Patents

Literature

102results about How to "Improve final yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

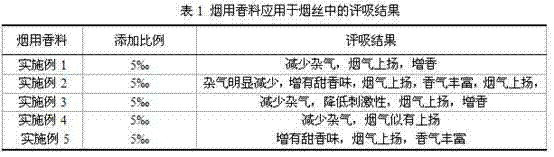

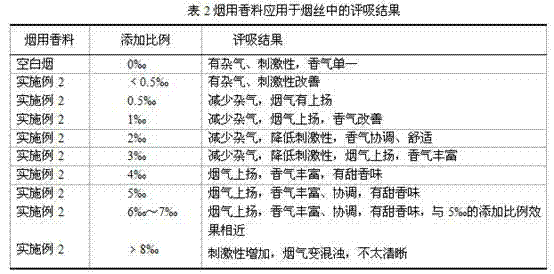

Preparation method for reaction type spice for cigarette and application of reaction type spice to cigarette

ActiveCN103045369AEasy to operateImprove final yieldTobacco treatmentEssential-oils/perfumesAmino acidAlcohol ethyl

The invention discloses a preparation method for reaction type spice for cigarette and an application of the reaction type spice to the cigarette. The preparation method comprises the following steps of: through a certain pre-treatment, refluxing and extracting alcohol to obtain concentrated solution with the solid weight percentage of 40-60%, adding amino acid and carbohydrate to the concentrated solution, reasonably controlling key indexes, such as a pH value, temperature and time, of a reaction to carry out the reaction to prepare the reaction type spice for the cigarette. The reaction type spice disclosed by the invention is applied to the cigarette to obtain an ideal effect and guarantee that the smoke of cigarette products rises, the fragrance is more abundant and harmonious, and the quality of the cigarette is remarkably improved; and the process route of the invention has strong operability and high yield.

Owner:CHINA TOBACCO GUANGDONG IND +1

Coptis chinensis total alkaloid extracting technique

InactiveCN101269132ALow costEasy to processAntibacterial agentsAntimycoticsSide effectResource utilization

The invention relates to the extraction technology of a rhizoma coptidis total alkaloid and the process flow is as follows: raw materials (rhizoma coptidis or coptis fibrous roots or coptis leaves), pulverization (Coptis fibrous roots or coptis leaves need no pulverizing.), addition of right amount of sulphuric acid of 0.01 to 10 percent for soaking, heated extraction for four times, preconcentration, sediment of sodium chloride and high-valencied metal salt, filtration, drying and products of rhizoma coptidis total alkaloid. The main active ingredients for the product are berberine, coptisine, jateorrhizine, palmatine, epiberberine and other active coptis ingredients, the content of rhizoma coptidis total alkaloid is over 20 percent, wherein, the content of berberine is over 10 percent. The product adopts coptis fibrous roots and so on as raw materials to extract rhizoma coptidis total alkaloid, which is different from the traditional extraction of berberine. The extraction technology improves the pure quotient of the product and particularly eliminates cold-natured ingredients of toxic and side effect through the operating procedure of impurity eliminating, thereby improving the product quality. Besides the traditionally-utilized berberine, the product still contains a large quantity of other active coptis ingredients such as coptisine, jateorrhizine, palmatine, epiberberine and so on. The product has a higher utilization rate of resources and a higher security of products, and the effective function and action of rhizoma coptidis can be brought into a better play.

Owner:SOUTHWEST UNIV

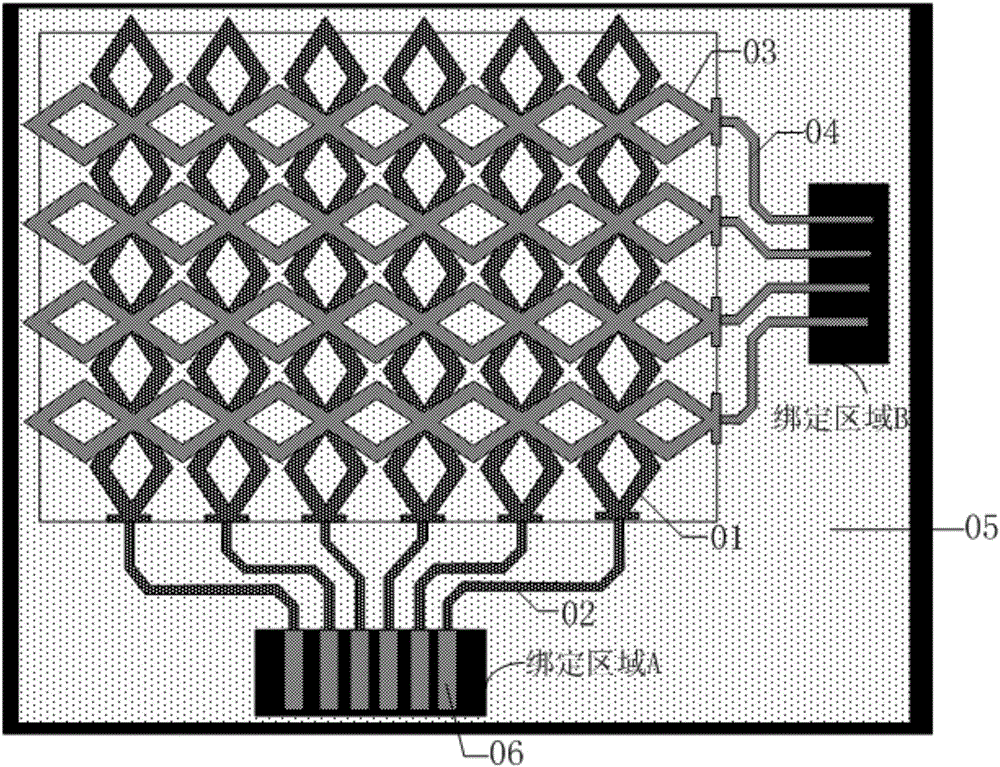

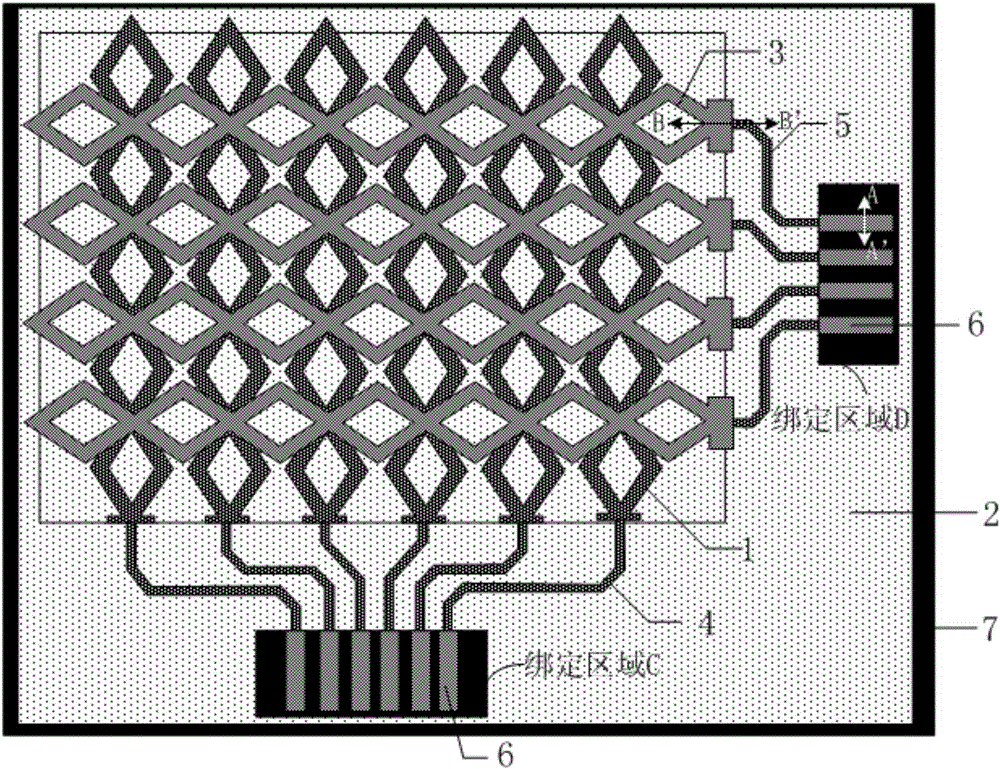

Touch screen and manufacturing method thereof as well as display device

ActiveCN106201145AImprove corrosion resistancePlay a protective effectInput/output processes for data processingDisplay deviceEngineering

The invention discloses a touch screen and a manufacturing method thereof as well as a display device. The touch screen comprises a substrate base plate, and a first touch electrode, a first insulating layer and a second touch electrode which are arranged on the substrate base plate in sequence, wherein the first touch electrode and the second touch electrode are mutually crossed and are of a metal lattice shape; the touch screen further comprises a first signal line which is electrically connected with the first touch electrode, and a second signal line which is electrically connected with the second touch electrode; and metal protection layers are arranged on the first signal line and the second signal line located in a binding region of the touch screen. The metal protection layers are arranged on the first signal line and the second signal line located in the binding region of the touch screen and can be used for protecting the first signal line and the second signal line, so that the anti-corrosion capability of the touch screen is integrally improved, and furthermore, the final yield of a product can be improved through corrosion resistance dependence authentication.

Owner:BOE TECH GRP CO LTD +1

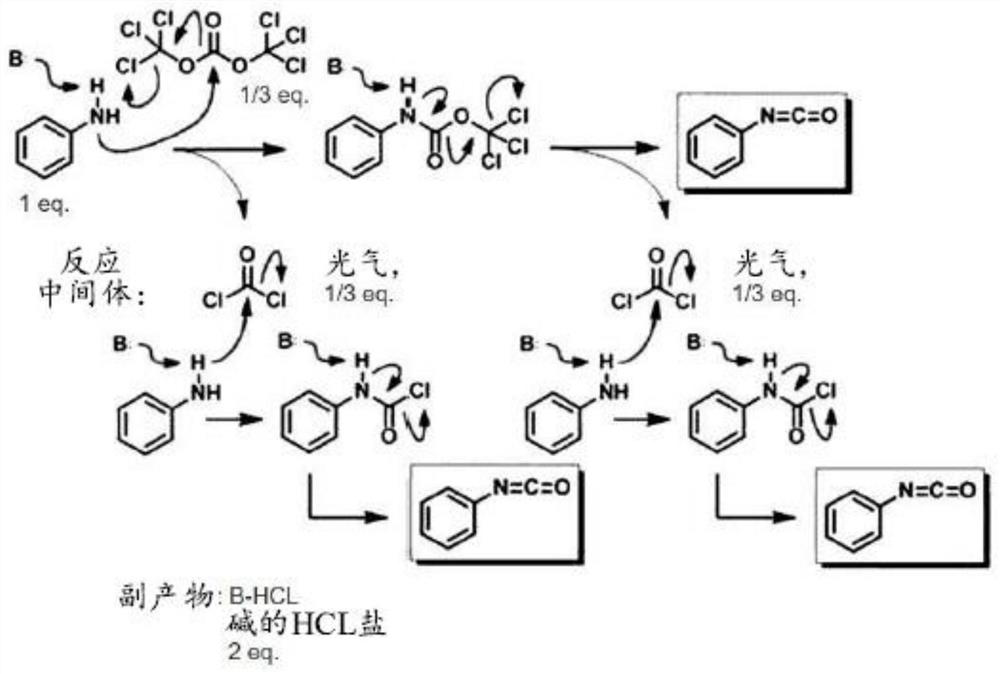

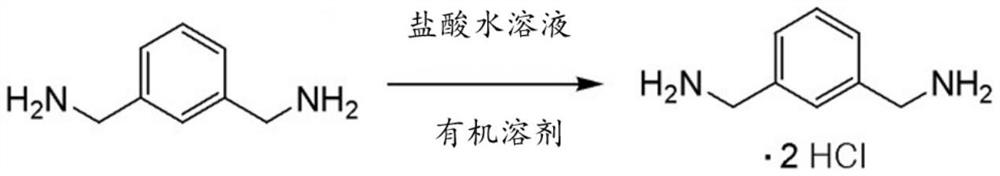

Method for manufacturing diisocyanate and optical lens

ActiveCN112292413ALow toxicityImprove convenienceIsocyanic acid derivatives preparationAmino compound purification/separationOrganic solventOptic lens

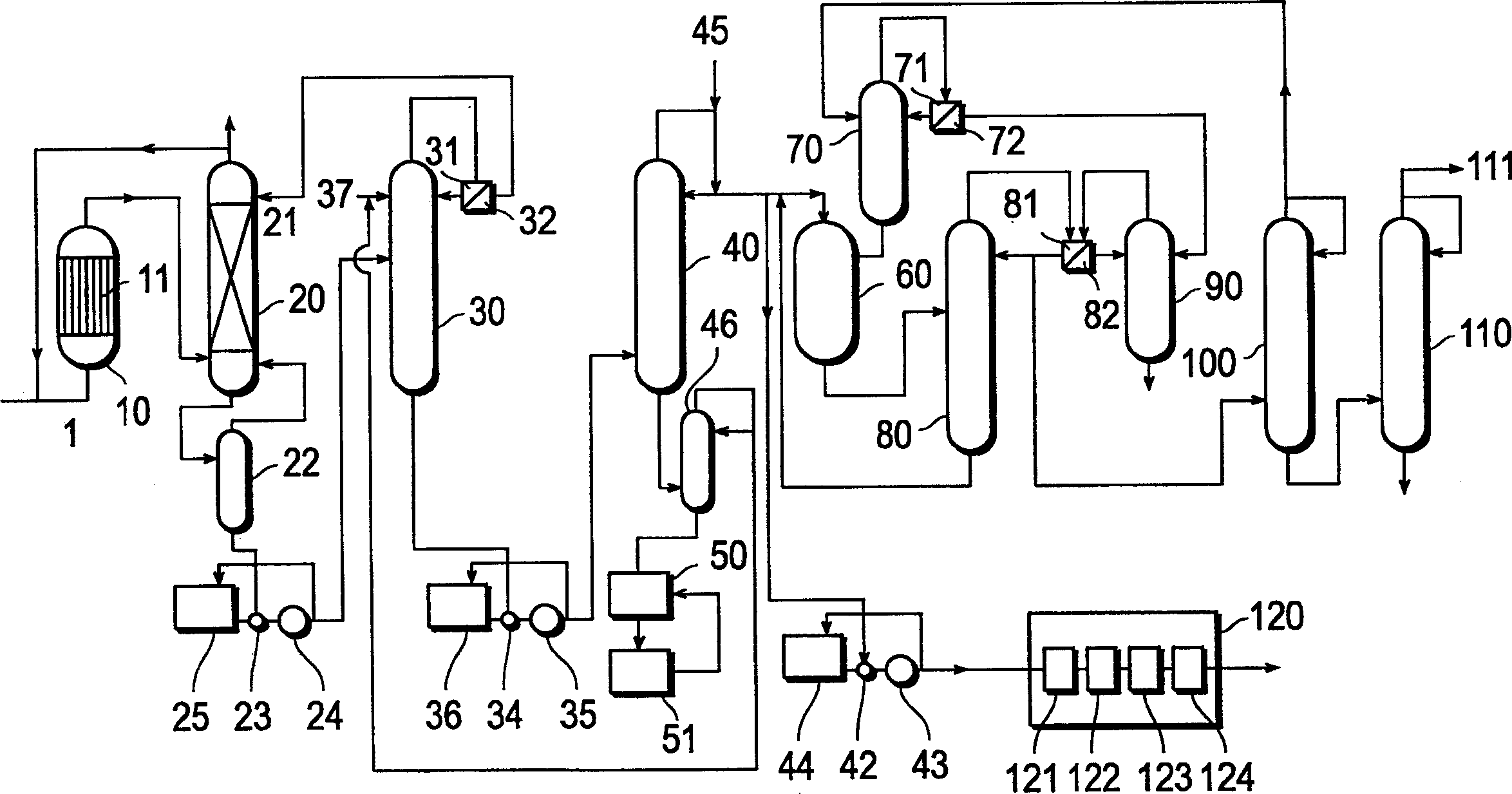

Provided is a method for manufacturing diisocyanate and an optical lens in which, during the manufacture of diisocyanate from diamine via diamine hydrochloride, use is made of an aqueous hydrochloricacid solution and an organic solvent instead of hydrogen chloride gas and solid-phase triphosgen instead of phosgen gas while reaction conditions are controlled, whereby the diisocyanate of high quality can be manufactured at excellent yield, with the causation of less environmental problems.

Owner:WOORI FINE CHEM CO LTD

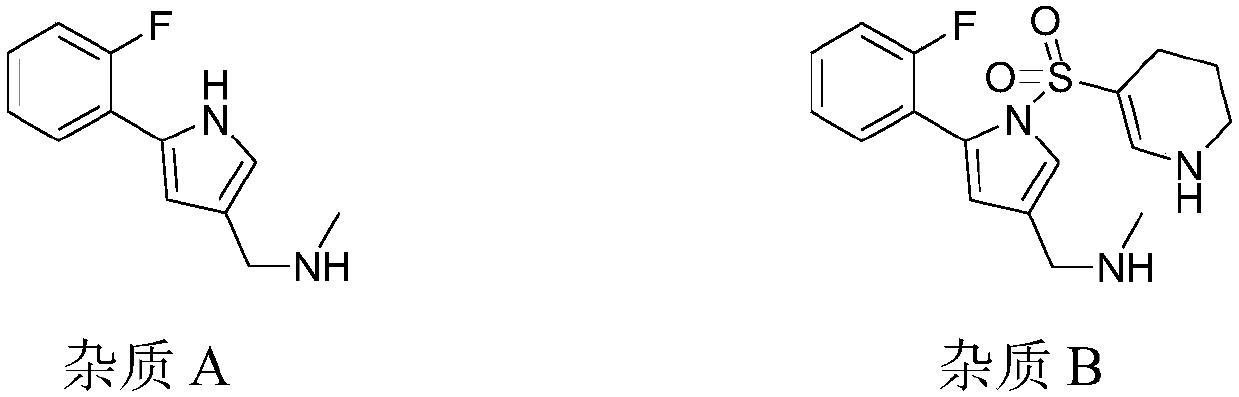

Synthetic process for Vonoprazan fumarate

PendingCN107778286AReduce contentImprove removal efficiencyOrganic chemistryMethylamine hydrochloridePyridine

The invention provides a preparation method for preparing high-purity 5-(2-fluorophenyl)-N-methyl-1-(3-pyridine sulfonyl)-1H-pyrrole-3-methylamine fumarate. The method comprises the following steps: taking 5-(2-fluorophenyl)-N-methyl-1-(3-pyridine sulfonyl)-1H-pyrrole-3-methylamine hydrochloride as an intermediate; carrying out alkali treatment, and then salifying the treated intermediate with fumaric acid to obtain a finished product. A final product prepared by adopting the method has high purity and low content of key impurities; in addition, the purification and post treatment steps of fumarate are simplified, and the yield is remarkably improved.

