Patents

Literature

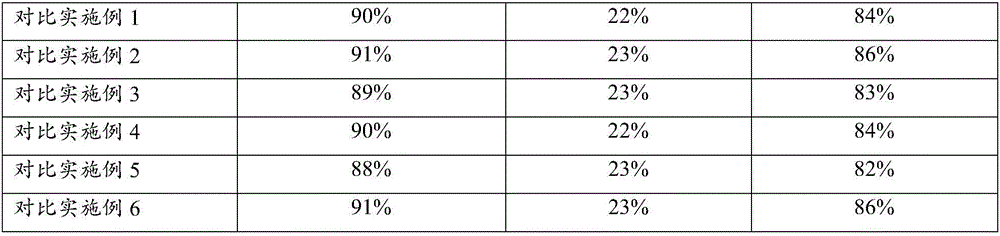

37results about How to "Improve sticking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

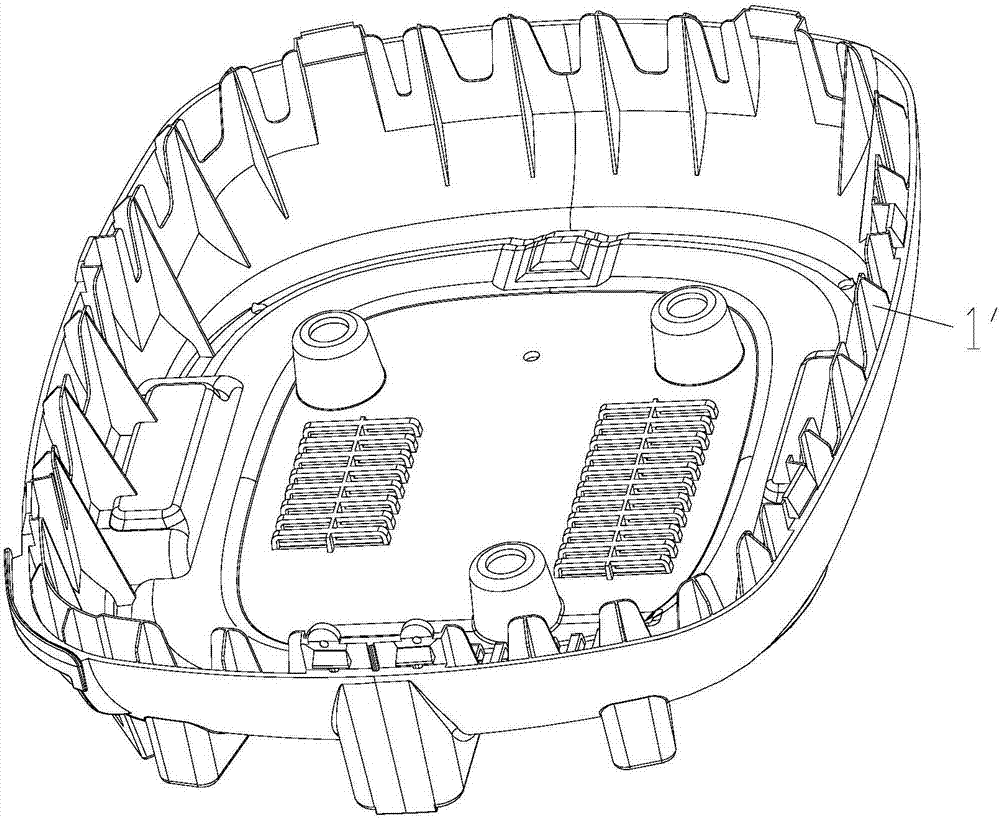

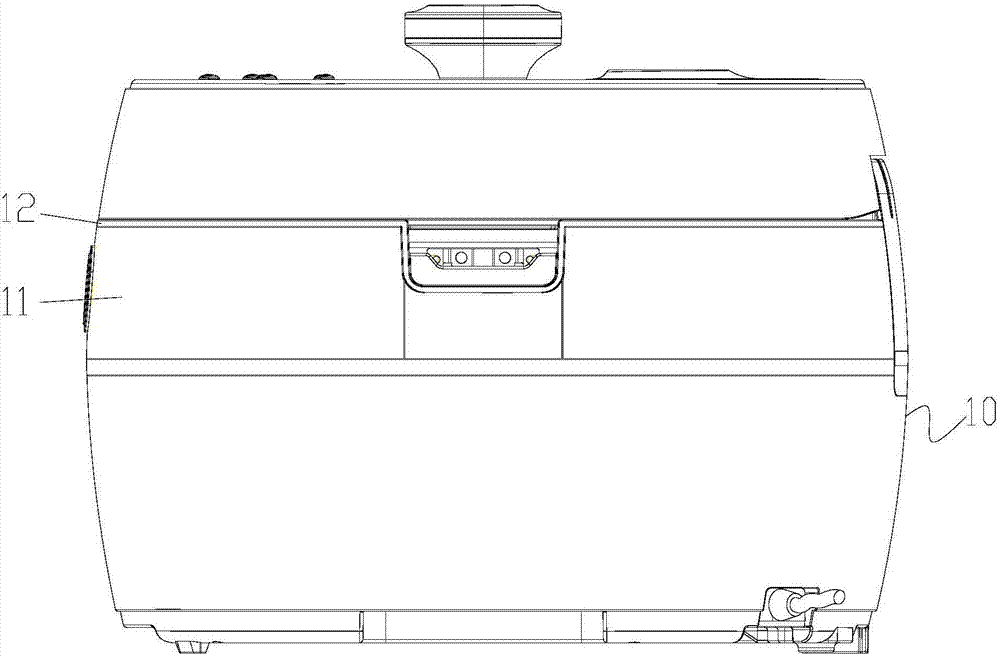

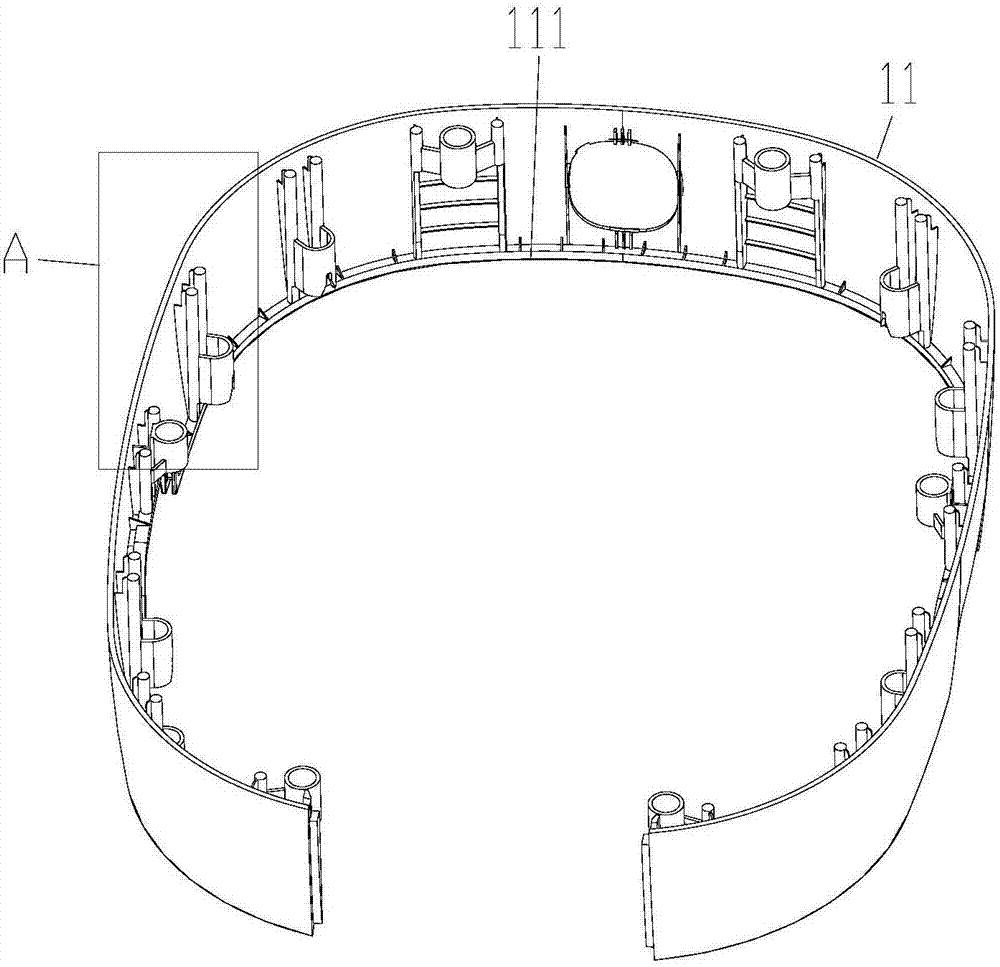

Cooking utensil

PendingCN107874584AImprove structural strengthImprove sticking phenomenonPressure-cookersCooking vessel constructionsEngineeringCooker

The invention relates to a cooking utensil. The cooking utensil comprises a shell body, the shell body comprises a first shell body and a second shell body connected with each other, a limiting rib matched with the second shell body is installed on the inner wall of the first shell body, and a strengthening column is connected with the limiting rib. The cooking utensil solves the problem of poor intensity of the limiting rib on a pot body of an electric pressure cooker in the prior art.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

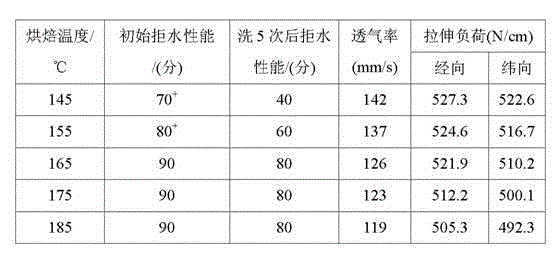

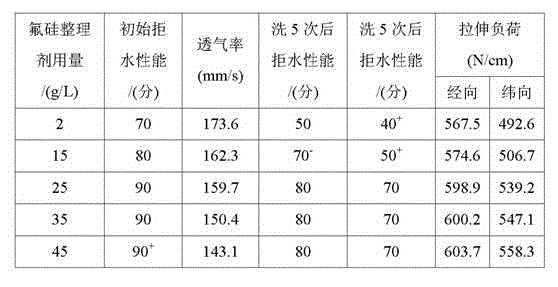

Matte flame-retardant cold-resistant covering cloth

ActiveCN104401084AImprove flame retardant performanceGood mechanical propertiesFibre typesSynthetic resin layered productsEngineeringFire retardant

The invention relates to matte flame-retardant cold-resistant covering cloth. The covering cloth is prepared by performing gumming dipping and drying on base cloth, employing a PVC surface membrane and a PVC bottom membrane to bond with two faces of the base cloth, performing cooling fixing, then employing a fluorosilicone finishing agent to perform surface function processing, and then performing drying and reeling. A double-face bonding production technology of plain base cloth and the PVC surface membrane and the PVC bottom membrane is employed, also a flame retardant and a cold-resisting agent are added into the formula of the PVC membrane, so that the flame retardation performance and the cold resistant performance of the product are improved. The covering cloth possess good flame retardation performance, mechanical properties, cold resistance and the like, and also is greatly improved in applicability and added value by coating the covering cloth surface with a layer of the fluorosilicone finishing agent.

Owner:ZHEJIANG BOTAI PLASTIC

Frozen dumpling modifying agent, preparation method thereof and application

InactiveCN101744021AImprove dough sticking rollerImprove sticking phenomenonDough treatmentPre-baking dough treatmentFreeze thawingEnzyme

The invention belongs to the technical field of frozen dumpling processing by additives, in particular to a frozen dumpling modifying agent, a preparation method thereof and application. The frozen dumpling modifying agent is prepared from the following components in percentage by weight via mixing: 35 to 42 parts of active soybean meal, 25 to 38 parts of konjaku flour, 5 parts of complex enzyme, 8 to 12 parts of carrageenin and 10 to 20 parts of modified starch. The modifying agent can adapt to the process requirements of the mechanized production of the frozen dumplings, improve the quality of finished products of the frozen dumplings, effectively improve the mechanical stirring resistance degree of the flour dough of the frozen dumplings, reduce the roll adhesion phenomenon of cheeks during the mechanized production, can simultaneously improve the boil resistance performance, the smooth performance and the freeze-thaw stability of the frozen dumplings, and improve the external appearance and the mouth feeling of the frozen dumplings.

