Automobile glass guide rail automatic gluing and installation tooling

A technology for automotive glass and installation tooling, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of constant, labor-intensive, and time-consuming problems such as difficult glue amount and trajectory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

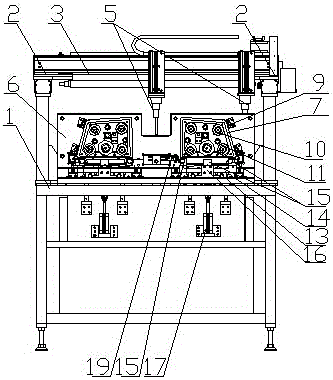

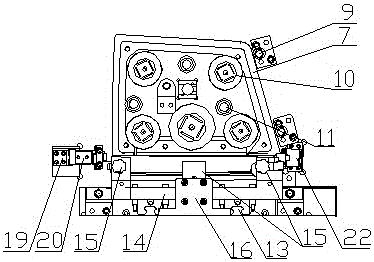

[0013] Such as figure 1 , 2 , 3, and 4, the present invention includes a frame 1, a pair of longitudinal slides 2, a transverse slide 3, a bottom plate 6 and a pair of gluing mechanisms, and a pair of vertical slides 2 are provided on both sides of the top of the frame 1, The two ends of the horizontal sliding table 3 are respectively installed on a pair of sliders of the vertical sliding table 2. A pair of glue removal nozzles 5 are arranged on the sliders of the horizontal sliding table 3. The bottom plate 6 is installed in the frame 1. The mechanism includes a glass positioning device, a track connecting device, a glue filling device and a sealing device. The glass positioning device includes a glass positioning frame 7, a set of bottom limit posts 8, a set of side limit posts 9, a set of glass suction cups 10, a A set of support bases 11 and a set of cylinders, a glass positioning frame 7, a set of bottom limit columns 8 and a set of side limit columns 9 are installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com