Patents

Literature

34results about How to "Continuous automatic operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

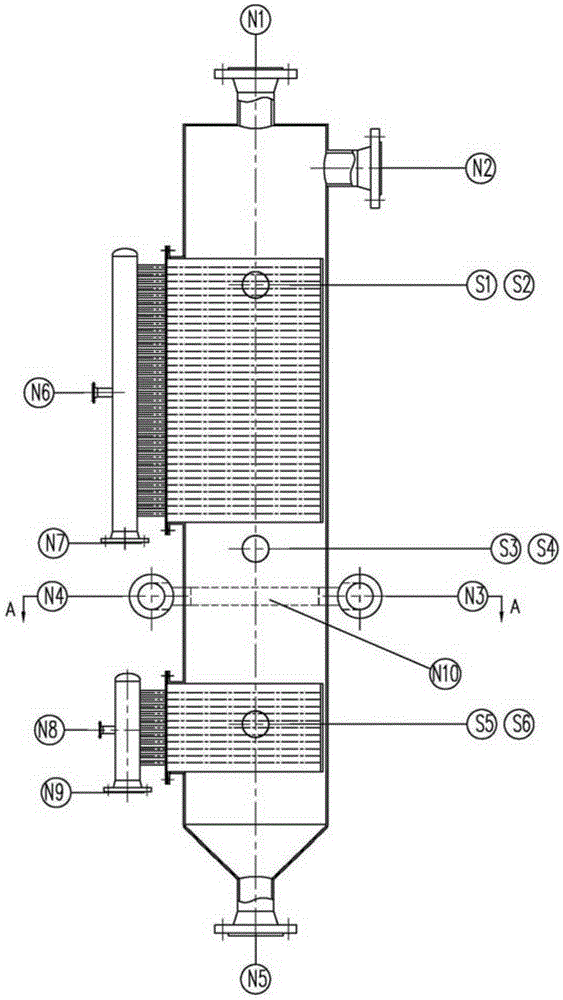

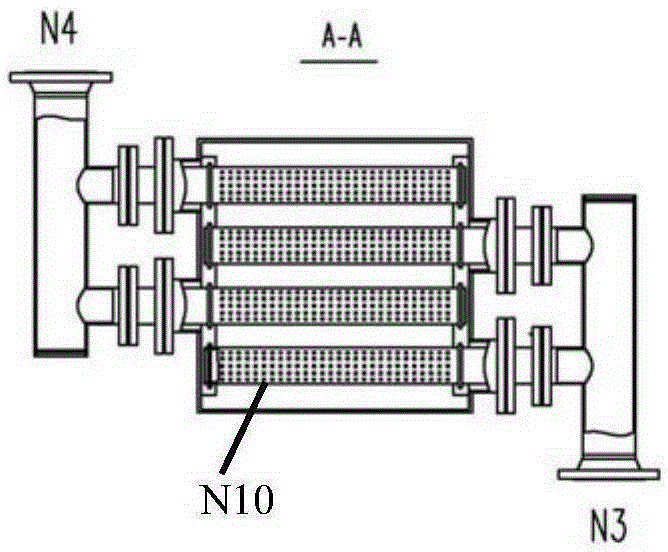

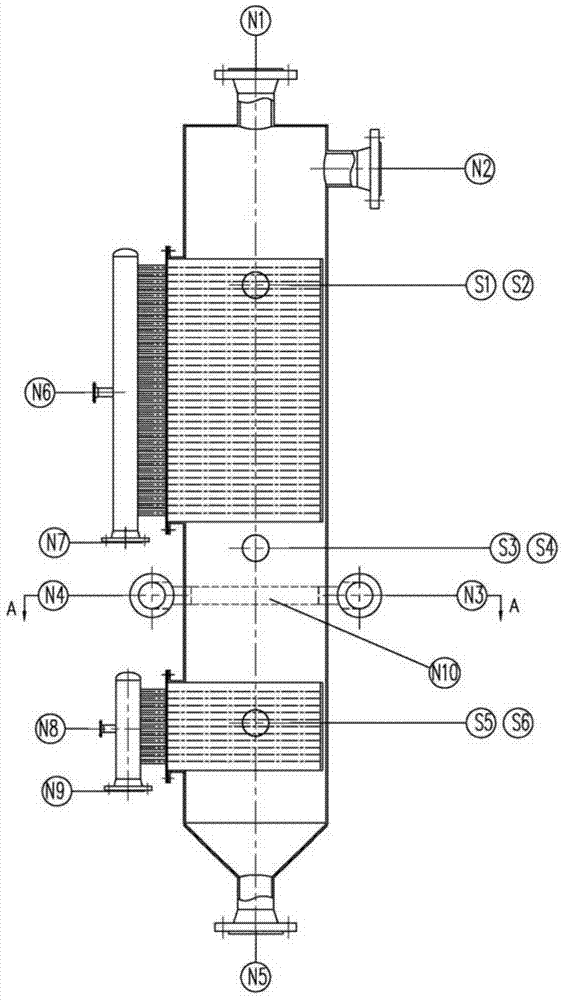

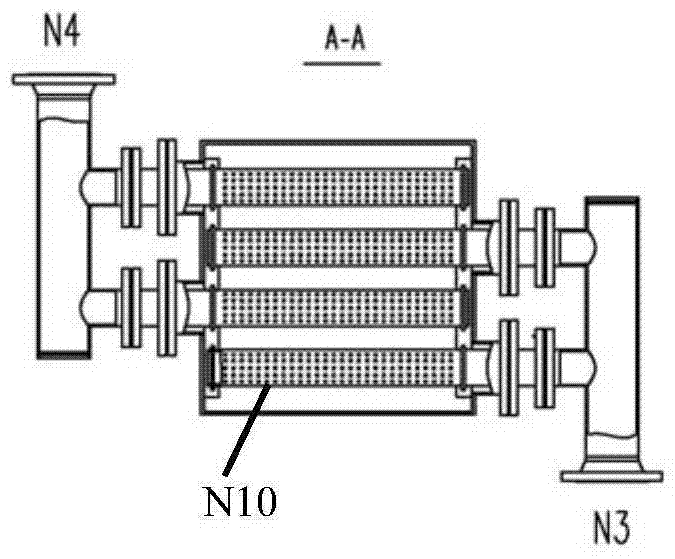

Membrane technology-based ionic rare earth ore extraction technology and device therefor

The invention relates to a membrane technology-based ionic rare earth ore extraction technology and a device therefor. The membrane technology-based ionic rare earth ore extraction technology comprises the following steps of removing impurities in a rare earth ore percolation liquid, carrying out solid-liquid separation by a ceramic membrane to remove suspended solids in the rare earth ore percolation liquid, carrying out nanofiltration on the ceramic membrane clear liquid for further enrichment concentration, treating the ceramic membrane concentrated solution by a plate-and-frame filter press, removing dreg, when the rare earth ore percolate has the content of 60-70g / L after nanofiltration concentration, feeding the rare earth ore percolate into an extraction unit, carrying out extraction separation of a single rare earth element, and directly feeding the nanofiltration clear liquid rich in an extraction agent back to a percolation unit. Through the membrane separation and integration technology, the rare earth ore percolate is subjected to purification, separation, and concentration enrichment so that rare earth ions in the percolate are purified and concentrated and the next extraction process is convenient, and the rare earth ore percolation liquid subjected to separation from rare earth has a low rare earth ion concentration and a high extraction agent concentration and can be directly used for the percolation process. The membrane technology-based ionic rare earth ore extraction technology greatly improves a rare earth ion recovery rate, reduces a percolation waste water discharge amount and has obvious environmental and economic benefits.

Owner:JIANGSU JIUWU HITECH

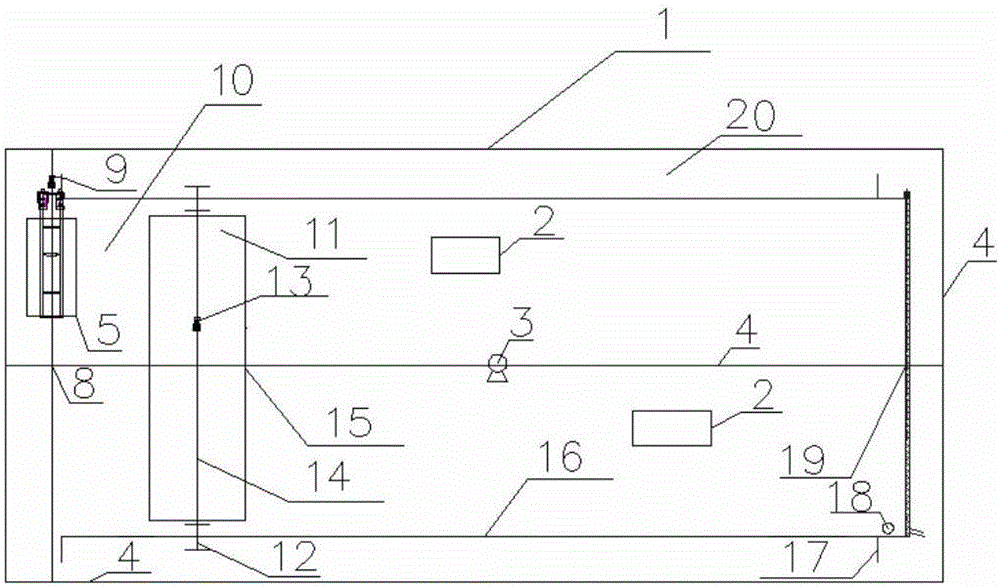

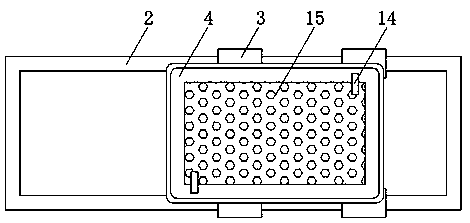

Humidifying and condensation type sea water desalinating device

ActiveCN107176639ACompact structureHome-friendlyBatteries circuit arrangementsGeneral water supply conservationWater desalinationSaline water

The invention discloses a humidifying and condensation type sea water desalinating device, and the sea water desalinating device comprises a heat radiating chamber, a condensing chamber, an evaporating chamber and a seawater desalinating tank body sequentially arranged from top to bottom, wherein the condensing chamber is communicated with the evaporating chamber, a semiconductor refrigerating mechanism is arranged in the division position between the heat radiating chamber and the condensing chamber, a hot end of the semiconductor refrigerating mechanism is positioned in the heat radiating chamber, and a cold end of the semiconductor refrigerating mechanism is positioned in the condensing chamber; the hot end is connected with a semiconductor heating module through a heat radiating bottom plate; the cold end is connected with a semiconductor refrigerating module through a cold conducting bottom plate; a fresh water collecting device is arranged, below the semiconductor refrigerating module, in the condensing chamber; the fresh water collecting device is communicated with a fresh water tank; an air inlet and an air outlet communicated with the air inlet are formed, in the position of the semiconductor heating module, in the heat radiating chamber; an air duct communicated with the air outlet is arranged in the evaporating chamber; and a hot sea water inlet and a strong brine discharge hole are formed in the evaporating chamber. The humidifying and condensation type sea water desalinating device is compact in structure and convenient for home application.