Owner:河南兴泰科技实业有限公司

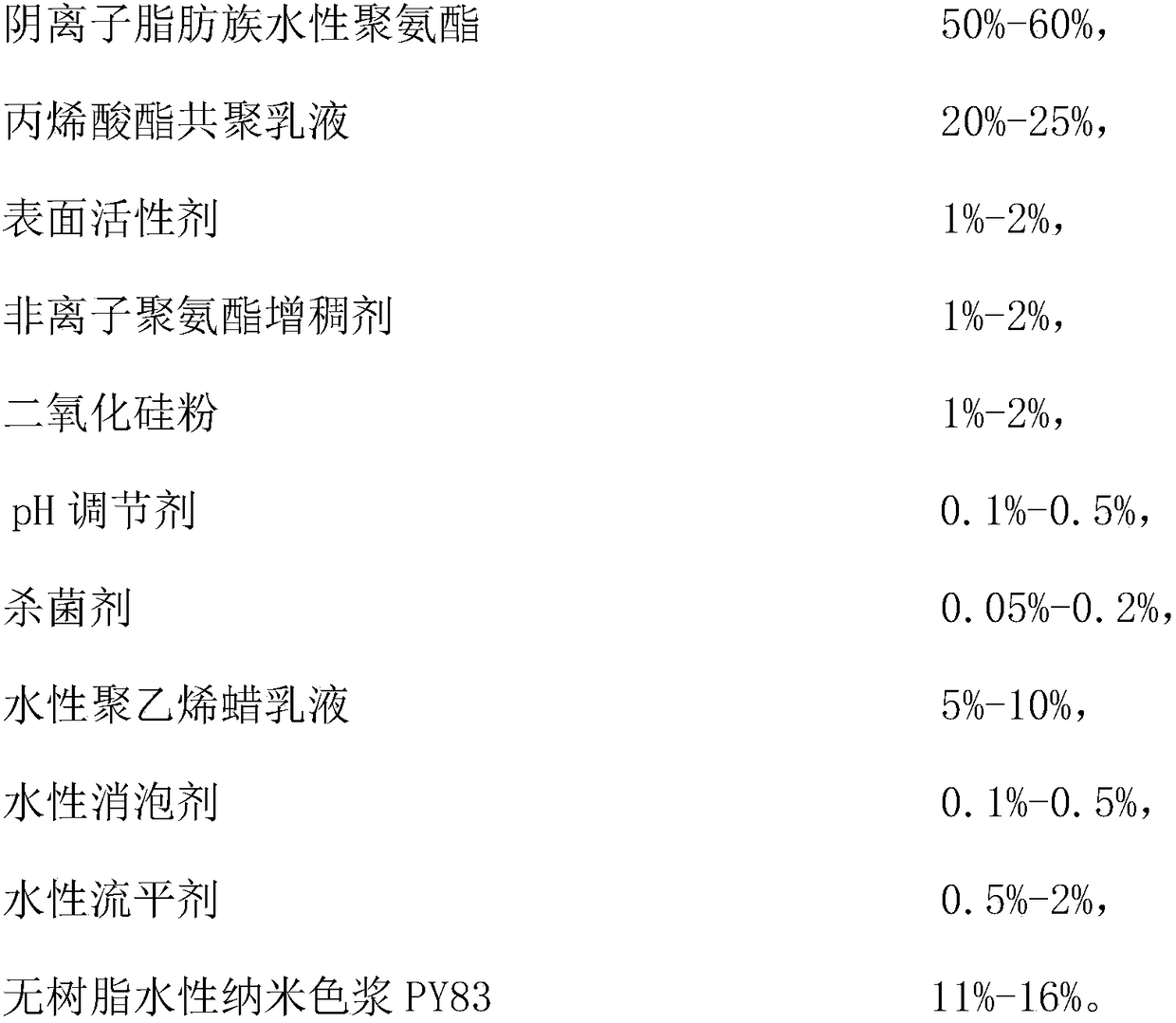

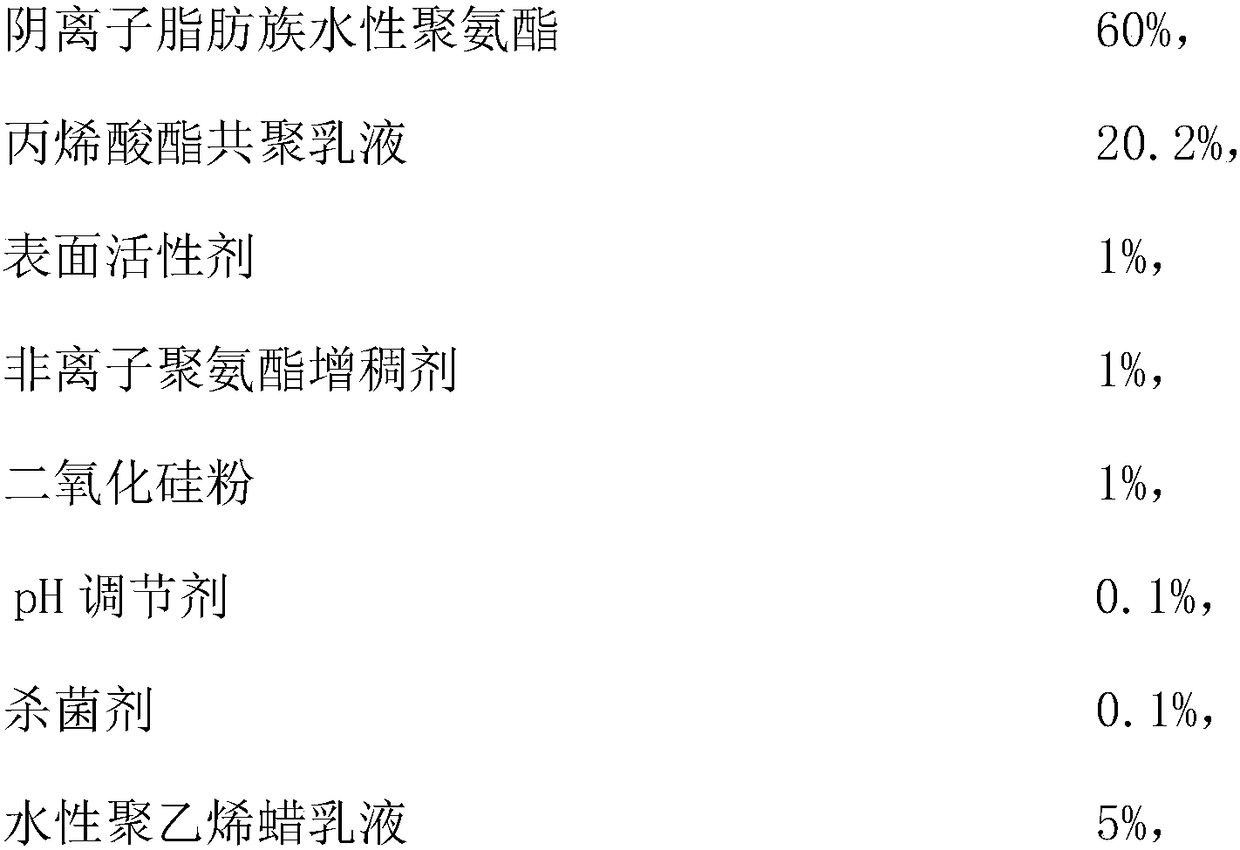

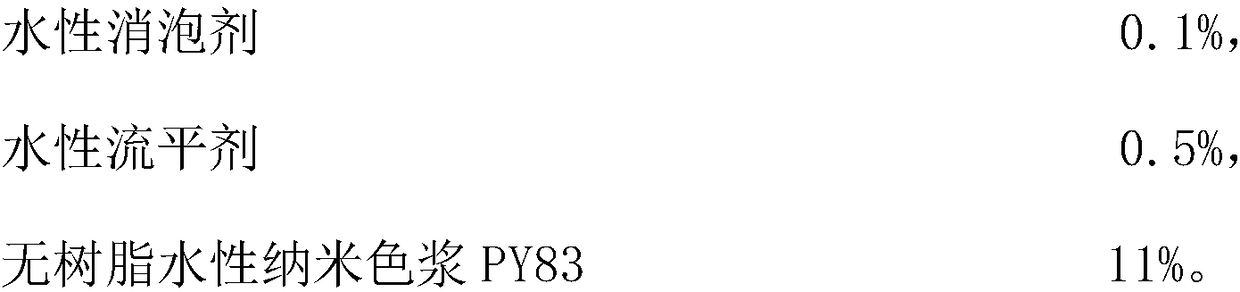

Water-based gravure yellow ink for soft PVC decoration film, and preparation method thereof

The invention relates to a water-based gravure yellow ink for a soft PVC decoration film. The water-based gravure yellow ink comprises, by mass, 50-60% of anionic aliphatic waterborne polyurethane, 20-25% of an acrylate copolymer emulsion, 1-2% of a surfactant, 1-2% of a nonionic polyurethane thickener, 1-2% of silica powder, 0.1-0.5% of a pH adjuster, 0.05-0.2% of a bactericide, 5-10% of an aqueous polyethylene wax emulsion, 0.1-0.5% of an aqueous defoamer, 0.5-2% of an aqueous leveling agent and 11-16% of a resin-free aqueous nanometer color paste PY83. The invention also provides a preparation method of the aqueous gravure yellow ink. The ink has the advantages of good resolubility, no clogging, good adhesion to a substrate, no after-tack, few bubbles in the use process, convenience inpackaging and construction, high bonding strength, and excellent resistance to yellowing and weathering; and the preparation method has the advantages of simplicity, easiness in control, no grinding process, and improvement of the production efficiency.

Owner:中山创美涂料有限公司

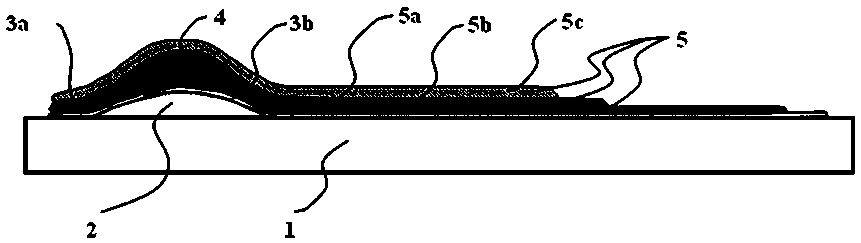

Heating substrate for thermal print head and manufacturing method of heating substrate

PendingCN109693451AExtended service lifeStrong hydrophobicity and oleophobicityPrintingInorganic materialsTransition layer

The invention provides a heating substrate for a thermal print head. The heating substrate comprises an insulating substrate, wherein a bottom glaze layer is arranged on the surface of the insulatingsubstrate in whole or in part, a common electrode and an individual electrode are arranged on the surface of the insulating substrate and the bottom glaze layer, a heating resistance body is configured between the two electrodes in the main printing direction, the heating resistance body is connected to one end of the common electrode in the sub-printing direction, and a printing power source is connected to the other end of the common electrode ; the heating resistance body is connected to one end of the individual electrode in the sub-printing direction, a control IC is connected to the other end of the individual electrode; the surfaces of the heating resistance body, the common electrode and a part of the individual electrodes are covered with an insulating protective layer, a transition layer is arranged on the protective layer, and a hydrophobic and oleophobic functional layer is arranged on the transition layer, and the functional layer is made of an inorganic material, the protective layer, the transition layer and the functional layer form a surface composite layer. The heating substrate for the thermal print head has high hydrophobic and oleophobic ability, the phenomenonof carbon deposition and paper sticking in the printing process can be improved, and the service life of the thermal print head can be prolonged.

Owner:SHANDONG HUALING ELECTRONICS

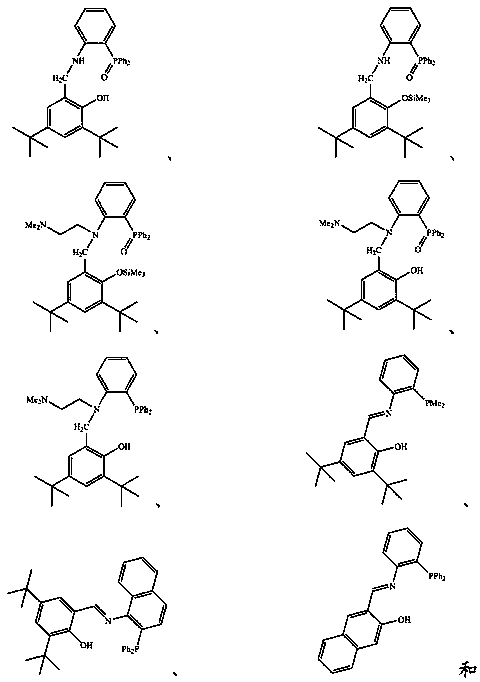

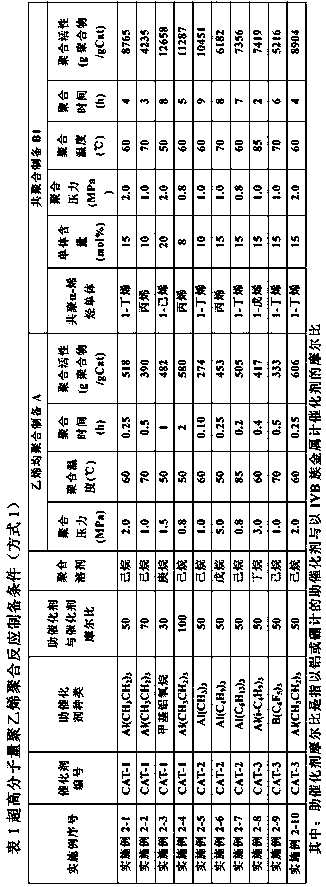

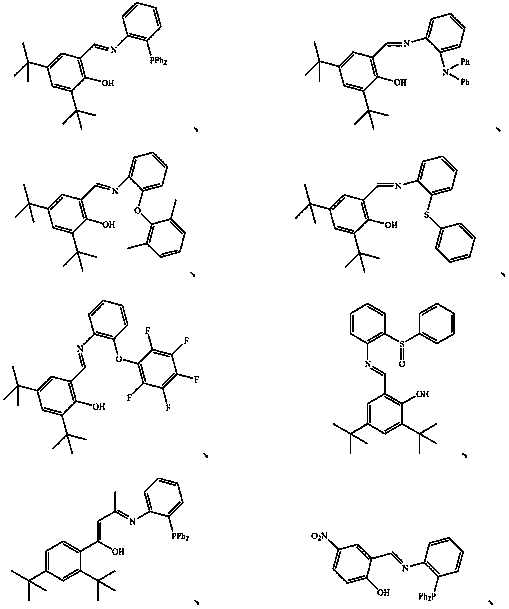

Ultra-high molecular weight polyethylene, production method and applications

ActiveCN107936161AUnit content is adjustable and controllableParticles in good shapePolymer sciencePolymer chemistry

The invention relates to copolymerized ultra-high molecular weight polyethylene, a production method and applications. Compared to the homopolymerized ultra-high molecular weight polyethylene in the prior, the copolymerized ultra-high molecular weight polyethylene of the present invention has the significantly-improved processability, and further has improved wear resistance and improved impact strength.

