Production method of isomaltooligosacharide and animal feed additive

A technology of malt syrup and cassava, applied in animal feed, animal feed, application, etc., to reduce production costs, improve sticking phenomenon, and increase the final yield of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

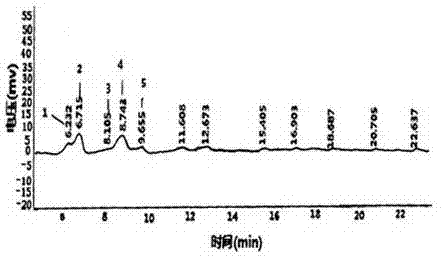

[0040] Example 1: The relationship between the particle size of starch milk in cassava homogenate and the yield of filtrate, filter cake and isomaltooligosaccharide after saccharification

[0041] Immediately after harvesting, fresh cassava is peeled and cut into pieces of about 1cm 2 The cassava grains were pulverized for 1 min with a high-speed universal pulverizer. The crushed cassava homogenate has a Baume degree of 28, and it is placed in an oven at 105°C for 4 hours. After drying until the weight does not change, its moisture content is measured to be 65%, so the cassava homogenate contains 35% dry matter. The dried powder was hydrolyzed with 6N hydrochloric acid for 2 hours, and the DE value was determined by the method of Fihring's reagent to be 95.5%, that is, the starch content in the fresh cassava was 33.42% based on glucose.

[0042] Four kinds of cassava homogenate samples passed through different mesh sieves of 10, 40, 60, and 100 mesh were prepared respective...

Embodiment 2

[0049] (1) Cut the peeled 1cm 2 Fresh cassava grains are mechanically crushed twice to pass through a 100-mesh sieve to obtain cassava homogenate;

[0050] (2) Gradually add 50 g of compound enzyme preparation into 1000 g of cassava homogenate with a pH of 5.3, react at 55°C for 0.5 h, and keep stirring during the process. After the reaction, adjust the pH of the system to 6.0 and add 0.10 mL of high-temperature α-amylase (40000 U / mL), stir and liquefy in a boiling state for 2 hours, after the reaction is completed, lower it to normal temperature, add hydrochloric acid to adjust the pH to 3.5 to inactivate the enzyme, and obtain a liquefied solution ;

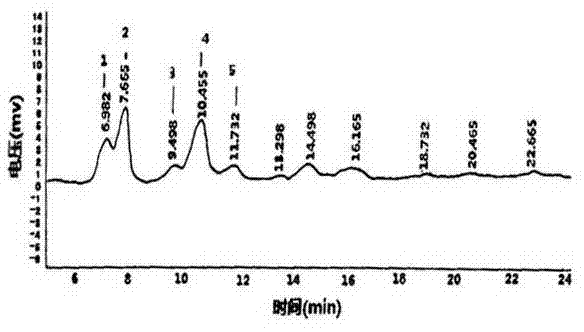

[0051] (3) Adjust the pH value of the liquefaction solution to 5.8, add 0.1g Amano fungal amylase (15000U / g) at 60°C, add 0.1mL transglucosidase (300000U / mL) after reacting for 8 hours, and continue at 60°C After reacting for 45 hours, the saccharification solution was obtained after the enzyme was inactivated, which was ordi...

Embodiment 3

[0061] (1) Divide 1cm 2 Fresh cassava grains are mechanically crushed twice to pass through a 100-mesh sieve to obtain cassava homogenate.

[0062] (2) Gradually add 0.01 g of compound enzyme preparation into 1000 g of cassava homogenate with a pH of 5.5, react at 60° C. for 10 h, and keep stirring during the process. After the reaction, adjust the pH of the system to 6.0 and add 10mL of high-temperature α-amylase (40000U / mL), stir and liquefy in boiling state for 0.5h, after the reaction is completed, lower it to normal temperature, add hydrochloric acid to adjust the pH to 3.5 to inactivate the enzyme, and obtain a liquefied solution ;

[0063] (3) Adjust the pH value of the liquefaction solution to 5.8, add 10g Amano fungal amylase (15000U / g) at 60°C, add 10mL transglucosidase (300000 U / mL) after reacting for 0.5h, and continue at 60°C After reacting for 5 hours, the temperature was raised to 75°C to inactivate the enzyme for 10 minutes to obtain a saccharification soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com