A lubricant for rolling titanium and titanium alloy strips

A titanium alloy plate and lubricant technology, which is applied in the field of lubricants for titanium and titanium alloy plate and strip rolling, can solve the problems of titanium tool die adhesion and easy cracking, and achieves improved plate surface quality, low energy consumption, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Add 350.0g engine oil and 50.0g tallow into the reaction kettle, heat to 55-65°C, start the agitator and control the speed to 60r / min;

[0022] Step 2: Add 15.0g compound emulsifier (Span-80 and Tween-80 series emulsifiers are prepared at 1:1), 0.25g fluorinated graphene, 1.0g 2,6 di-tert-butyl-p-cresol, 2.5g Higher fatty acid, 0.25g methyl silicone oil, 2.5g tricresyl phosphate, 2.5g triethanolamine and 76.0g water were successively added into the reaction kettle, stirred while adding, continuously stirred for 2-3 hours and cooled to normal temperature.

Embodiment 2

[0024] Step 1: Add 350.0g engine oil and 50.0g tallow into the reaction kettle, heat to 55-65°C, start the agitator and control the speed to 60r / min;

[0025] Step 2: Add 15.0g compound emulsifier (Span-80 and Tween-80 series emulsifiers are prepared at 1:1), 0.5g fluorinated graphene, 1.0g 2,6 di-tert-butyl-p-cresol, 2.5g Higher fatty acid, 0.25g methyl silicone oil, 2.5g tricresyl phosphate, 2.5g triethanolamine and 75.75g water were successively added into the reaction kettle, stirred while adding, continuously stirred for 2-3 hours and cooled to normal temperature.

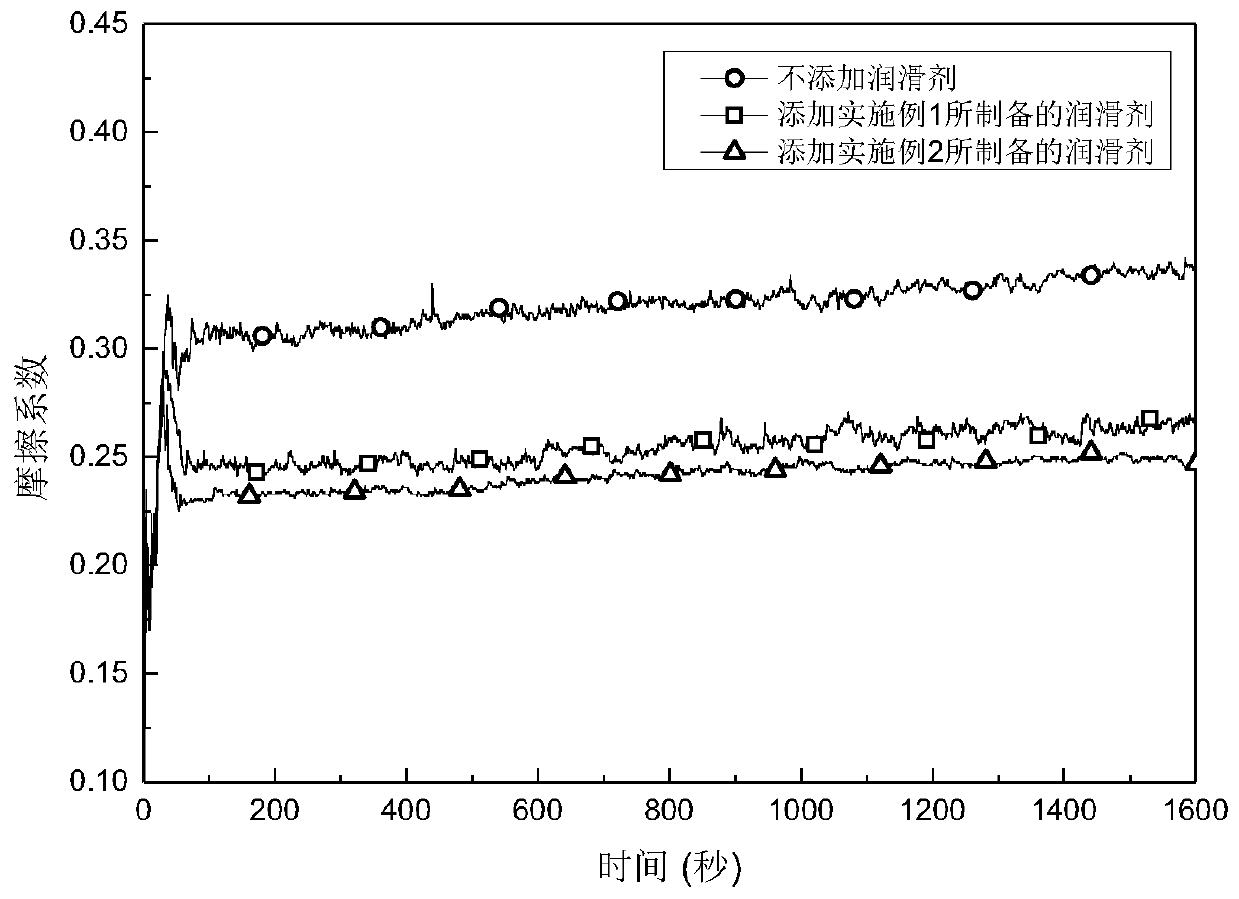

[0026] The friction and wear characteristics test of the lubricant prepared in Examples 1-2 was completed on a UMT-2MT friction testing machine, using ball-plane contact and reciprocating sliding. The upper sample is GCr15 steel ball with a diameter of Φ4mm; the material of the lower sample is titanium alloy TC11, the sample is ground, the surface roughness is Ra=1.6μm, and the upper and lower samples are clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com