Patents

Literature

76results about How to "Increase grinding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

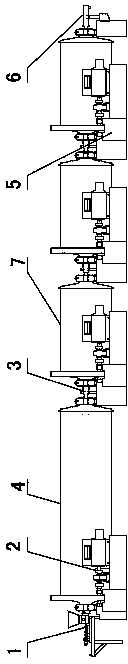

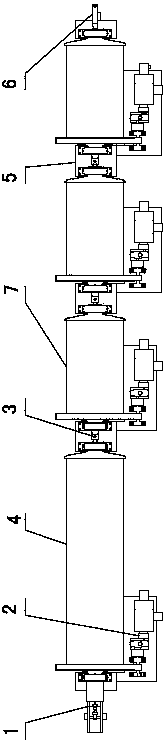

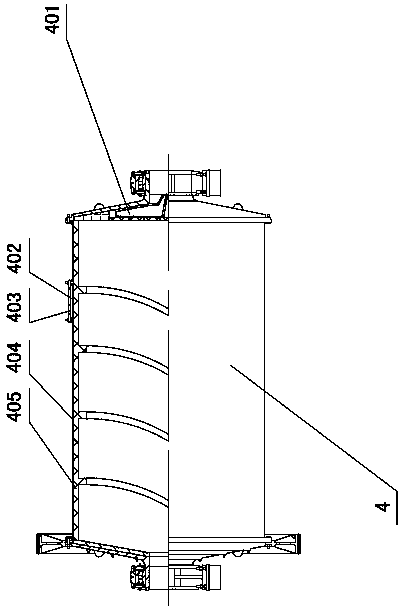

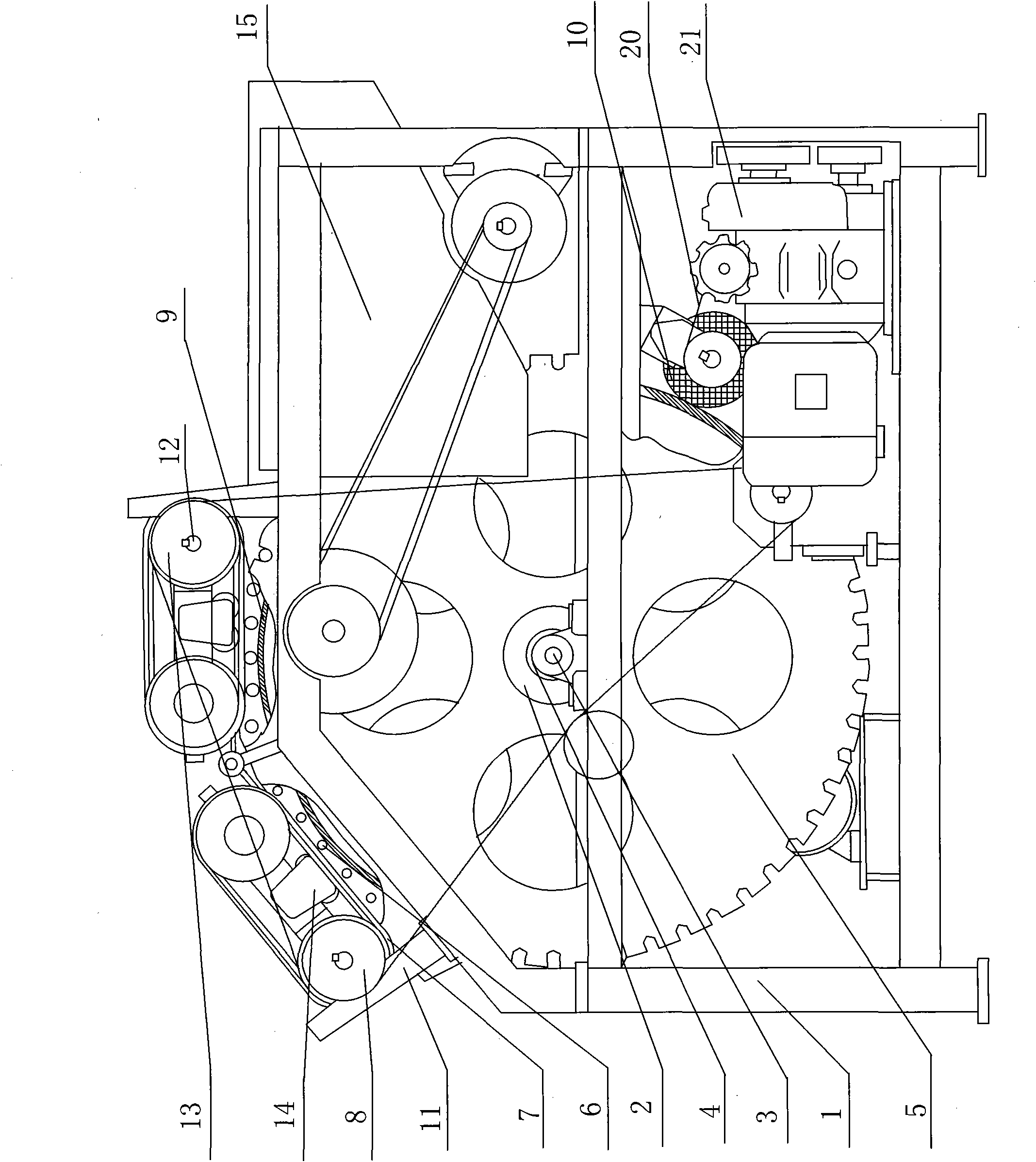

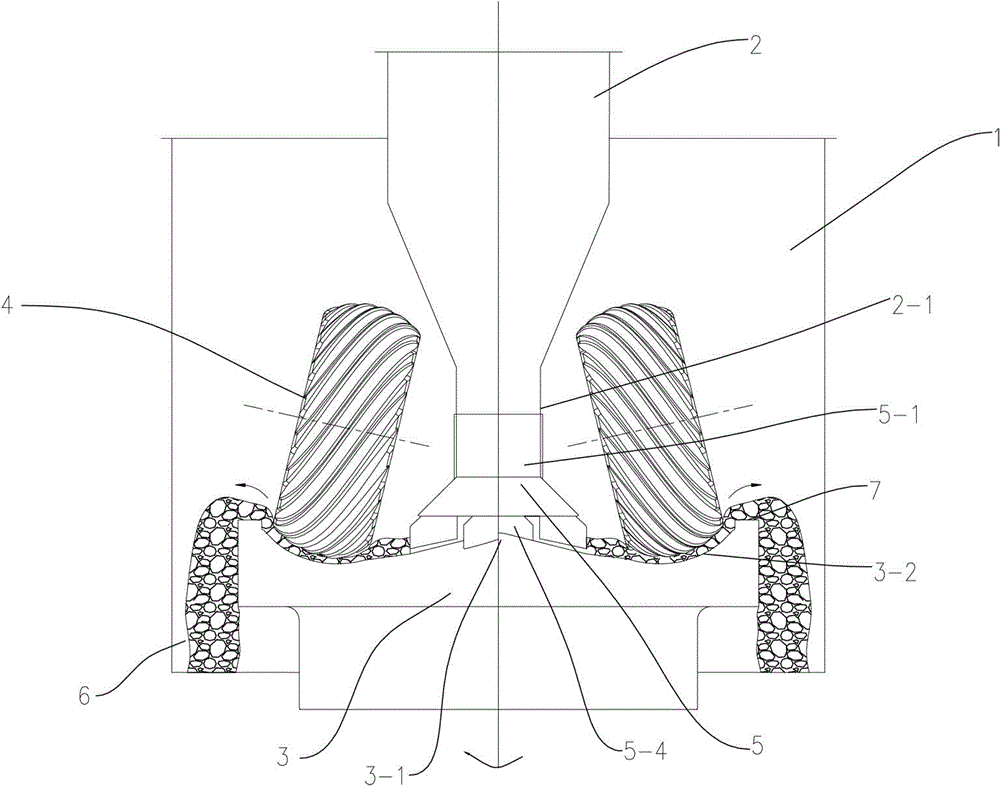

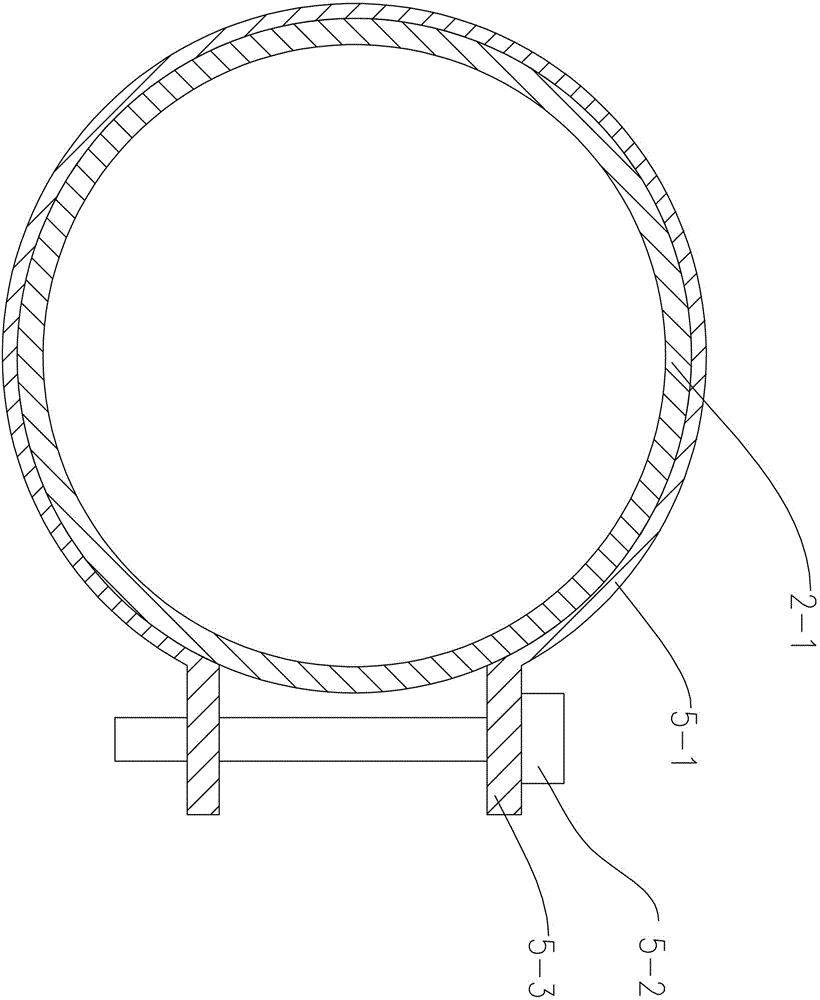

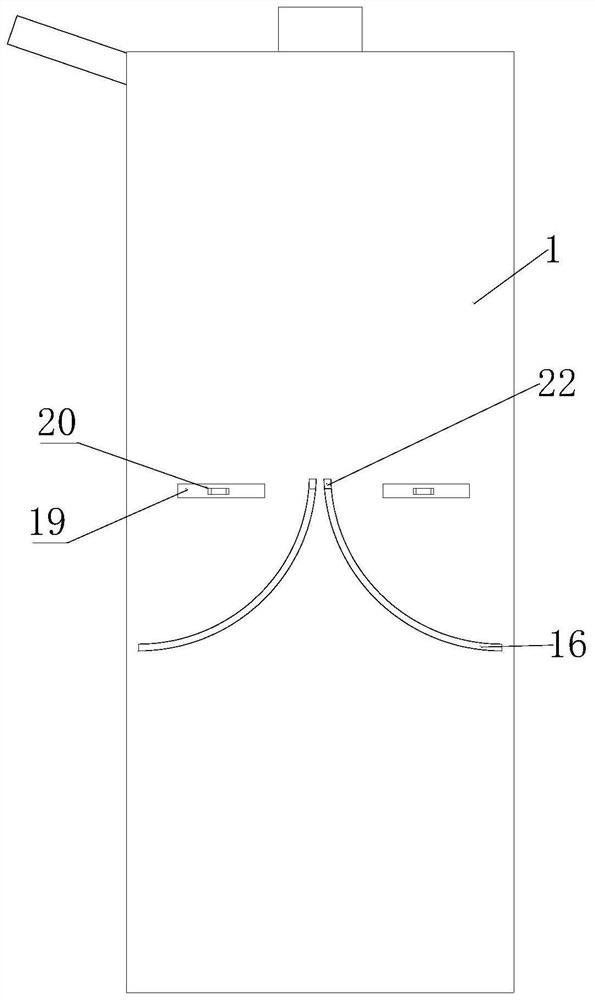

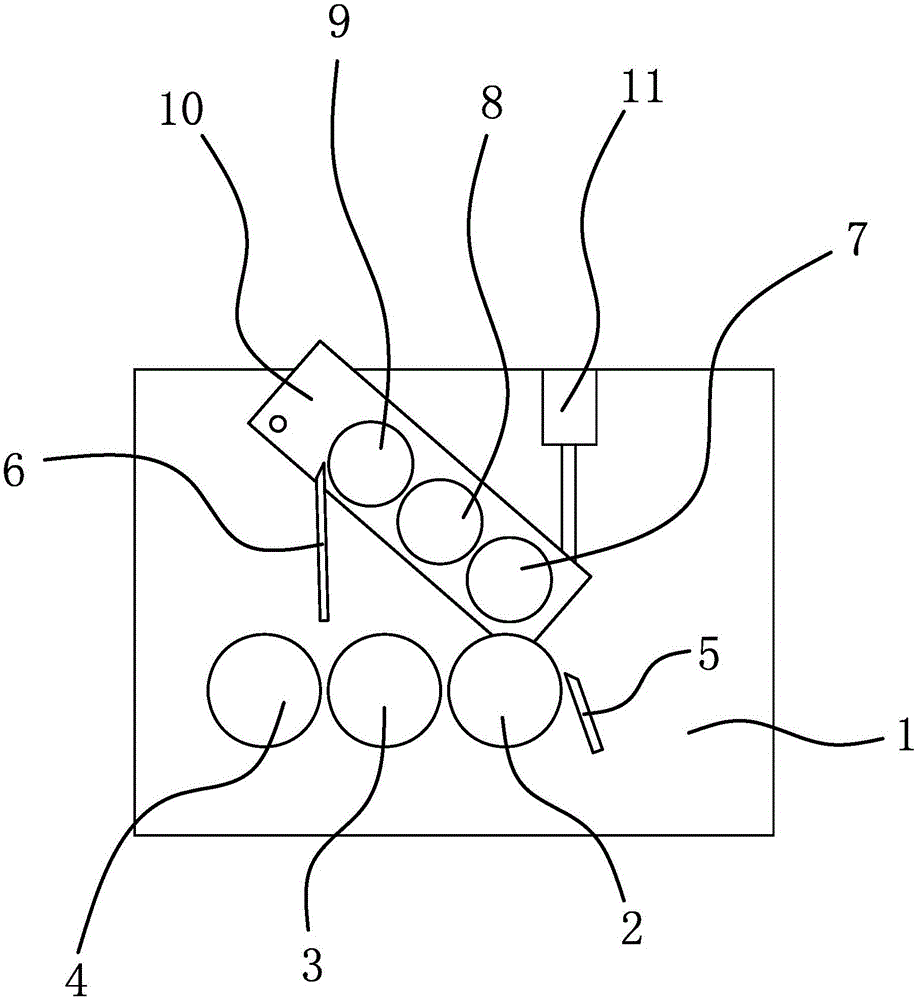

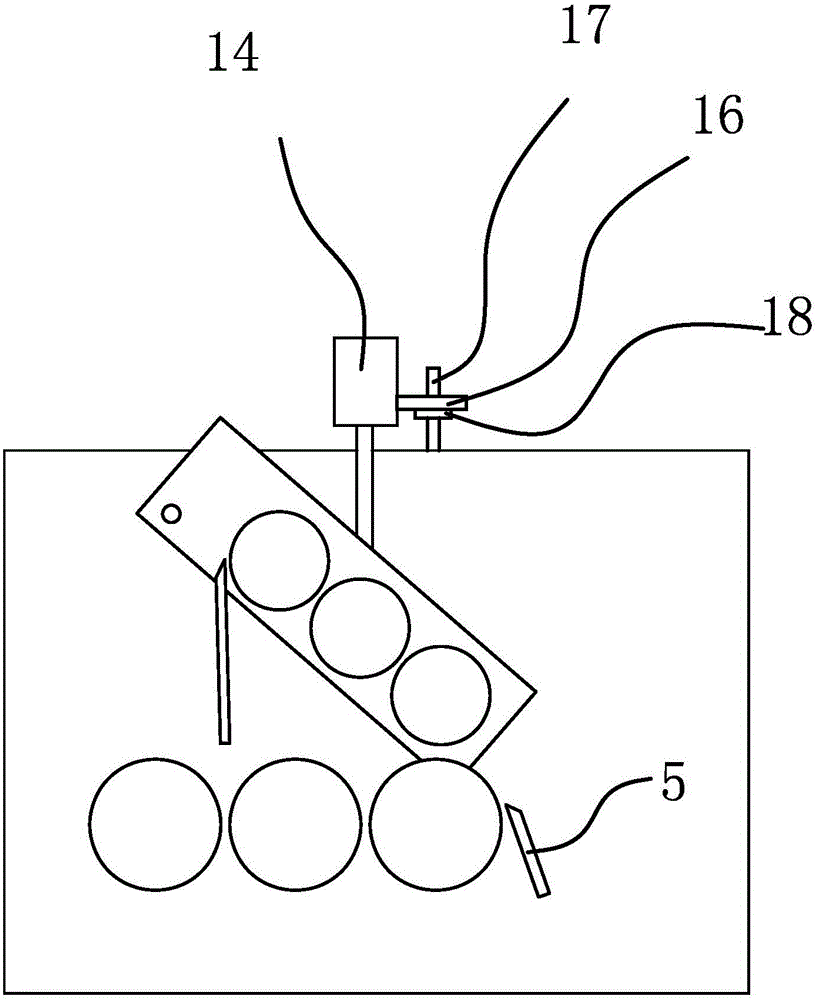

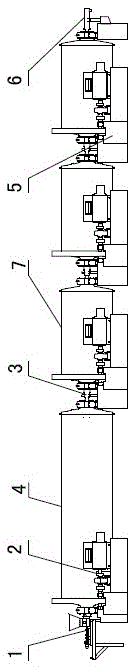

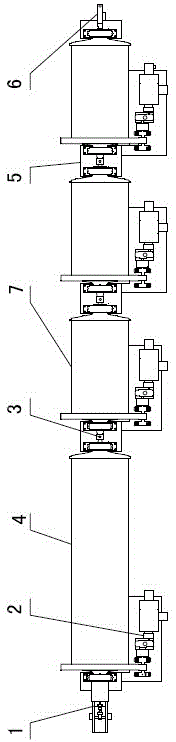

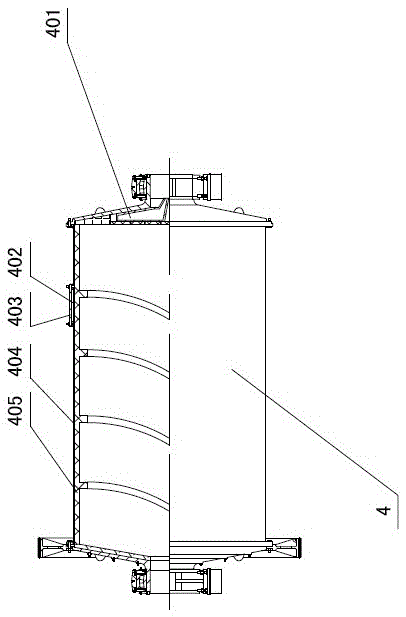

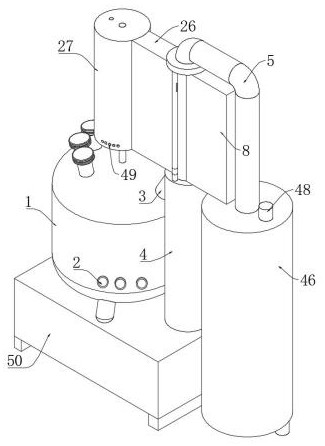

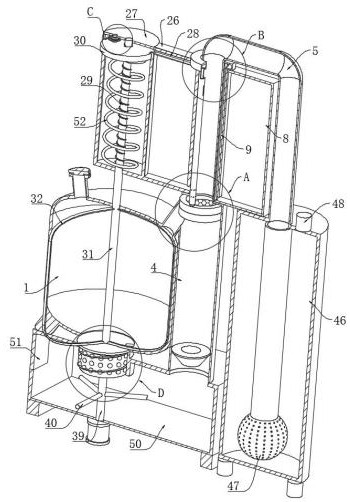

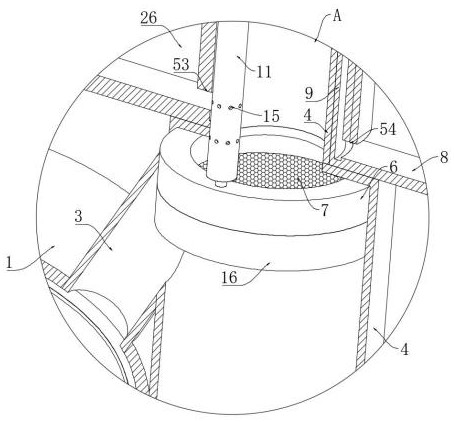

Tandem continuous ball mill and ball milling method

The invention discloses a tandem continuous ball mill and a ball milling method and belongs to the technical field of equipment for producing ceramic products and ball milling technologies. A feeding device (1) is communicated with a feeding end of a first-stage ball milling tank (4), wherein a plurality of second-stage ball milling tanks (7) are connected in series; the length of the first-stage ball milling tank (4) is 1.5-3 times that of one second-stage ball milling tank (7); an inner cavity of the first-stage ball milling tank (4) has a taper of which the diameter is gradually reduced from the feeding end to the discharging end. The tandem continuous ball mill can be used for materials with different sizes; the discharging mode is changed from the traditional overflow into flow extraction; in the ball milling method, materials with different particle sizes are pertinently added; after materials of which the particle sizes are 0.5-15mm are pulped, the pulped materials are directly added in each second-stage ball milling tank (7) through a connecting device (3); after materials of which the particle sizes are 0.1-0.5mm are pulped, the pulped materials are directly added in the tail-end second-stage ball milling tanks (7) through the connecting devices (3), so that the grinding efficiency is greatly improved.