Owner:四川弘远药业有限公司

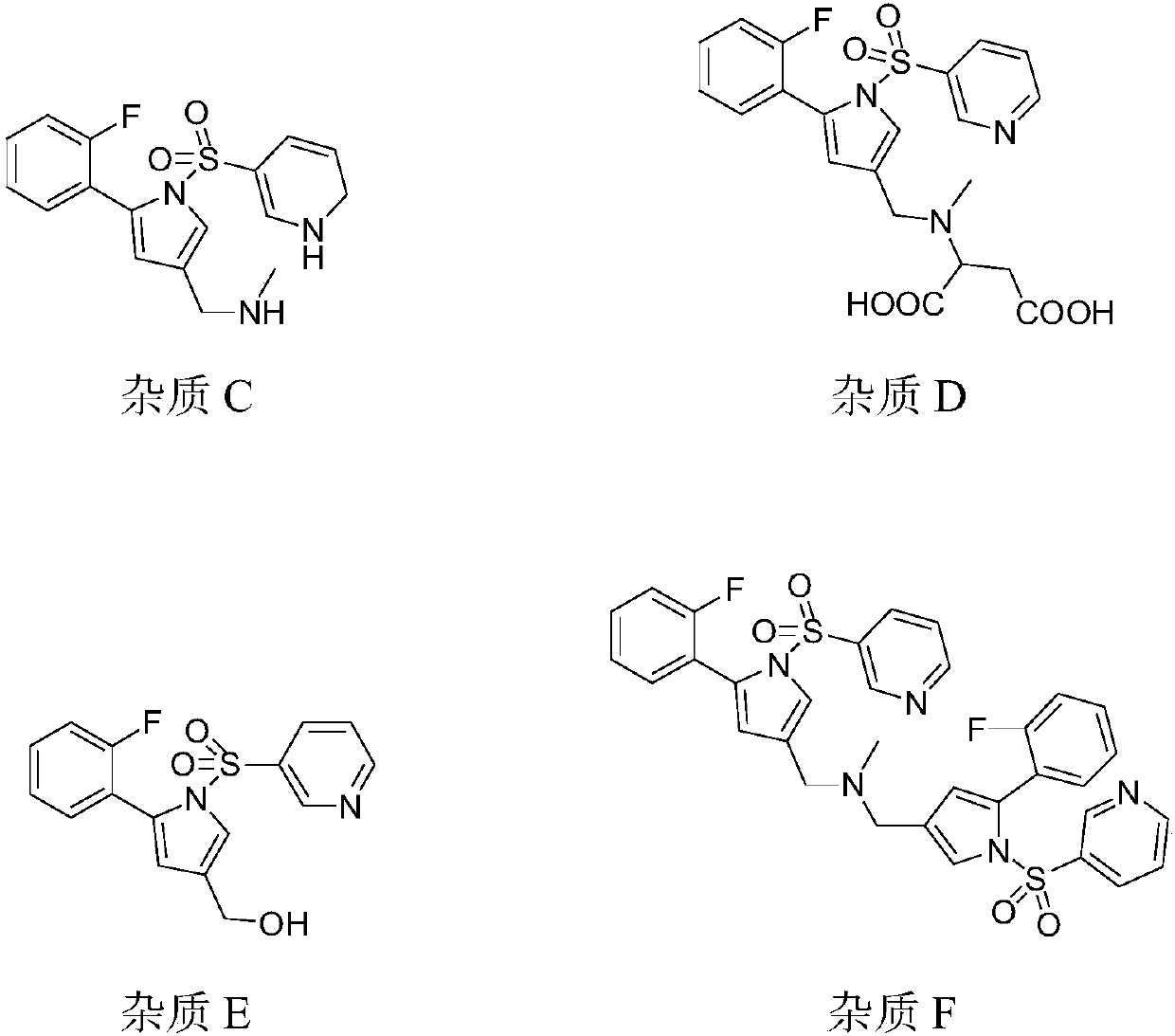

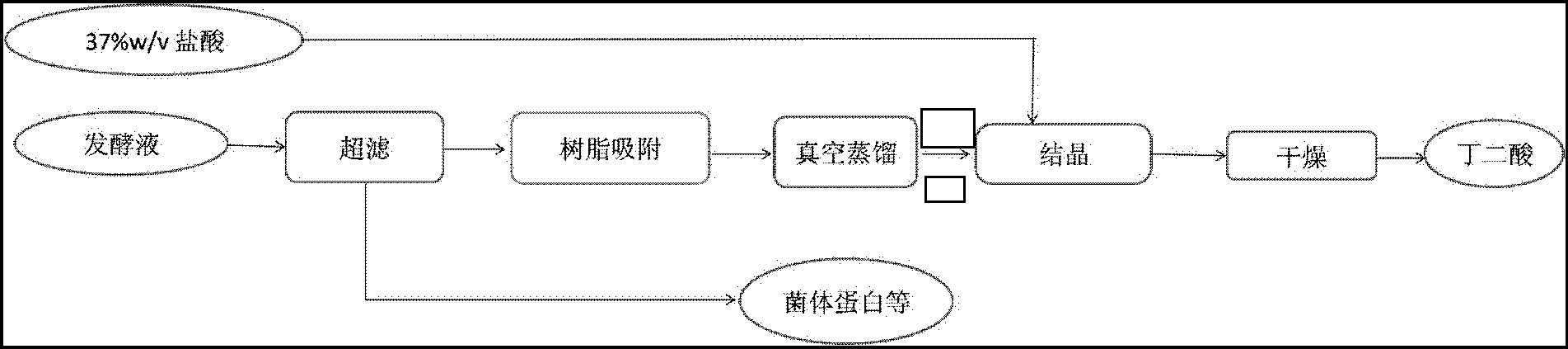

Method for separating and purifying succinic acid from fermentation broth

InactiveCN102363594AHigh viscosityHigh clarityCarboxylic compound separation/purificationUltrafiltrationSuccinic acid

The invention belongs to a technology for separating succinic acid from fermentation products, and specifically relates to a method for separating and purifying succinic acid from fermentation broth. According to the invention, separation and purification of succinic acid can be realized by the operations of appropriate units and effective combinations of the units, such that defects of existing succinic acid separation and purification technologies of complicated process and poor economical efficiency can be overcome. Therefore, a novel economic technology for separating and purifying succinic acid from fermentation broth is established. Specifically, the fermentation broth is clarified through ultrafiltration. Resin decoloration is used for replacing traditional active carbon decoloration, such that the final succinic acid yield can be improved. Succinic acid crystals are directly obtained through crystallization. With the technology, the purity of the separated succinic acid reaches 99.5%, and the yield is higher than 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

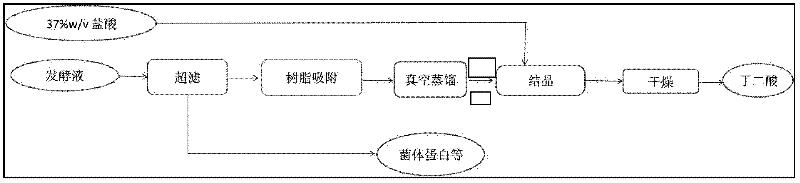

Preparation method of 2,2-dimethyl-3-hydroxypropanal and application thereof in preparation of neopentyl glycol

ActiveCN108017510AWide variety of sourcesEffective cost controlOrganic compound preparationHydroxy compound preparationWastewaterReaction system

The invention provides a preparation method of 2,2-dimethyl-3-hydroxypropanal and application thereof in preparation of neopentyl glycol. The 2,2-dimethyl-3-hydroxypropanal is prepared from an epoxy compound by a hydroformylation method. The method has the advantages of good atom economy, low raw material cost, no wastewater generation, and high yield. The invention also provides the application of the 2,2-dimethyl-3-hydroxypropanal in preparation of the neopentyl glycol. The application method circumvents the disadvantages of the conventional methods in the prior art, the reaction system is simple, and the industrial application prospect is excellent.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of 4,4'-biphenol diglycidyl ether

ActiveCN102030726AReduce hydrolysis side reactionsHigh yieldOrganic chemistryTwo stepEpichlorohydrin

The invention discloses a preparation method of 4,4'-biphenol diglycidyl ether. In the preparation method provided by the invention, 4,4'-biphenol and epichlorohydrin are used as raw materials to be synthesized by a two-step method under the effect of a heterogeneous catalyst. The preparation method comprises the following steps: firstly, carrying out a ring-opening etherifying reaction, then carrying out a ring-closing reaction, and in the alkalizing process, separating out water generated in the reaction by a water-separating technique, so that the reaction shifts to the right at equilibrium, and various hydrolysis secondary reactions in the system can be controlled. The product obtained by the technique has high epoxide equivalent and high yield, the technique has simple reaction steps and is convenient for posttreatment, and experimental results show that the epoxide number is 0.65-0.67, and the melting range is 159.1-160.4 DEG C.