Owner:GUANGDONG UNIV OF TECH

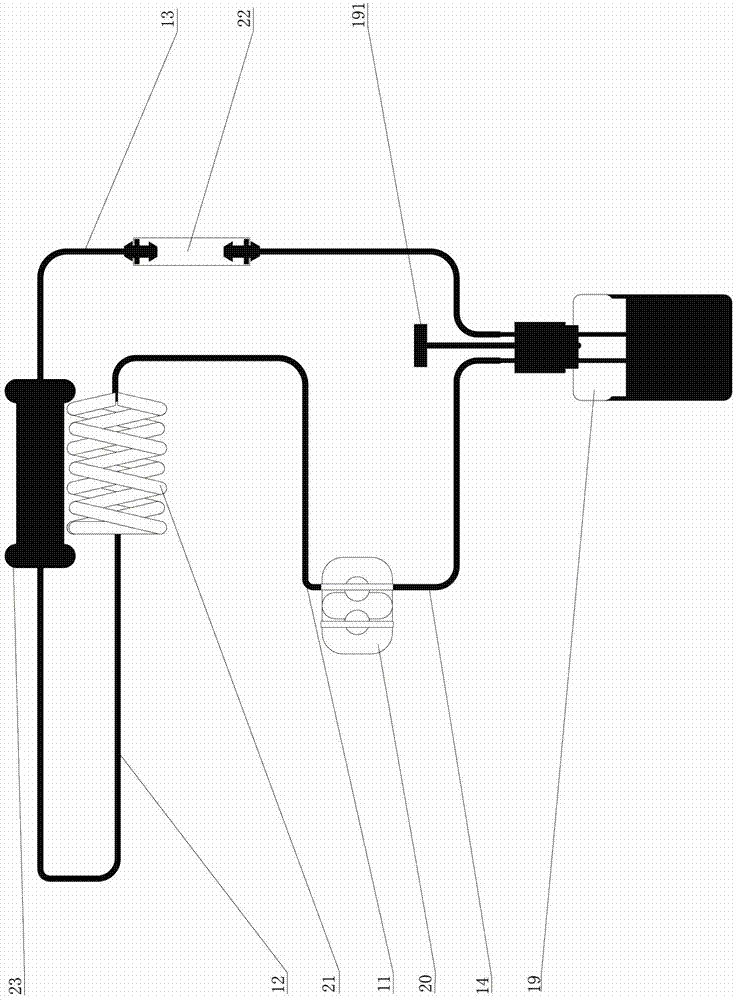

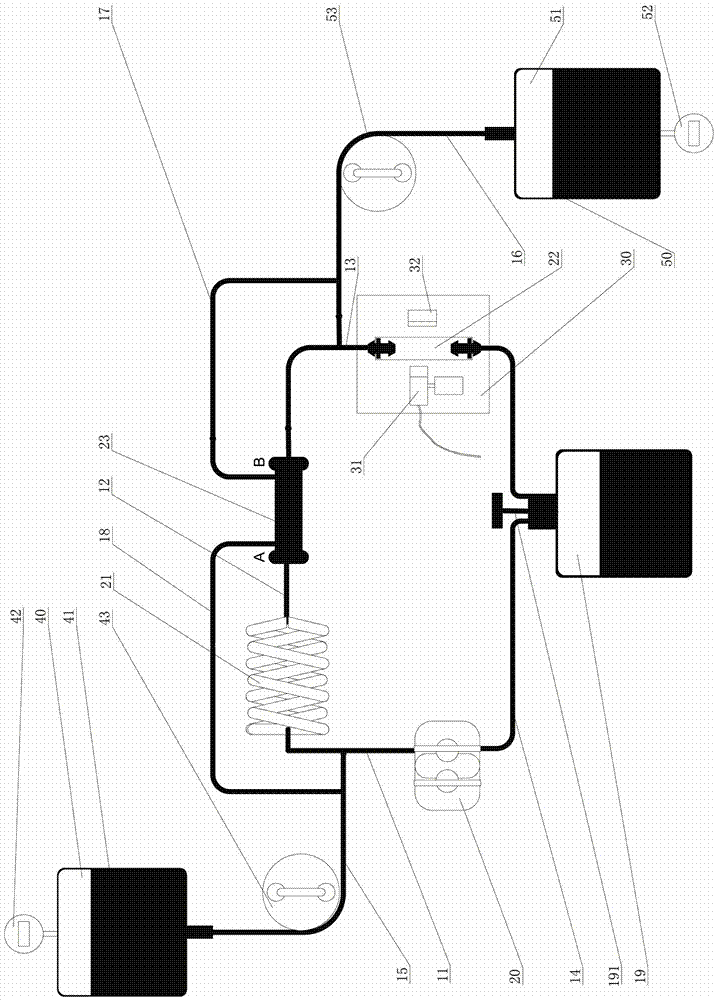

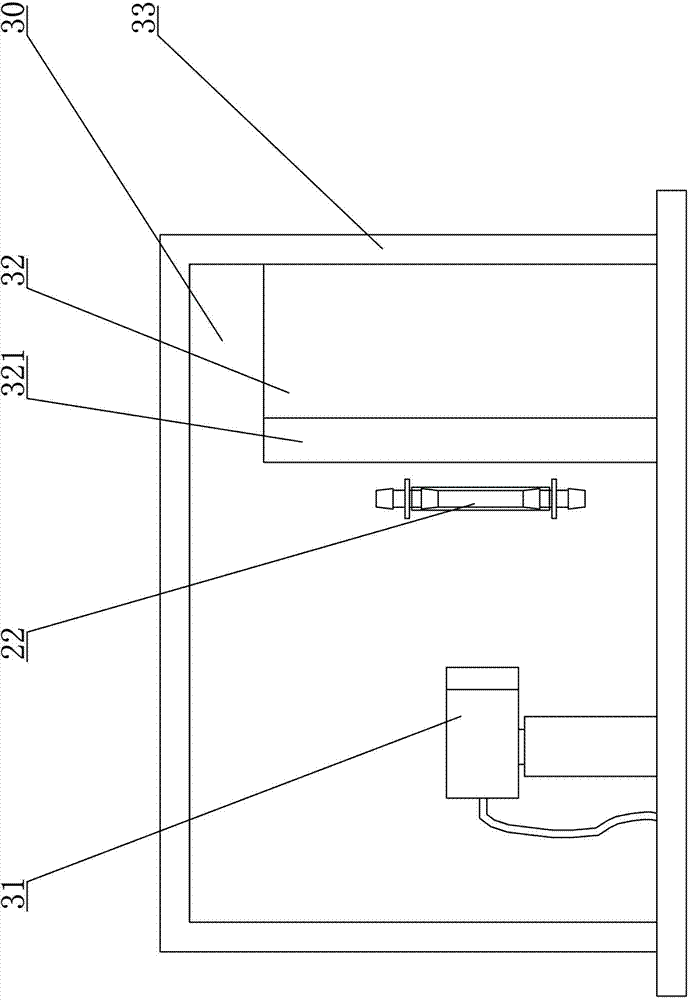

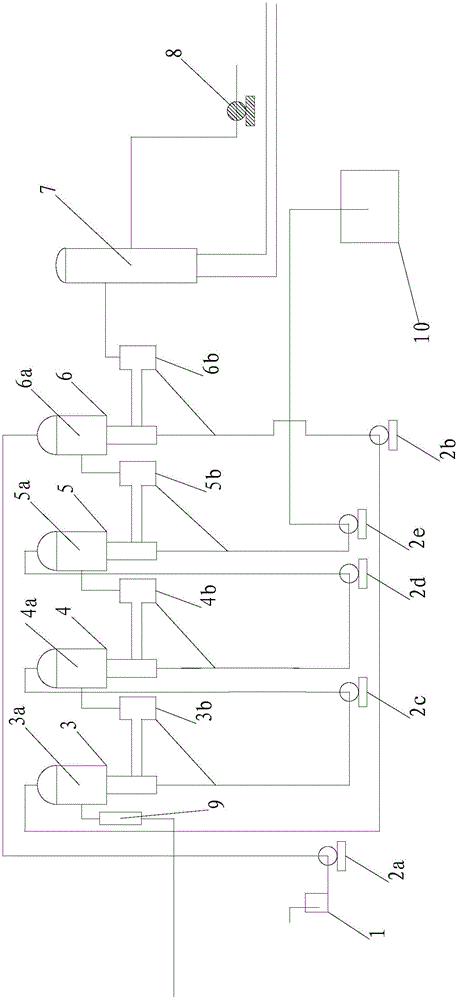

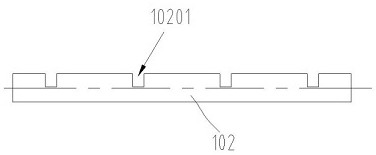

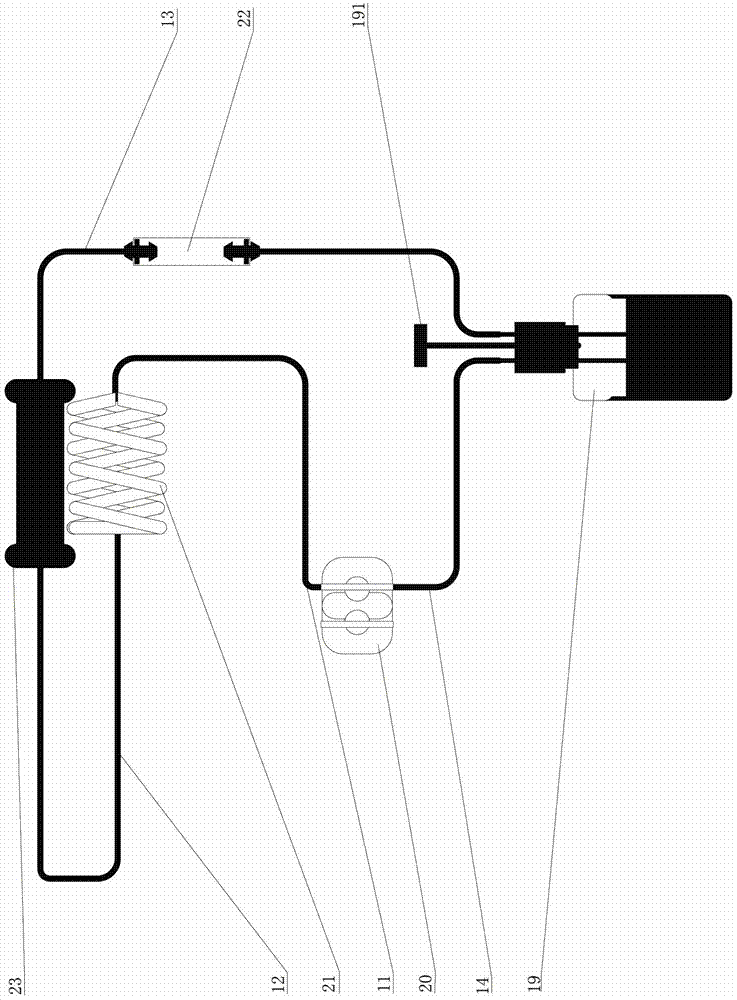

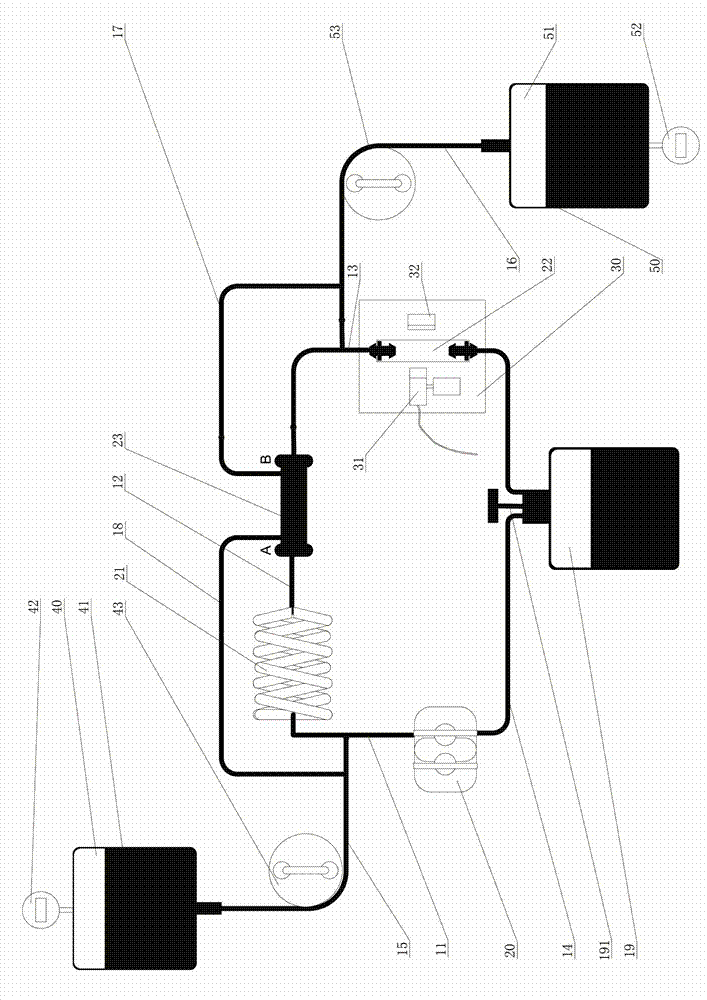

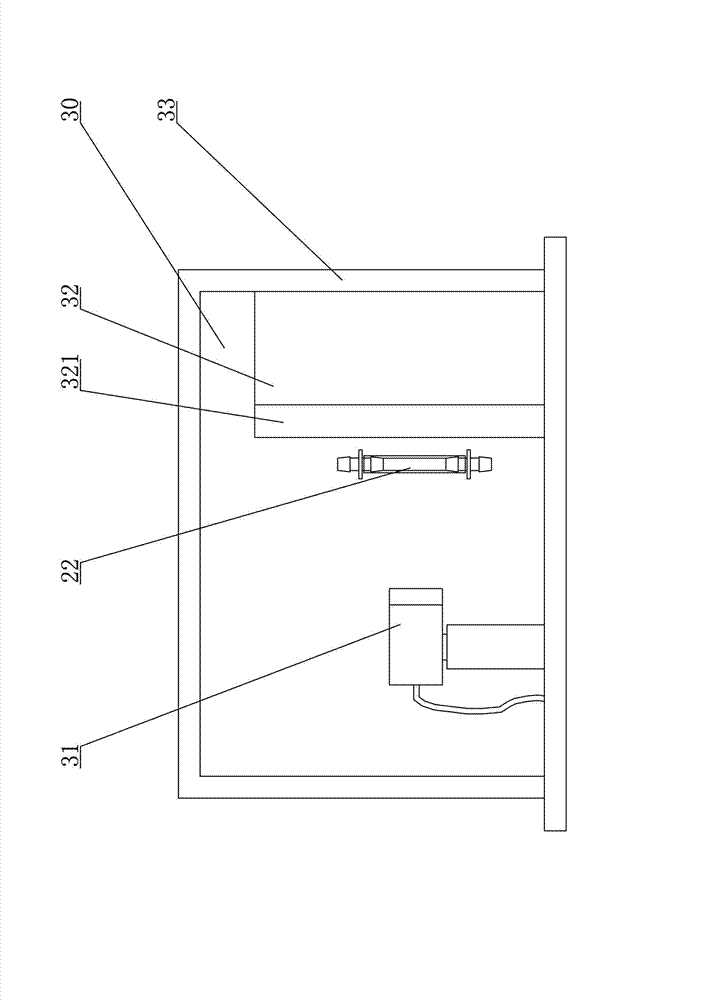

Cell culture pipeline device and automatic cell culture system

ActiveCN103031250AExchange enoughEfficient growth processBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpCulture fluid

The invention discloses a cell culture pipeline device, which comprises a main circulating pump, a gas exchange tube, a culture tube and a culture solution main library which are sequentially connected through a guide tube, wherein a micro-pore exhaust hole communicated with the atmosphere is formed on the culture solution main library; the gas exchange tube is a cured silicone tube; and the main circulating pump is a finger peristaltic pump. The invention also discloses an automatic cell culture system, which comprises a sensor arranged nearby a transparent testing container, and also comprises a liquid filling device which is connected with a first guide tube through a fifth guide tube and a waste liquid recovery device which is connected with a third guide tube through a sixth guide tube. The cell culture pipeline device is simple in structure, easy and convenient to operate and high in culture efficiency, as well as the automatic cell culture system employing the cell culture pipeline device.

Owner:浙江赛尚医药科技有限公司

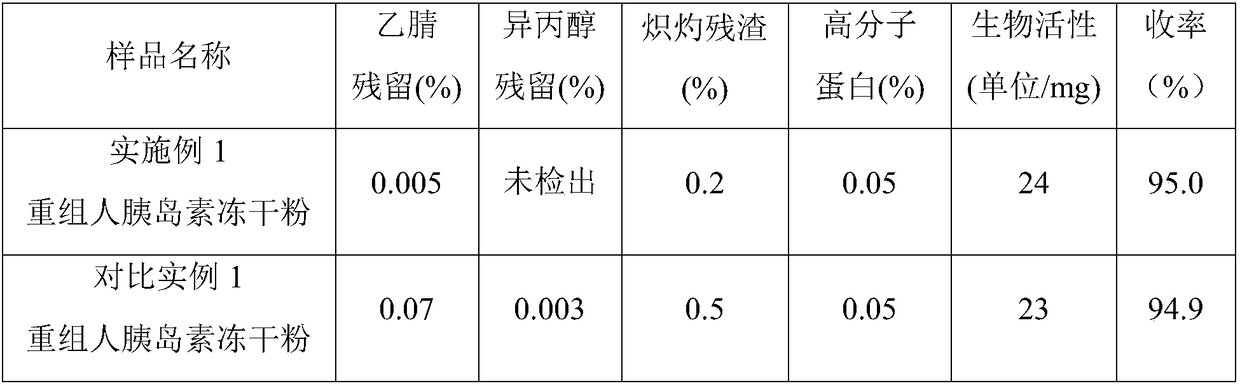

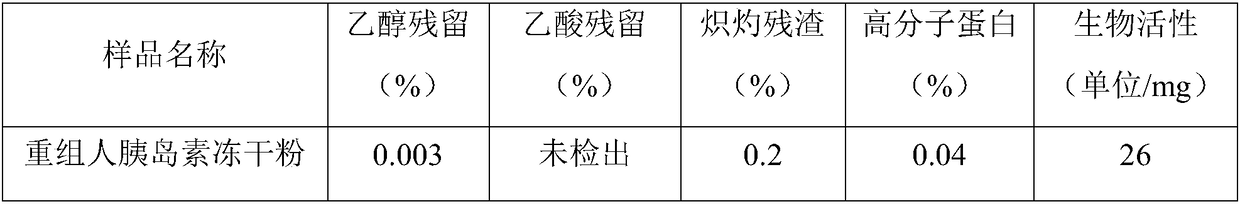

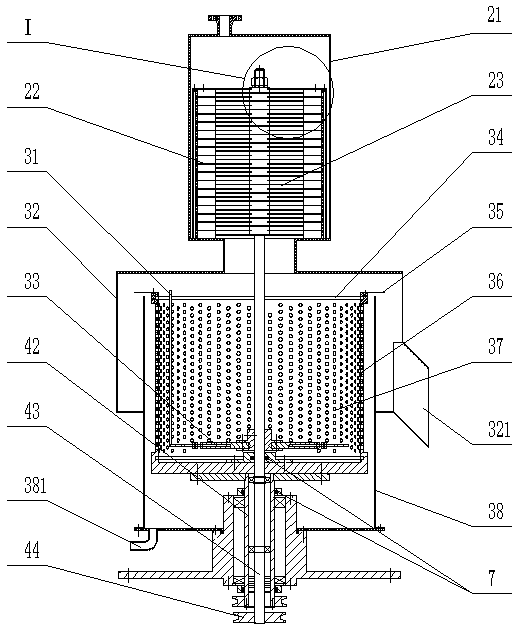

Washing method for insulin crystal or insulin analogue crystal

ActiveCN108929376ASignificant progressEasy to change liquidPeptide preparation methodsInsulinsSolventInsulin Analogue

The invention discloses a washing method for an insulin crystal or an insulin analogue crystal. The method adopts a hollow fiber membrane to process insulin crystal suspension or insulin analogue crystal suspension. The effective combination of crystal washing, liquid changing and crystal suspension condensation, washing effects can be strengthened, and produce solvent residues and residue on ignition are low; The method can realize continuously automatic operation; and the method is simple in process and easy in operation, technology stability and production efficiency can be enhanced, and therefore, the method is especially suitable for applications on large-scale industrial production.