Owner:SINOPEC YANGZI PETROCHEM +1

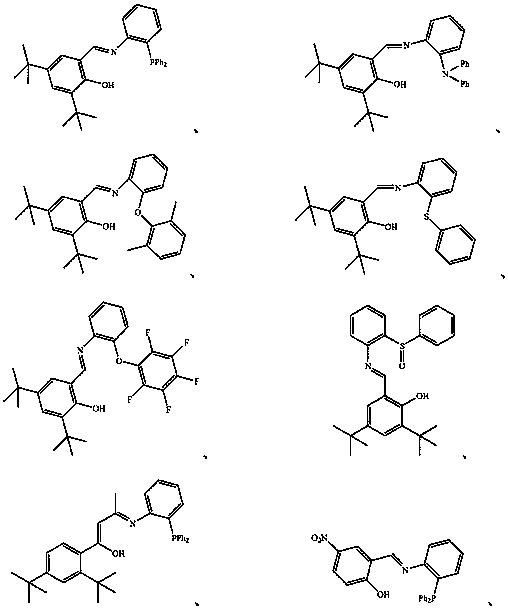

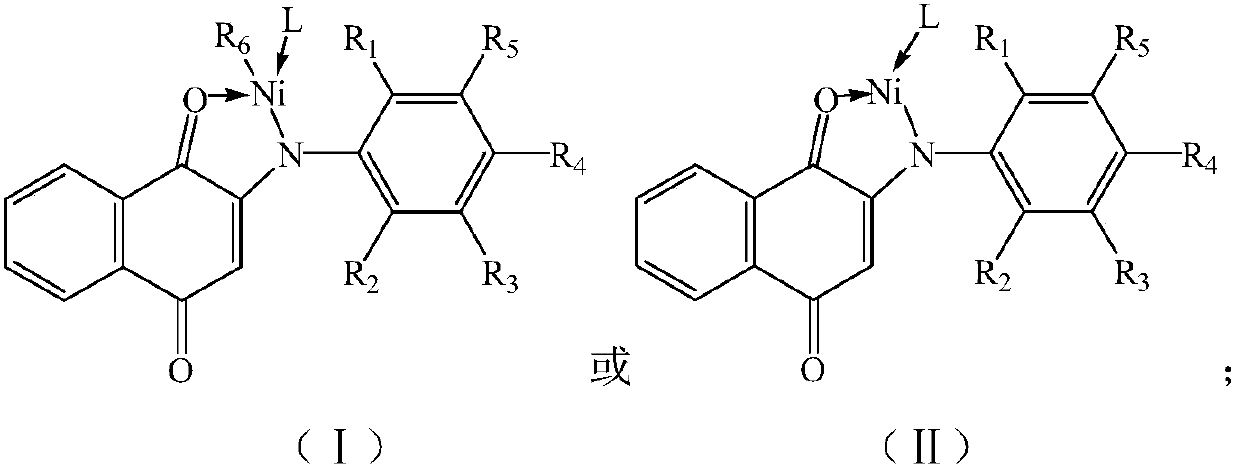

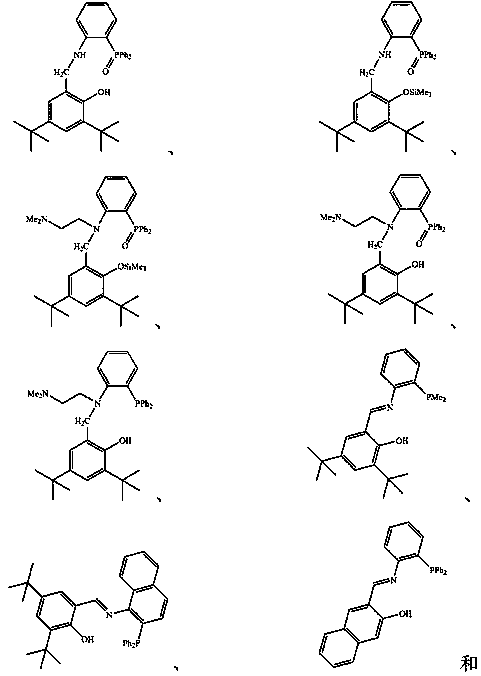

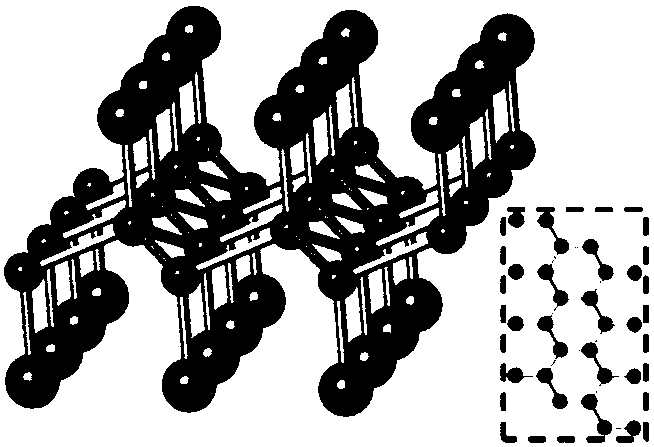

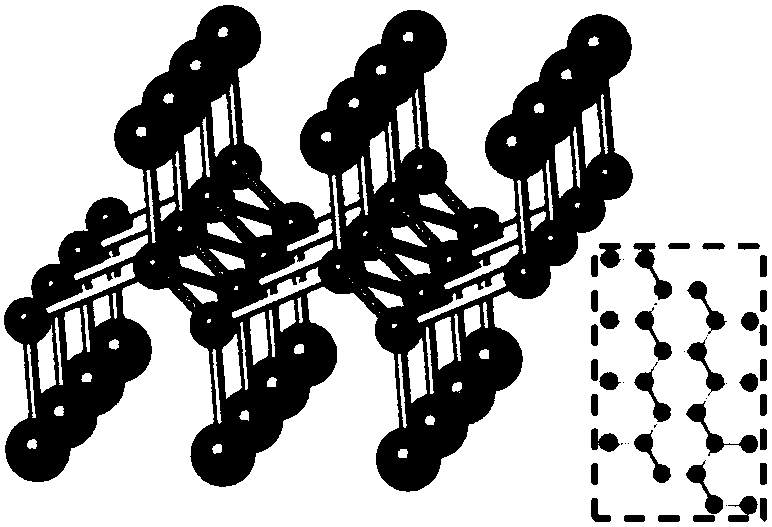

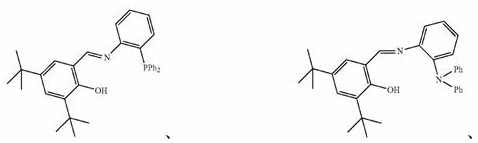

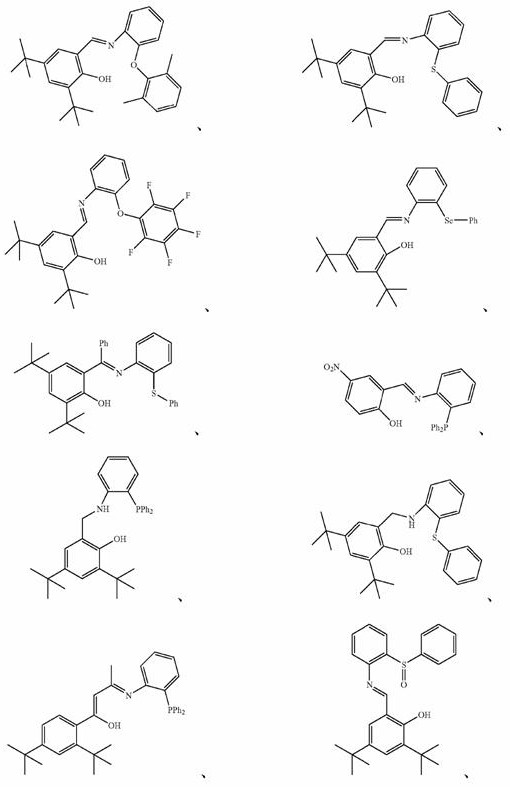

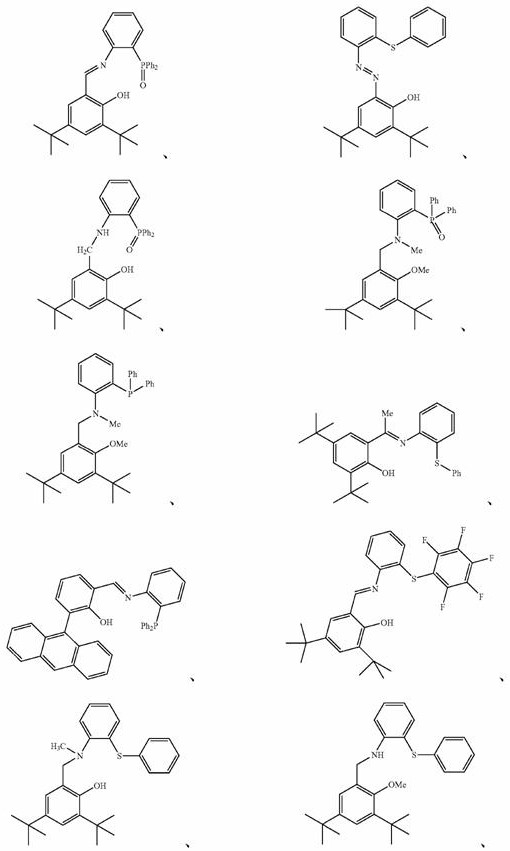

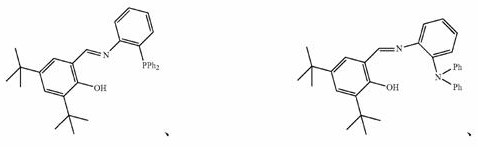

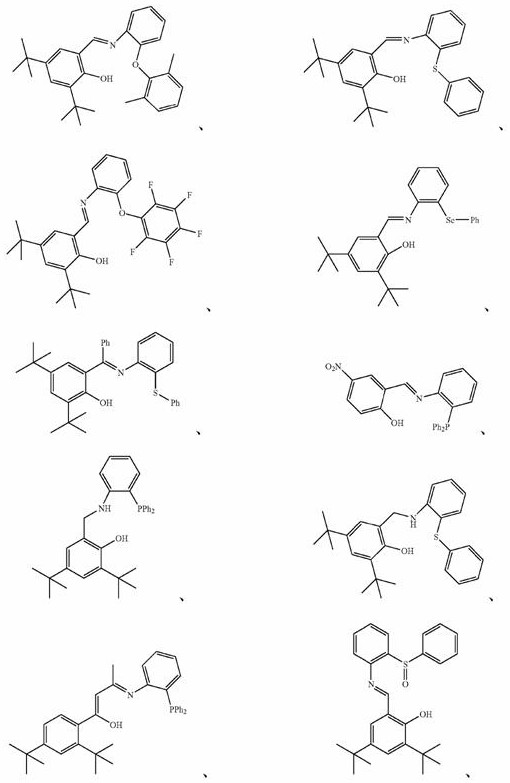

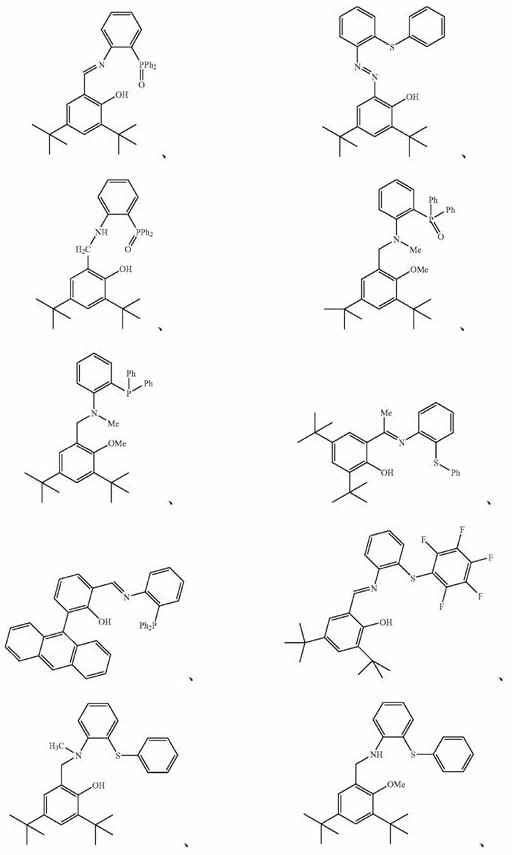

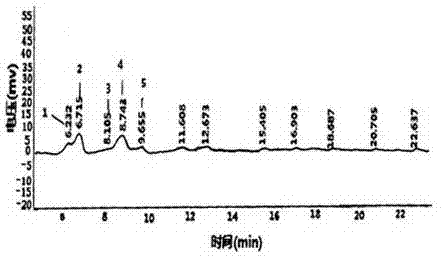

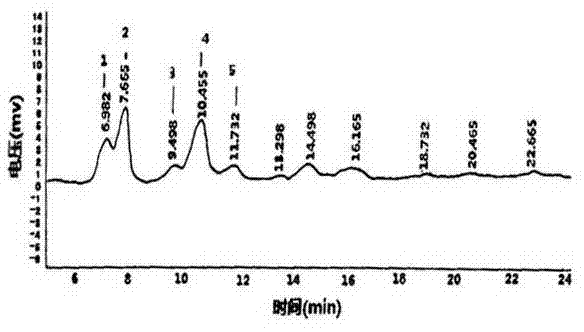

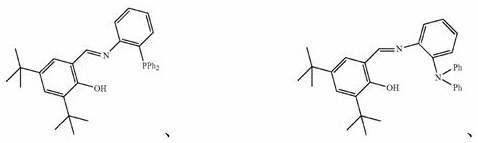

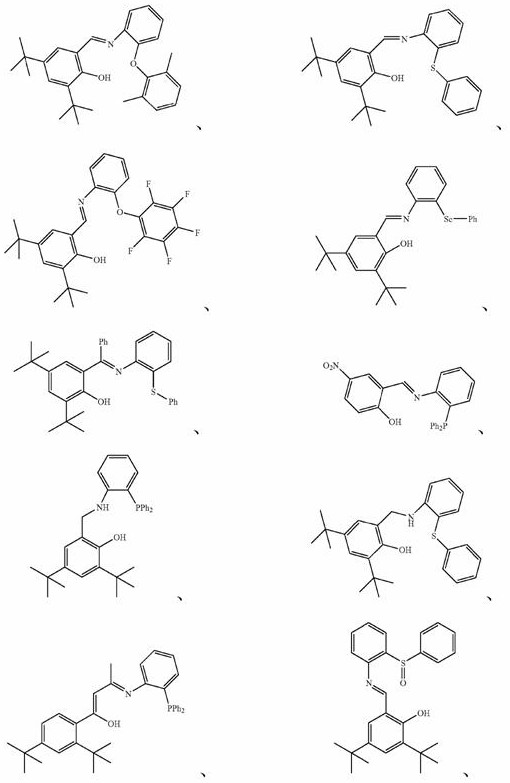

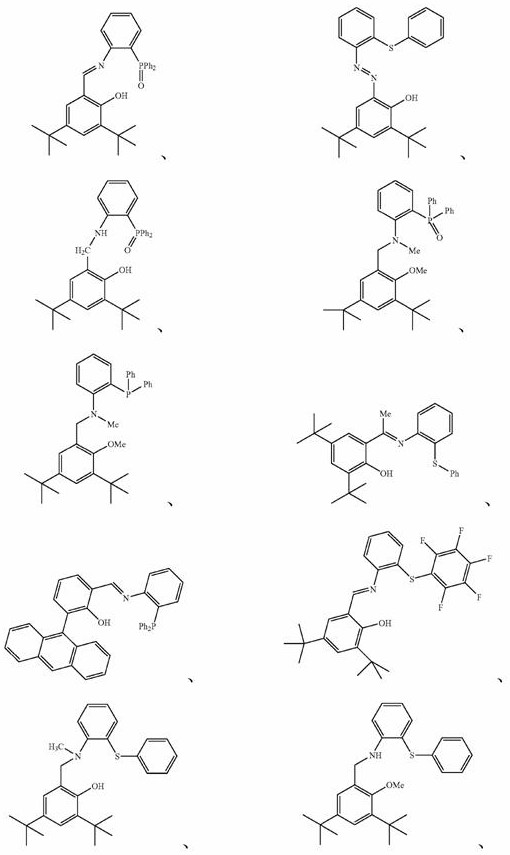

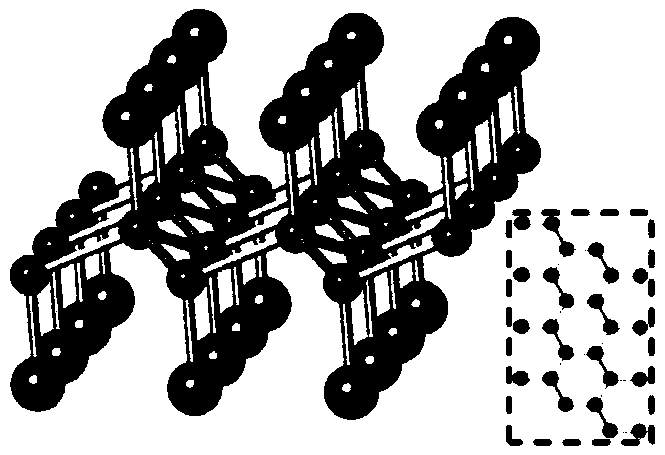

Heterogeneous polymerization reaction catalyst and application of heterogeneous polymerization reaction catalyst to preparing homopolymer and copolymer

The invention relates to a heterogeneous polymerization reaction catalyst and application of the heterogeneous polymerization reaction catalyst to preparing a homopolymer and a copolymer. The heterogeneous polymerization reaction catalyst mainly comprises a supported catalyst promoter A and a catalyst B, the structure of the catalyst B is shown in the formula (I) or the formula (II), R1-R5 are respectively independently chosen from hydrogen, alkyl group, substituendum of the alkyl group, alkoxy group, alkyl sulphanyl, halogen, nitryl, aryl group or substituendum of the aryl group in the formula, the adjacent groups in the R1-R5 form a ring and the number of the formed ring structures is less than 4, R6 is the alkyl group or the aryl group, and L is alkyl group substituted phosphine or allyl. The heterogeneous polymerization reaction catalyst can be used to prepare the homopolymer and the copolymer, the activity is relatively high, the tolerance of the polar functional group is relatively good, the molecular weight of the prepared polymer is relatively large, the distribution of the molecular weight is relatively narrow, the morphology is controllable, no subsequent processing is needed, and the phenomenon of adhesion on a kettle is effectively improved.

Owner:DONGHUA UNIV

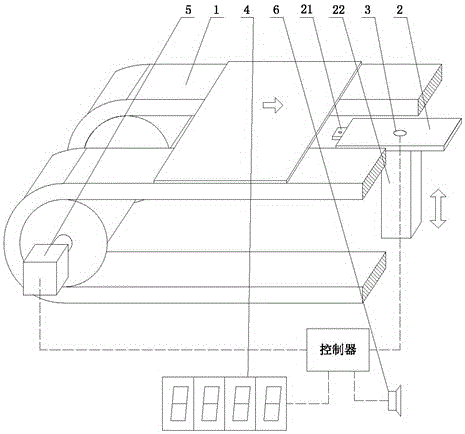

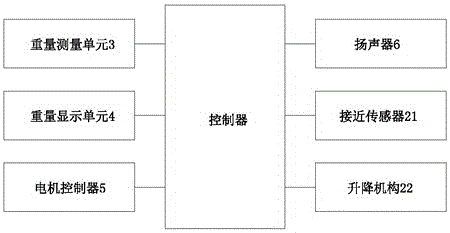

Battery piece bonding detection method

The invention discloses a battery piece bonding detection method. The weight of a battery piece on a conveying belt is detected to judge if the weight is in a specification range of single battery piece to judge piece break and bad piece bonding so as to prevent defective products from entering subsequent stations. The battery piece bonding detection method has such advantages as reasonable structure and convenience for control. A traditional conveying belt is improved to realize the bonding detection of the battery piece and to timely remind operators to prevent the bad bonding piece from entering the subsequent procedures so as to cause bad consequences of production line blockage or piece break. The battery piece bonding detection method can preferably improve the battery piece bonding phenomenon in a traditional process, and is excellent in practical value.

Owner:武汉中导光电设备有限公司

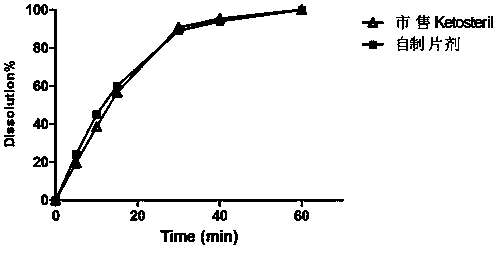

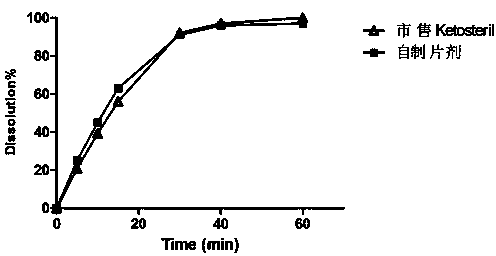

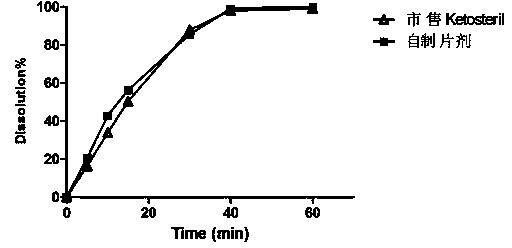

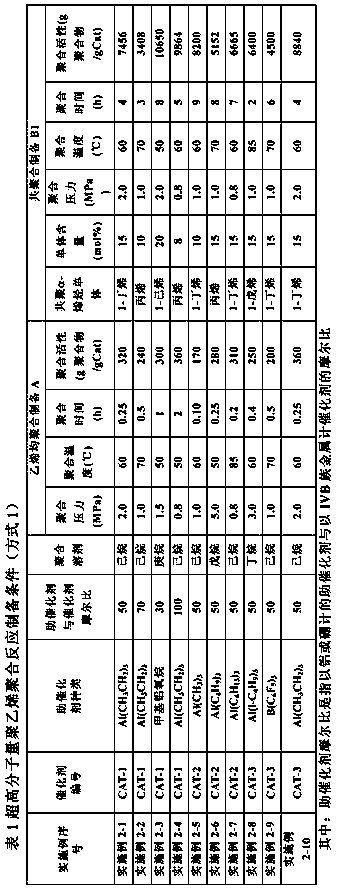

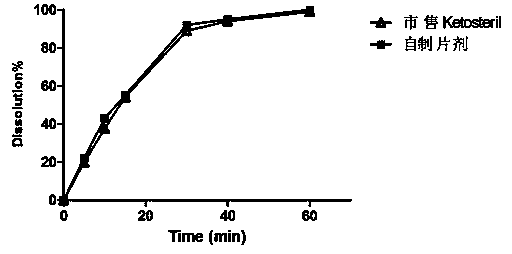

Compound alpha-ketoacid tablet and preparation method thereof

ActiveCN103463014AImprove liquidityAvoid clumpingPharmaceutical non-active ingredientsUrinary disorderPolyethylene glycolDissolution