Owner:兰州精细化工有限责任公司

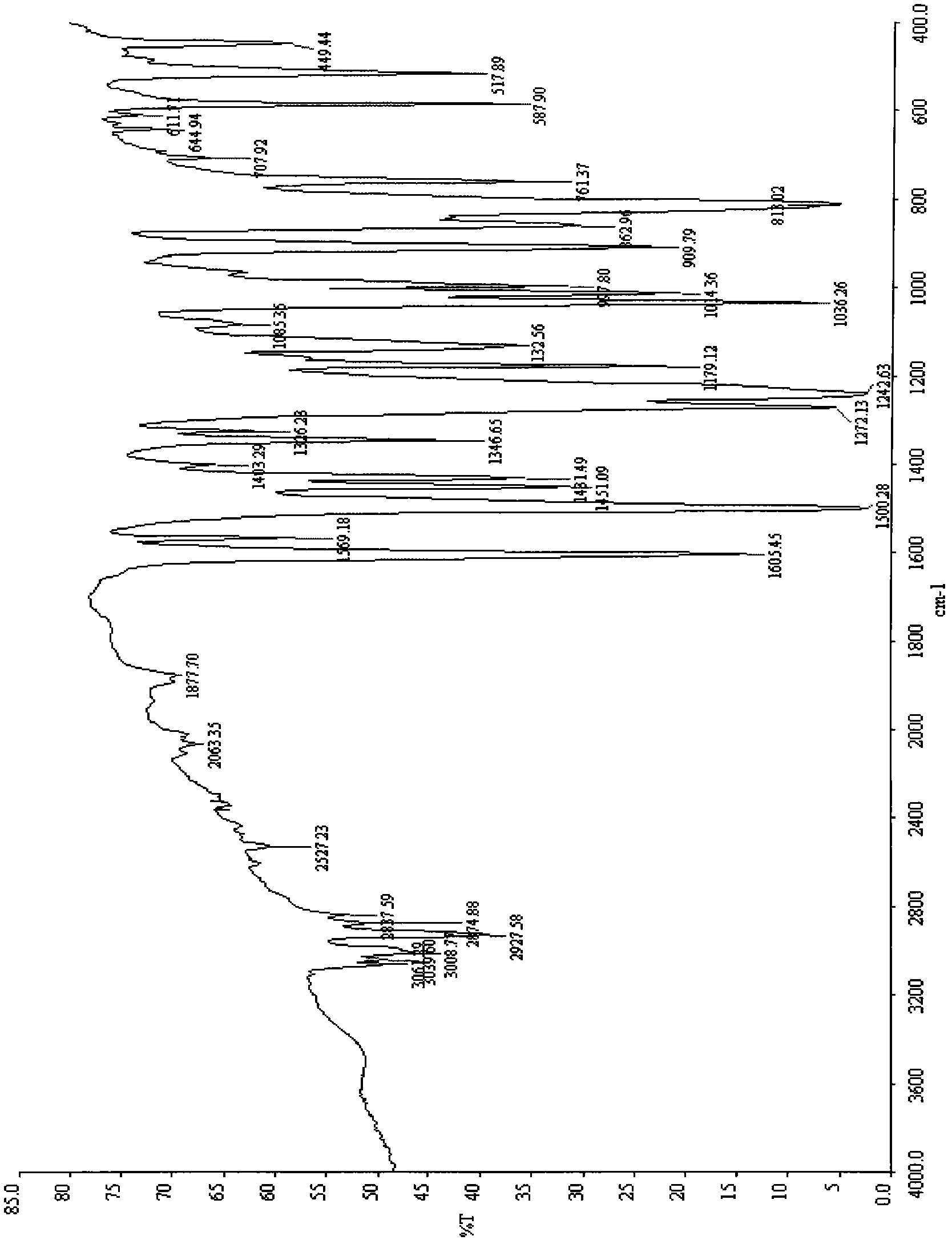

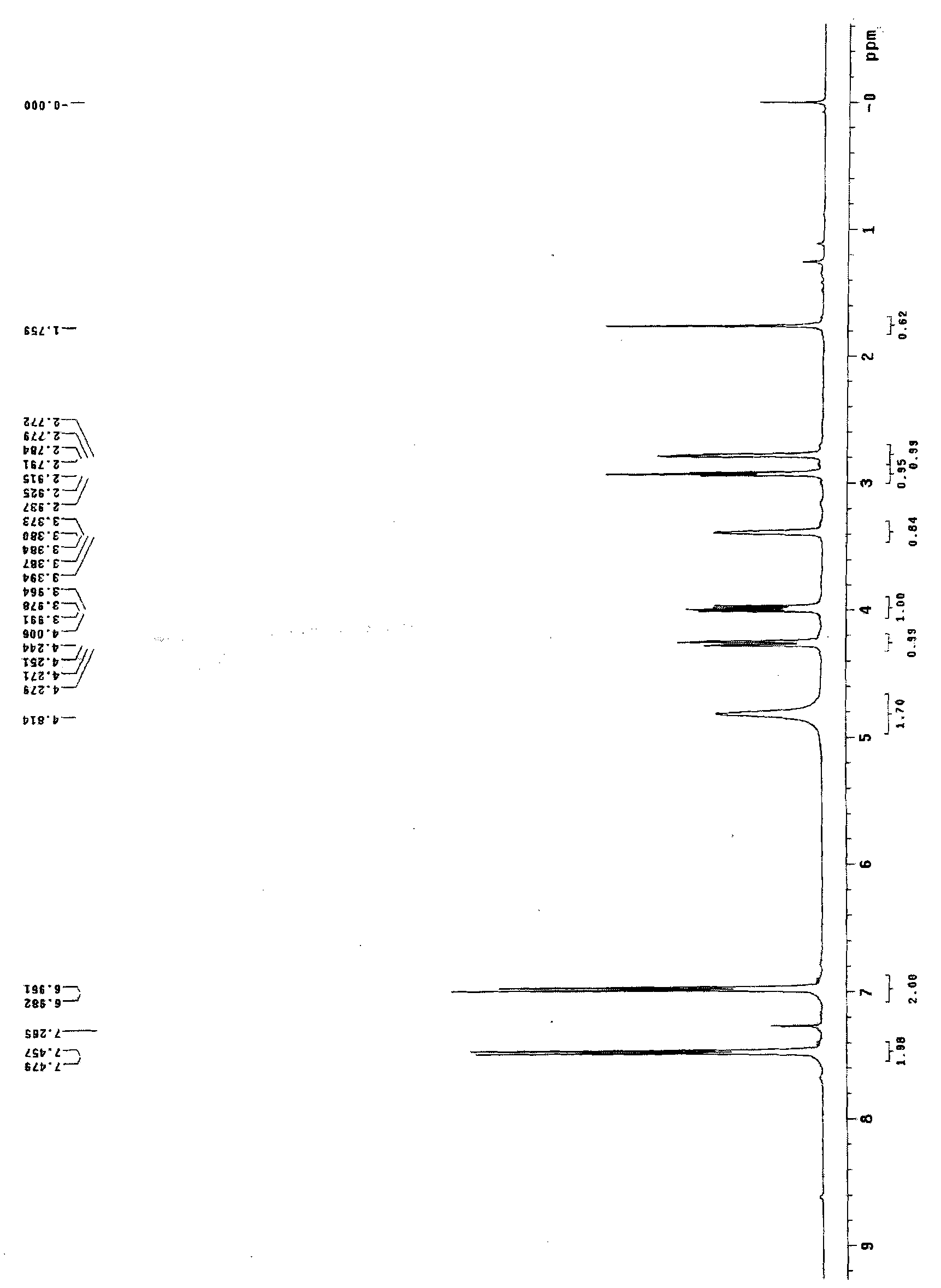

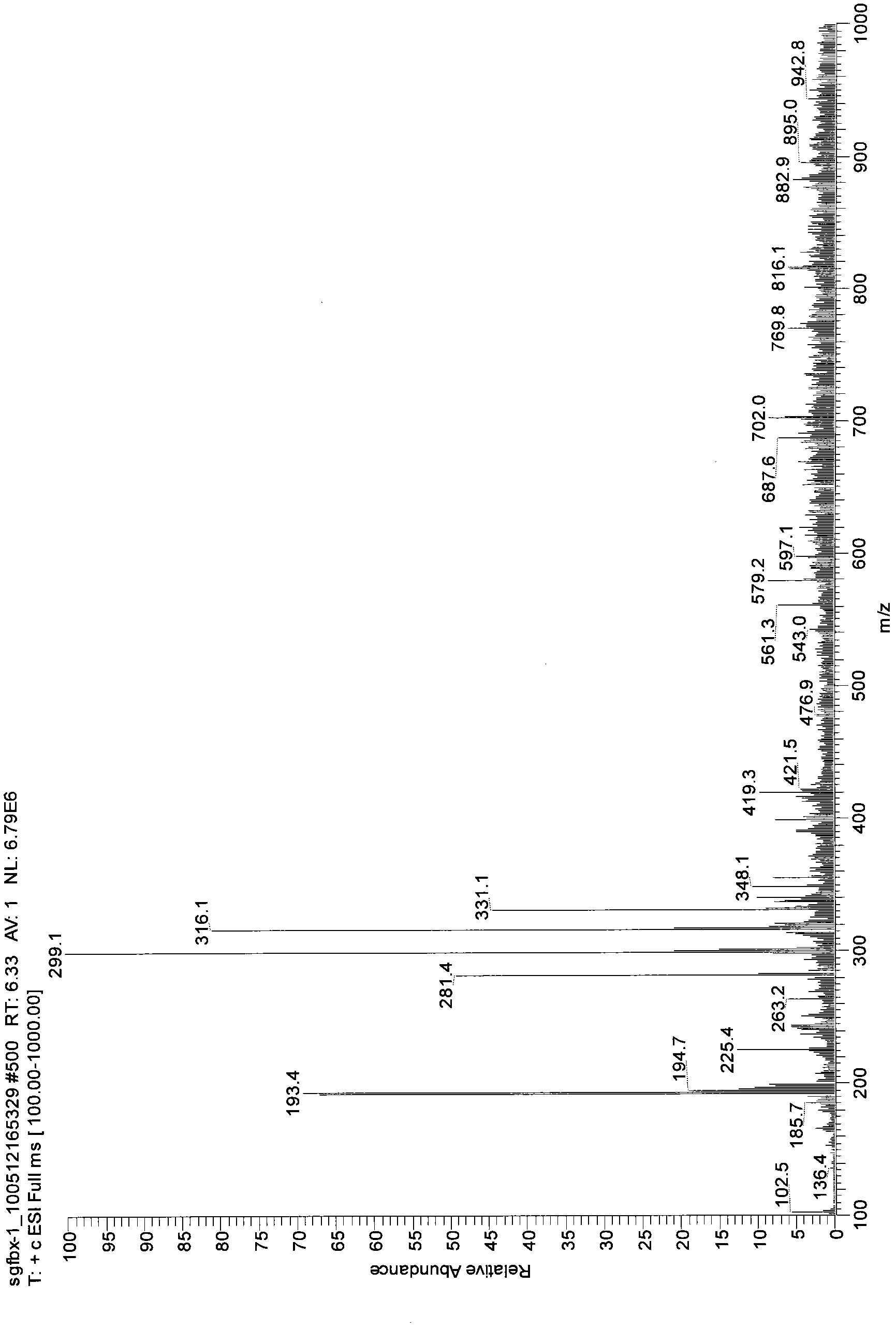

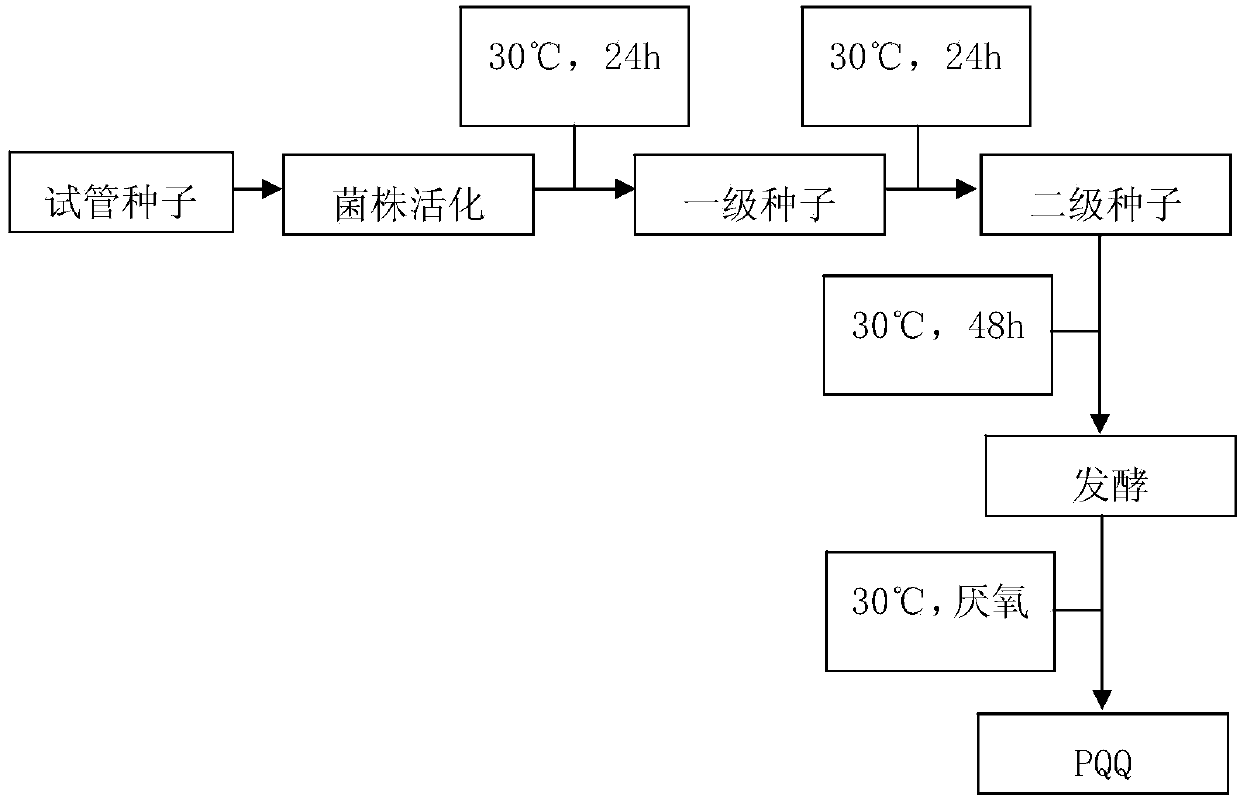

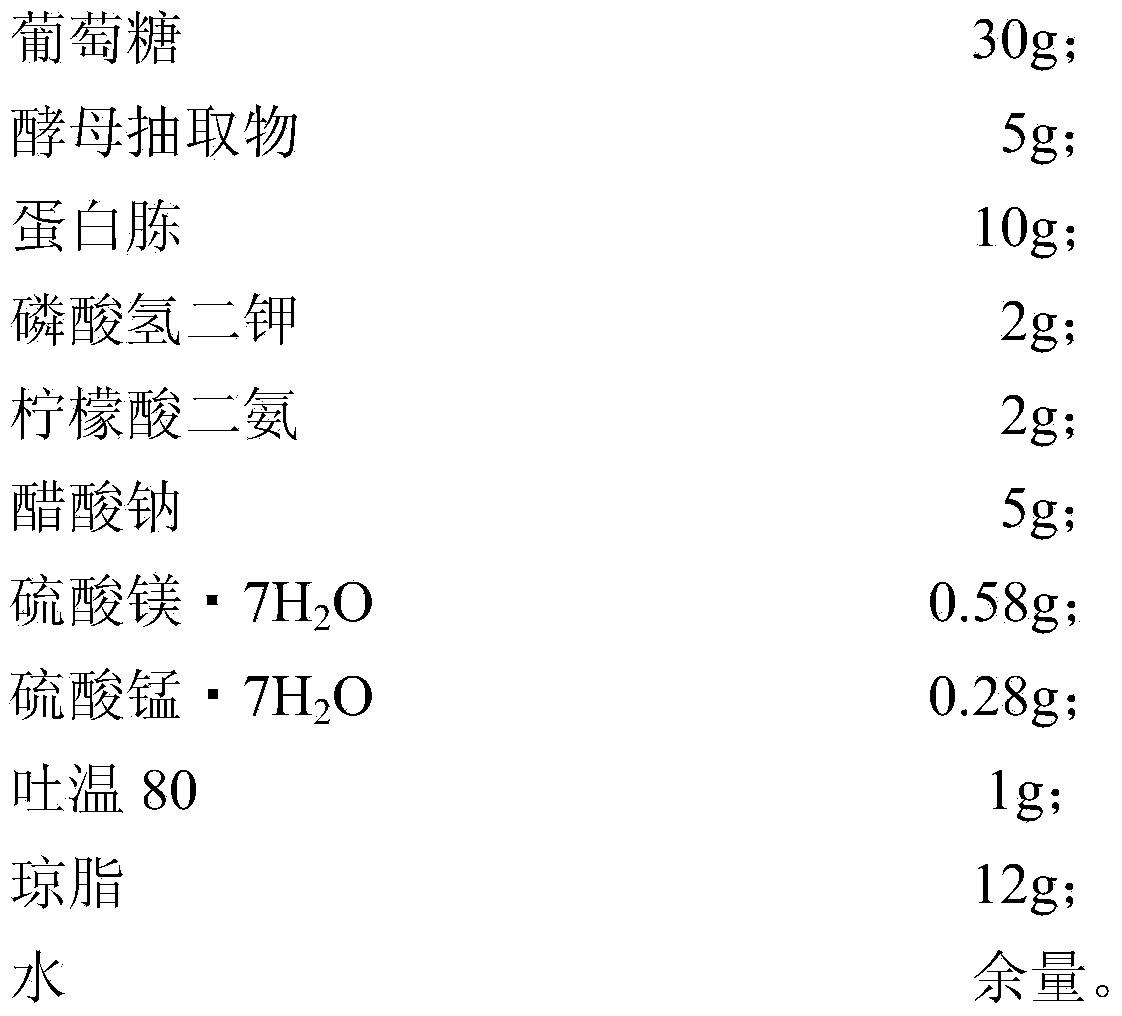

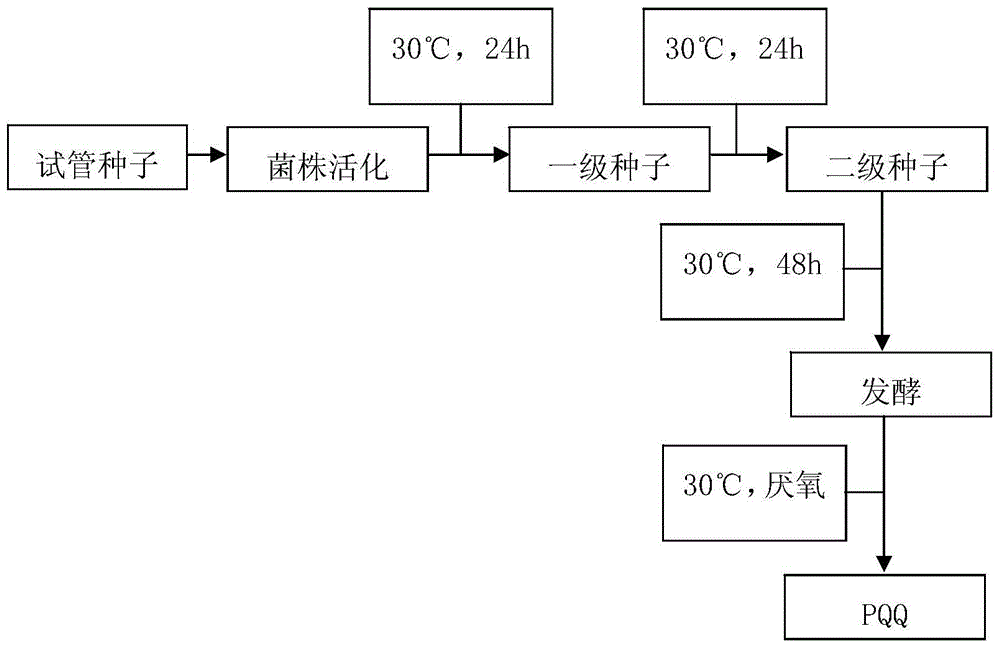

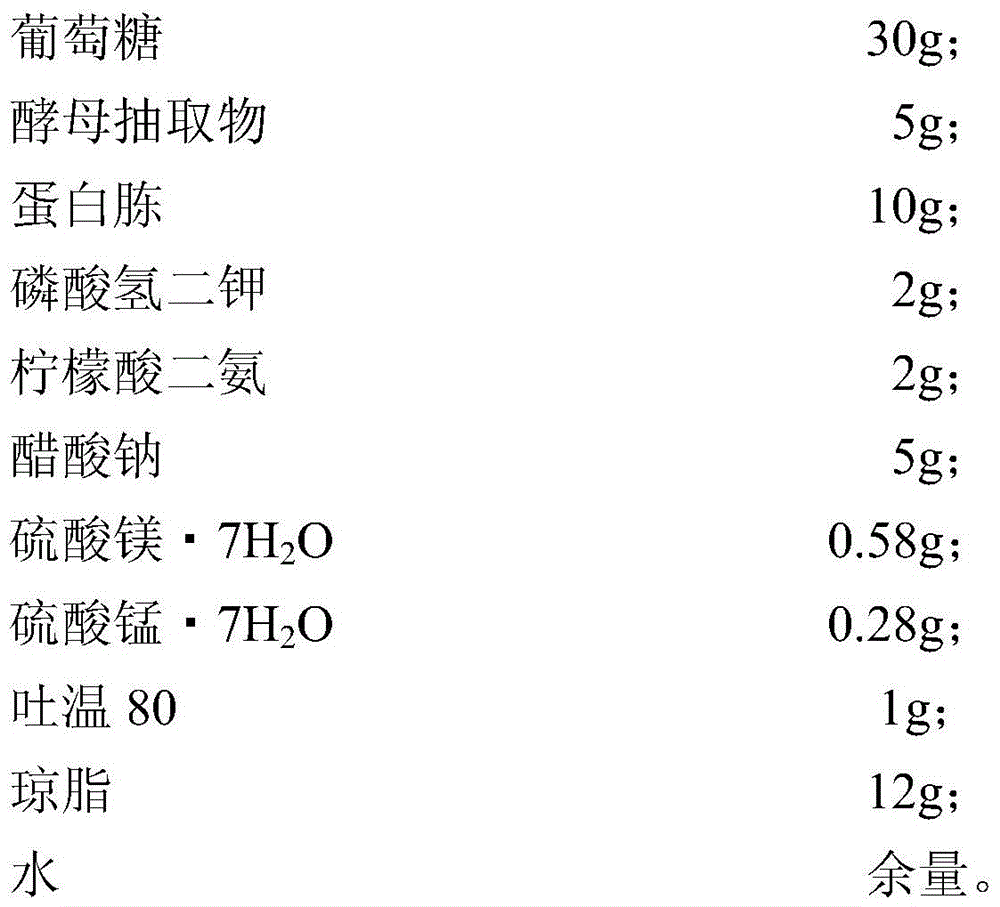

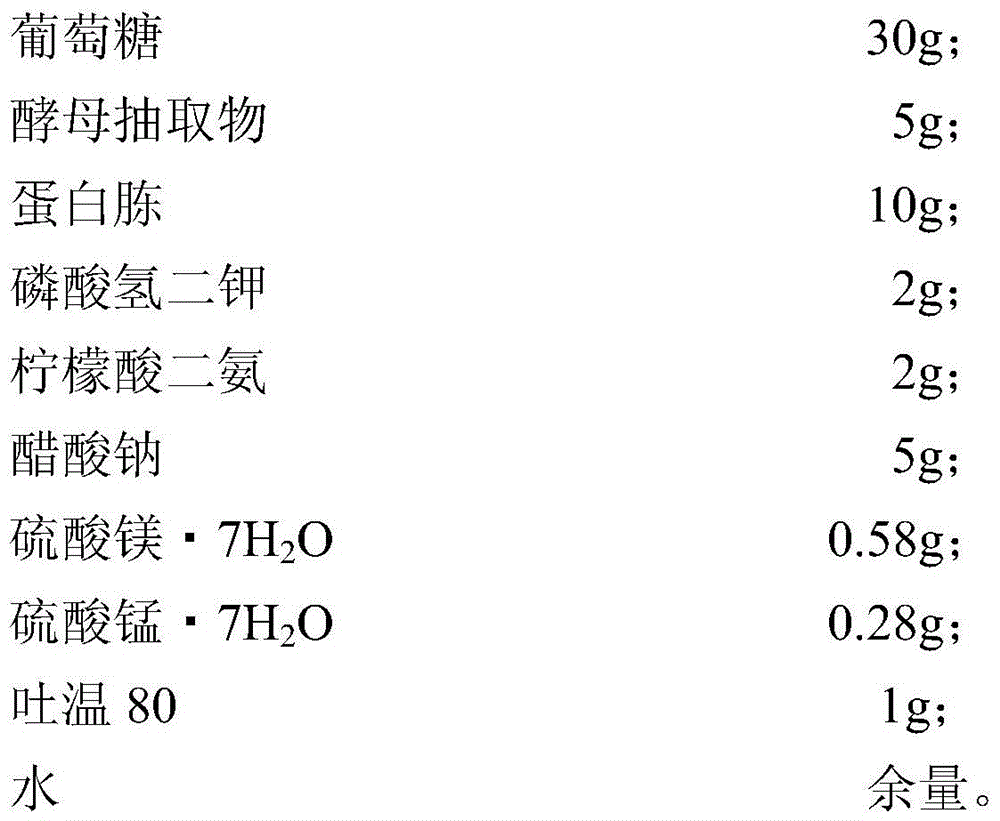

Method for synthesizing pyrroloquinoline quinone through lactobacillus fermentation

ActiveCN103740780AImprove final yieldMicroorganism based processesFermentationMicroorganismFood grade

The invention discloses a method for synthesizing pyrroloquinoline quinone through lactobacillus fermentation. The method comprises the following steps: activating the lactobacillus plantarum PQQ-1 which is stored in an agar subculture medium through an activation culture medium, and then carrying out stationary culture of the lactobacillus plantarum PQQ-1 at a temperature ranging from 20 to 40 DEG C for 16-30h to from primary seeds; further carrying out enlarging stationary culture of the primary seeds at a temperature ranging from 20 to 40 DEG C through a primary seed culture medium for 16-30h to form secondary seeds; and further carrying out enlarging stationary culture of the secondary seeds at a temperature ranging from 20 to 40 DEG C through a secondary seed culture medium for 42-54h and then starting the fermentation stage, and carrying out anaerobic culture in a production fermentation culture medium at a temperature ranging from 20 to 40 DEG C for 54-66h to obtain the PQQ. The used lactobacillus is a food-grade safe microorganism; and the PQQ is obtained through fermentation, and is high in yield and bright in application prospect.

