Dry etching machine and lower electrode of dry etching machine

A dry etching and electrode technology, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems that affect the product qualification rate and stress concentration, and achieve the effects of improving the phenomenon of sticking chips, cooling quickly and effectively, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

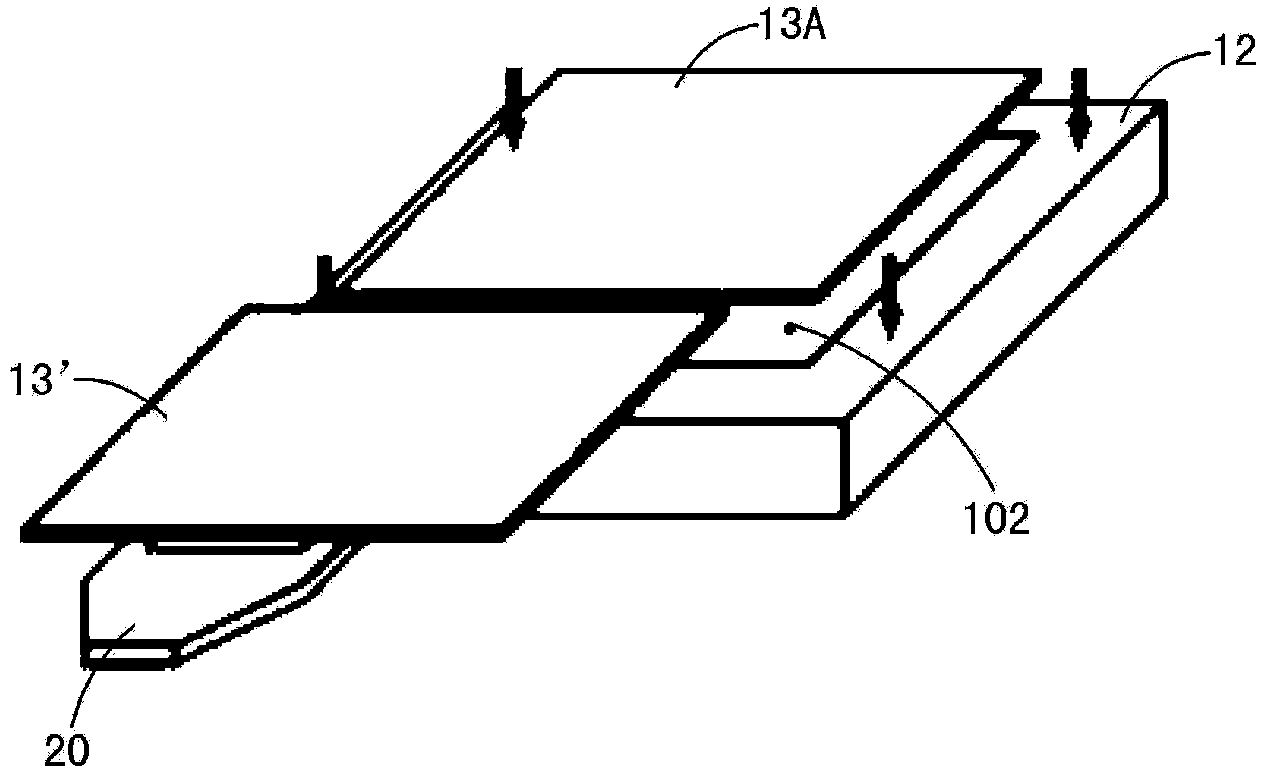

[0033] First refer to Figure 4 The basic configuration of the dry etching machine 1 will be described. Such as Figure 4 As shown, it shows the schematic diagram of the basic structure of dry etching machine, dry etching machine 1 has a reaction chamber 10, the top of this reaction chamber 10 is provided with upper electrode 11, the bottom of this reaction chamber 10 is opposite to upper electrode 11 A lower electrode 12 is configured, and the lower electrode 12 can carry a substrate 13 to be dry-etched. The upper electrode 11 is connected to a power source 31, and the lower electrode 12 is grounded. The reaction chamber 10 is also provided with an inlet pipe 21 for entering the etching gas and an exhaust pipe 22 for discharging the processed gas.