Owner:GUANGDONG EDING IND

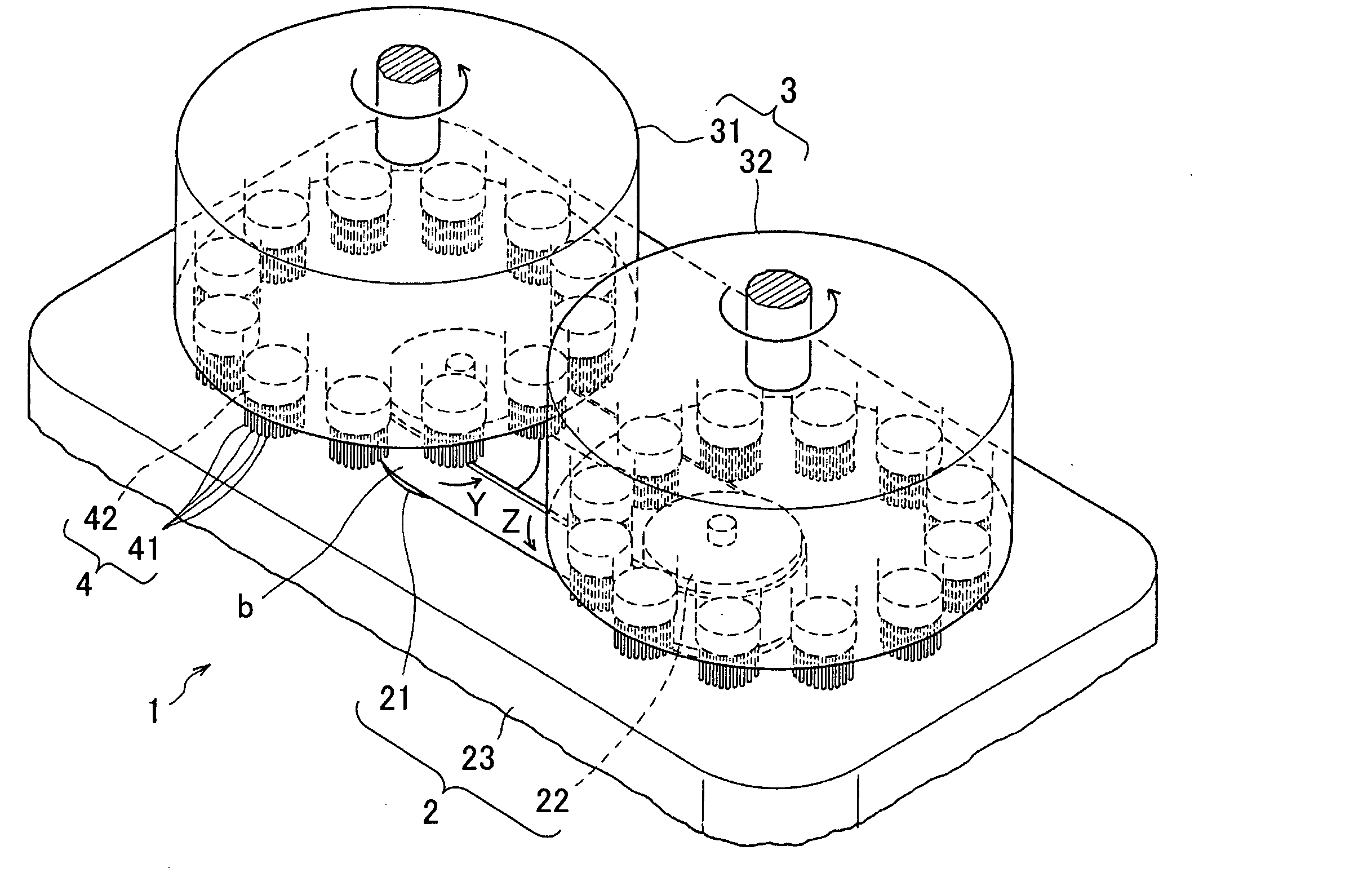

Grinding Apparatus And Grinding System

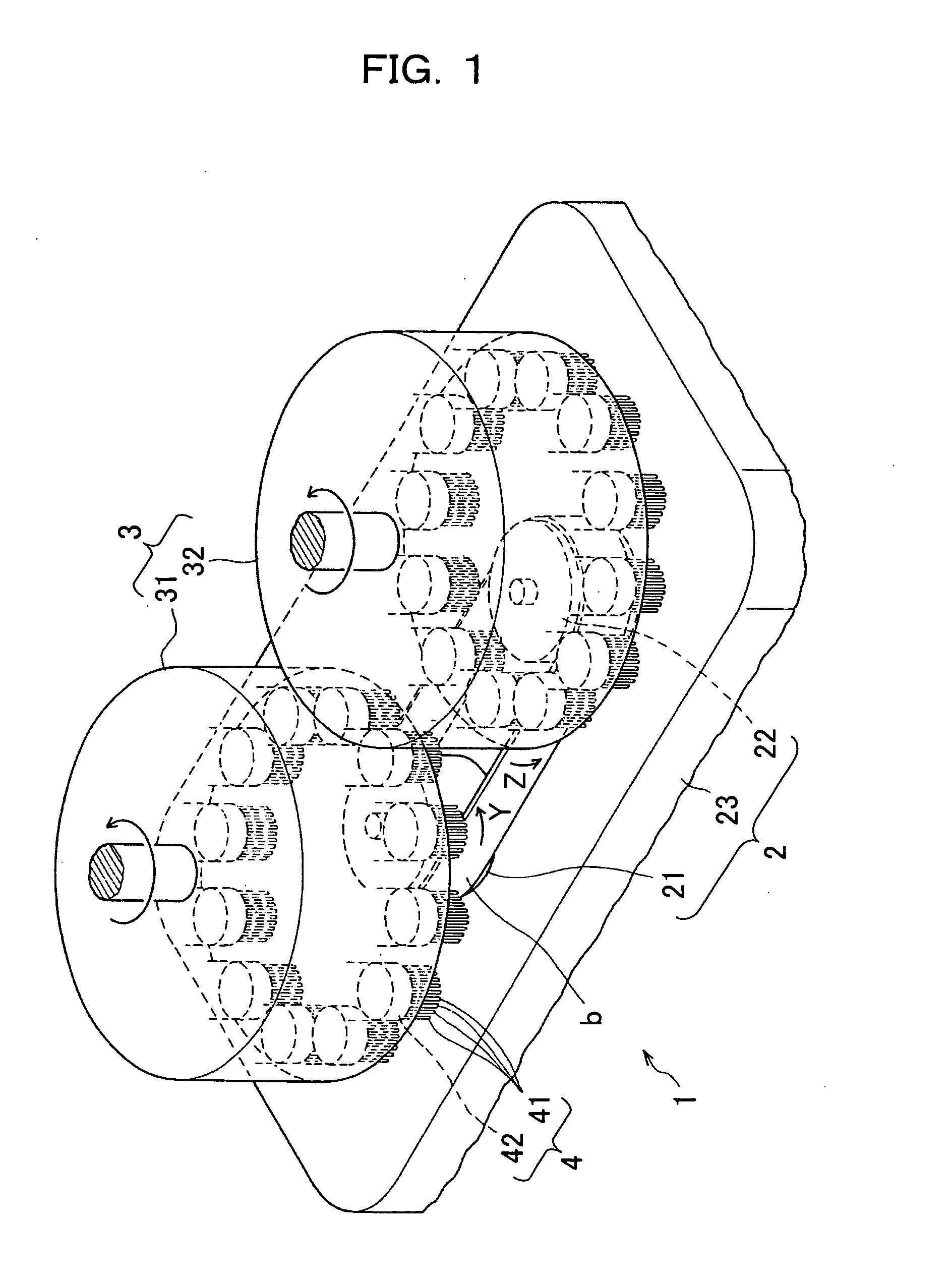

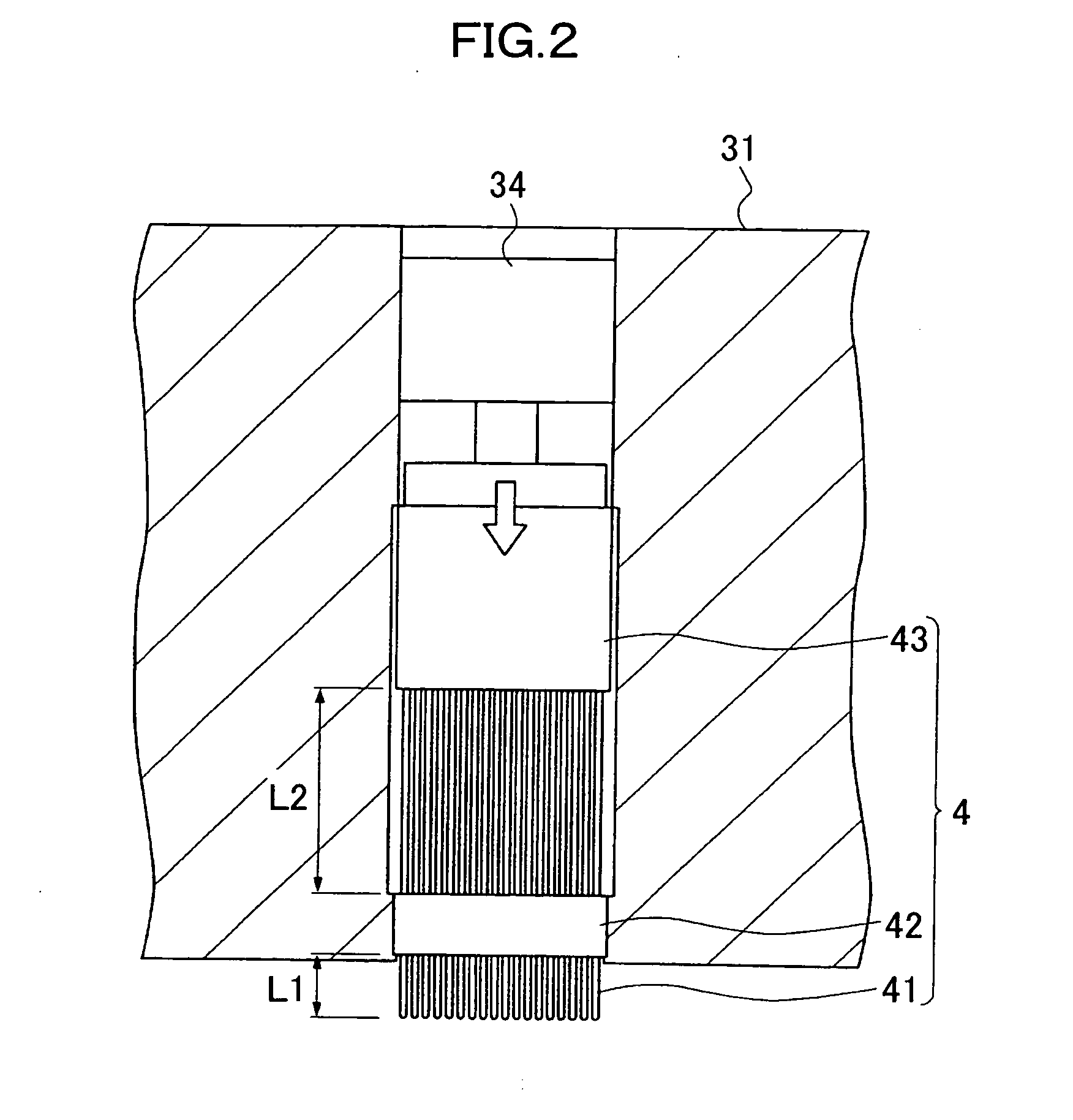

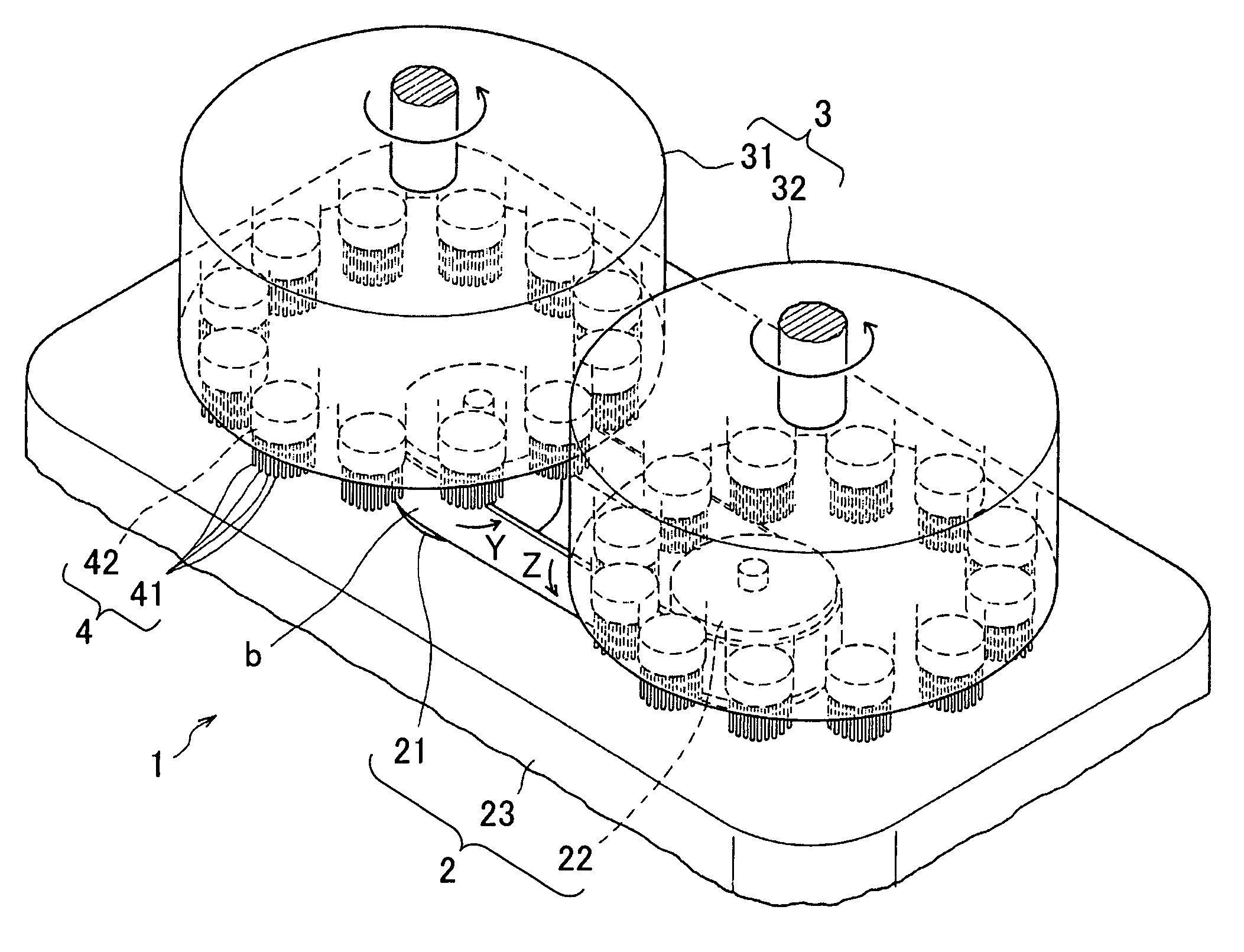

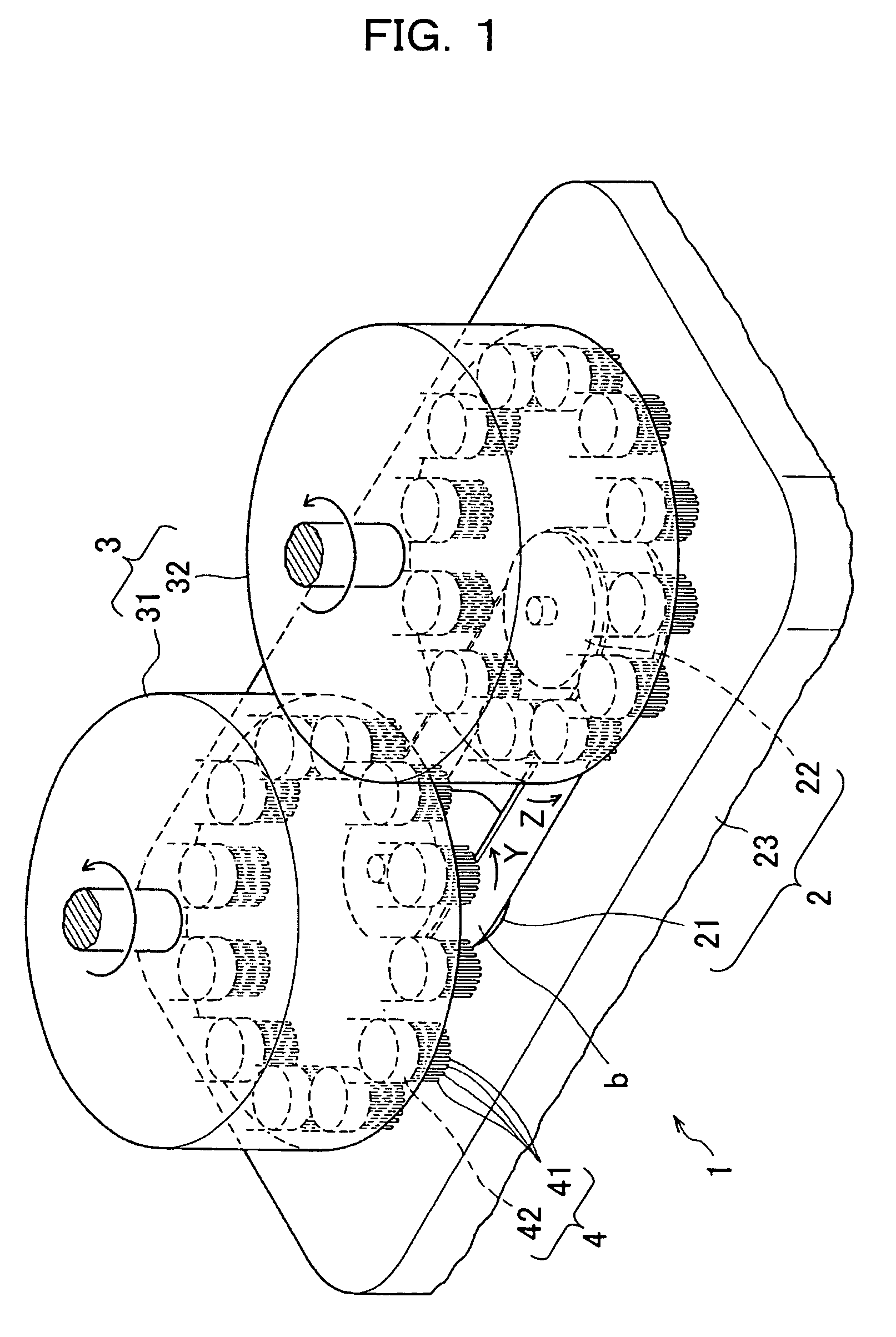

ActiveUS20080064304A1Extend grinding timeDecrease in grind forceEdge grinding machinesPolishing machinesEdge surfaceMechanical engineering

