Coating grinding device

A grinding device and coating technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems of affecting coatings, low grinding efficiency, and poor grinding effect, and achieve the effect of prolonging grinding time, improving grinding efficiency, and grinding thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

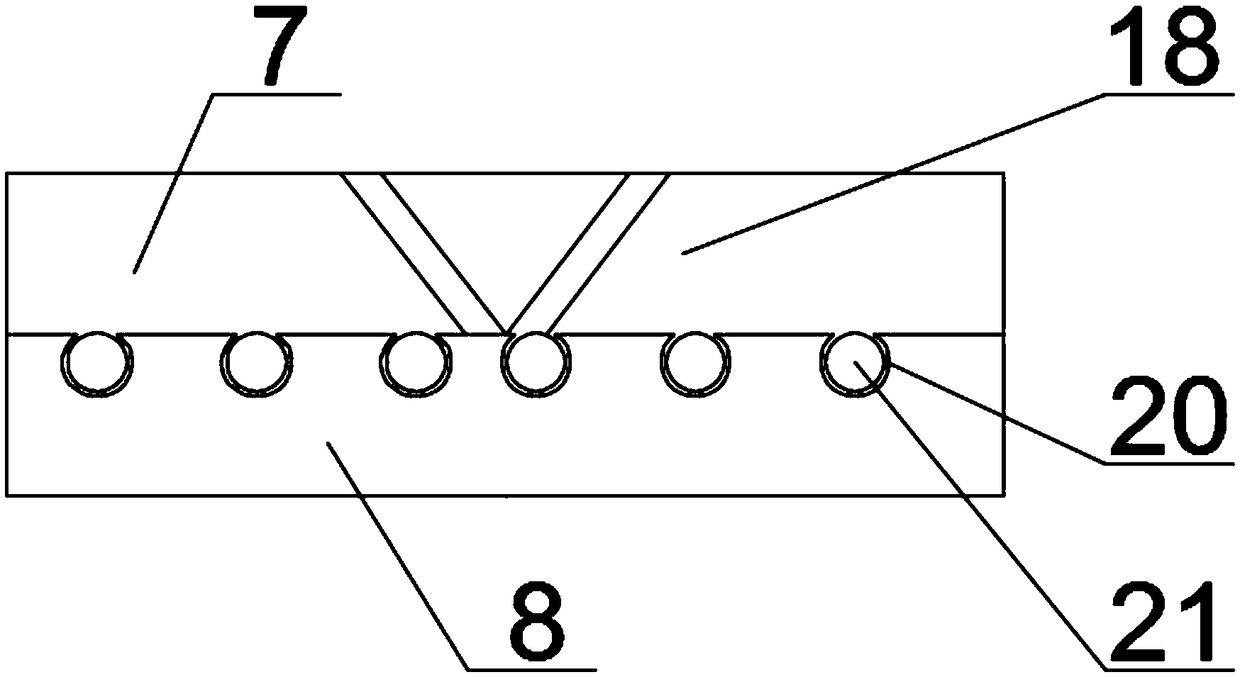

[0027] Such as Figure 5 As mentioned above, the difference between this embodiment and Embodiment 1 is that the spiral blade 14 is provided with a filter screen, and the mesh number of the filter screen is the same as that of the filter plate 15. By setting the screw blade 14 with the same mesh as the filter plate The number of filter screens is convenient to make the paint that meets the requirements drop, avoiding the re-grinding of the paint that meets the requirements, and avoiding the reduction of grinding efficiency.

