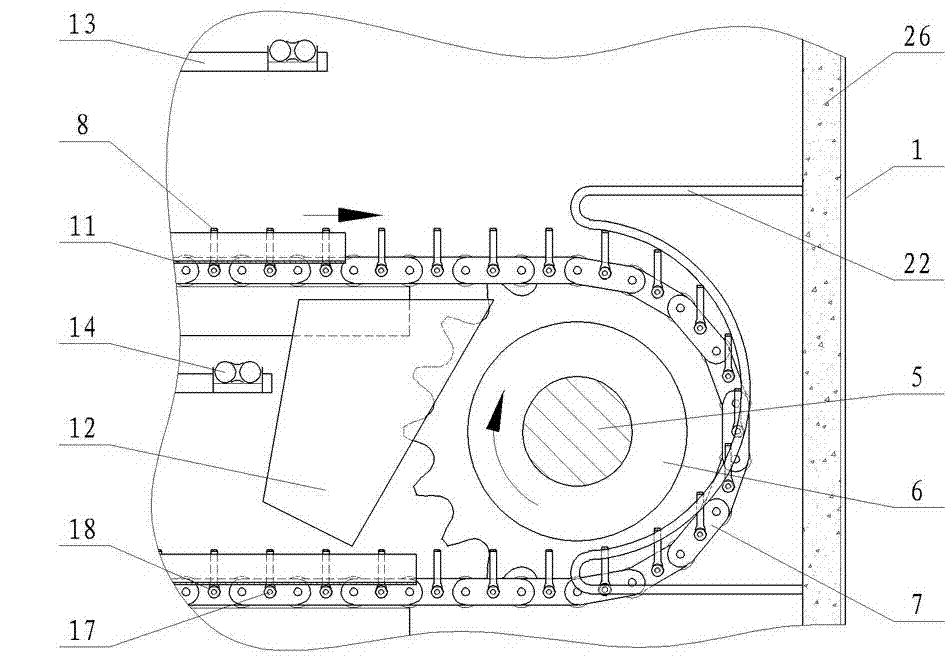

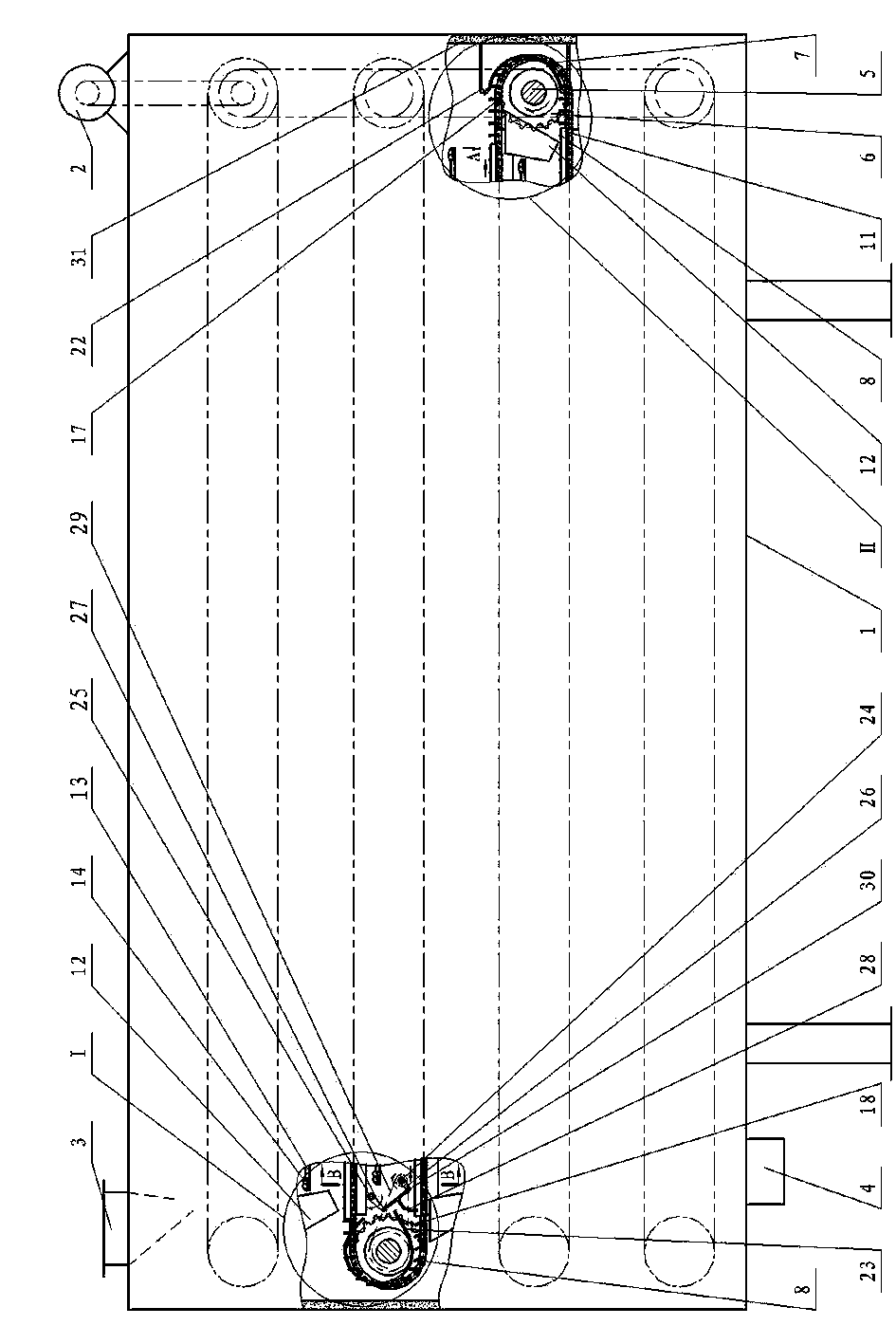

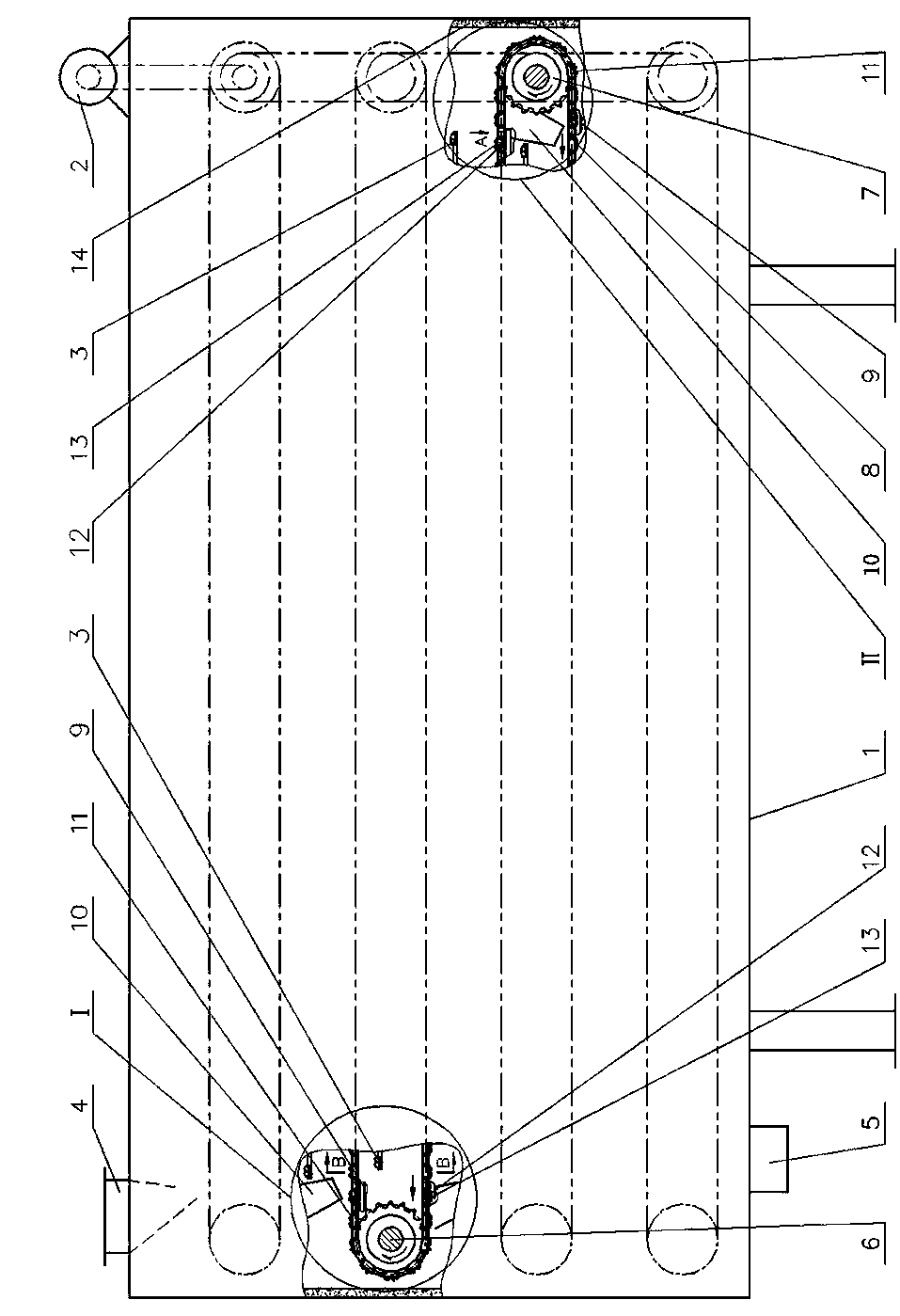

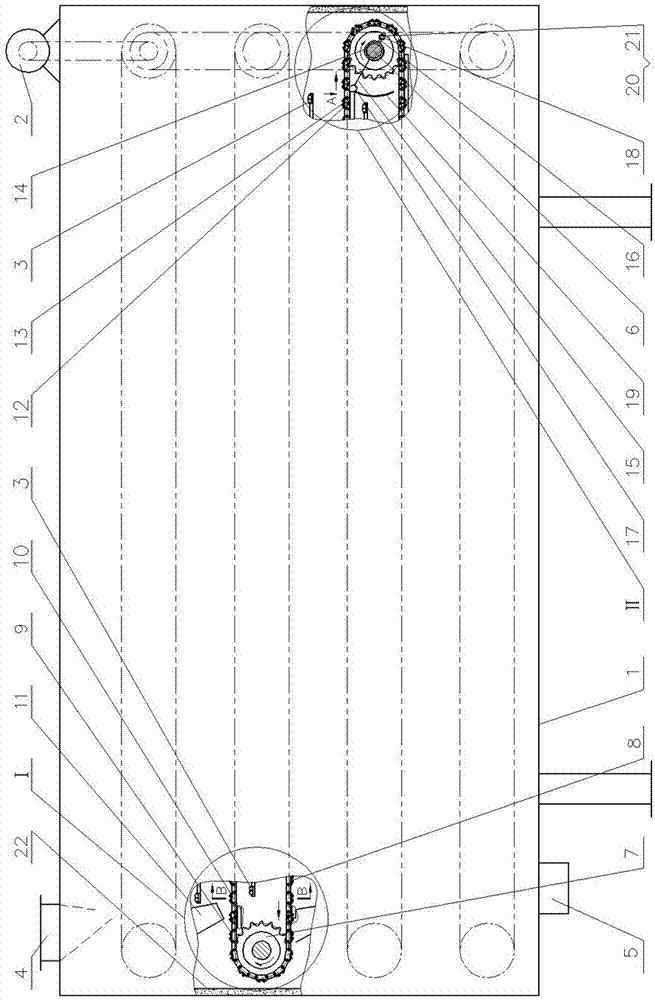

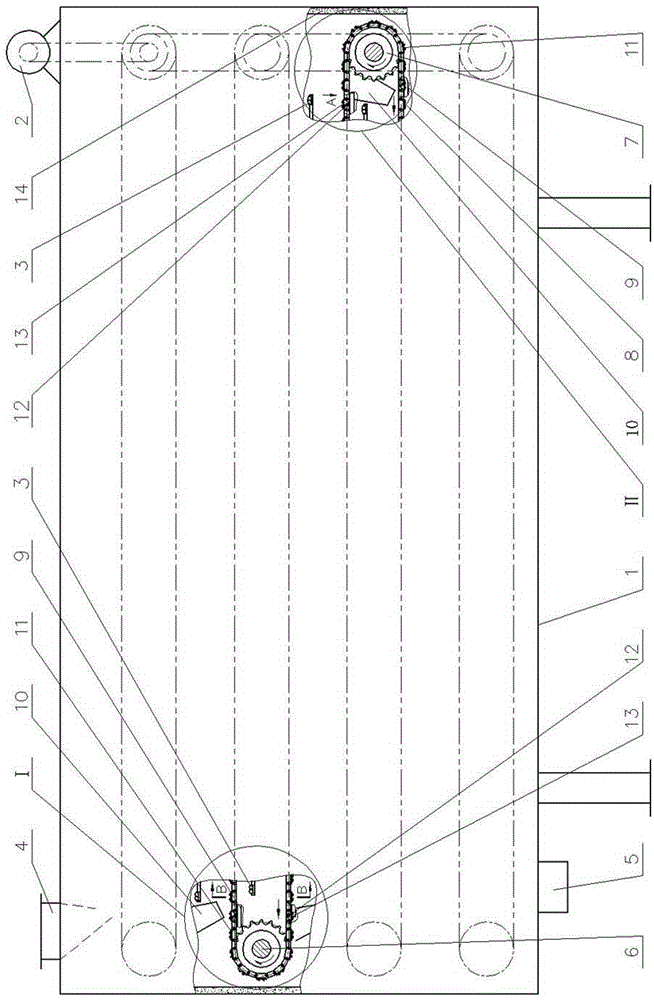

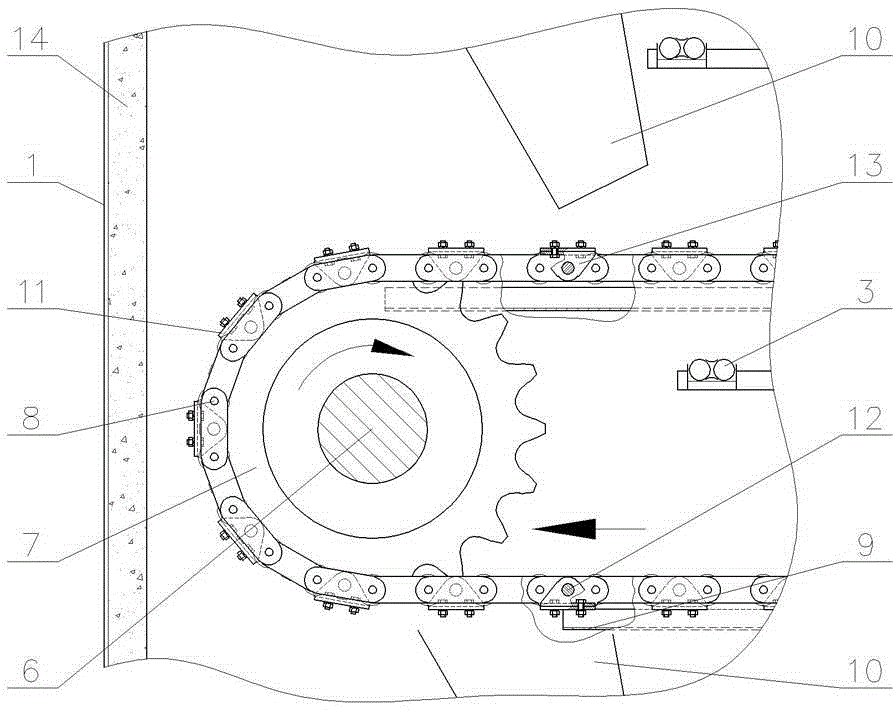

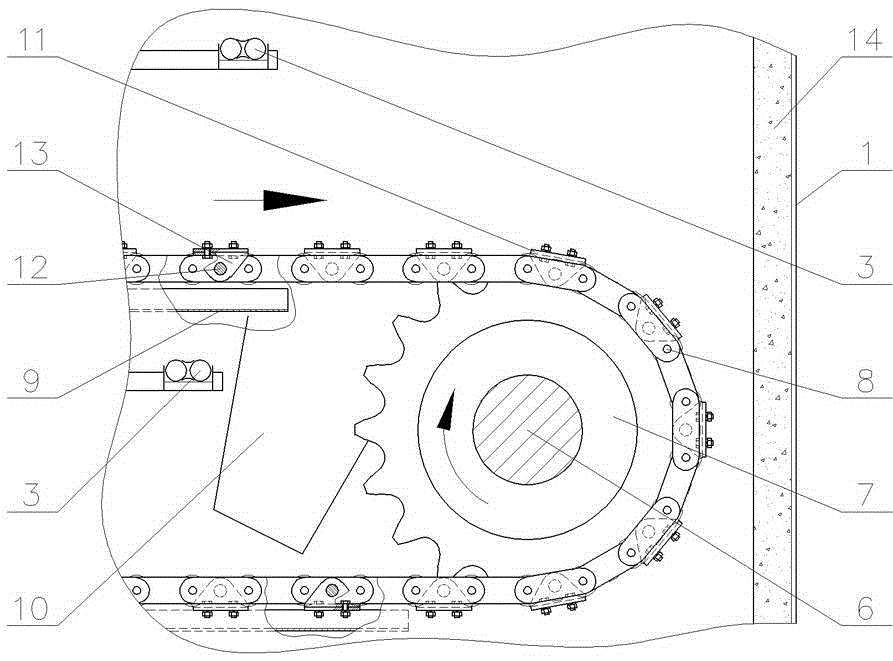

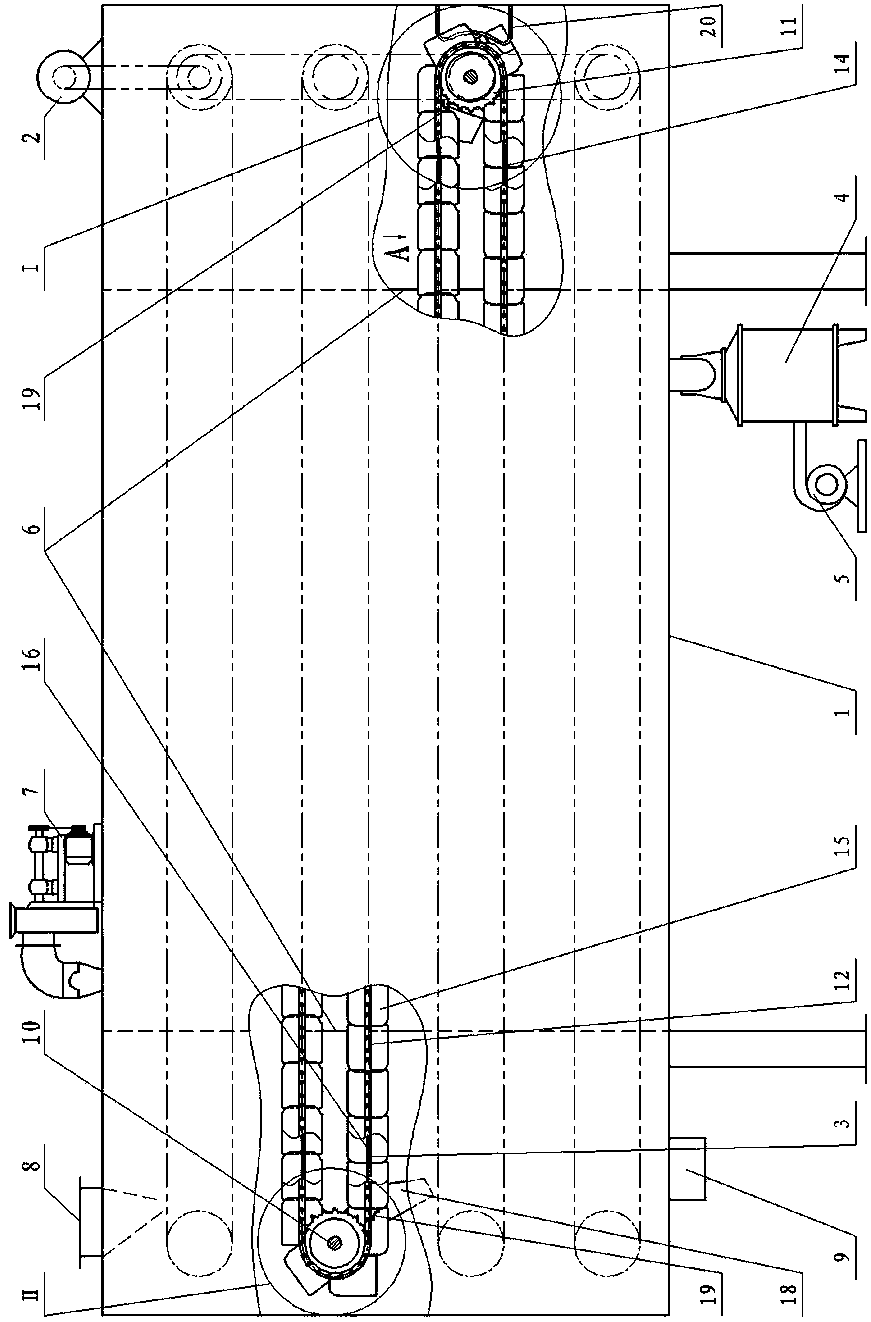

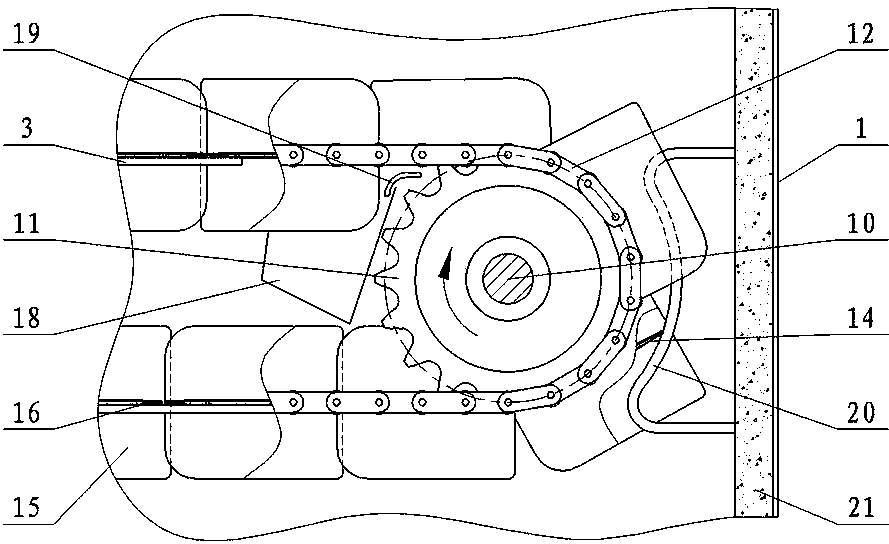