The invention relates to a compound alpha-ketoacid tablet free from talcum powder and a preparation method of the tablet. The tablet prepared by using the preparation method is good in compressibility, beautiful in appearance, high in disintegration speed, high in dissolution rate and high in long storage stability. According to the preparation method provided by the invention, a dry granulation method is used, all the ingredients are prevented from contacting water or other wetting agent, and therefore, the tablet can be stably stored for long time, and the content of effective ingredient is ensured. The content of the polyethylene glycol in the prescription is optimized, the talcum powder or the analogue with composition similar with that of the talcum powder are not contained in the prescription, no disintegrating agent needs to be added, the problems of clustering phenomenon and quite large viscidity in a wet granulation process in the traditional production are solved, the medication safety is ensured, and the product can be stably produced with quality and high safety.

Owner:SHENYANG PHARMA UNIVERSITY +1

Ultra-high molecular weight polyethylene, production method and applications

ActiveCN107936162AUnit content is adjustable and controllableParticles in good shapePolymer scienceWear resistance

The invention relates to copolymerized ultra-high molecular weight polyethylene, a production method and applications. Compared to the homopolymerized ultra-high molecular weight polyethylene in the prior, the copolymerized ultra-high molecular weight polyethylene of the present invention has the significantly-improved processability, and further has improved wear resistance and improved impact strength.

Owner:SINOPEC YANGZI PETROCHEM +1

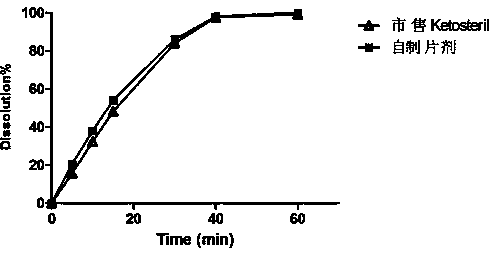

Compound alpha-ketoacid tablet free of talcum powder and preparation process thereof

ActiveCN103520156AGuaranteed stabilityGuaranteed contentMetabolism disorderUrinary disorderPolyethylene glycolDissolution

The invention relates to a compound alpha-ketoacid tablet free of talcum powder and a preparation process thereof. The conventional preparation process is changed without adding the talcum powder; the tablet prepared by the method has good compressibility, attractive appearance, high disintegrating speed, high dissolution rate, high stability in long-term placement and high medicinal safety. Wet granulation is performed separately according to the acidic and alkaline ingredients and the mass balance ratio of main medicines, i.e., a meta-alkaline ingredient, a meta-acidic ingredient and a nearly neutral ingredient are subjected to wet granulation separately, and then mixing, tabletting and coating are performed, so that the direct contact among the ingredients is avoided, long-term stable placement can be realized and the contents of the active ingredients are guaranteed. A disintegrating agent internal and external addition method is adopted in the formula, the content of polyethylene glycol is optimized, and no talcum powder or analogs with ingredients similar to the talcum powder are included in the formula, so that the problems of agglomeration phenomenon and larger viscosity in the granulation process are solved, and the safety in medication is guaranteed.

Owner:SHENYANG PHARMA UNIVERSITY +1

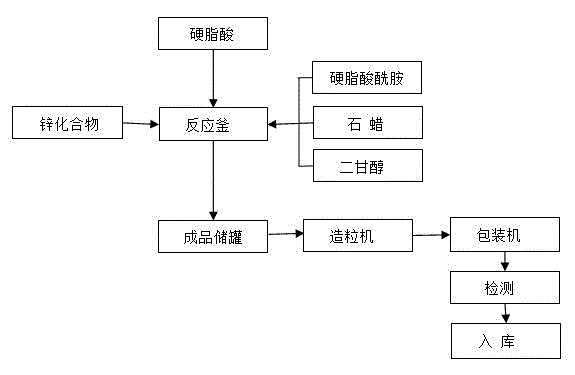

Aliphatic acid zinc soap rubberlike internal releasing agent

The invention discloses an aliphatic acid zinc soap rubberlike internal releasing agent. Raw materials of the aliphatic acid zinc soap rubberlike internal releasing agent comprise, by mass, 450-650 kg of stearic acid, 25-40 kg of zinc compounds, 350-450 kg of octadecanamide, 90-100 kg of paraffin and 5-15 kg of DiethyleneGlycol; a preparation method of the aliphatic acid zinc soap rubberlike internal releasing agent comprises the steps that 1 the stearic acid is put, quantitative stearic acid is put in a reaction still and heated and stirred; 2 the zinc compounds are put; 3 the octadecanamide, the paraffin and the DiethyleneGlycol are put in sequence; 4 product prilling is conducted; 5 a product is packed. According to the aliphatic acid zinc soap rubberlike internal releasing agent, an internal lubrication function is obtained, the viscosity of a rubber material can be reduced, the flowing property of the rubber material can be improved, the force of friction between the rubber material and the surface of a metal when contacts can also be lowered, and sliding between the rubber material and the metal is improved; accordingly, the demoulding property of a finished product is improved, and the demoulding effect on a complex mould is particularly good.