Owner:ZHEJIANG UNIV

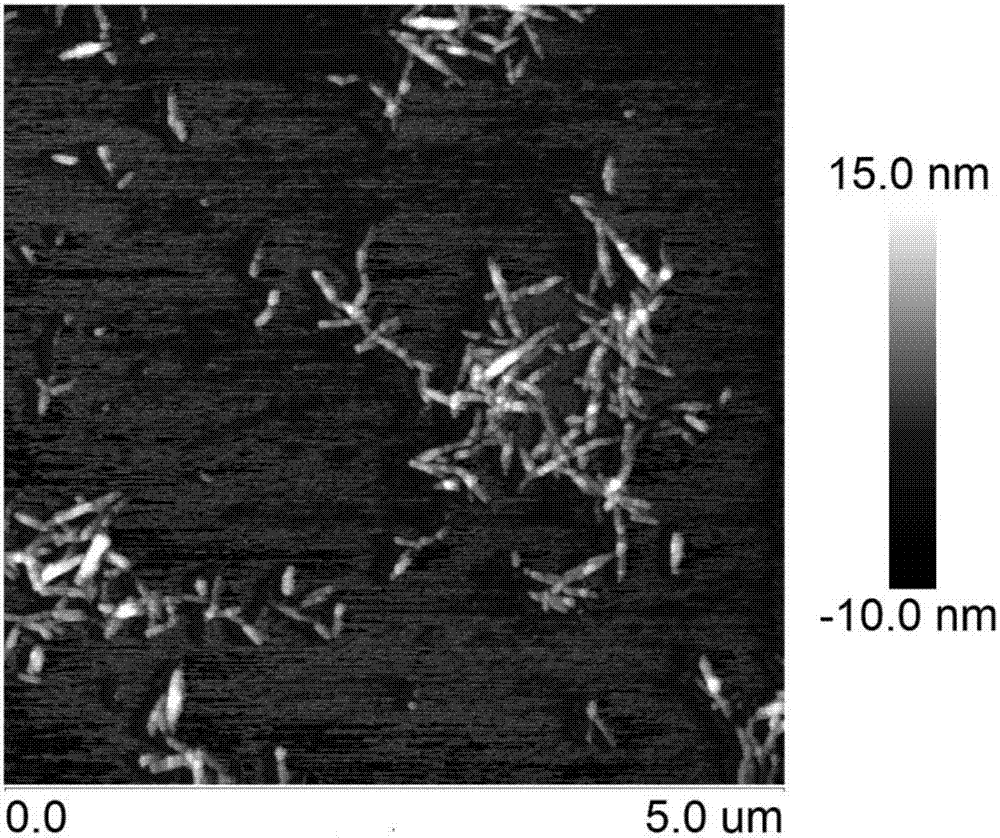

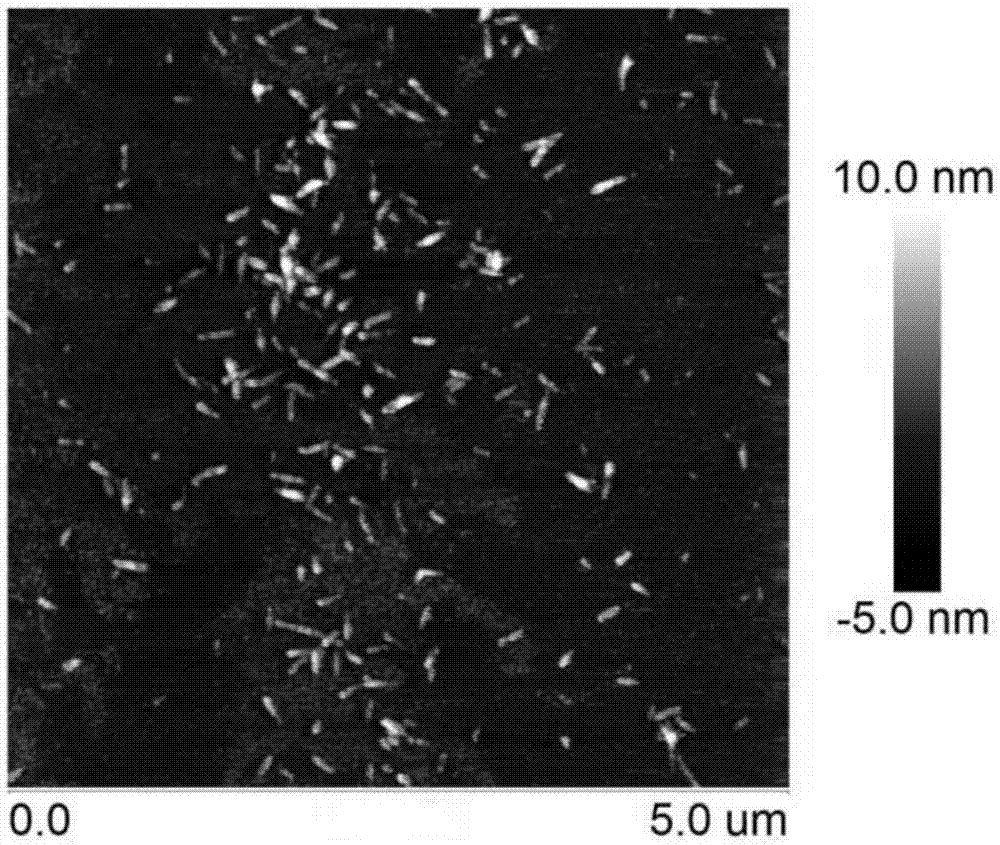

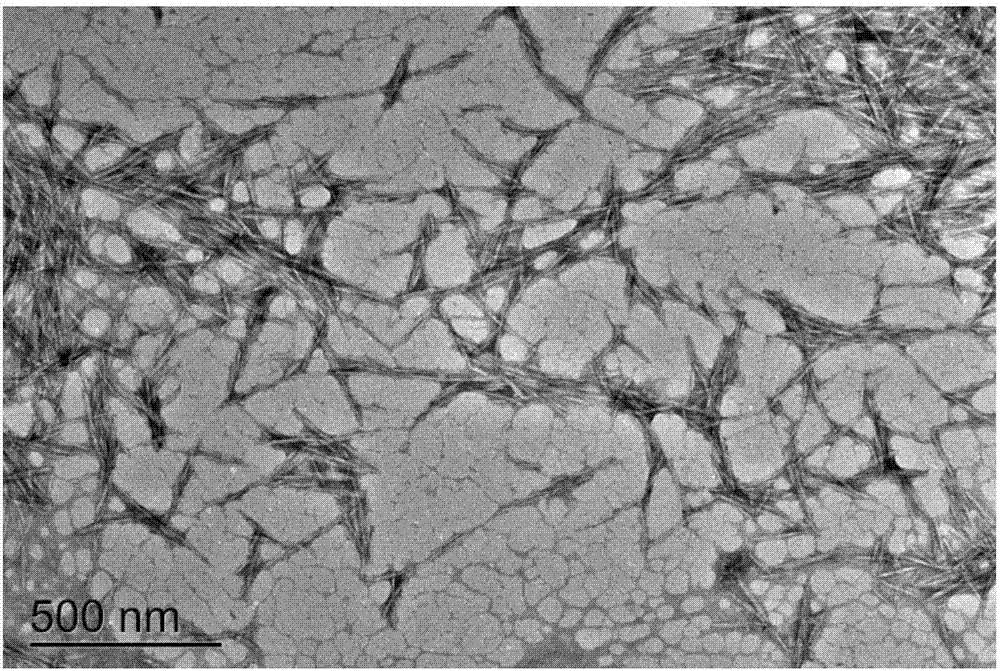

Method for preparing nano cellulose from plant fibers

InactiveCN107447565AImprove final yieldReduce processing timeWashing/displacing pulp-treating liquorsPulping with acid salts/anhydridesFreeze-dryingAcid hydrolysis

The invention discloses a method for preparing nano cellulose from plant fibers. The method comprises the following steps of adding sulfuric acid with mass concentration of 45%-55% into the plant fibers to perform pre-treating for 10-20 minutes at a temperature of 30-55 DEG C, wherein a massic volume ratio of the plant fibers to the sulfuric acid is 1g to (6-10) ml; after pre-treatment is ended, centrifugally washing to remove the sulfuric acid and collecting washing liquid, and separately recycling the sulfuric acid and carbohydrate in the washing liquid through a membrane separating method; neutralizing residual sulfuric acid in a pre-treated solid with alkaline to obtain a pre-treated solid, performing disc-milling on the pre-treated solid with a disc-milling gap of 50 mu m-100mu m, and performing high-pressure homogenizing to obtain nano cellulose suspension liquid; and performing freeze-drying or spray-drying on the suspension liquid to obtain the nano cellulose. Compared with a convention method of preparing the nano cellulose by acid hydrolysis, the method has the advantages of high yield and less time consumption, and provides a new idea for industrial production of the nano cellulose.

Owner:SOUTH CHINA UNIV OF TECH

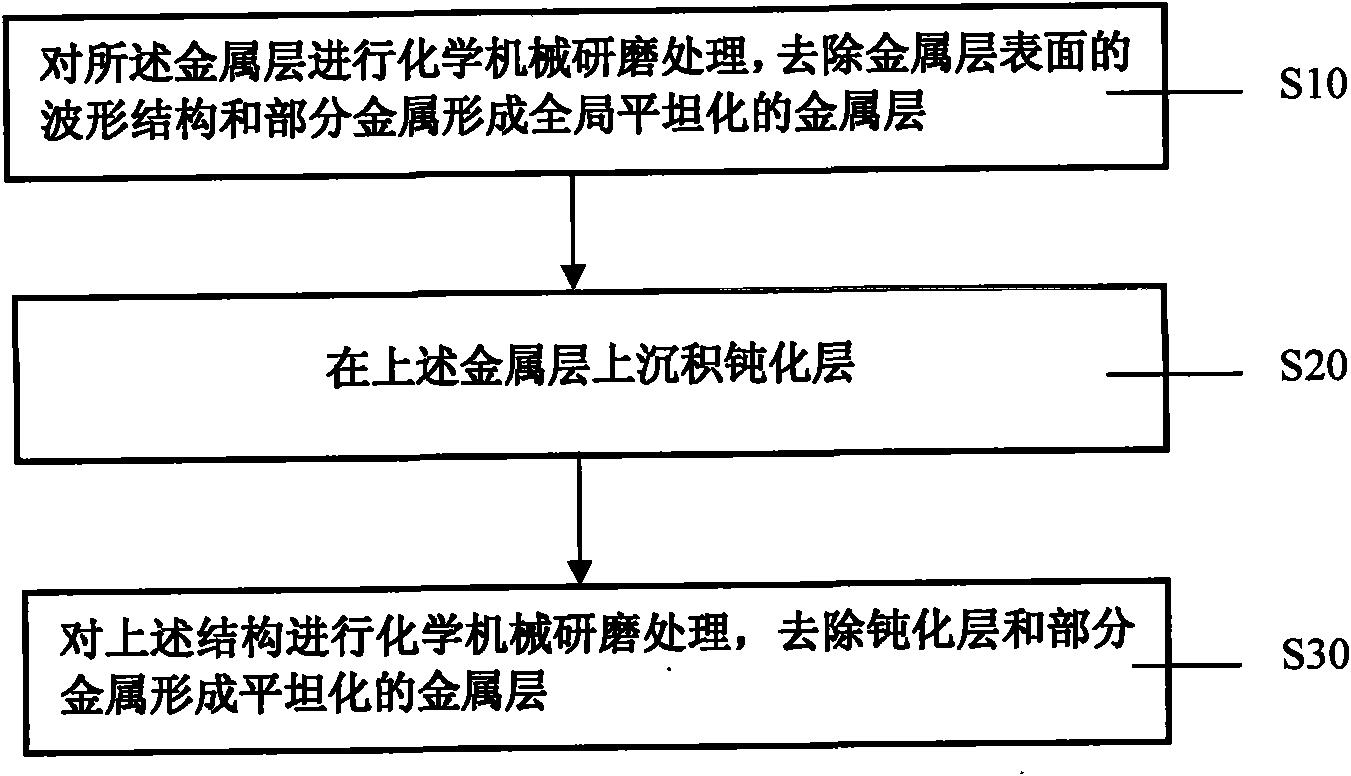

Method for reworking metal layer

InactiveCN101783292AImprove final yieldReduce surface defectsSemiconductor/solid-state device manufacturingMetallurgyMicroparticle

The invention provides a method for reworking a metal layer, which is applied in the field of integrated circuit manufacture. The method comprises the following steps: carrying out chemical mechanical lapping treatment on the metal layer, and removing a waveform structure and partial metal from the surface of the metal layer to form a globally planarized metal layer; depositing a passivation layer on the metal layer; and carrying out chemical mechanical lapping treatment on the structure, and removing the passivation layer and partial metal to form a planarized metal layer. The method for reworking the metal layer can greatly reduce surface defect caused by a normal chemical mechanical lapping process, such as the defects of metal, chemical, grinding fluid residue, microparticle residue and the like, even metal surface corrosion and crater defect, can remarkably improve the defect after the chemical mechanical lapping process, and increase the rate of good products.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

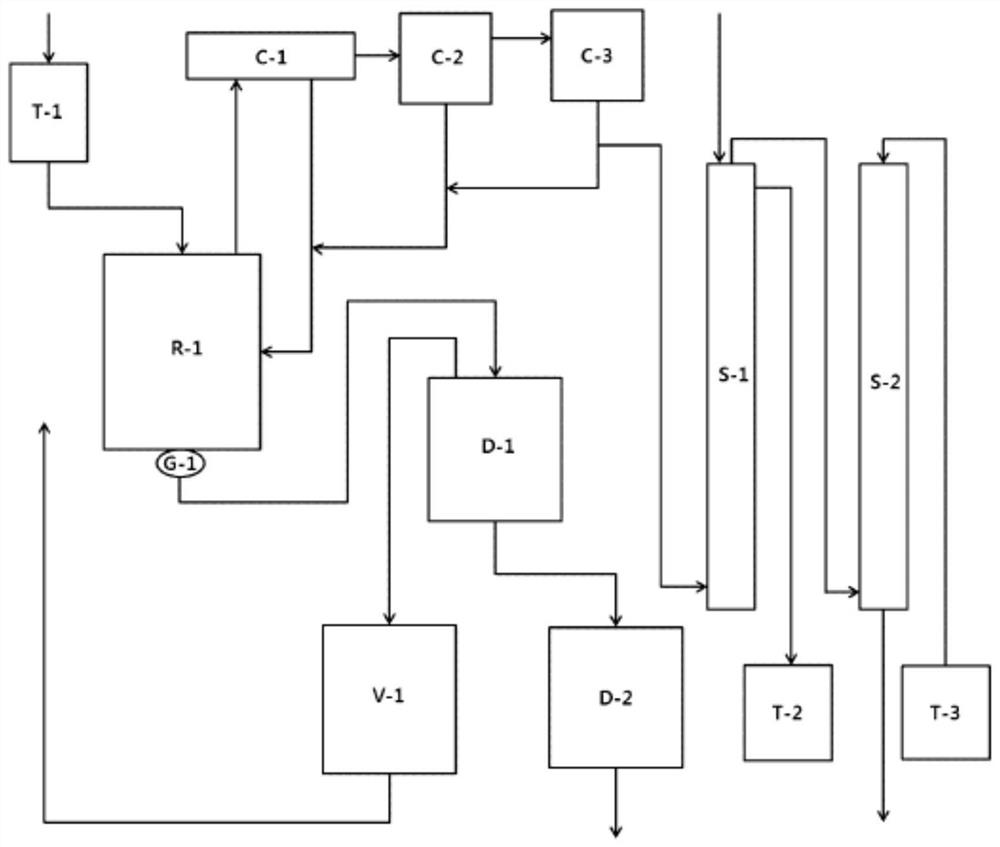

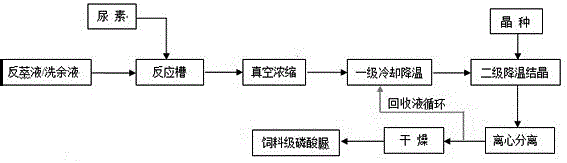

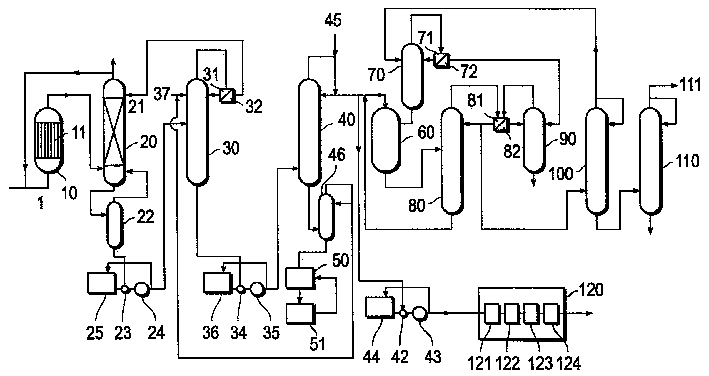

Method for continuously producing feed-grade urea phosphate from wet-method purified phosphoric acid strip liquor or washing residual liquid

InactiveCN106349116AAvoid the effects of crystallizationReduce manufacturing costUrea derivatives preparationOrganic compound preparationPhosphoric acidSuspending Agents

The invention discloses a method for continuously producing feed-grade urea phosphate from wet-method purified phosphoric acid strip liquor or washing residual liquid. The method comprises the following steps: firstly, adding the wet-method purified phosphoric acid strip liquor or washing residual liquid of which the concentration of P2O5 is 25-40% into a reaction tank, controlling the temperature to be 60-85 DEG C, stirring at a speed of 100-200r / min, keeping the temperature for 10-20 minutes, adding urea into the reaction tank in a mole ratio of phosphoric acid to urea of 1:(1.0-1.2), performing a stirring reaction for 60-90 minutes, and concentrating reaction liquid under a vacuum condition to increase the concentration of P2O5 to be 48-55%, so as to form a concentrated reactant material; reducing the temperature of the concentrated reactant material to be 5-40 DEG C, adding a crystal seed, and performing cooling constant-temperature crystallization under a stirring condition of 5-30r / min so as to separate urea phosphate; and performing centrifugal separation on the urea phosphate, and drying, thereby obtaining the feed-grade urea phosphate. The production cost is relatively low when being compared with that of industrial phosphoric acid or hot-method phosphoric acid, no activating agent, suspending agent and the like are needed in the production process, the process procedures are simple, and relatively high economic and environment-friendly values can be made.

Owner:HUBEI SANNING CHEM

Preparation of pyridine derivative

Production of pyridine derivative is carried out by reacting ketone compound with propiolic amine by catalyst, obtaining reacting liquid, filtering reacting liquid, removing catalyst, concentrating filtrate, column chromatographing, separating, and using basic substance or neutralized silica gel by basic substance in column chromatographing separation as column chromatography filler. It achieves less loss and higher final efficiency.