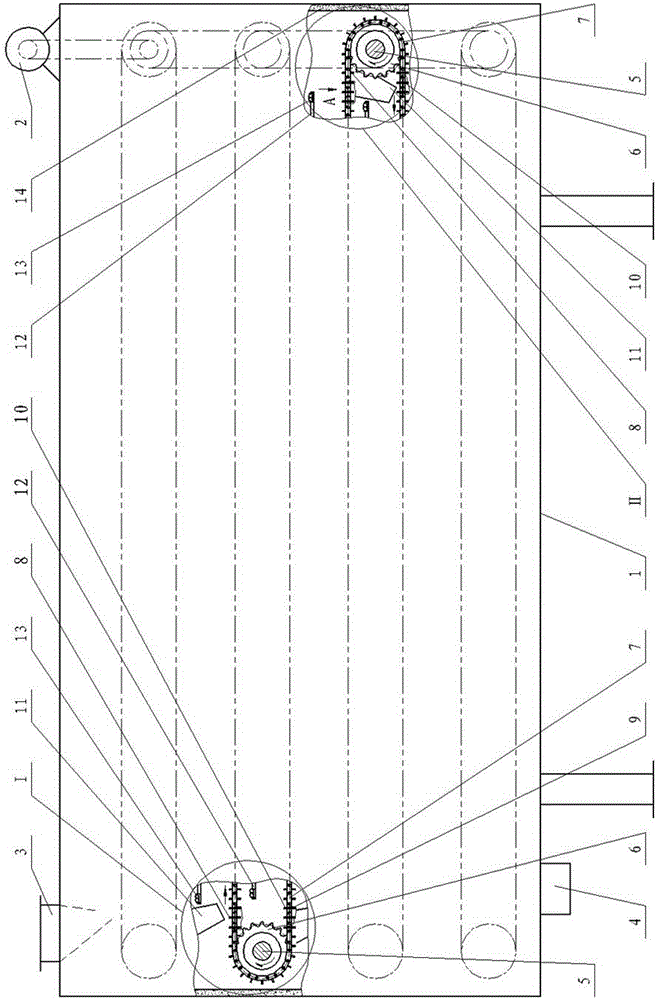

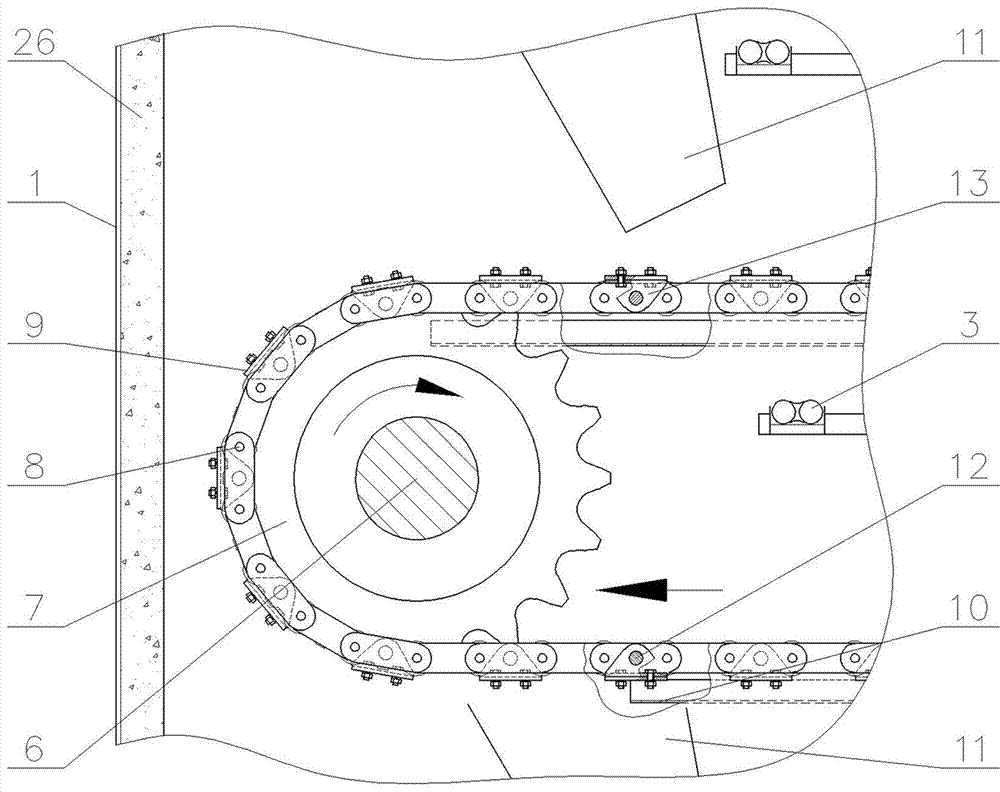

Continuous corncob dryer

InactiveCN103070233BEasy to removeReduce the temperatureSeed preservation by dryingDrying machinesEngineeringSprocket

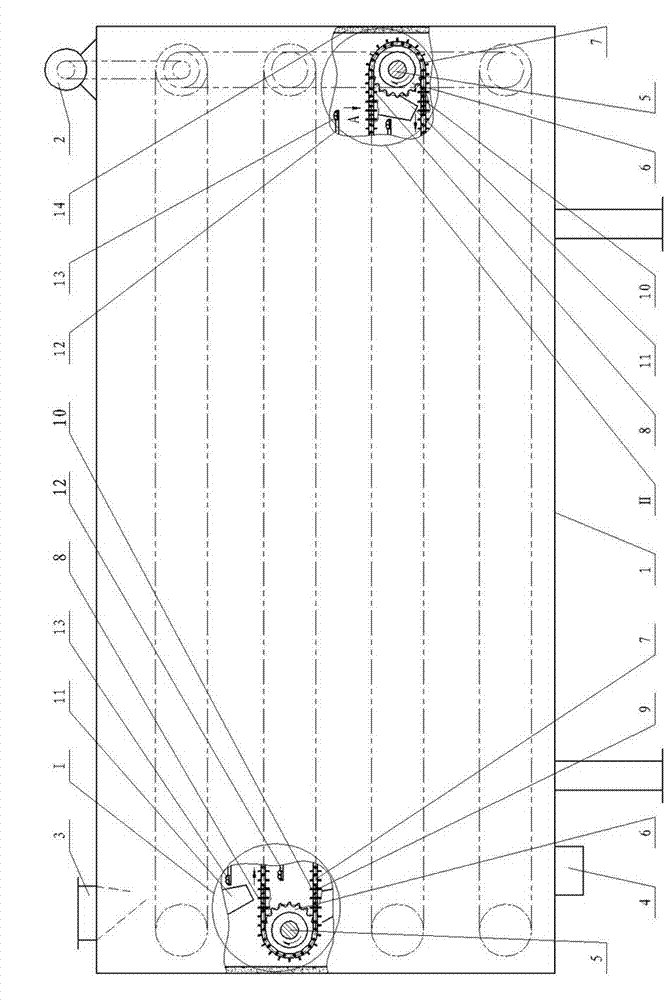

The invention provides a continuous corncob dryer, which is characterized in that an inner part of a tank body is divided into three parts by clapboards vertically; an air heater with a blower is arranged on a bottom part of the tank body in the middle; a draught fan and a feed inlet are arranged on a top part; a discharge hole is arranged on a bottom part; a plurality of conveyer devices driven by transmission devices to operate are arranged in the tank body; two conveyer chain wheels are arranged on a shaft of each conveyer device; a conveyer chain is hung on the conveyer chain wheels on the same ends of the shafts; inner ends of chain pins of the conveyer chains are correspondingly provided with pin shafts toward inner sides at intervals of the same section number in an extended way; two molding panels with a plurality of ventilation holes are bent, concave surfaces of the molding panels are in fit connection, and baffle plates are fixedly arranged on two ends of the molding panels, so that molding chain plates are formed; the type I molding chain plate and the type II molding chain plate with different lengths are alternately hung on the pin shafts extending out of the two conveyer chains of the same conveyer device; each molding chain plate is arrayed and supported on a guide rail to form a slot type material channel; and a material guiding slot is arranged under a tail end of the channel. The continuous corncob dryer has a large range of reducing moisture, good drying uniformity, and reliability in operation.