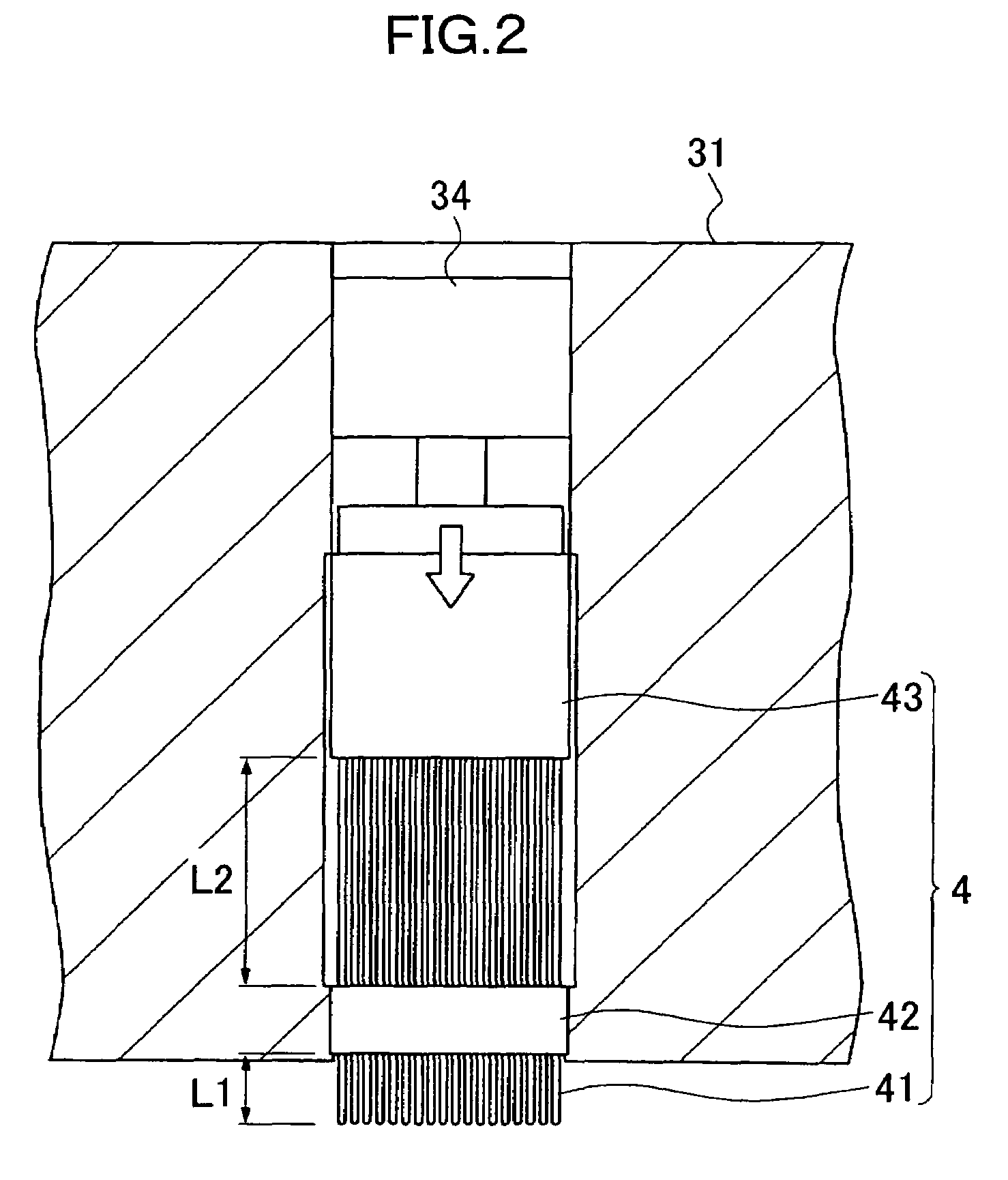

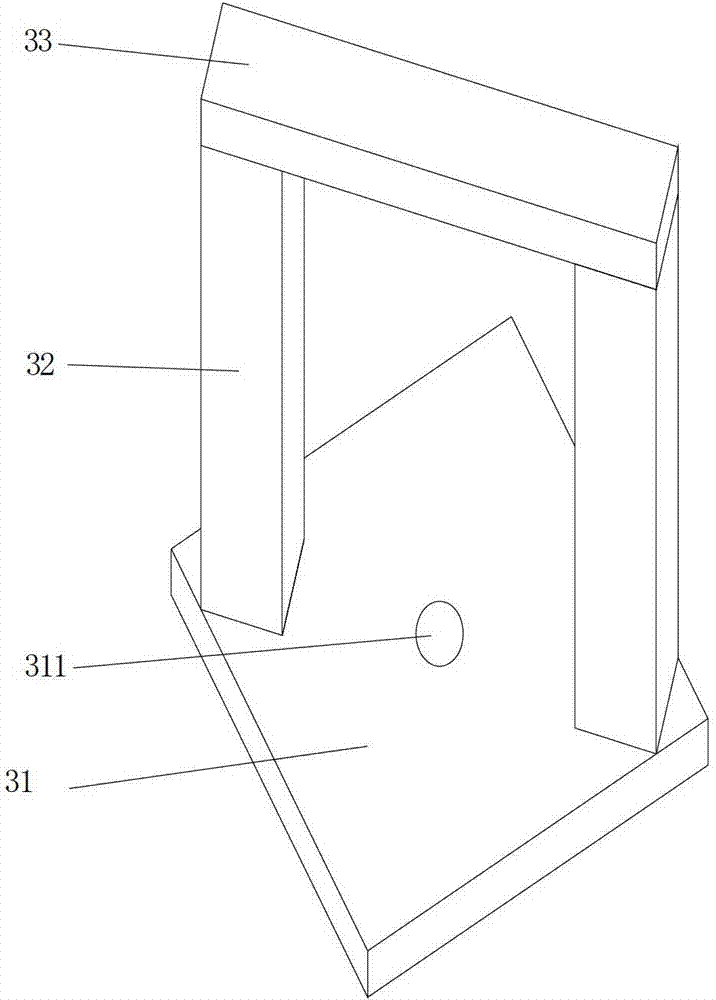

A grinding apparatus and a grinding system capable of efficient and superior grinding performance prevent the falling of a belt during the grinding of an edge surface thereof. The apparatus includes two rotating bodies 31 and 32 each having segment brushes 4, 4, . . . attached in the circumferential direction at the edge thereof. The rotating bodies 31 and 32 are rotated in the same direction. The tip of the segment brushes 4, 4, . . . is opposed to one edge surface of a belt b stretched between a driving roller 21 and a driven roller 22. The segment brushes 4 of the two rotating bodies enter toward the belt b at appropriate locations on the one edge surface, such that the falling of the belt can be prevented. A grinding apparatus 1 includes a grinder 3 consisting of the rotating bodies 31 and 32, and a holder consisting of the rollers 21 and 22 and a casing 23 by which the rollers are rotatably supported. A plurality of such grinding apparatuses 1 are disposed at regular intervals, whereby a grinding system 10 is constructed.

Owner:TOYOTA JIDOSHA KK

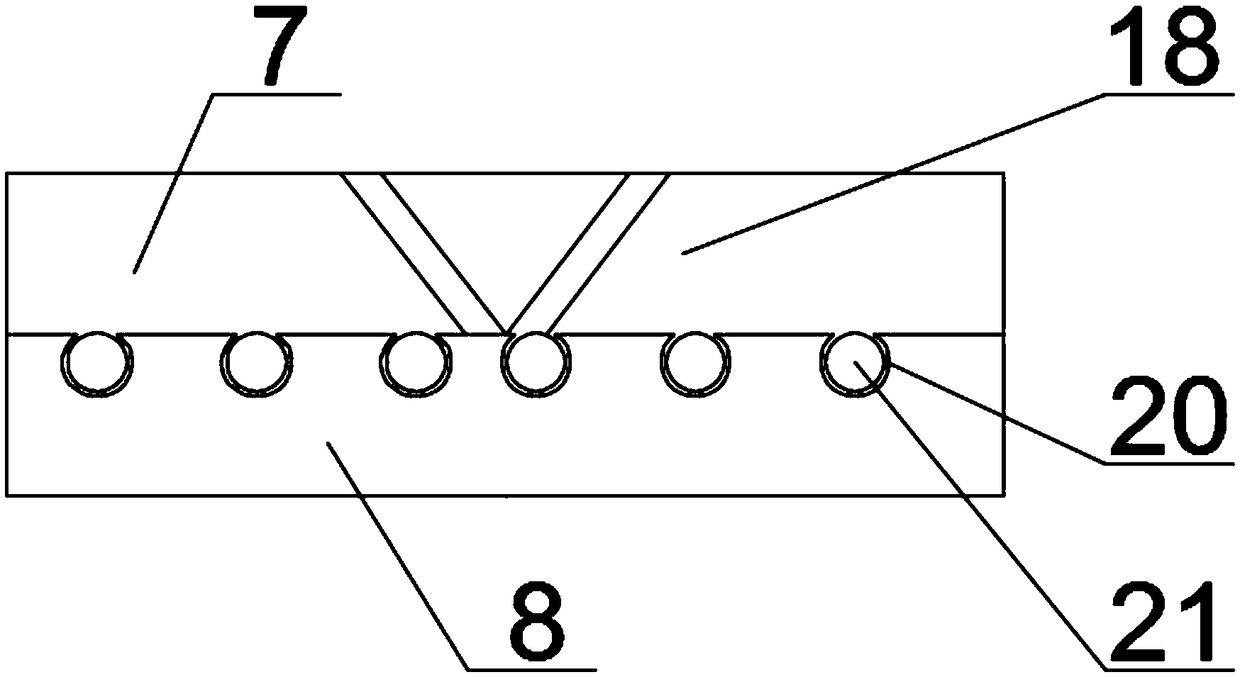

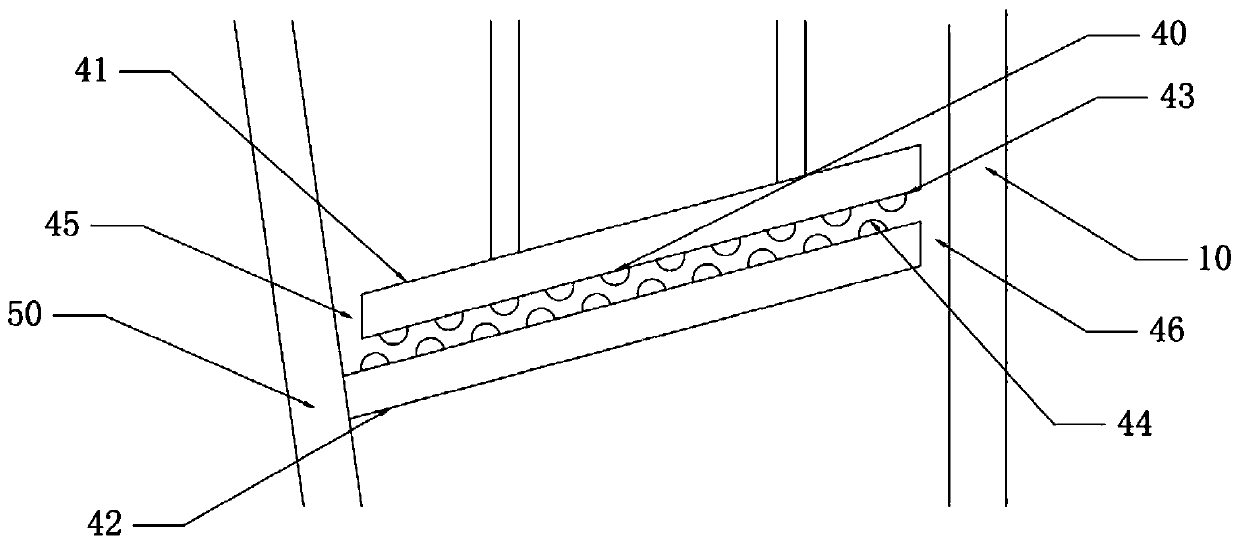

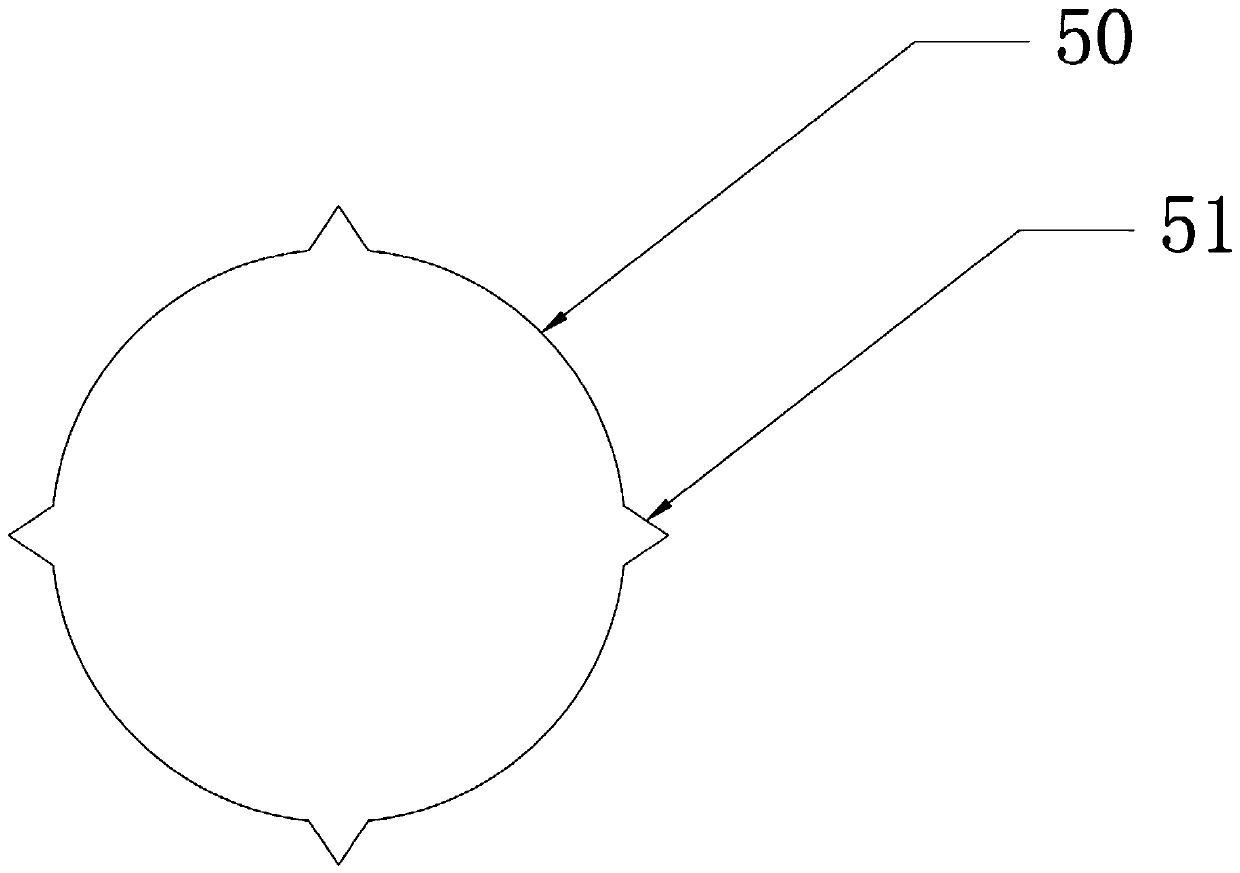

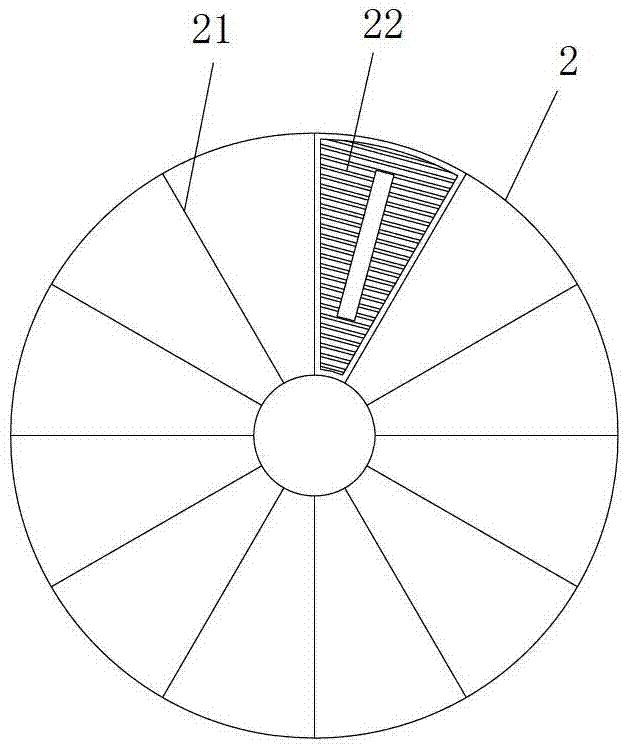

Grinding apparatus and grinding system

ActiveUS7500905B2Preventing the falling of the metal beltEfficient grindingEdge grinding machinesPolishing machinesEdge surfaceEngineering

A grinding apparatus and a grinding system capable of efficient and superior grinding performance prevent the falling of a belt during the grinding of an edge surface thereof. The apparatus includes two rotating bodies 31 and 32 each having segment brushes 4, 4, . . . attached in the circumferential direction at the edge thereof. The rotating bodies 31 and 32 are rotated in the same direction. The tip of the segment brushes 4, 4, . . . is opposed to one edge surface of a belt b stretched between a driving roller 21 and a driven roller 22. The segment brushes 4 of the two rotating bodies enter toward the belt b at appropriate locations on the one edge surface, such that the falling of the belt can be prevented. A grinding apparatus 1 includes a grinder 3 consisting of the rotating bodies 31 and 32, and a holder consisting of the rollers 21 and 22 and a casing 23 by which the rollers are rotatably supported. A plurality of such grinding apparatuses 1 are disposed at regular intervals, whereby a grinding system 10 is constructed.

Owner:TOYOTA JIDOSHA KK

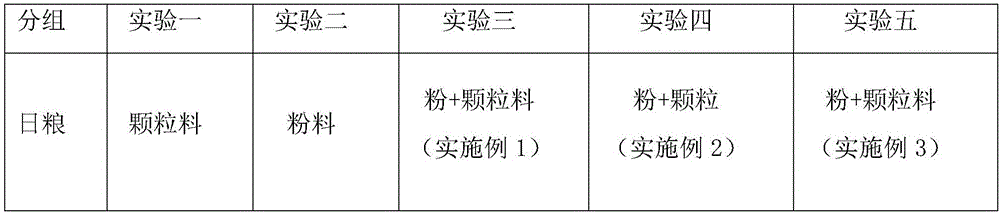

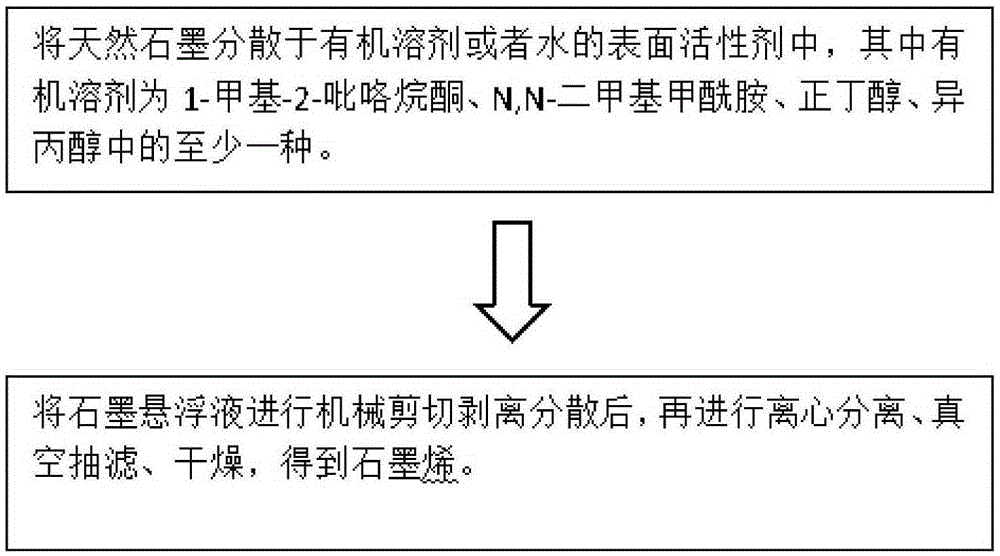

Compound feed for promoting development of muscular stomach of broiler and preparation method of compound feed

The invention belongs to the fields of a feed composition and feed processing, particularly relates to a compound feed for promoting the development of the muscular stomach of a broiler, and further provides a preparation method of the feed. The content of crude fibers in percentage by mass of the compound feed is greater than or equal to 4%, and the compound feed is mainly prepared from the following raw materials in parts by weight: 45-60 parts of corn, 3-15 parts of whole wheat grains, 1-3 parts of tropina, 1-5 parts of cottonseed meal, 1-5 parts of oat hull, 0.8-2 parts of calcium hydrogen phosphate, 1-2.5 parts of amino acids, 0.05-0.3 part of sodium humate, 0.05-0.1 part of a mycotoxin adsorbent, 0.02-0.1 part of betaine, 0.1-0.5 part of choline chloride, 0.05-0.3 part of a compound enzyme preparation, 0.5 part of a compound premix, 3-6 parts of fat, and 0.5-5 parts of probiotics. The compound feed disclosed by the invention can notably increase the weight of fresh chicken's gizzards, compared with the weight of each fresh chicken's gizzards of a broiler fed with a common feed, the weight of each fresh chicken's gizzard of the broiler fed with the compound feed is increased by 2-5 grams, and compared with the weight of each fresh chicken's gizzards of a broiler fed with granular feeds, the weight of each fresh chicken's gizzard of the broiler fed with the compound feed is increased by 8-15 grams.