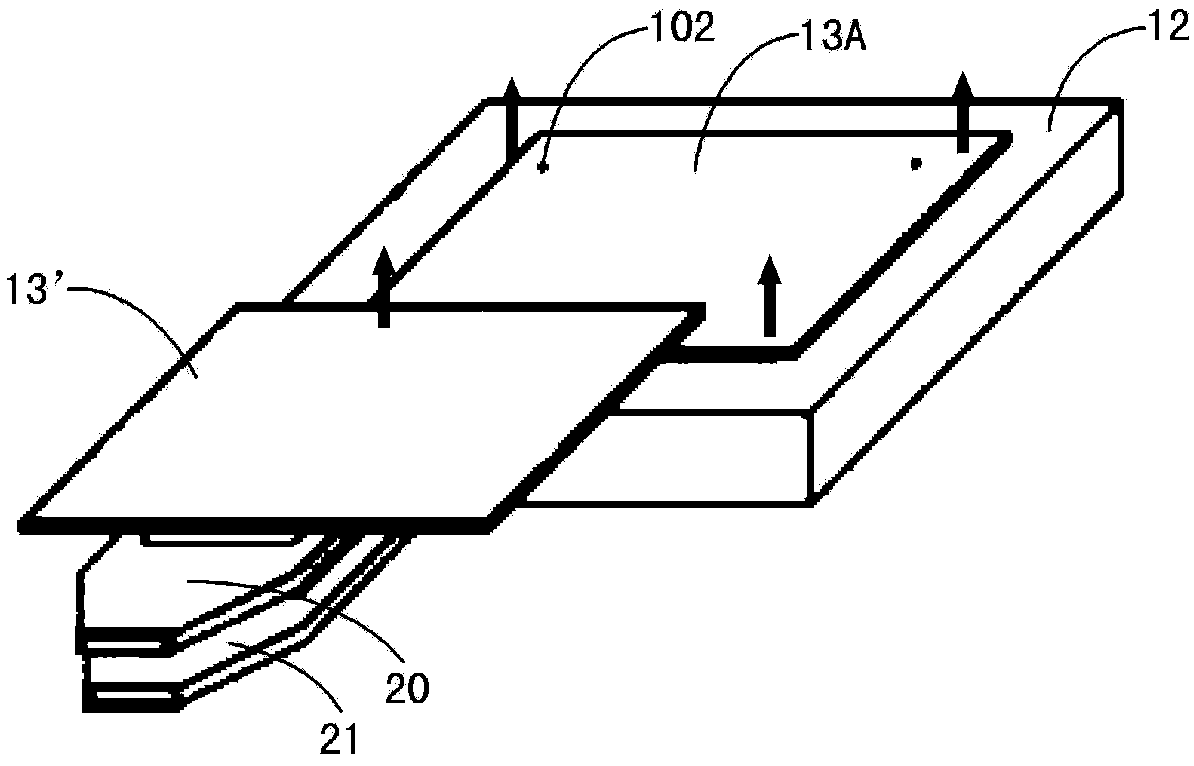

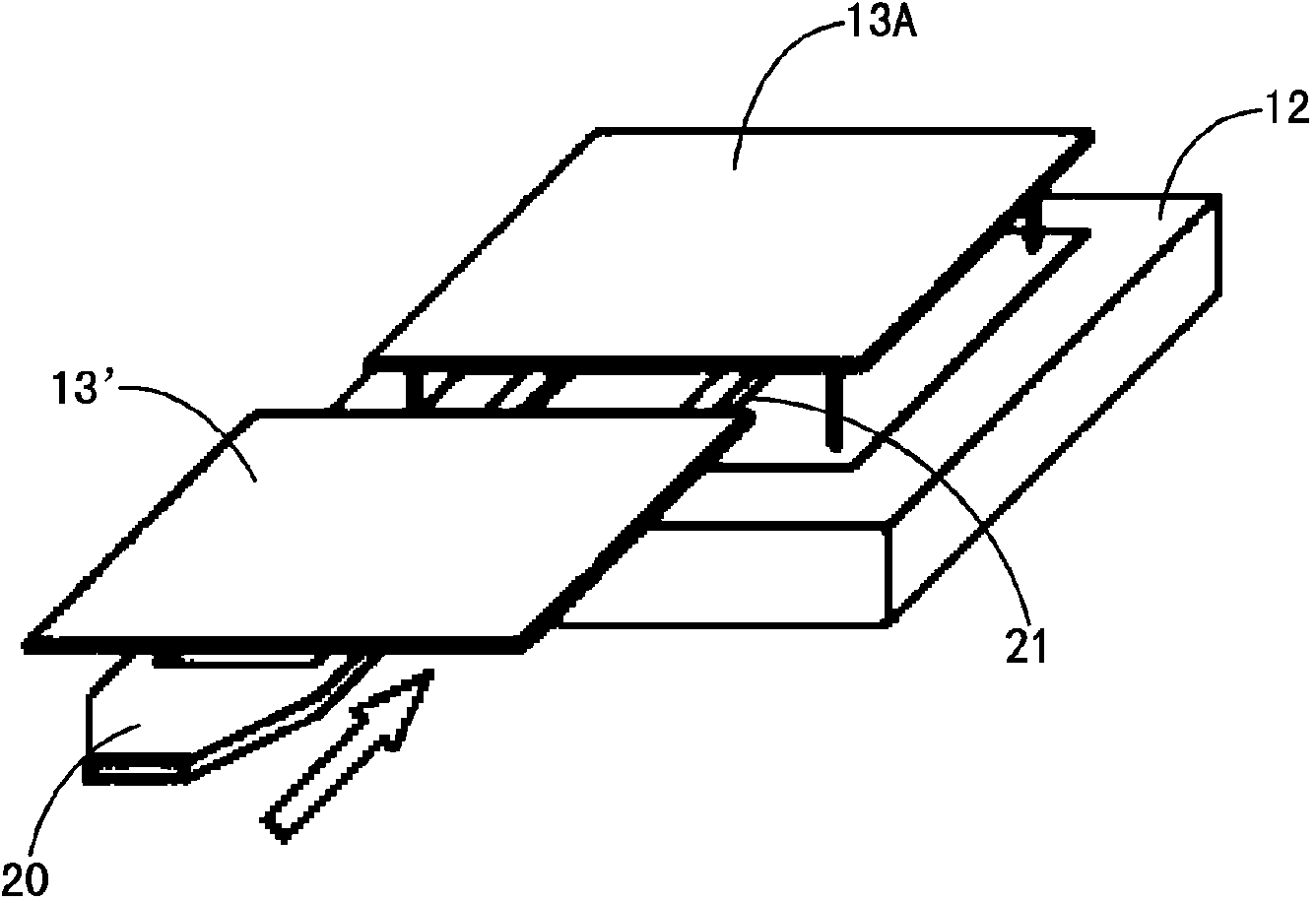

[0034] Then, the procedure of etching treatment using the above-mentioned dry etching machine 1 will be described. First, through the arm 20 (see Figure 1A-Figure 1H ) placing the substrate 13 to be dry-etched on the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com