Owner:ZHEJIANG WEIXIANG TECH GRP CO LTD

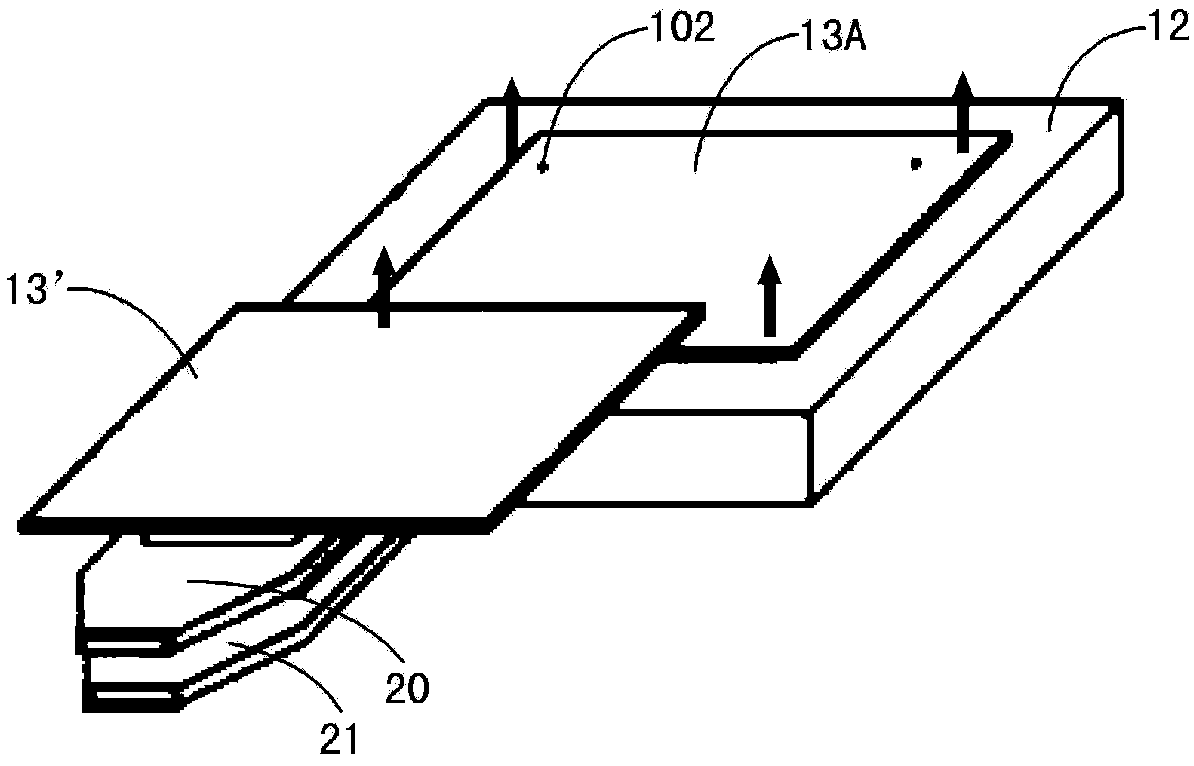

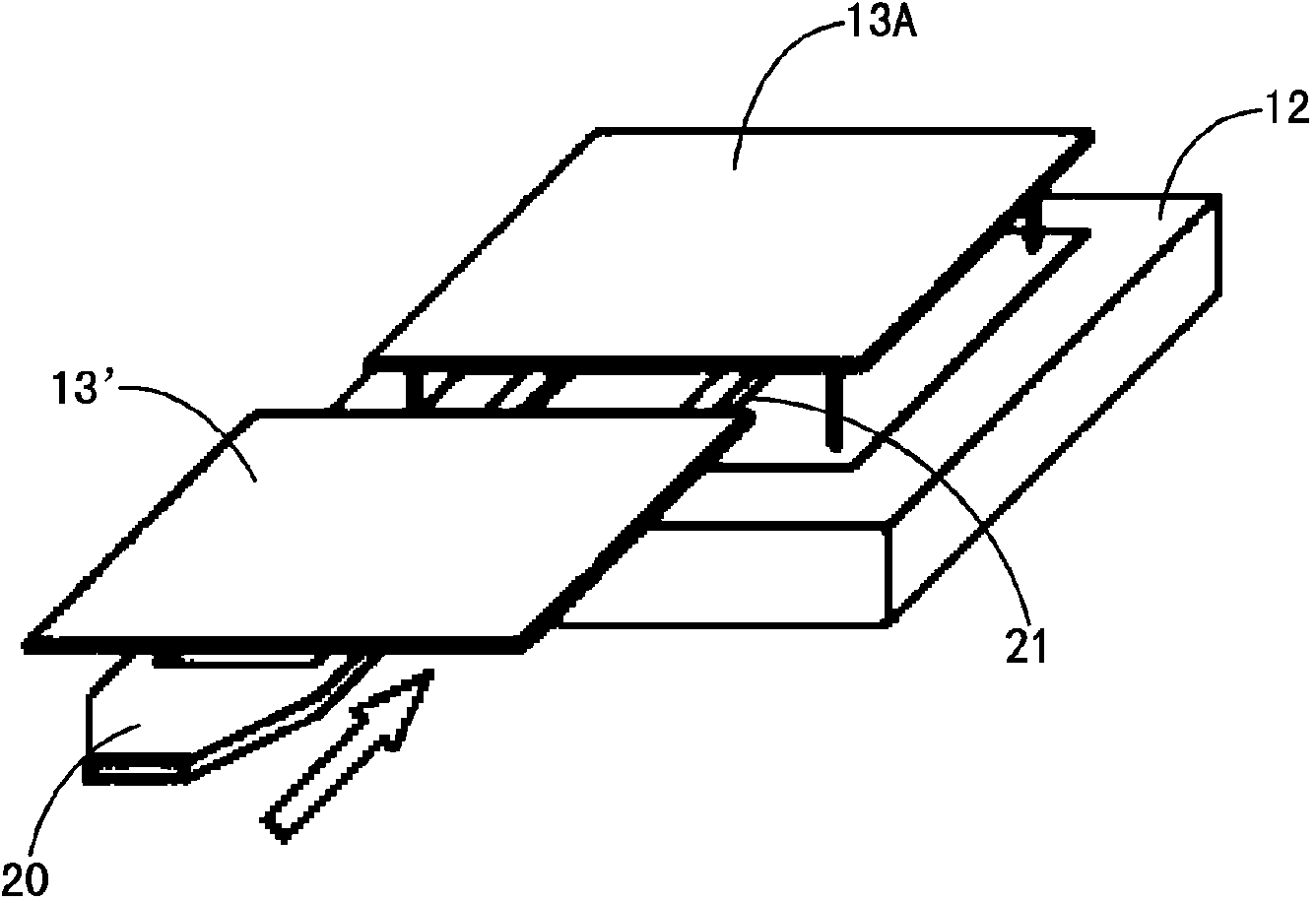

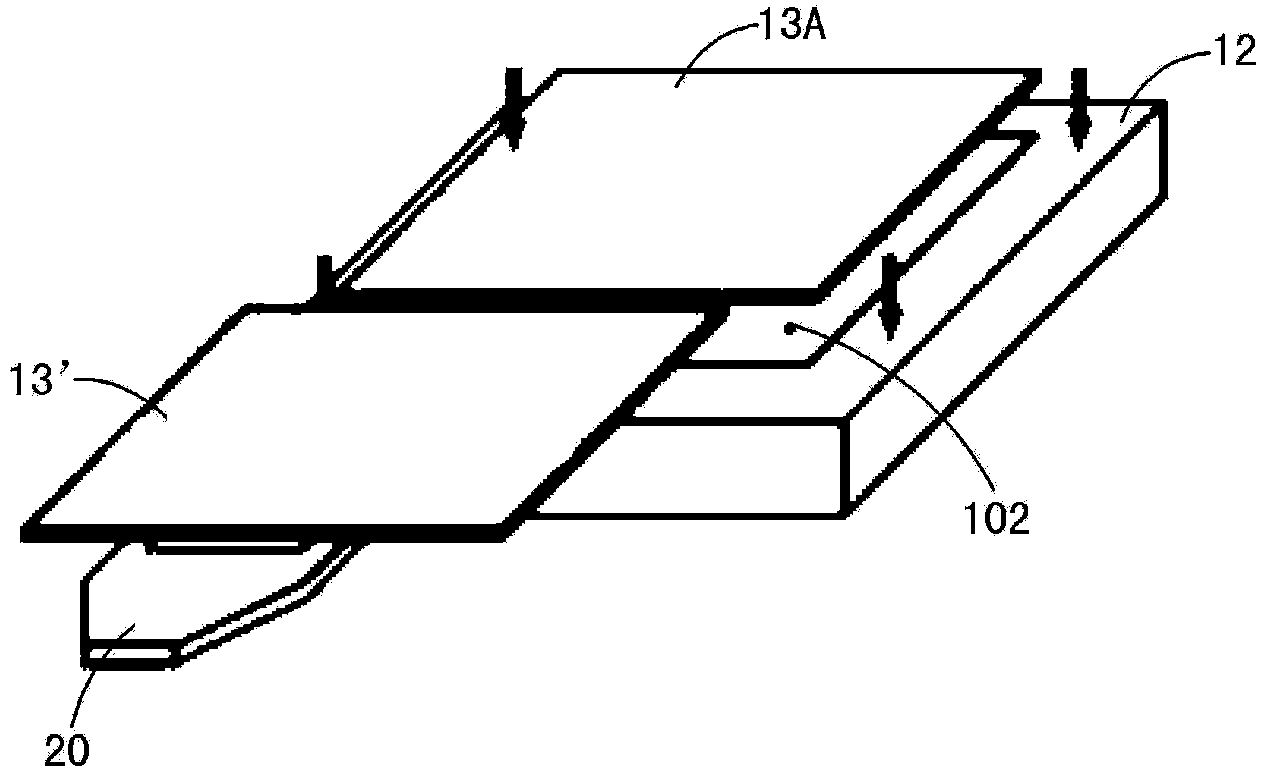

Dry etching machine and lower electrode of dry etching machine

InactiveCN103903953AAvoid breakingImprove sticking phenomenonElectric discharge tubesChinese charactersOptoelectronics

The invention relates to a dry etching machine and a lower electrode of the dry etching machine. The dry etching machine is used for conducting dry etching treatment on a substrate. The dry etching machine comprises an upper electrode and the lower electrode which is arranged opposite to the upper electrode. A plurality of salient points are formed on the upper surface used for bearing the substrate of the lower electrode, the salient points are arranged around the upper surface of the lower electrode, or the salient points are arranged on the upper surface of the lower electrode in a crossed shape or in a shape like a Chinese character 'tian'. By means of the dry etching machine and the lower electrode of the dry etching machine, the substrate sticking phenomenon can be avoided, cooling can be effectively achieved, meanwhile, salient point ripples are avoided, and therefore the percent of pass of products is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

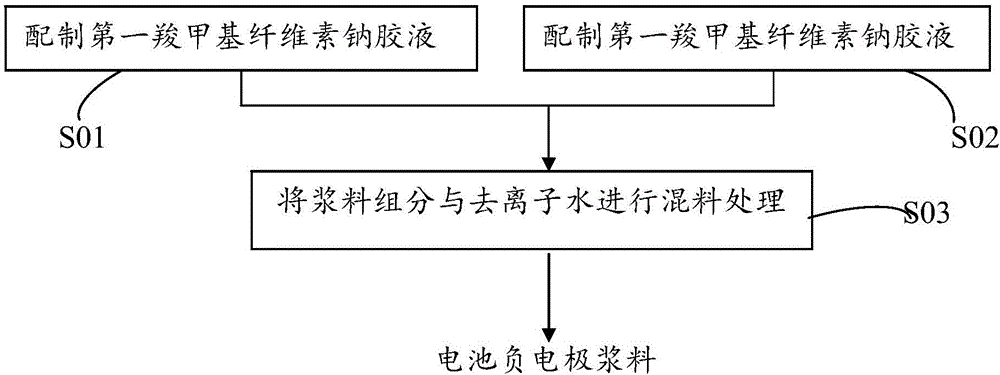

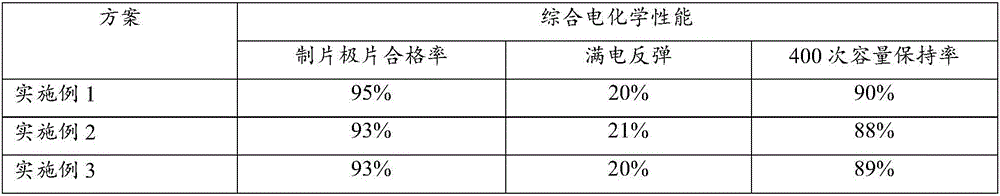

Battery negative electrode, preparation method thereof and lithium ion battery

InactiveCN106129417AImprove electrochemical performanceImprove thickness uniformityCell electrodesSecondary cellsAdhesiveMass ratio

The invention provides a battery negative electrode, a preparation method thereof and a lithium ion battery. The battery negative electrode comprises a current collector and a negative electrode active material layer arranged on the surface of the current collector in a coating manner, wherein the negative electrode active material layer comprises negative electrode active materials, conductive agents and an adhesive; the adhesive contains aqueous adhesives, first sodium carboxymethylcellulose and second sodium carboxymethylcellulose; the degree of substitution of first sodium carboxymethylcellulose is 0.95-1.0; the degree of substitution of second sodium carboxymethylcellulose is 0.8-0.85; the mass ratio of first sodium carboxymethylcellulose to second sodium carboxymethylcellulose is (0.5-0.75) to (0.5-0.75). The battery negative electrode has good active layer thickness uniformity, thus endowing the battery negative electrode with excellent comprehensive electrochemical properties.