Owner:LIAONING WELLHOPE AGRI TECH

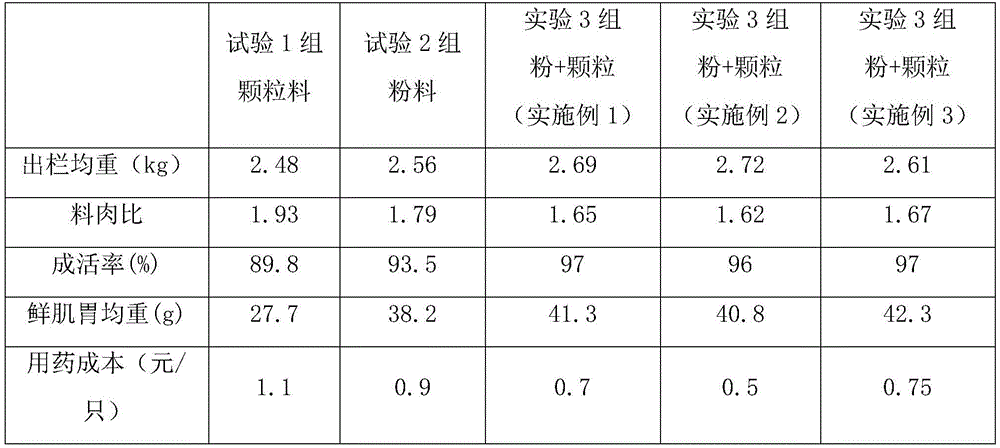

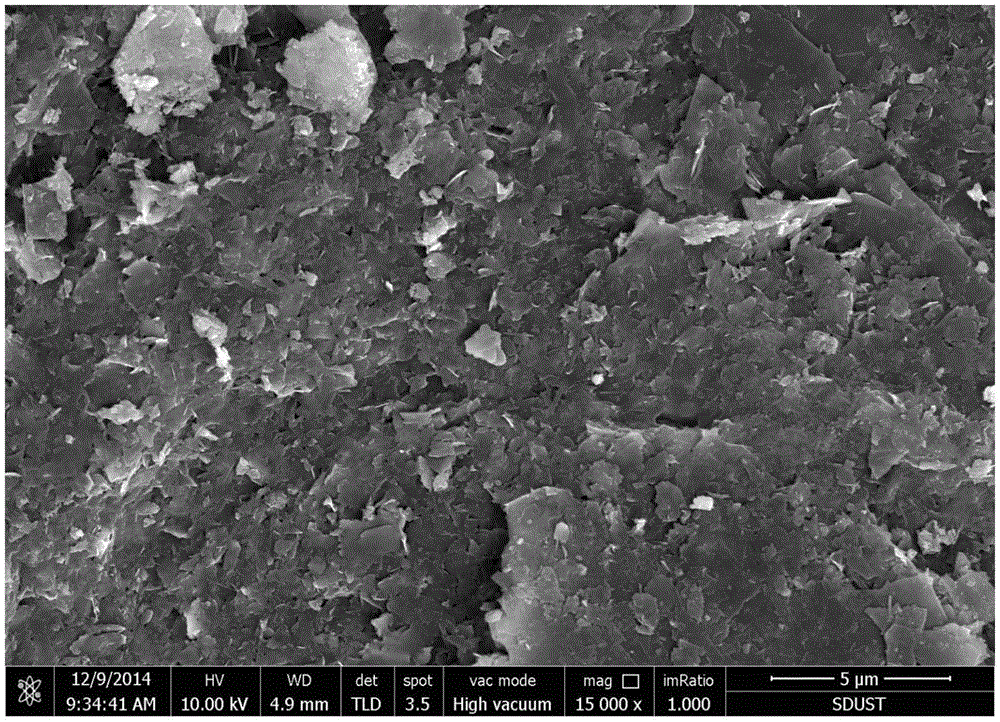

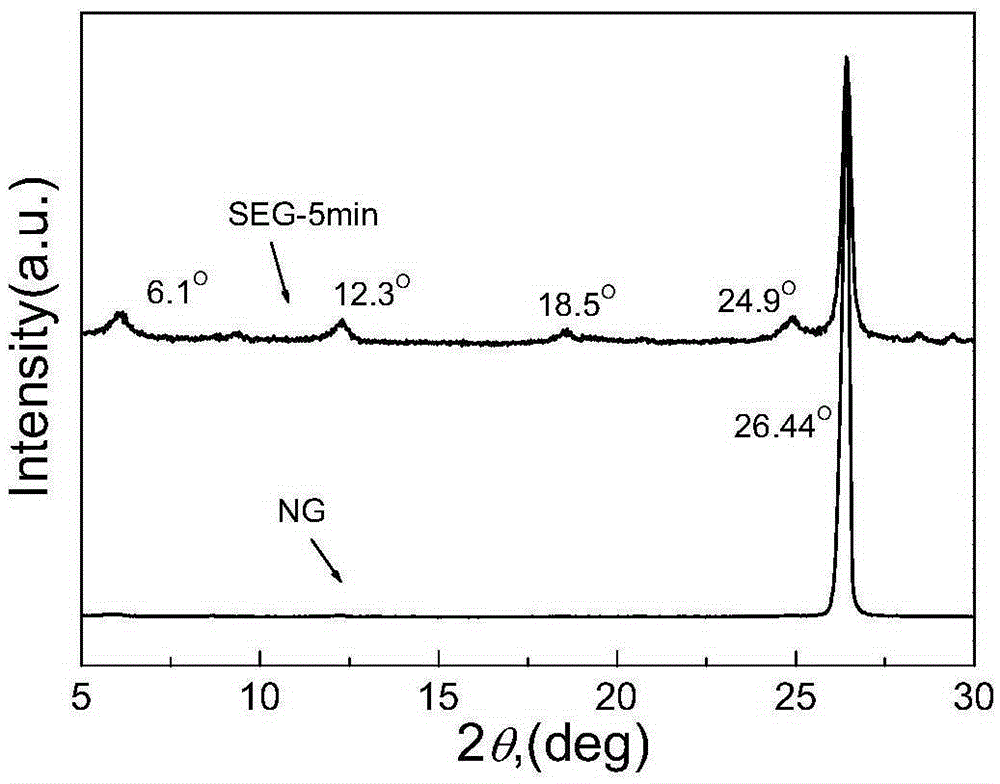

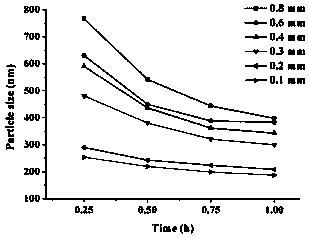

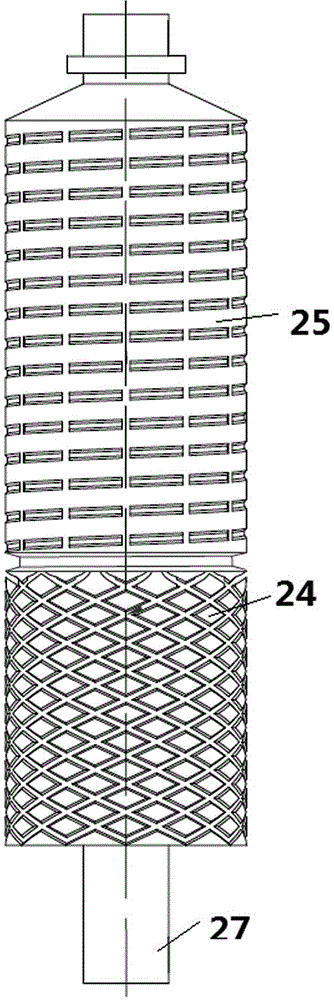

Preparation method for graphene

InactiveCN105347332AIncrease path lengthIncrease shearing and grinding time and frequencyDefective grapheneSolvent

The invention provides a preparation method for graphene. The preparation method comprises: S1, dispersing natural graphite in a solvent to obtain a graphite suspension; S2, shearing the graphite suspension in a colloid mill; and S3, carrying out centrifugal separation on the sheared graphite suspension to obtain a supernatant, and carrying out vacuum suction filtration and drying on the supernatant to obtain graphene. By using the natural graphite powders which are wide in raw material source and cutting the graphite with the colloid mill, graphite granules can be effectively stripped through a physical action of a severe shear force, a frictional force, high-frequency vibration and high-speed vortex, so that the production efficiency is greatly improved and the graphene can be industrially prepared in batches. Meanwhile, the prepared graphene is few in defect, high in yield, low in cost, good in dispersity and high in quality, and the application range of the graphene is greatly expanded.

Owner:SHANDONG UNIV OF SCI & TECH

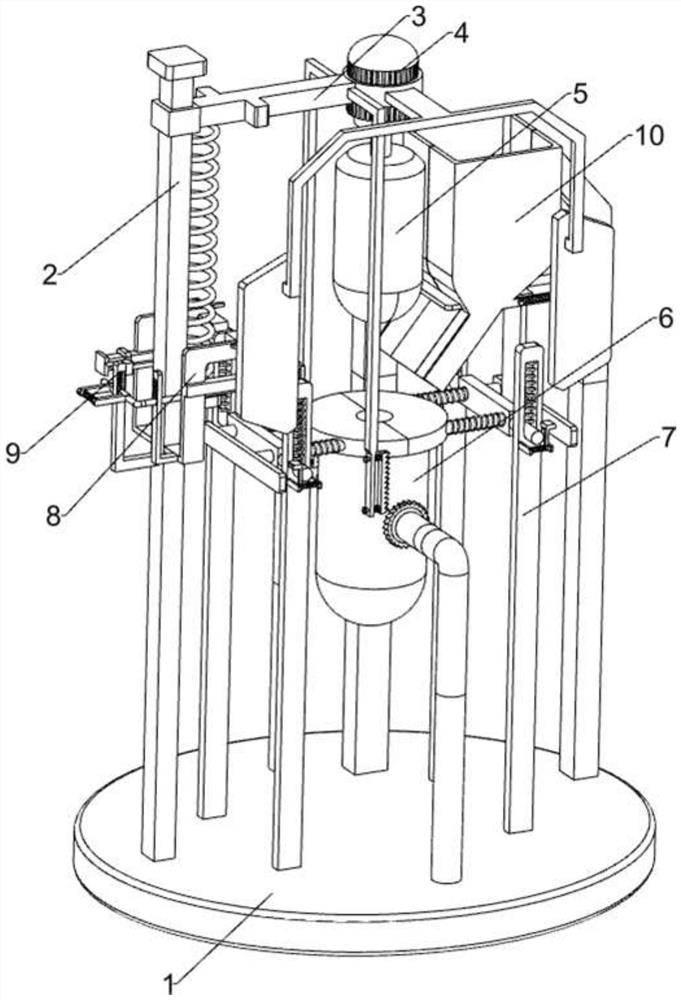

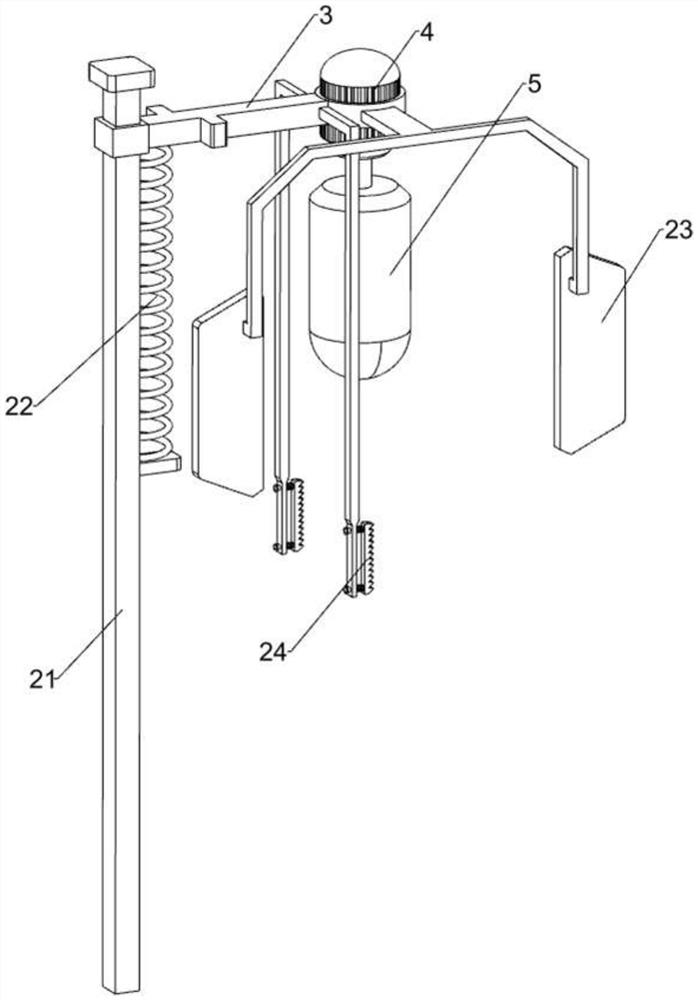

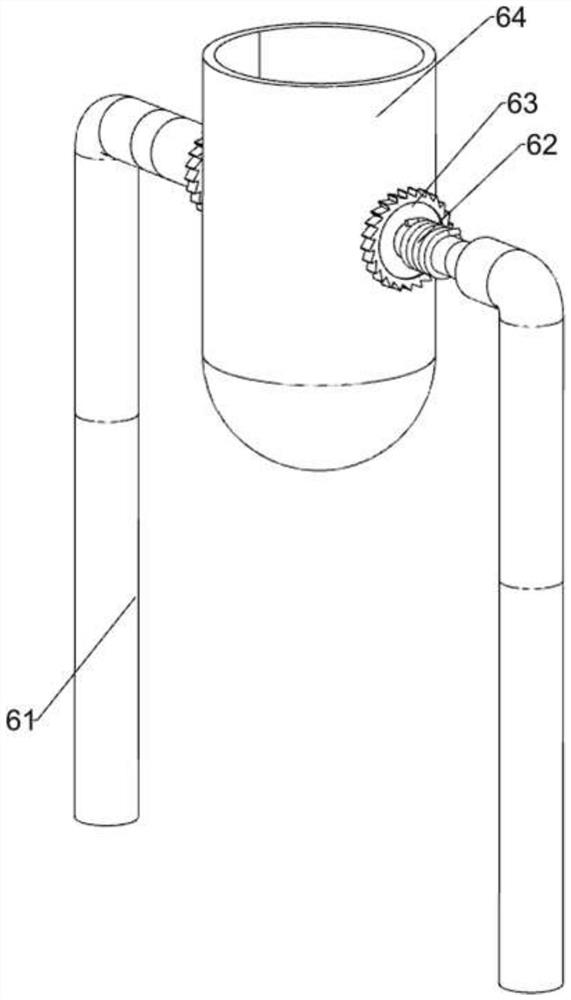

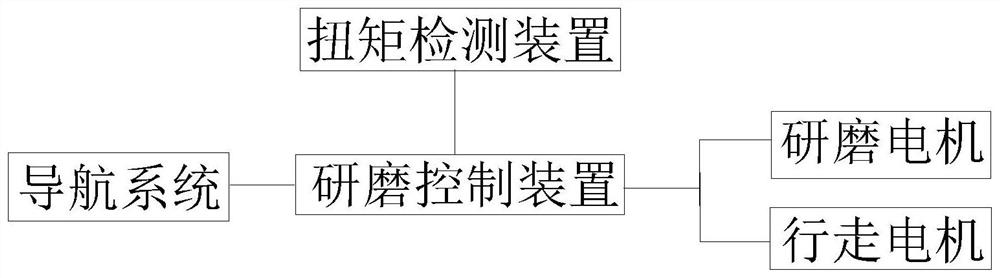

Coating grinding device

ActiveCN108722560AIncrease grinding timeGrind thoroughlyCocoaGrain treatmentsSpiral bladeElectric machinery

The invention relates to a coating grinding device and belongs to the technical field of coating production. The coating grinding device comprises a base, a support seat, support pillars, a support plate and an outer shell, wherein an inner shell is arranged in the outer shell; a first grinding plate is arranged on the bottom part of the inner shell; a material collecting chamber is arranged on the bottom part of the outer shell and is provided with a discharge hole and a discharge valve; a second grinding plate is arranged on the top part of the support seat and is connected with a first motor through a first rotary shaft; the first grinding plate is connected with a second motor through a second rotary shaft; and a spiral blade is arranged on the outer part of the inner shell. Accordingto the coating grinding device provided by the invention, through arranging a spiral groove and a grinding ball, the grinding time is prolonged, and the thoroughness in grinding is realized; and through arranging the spiral blade, a coating which does not meet the requirement is directly ground again so as to reach to the required grinding level at a time, so that the grinding efficiency is improved.

Owner:安徽漫画树涂料股份有限公司

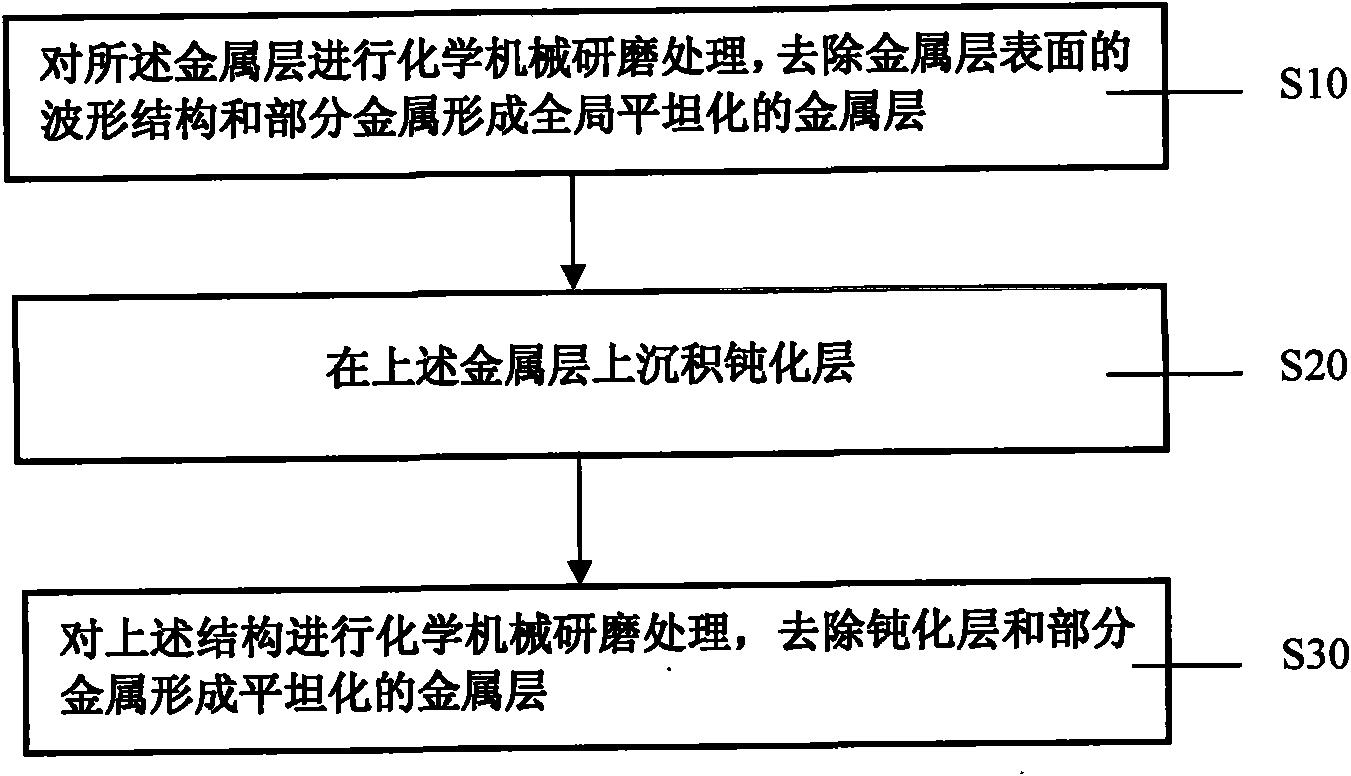

Method for reworking metal layer

InactiveCN101783292AImprove final yieldReduce surface defectsSemiconductor/solid-state device manufacturingMetallurgyMicroparticle

The invention provides a method for reworking a metal layer, which is applied in the field of integrated circuit manufacture. The method comprises the following steps: carrying out chemical mechanical lapping treatment on the metal layer, and removing a waveform structure and partial metal from the surface of the metal layer to form a globally planarized metal layer; depositing a passivation layer on the metal layer; and carrying out chemical mechanical lapping treatment on the structure, and removing the passivation layer and partial metal to form a planarized metal layer. The method for reworking the metal layer can greatly reduce surface defect caused by a normal chemical mechanical lapping process, such as the defects of metal, chemical, grinding fluid residue, microparticle residue and the like, even metal surface corrosion and crater defect, can remarkably improve the defect after the chemical mechanical lapping process, and increase the rate of good products.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

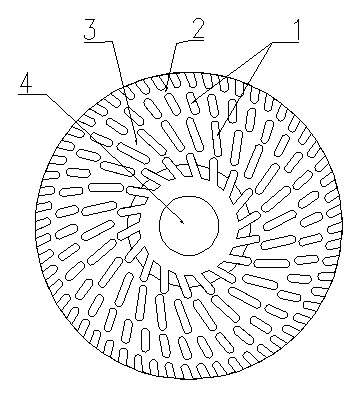

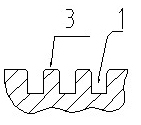

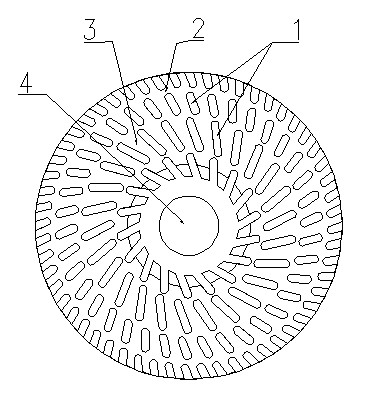

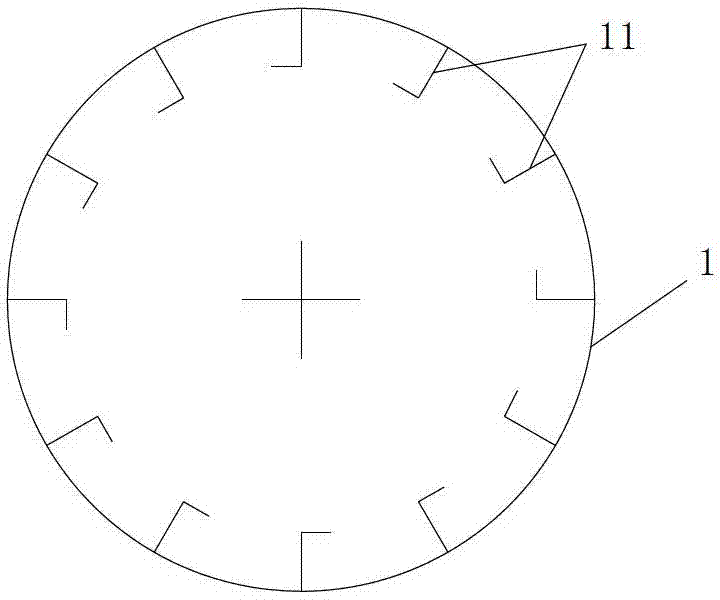

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606AReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

The invention discloses a grinding table of a disc grinder for preparing synthetic fiber pulp, which comprises a grinding plate, wherein the working surface of the grinding plate is provided with a plurality of grooves; the grooves are distributed in a multiple-layer concentric circle mode around the grinding plate; the grooves are evenly distributed on each layer of the concentric circle; grinding teeth are formed on the grinding plate between every two adjacent grooves on the same circle; and a pulp baffle plate is formed at the gap between any two adjacent layers. The invention can prolongthe the residence time of materials in the disc grinder, weaken the cut-off function of the grinding table, enhance the effects of crushing, kneading and fibrillation on the fibers, and greatly improve the microfibrillation degree of the pulp fibers.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Preparation method for producing calcium-carbonate-containing lithographic ink through one-step kneading method

ActiveCN103087587AGood dispersionDecrease and increase stirring timeInksPhysical chemistryHigh calcium

The invention relates to the technical field of lithographic ink, and particularly relates to a preparation method for producing calcium-carbonate-containing lithographic ink through a one-step kneading method. The preparation method comprises the following step: simultaneously adding 15-30% of calcium carbonate filter cake, 10-30% of tinting pigment and 20-40% of pigment binder into a kneading machine, thus preparing the mixed base ink having a high calcium carbonate concentration through a one-step kneading method. Compared with the prior art, the invention simplifies the production process, improves the production efficiency, lowers the production cost, increases the calcium carbonate content in the ink and can obtain lithographic ink having favorable ink gloss and flowability, thus having broad market prospects.