Owner:ZHEJIANG UNIV OF TECH

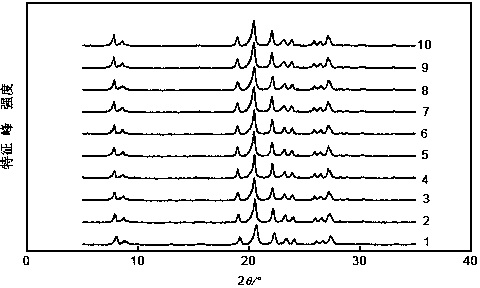

Preparation method of hydrogen type EUO (europium oxide) type molecular sieve

ActiveCN103626200AEmission reductionImprove final yieldCrystalline aluminosilicate zeolitesTetramethylammonium hydroxideMolecular sieve

The invention discloses a preparation method of a hydrogen type EUO (europium oxide) type molecular sieve. The preparation method comprises the steps of uniformly mixing water, a template agent, quaternary ammonium base, a silicon source and an aluminum source when the quaternary ammonium base is tetramethyl ammonium hydroxide, tetraethyl ammonium hydroxide or tetrapropyl ammonium hydroxide; uniformly mixing the water, the quaternary ammonium base, the silicon source and the aluminum source when the quaternary ammonium base is hexamethonium hydroxide, putting the mixture into a reaction kettle for reaction, filtering, washing, drying and roasting to obtain a hydrogen type EUO molecular sieve sample. The preparation method disclosed by the invention has the advantages of low energy consumption and simple preparation without pollution.

Owner:TAIYUAN UNIV OF TECH +1

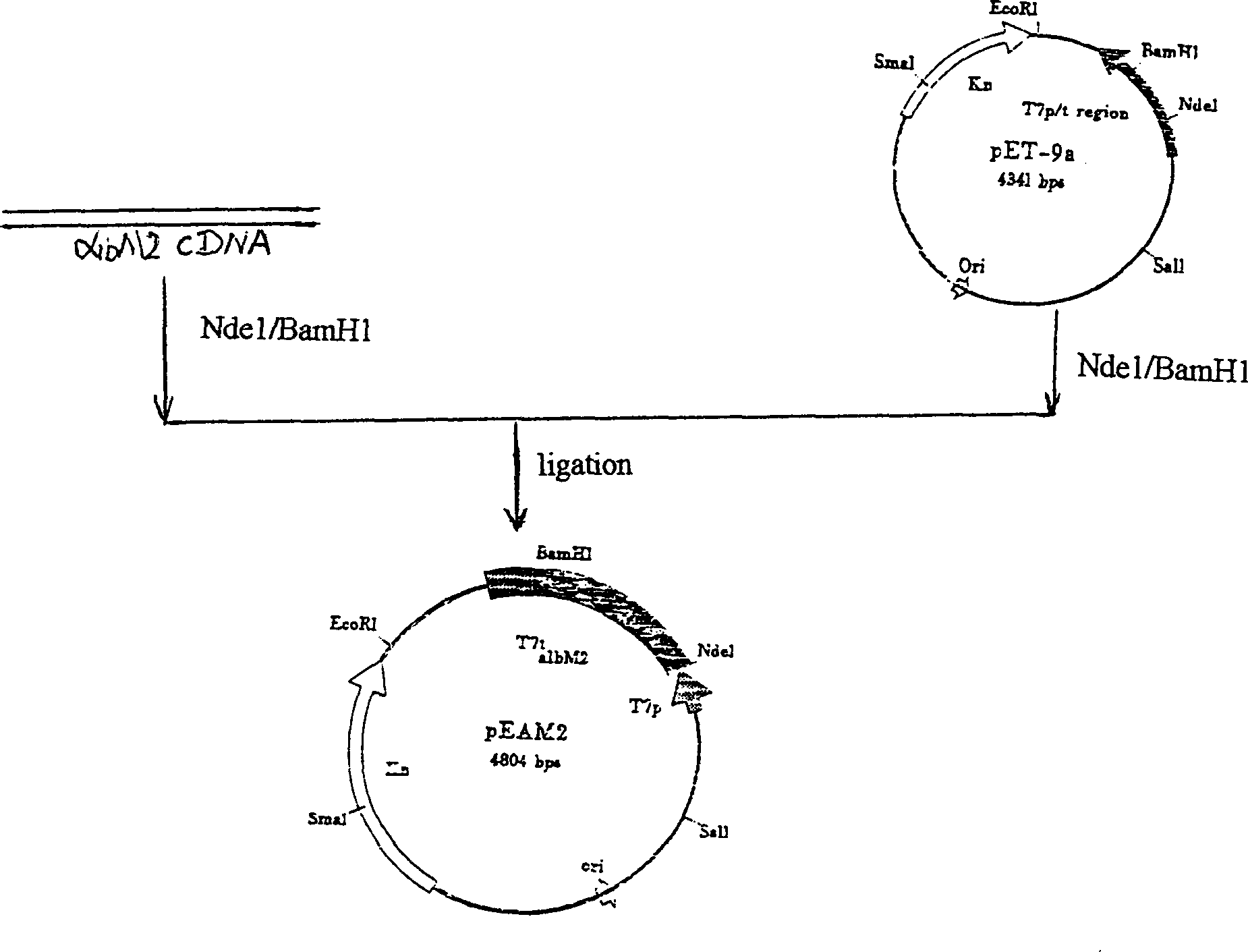

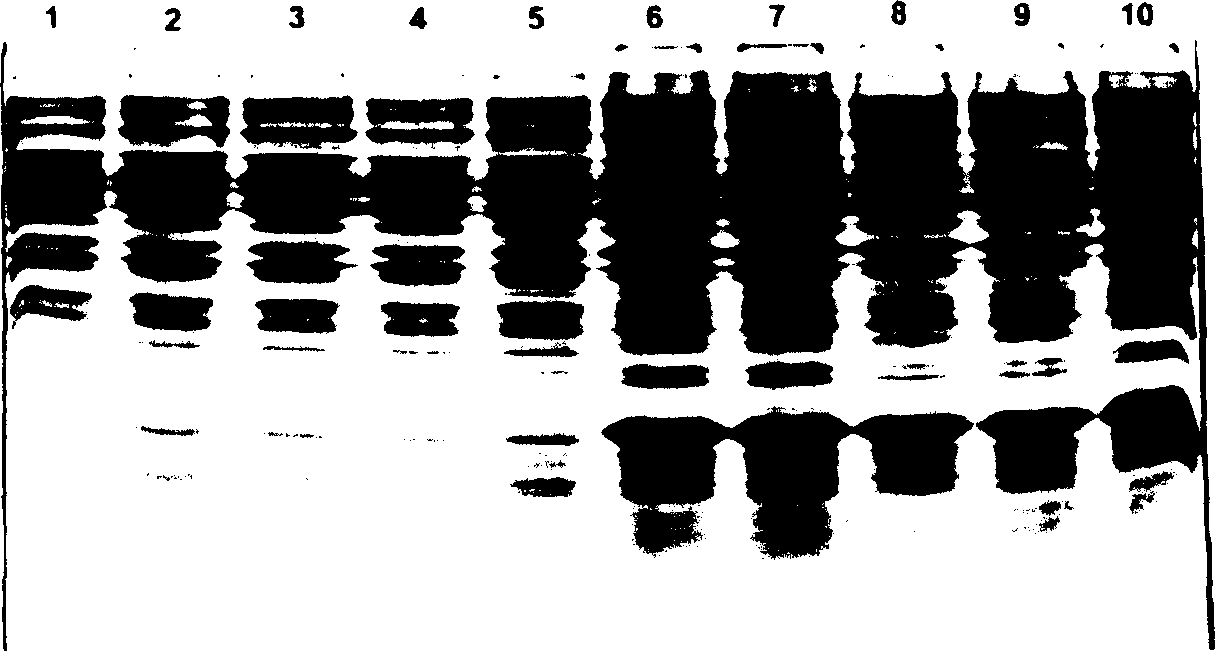

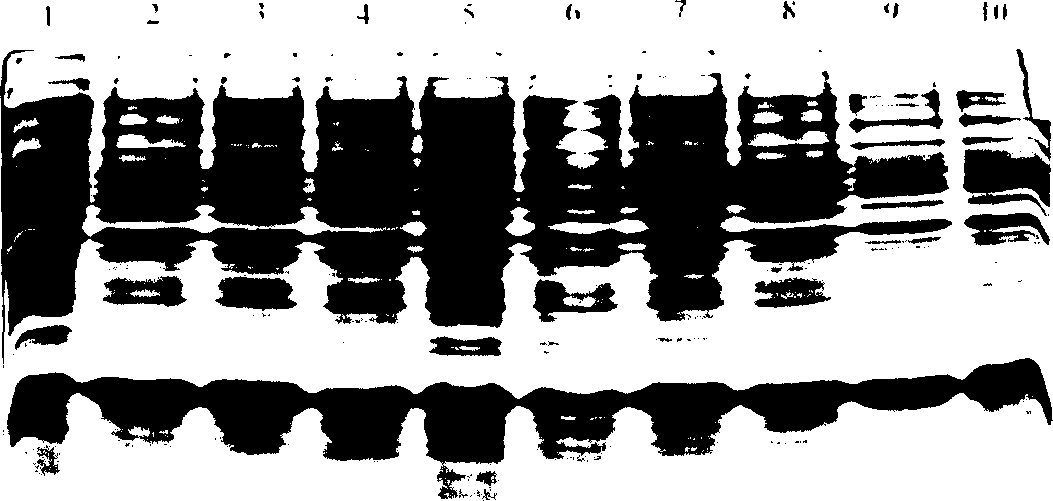

Novel process for genetic engineering preparation of insulin and insulin analogs

The invention provides a novel process for genetic engineering preparation of insulin and insulin analogs, which comprises enzyme cutting insulin precursor with parenzyme, then isolating insulin, wherein the insulin precursor comprises the following elements from amino end to carboxyl end, (1) spacing peptide element with formula (Xaa)mZ, (2) insulin B chain element, (3) joint peptide element with formula (Xaa)nZ, and (4) insulin A chain element.

Owner:费俭

A method of extracting 1,5-pentanediamine from a 1,5-pentanediamine salt solution system

ActiveCN107043333AStrong applicabilityImprove final yieldAmino compound purification/separationOrganic compound preparationSolution systemCost competitiveness

The invention provides a method of extracting 1,5-pentanediamine from a 1,5-pentanediamine salt solution system. An alkaline compound is added into the 1,5-pentanediamine salt solution system to form a solution system containing free-state 1,5-pentanediamine, and then the solution system containing the free-state 1,5-pentanediamine is distilled / evaporated in a vacuum scraping plate dryer. The degree of vacuum during distillation / evaporation is -0.015 to -0.05 MPa, and the temperature is 120-250 DEG C. The method is suitable for various salt forms of the 1,5-pentanediamine, and is higher in applicability and more cost-competitive. The vacuum scraping plate dryer is adopted as an evaporation device so that the final yield of the pentanediamine is greatly increased. Solid compounds do not influence a distillation / evaporation process. Solid liquid separation after the alkaline compound is added is not required and evaporation is performed directly, thus simplifying the process steps.

Owner:CATHAY R&D CENT CO LTD +1

Preparing method for acrylic acid

InactiveCN1472187AAvoid formingImprove final yieldOrganic compound preparationCarboxylic compound separation/purificationOligomerFractionating column

Owner:NIPPON SHOKUBAI CO LTD

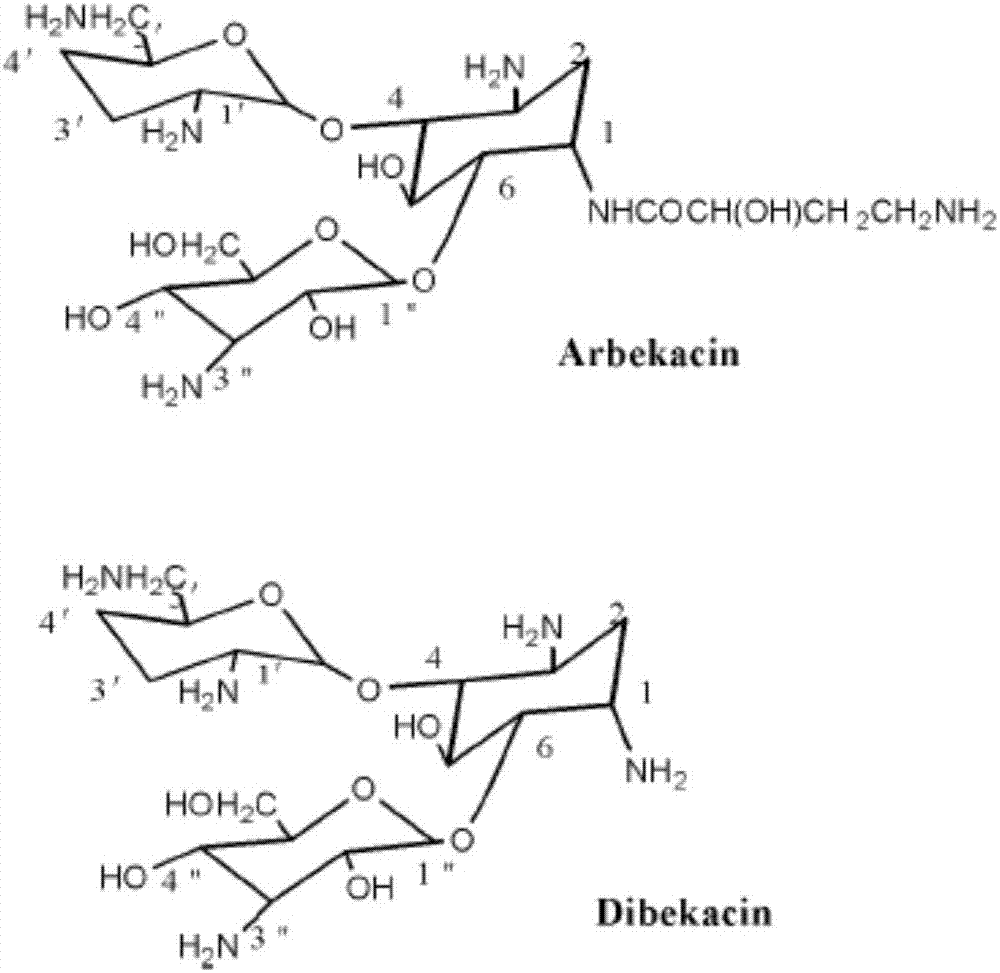

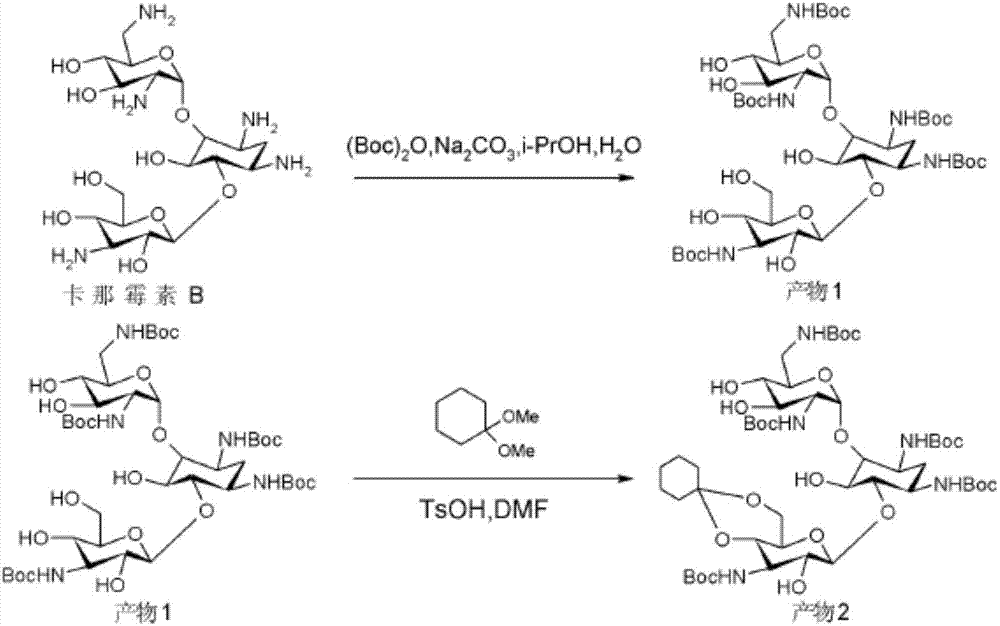

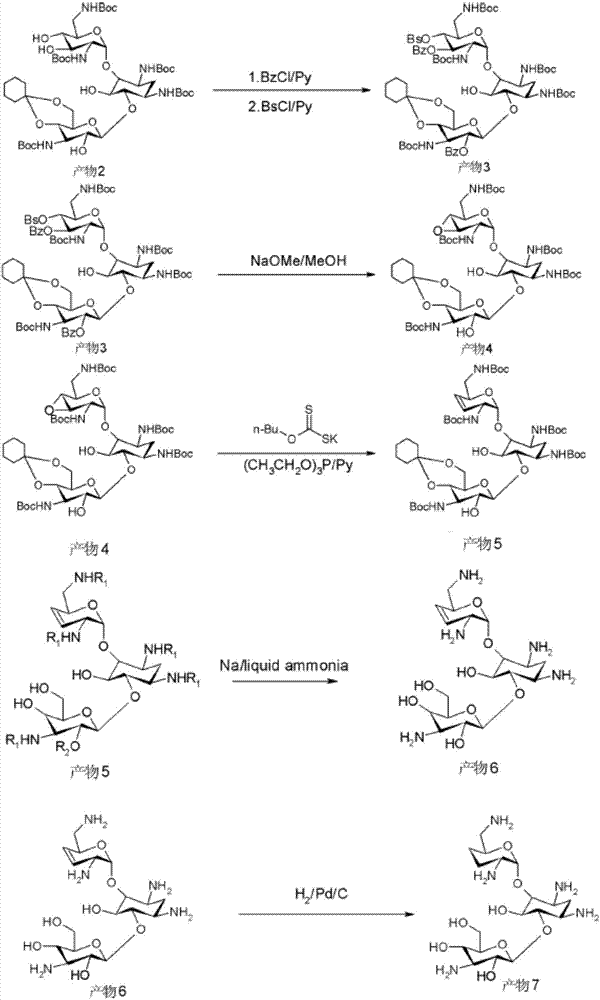

Preparation method for Arbekacin intermediate Dibekacin

ActiveCN106946957AEasy routeThe synthesis process is simpleSugar derivativesSugar derivatives preparationDibekacinChemistry

The invention discloses a preparation method for an Arbekacin intermediate Dibekacin. P-toluenesulfonic acid, kanamycin B and PhCH(OMe)2 are first mixed to react, forming ring protection on the hydroxyl groups at sites 4'' and 5'' of kanamycin B, R groups (R=BnSO2) are then used for replacing hydrogen atoms of -NH2 groups at sites 1, 3, 2', 5' and 3'' and -OH groups at sites 3', 4' and 2'', -OR groups at sites 3' and 4' are then removed and ring opening is carried out at sites 4'' and 5'', and finally, R(R=BnSO2) group protection is removed, so that Dibekacin is obtained. The route of the preparation method for Dibekacin disclosed by the invention is simple, and the synthesis process is simplified; moreover, final yield is high, the yield reaches 53.4 percent, the purity of obtained Dibekacin is high, and the purity is 98 percent. The protective reagent dimethoxymethylbenzene used in the first step is cheap and easy to obtain.