Owner:LUNAN PHARMA GROUP CORPORATION

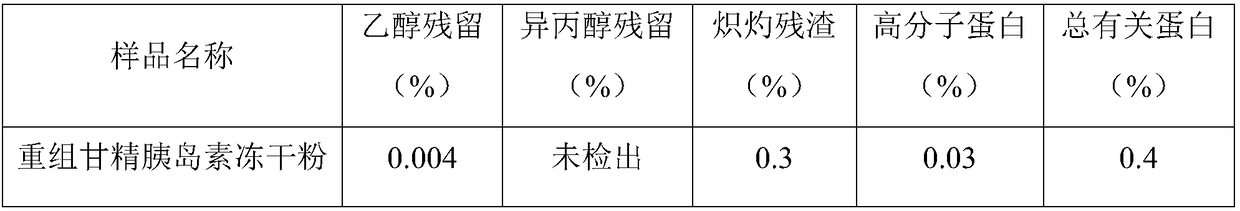

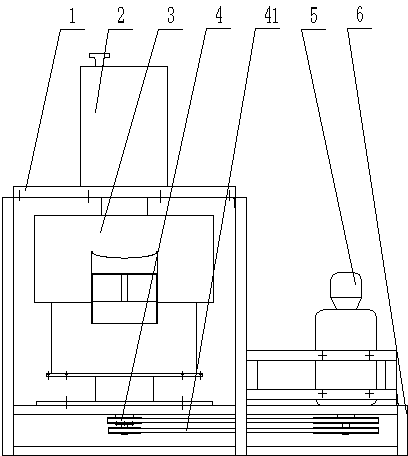

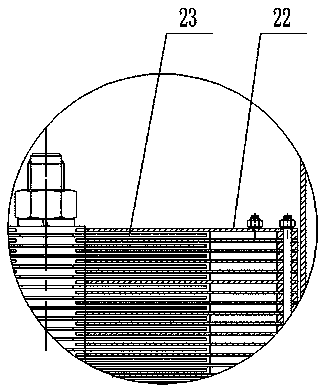

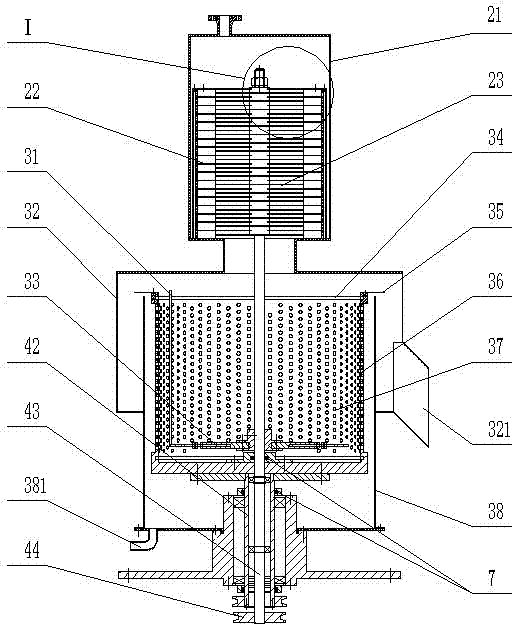

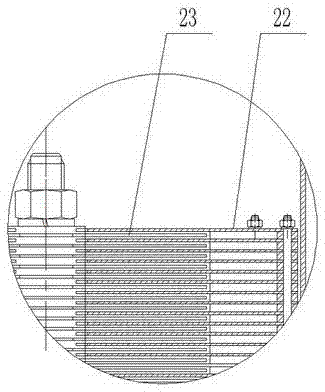

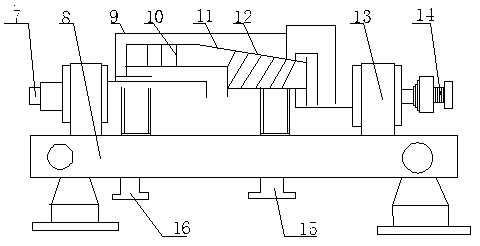

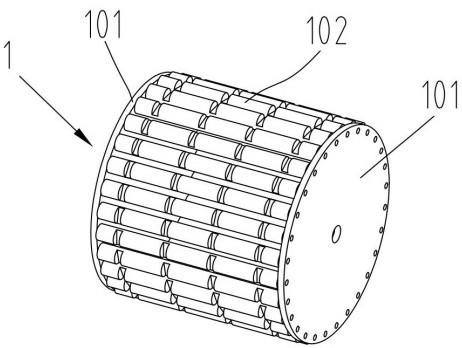

Sludge breaking and centrifugal filtration integrated machine

InactiveCN103641284AThe crack cycle is shortIncreased rate of anaerobic digestionSludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to a sludge breaking and centrifugal filtration integrated machine, and aims to provide a sludge breaking and centrifugal filtration integrated machine which is low in running cost, good in sealing property and small in occupied area. The sludge breaking and centrifugal filtration integrated machine comprises a base, a transmission device, a sludge breaking device and a centrifugal filtration device, wherein the transmission device comprises a belt pulley, a belt, an inner shaft and an outer shaft, wherein the inner shaft and the outer shaft are concentric and are respectively connected with the motor through the belt pulley and the belt, the sludge breaking device comprises a breaking cavity fixedly connected with the base through a bracket, fixed discs arranged on the inner wall of the breaking cavity and movable discs arranged on the inner shaft, the fixed discs and the movable discs are distributed in a staggered manner along the axial direction, the centrifugal filtration device comprises a filtering cavity shell, a water collecting channel with a water outlet pipe at the bottom, an elastic scraper, an annular baffle, and a filtering rotating hub arranged on the outer shaft, the bottom of the filtering cavity shell is fixedly connected with the outer side wall of the water collecting channel, a slag outlet hole is arranged at the lower part of the side wall of the filtering cavity shell, the annular baffle is arranged at the outer side of the upper edge of the filtering rotating hub, and the lower end of the elastic scraper is fixed on the inner shaft through a scraper rack.

Owner:NORTHEASTERN UNIV

High fructose syrup quadruple-effect concentration evaporator

InactiveCN104645645AContinuous automatic operationImprove work efficiencyFructose productionGlucose productionReboilerAir pump

Owner:武汉市金德戈糖业有限公司

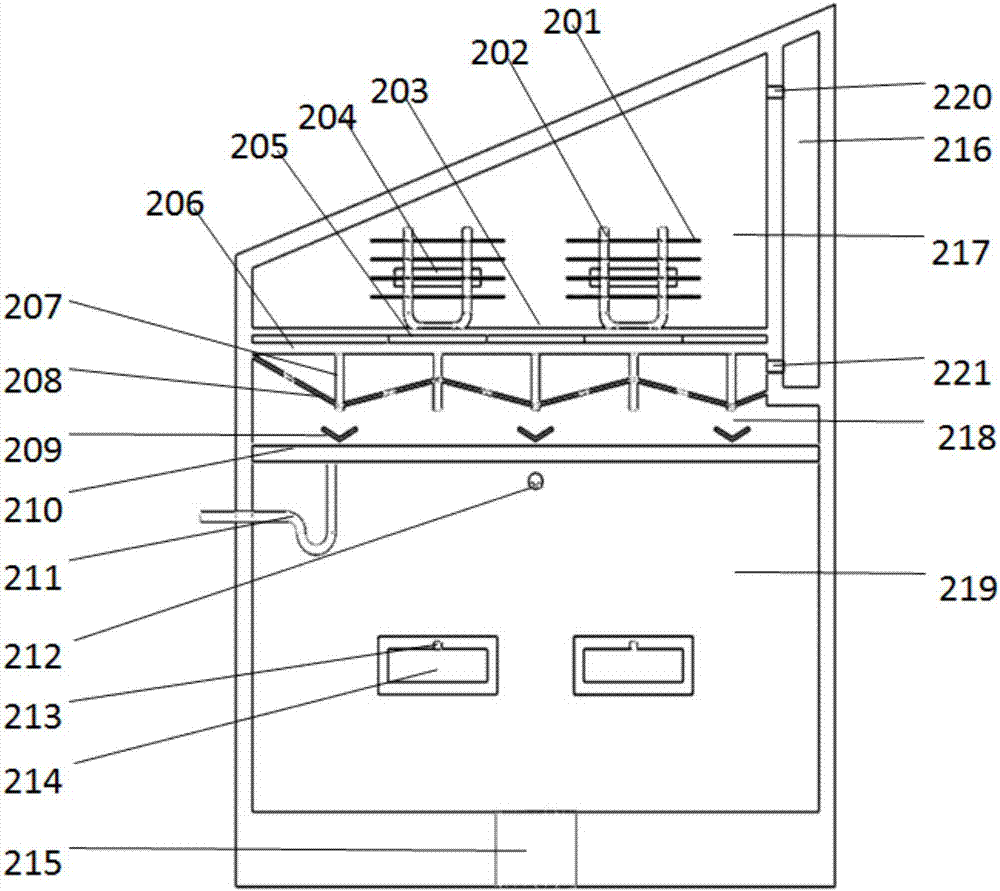

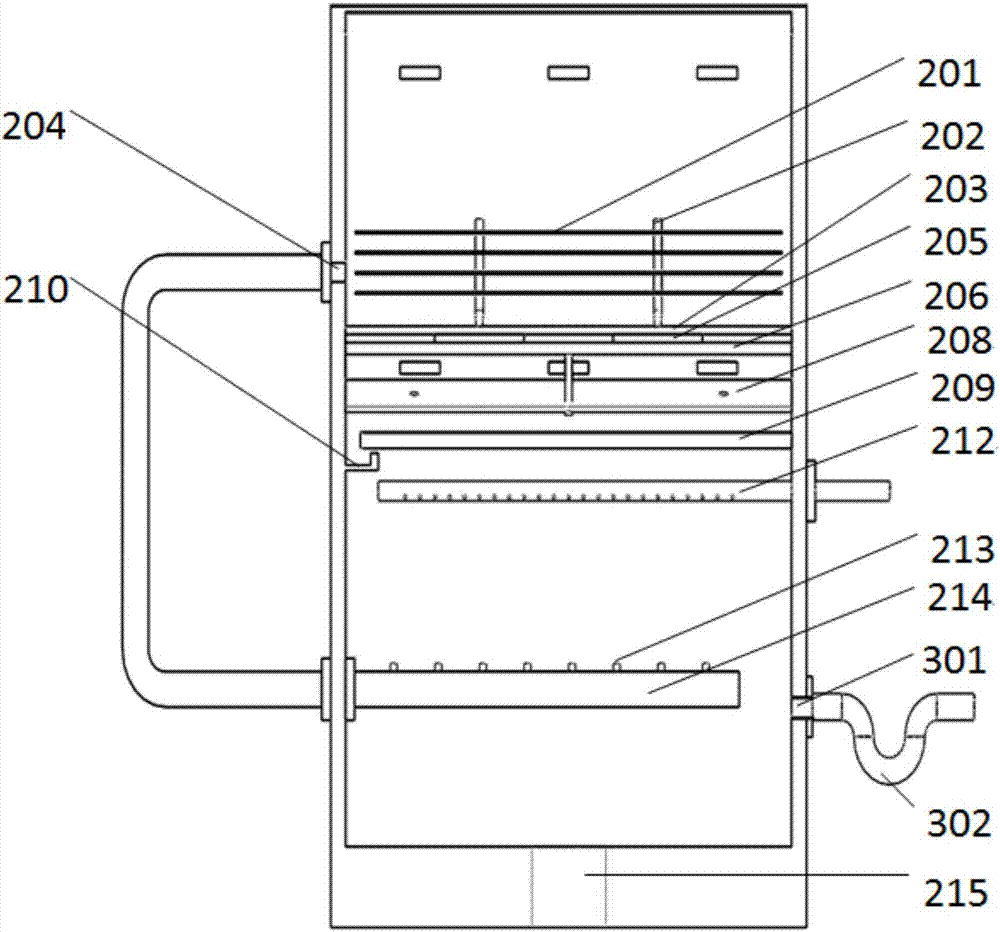

Continuous-deep-dewatering and solar-energy synergy sludge drying method

ActiveCN105819663AImprove distributionImprove dehydration effectSludge treatment by de-watering/drying/thickeningResource utilizationMoisture

The invention belongs to the technical field of sludge treatment and disposal, and relates to a continuous-deep-dewatering and solar-energy synergy sludge drying method. The continuous-deep-dewatering and solar-energy synergy sludge drying method includes the steps that primarily-dewatered sludge is subjected to continuous deep dewatering, and then subjected to solar-energy drying treatment, wherein continuous deep dewatering treatment comprises the sludge modifying treatment process and the squeezed dewatering treatment process. The invention further provides a continuous-deep-dewatering and solar-energy synergy sludge drying system. The continuous-deep-dewatering and solar-energy synergy sludge drying method can be widely applied to dewatering treatment of primarily-dewatered sludge of a sewage treatment plant, the moisture content of the primarily-dewatered sludge is reduced to 30% to 40% from 75% to 85%, and reduction, harmless and resource utilization of sludge is finally achieved.

Owner:TONGJI UNIV +1

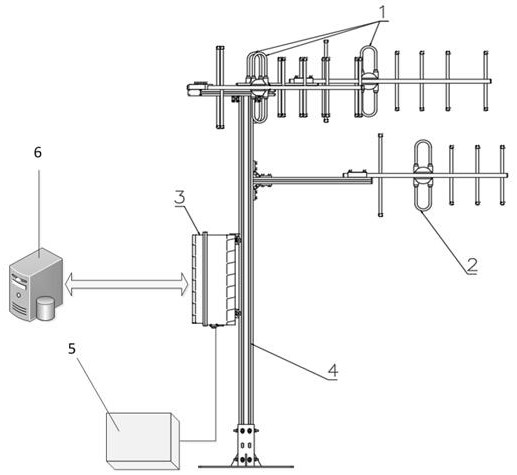

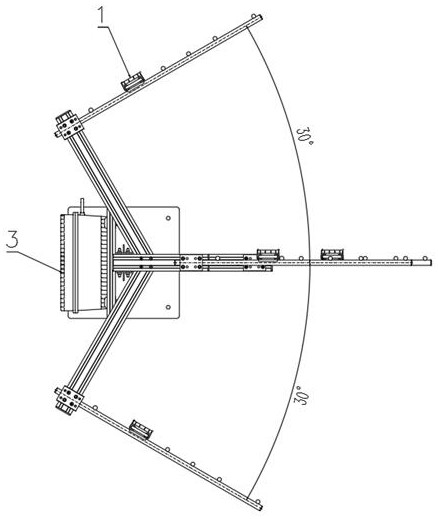

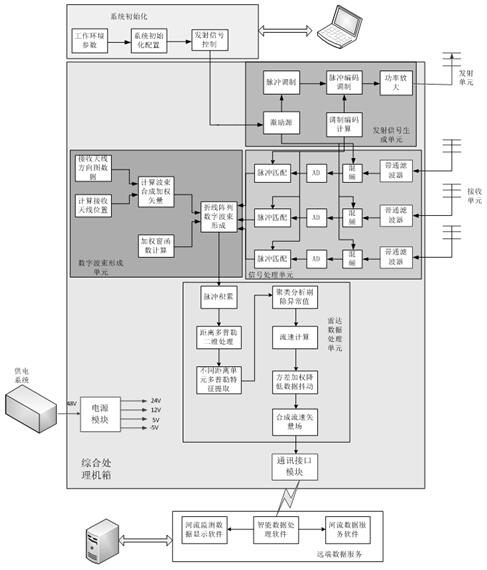

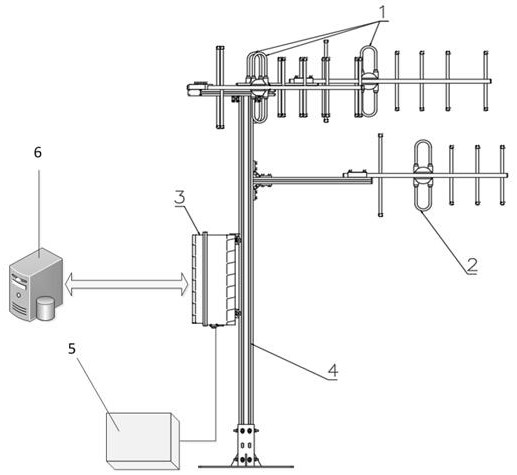

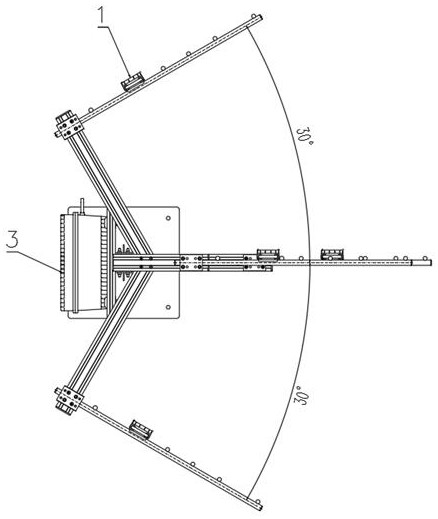

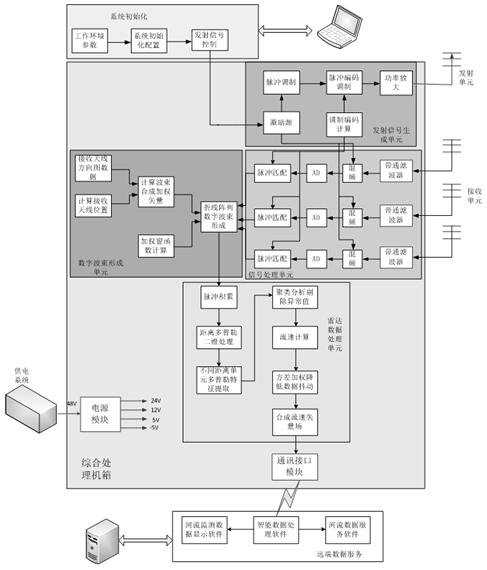

River surface flow field accurate measurement radar based on computational intelligence

ActiveCN113820708ASimple designSolve the real problemFull-field flow measurementRadio wave reradiation/reflectionHardware structureRadar systems

The invention discloses a river surface flow field accurate measurement radar based on computational intelligence, and particularly relates to the technical field of flow measurement. The radar comprises a software structure and a hardware structure. The radar system adopts a coding technology on a signal waveform to realize interference resistance, adopts a fuzzy clustering intelligent algorithm to ensure stability and reliability of observation data, adopts broken line array weighted optimization to realize high-precision river surface vector field synthesis under a large visual angle condition, adopts a variance weighted intelligent algorithm to reduce data jitter and improve stability of observation vector data, and adopts remote data analysis based on big data and an artificial intelligence technology. Intelligent algorithms such as an anti-interference means, an intelligent processing technology, a high-resolution broken line array angle resolution technology, a fuzzy clustering technology and a filtering jitter reduction technology are integrated, a corresponding hardware structure is designed for related intelligent technologies, and the problems existing in traditional equipment are effectively solved.