Owner:茂名阪田油墨有限公司

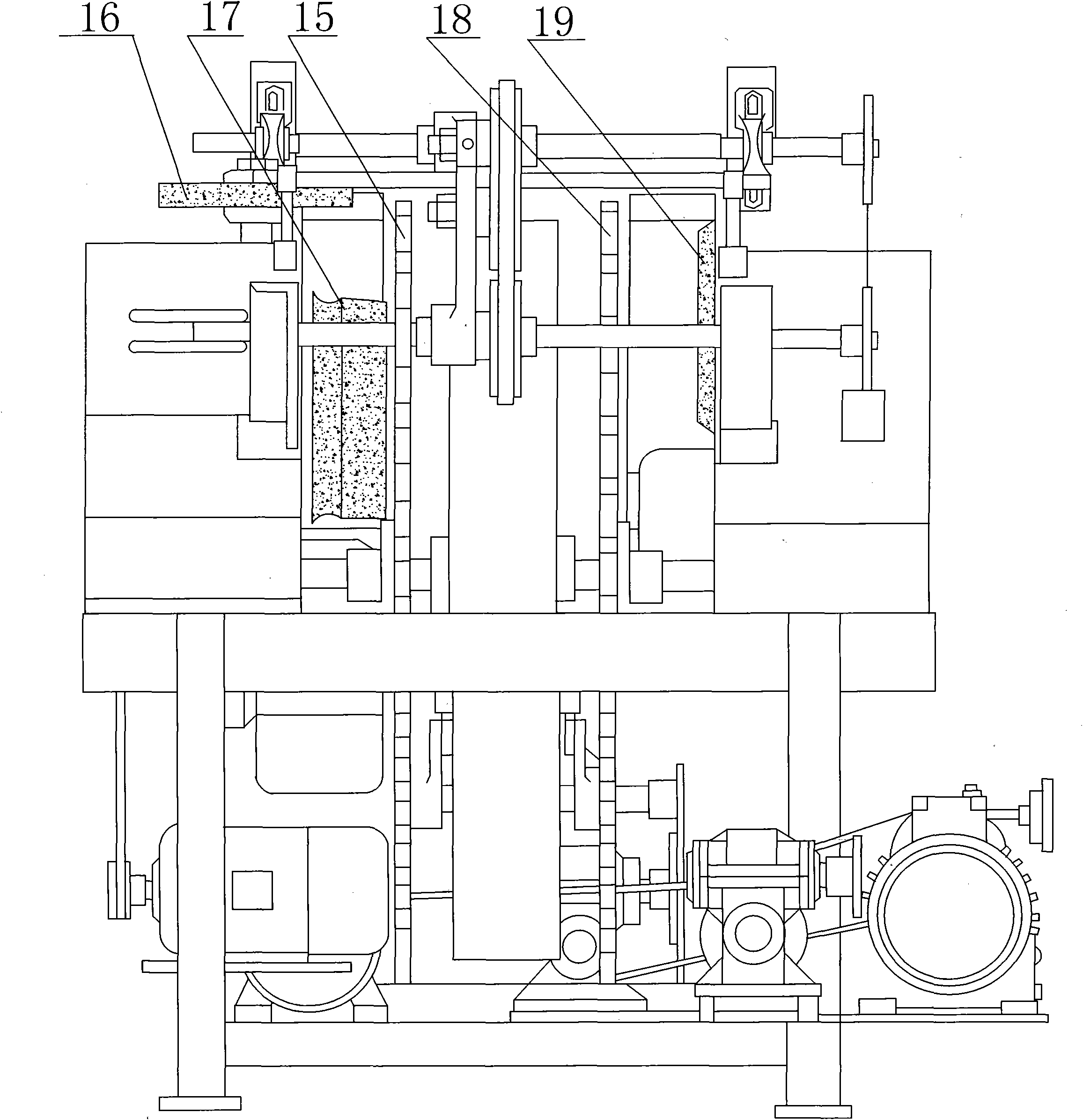

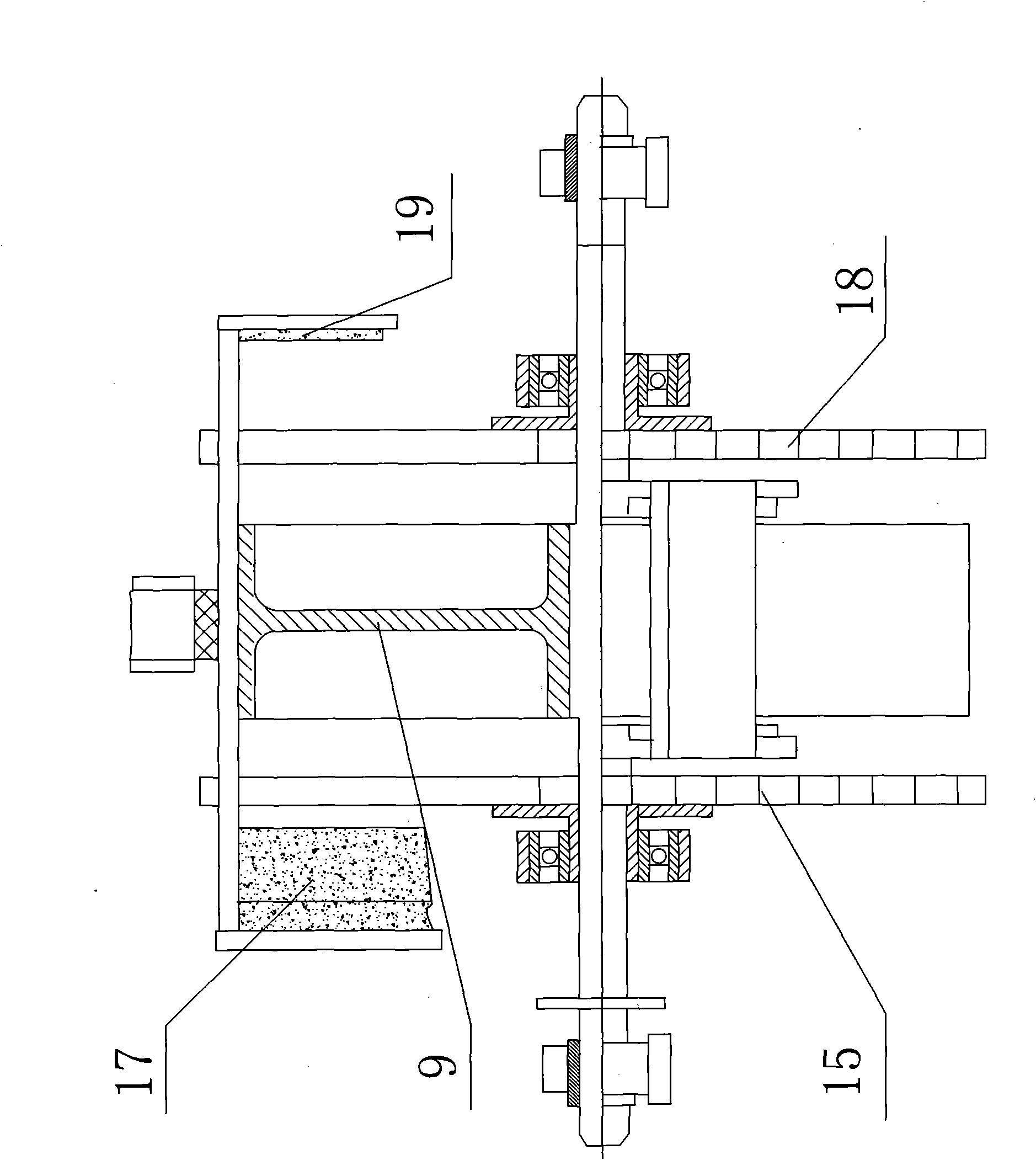

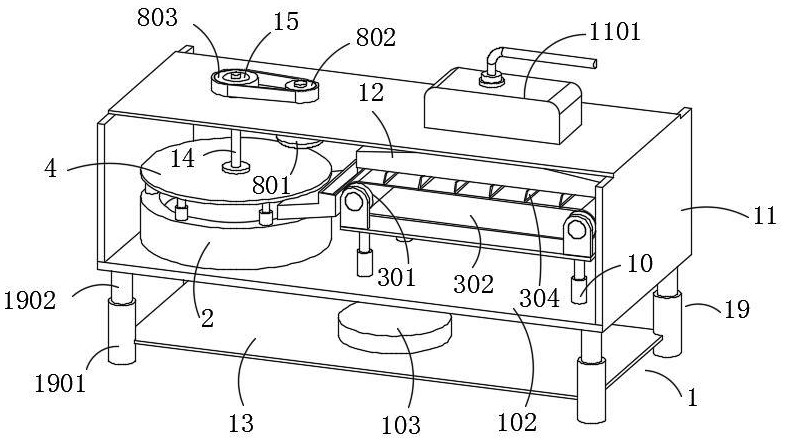

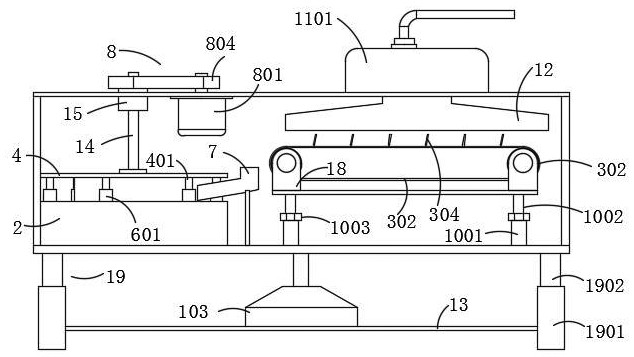

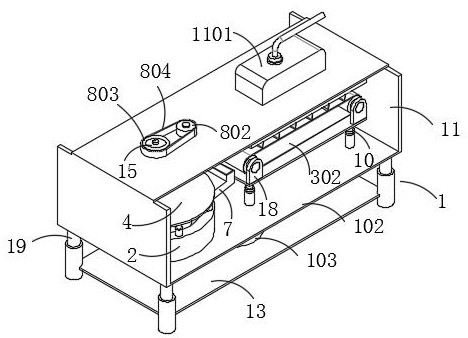

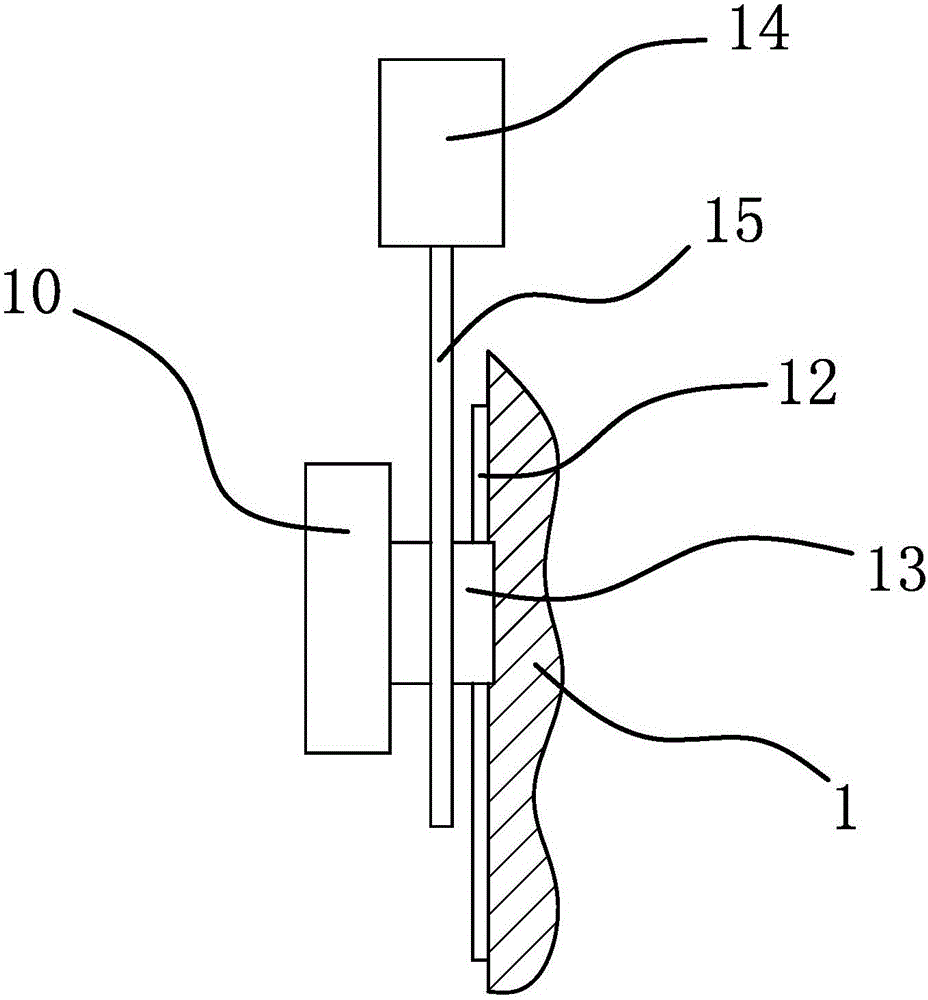

Wood round rod grinding forming machine and wood round rod machining method

The invention discloses a wood round rod grinding forming machine and a wood round rod machining method. The conventional wood round rod production process is to machine a wood round rod cut to length by a half-round head chamfering machine to form a half-round head, sand the half-round head and turn the round rod with the processed half-round head into a branch tip shape by using a bench type woodworking machine tool and manually sanding the round rod on the machine tool by using abrasive cloth after turning. The machine comprises a machine frame (1) fixed with a feeding tank, wherein a motor in the machine frame drives a riding wheel (9) through a transmission mechanism; the riding wheel is positioned between two grooved pulleys; the grooved pulley is sleeved on the shaft of the riding wheel; belt pulleys (8) which are opposite to the riding wheel in rotating direction is arranged on a machine frame above the riding wheel; a belt (7) between the belt pulleys is pressed on the ridingwheel (9) by a round rod (6); and driving sand wheel groups are arranged on the side faces of the grooved wheels. The machine and the method are used for producing wood product such as wood round rods.

Owner:HEILONGJIANG LINKE WOODEN PROD

Nano sulfate reducing bacteria corrosion preventive coating for gathering and transferring pipeline and manufacturing method thereof

ActiveCN101328382AImprove corrosion resistanceHigh glossAnti-corrosive paintsPolyether coatingsDiacetone alcoholSulfate-reducing bacteria

Nano sulfate reducing bacteria corrosion resistant paint for a gathering pipeline is applied to the anticorrosion paint for the oil and gas collecting pipeline. The paint comprising an agent A and an agent B is characterized in that: the agent A consists of bisphenol A epoxy resin, normal butyl alcohol, xylene, diacetone alcohol, polyether modified dimethyl polysiloxane, a macromolecular block copolymer containing a pigment compatible group, foam breaking polysiloxane, polyether siloxane copolymer, polyacrylate, macromolecular polyocarboxy acid containing amino derivatives, metronidazole, nano titanium dioxide, nano silicon dioxide, chrome oxide green, talcum powder and scale graphite; and the agent B consists of a polyamide addition compound, normal butyl alcohol and diacetone alcohol. The paint has the advantages of: an isolated layer is coated between a metal surface and sulfate reducing bacteria inside the pipeline, thereby not only improving the corrosion and abrasion resistant performance of the pipeline, but also preventing the sulfate reducing bacteria from adhering to the metal surface and consequently solving the problem of corrosion caused by the sulfate reducing bacteria.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