Owner:SHANDONG UNIV OF TECH

Cooling discharge type corncob drying machine

InactiveCN103070236BReduce the temperatureGuaranteed temperatureSeed preservation by dryingDrying machinesEngineeringCondensate pump

The invention provides a cooling discharge type corncob drying machine. The cooling discharge type corncob drying machine is characterized in that the inner part of a box is divided into an upper region and a lower region by a separator plate I; the lower region is divided into three parts by a separator plate II; the separator plate I and separator plates III and IV located at the lower part of the box form a cooling region; a water heater is arranged at the bottom of the middle box; the cooling region is connected with the air inlet of the water heater by a blower; the air outlet of the water heater is connected with the middle part of the box; one end of each heat exchange box at the uppermost part in the box is communicated with the middle part of the box, and the other end of the heat exchange box is connected with an induced draft fan; two ends of each heat exchange box in the lower place are connected with the water heater by a circulating water pump; a condensate water pump is connected with straight water pipes in each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device are arranged in the box; each forming chain plate is supported on a guide rail to form a groove-shaped material channel; a guide chute is arranged under the tail end of the channel; a feed port is formed in the top part of the box; and a discharge port is formed in the bottom of the box. The cooling discharge type corncob drying machine is good in drying effect and low in energy consumption, and corncobs can be packaged directly after being dried by the drying machine.

Owner:SHANDONG UNIV OF TECH

Infrared corn cob drying machine with shifting mechanisms

InactiveCN103843884BSolve the problem of high breakage rateSolve the rotation problemDrying solid materials with heatFood processingEngineeringHeat transfer efficiency

The invention provides an infrared corn cob drying machine with shifting mechanisms, which is characterized in that a box is internally provided with a plurality of conveying devices driven to run by a drive device I, one end of a stud is screwed into a screw hole in a chain link on the inner side of a chain, two ends of a shifting lever are idly arranged in the middle of the stud in a sleeving manner, a blind hole is internally provided with a spring and a steel ball stop collar which are fixed in the middle of the stud, two steel balls fall into a spherical pit of the shifting lever, each conveying device is provided with chute feeders respectively corresponding to an upper horizontal section and a lower horizontal section of the chain, a guide chute is arranged below the tail end of the chute feeder, a radiation appliance is arranged above the chute feeder, two ends of each conveying device are respectively provided with a limiting rod I and a limiting rod II, and a shifting mechanism is arranged at each chain wheel below a feed opening, so as to force each shifting lever to do reverse autorotation with speed equal to that of a corotation angle around the stud while corotating along with the chain wheel when travelling to the chain wheel for reversing; the feed opening is formed in the top of the box, and a discharge opening is formed in the bottom of the box. The infrared corn cob drying machine is high in heat transfer efficiency, low in energy consumption, reasonable in structure and reliable to work.

Owner:SHANDONG UNIV OF TECH

Waste heat recovering ear-corn drying machine

InactiveCN103070234BReduce the temperatureReduce moisture contentFood processingClimate change adaptationChinese charactersEngineering

The invention provides a waste heat recovering ear-corn drying machine, which is characterized in that the chamber of the drying machine is divided into an upper area and a lower area by a partition I; the lower area is divided into three parts by partitions II; the bottom of the middle chamber is provided with an air heater with a blower; a plurality of heat exchange boxes are arranged in the upper area and are communicated with one another by annular air pipes; the heat exchange boxes on the lower part are communicated with the middle of the lower area of the chamber; the heat exchange boxes on the upper part are connected with an induced draft fan mounted at the top of the chamber; a water pump at the top of the chamber is connected with a straight pipe inserted in each heat exchange box by a water pipe which is shaped like a Chinese character 'YUE'; a plurality of conveying devices running under the driving of a driving device are arranged in the chamber; molding link plates of I and II types are hung on a pin shaft extending out of the inner side of a conveying chain at intervals and are arrayed and supported on a guide rail to form a trough material channel; a guide chute is arranged below the tail end of the channel; and a feed inlet and a discharge port are formed at the top and the bottom of the chamber respectively. The waste heat recovering ear-corn drying machine is large in moisture reducing range, good in preheating effect and reliable in working.

Owner:SHANDONG UNIV OF TECH

Infrared corncob drying machine with limiting sleeve

InactiveCN103081993BSolve the problem of high breakage rateReduce hindranceDrying solid materials with heatFood processingInfraredSide chain

Owner:SHANDONG UNIV OF TECH

Rigid-flexible-liquid coupling loss reduction bionic picking elastic claw and pepper harvester

InactiveCN113519268AReduce the impactReduce collision forceProgramme-controlled manipulatorGripping headsLiquid mediumHot peppers

The invention provides a rigid-flexible-liquid coupling loss reduction bionic picking elastic claw and a pepper harvester. The rigid-flexible-liquid coupling loss reduction bionic picking elastic claw comprises a skin layer, a far-end finger, a middle finger and a near-end finger; the skin layer wraps the outer surfaces of the far-end finger, the middle finger and the near-end finger which are hinged in sequence; each of the far-end finger, the middle finger and the near-end finger is provided with a phalanx, a fascia layer, a muscle and tendon layer and a blood vessel layer, the phalanx is wrapped by the muscle and tendon layer, the muscle and tendon layer is wrapped by the fascia layer, and a plurality of blood vessel layers are arranged in the muscle and tendon layer; and the blood vessel layer is a sealed tube which can be filled with a liquid medium. According to the rigid-flexible-liquid coupling loss reduction bionic picking elastic claw, the finger of a person is used as a bionic prototype, so that the problem of high damage rate of a traditional elastic claw on the pepper harvester during pepper picking is solved.