Owner:南京微麦科斯电子科技有限责任公司

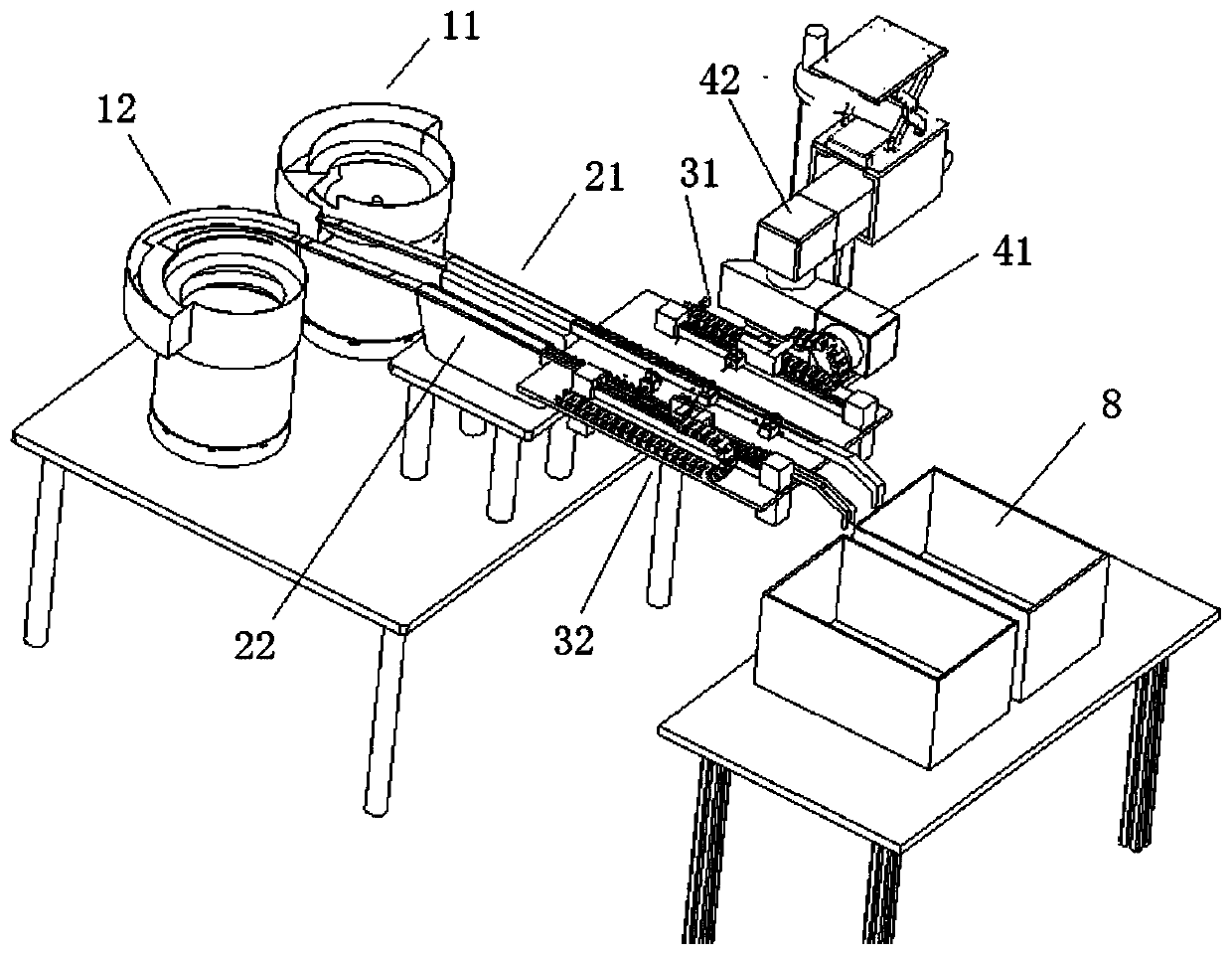

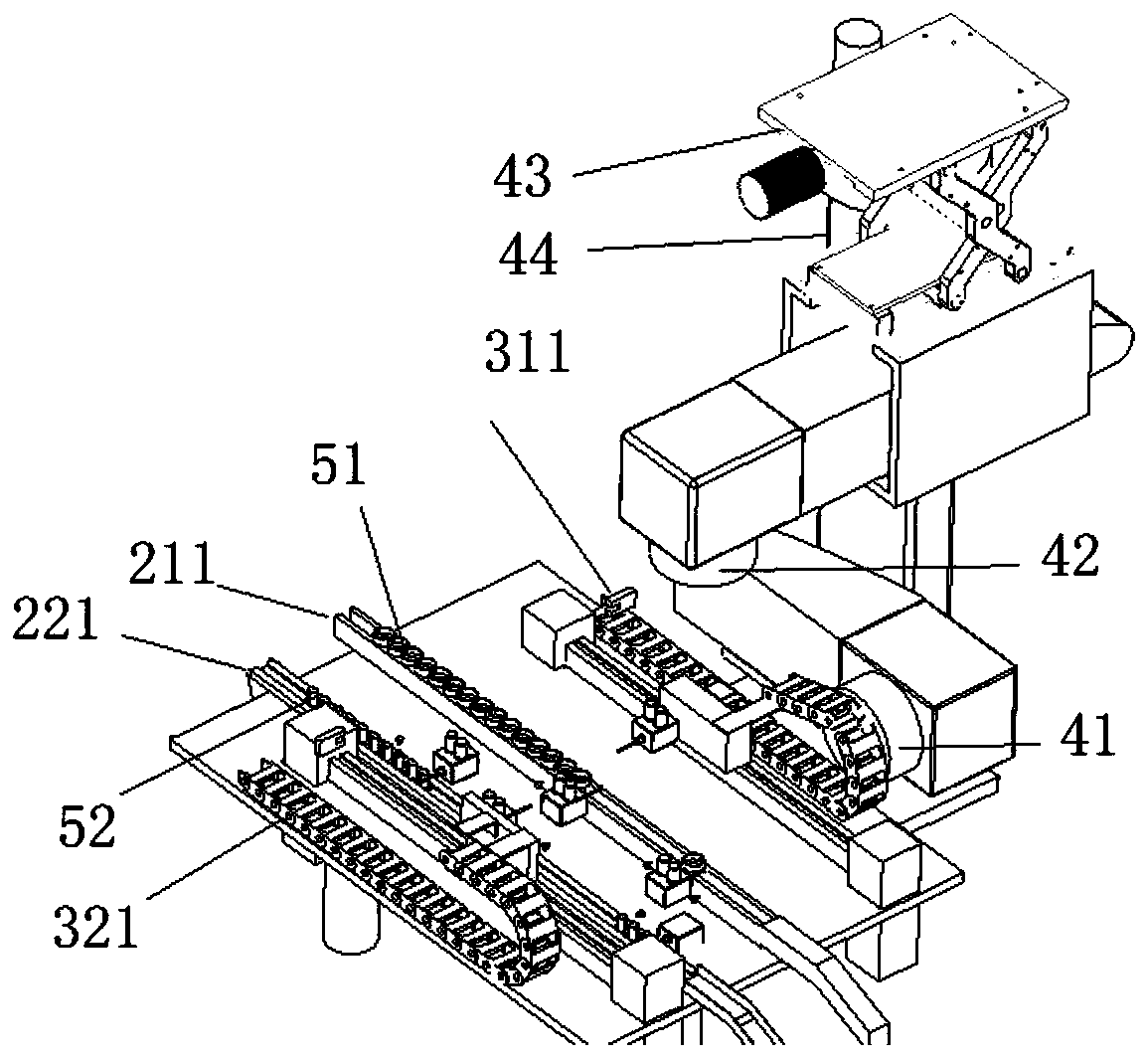

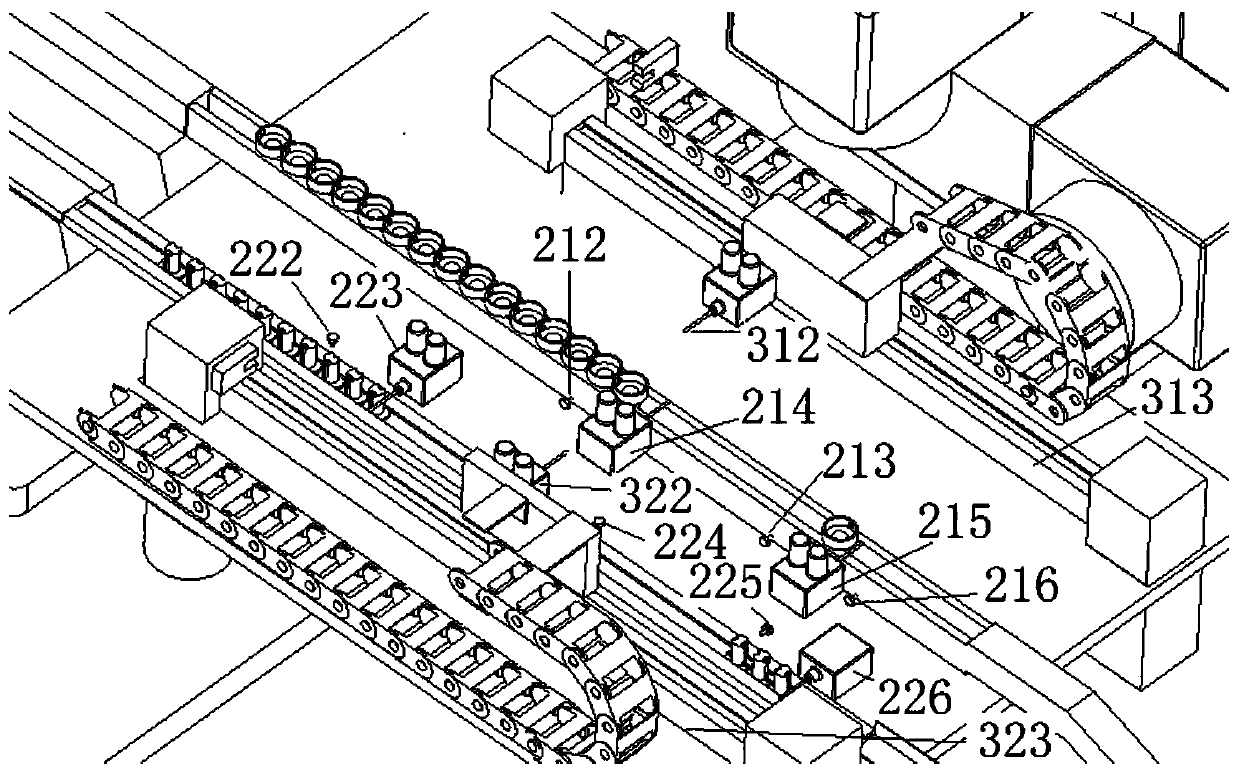

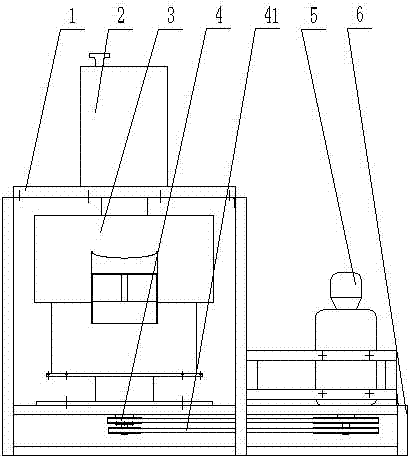

Automatic labelling pretreating device for inserting core of sensor housing and use method

PendingCN110153564AAvoid quality problems such as missing processingNo manualLaser beam welding apparatusEngineeringPre treatment

The invention discloses an automatic labelling pretreating device for an inserting core of a sensor housing, and relates to an automatic treating system. The device comprises a first feeding mechanism, a second feeding mechanism, a first conveying mechanism, a second conveying mechanism, a first pushing mechanism, a second pushing mechanism, a first laser head and a second laser head, wherein thefirst feeding mechanism is used for feeding the housing to the first conveying mechanism; the second feeding mechanism is used for feeding the inserting core to the second conveying mechanism; the first pushing mechanism is used for transferring the housing from the first conveying mechanism to a focusing point position on the first laser head for labelling and transferring to a focusing point position on the second laser head for pretreating; and the inserting core on the second conveying mechanism is transferred to the focusing point position on the second laser head for pretreating throughthe second pushing mechanism. The system is complete and can run without manual interference, so that the human resources can be greatly saved.