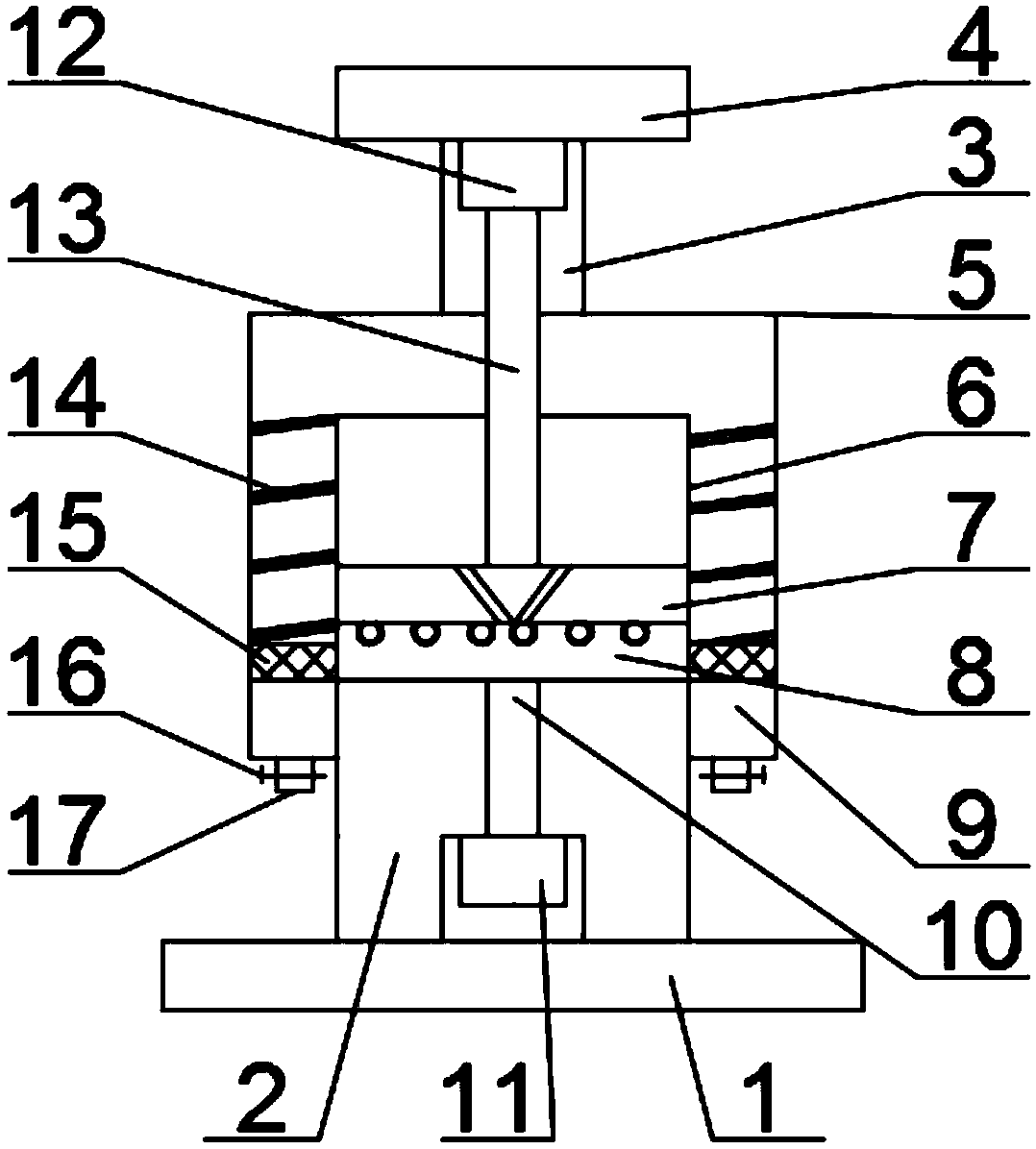

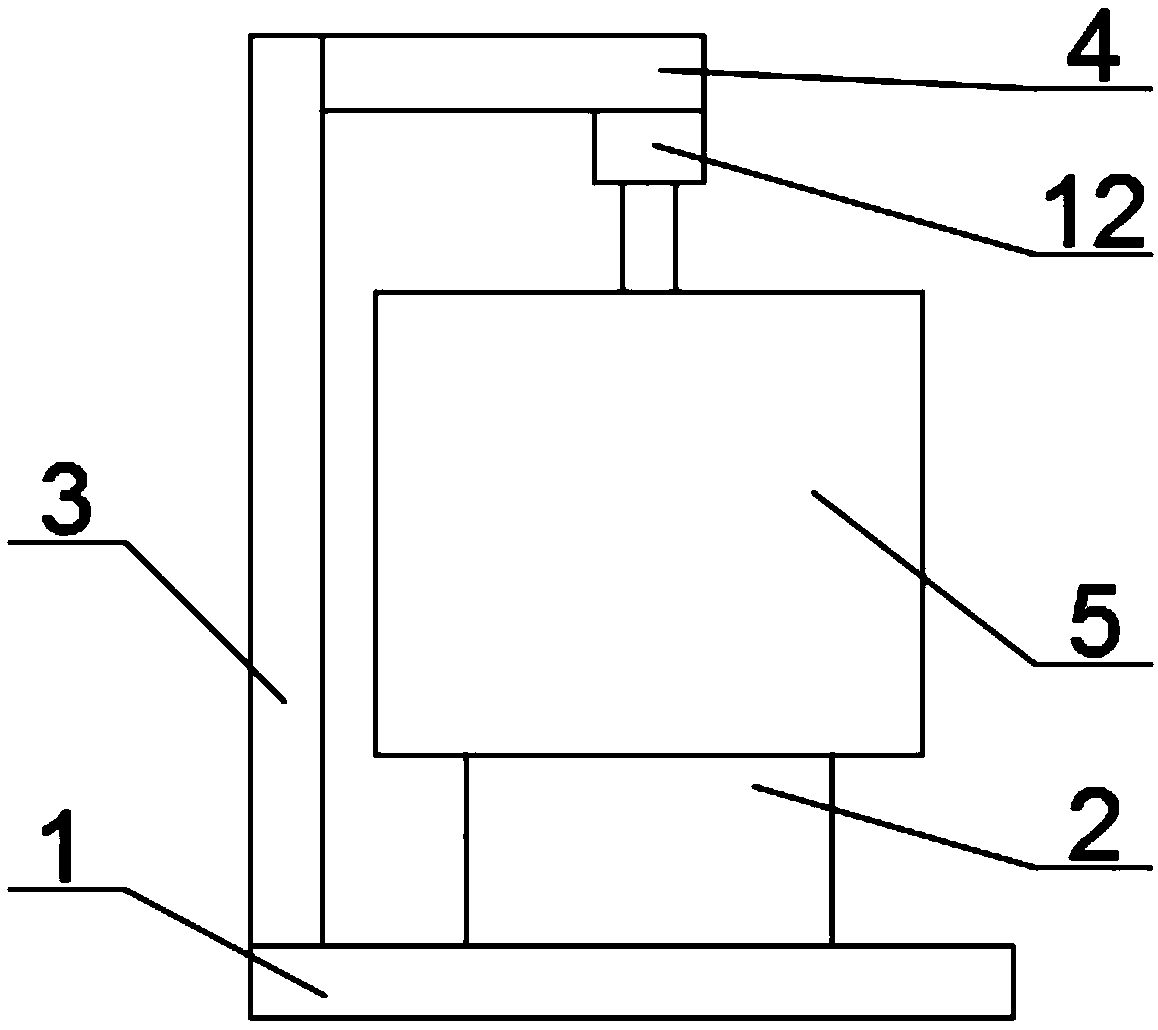

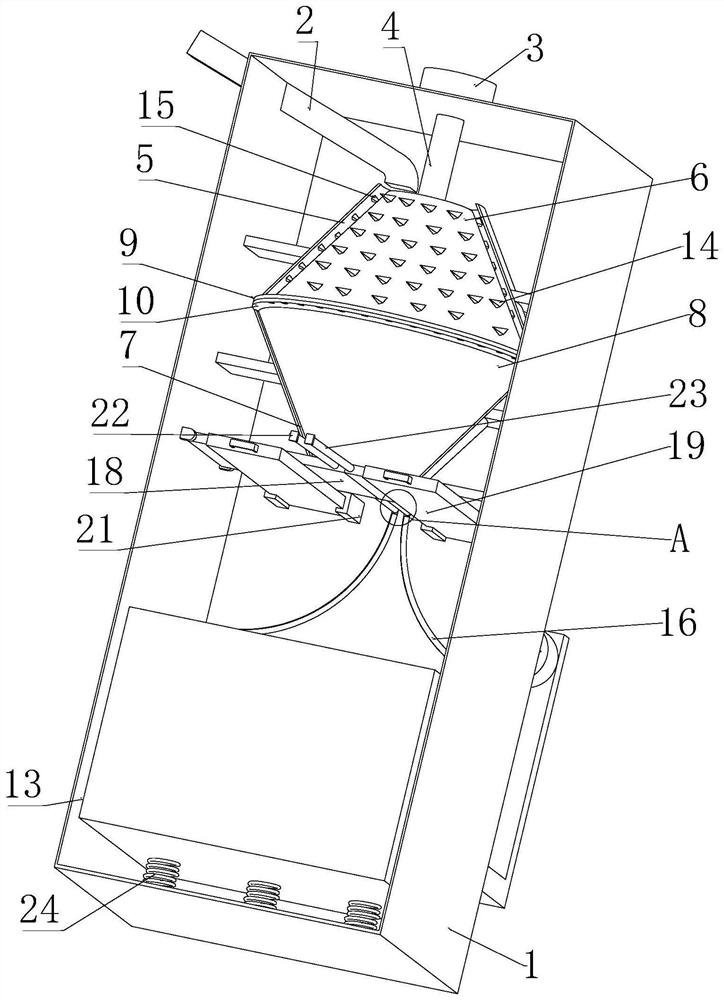

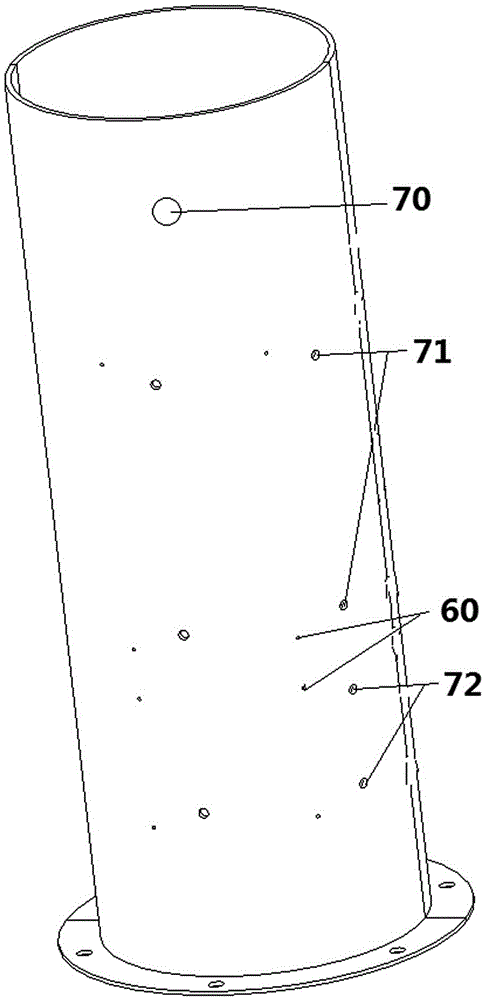

Vertical mill device for milling ceramic raw materials

ActiveCN103599827ASolve the accumulationIncrease grinding timeGrain treatmentsEngineeringMechanical engineering

The invention relates to a vertical mill device for milling ceramic raw materials. The vertical mill device comprises a vertical mill shell, a material tank, a milling disc, a milling roller, and a scrapping plate device positioned at the lower end of the material tank, wherein a shell body of the scrapping plate device is sleeved on a shell of a material outlet in the lower end of the material tank by two connection plates which are tensioned by bolts; the two connection plates are positioned at two ends of the shell body; scraping plates positioned at the bottom of the scrapping plate device are distributed in a circumference manner at intervals along the bottom of the shell body; the bottoms of the scrapping plates fit with an upwards raised tapered non-milling area in the center of the milling disc; a body of the milling roller is uniformly coated by a roller cover with inclined teeth, and the roller cover between two adjacent inclined teeth can form a particle channel. The vertical mill device has the advantages that the scrapping plate device is positioned at the lower end of the material discharging hole of the material tank, so that the problem that the ceramic raw materials are accumulated close to the center of the milling disc can be effectively solved; the inclined teeth are adopted for milling, so that the milling time of milled materials can be prolonged, and further the crushing efficiency is improved.

Owner:GUANGDONG BOFFIN MECHANICAL & ELECTRICAL CO LTD

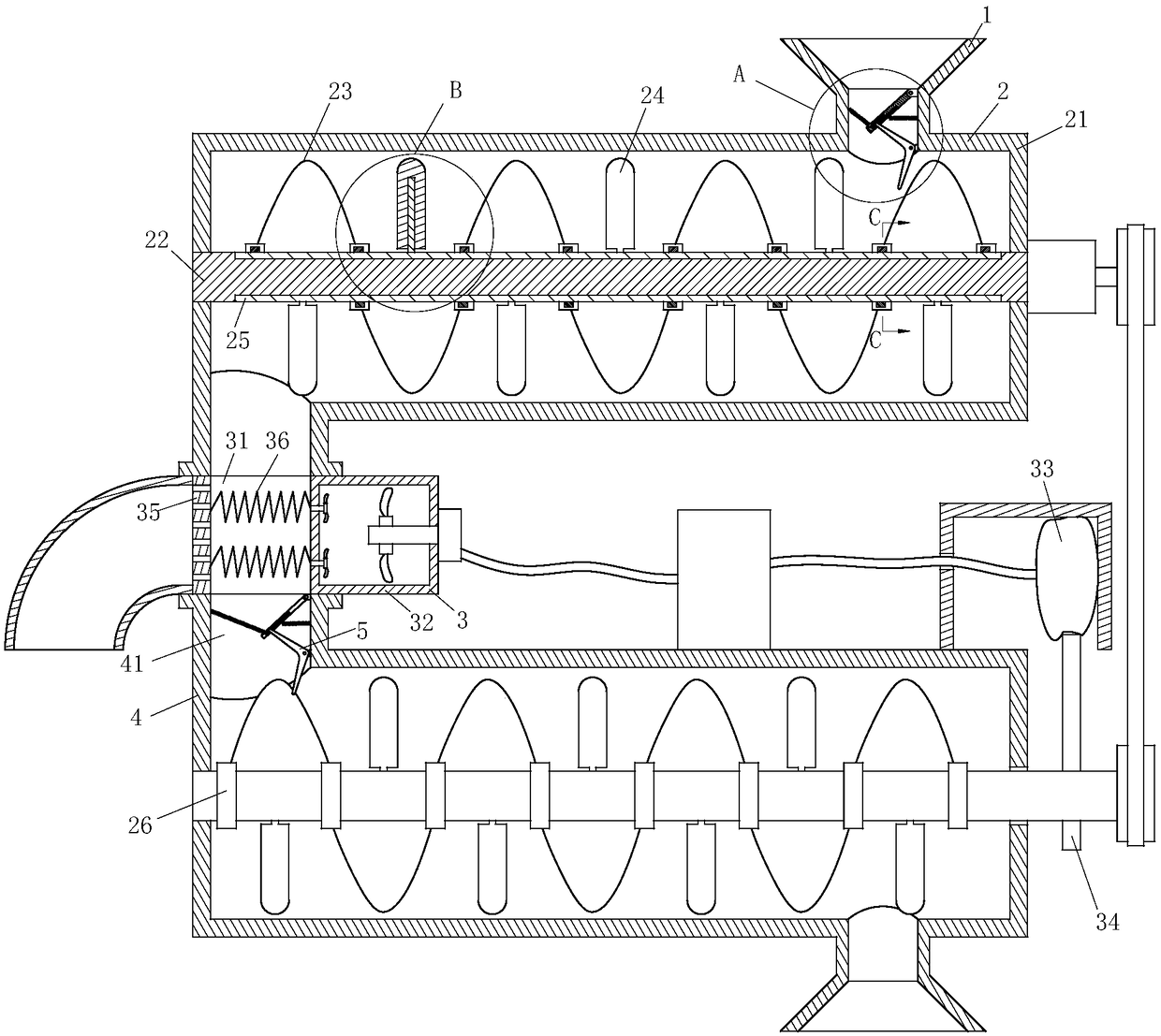

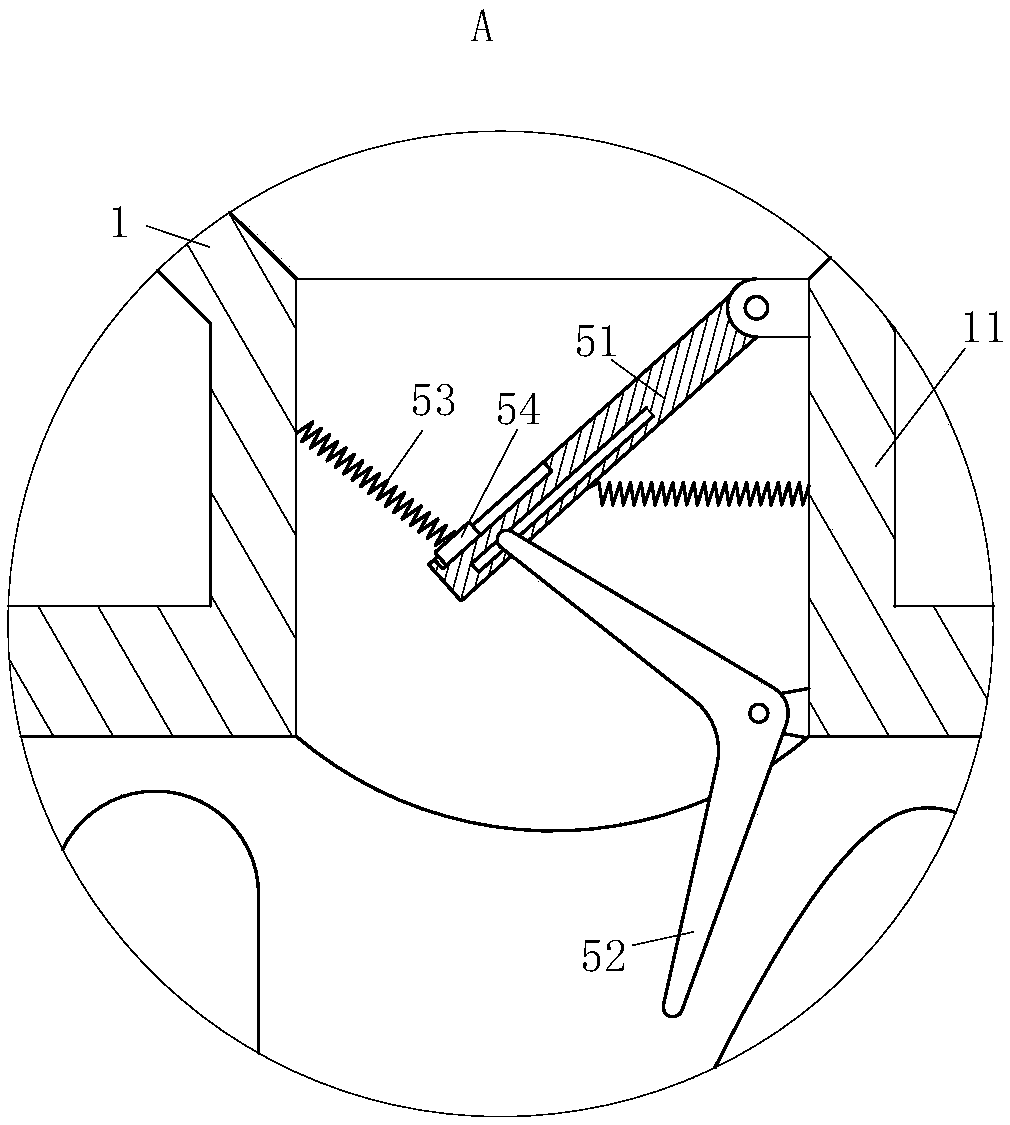

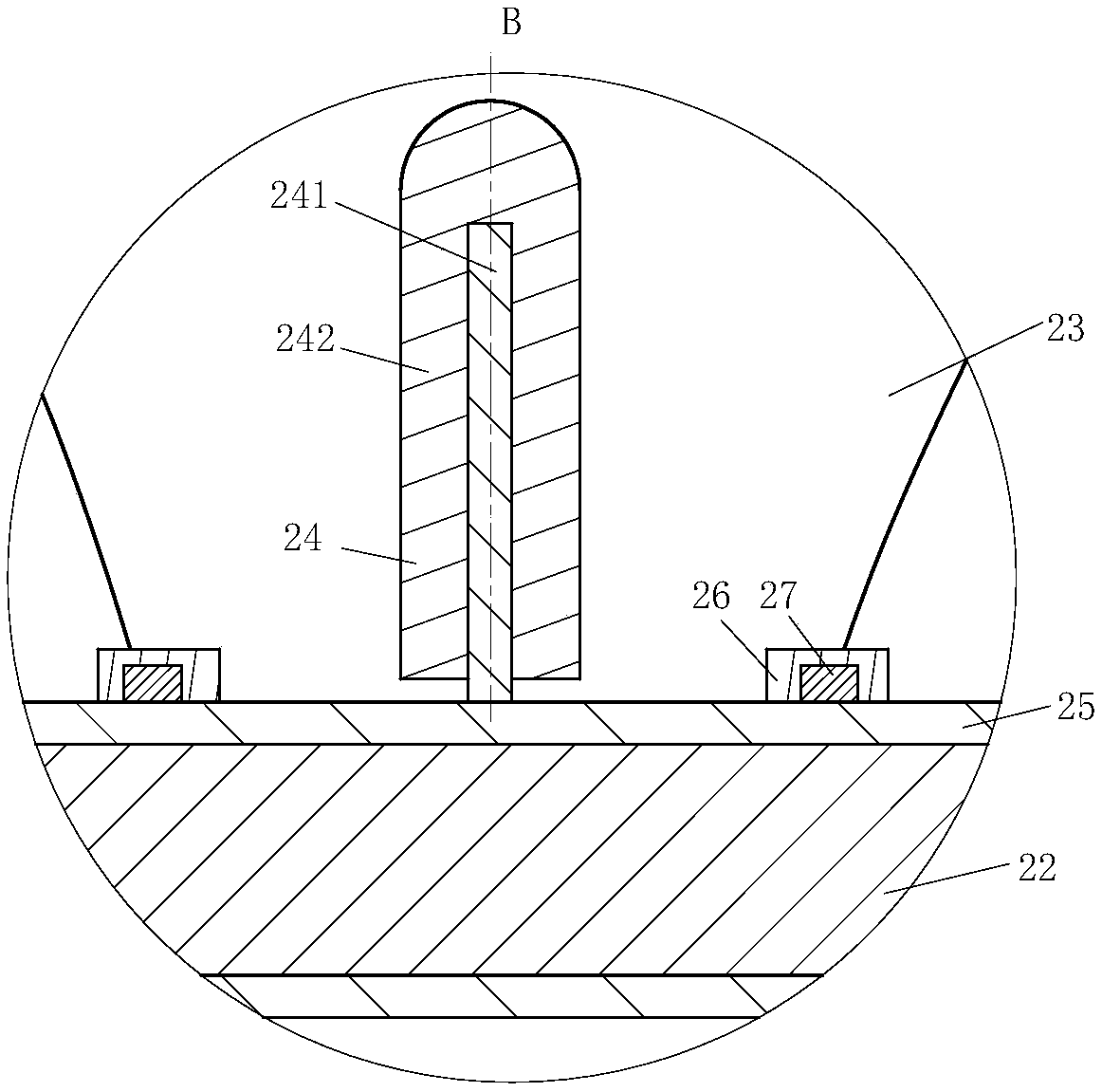

Activated carbon grinding equipment

ActiveCN109499721AReduce propulsion speedImprove adsorption capacityGrain treatmentsActivated carbonEngineering

The invention belongs to the technical field of grinding equipment and particularly relates to activated carbon grinding equipment. The activated carbon grinding equipment comprises a hoper, a first-stage grinding device, a screening module and a second-stage grinding device. The first-stage grinding device and the second-stage grinding device conduct driving synchronously. The first-stage grinding device comprises a grinding box, a grinding rotary shaft, a grinding spiral lamina and grinding rods. The grinding rotary shaft is connected to the interior of the grinding box. The grinding rotaryshaft is provided with grooves in the length direction. Magnets I are inlaid in the grooves. The grinding rotary shaft is sleeved with a plurality of grinding rings distributed uniformly. The grindingrings are provided with magnets II. The grinding spiral lamina is fixed to the grinding rings. The screening module is used for screening out activated carbon meeting the standards and guiding activated carbon not meeting the standards into the second-stage grinding device for continuous grinding. According to the activated carbon grinding equipment, differential rotation is formed between the grinding rotary shaft and the grinding spiral lamina, the grinding time of the activated carbon is prolonged, the activated carbon is ground more sufficiently, and the grinding quality is improved.

Owner:金寨智行知识产权运营有限公司

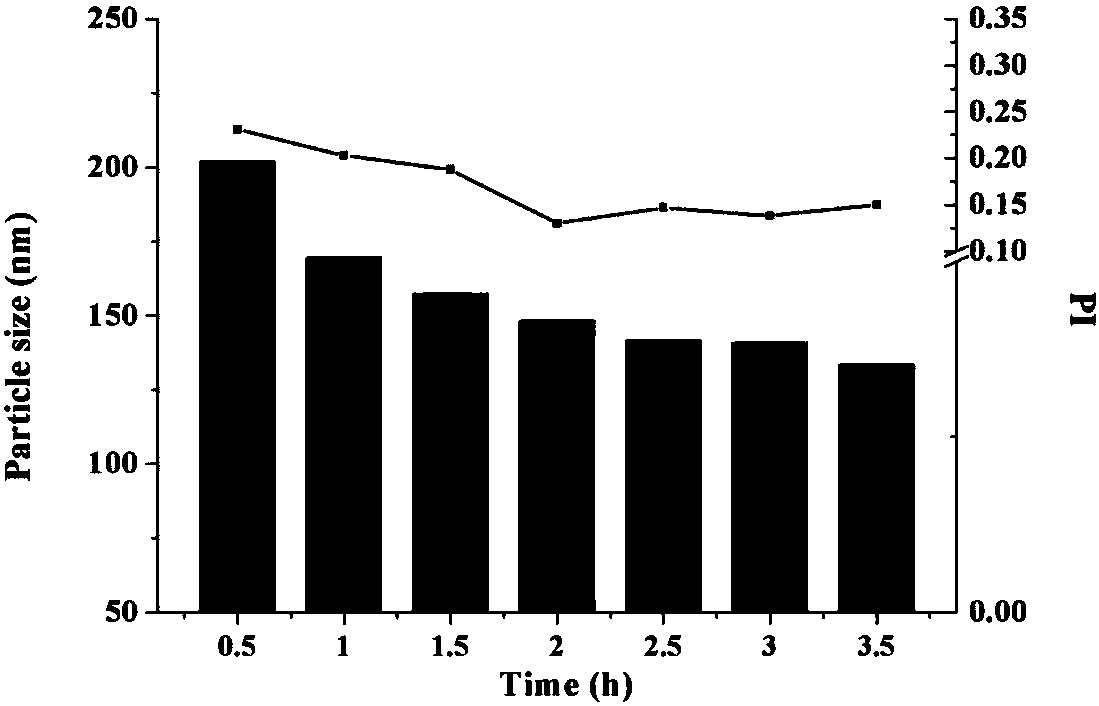

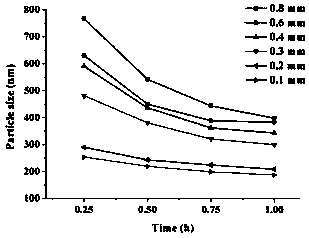

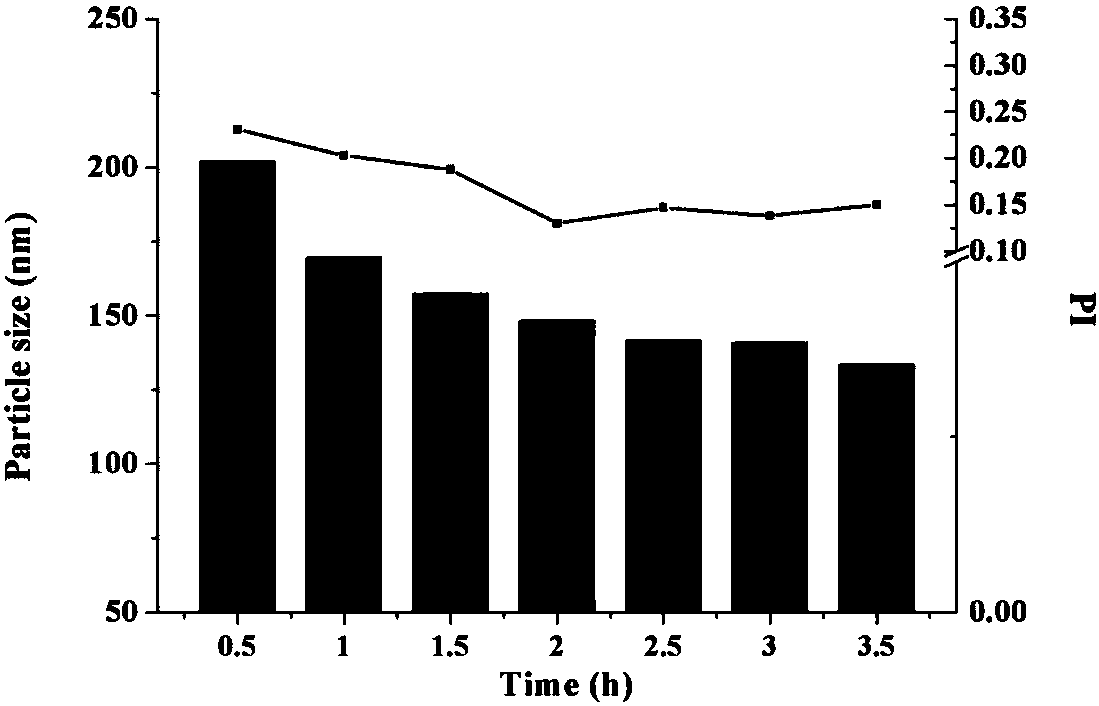

Andrographolide nanometer suspension agent

ActiveCN109568265ASimple prescriptionReduce dosageAntibacterial agentsOrganic active ingredientsChemistryNanometre

The invention provides an andrographolide nanometer suspension agent. The andrographolide nanometer suspension agent includes andrographolide particles with the effective average particle size less than 1000 nm and one or more anionic surface stabilizers. According to the nanometer suspension agent, the prescription is simple, the preparation process is simplified and controllable, industrialization is easy, the efficiency is high, preparation stability is good, and dilution resistance is achieved.

