Manufacturing method of pressure vessels

A technology of pressure vessel and manufacturing method, applied in manufacturing tools, forming tools, applications, etc., can solve the problems of high welding requirements, high production cost, laborious and laborious, etc., and achieve good forming effect, reduce friction, and improve operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific implementations below.

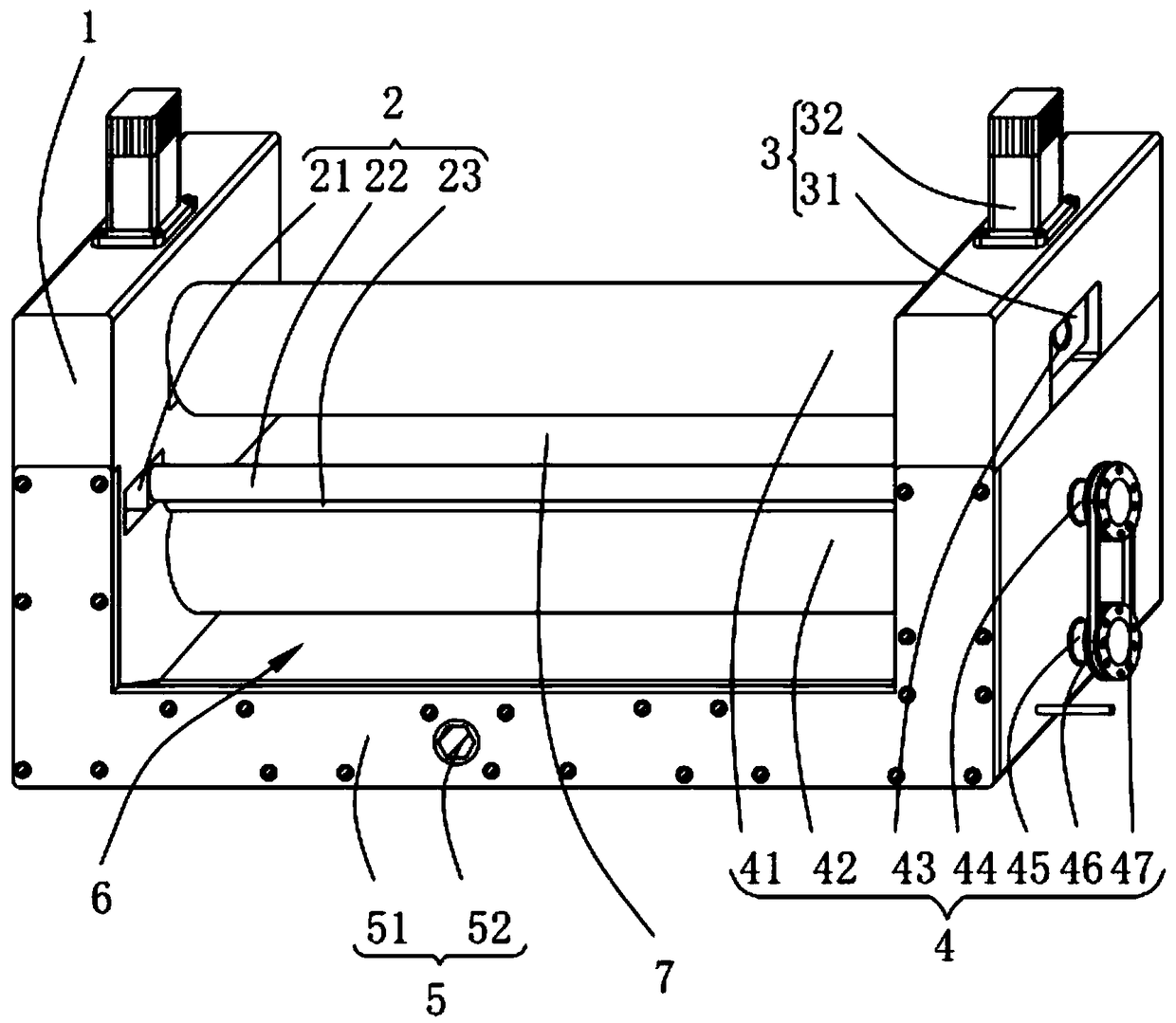

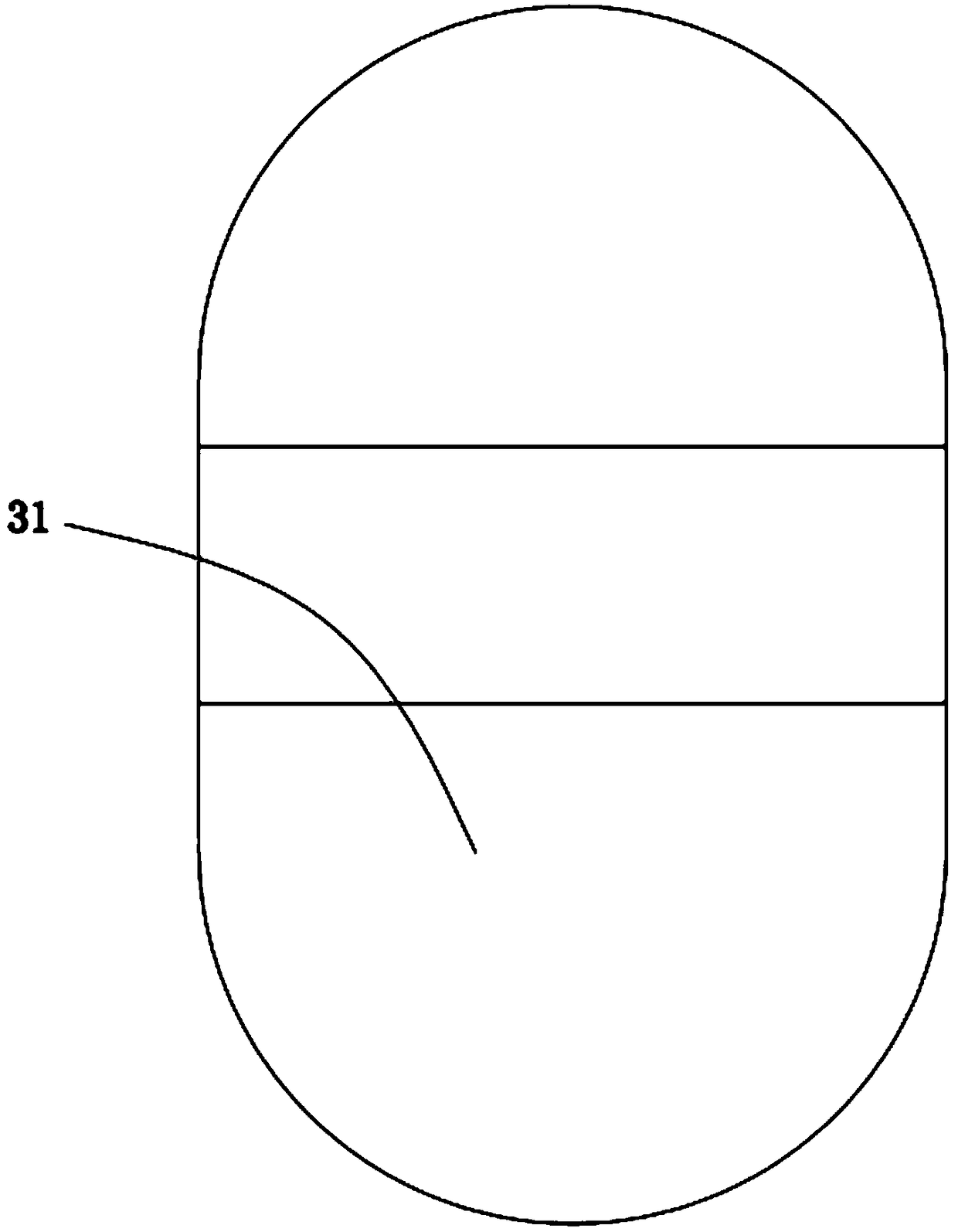

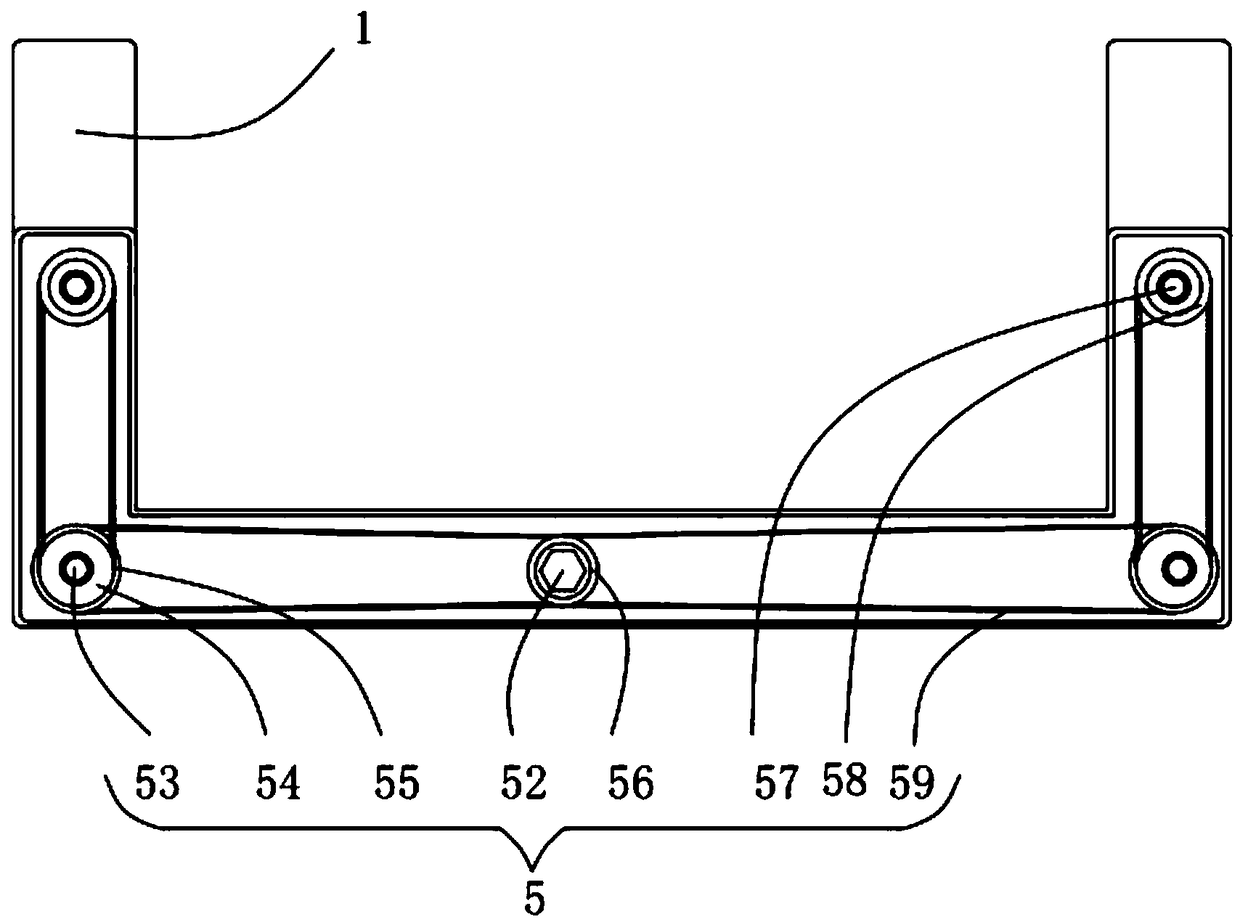

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a method for manufacturing a pressure vessel includes the following steps:

[0030] S1, cutting the plate into a plate shape with a plate cutting machine;

[0031] S2, put the plate obtained in S1 into a spiral structure in the plate rolling machine;

[0032] S3, the head and tail of the plates made in S2 are welded together by submerged arc welding; submerged arc welding has better welding quality;

[0033] S4, the two ends of the pressure vessel made in S3 are welded and sealed with steel plates;

[0034] S5, transport the pressure vessel made in S4 to the next process;

[0035] The plate rolling machine used in this method includes a fixing frame 1, the fixing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com