Battery piece bonding detection method

A detection method and cell technology, applied in sorting and other directions, can solve the problems of cell sticking, affecting continuity, production line blockage, etc., and achieving the effect of reasonable structure, small size and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

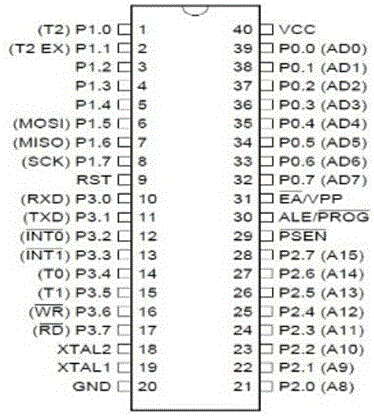

[0033] In embodiment 1, the controller selects the AT89S52 single-chip microcomputer of ATMEL Company.

[0034] image 3 It is a schematic diagram of the single-chip microcomputer selected in Embodiment 1 of the present invention, Figure 4 is a schematic diagram of the weight measuring unit in Embodiment 1 of the present invention, Figure 5 It is a schematic diagram of the weight display unit in Embodiment 1 of the present invention, Figure 6 is a schematic diagram of the motor controller in Embodiment 1 of the present invention, Figure 7 is a schematic diagram of the speaker in Embodiment 1 of the present invention.

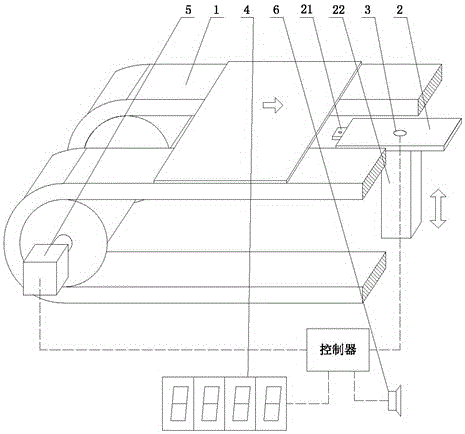

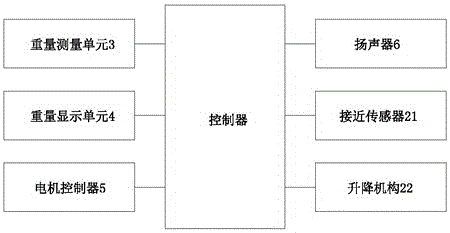

[0035] It can be seen from the figure that a pallet 2 is installed near the conveyor belt 1, a proximity sensor 21 is provided on the edge of the pallet 2, a weight detection unit 3 is provided in the center of the pallet 2, and a lifting mechanism 22 is provided at the bottom of the pallet 2; a weight display unit is also provided near the conveyor belt ...

Embodiment 2

[0043] The controller in embodiment 2 selects Mitsubishi FX2N series PLC.

[0044] PLC does not require complex line connections, because it has internal functions such as storing programs, executing logic operations, sequence control, timing, and counting, and only needs to determine input points and output points and perform logic programming.

[0045] In Embodiment 2, relay input and relay output can be set for each component. For example, the proximity sensor is defined as X1, the weight detection unit is set as X2, the lifting mechanism is set as Y1, the weight display unit is set as Y2, and the motor The controller is set to Y3 and the speaker is set to Y4.

[0046] By programming or drawing a ladder diagram, it is set that when the proximity sensor X1 has an input, the lifting mechanism Y1 has an output; when the weight detection unit X2 has an input, the weight display unit Y2 has an output, and according to the measurement result of the weight detection unit, the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com