Owner:SHINEWAY PHARMA GRP LTD +1

Epoxy resin material compatible with liquid oxygen and preparation method of epoxy resin material

The invention relates to an epoxy resin material compatible with liquid oxygen and preparation method of epoxy resin material, and belongs to the technical field of resin material modification. The epoxy resin material compatible with liquid oxygen is composed of the following components in parts by weight: 85-95 parts of epoxy resin, 5-15 parts of a fire retardant and 8-12 parts of a curing agent, wherein the fire retardant is selected from at least one of octabromoether, phosphorus oxychloride, phosphoryl chloride, phosphorus trichloride, melamine, dimethyl methylphosphonate, aluminium hydroxide and magnesium hydroxide. The epoxy resin material provided by the invention has the beneficial effect that the epoxy resin material compatible with the liquid oxygen has no obvious reaction such as explosion, combustion and flash with the liquid oxygen according to ASTMD2512(2008) standard detection, so that the epoxy resin is compatible with the liquid oxygen.

Owner:DALIAN UNIV OF TECH

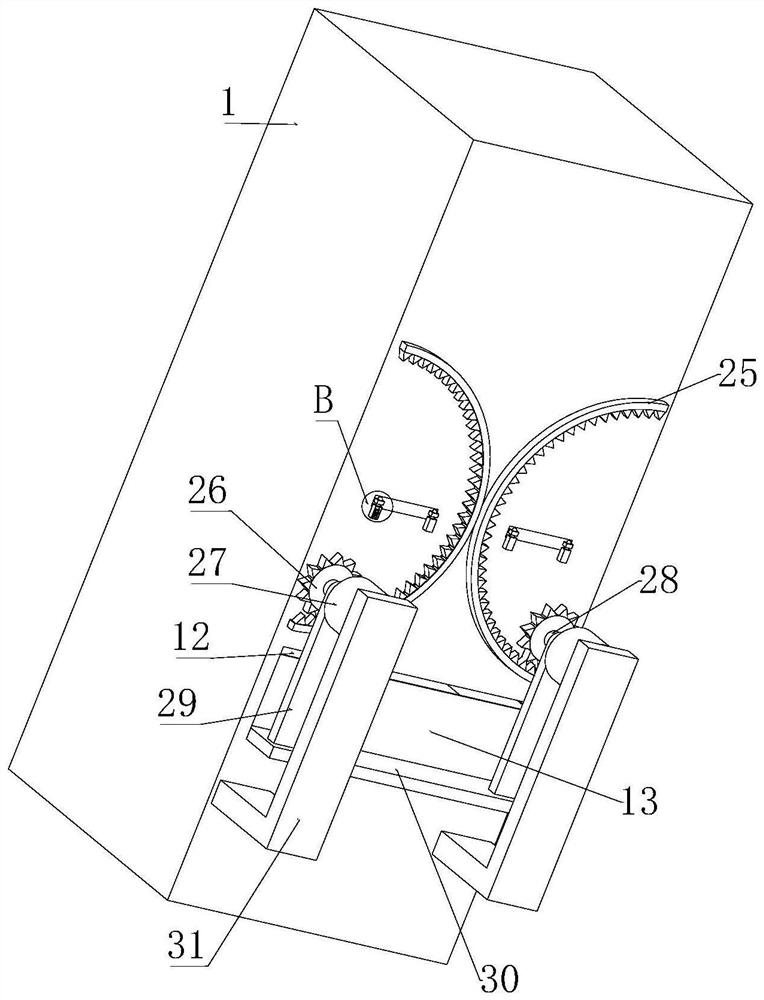

Discharging and screening device for metal powder grinding

The invention discloses a discharging and screening device for metal powder grinding. The discharging and screening device comprises a box body, a discharging device and a screening device. The discharging device comprises two discharging plates, the two discharging plates are rotatably connected to the inner walls of the left side and the right side of the box body respectively, and two gears are engaged with two semicircular gear rings respectively. The screening device comprises a plurality of first springs, and a lifting plate penetrates through a through groove and extends out to make contact with the bottoms of rotating rods. The two gears drive the two semicircular gear rings to rotate respectively when rotating, then the two discharging plates rotate, and the two discharging plates abut against each other when rotating upwards to be in a horizontal state. When metal powder ground in a grinding device needs to be discharged, the two gears rotate to drive the two discharging plates to rotate downwards, and the ground metal powder and metal powder on the two discharging plates fall into the screening device, so that the loss of the metal powder is reduced, and the metal powder grinding and screening efficiency is improved.

Owner:李素侠

Andrographolide nanometer suspension agent

ActiveCN109568264AReduce dosageFix stability issuesAntibacterial agentsOrganic active ingredientsChemistryAndrographolide

The invention provides an andrographolide nanometer suspension agent. The andrographolide nanometer suspension agent includes andrographolide particles with the effective average particle size less than 1000 nm and one or more anionic surface stabilizers. According to the nanometer suspension agent, the prescription is simple, the preparation process is simplified and controllable, industrialization is easy, the efficiency is high, preparation stability is good, and dilution resistance is achieved.

Owner:SHINEWAY PHARMA GRP LTD +1

Granulating device for chicken feed production

PendingCN112956717AImprove work efficiencyIncrease the areaFeeding-stuffFood processingBiotechnologyElectric machinery

The invention discloses a granulating device for chicken feed production. The granulating device comprises a granulating platform, a granulating disc and a material conveying assembly, the granulating platform comprises four groups of telescopic rods, a bottom plate and a lifting motor, the granulating disc is fixedly mounted on the upper surface of the bottom plate, a grinding disc is rotatably mounted in the granulating disc, a conical grinding head is arranged at the bottom of the grinding disc, a conical grinding groove is formed in the granulating disc, the conical grinding head and the conical grinding groove are arranged in a matched mode, a feeding groove is fixedly formed in the position, located on one side of the grinding disc, of the upper surface of the bottom plate, the material conveying assembly is arranged on one side of the feeding groove, the top of the grinding disc is in transmission connection with a first driving assembly, screw sleeves are annularly arrayed on the position, located on the outer ring of the conical grinding groove, of the upper surface of the granulating disc at equal intervals, screws are annularly arrayed on the position, located on the outer ring of the conical grinding head, of the bottom surface of the grinding disc at equal intervals, and one ends of the screws are in threaded connection with the interiors of the screw sleeves. Automatic feeding is achieved, the working efficiency is improved, the grinding area is increased, and the grinding time is prolonged.

Owner:庞淑红

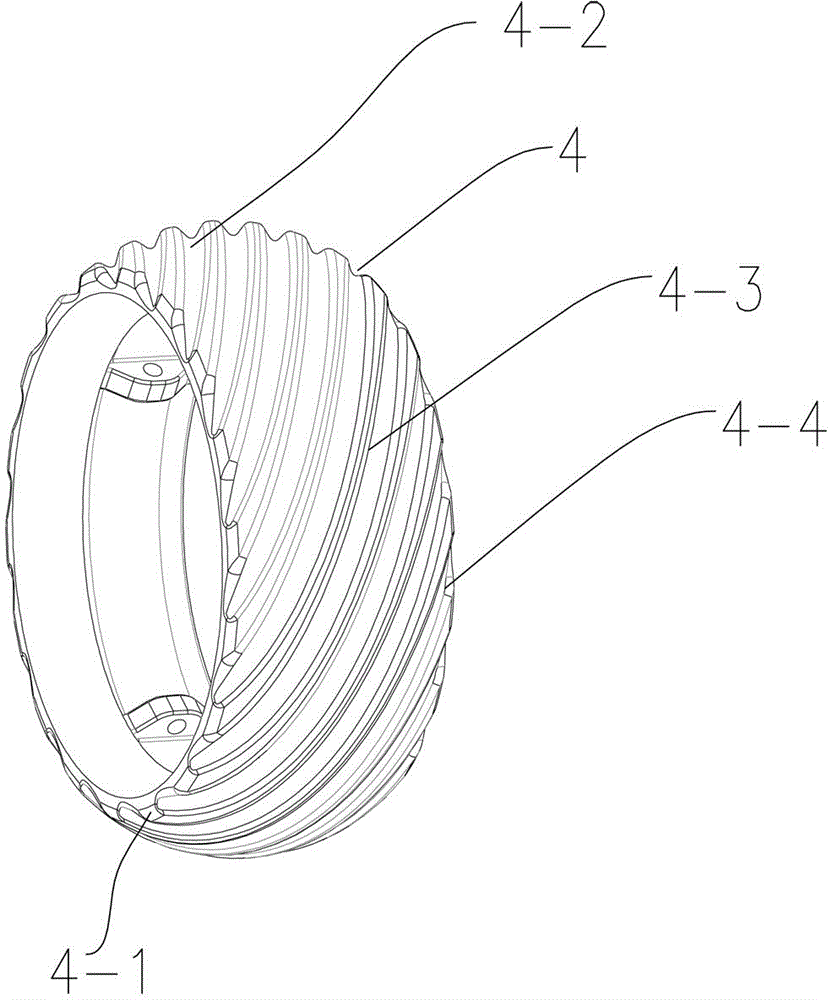

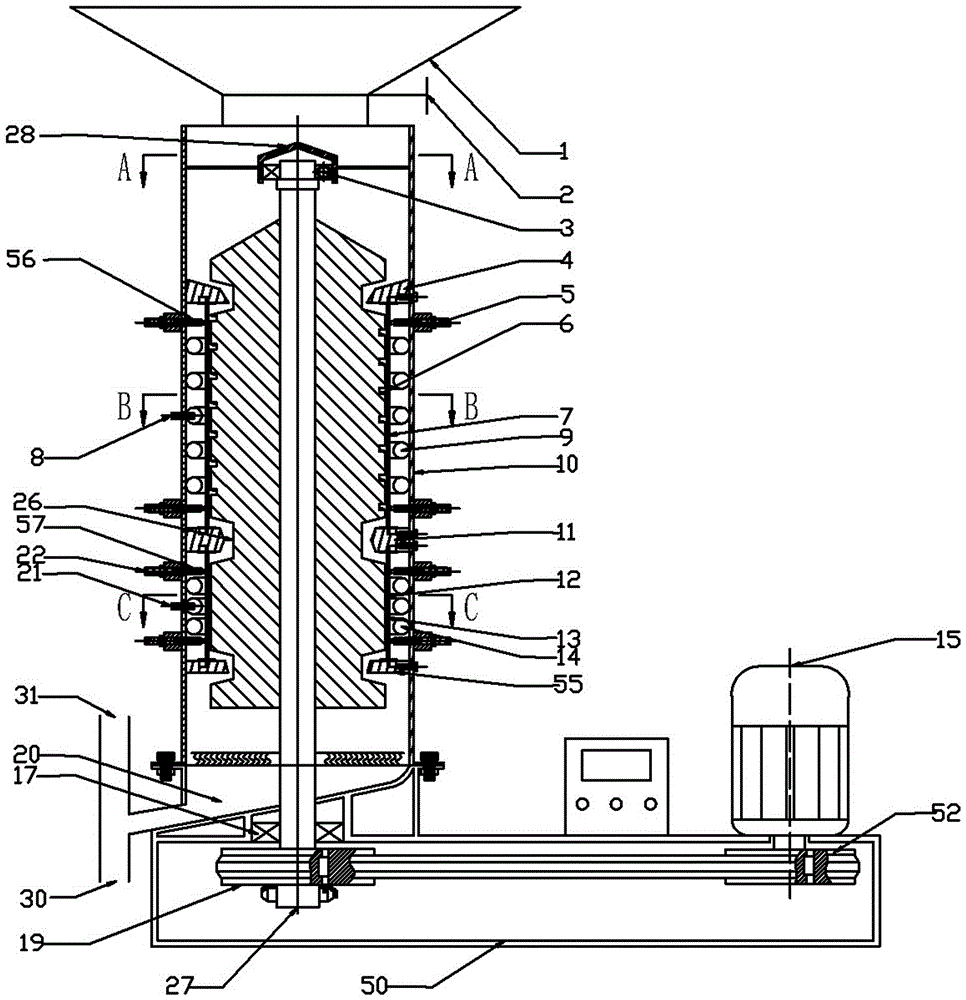

Grinding type tartary buckwheat huller with dynamic pressure regulation

ActiveCN106391174AGrinding pressure is low and adjustableUnbreakableGrain huskingGrain polishingPolygonum fagopyrumWorking pressure

The invention discloses a grinding type tartary buckwheat huller with dynamic pressure regulation, which belongs to the field of grain hulling machines. The huller comprises a shell, wherein a grinding cylinder is vertically fixed in the middle of the shell; grinding air bags are arranged between the grinding cylinder and the side wall of the shell; a grinding roller is concentrically arranged in the grinding cylinder; a feed hopper is arranged on the top part of the grinding cylinder; a feed control gate is arranged on the bottom part of the feed hopper; a kneading cylinder is arranged right under the grinding cylinder; kneading air bags are arranged between the kneading cylinder and the shell; a kneading roller is concentrically arranged in the kneading cylinder; a draining slot is arranged under the kneading cylinder; a hulling discharge hole and a cleaning device connector are arranged under the draining slot. During the whole hulling process, with the buffer functions of the grinding air bags and the kneading air bags, the working pressure on tartary buckwheat is less and can be dynamically regulated, and the rate of perfect kernels of tartary buckwheat hulling is effectively improved.

Owner:NORTHWEST A & F UNIV

Roll grinding machine grinding in circulating way

ActiveCN105879962AHigh degree of automationHigh utility valueGrain treatmentsPulp and paper industryAutomation

The present invention provides a roll grinding machine grinding in a circulating way, belonging to the technical field of machinery. The present invention solves the problem of low automation degree in the prior art. The roll grinding machine grinding in a circulating way comprises a machine frame, a front roller, a middle roller and a rear roller. The front roller, the middle roller and the rear roller are all axially fixedly connected to the machine frame. The front roller, the middle roller and the rear roller are disposed in parallel along the horizontal direction and clearances through which oil ink or paste passes exist between every two adjacent rollers. The front roller, the middle roller and the rear roller form a grinding portion for grinding the oil ink. The machine frame is also connected with an ink delivery mechanism. The ink delivery mechanism is positioned at the upper part of the grinding portion. The front roller is provided with a scraper I for collecting the oil ink or paste. A scraper II is disposed between the rear roller and the middle roller, and an edge of the scraper II is close to the ink delivery mechanism. The roll grinding machine grinding in a circulating way is compactly structured and highly automated.

Owner:常熟东南高新技术创业服务有限公司

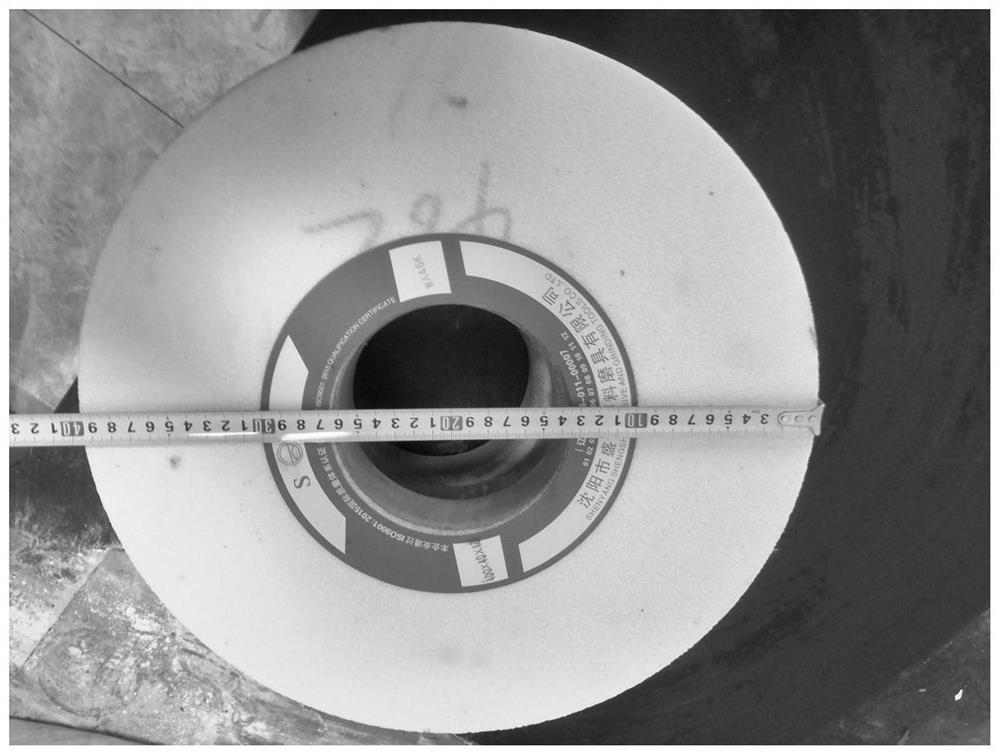

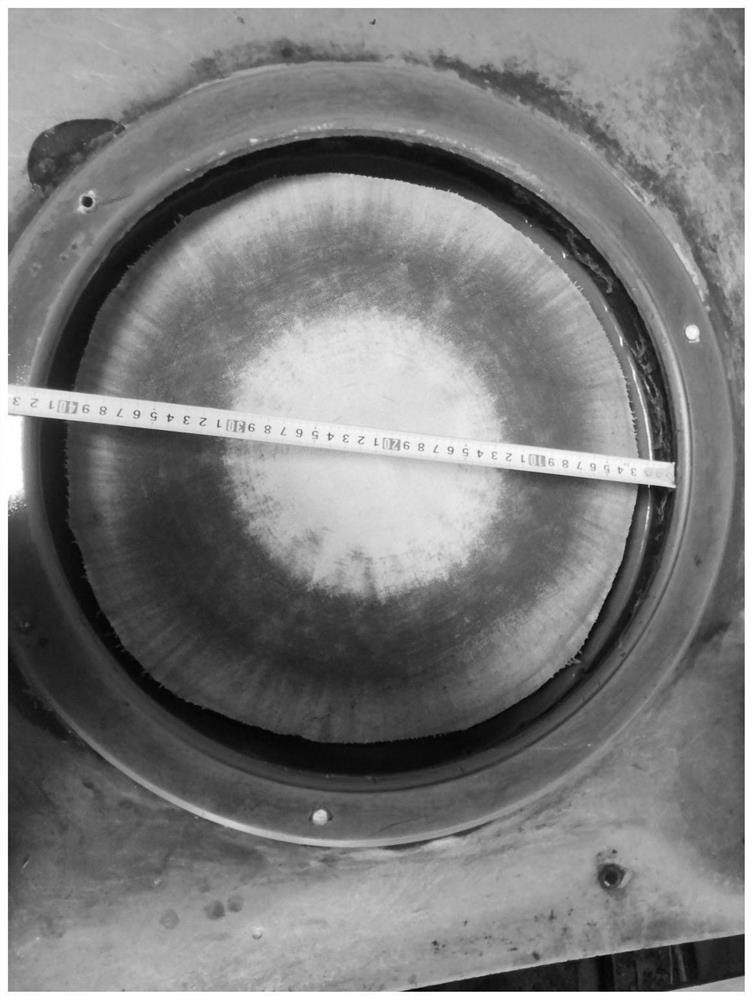

Efficient metallographic examination sample grinding method

PendingCN114397162AShorten grinding timeReduce sample preparation timePreparing sample for investigationTest samplePlanishing

The invention discloses an efficient metallographic test sample grinding method, and belongs to the technical field of metallographic sample preparation. The invention aims to improve the grinding efficiency of the metallographic specimen. According to the method, a metallographic specimen grinding machine is adopted for grinding through a 50 # grinding wheel, the diameter of the grinding wheel is 400 mm, the grinding depth is 0.5 mm, and the grinding time is 45-50 s; a grinding and polishing machine is adopted for grinding through 240 # abrasive paper, the diameter of the abrasive paper is 300 mm, the rotating speed is 1450 r / min, and the grinding time is 20-22 s; rough polishing is carried out through a grinding and polishing machine by combining canvas with carborundum suspension liquid, the diameter of the canvas is 400 mm, the rotating speed is 1450 r / min, and the grinding time is 25-30 s; fine polishing is carried out by combining woolen cloth and aluminum oxide polishing powder suspension through a grinding and polishing machine, the diameter of the woolen cloth is 400 mm, the rotating speed is 1450 r / min, and the grinding time is 18-20 s. According to the invention, the grinding time is reduced by 213s.