Owner:武汉海创电子股份有限公司

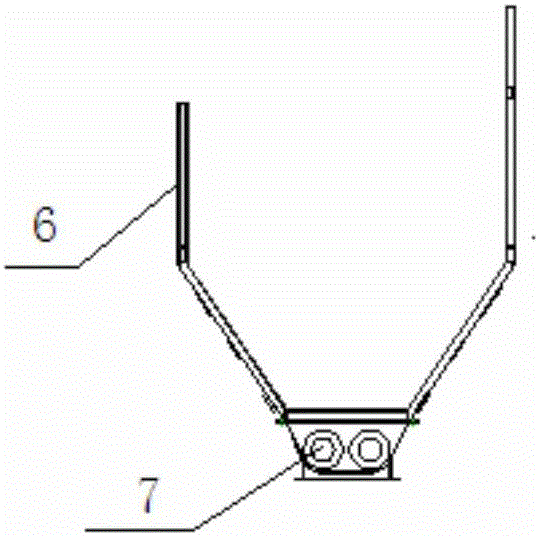

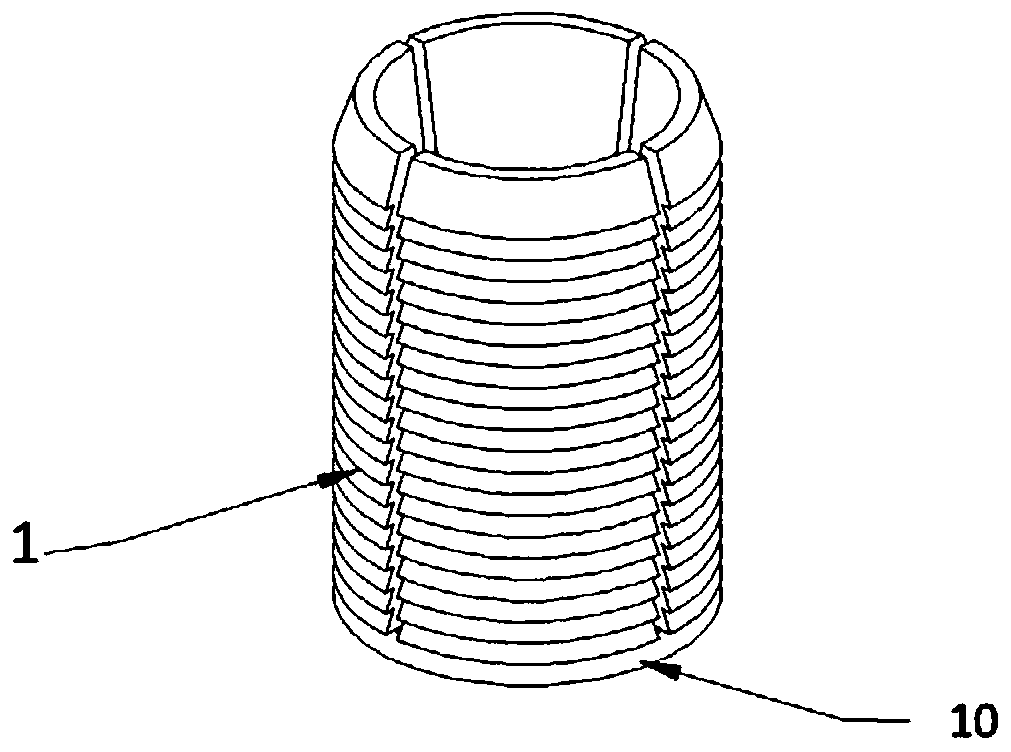

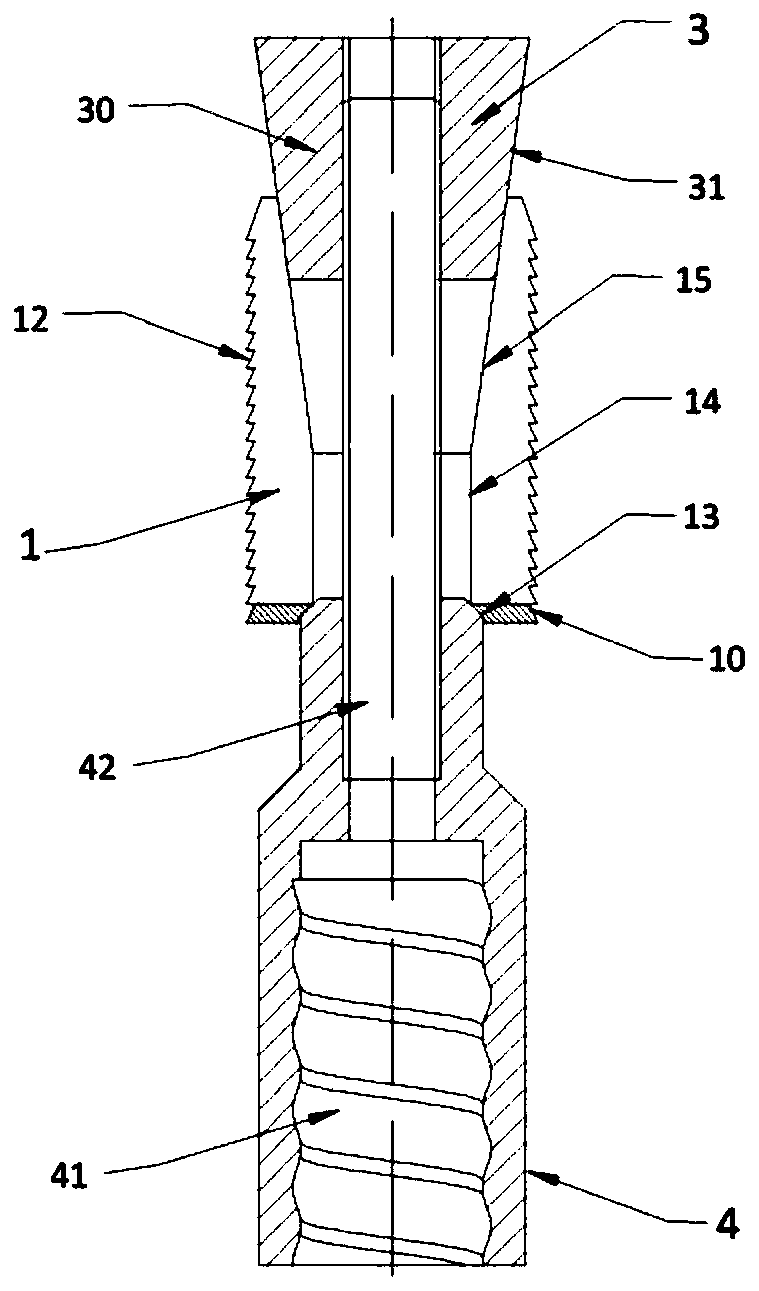

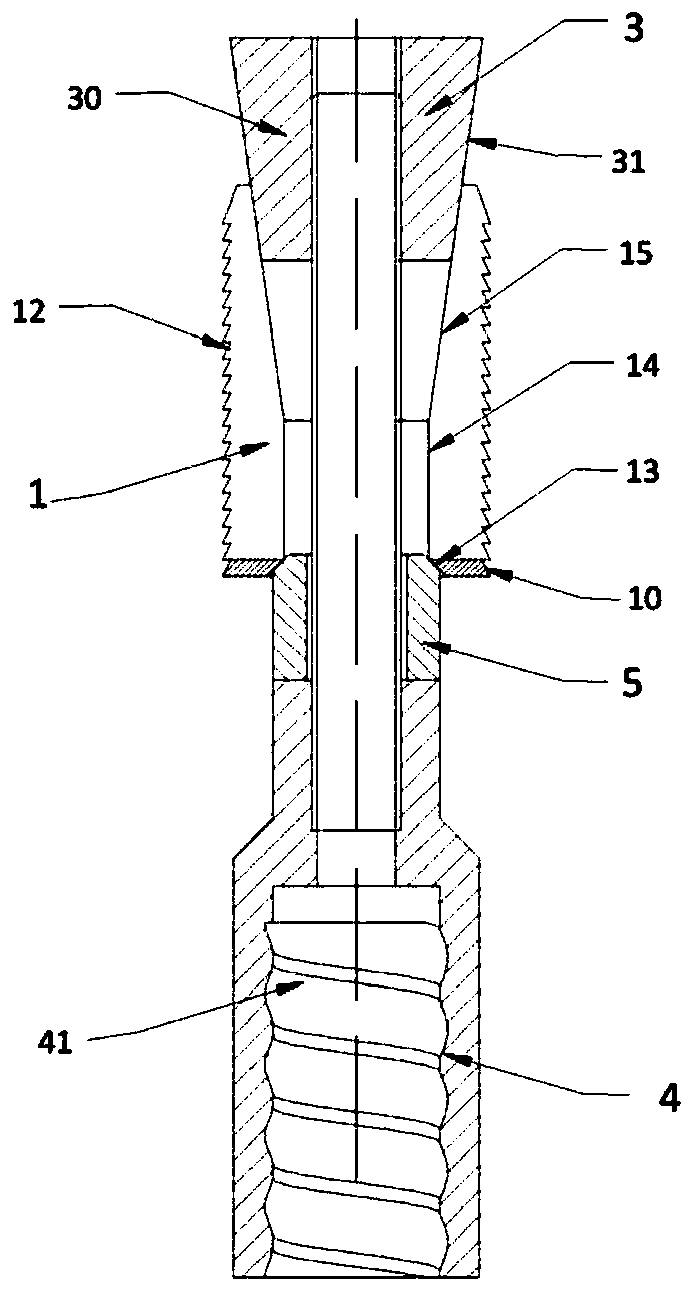

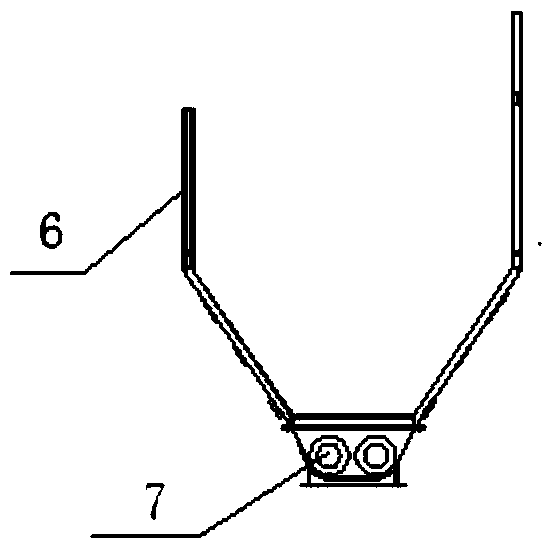

Prestressed expanding shell anchor rod and construction method thereof

PendingCN111594242AReduce manufacturing costIncrease anchoring forceAnchoring boltsClassical mechanicsRock bolt

The invention discloses a prestressed expanding shell anchor rod. The prestressed expanding shell anchor rod comprises an expanding shell and further comprises an expanding shell inner wedge and an anchor rod which are arranged at the two ends of the expanding shell, the expanding shell comprises an expanding shell connecting part and expanding shell pieces, and the expanding shell pieces are circumferentially arranged on the expanding shell connecting part; the expanding shell inner wedge is in sliding contact with the top of the expanding shell; the anchor rod comprises an anchor rod body, ascrew rod is fixedly mounted at one end of the anchor rod body through a connecting sleeve and is in transmission connection with the expanding shell inner wedge through a thread, and the top of theconnecting sleeve is in extrusion contact with the bottom of the expanding shell; and the anchor rod is rotated to drive the expanding shell inner wedge to move into the expanding shell so as to pushthe expanding shell pieces to deform outwards until the expanding shell connecting part breaks, and finally the expanding shell pieces expand to the hole wall to apply prestress to rock mass. Meanwhile, a construction method of the prestressed expanding shell anchor rod is further provided. The prestressed expanding shell anchor rod has the advantages that the cost is low, anchoring performance isgood, and mechanization and automatic operation are convenient to realize.

Owner:浙江聚能岩土锚固研究有限公司

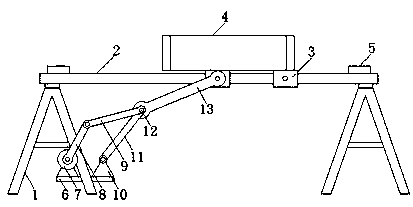

Tapping channel castable production and screening device

PendingCN109396018AContinuous automatic operationEasy to replaceSievingScreeningHinge jointEngineering

The invention relates to the technical field of castable production, and discloses a tapping channel castable production and screening device which comprises four brackets, wherein a sliding chute frame is fixedly connected with the tops of the brackets; four sliding blocks are slidably connected with the obverse side and the reverse side of the sliding chute frame correspondingly; a screening body is movably connected with the tops of the sliding blocks; limiting plates are fixedly connected with the top of the sliding chute frame and positioned on two sides of the screening body; and two mounting plates are fixedly connected with the lower part of the bracket on the left side. The tapping channel castable production and screening device has the beneficial effects that during the operation of a motor, a transmission rod can be driven by the motor to periodically and circumferentially rotate; at the time, a driven rod can be driven by the transmission rod to move; the ends, far away from a connecting shaft, of the transmission rod and an auxiliary rod are unmovable, so that at the time, the connecting shaft can periodically and circumferentially move with the hinge joint between the auxiliary rod and a fixing seat as a supporting point; and at the time, the sliding blocks can be driven by a push rod to periodically slide left and right on the sliding chute frame, and the screening body can synchronously move along with the sliding blocks.

Owner:HUZHOU CITY HUICHENG MARINE COVERING

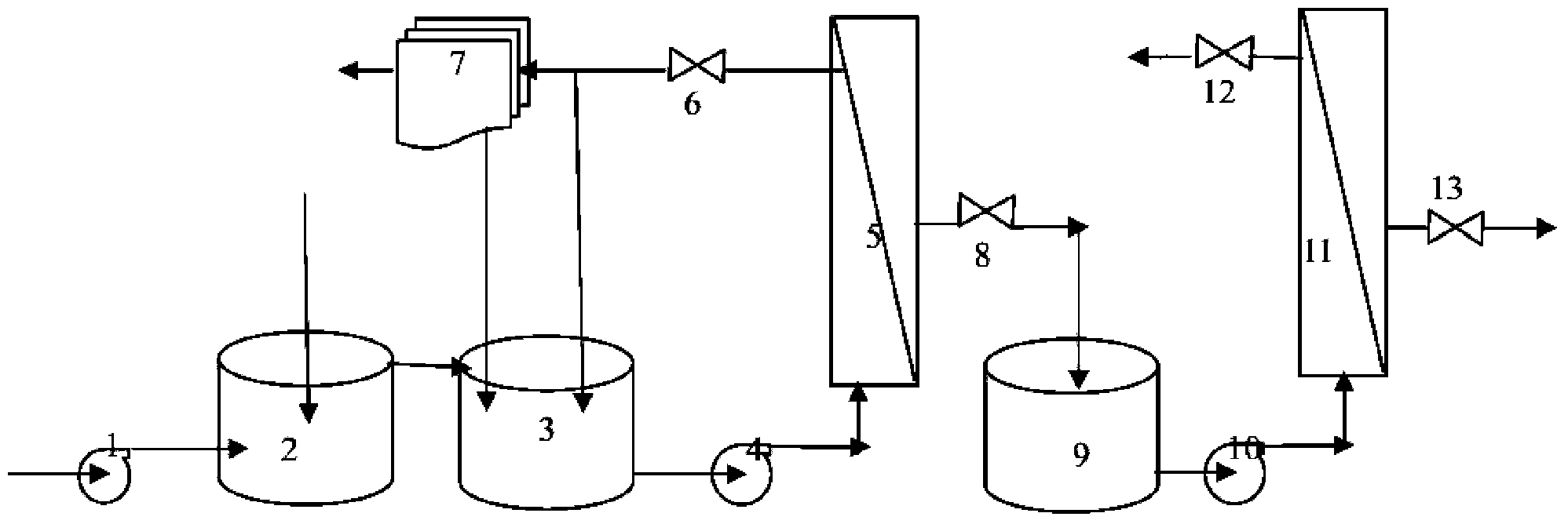

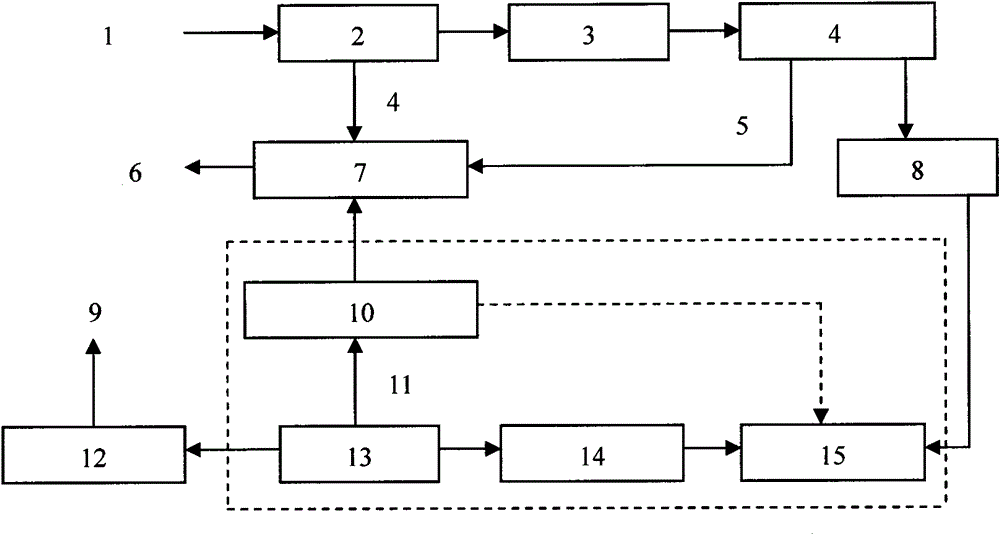

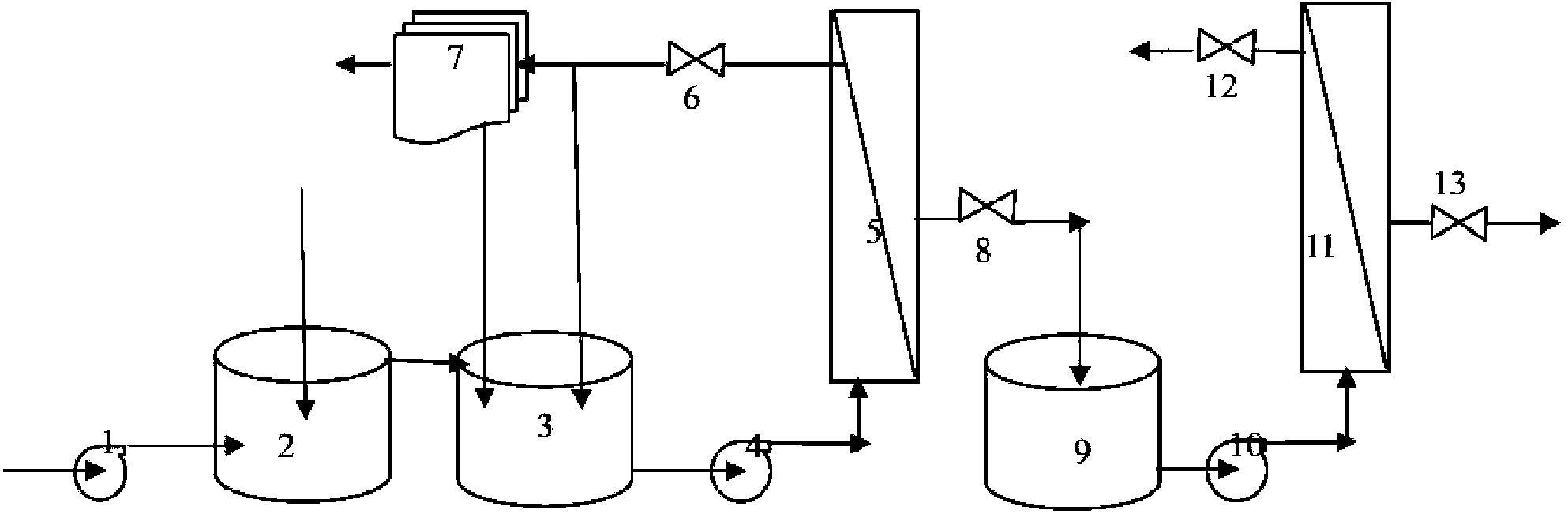

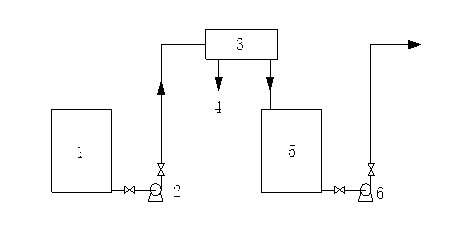

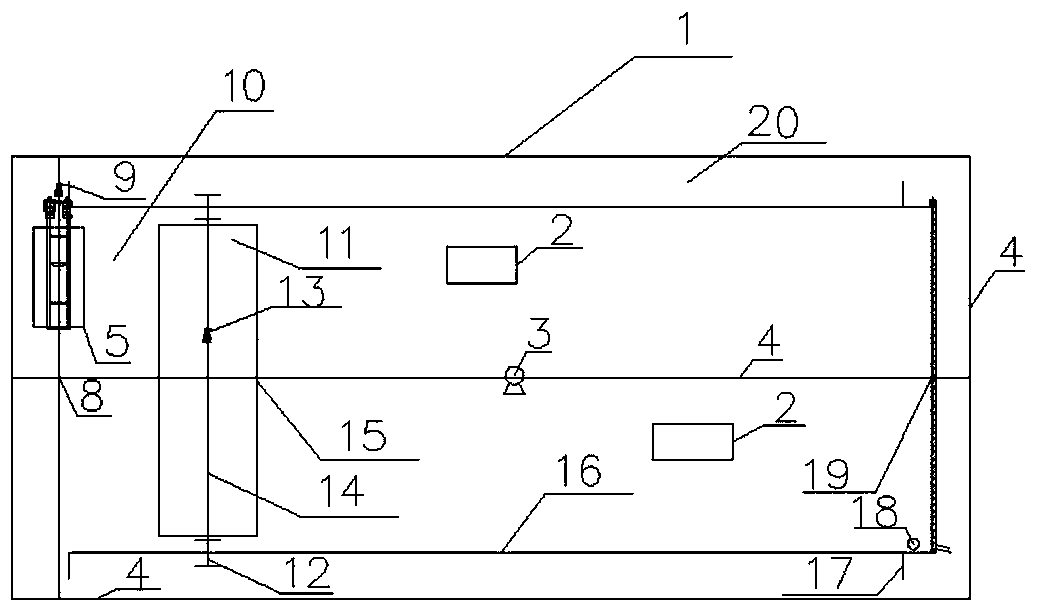

Resource recovery-based automatic corrugated board glue making system

InactiveCN102796467AEasy to adjustThe running screen is accurate and clearStarch adhesivesCycle controlSoftware

The invention discloses a full-automatic glue making system for improving corrugated board glue making performance and resource recovery. The system mainly comprises two aspects, namely a full-automatic corrugated board glue making system and a resource recovery-based corrugated board glue making recycle process (a domestic wastewater recovery process flow diagram is shown as figure 1). The full-automatic corrugated board glue making system mainly comprises software and hardware equipment of the glue making system, and matched large and small cycle control systems; by high process control over pasting temperature, viscosity, solid content and glue temperature, unstable glue quality caused by human factors is radically avoided, the high quality of products is ensured, and high efficiency and low consumption in the production process are ensured. The resource recovery-based corrugated board glue making recycle process mainly comprises steps of using the treated domestic wastewater as production water for the automatic glue making process and treating and recycling glue making wastewater. By the two aspects, water for the whole production system is organically cycled, so that cyclic production is realized, water resources are recycled, the full-automatic glue making system accords with low-carbon production and environmental protection concepts supported by China, and a green idea is combined into the glue making system.