Owner:JIAN UTILITY TECH CO LTD

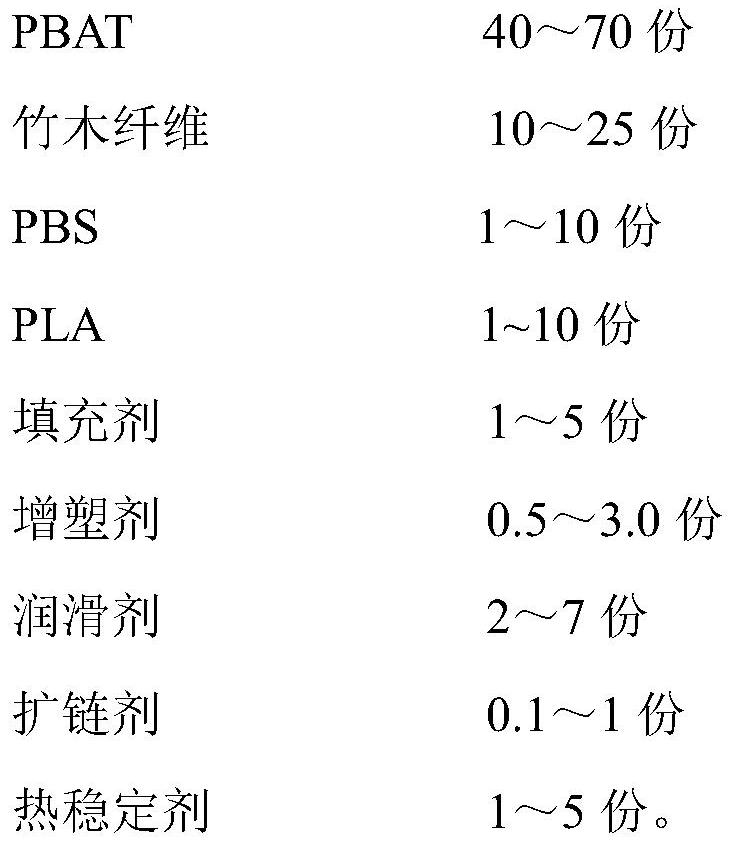

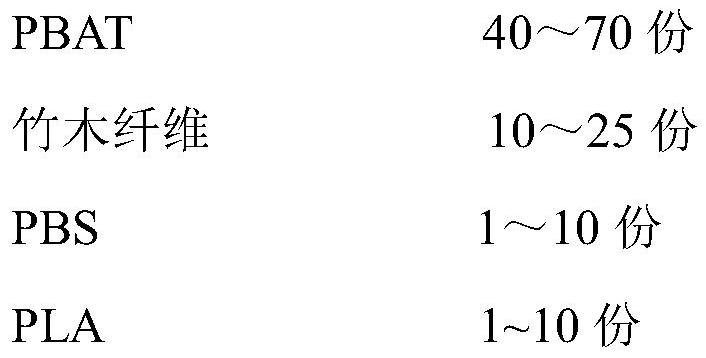

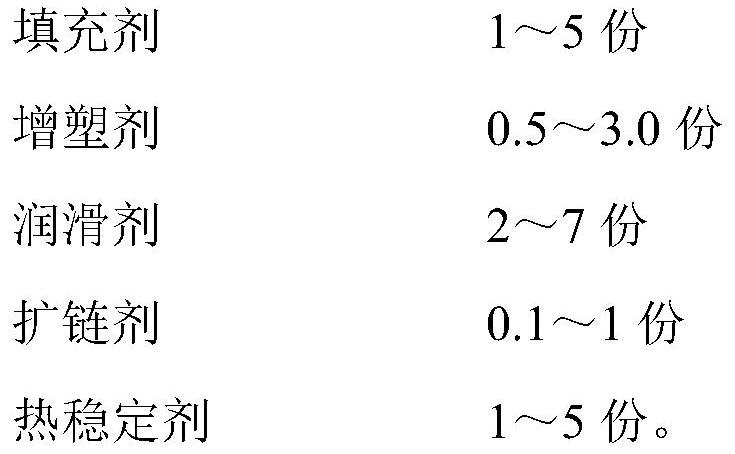

Novel composite degradable plastic material for injection molding and preparation method thereof

The invention belongs to the technical field of biodegradable materials, and particularly relates to a novel composite degradable plastic material for injection molding and a preparation method thereof. The novel composite degradable plastic material for injection molding is prepared from the following components in parts by weight: 40-70 parts of PBAT, 10-25 parts of bamboo and wood fibers, 1-10 parts of PBS, 1-10 parts of PLA, 1-5 parts of a filler, 0.5-3.0 parts of a plasticizer, 2-7 parts of a lubricant, 0.1-1 part of a chain extender and 1-5 parts of an antioxidant. The novel composite degradable plastic material for injection molding is good in biodegradability, low in raw material cost, high in percent of pass and high in production efficiency; and the invention also provides a preparation method of the novel composite degradable plastic material.

Owner:SHANDONG RUIFENG CHEM

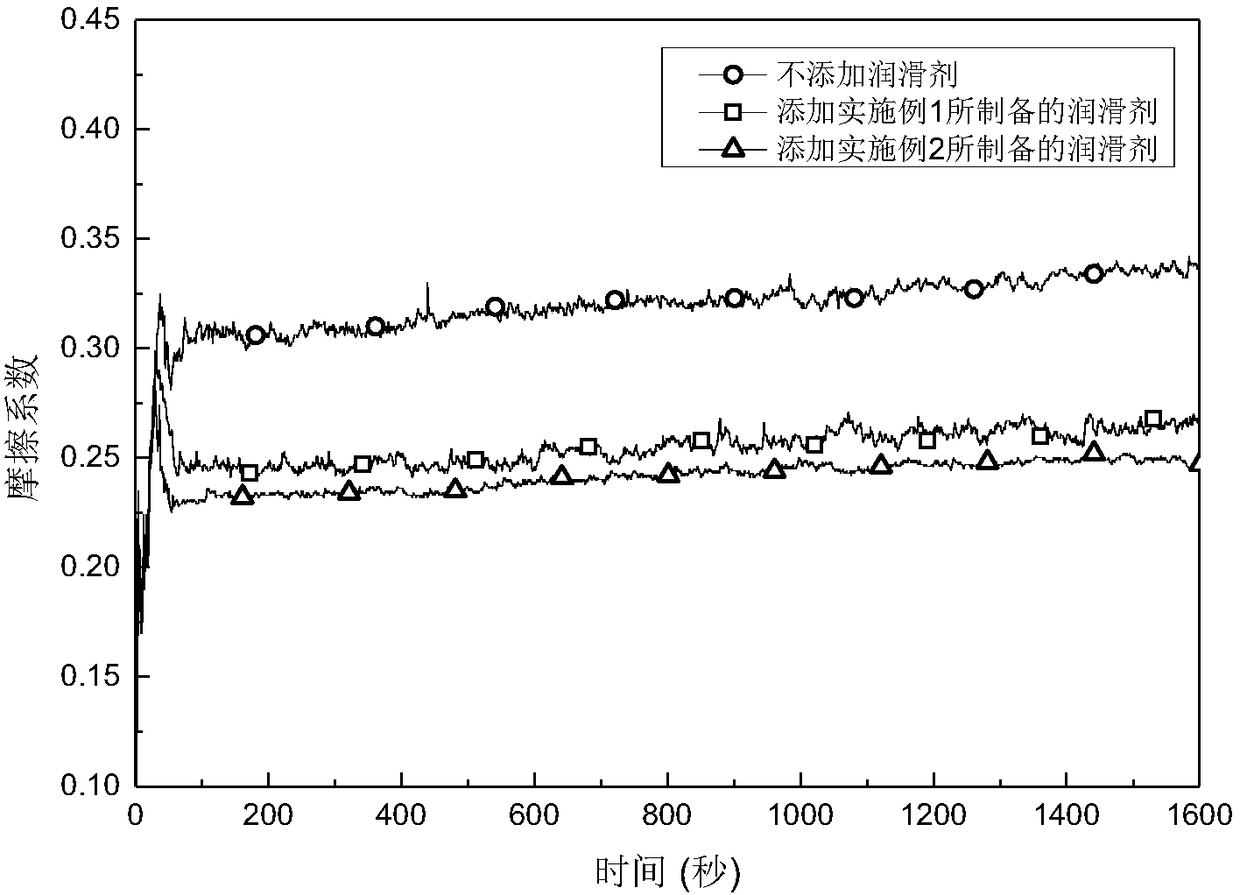

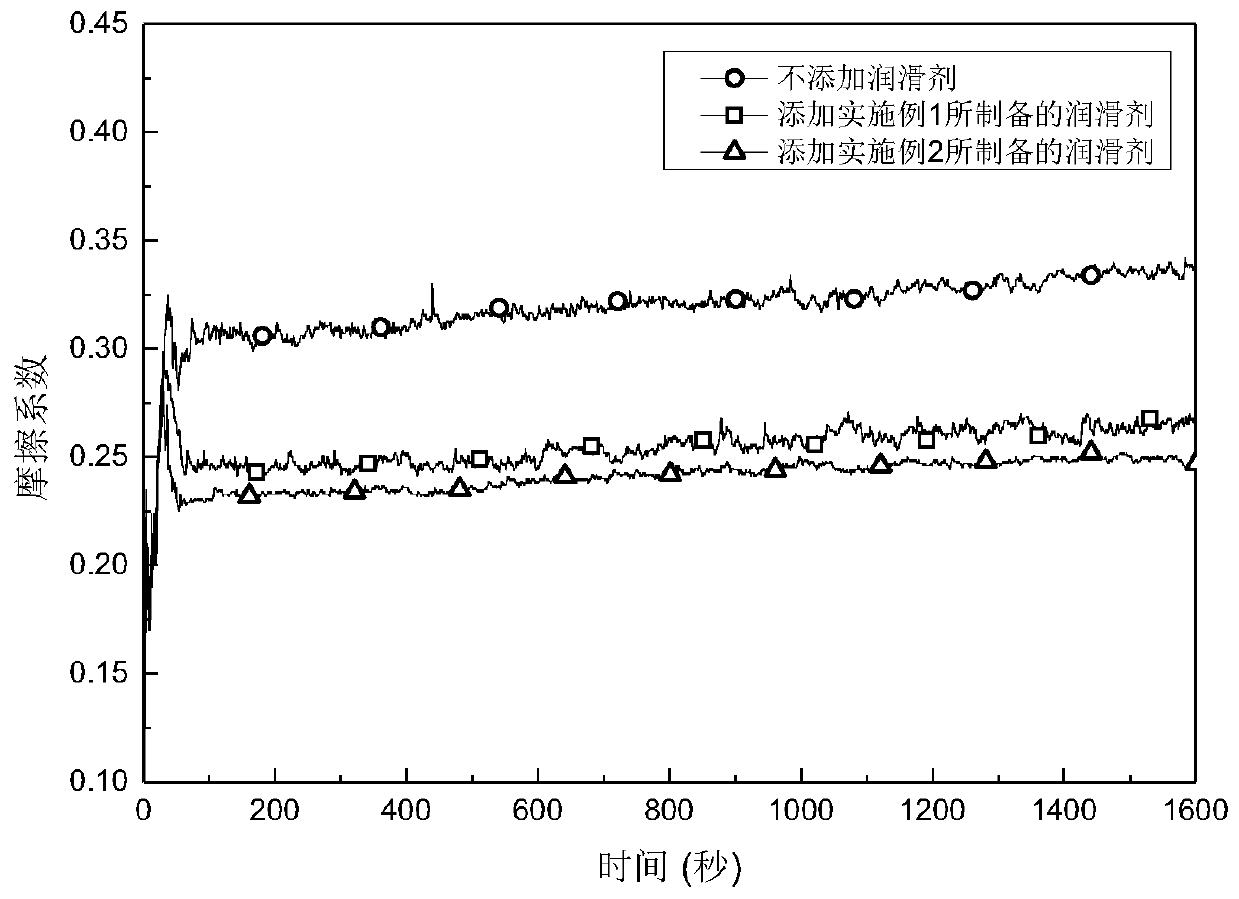

Rolling lubricant for titanium and titanium alloy plate strips

ActiveCN108277075AReduce energy consumptionImprove sticking phenomenonLubricant compositionHalogenTemperature resistance

The invention belongs to the technical field of rolling lubrication and in particular relates to a rolling lubricant for titanium and titanium alloy plate strips. The lubricant is composed of the following substances in percentage by mass: 70.0-75.0% of engine oil, 5.0-10.0% of beef tallow, 2.0-4.0% of a compound emulsifier, 0.05-0.1% of fluorinated graphene, 0.1-0.5% of an antioxidant, 0.5-1.0% of an oiliness agent, 0.01-0.05% of an antifoaming agent, 0.5-1.0% of an extreme pressure agent, 0.5-1.5% of an anti-rust agent and the balance of water. The lubricant disclosed by the invention is prepared by applying a nanometer technology the lubricant on the basis of the traditional rolling lubricant and combining the characteristic that halogen elements can form layered structural compounds with titanium. The lubricant has the characteristics of low energy consumption and high temperature resistance, the roll banding phenomenon in the processing flow is improved, the service life of a roller is prolonged, and the plate quality is improved.

Owner:UNIV OF SCI & TECH BEIJING

Application of chromeplate stamp die in process of preparing clopidogrel hydrogen sulfate tablets

InactiveCN102398378AImprove sticking phenomenonOrganic active ingredientsPill deliveryChemistryClopidogrel hydrogen sulfate

The invention relates to a stamp die of a tablet press which improves the sticking problem in the process of preparing clopidogrel hydrogen sulfate tablets, in particular to a chromeplate stamp die of a tablet press which is able to improve the sticking problem in the process of preparing clopidogrel hydrogen sulfate tablets greatly.

