Method for reworking metal layer

A metal layer and heavy industry technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as unsatisfactory results, metal surface erosion, chip scrapping, etc., to achieve the effect of improving the final yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

[0031] The invention proposes a metal layer rework method, which can greatly reduce metal residue defects, increase wafer output and reduce wafer scrapping.

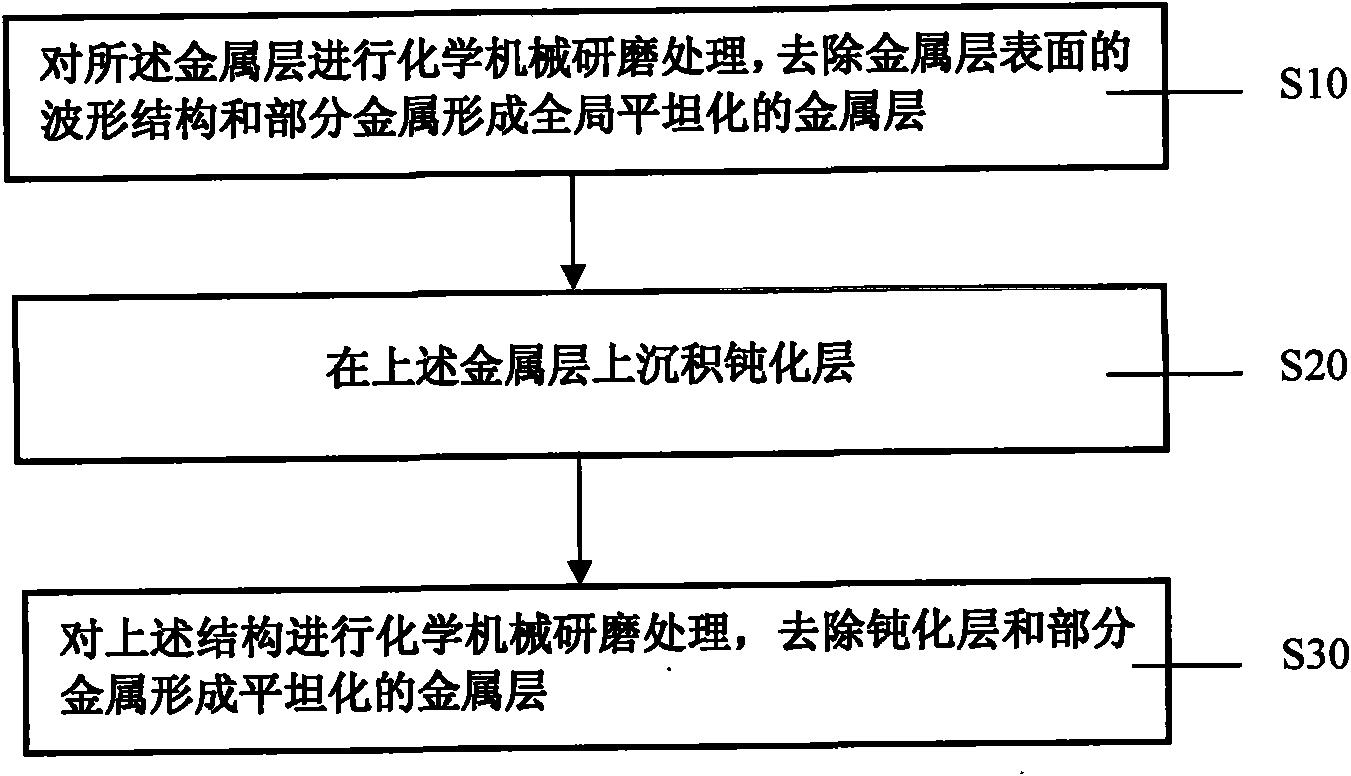

[0032] Please refer to figure 2 , figure 2 Shown is a flow chart of a metal layer reworking method in a preferred embodiment of the present invention. from figure 2 It can be seen that the present invention proposes a metal layer reworking method, which includes the following steps:

[0033] Step S10: performing chemical mechanical grinding on the metal layer, removing the corrugated structure and part of the metal on the surface of the metal layer to form a globally planarized metal layer;

[0034] Step S20: depositing a passivation layer on the metal layer;

[0035] Step S30: performing a chemical mechanical polishing proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com