Owner:黄遂兢

Sludge breaking and centrifugal filtration integrated machine

InactiveCN103641284BThe crack cycle is shortIncreased rate of anaerobic digestionSludge treatment by de-watering/drying/thickeningSludgeElectric machinery

The invention relates to a sludge breaking and centrifugal filtration integrated machine, and aims to provide a sludge breaking and centrifugal filtration integrated machine which is low in running cost, good in sealing property and small in occupied area. The sludge breaking and centrifugal filtration integrated machine comprises a base, a transmission device, a sludge breaking device and a centrifugal filtration device, wherein the transmission device comprises a belt pulley, a belt, an inner shaft and an outer shaft, wherein the inner shaft and the outer shaft are concentric and are respectively connected with the motor through the belt pulley and the belt, the sludge breaking device comprises a breaking cavity fixedly connected with the base through a bracket, fixed discs arranged on the inner wall of the breaking cavity and movable discs arranged on the inner shaft, the fixed discs and the movable discs are distributed in a staggered manner along the axial direction, the centrifugal filtration device comprises a filtering cavity shell, a water collecting channel with a water outlet pipe at the bottom, an elastic scraper, an annular baffle, and a filtering rotating hub arranged on the outer shaft, the bottom of the filtering cavity shell is fixedly connected with the outer side wall of the water collecting channel, a slag outlet hole is arranged at the lower part of the side wall of the filtering cavity shell, the annular baffle is arranged at the outer side of the upper edge of the filtering rotating hub, and the lower end of the elastic scraper is fixed on the inner shaft through a scraper rack.

Owner:NORTHEASTERN UNIV LIAONING

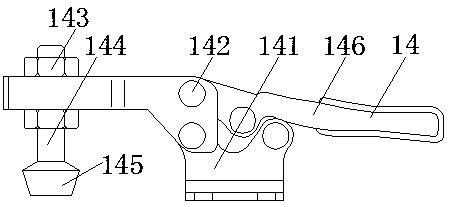

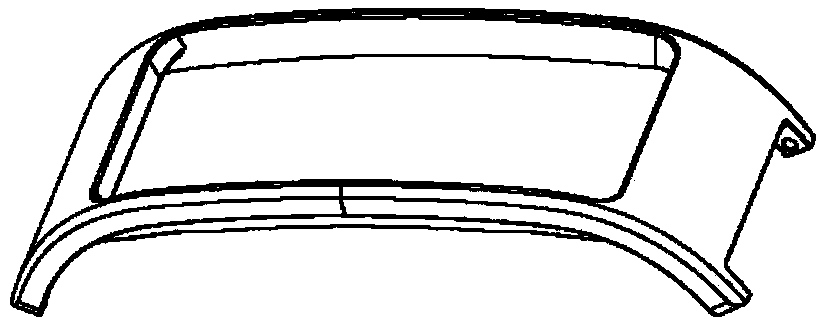

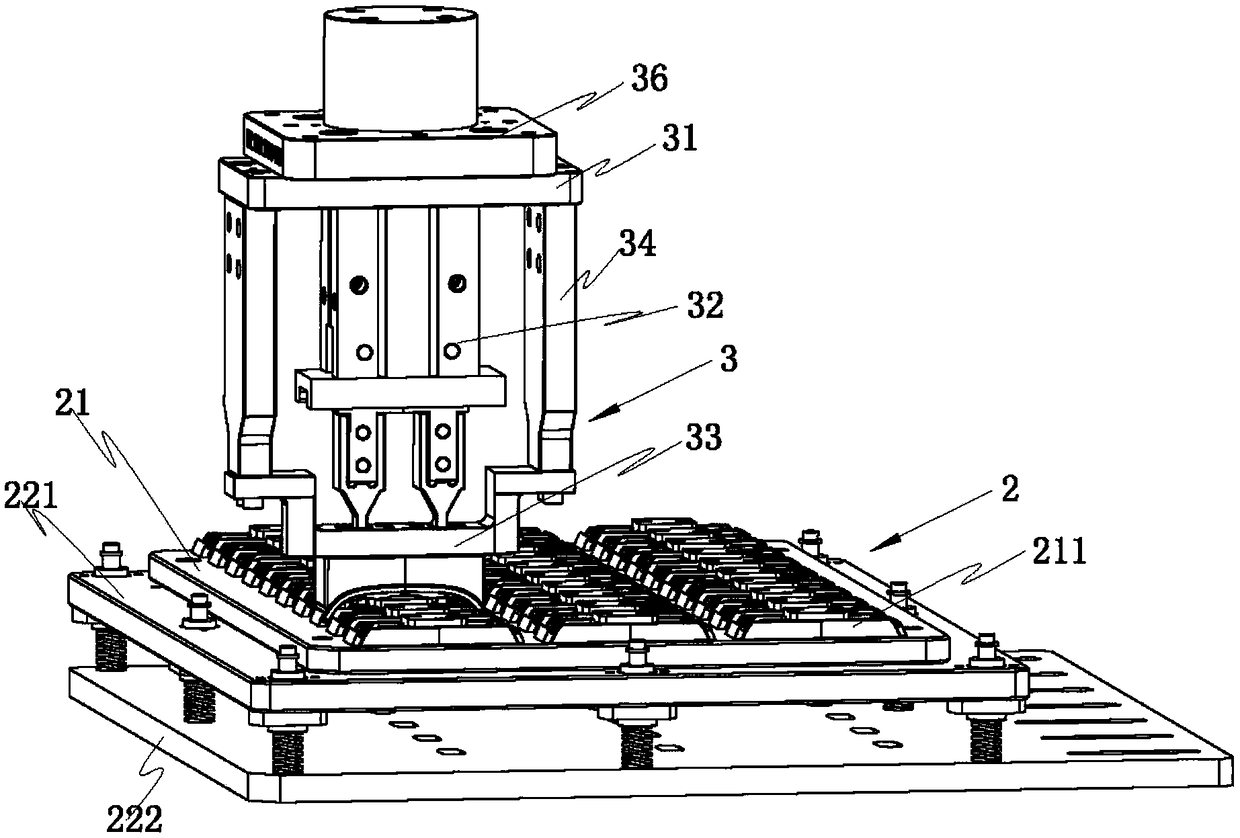

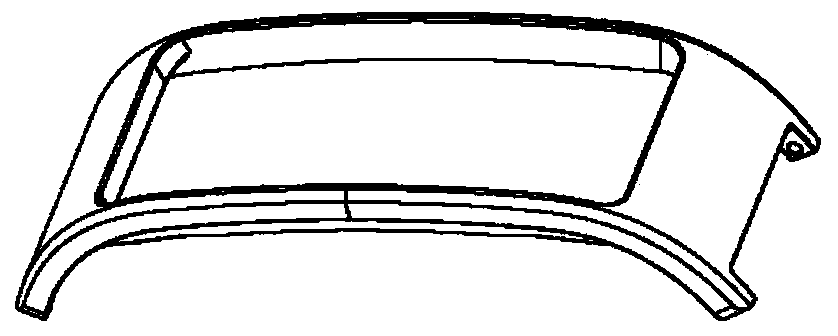

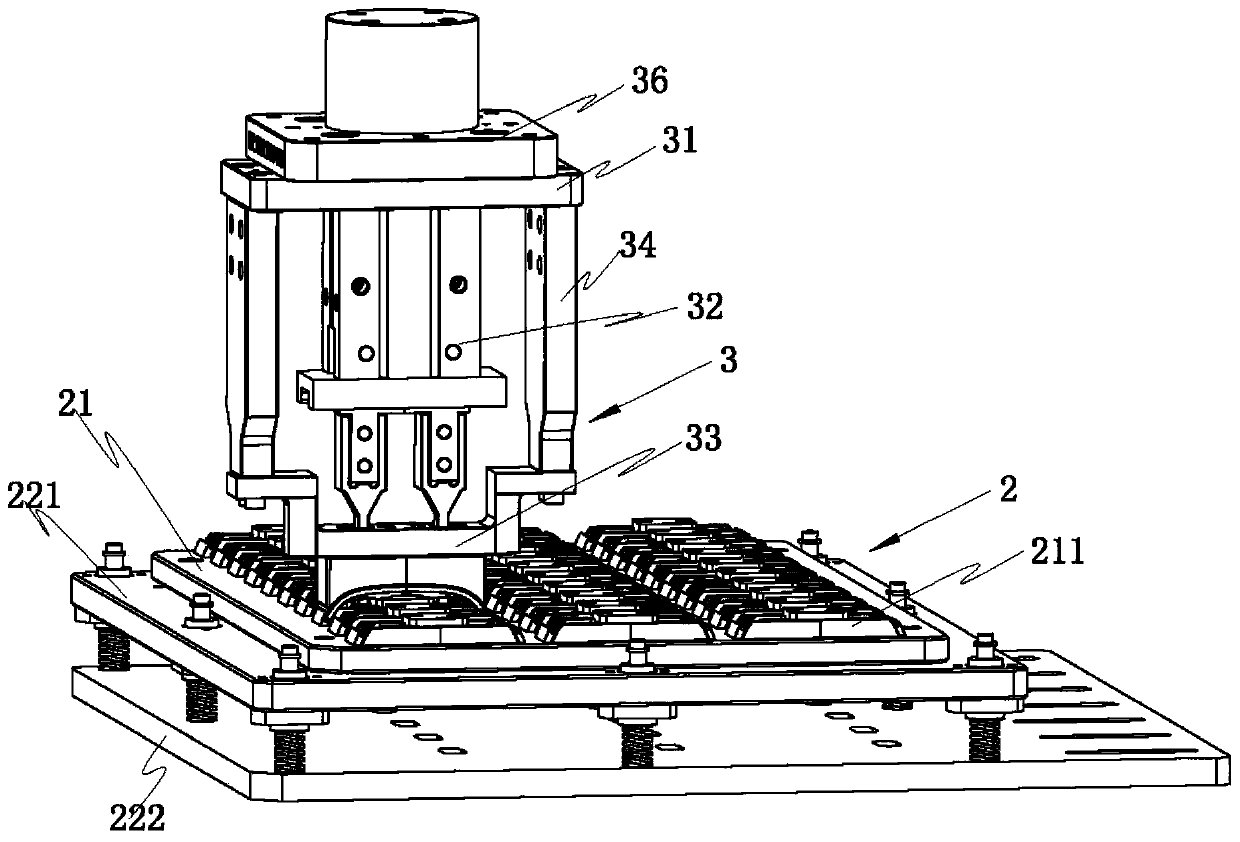

Locating and clamping device and semi-automatic drawing method for metal product

ActiveCN109227319AProblems preventing subsequent drawing errorsAvoid three injuriesGrinding machinesGrinding work supportsSemi automaticEngineering

The invention relates to the technical field of drawing of metal products, in particular to a locating and clamping device for a metal product. The locating and clamping device comprises a floating locating plate and a clamping tool, the floating locating plate is used for placing the located metal product, and the clamping tool is installed on a mechanical arm and used for clamping the metal product. The invention further relates to a method for applying the locating and clamping device for the metal product to semi-automatic drawing of the metal product. The method comprises the following steps of S1, locating the metal product on the floating locating plate, and driving the clamping tool to clamp the metal product on the floating locating plate through the mechanical arm, and afterwardsmoving the metal product on a grass turbine; S2, utilizing the grass turbine for drawing the metal product, and driving the clamping tool to place the metal product on a turnover disc through the mechanical arm after drawing machining is completed. According to the locating and clamping device and the method, the metal product can be automatically taken and placed, semi-automatic drawing production is achieved, a large amount of labor is saved, and the production efficiency is improved.