Owner:北京华禧联合科技发展有限公司

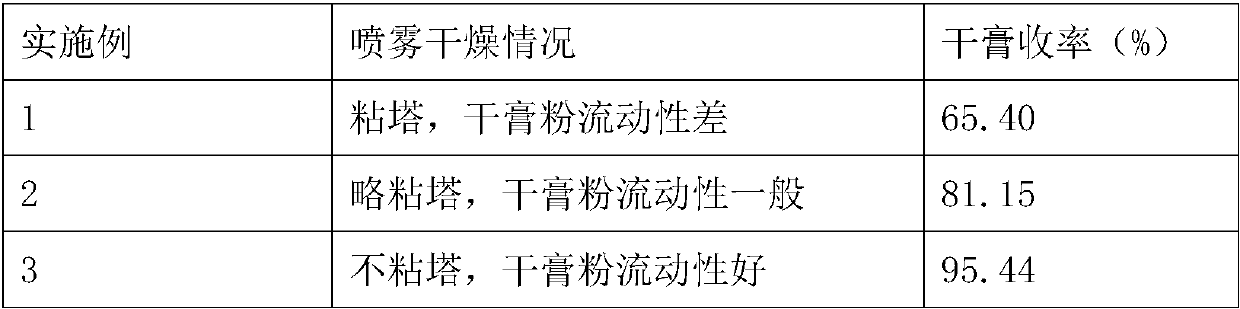

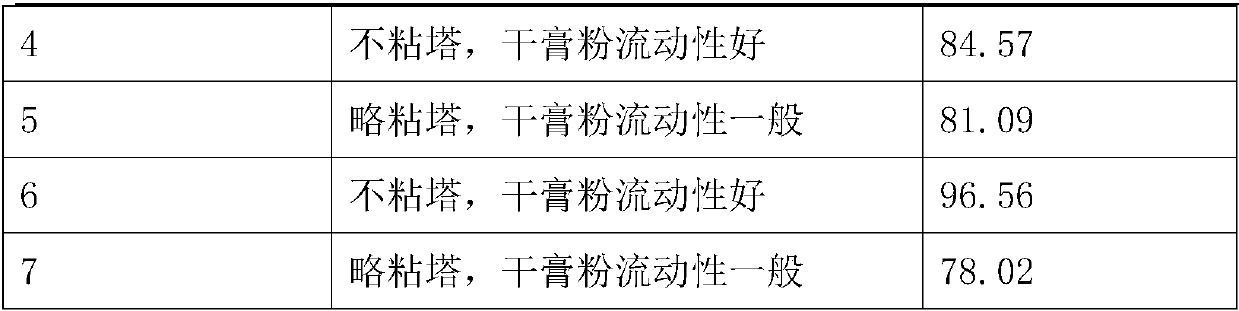

Spray drying method for Chinese traditional medicine formula granules

InactiveCN110448588AImprove wall sticking phenomenonHigh yieldPowder deliveryMacromolecular non-active ingredientsMaterial consumptionChinese traditional medicine

The invention relates to the technical field of production of Chinese traditional medicine formula granules, in particular to an improved spray drying process for the Chinese traditional medicine formula granules. By adopting the spray drying method, especially using specific auxiliary materials, the use number of the auxiliary materials in the formula granules can be controlled to be in the minimum range, the dosage of a patient is reduced, the wall attachment phenomenon in the spray drying process can also be greatly avoided, and material consumption in the spray drying process is reduced, which is quite beneficial for industrial production.

Owner:BEIJING INCREASEPHARM CORP LTD

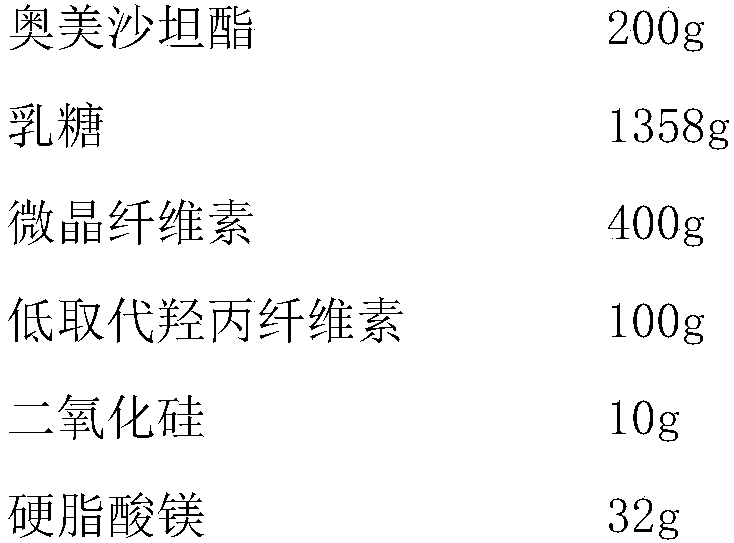

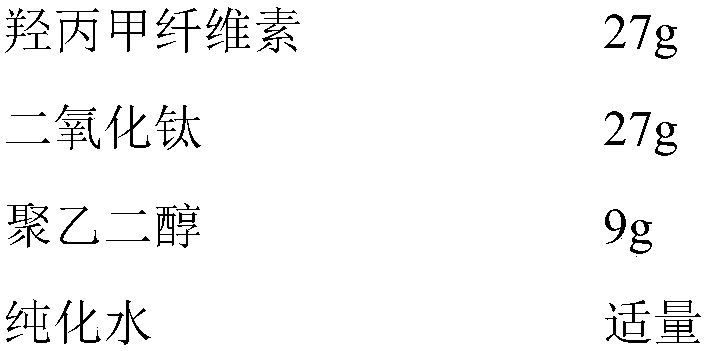

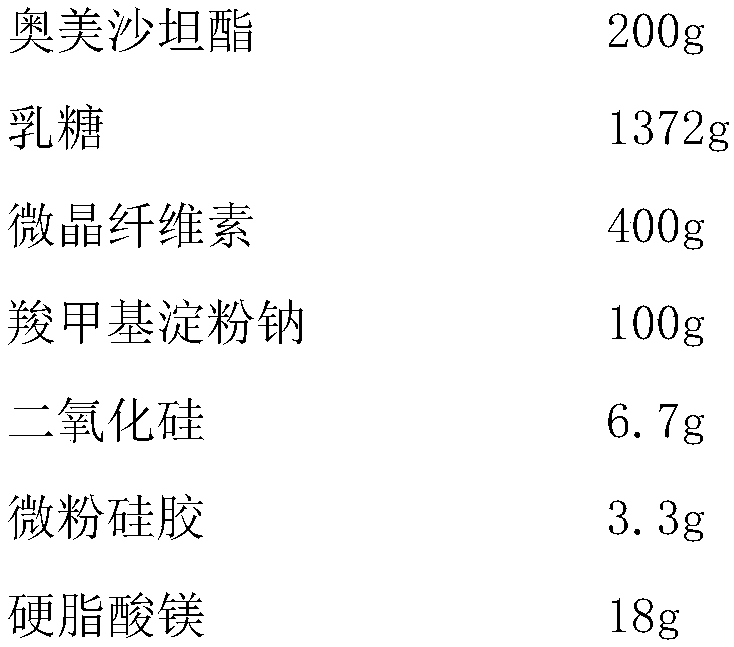

A kind of tablet containing olmesartan medoxomil and preparation method thereof

ActiveCN107998097BFast dissolution rate in vitroImprove in vitro dissolutionOrganic active ingredientsPharmaceutical non-active ingredientsOlmesartanPolyethylene glycol

The invention discloses a tablet containing olmesartan medoxomil and a preparation method of the tablet. The tablet is composed of olmesartan medoxomil, a disintegrating agent, a filling agent, a diluent, an anti-sticking agent and a lubricating agent. The preparation method disclosed by the invention comprises the following steps: performing jet milling treatment on olmesartan medoxomil, and mixing with the anti-sticking agent to pass through a 30-mesh sieve; mixing with other medicinal auxiliary materials, and directly tabletting; performing film coating on the tablet core after tabletting,wherein the film coating premixed agent is composed of the following materials: hydroxypropyl methylcellulose, titanium dioxide and polyethylene glycol. The olmesartan medoxomil tablet provided by theinvention is high in in-vitro dissolution rate, high in bioavailability, excellent in stability and mechanical strength, less in odor, sticking-free and suitable for large-scale mass production.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Novel MY-R soft PVC gravure ink and preparation method thereof

The invention discloses novel MY-R soft PVC gravure ink and a preparation method, and relates to the technical field of gravure ink, and the novel MYR soft PVC gravure ink is prepared by the following steps: weighing 50% of a binder, 38% of a pigment, 2% of a filler, 4% of a diluent, 1% of an anti-skinning agent, 1% of an anti-reverse printing agent, 2.2% of a slipping agent, 0.3% of a drying agent, 0.2% of a pH regulator, 0.3% of a dispersing agent, 0.3% of a catalyst, 0.2% of a surfactant, 0.2% of a defoamer, and 0.3% of a levelling agent; pouring the weighed binder into a reaction container, sequentially adding the filler, the anti-skinning agent, the anti-reverse printing agent, the slipping agent, the drying agent, the pH regulator, the dispersing agent, the catalyst and the surfactant, conducting reacting for 2-2.5 hours at the temperature of 20-25 DEG C, adding the defoamer and the leveling agent, and continuously conducting stirring for 15-20 minutes; and adding the pigment at the temperature of 20-25 DEG C, continuously conducting stirring for 20-25 minutes, adding the diluent, conducting stirring for 5-10 minutes, and collecting the material. The printing ink is not easy to block, good in adhesive force to a base material, free of after-tack, few in bubbles in the using process, high in bonding strength and simple in preparation method.