Owner:CHANGZHOU FANGYUAN PHARMA +1

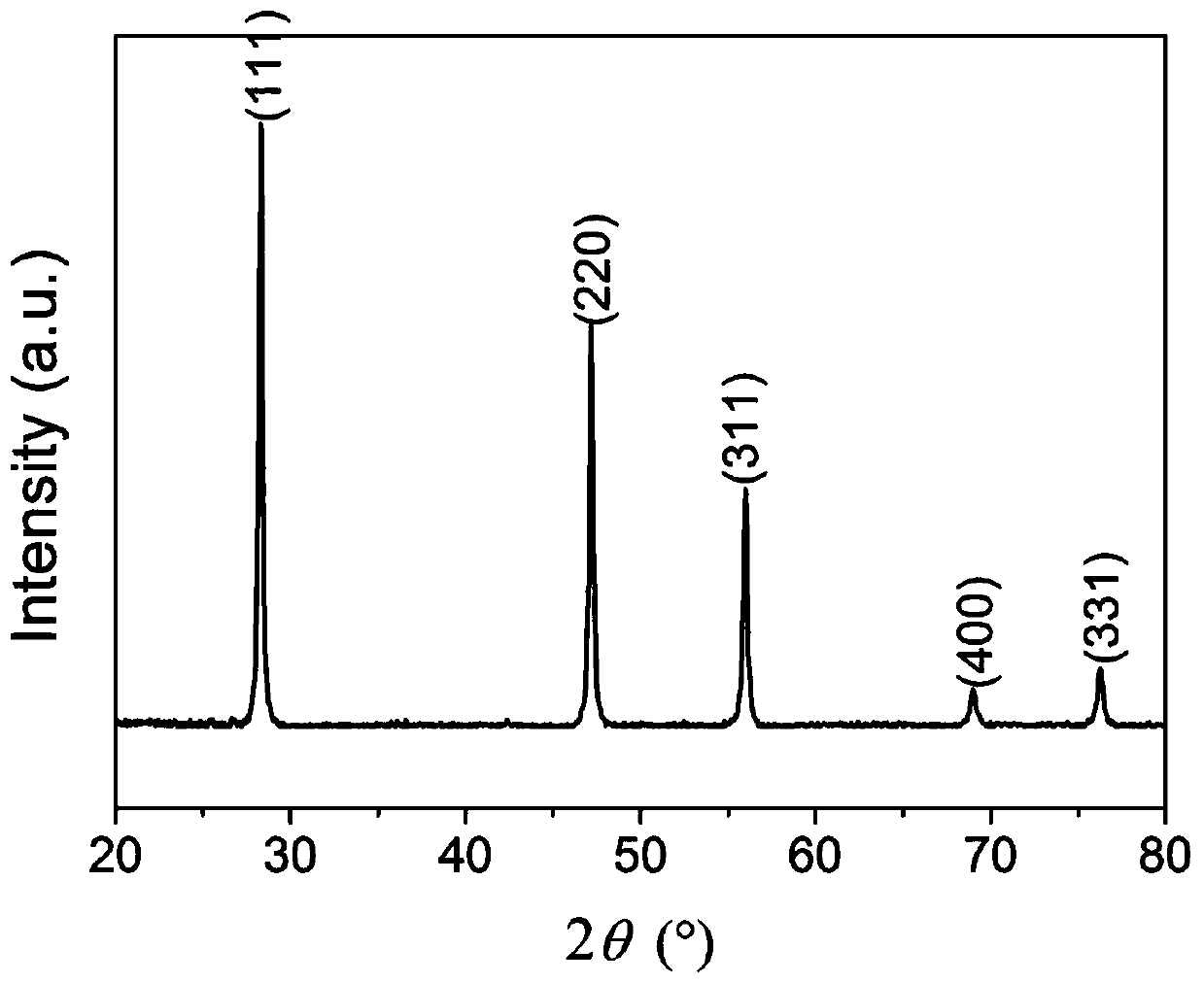

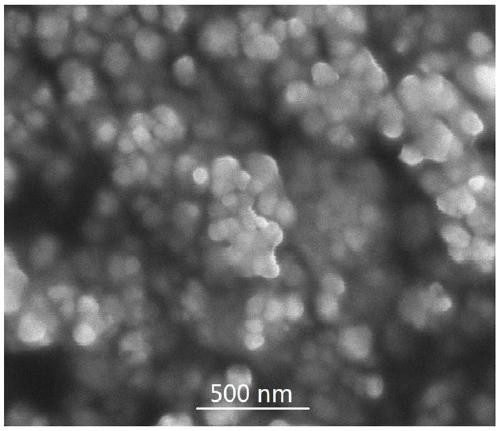

High-efficiency low-temperature molten-salt preparation method of nano Si

InactiveCN109721057AIncrease dosageAvoid pollutionNanotechnologySilicon compoundsIce waterVacuum drying

The invention discloses a high-efficiency low-temperature molten-salt preparation method of nano Si, and belongs to the technical field of inorganic material synthesis. The method comprises the following specific steps: using a Si source (SiO2 or silicate) and coarse particle Mg powder or Al powder as reaction raw materials, using a quaternary chloride salt with a specific molar ratio of KCl to CaCl2 to NaCl to AlCl3 as a low-temperature molten salt, putting the reaction raw materials and the low-temperature molten salt into a ball milling tank, performing ball milling for 3-5 h, performing heat treatment in an oven at 150-180 DEG C for 8-12 h, putting the ball milling tank in 0 DEG C ice water, performing cooling, repeating the above ball milling and heat treatment processes, washing theobtained product by using hydrochloric acid, performing centrifugal separation, performing treatment by using hydrofluoric acid, and performing vacuum drying to obtain the nano Si powder. The preparation method provided by the invention has higher efficiency (a Si yield can reach 88.1-95.6%), a simple preparation process, lower costs, simple and easy equipment, and environmental friendliness, andcan be directly used for industrialized production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

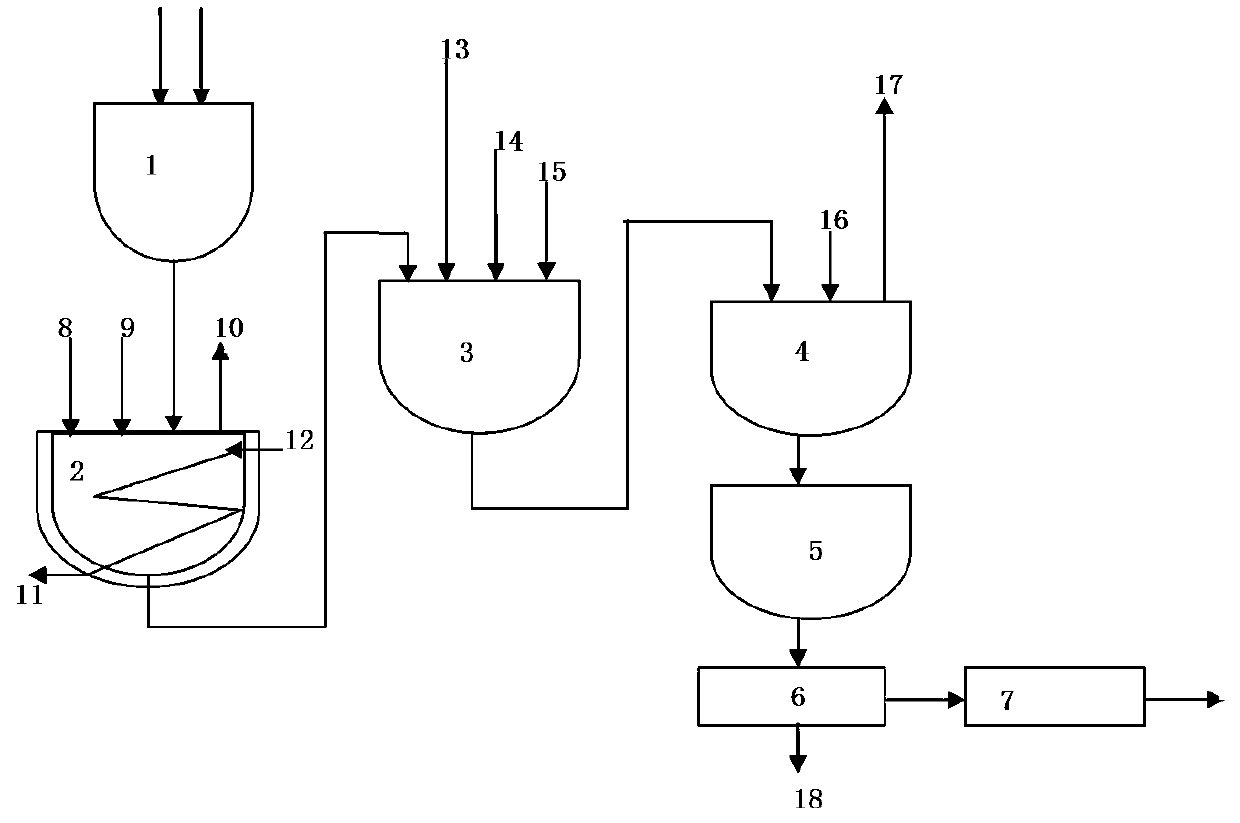

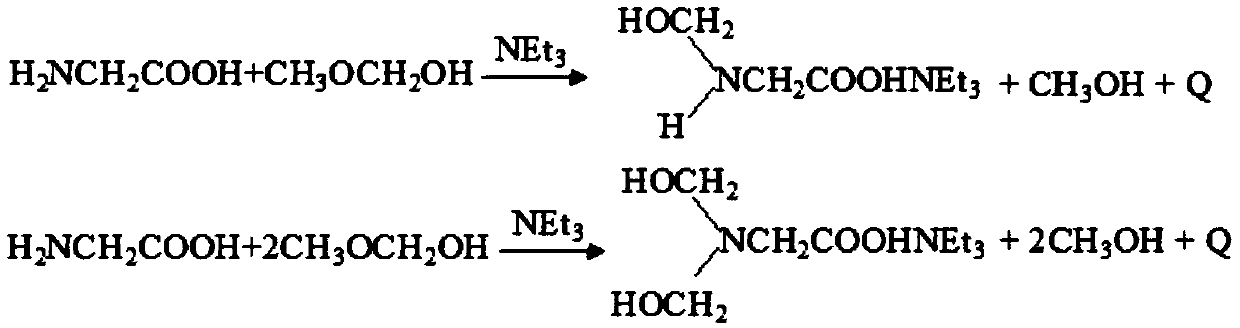

Glyphosate synthesis technology and device

PendingCN110862413AFast depolymerization reactionThorough responseGroup 5/15 element organic compoundsBiotechnologyPhosphorous acid

Provided is a glyphosate synthesis technology. The glyphosate synthesis technology is characterized in that a metal alkoxide organic compound is adopted as a catalyst for glyphosate synthesis and particularly for depolymerization and addition during glyphosate synthesis. The glyphosate synthesis technology includes the following steps: an alcohol and paraformaldehyde are mixed and stirred to be uniform, the catalyst is added into a mixture solution or directly added into an alcohol solution of formaldehyde, and a transparent mixture solution is generated; triethylamine and glycine are added into the transparent mixture solution, stirring is conducted to carry out an addition reaction, and after the addition reaction is finished, dimethyl phosphite is added into the mixture solution to carry out a condensation reaction; and after the condensation reaction is finished, hydrochloric acid is added into the mixture solution to carry out hydrolysis, and then through crystallization, washingand drying, glyphosate is obtained. According to the technical scheme of the glyphosate synthesis technology, the specific catalyst is adopted, therefore, glyphosate synthesis reaction speed and selectivity are improved, reaction speeds of depolymerization and addition are high, the reactions are conducted completely, the final yield of a glyphosate product obtained through the glyphosate synthesis technology is increased by 3% or above compared with the final yield of a glyphosate product obtained through traditional technologies, and thus the glyphosate synthesis technology has a reaction advantage, an energy-saving advantage, a coat advantage and an environment-friendly advantage.

Owner:HUBEI TAISHENG CHEM

Method for preparing ethanol by adding Mn (II) salt for promoting simultaneous saccharification and fermentation of straw

InactiveCN103436588AHigh activityImprove final yieldBiofuelsMicroorganism based processesChemistryFermentation broth

The invention provides a method for preparing ethanol by adding Mn (II) salt for promoting simultaneous saccharification and fermentation of straw. The method comprises the steps of: after grinding and sieving straw stalks, selecting glycol as a liquefier, carrying out liquefaction pretreatment under the catalysis action of concentrated sulfuric acid, and carrying out washing and suction filtration to obtain a fermentation substrate; selecting pachysolen tannophilus and saccharomyces cerevisiae as fermentation microorganisms, respectively taking the two types of yeast after slant culture and activating in a YEPD (Yeast Extract Peptone Dextrose) liquid culture medium, loading a culture medium mixed liquor by using a hemocytometer, determining the yeast concentration through microscopic counting, and diluting to suitable concentration; respectively adding the fermentation substrate, a MnSO4 solution, cellulase and the diluted yeast mixed liquor into a fermentation tank, and after adjusting to a suitable solid-liquid mass ratio by using sterile water, carrying out simultaneous saccharification and fermentation under the condition of constant temperature; finally determining the ethanol concentration in fermentation liquor by using a spectrophotometric method, and calculating to obtain the final yield of the ethanol. According to the method, the related raw materials are wide in sources, and the method is convenient to operate, and can be used for reducing the dosage of the cellulase so as to lower the process cost and starting biochemical reaction at low temperatures, thus providing a new train of thought for a production process in the field.

