Grinding control method, grinding control device and floor grinding robot

A control method and technology of a control device are applied in the directions of grinding automatic control device, grinding drive device, and parts of grinding machine tools, etc., which can solve problems such as poor floor grinding flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

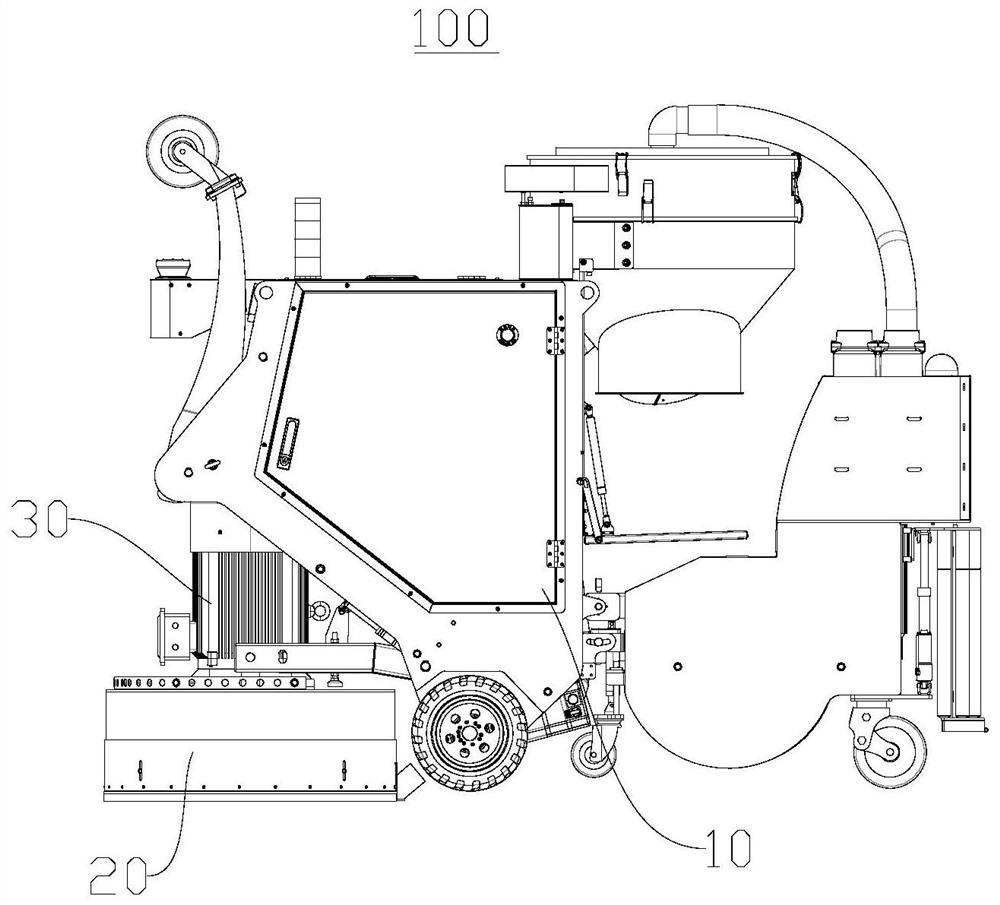

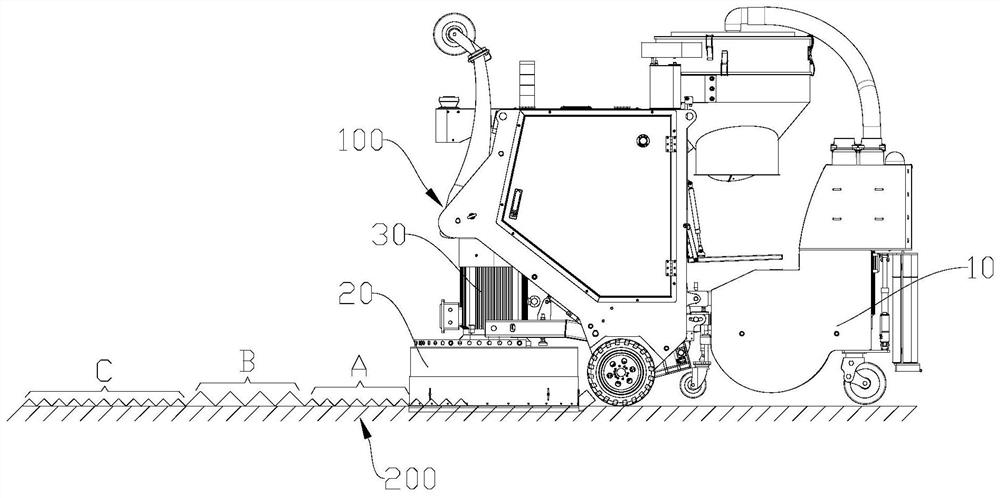

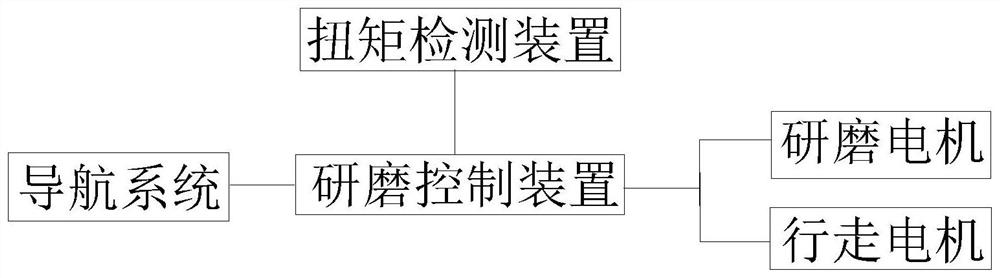

[0036] like figure 1 , figure 2 As shown, the embodiment of the present application provides a floor grinding robot 100 . The floor grinding robot 100 includes a traveling motor 10 , a grinding disc 20 , a grinding motor 30 and a grinding control device. The walking motor 10 is used to drive the floor grinding robot 100 to walk, and the grinding motor 30 is used to drive the grinding disc 20 to rotate.

[0037] In this embodiment, the grinding disc 20 is directly connected to the output end of the grinding motor 30 . In some embodiments, the grinding motor 30 may also be connected to the grinding disc 20 through a transmission mechanism such as a worm gear.

[0038] In this embodiment, the floor grinding robot 100 is further provided with a navigation system, and the navigation system plans a route for the floor grinding robot 100, so that the floor grinding robot 100 drives the grinding disc 20 to grind different positions on the ground 200, which can realize autonomous I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com