Owner:东莞市万润涂料有限公司

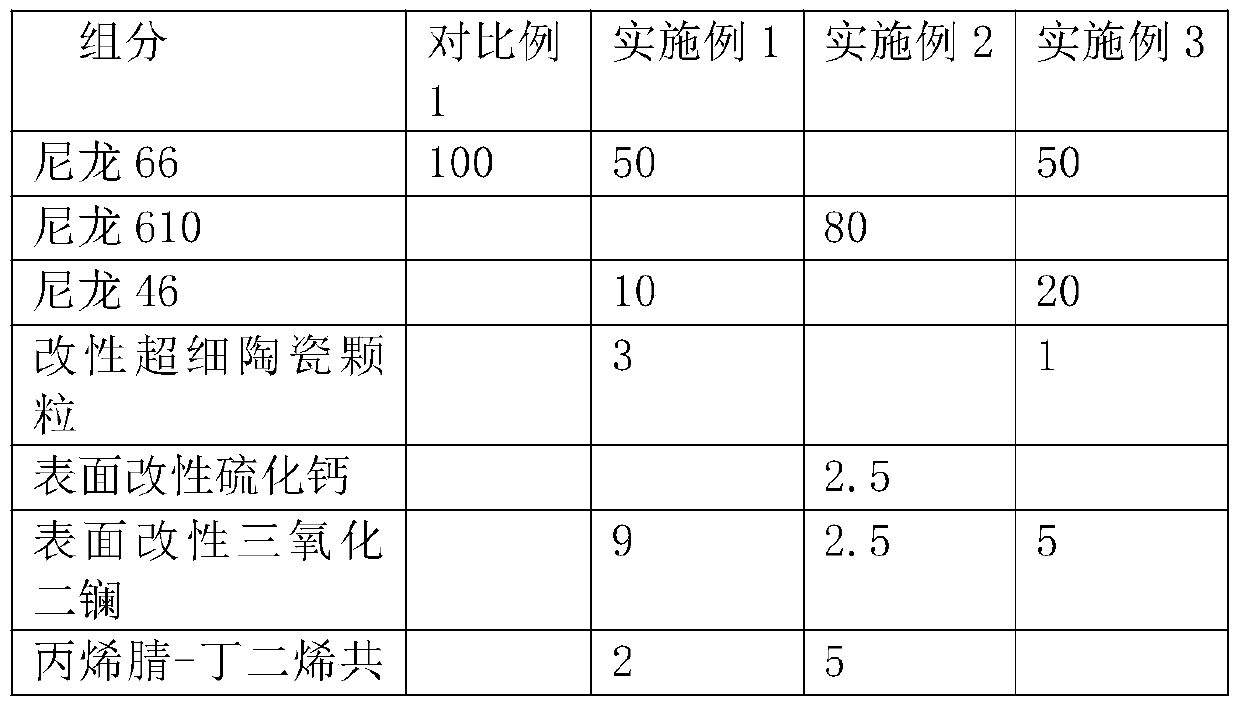

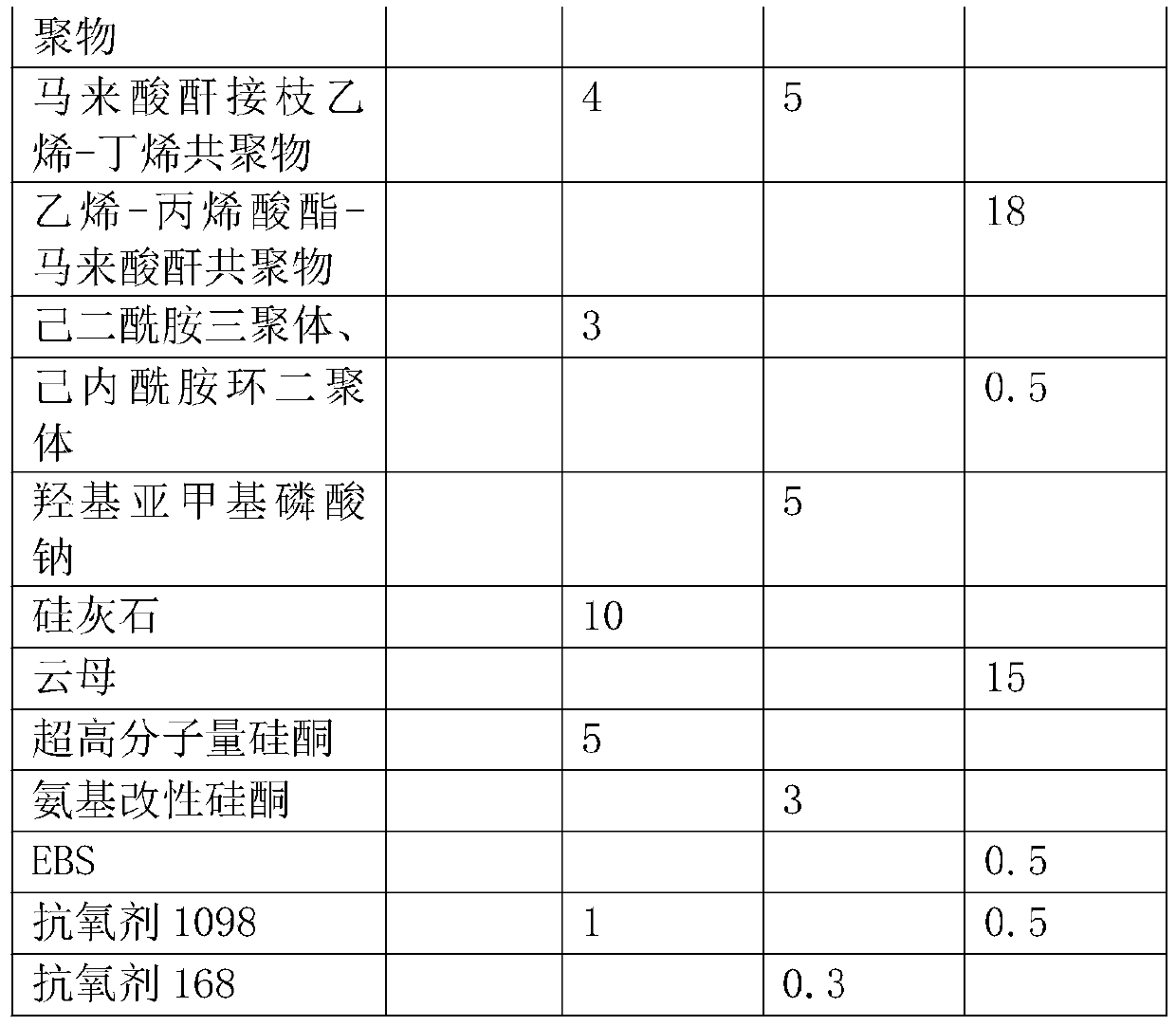

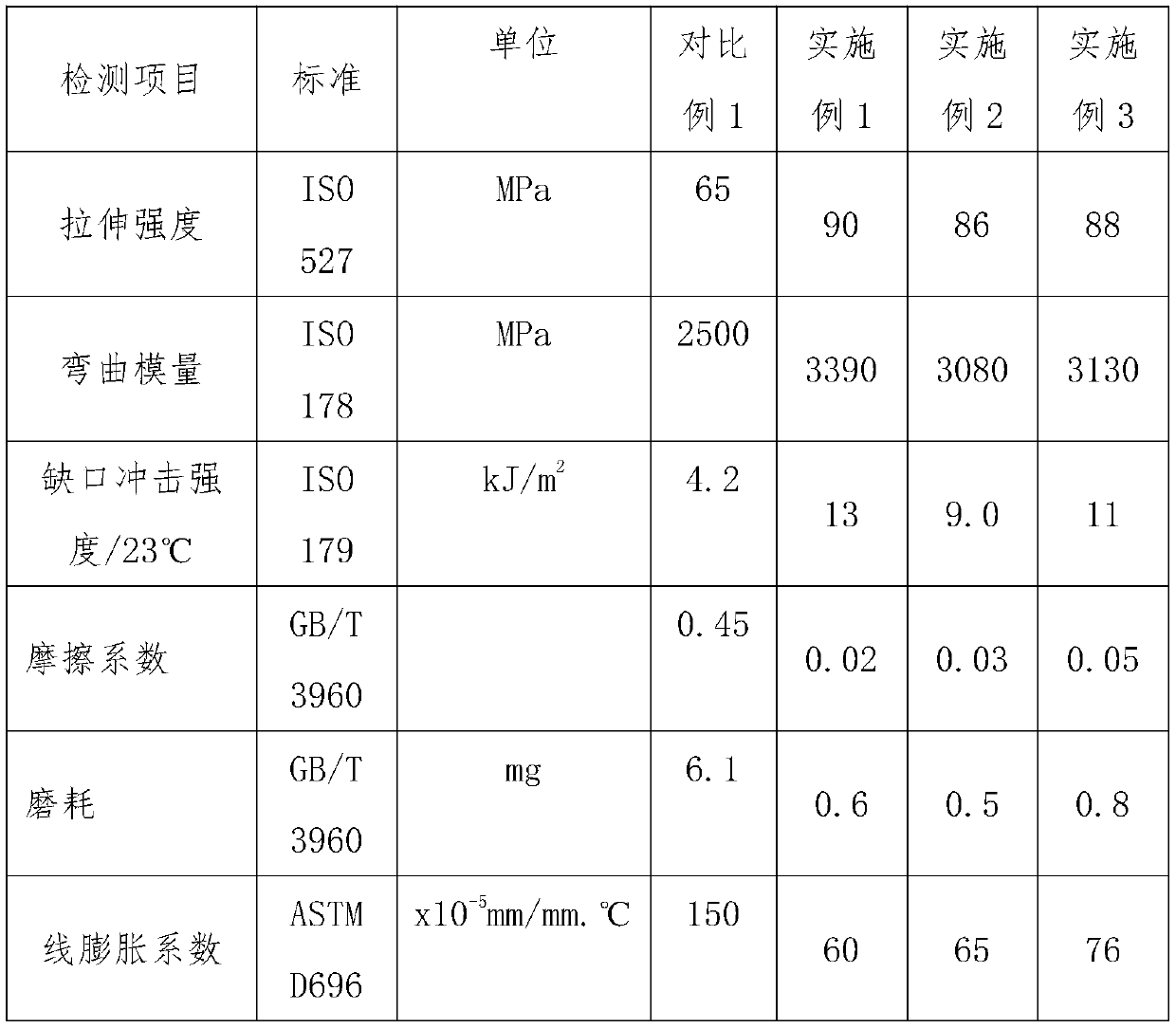

High-wear resistance and high-dimensional stability steering turbine material and preparation method thereof

PendingCN110964317AInhibition of water absorptionSmall coefficient of linear expansionThermal ageingPolyamide

The invention relates to a high-wear resistance and high-dimensional stability steering turbine material and a preparation method thereof. The material comprises the following components by weight: 60-80 parts of polyamide, 5-12 parts of a wear-resistant assistant, 0-15 parts of a filling agent, 6-18 parts of an anti-shrinking agent, 0.5-5 parts of a nucleating agent, 0.5-5 parts of a lubricatingagent and 0.3-1 part of an antioxidant. The high-wear resistance and high-dimensional stability steering turbine material disclosed by the invention has very good mechanical properties, and has the characteristics of self-lubricating properties, small friction coefficient, excellent wear resistance, long service life, easy processing, good molding performance, excellent mechanical properties, goodheat resistance, excellent low-temperature resistance and the like, and a hollow blow molding product has the characteristics of light weight, high strength, good dimensional stability, excellent heat resistance, high apparent quality, high yield, short molding period and the like; in addition, the product also has good long-term thermal aging performance.

Owner:NANJING JULONG SCI&TECH CO LTD

Spray drying method for herba pogostemonis formula granules

PendingCN110448593AImprove sticking phenomenonIncrease dry paste yieldPowder deliveryNervous disorderMedicineSpray drying

The invention relates to the technical field of production of traditional Chinese medicine granules, in particular to an improved spray drying technology for herba pogostemonis formula granules. By means of the spray drying method, specific accessory ingredients are especially adopted, the using amount of the accessory ingredients in the formula granules can be controlled, the taking dose of a patient can be reduced, and moreover, the phenomenon that the granules adhere to a tower in the spray drying process can be greatly improved. The dry paste yield of the herba pogostemonis formula granules in the spray drying process is greatly improved.

Owner:BEIJING INCREASEPHARM CORP LTD

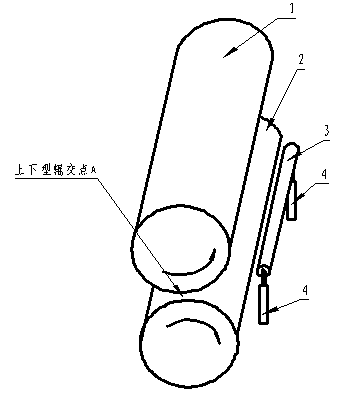

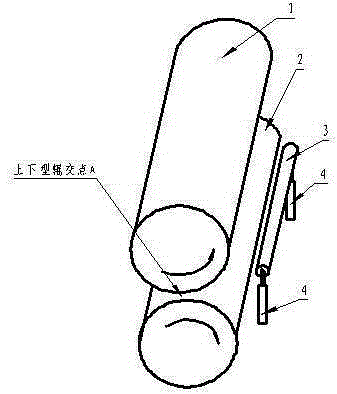

Roller sticking resisting device for inside liner

The invention relates to a roller sticking resisting device for an inside liner, which belongs to the mechanical field of rubber. The roller sticking resisting device is provided with an upper molding roller and a lower molding roller, which are parallel with each other, and is characterized in that a carrier roller is parallel with one sides of the lower and upper molding rollers; and the two ends of a rotation shaft of the carrier roller are fixedly arranged on a vertical cylinder rod. According to the roller sticking resisting device, the roller sticking phenomenon is effectively alleviated, unqualified films because of unqualified width or folding caused by roller sticking are reduced, the return ratio of unqualified semi-finished products is reduced, returned glue is reduced by 64% compared with unimproved devices, the roller sticking problem is basically solved, the cost is saved, the unnecessary waste is reduced and the labor is reduced at different levels.

Owner:TRIANGLE TIRE

Ultra-high molecular weight polyethylene, its production method and its application

ActiveCN107936161BUnit content is adjustable and controllableParticles in good shapePolymer sciencePolymer chemistry

The invention relates to a copolymerized ultra-high molecular weight polyethylene, its production method and application. The co-polymerized ultra-high molecular weight polyethylene has significantly improved processability compared to prior art homopolymerized ultra-high molecular weight polyethylene, and exhibits improved wear resistance and impact strength properties.

Owner:SINOPEC YANGZI PETROCHEM +1

Ultra-high molecular weight polyethylene, its production method and its application

ActiveCN107936164BUnit content is adjustable and controllableParticles in good shapePolymer sciencePolymer chemistry

The invention relates to a copolymerized ultra-high molecular weight polyethylene, its production method and application. The co-polymerized ultra-high molecular weight polyethylene has significantly improved processability compared to prior art homopolymerized ultra-high molecular weight polyethylene, and exhibits improved wear resistance and impact strength properties.

Owner:SINOPEC YANGZI PETROCHEM +1

Production method of isomaltooligosacharide and animal feed additive

ActiveCN102626177BFacilitated releaseFully dissolvedAnimal feeding stuffFermentationBiotechnologyIsomaltooligosaccharide

The invention relates to the technical field of isomaltooligosacharide and especially relates to a production method of isomaltooligosacharide. The production method of isomaltooligosacharide comprises the following steps of crushing cassava to obtain uniform cassava pulp, adding a complex enzyme preparation into the uniform cassava pulp, adding high-temperature alpha-amylase into the mixture to obtain a liquefaction liquid, treating the liquefaction liquid orderly through fungal amylase and transglucosidase to obtain a saccharification liquid which is common isomaltooligosacharide 500, diluting 1kg of the saccharification liquid until dry matter content is in a range of 8 to 10wt%, adding 0.3 to 0.6g of active dry yeast into the diluted saccharification liquid to obtain a fermentation broth which is isomaltooligosacharide 900, and mixing the fermentation broth and the liquefaction liquid according to a weight ratio of (3 to 4): 1 to obtain isomaltooligosacharide 500 which does not contain glucose, wherein the total content of isomaltose, panose and isomaltotriose is great than or equal to 35%. The invention also relates to an animal feed additive. The animal feed additive is prepared by adding corn protein powder into different types of isomaltooligosacharide syrup obtained by the production method and drying the mixture.

Owner:BAOLINGBAO BIOLOGY

Ultra-high molecular weight polyethylene, its production method and its application

ActiveCN107936162BUnit content is adjustable and controllableParticles in good shapePolymer sciencePolymer chemistry

The invention relates to copolymerized ultra-high molecular weight polyethylene, a production method and applications. Compared to the homopolymerized ultra-high molecular weight polyethylene in the prior, the copolymerized ultra-high molecular weight polyethylene of the present invention has the significantly-improved processability, and further has improved wear resistance and improved impact strength.

Owner:SINOPEC YANGZI PETROCHEM +1

Improvement method for finishing and trimming of double-zero foil material

PendingCN113896026AAvoid sticking phenomenonNo stickyArticle deliveryWebs handlingCircular discVertical edge

The invention discloses an improvement method of finishing and trimming of a double-zero foil material. According to the improvement method, the shearing overlapping amount of a cutting disc and the winding speed and the winding tension of a winding sleeve are adjusted according to the plate type condition of a material roll, when the measurement result is within the range of a standard plate type, it can be guaranteed that the winding sleeve conducts winding evenly, cutting of the cutting disc is free of vertical edges, and the material roll is wound normally without sticking damage; and when the measurement result exceeds the range of the standard plate type, vertical edges at the edge part of the material roll are reduced by reducing the shearing overlapping amount and reducing the rolling speed and the rolling tension of the rolling sleeve, and the phenomenon of adhesion between adjacent material roll layers due to vertical edge accumulation is improved.

Owner:INNER MONGOLIA LIANSHENG NEW ENERGY MATERIALS CO LTD

A lubricant for rolling titanium and titanium alloy strips

ActiveCN108277075BReduce energy consumptionLow temperature resistanceLubricant compositionHalogenAntioxidant

The invention belongs to the technical field of rolling lubrication and in particular relates to a rolling lubricant for titanium and titanium alloy plate strips. The lubricant is composed of the following substances in percentage by mass: 70.0-75.0% of engine oil, 5.0-10.0% of beef tallow, 2.0-4.0% of a compound emulsifier, 0.05-0.1% of fluorinated graphene, 0.1-0.5% of an antioxidant, 0.5-1.0% of an oiliness agent, 0.01-0.05% of an antifoaming agent, 0.5-1.0% of an extreme pressure agent, 0.5-1.5% of an anti-rust agent and the balance of water. The lubricant disclosed by the invention is prepared by applying a nanometer technology the lubricant on the basis of the traditional rolling lubricant and combining the characteristic that halogen elements can form layered structural compounds with titanium. The lubricant has the characteristics of low energy consumption and high temperature resistance, the roll banding phenomenon in the processing flow is improved, the service life of a roller is prolonged, and the plate quality is improved.

Owner:UNIV OF SCI & TECH BEIJING

Device for preventing roller sticking of inner lining of tire

Owner:QINGDAO HUASHENG RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com