Multifunctional aluminum profile stretch-bending forming die and stretch-bending forming process

A technology for drawing and bending aluminum profiles, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large manual installation and disassembly workload, affecting tooling accuracy, and high tooling costs, so as to improve processing efficiency and final products. efficiency, reduce labor costs, and reduce tooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

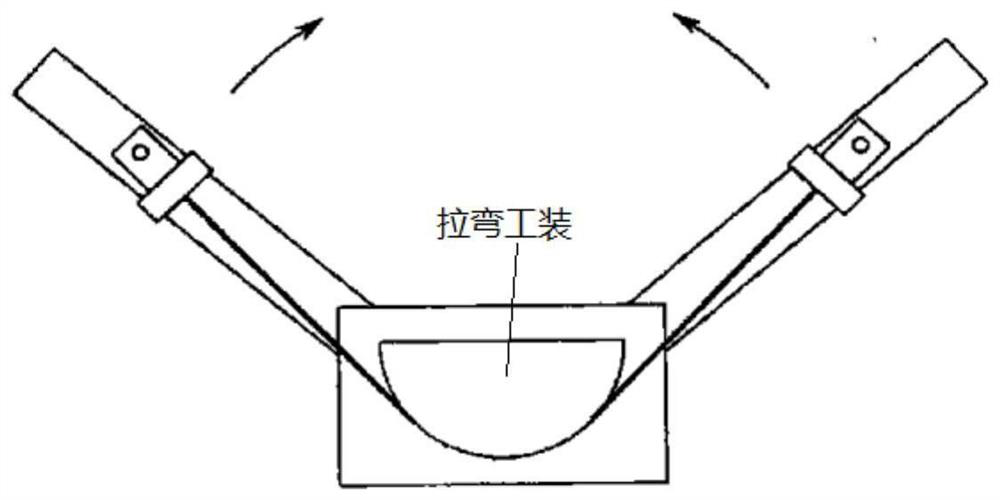

[0048] The tooling and supporting processing technology designed and developed by this patent are used for stretch bending production of large-scale high-precision extrusion structural parts in aviation. This product has the characteristics of large curvature radius and high precision requirements, and has high processing difficulty and Technical barriers, the section of the profile to be processed such as Figure 5 shown.

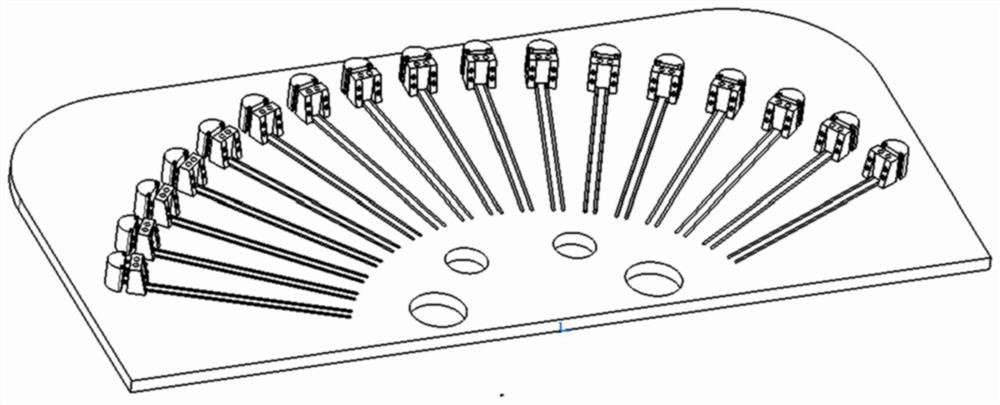

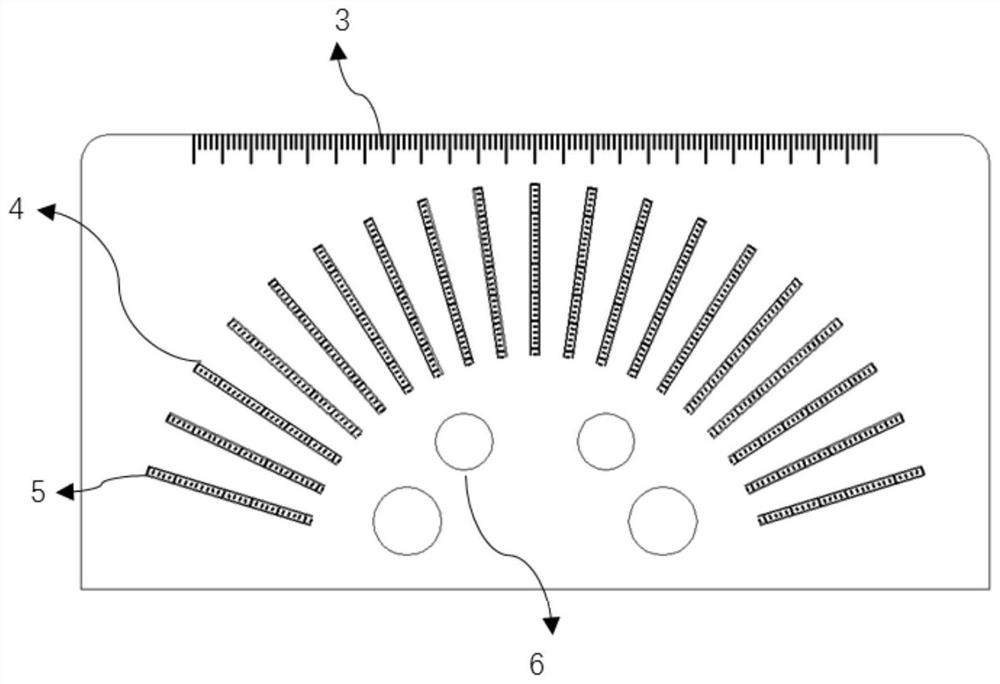

[0049] First, fix the tooling base plate on the stretch bending equipment platform, align the arc positioning block with the required scale of the tooling base plate according to the radian requirements of the parts, and connect it with bolts at the required positions. Then adjust the slide rail in the fine-tuning positioning block and the arc-shaped positioning block so that the height adjustment nut on the arc-shaped positioning block matches the bolt end of the arc fine-tuning nut on the fine-tuning positioning block, and adjust the bolt on the slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com