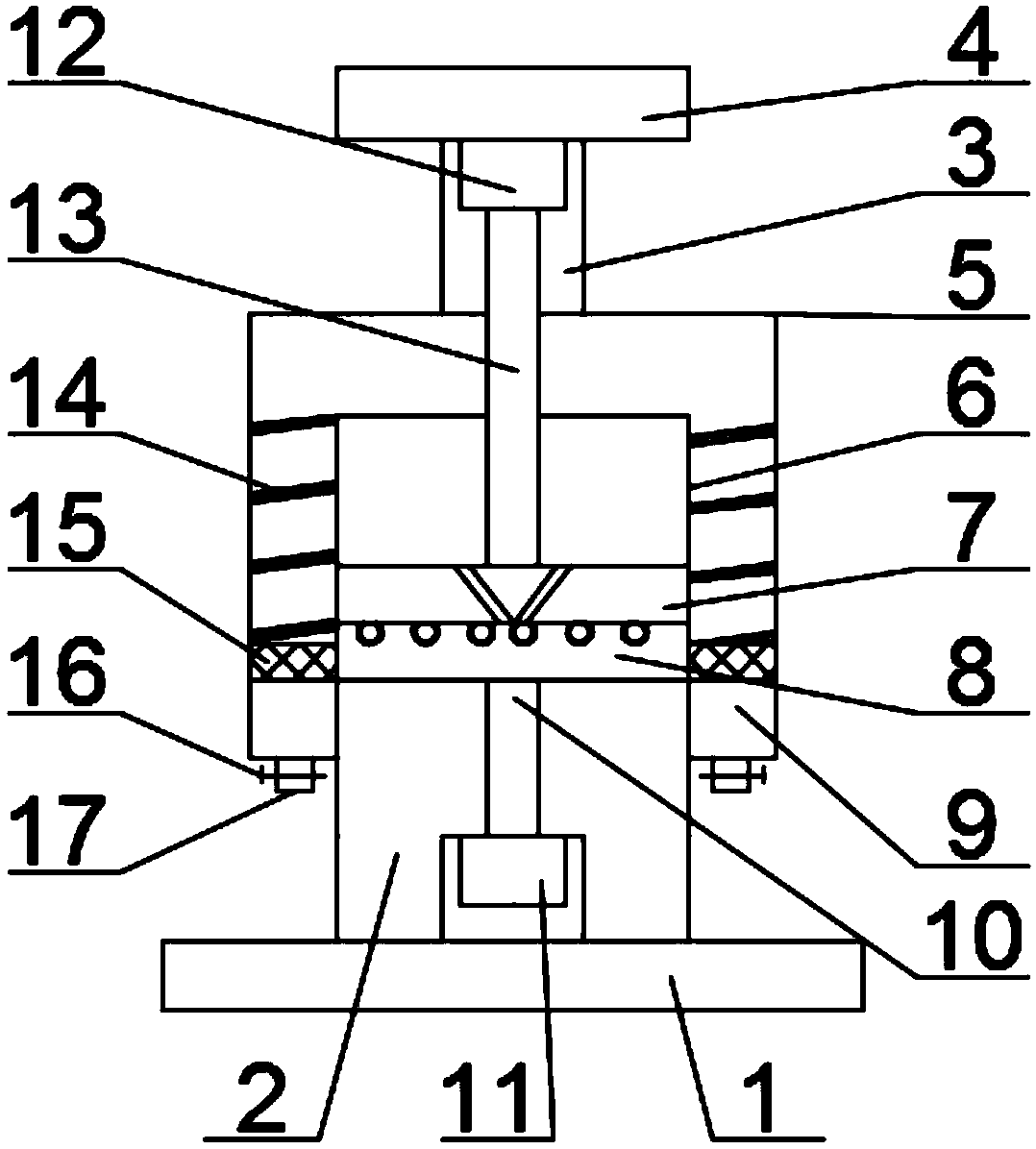

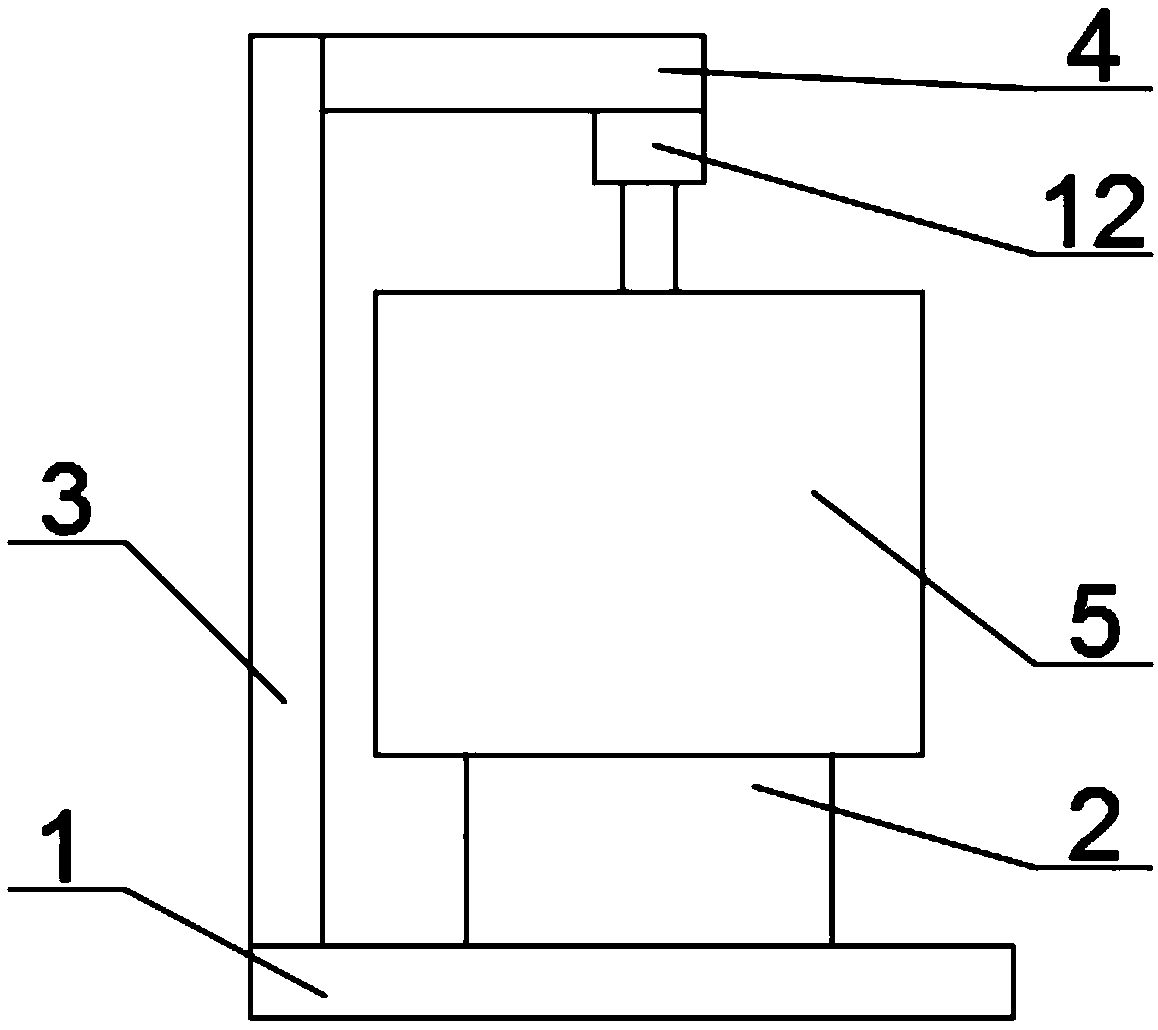

[0028] The working principle is as follows: the paint to be ground is added to the first millstone 7 in the inner shell 6 through the outer shell 5, and the paint falls from the through hole 18 on the first millstone 7 between the first millstone 7 and the second millstone 8, and the The first motor 11 and the second motor 12 make the two grinding discs move relative to each other for grinding. The ground paint enters the spiral groove 19 and is further g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com