Owner:GEER TECH CO LTD

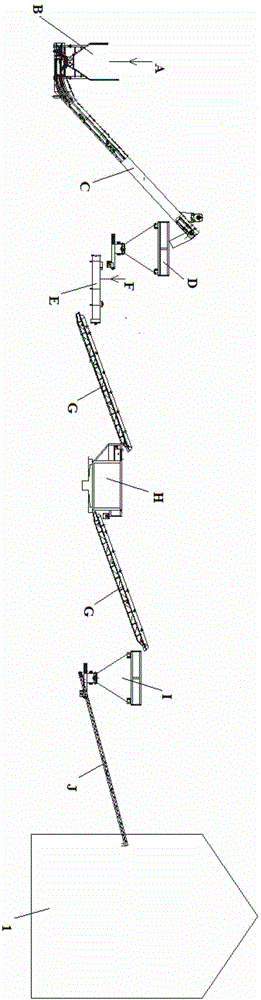

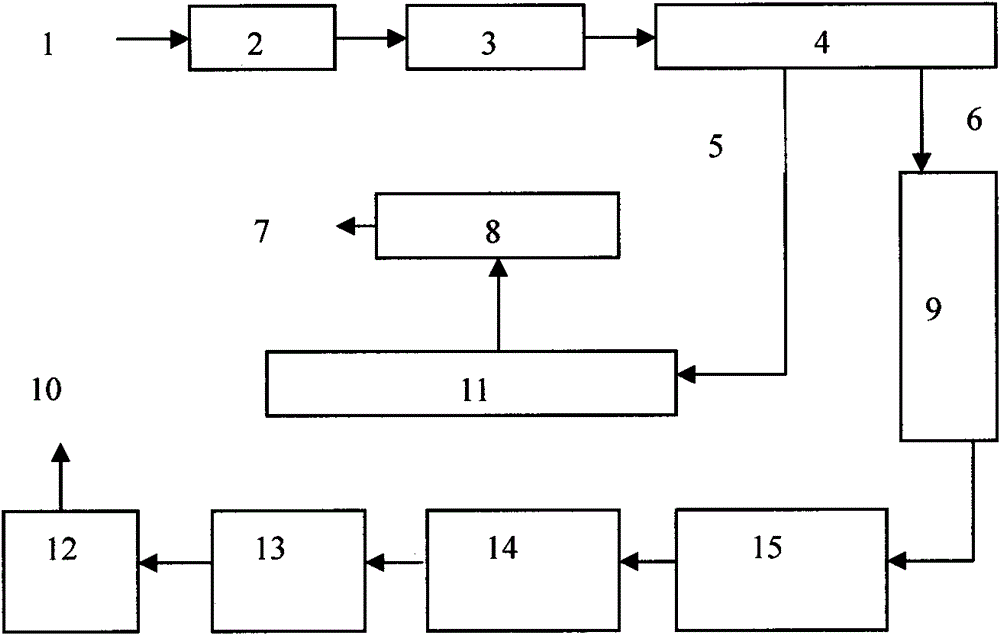

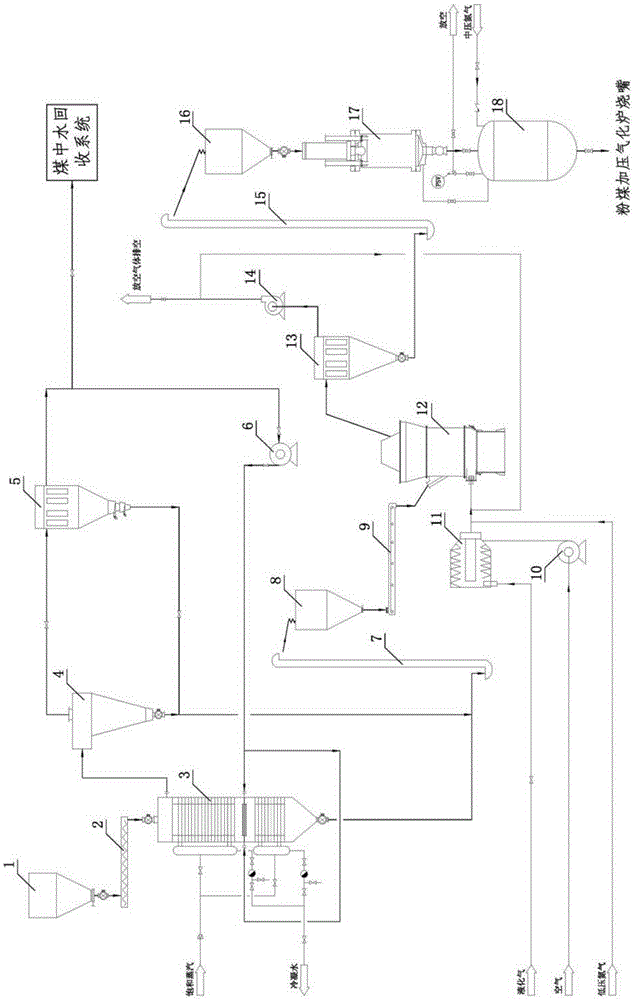

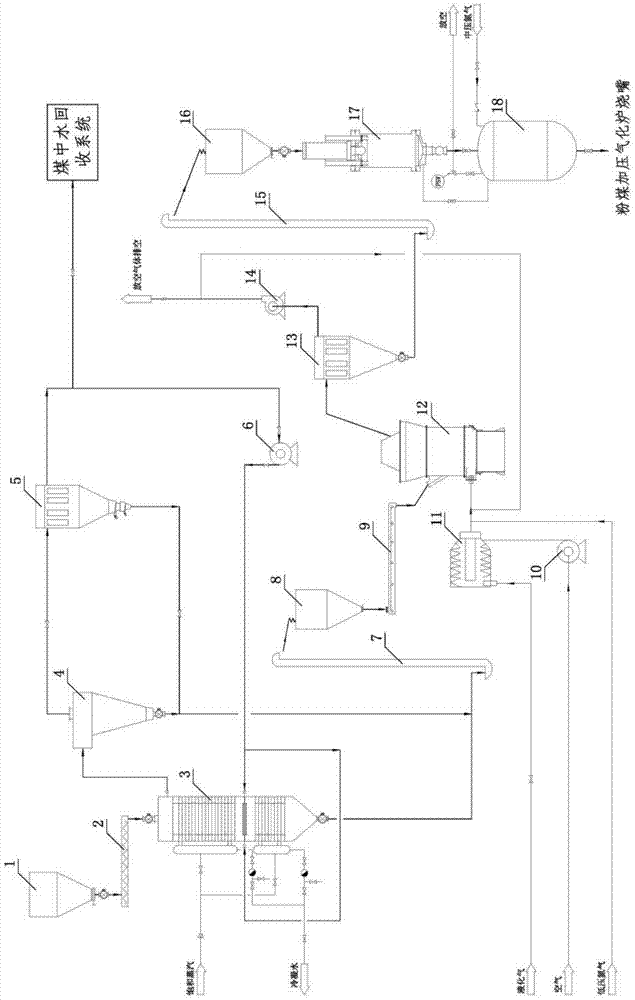

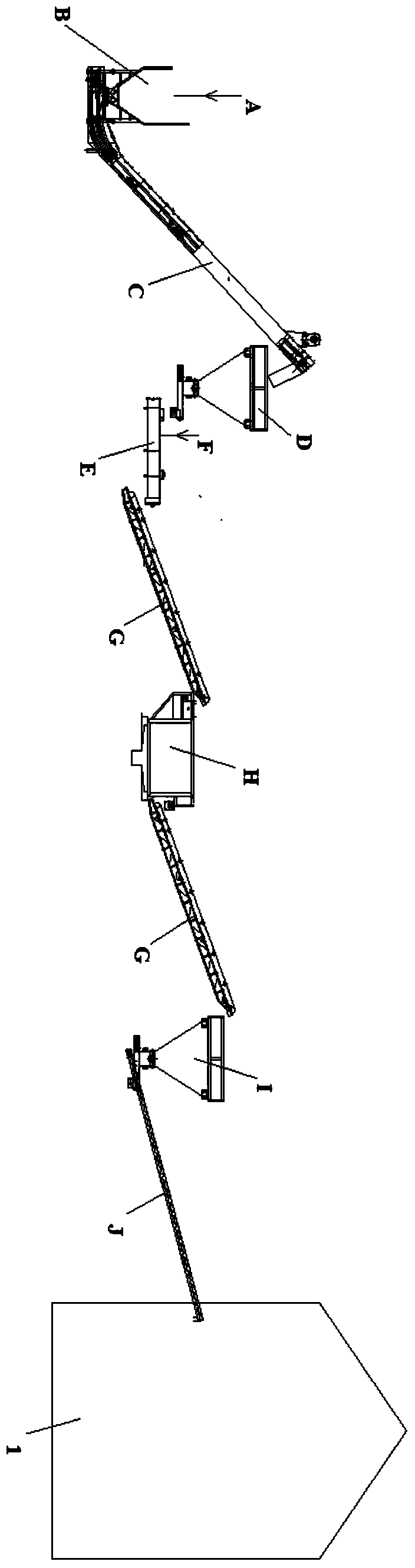

Method for predrying, powdering and conveying feed coal and special processing system thereof

ActiveCN105255519AObvious advantages of environmental protection and energy savingImprove thermal efficiencyDrying solid materials with heatChemical industryFluidized bed dryingProcess engineering

The invention discloses a method for predrying, powdering and conveying feed coal and a special processing system thereof. The method comprises the following steps that 1, coom in a predrying feeding bin is conveyed into a fluid bed drying oven to be predried, and the obtained predried coom enters a powdering feeding coal bunker; 2, the predried coom is fed into a coal pulverizer from the powdering feeding coal bunker to be pulverized to obtain pulverized coal to be fed into a pulverized coal bunker; 3, the pulverized coal is conveyed into a high-pressure pulverized coal tank through a solid pulverized coal conveying pump. The special processing system comprises the feeding bin, the fluid bed drying furnace, the powdering feeding coal bunker, the coal pulverizer, the pulverized coal bunker, the solid pulverized coal conveying pump and the high-pressure pulverized coal tank which are connected in sequence. The feed coal drying effect is good, and energy is saved; the coal pulverizing and drying operation is safer, the pulverized coal conveying energy consumption is small, and efficiency is high.