Owner:JIANGSU UNIV

Bead black tea manufacturing method

InactiveCN102210362BIncrease profitSolve the problem of high breakage ratePre-extraction tea treatmentGreen teasMechanical engineering

The invention discloses a processing method of bead-shaped black tea, which comprises: the green tea is a variety of medium and small leaves, and one bud has 3 and 4 leaves; 12cm, ambient temperature and humidity are 20°C-30°C and 90%-95%, turning 3-6 times during the process; dehydration temperature 80°C-90°C, leaf temperature 60°C-70°C, time 1min-2min, after dehydration Reduce to normal temperature; shape in two times; use electric rollers to continuously fix the greens at a temperature of 100°C-110°C, so as to avoid bursting points and evenly throw leaves. 3cm to 5cm; for the tea leaves that have been spread after the fire, the temperature for increasing the aroma is 110°C-130°C, and the time is 5min-7min. The present invention has a bead-like appearance, can reduce the broken rate of rolled leaves, improve the integrity of buds and leaves, and ensure uniform fermentation.

Owner:GUIYANG CHUNQIU INDAL

Continuous type infrared corncob drying machine

InactiveCN103081991BImprove heat transfer efficiencyStrong penetrating powerDrying solid materials with heatFood processingInfraredHeat transfer efficiency

The invention provides a continuous type infrared corncob drying machine which is characterized in that a box body is internally provided with a plurality of conveying devices driven by a transmission device to run, wherein I type and II type material pulling rods with two different lengths are fixedly arranged between two chains of the same conveying device at an interval; parts of each conveying device, which correspond to upper and lower sections of horizontal sections of the chains, are respectively provided with material supporting plates; material guide grooves are arranged below the tail ends of the material supporting plates; radiation devices are arranged above the material supporting plates; radiation racks of the radiation devices are suspended on the box body; the two ends of an infrared radiation element which downwards radiates infrared rays in a single direction are mounted on the radiation racks; and a feeding opening is arranged on the top of the box body, and a discharging opening is formed at the bottom of the box body. The continuous type infrared corncob drying machine disclosed by the invention has the advantages of high heat transferring efficiency, low energy consumption and good drying uniformity.

Owner:SHANDONG UNIV OF TECH

Elastic Blanking Infrared Corn Cob Dryer

InactiveCN104855507BEliminate the phenomenon of being stuck in the guide grooveEvenly absorbs radiant heatDrying solid materials with heatSeed preservation by dryingGear driveEngineering

The invention provides an elastic blanking infrared corn cob dryer, which is characterized in that: a plurality of conveying devices driven by a transmission device are arranged in the box, and a plurality of material shifting rods are fixed on two ends of the same conveying device through two joints at the ends. Each chain corresponds to the curved plate protruding inward, and each conveying device is respectively provided with supporting troughs corresponding to the upper and lower horizontal sections of the chain, and the bottom of the upper section of the supporting trough is supported on the side of the box by a beam. The blanking device on the wall is fixed on the beam and has a plurality of support sleeves parallel to the support plates evenly fixed between the two support plates with slideways. After the rod compresses the spring, it slides axially along the inner hole of the supporting sleeve. There is a material guide groove under the end of the lower supporting trough, a radiation device is installed above the supporting trough, a material inlet is installed on the top of the box, and an outlet is installed on the bottom. feed port. The invention has high drying efficiency, good drying uniformity, simple structure and reliable operation.

Owner:SHANDONG UNIV OF TECH

Water circulation pre-heating type corncob drier

InactiveCN103070235BMeet delivery needsSolve the problem of high breakage rateSeed preservation by dryingWater circulationEngineering

The invention provides a water circulation pre-heating type corncob drier. The water circulation pre-heating type corncob drier is characterized in that a box is partitioned into an upper region and a lower region by a partition plate I; the lower region is partitioned into three parts by partition plates II; a water gas heater is arranged at the bottom of the middle of the box; one end of a heat exchange box above a first conveying device is communicated with the middle of the box, and the other end of the heat exchange box is connected with an induced draft fan which is arranged on the top of the box; two ends of each heat exchange box between upper and lower groove-shaped material channels of the first conveying device are connected with the water gas heater through a circulating water pump; a condensing water pump which is arranged on the top of the box is connected with a straight water pipe which is inserted into each heat exchange box by an annular water pipe; a plurality of conveying devices which are driven by a transmission device to rotate are arranged in the box; a first moulding chain plate and a second moulding chain plate are suspended on a pin shaft of a chain extending inwards at intervals and supported on a guide rail to form a groove-shaped material channel; a material guide groove is formed below the tail end of the channel; a charging hole is formed on the top of the box; and a discharging hole is formed at the bottom of the box. The water circulation pre-heating type corncob drier is good in preheating and drying effect, and reliable in operation.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com