Owner:建龙北满特殊钢有限责任公司

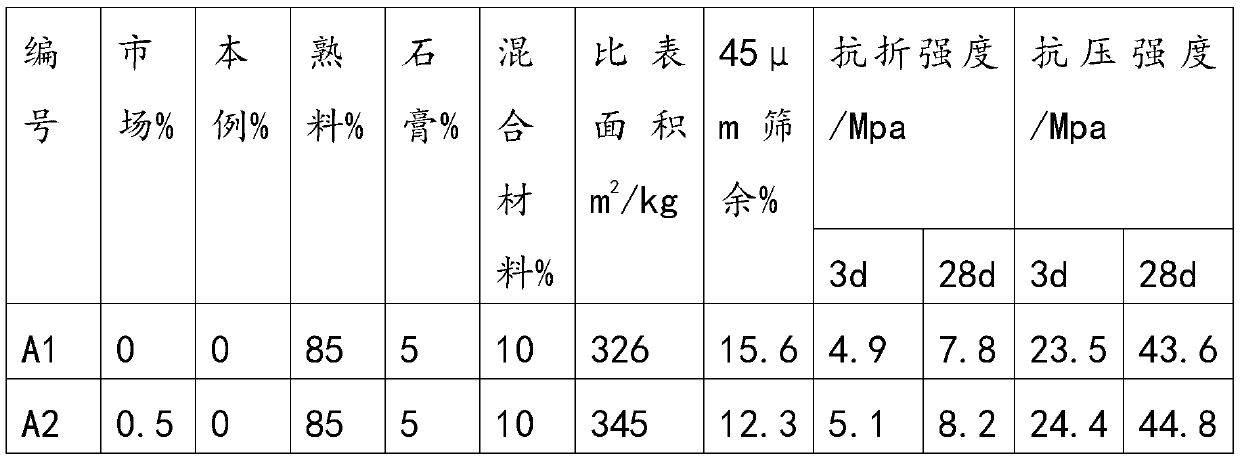

Novel powdery cement grinding aid and preparation method thereof

The invention discloses a novel powdery cement grinding aid, and relates to the field of building materials. The novel powdery cement grinding aid comprise, by weight, 40-60 parts of fly ash, 14-23 parts of sulphoaluminate cement, 25-35 parts of anhydrous sodium sulfate and 1-2 parts of a synergistic solution, wherein the synergistic solution is prepared by a simple chemical reaction of diethanolmonoisopropanolamine, hydrochloric acid, a foaming agent and water. The invention also discloses a preparation method of the novel powdery cement grinding aid. The novel powdery cement grinding aid can effectively improve the particle fineness of the powder, increase the output per machine-hour of a grinding machine, increase the strength of the cement and reduce the use amount of cement clinker,and has the advantages of good grinding dispersibility, good grinding aiding effect, simplicity in processing and preparation, low cost and stable performances.

Owner:湖南格林朗科技有限公司

Tandem continuous ball mill and ball milling method

Owner:GUANGDONG EDING IND

Dry powder grinding equipment for processing dry powder extinguishing agent

ActiveCN113019637AAchieve the effect of automatic pouringAffect qualityGrain treatmentsElectric machineryStructural engineering

The invention relates to grinding equipment, in particular to dry powder grinding equipment for processing a dry powder extinguishing agent. The dry powder grinding equipment for processing the dry powder extinguishing agent is well in dust shielding effect and has an automatic material pouring function. According to the technical scheme, the dry powder grinding equipment for processing the dry powder extinguishing agent comprises a base, a grinding mechanism, a connecting rod, a motor, a grinding block and a placing mechanism. The grinding mechanism is arranged at one side of the top of the base; the connecting rod is arranged at one side of the grinding mechanism in a sliding manner; the motor is arranged at one side of the connecting rod; the grinding block is arranged on an output shaft of the motor; and the placing mechanism is arranged at the top of the base. After a first wedge-shaped block moves upwards to be separated from a first baffle and a first stop block, under the action of a third spring, the first baffle is driven to move inwards to be reset, the first baffle plays a role in blocking dust, and the situation that some dust and impurities enter a containing frame, and the quality of dry powder is affected is avoided.

Owner:福建省闽莲消防科技有限公司

Preparation equipment for cosmetic titanium dioxide

ActiveCN114669247AFully filteredReduce loss rateDispersed particle filtrationTransportation and packagingPhysical chemistryInlet valve

The invention relates to the technical field of titanium dioxide preparation, in particular to preparation equipment for cosmetic titanium dioxide, which comprises a reaction kettle, an air inlet valve fixedly communicated with the bottom end of the side wall of the reaction kettle, and a gas separation device mounted between a blanking barrel and a second air outlet pipe; the solid separation device is mounted between the top of the reaction kettle and the second gas outlet pipe; and the stirring mechanism is mounted in the reaction bin. According to the device, through the arrangement of the gas separation device, titanium dioxide powder directly falls into the reaction bin along the blanking barrel in the filtering treatment process, and the situation that the amount of the titanium dioxide powder contained in chlorine is increased due to the fact that the titanium dioxide powder falling downwards is mixed with flowing chlorine again is avoided; therefore, the filtering burden increase caused by the increase of the titanium dioxide content in the chlorine is avoided, and the loss rate of the titanium dioxide is reduced.

Owner:江苏沪申钛白科技有限公司

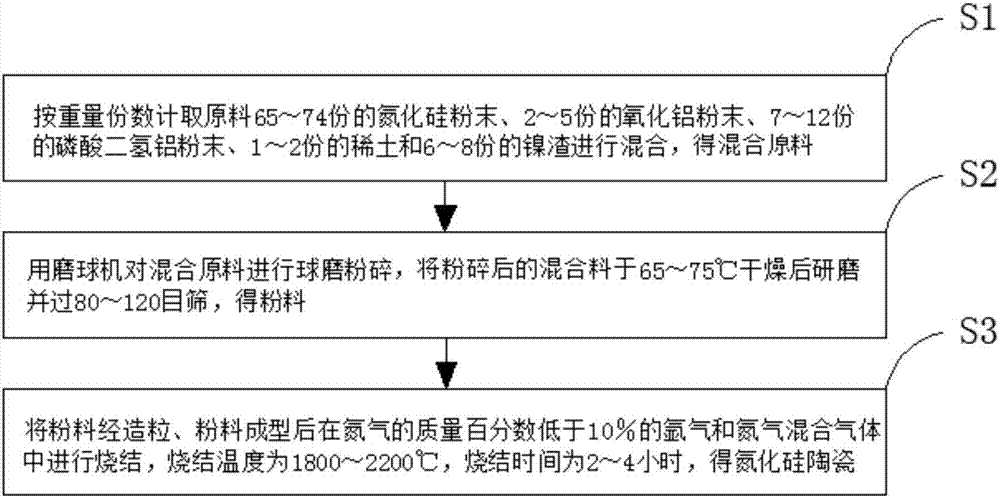

Ceramic ball and manufacture method thereof

The invention relates to a ceramic ball and a manufacture method thereof. The ceramic ball comprises the following raw materials, by weight part, 65-74 parts of silicon nitride powder, 2-5 parts of alumina powder, 7-12 parts of aluminium dihydrogen phosphate powder, 1-2 parts of rare earth and 6-8 parts of nickel residue. Rare earth in the ceramic ball can effectively optimize the microstructure, so that the toughness and strength of silicon nitride ceramics are obviously improved. Through addition of the nickel residue, the manufacture cost is reduced. The nickel residue undergoes comprehensive utilization, so that the manufactured silicon nitride ceramics has excellent performance, such as mechanical properties.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

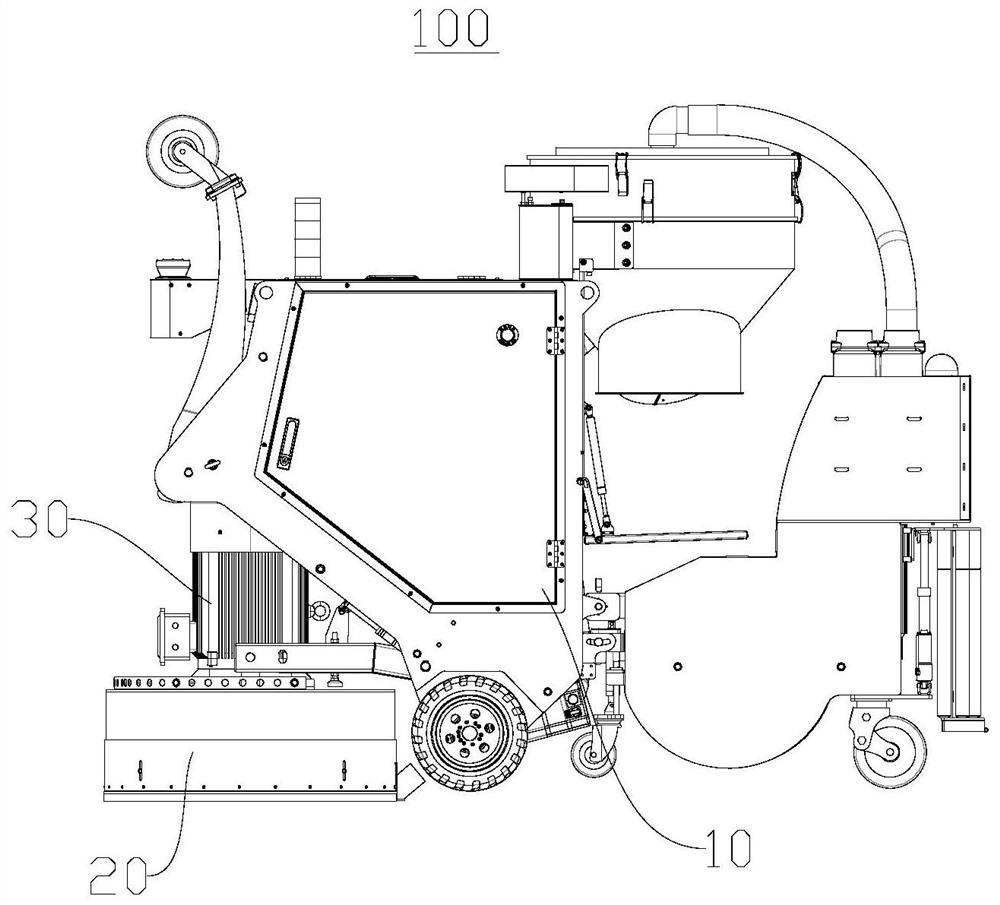

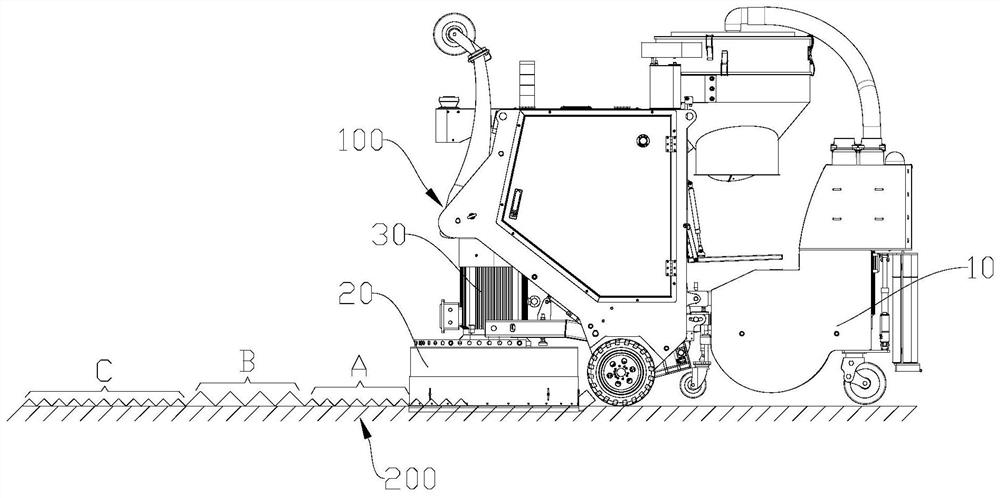

Grinding control method, grinding control device and floor grinding robot

PendingCN114683111AControl walking speedGuaranteed grinding qualityGrinding drivesGrinding feed controlControl engineeringElectric machinery

The invention provides a grinding control method, a grinding control device and a floor grinding robot, and relates to the field of floor grinding robots. The grinding control method is used for the floor grinding robot and comprises the steps that operation parameters of a grinding motor are detected in the working process of the grinding motor; judging whether the grinding disc meets the raised ground or not according to the operation parameters of the grinding motor; when it is judged that the grinding disc meets the protruding ground, the walking motor is controlled to reduce the rotating speed. When the grinding disc grinds the ground with different concave-convex degrees, related operation parameters of the grinding motor for driving grinding can be changed, when the grinding disc meets the ground with the large convex degree, the walking speed of the floor grinding robot is controlled by controlling the rotating speed of the walking motor, the standing time of the grinding disc on the ground at a certain position can be changed, and the grinding efficiency is improved. And the grinding time of the grinding disc at the position is changed, so that the grinding amount is controlled.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Solid-liquid mixing equipment for preparing ultra-fine slurry and mixing method of solid-liquid mixing equipment

PendingCN110548429ASpeed up the flowPrevent sprayingTransportation and packagingMixing methodsUltra fineSlurry

The invention relates to solid-liquid mixing equipment for preparing ultra-fine slurry and a mixing method of the solid-liquid mixing equipment. The mixing device comprises a dispersing cylinder, a rotating shaft, a grinding mechanism and a fixed sleeve, the dispersing cylinder comprises an upper cover, a lower cover and a side wall located between the upper cover and the lower cover, the dispersing cylinder is provided with a liquid feeding mouth, a solid feeding mouth and a discharging mouth; the rotating shaft is fixedly provided with a spiral packing auger and a dispersing disc, wherein the spiral packing auger is located in the fixed sleeve, and the dispersing disc is located above the fixed sleeve; the grinding mechanism includes a dynamic grinding disc and a static grinding disc located under the dynamic grinding disc, and the dynamic grinding disc and the static grinding disc rub against each other to grind materials. According to the solid-liquid mixing equipment, the structure is simple, the design is reasonable, use and operation are easy, maintenance is convenient, fully grinding and refining for the materials can be realized, and the ultra-fine slurry can be quickly prepared.

Owner:常熟世名化工科技有限公司

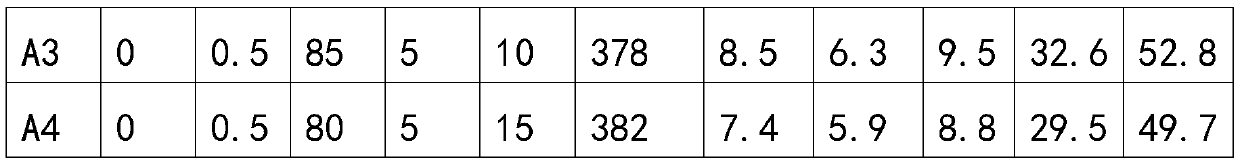

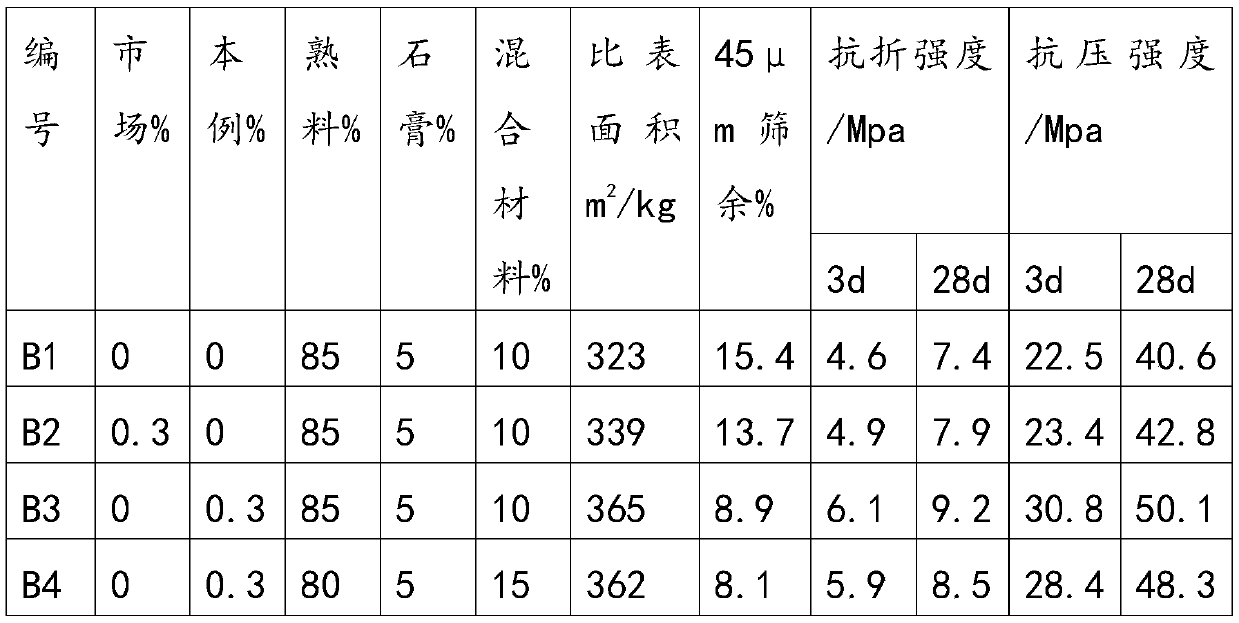

Preparation method of superfine slag powder admixture

The invention discloses a preparation method of a superfine slag powder admixture and relates to superfine slag powder. The preparation method of the superfine slag powder admixture can overcome disadvantages of the existing independent powder milling process. A dryer is adopted to dry slag; water content of the dried slag is controlled within 0.5-1.0%; a flap valve is arranged at a feed port of the dryer; the front part and the rear part of the dryer are sealed by labyrinth seal rings; a barrel of the dryer is provided with a thermal insulation layer; raising plates of the dryer are L-shaped and are centripetally and uniformly distributed; the number of the raising plates is 10-16 generally; a de-ironing separator is adopted to remove iron impurities from the dried slag; the slag is then fed into a ball mill for powder milling; and the superfine slag powder admixture is obtained.

Owner:厦门市易亨利工贸有限公司

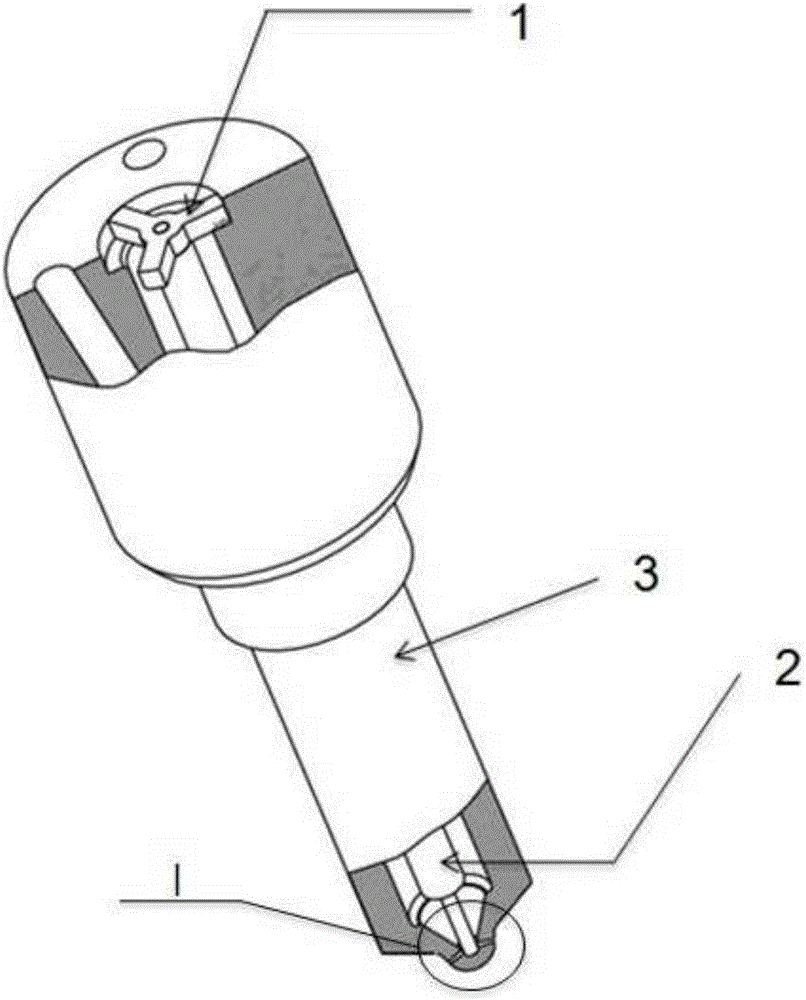

Grinding flow-guiding device suitable for grinding high-injection-pressure injection nozzle needle valve and grinding method

The invention discloses a grinding flow-guiding device suitable for grinding a high-injection-pressure injection nozzle needle valve. The grinding flow-guiding device comprises a locating pin and a flow guiding rod connected with the locating pin. The locating pin is arranged in a cavity of the injection nozzle needle valve to limit movement of the flow guiding rod, and the head of the flow guiding rod is located at an injection hole inlet of the injection nozzle needle valve to shield the circular bead on the lower half part of the injection hole inlet. A grinding method includes the steps of primary conventional grinding, secondary grinding conducted after installation of the grinding flow-guiding device, and re-grinding conducted after removal of the grinding flow-guiding device. According to the injection nozzle needle valve ground by the grinding flow-guiding device through the grinding method, at the aspect of injection nozzle performance, flow loss in an injection nozzle is further reduced, the flow coefficient is remarkably increased, the probability of cavitation erosion of an injection hole under high injection pressure is lowered, and the service life of the injection nozzle under the high injection pressure is prolonged. At the aspect of a process, the grinding time of the needle valve is prolonged, and the situation that according to a conventional grinding method, with increasing of the grinding time, the overall grinding degree of the injection hole inlet of the needle valve is improved, and interference between the injection holes occurs too early is avoided.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com