A method of continuous deep dehydration and solar energy synergistically drying sludge

A deep dehydration and dewatering sludge technology, applied in dehydration/drying/thickened sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of unmodified initial moisture content of sludge, land occupation Problems such as large area and limited solar efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

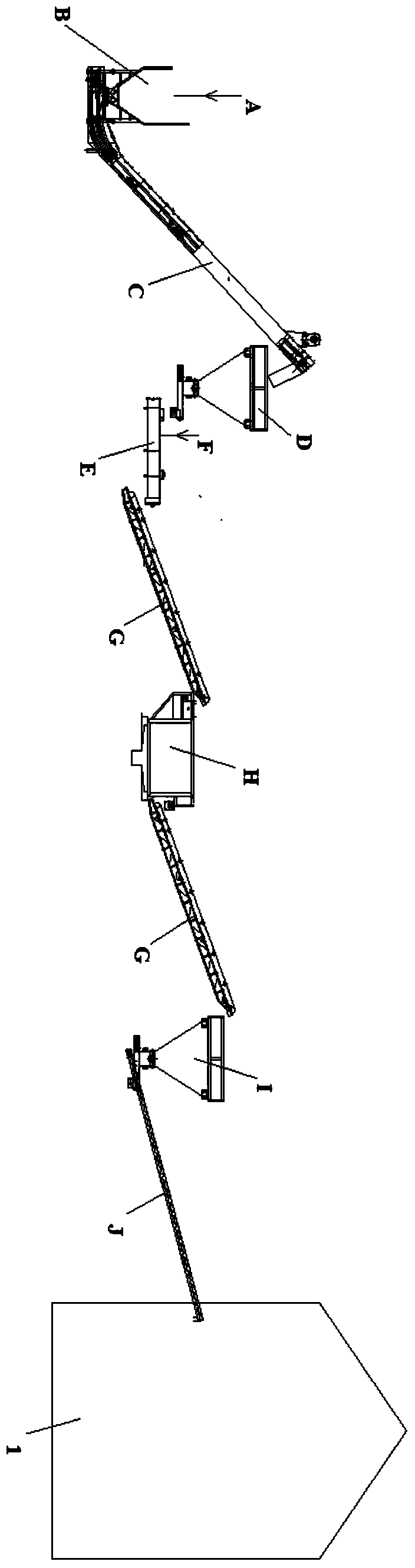

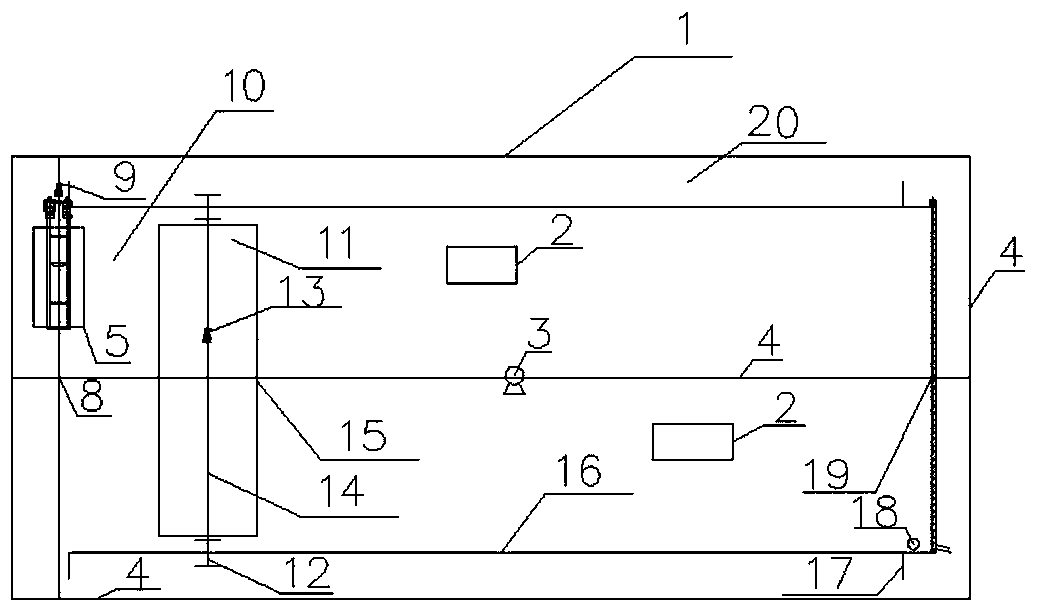

[0094] The moisture content of the primary dewatered sludge after the excess sludge of a sewage treatment plant in Jiangsu is dewatered by a belt filter press is 80%, and the output of the primary dewatered sludge is 2.0t / h. Such as figure 1 As shown, the primary dewatered sludge is successively passed through the primary dewatered sludge storage bin, the scraper conveyor, and the primary dewatered sludge buffer bin for continuous deep dehydration treatment. The continuous deep dehydration treatment of primary dewatered sludge includes 2 processes:

[0095] (1) Sludge modification: the primary dewatered sludge enters the sludge modification mixer from the primary dewatered sludge buffer storage bin, and the sludge composite modifier produced by Shanghai Shenyao Environmental Engineering Co., Ltd. with a sludge mass of 3.5% is added , the primary dewatered sludge and the sludge compound modifier are mixed and reacted in the sludge modification mixer for 3 minutes, and the powe...

Embodiment 2

[0100] The moisture content of the primary dewatered sludge after the excess sludge of a Shanghai sewage treatment plant is dewatered by a plate and frame filter press is 78%, and the output of the primary dewatered sludge is 2.5t / h. Such as figure 1 As shown, the primary dewatered sludge is successively passed through the primary dewatered sludge storage bin, the scraper conveyor, and the primary dewatered sludge buffer bin for continuous deep dehydration treatment. The continuous deep dehydration treatment of primary dewatered sludge includes 2 processes:

[0101] (1) Sludge modification: the primary dewatered sludge enters the sludge modification mixer from the primary dewatered sludge buffer tank, and the sludge composite modifier produced by Shanghai Shenyao Environmental Engineering Co., Ltd. with a sludge mass of 3.3% is added , the primary dewatered sludge and the sludge composite modifier are mixed and reacted in the sludge modification mixer for 2.5 minutes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com