Owner:CHONGQING UNIV

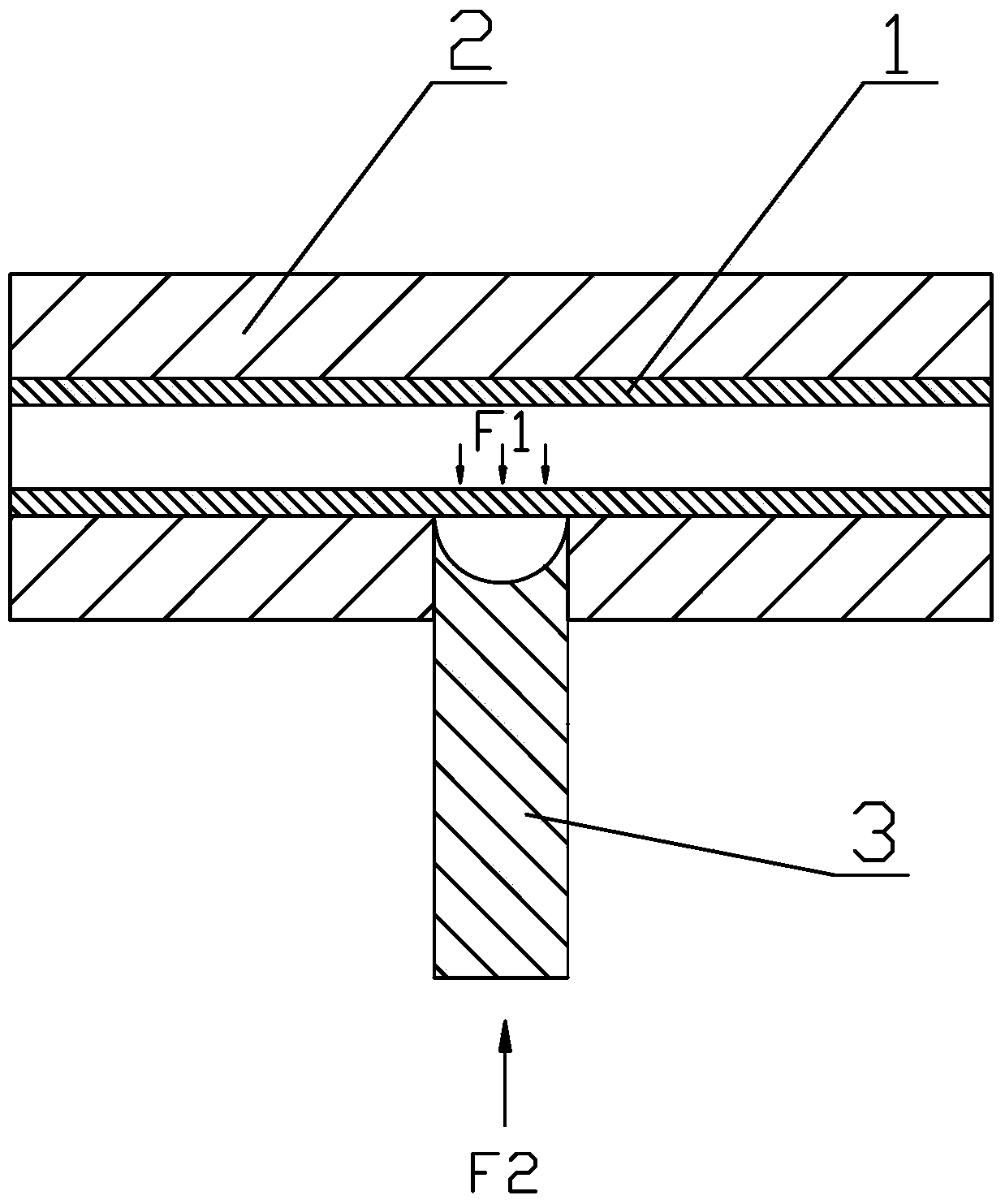

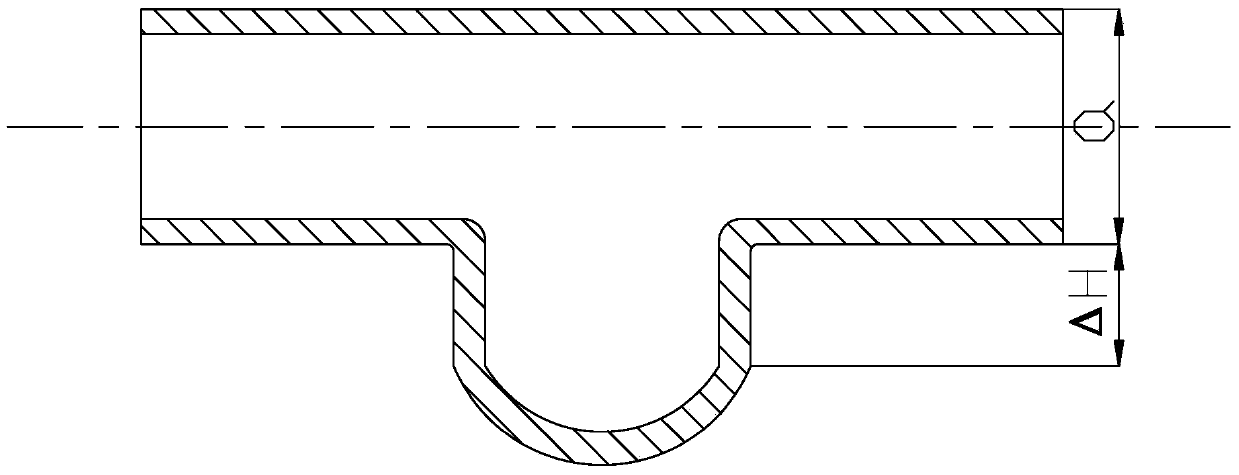

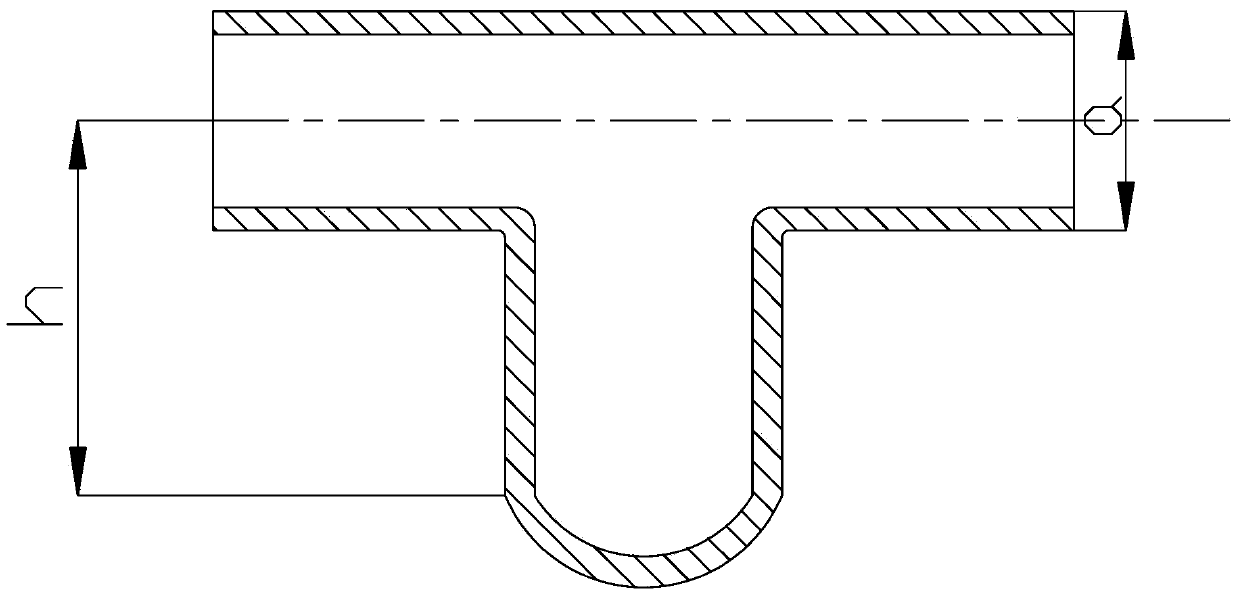

Hydraulic bulging forming method for colored metal three-way joint

ActiveCN103691795APrevent oxidationReduce or eliminate residual stressAbrasive blastingNonferrous metal

The invention discloses a hydraulic bulging forming method for a colored metal three-way joint. The method comprises the steps of 1, clearing and removing impurities and oil dirt attached to the inner surface and the outer surface of a colored metal pipe blank, and then smearing a lubricating agent on the outer surface of the colored metal pipe blank; 2, selecting a mold, and arranging the colored metal pipe blank with the lubricating agent into a mold cavity of the mold; 3, performing hydraulic bulging forming on the colored metal pipe blank arranged in the mold through a three-way hydraulic machine to obtain a semifinished three-way joint product; 4, performing thermal treatment on the semifinished three-way joint product; 5, repeatedly performing the step 2 and the step 3 on the semifinished three-way joint product subjected to the thermal treatment to obtain a formed piece; 6, performing stress removal thermal treatment on the formed piece; and 7, cutting off a branch pipe plug of the formed piece, then performing groove processing, and finally performing abrasive blasting to obtain a finished three-way joint product. According to the hydraulic bulging forming method disclosed by the invention, oxidization of the colored metal three-way joint in a manufacturing process is effectively prevented, the problems of residual stress and processing hardening in a forming process are alleviated or solved, and the yield of the product is obviously increased.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

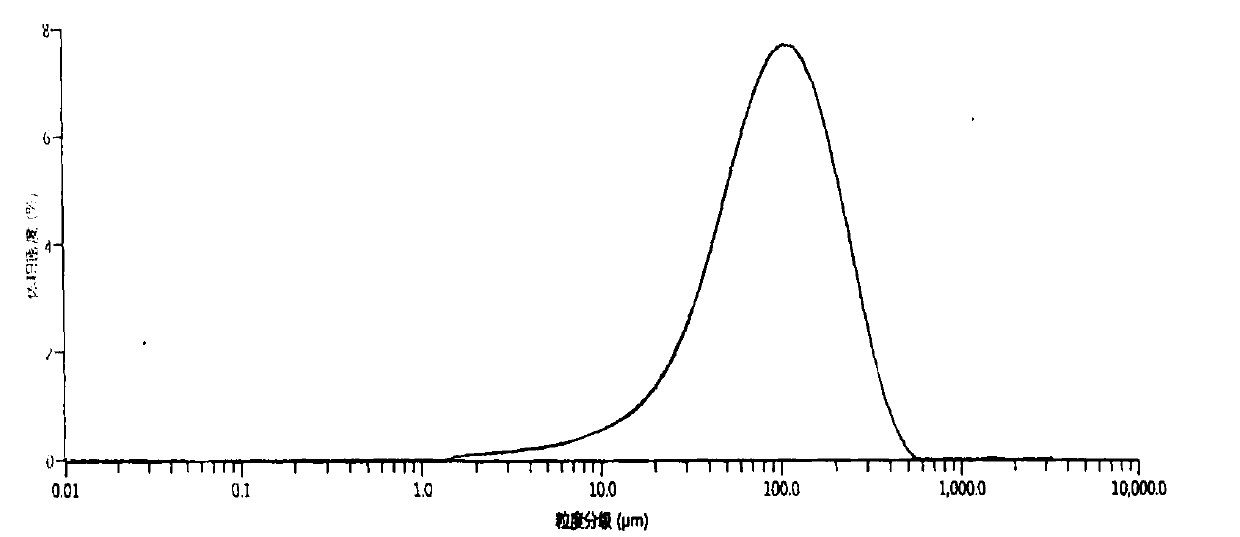

Method for preparing levulinic acid from steam explosion produced straw short fiber by adding polymerization inhibitor and performing solid acid catalysis

InactiveCN102675086ASmall granularityLarge specific surface areaOrganic compound preparationChemical recyclingFiberChemical industry

The invention discloses a method for preparing levulinic acid from steam explosion produced straw short fiber by adding polymerization inhibitor and performing solid acid catalysis. The method comprises the steps of using the straw short fiber which is produced by the steam explosion, performing hydrolysis to the straw short fiber tissue by using solid acid catalyst instead of liquid acid to obtain intermediate products such as hexose and the like, then dehydrating the hexose to obtain hydroxymethyl furfural, and finally performing ring opening and hydration to hydroxymethyl furfural to obtain the levulinic acid. The polymerization inhibitor of p-hydroxyanisole is added after optimization of conditions and pre-enzymolysis. The yield of levulinic acid reaches 25.2%, and the yield is 68.7 % of the theoretical yield. The reaction condition of the method is mild, and the catalyst shows high activity. The product does not contain inorganic acid, so that the product does not produce a lot of waste residue and corrode equipment. The catalyst can be separated from raw materials and the product easily, and accords with today's chemical industry green development direction. And also, the whole straw is no longer low-value used. Instead, the long fiber and the short fiber of the straw are separated to carry out stratified multistage directional transformation to achieve the diversification of straw products and high-value utilization of resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Vonoprazan fumarate preparation method

ActiveCN110734424AReduced purification stepsHigh yieldCarboxylic acid salt preparationPyrroleOXALIC ACID DIHYDRATE

The invention provides a vonoprazan fumarate preparation method, which comprises: reducing 5-(2-fluorophenyl)-1-(pyridine-3-ylsulfonyl)-1H-pyrrole-3-formaldehyde with a reducing agent, adding oxalic acid, carrying out a reaction to prepare a crude vonoprazan oxalate, refining the crude vonoprazan oxalate by using an organic solvent, and forming a salt with fumaric acid to prepare the vonoprazan fumarate. According to the invention, with the preparation method, the purification steps of the final product vonoprazan fumarate can be reduced, the high yield is guaranteed while the high product purity is obtained, the particle size of the obtained product is small, the requirements of preparations can be met, the product quality is guaranteed, and the production cost is controlled.

Owner:四川弘远药业有限公司

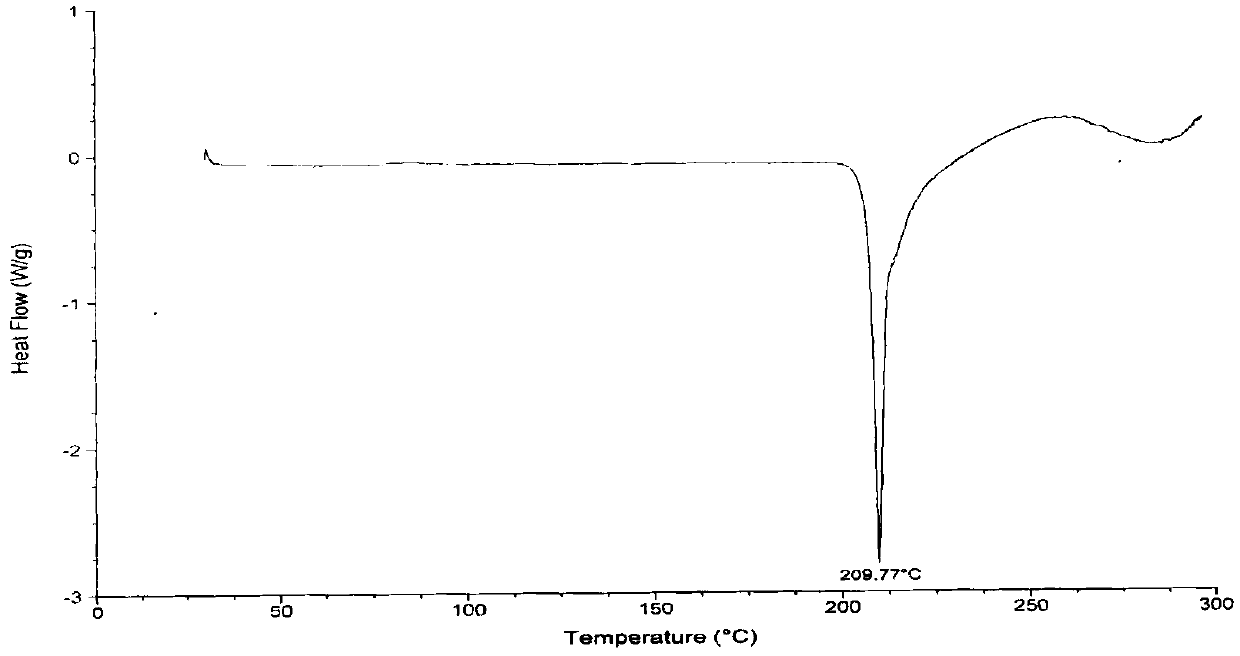

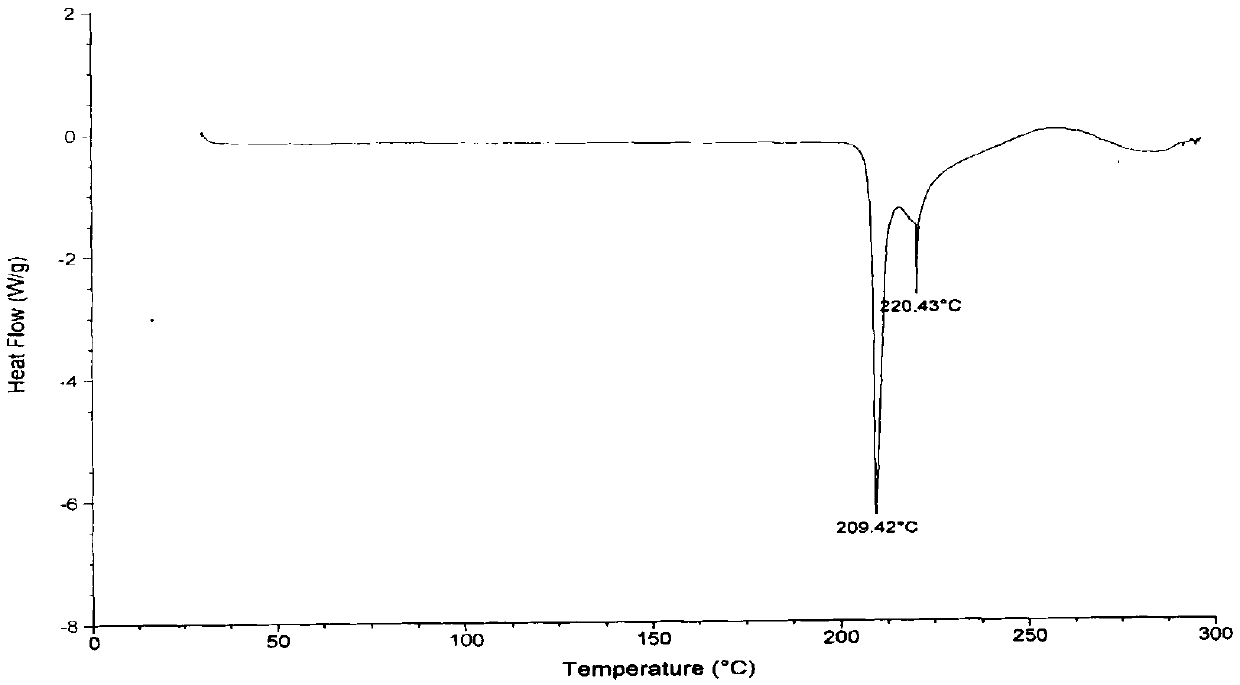

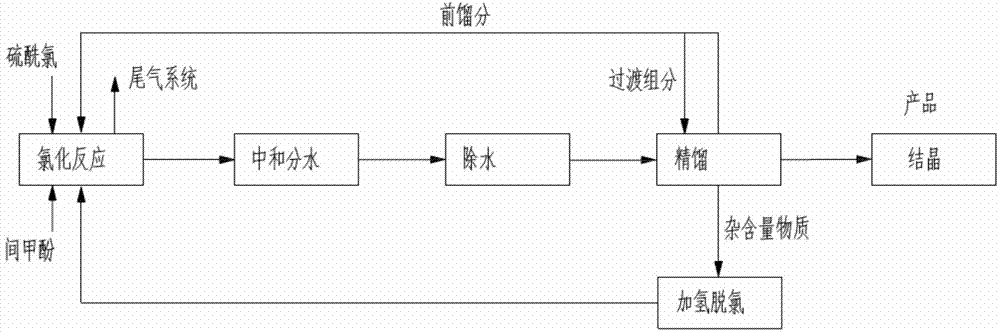

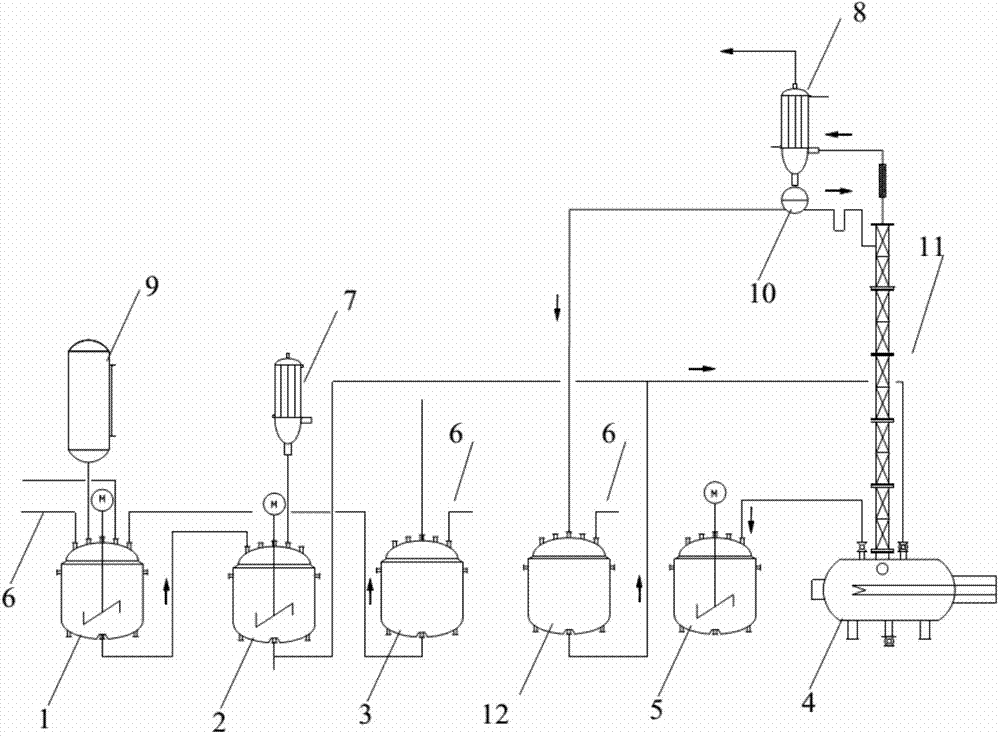

Synthesis method of 4-chloro-3-cresol and system thereof

ActiveCN103772153AWill not be chlorinated againNot chlorinatedOrganic chemistryOrganic compound preparationMolten stateCresol

The invention belongs to the field of organic compounds, and provides a synthesis method of 4-chloro-3-cresol. The method is characterized in that m-cresol is used as a raw material, sulfuryl chloride is used as a catalyst, the molar ratio of sulfuryl chloride to m-cresol is (0.5-1.0):1, and the reaction temperature is 0-50 DEG C. According to the synthesis method provided by the invention, without catalysts and solvents, chlorination reaction is performed at 30-40 DEG C in a molten state, and a main substance generated by the reaction is 4-chloro-3-cresol; the conversion rate of the reaction is controlled at 75-90%, and the generated target product is not chloridized again into a byproduct; by reusing the fraction and transition component before rectification, the final yield of the reaction is greatly improved; the distilled product can reach the standard directly; after recrystallization during which the solution temperature is 80-100 DEG C, the product is cooled to below 20 DEG C for discharge and filtration; the filtered water can be used for 5-10 times to obtain a finished product, and other treatment processes are saved.

Owner:湖南瑞冠生物化工科技有限公司

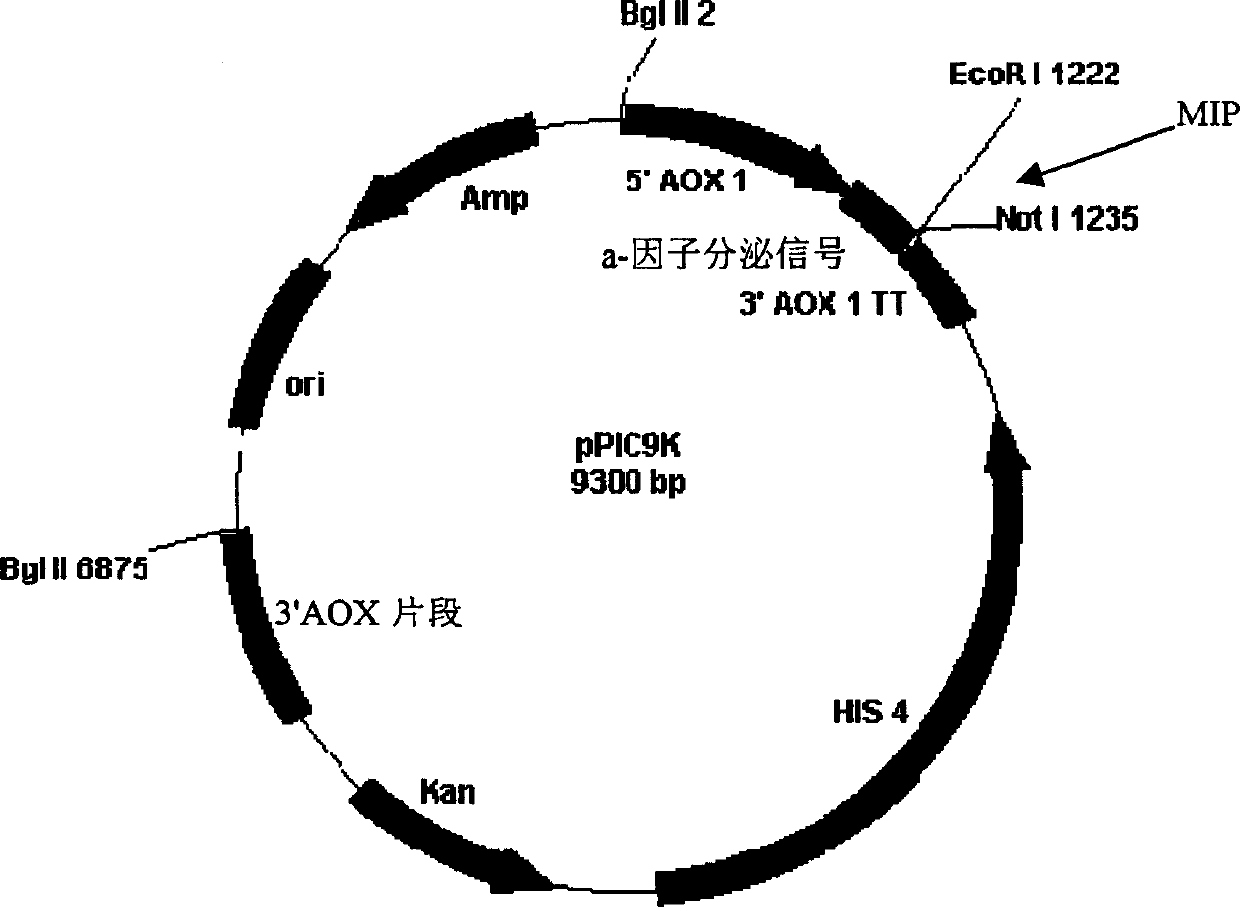

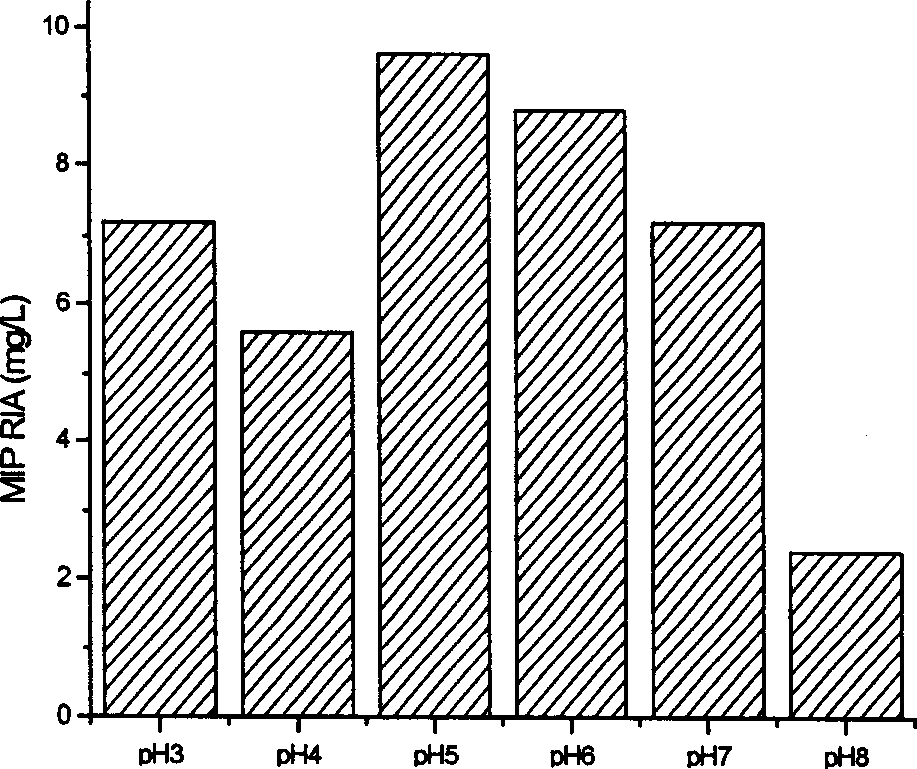

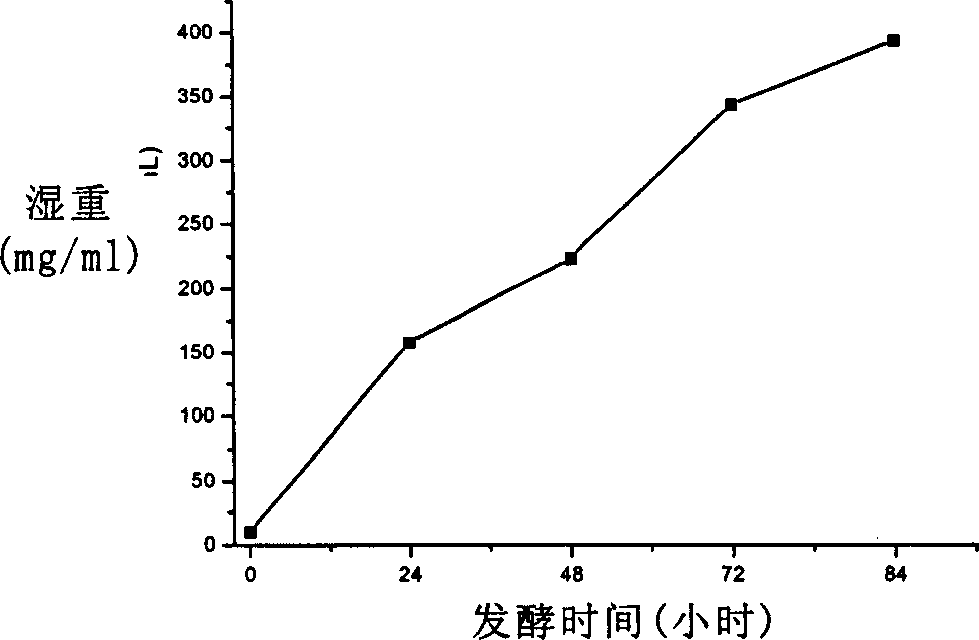

Method for preparing interferon

InactiveCN1451748AImprove final yieldSimple and fast operationPeptide preparation methodsFermentationLactoseBacterial strain

A process for preparing the alpha-16 interferon includes optimizing the gene sequence of alpha-16 interferon, choosing proper expression system, reconstructing the engineering bacterial strain able to effectively express it, and creating the fermenting and purifying technology with galactose or lactose. Its advantages are high yield, high expression and low cost.

Owner:SHANGHAI INST OF BIOLOGICAL PROD CO LTD

Method for separating and purifying succinic acid from fermentation broth

InactiveCN102363594BLow viscosityHigh clarityCarboxylic compound separation/purificationUltrafiltrationSuccinic acid

The invention belongs to a technology for separating succinic acid from fermentation products, and specifically relates to a method for separating and purifying succinic acid from fermentation broth. According to the invention, separation and purification of succinic acid can be realized by the operations of appropriate units and effective combinations of the units, such that defects of existing succinic acid separation and purification technologies of complicated process and poor economical efficiency can be overcome. Therefore, a novel economic technology for separating and purifying succinic acid from fermentation broth is established. Specifically, the fermentation broth is clarified through ultrafiltration. Resin decoloration is used for replacing traditional active carbon decoloration, such that the final succinic acid yield can be improved. Succinic acid crystals are directly obtained through crystallization. With the technology, the purity of the separated succinic acid reaches 99.5%, and the yield is higher than 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

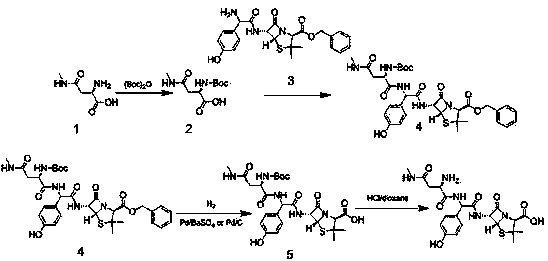

Synthesis method of aspoxicillin

ActiveCN104059087AMild reaction conditionsHigh selectivityOrganic chemistryBulk chemical productionPenicillinPropanoic acid

The invention discloses a synthesis method of aspoxicillin, belonging to the field of synthesis of chemical medicines.D-2-amino-3-methylaminopropionic acid and benzyl-protected oxyammonia penicillin used as raw materials are subjected to di-tert-butyl dicarbonate protection, esterification, deprotection and the like to synthesize the aspoxicillin. Compared with the past methods, the method disclosed by the invention has the advantages of small intermediate toxicity, fewer byproducts, fewer steps and low environmental pollution.

Owner:HUNAN ER KANG PHARMA

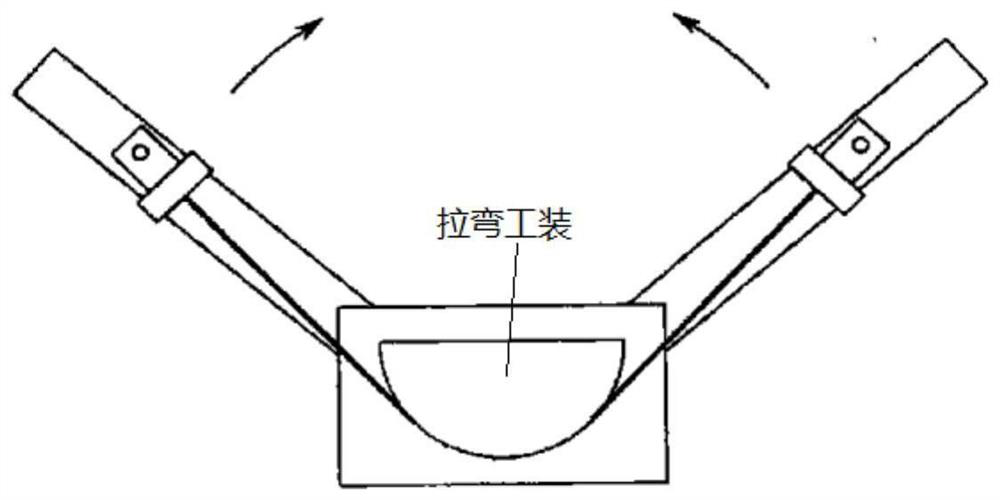

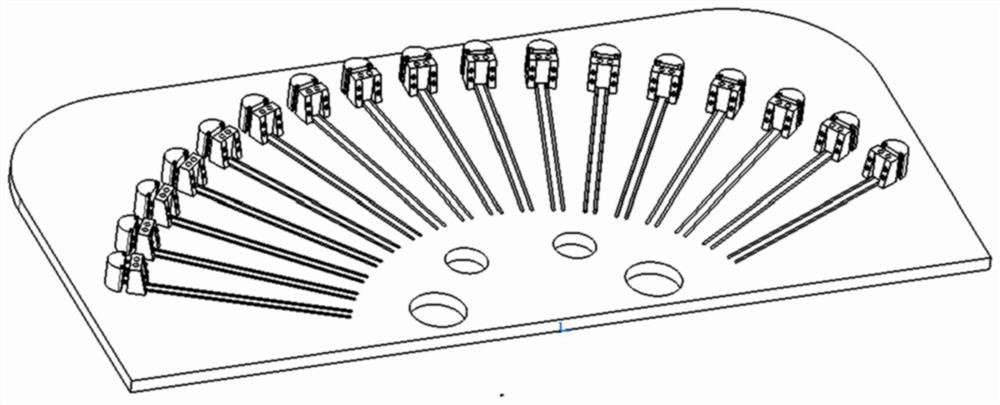

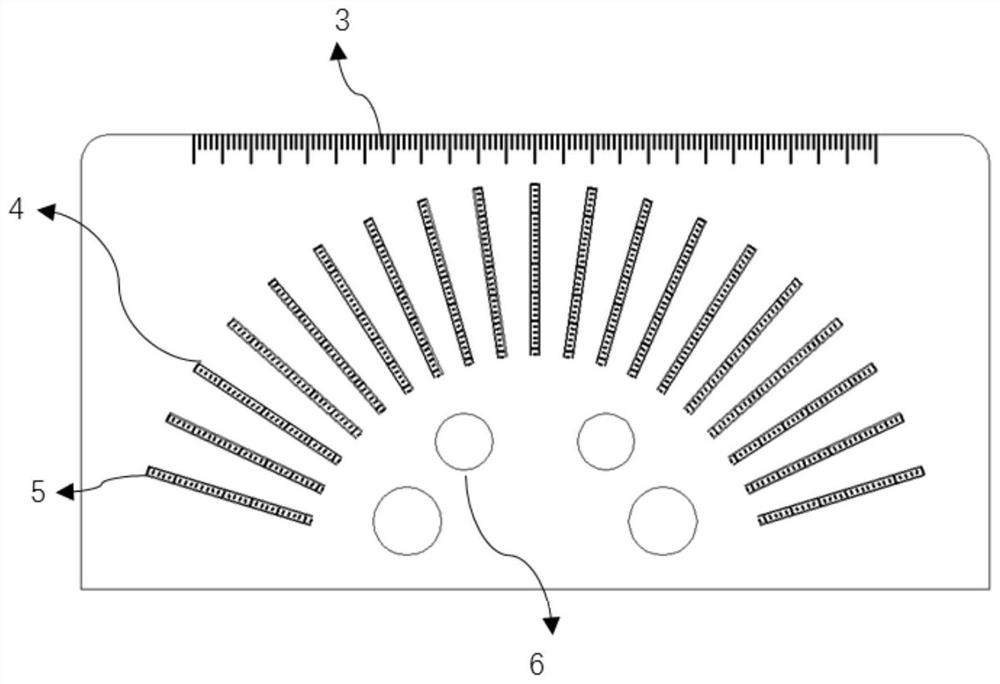

Multifunctional aluminum profile stretch-bending forming die and stretch-bending forming process

The invention relates to a multifunctional aluminum profile stretch-bending forming die and a stretch-bending forming process. The multifunctional aluminum profile stretch-bending forming die comprises a tool bottom plate and multiple radial radian positioning block slideways fixedly installed on the tool bottom plate, radian positioning blocks are installed on the radian positioning block slideways in a sliding manner, and the radian positioning blocks comprise arc-shaped positioning blocks and fine adjustment positioning blocks. Bolt connecting holes are formed in the longitudinal directionsof the fine adjustment positioning blocks, a height adjusting nut is slidably installed in each T-shaped groove in the sides, opposite to the fine adjustment positioning blocks, of the arc-shaped positioning blocks, and screw rods are arranged in the fine adjustment positioning blocks in a penetrating manner. Radian fine adjustment nuts corresponding to the height adjustment nuts are installed atthe positions, on the sides, opposite to the arc-shaped positioning blocks, of the fine adjustment positioning blocks, of the screw rods in a threaded manner, and fastening nuts are installed at thepositions, on the sides, away from the arc-shaped positioning blocks, of the fine adjustment positioning blocks, of the screw rods in a threaded manner. The problems that an existing high-strength aluminum alloy angle aluminum profile stretch-bending tool is simple in design, free of universality, high in tool cost, large in manual mounting and dismounting workload and prone to influencing tool precision are solved.

Owner:CHINA ZHONGWANG

A kind of method for synthesizing pyrroloquinoline quinone by lactic acid bacteria fermentation

ActiveCN103740780BImprove final yieldMicroorganism based processesFermentationMicroorganismPyrroloquinoline quinone

The invention discloses a method for synthesizing pyrroloquinoline quinone through lactobacillus fermentation. The method comprises the following steps: activating the lactobacillus plantarum PQQ-1 which is stored in an agar subculture medium through an activation culture medium, and then carrying out stationary culture of the lactobacillus plantarum PQQ-1 at a temperature ranging from 20 to 40 DEG C for 16-30h to from primary seeds; further carrying out enlarging stationary culture of the primary seeds at a temperature ranging from 20 to 40 DEG C through a primary seed culture medium for 16-30h to form secondary seeds; and further carrying out enlarging stationary culture of the secondary seeds at a temperature ranging from 20 to 40 DEG C through a secondary seed culture medium for 42-54h and then starting the fermentation stage, and carrying out anaerobic culture in a production fermentation culture medium at a temperature ranging from 20 to 40 DEG C for 54-66h to obtain the PQQ. The used lactobacillus is a food-grade safe microorganism; and the PQQ is obtained through fermentation, and is high in yield and bright in application prospect.

Owner:BIO RACE BIOTECH HANGZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com