Owner:SYNEFUELS CHINA

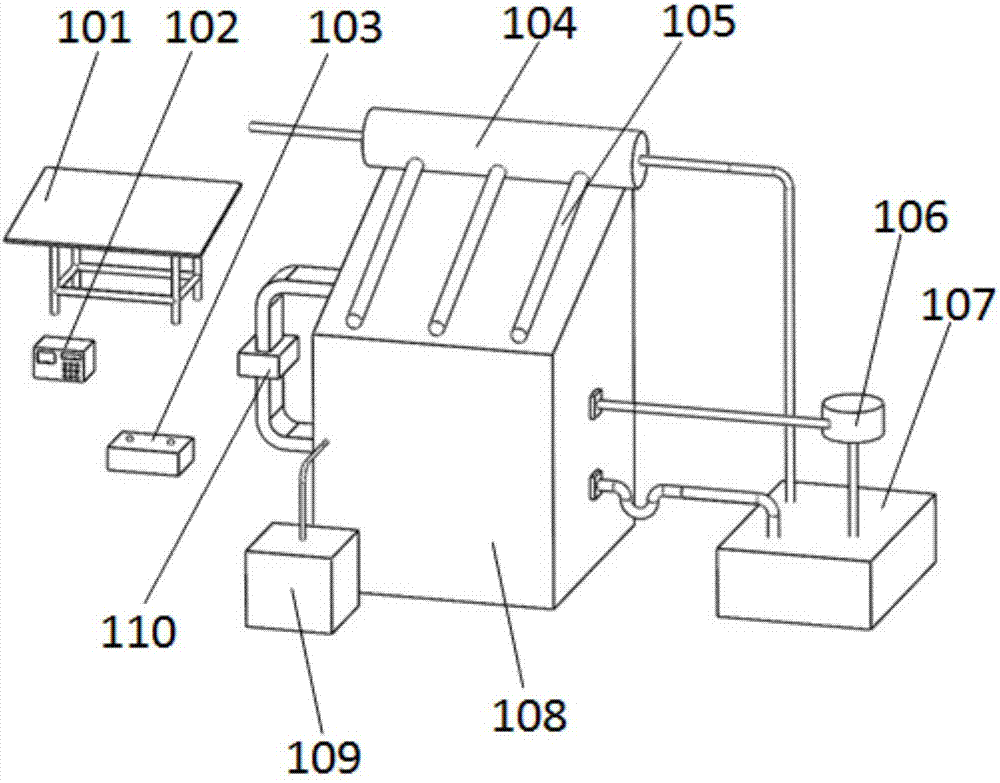

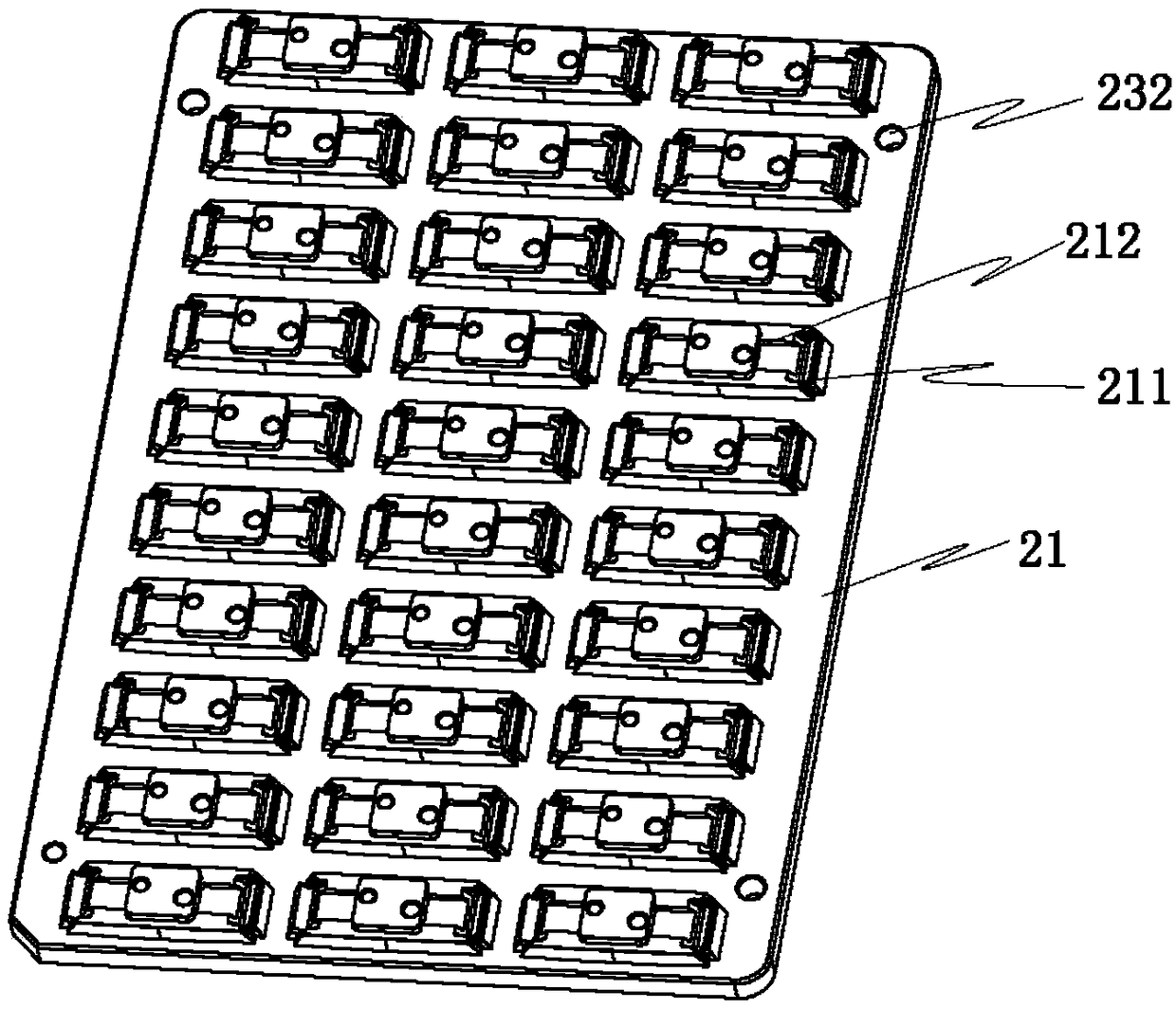

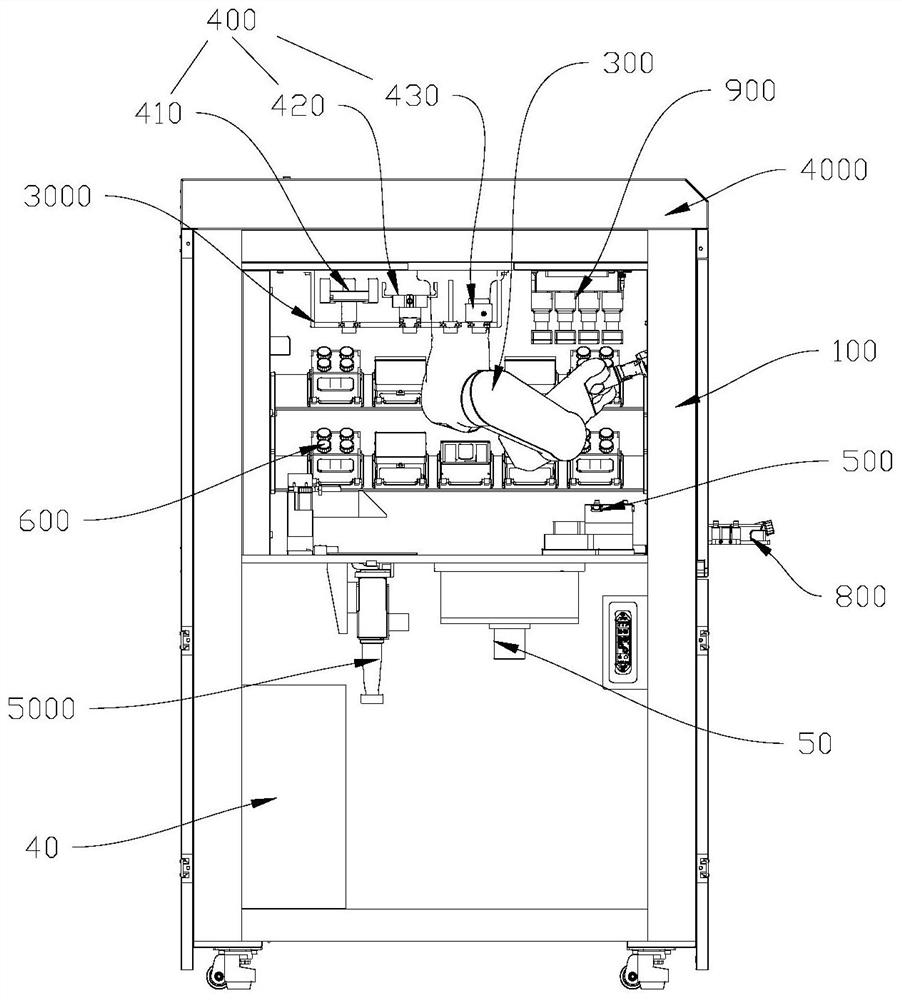

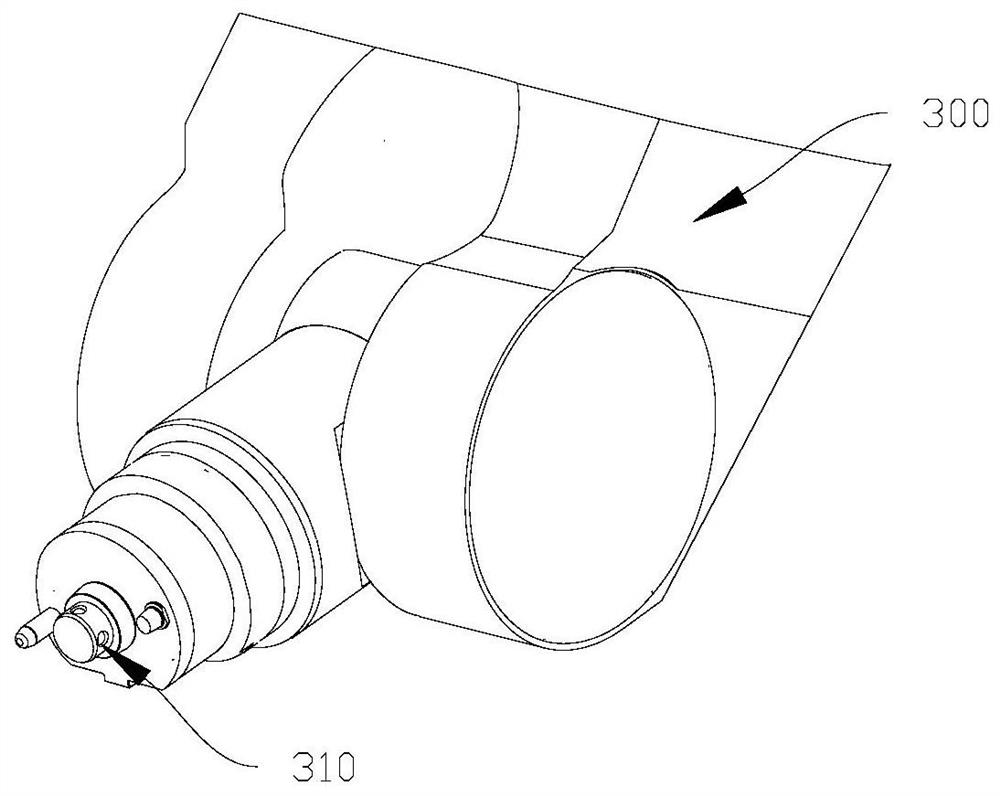

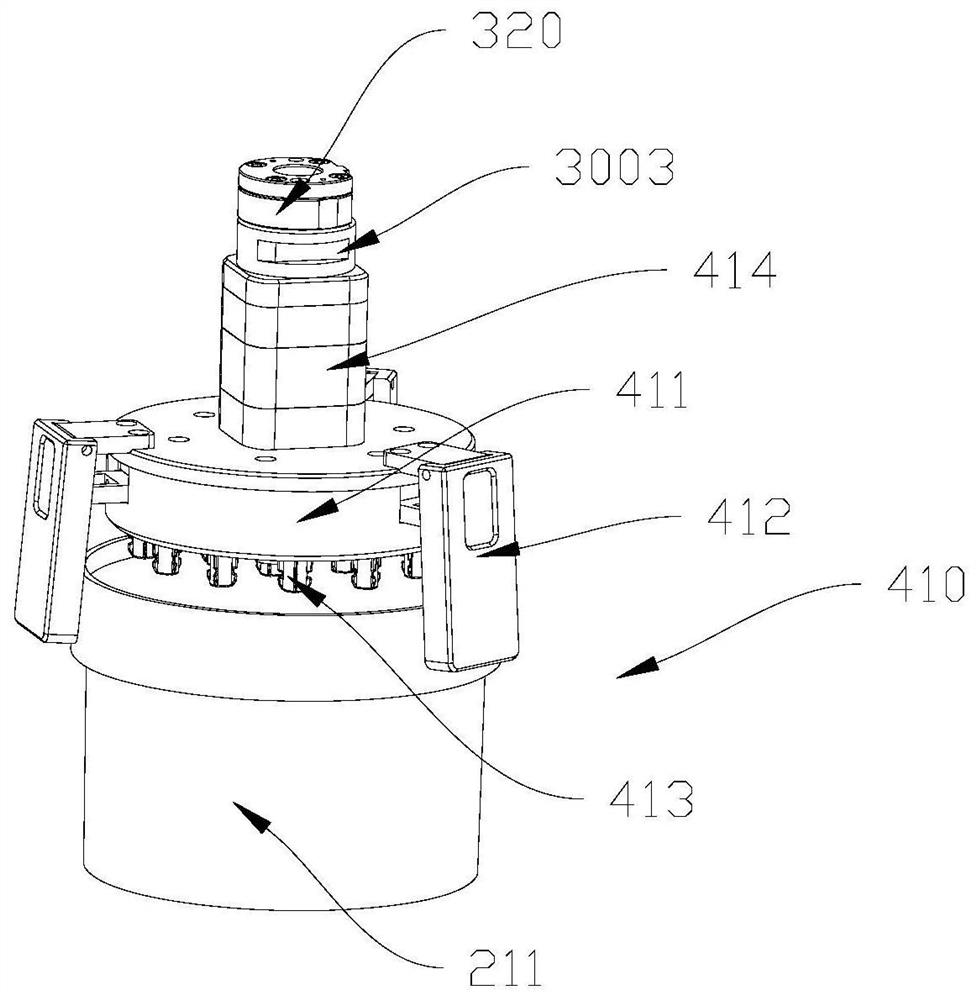

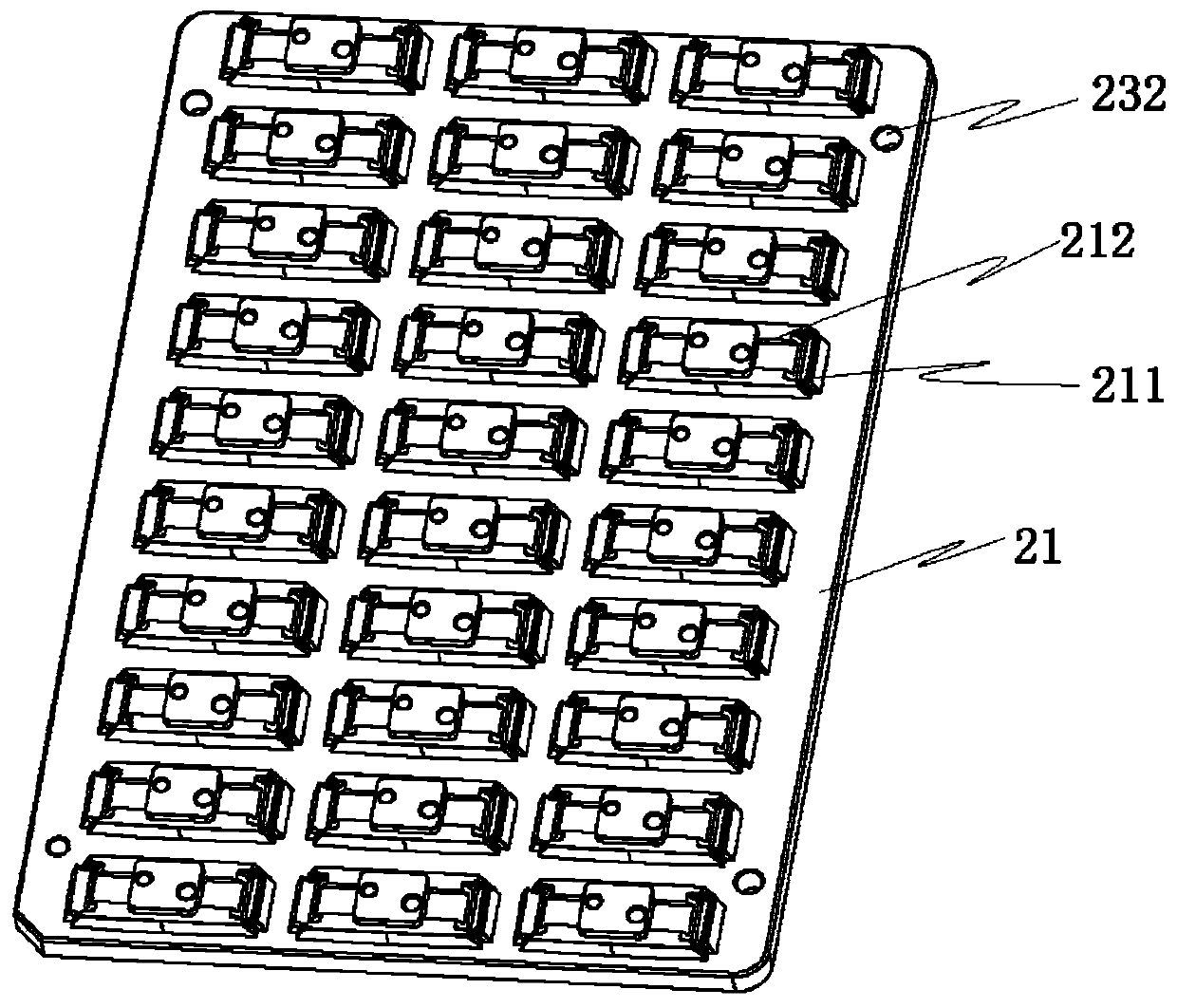

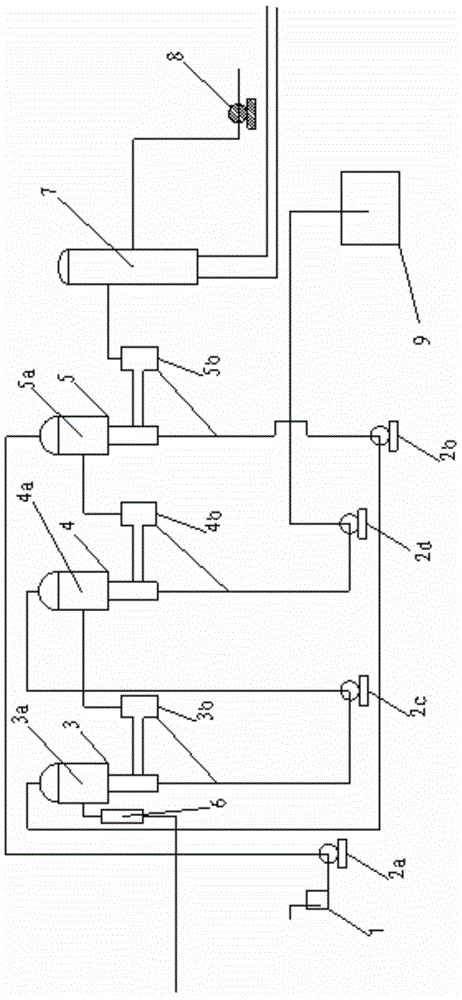

Automatic operation equipment for cell culture

PendingCN113353617AReduce dependenceStable automatic operation processBioreactor/fermenter combinationsConveyorsContinuous/uninterruptedControl system

The invention relates to automatic operation equipment for cell culture. The automatic operation equipment comprises a mechanical arm module, a clamping and moving module, an uncovering module, a consumable storage module, a liquid treatment module, a solid treatment module and a waste liquid treatment module; the uncovering module comprises an unfreezing uncovering mechanism and an uncovering and covering mechanism; under the instruction of a control system, the mechanical arm module cooperates with the consumable storage module, the uncovering module and the conveying module through the clamping and moving module and cooperates with the liquid treatment module to complete automatic culture of cells; and solid or liquid and other wastes generated in the operation process are recycled by the corresponding solid treatment module and the waste liquid treatment module. According to the technical scheme, the clamping and moving module is switched through the mechanical arm module, under cooperation of other functional modules, various operations manually achieved by experimenters are well simulated, continuous and uninterrupted operation can be achieved, the efficiency is high, dependence on the operation level and experience of the personnel is reduced, and the cell product difference caused by different batches is reduced.

Owner:REGENOVO BIOTECH

Membrane technology-based ionic rare earth ore extraction technology and device therefor

The invention relates to a membrane technology-based ionic rare earth ore extraction technology and a device therefor. The membrane technology-based ionic rare earth ore extraction technology comprises the following steps of removing impurities in a rare earth ore percolation liquid, carrying out solid-liquid separation by a ceramic membrane to remove suspended solids in the rare earth ore percolation liquid, carrying out nanofiltration on the ceramic membrane clear liquid for further enrichment concentration, treating the ceramic membrane concentrated solution by a plate-and-frame filter press, removing dreg, when the rare earth ore percolate has the content of 60-70g / L after nanofiltration concentration, feeding the rare earth ore percolate into an extraction unit, carrying out extraction separation of a single rare earth element, and directly feeding the nanofiltration clear liquid rich in an extraction agent back to a percolation unit. Through the membrane separation and integration technology, the rare earth ore percolate is subjected to purification, separation, and concentration enrichment so that rare earth ions in the percolate are purified and concentrated and the next extraction process is convenient, and the rare earth ore percolation liquid subjected to separation from rare earth has a low rare earth ion concentration and a high extraction agent concentration and can be directly used for the percolation process. The membrane technology-based ionic rare earth ore extraction technology greatly improves a rare earth ion recovery rate, reduces a percolation waste water discharge amount and has obvious environmental and economic benefits.

Owner:JIANGSU JIUWU HITECH

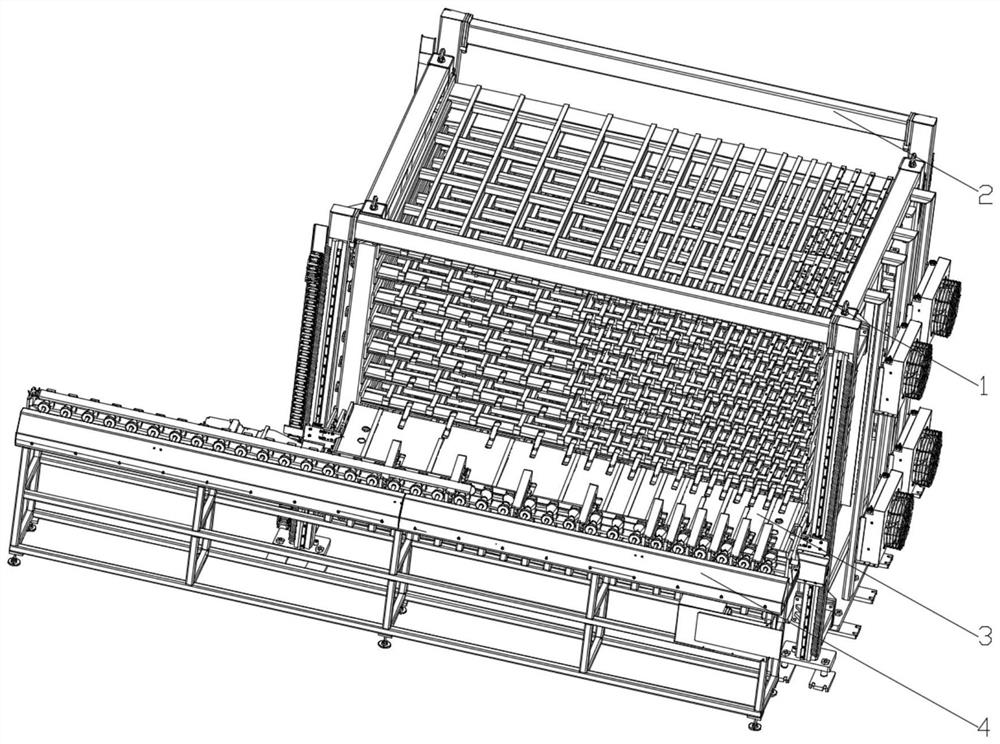

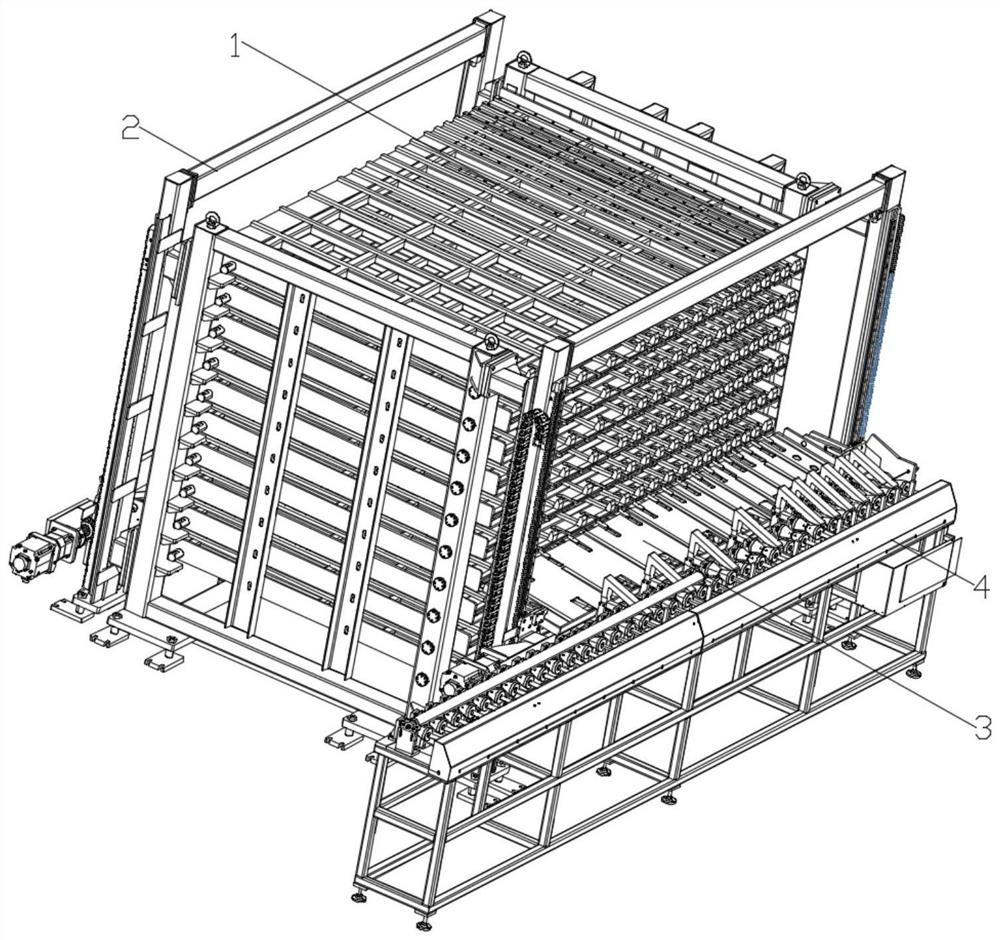

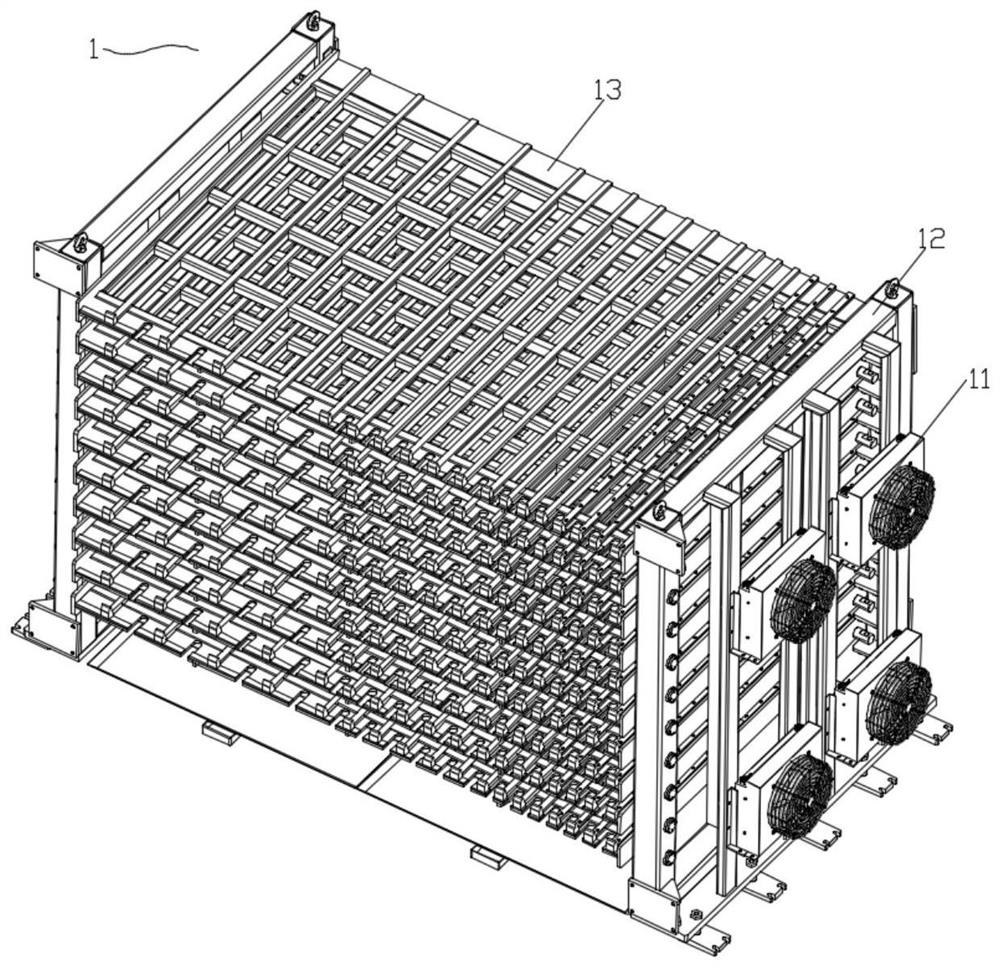

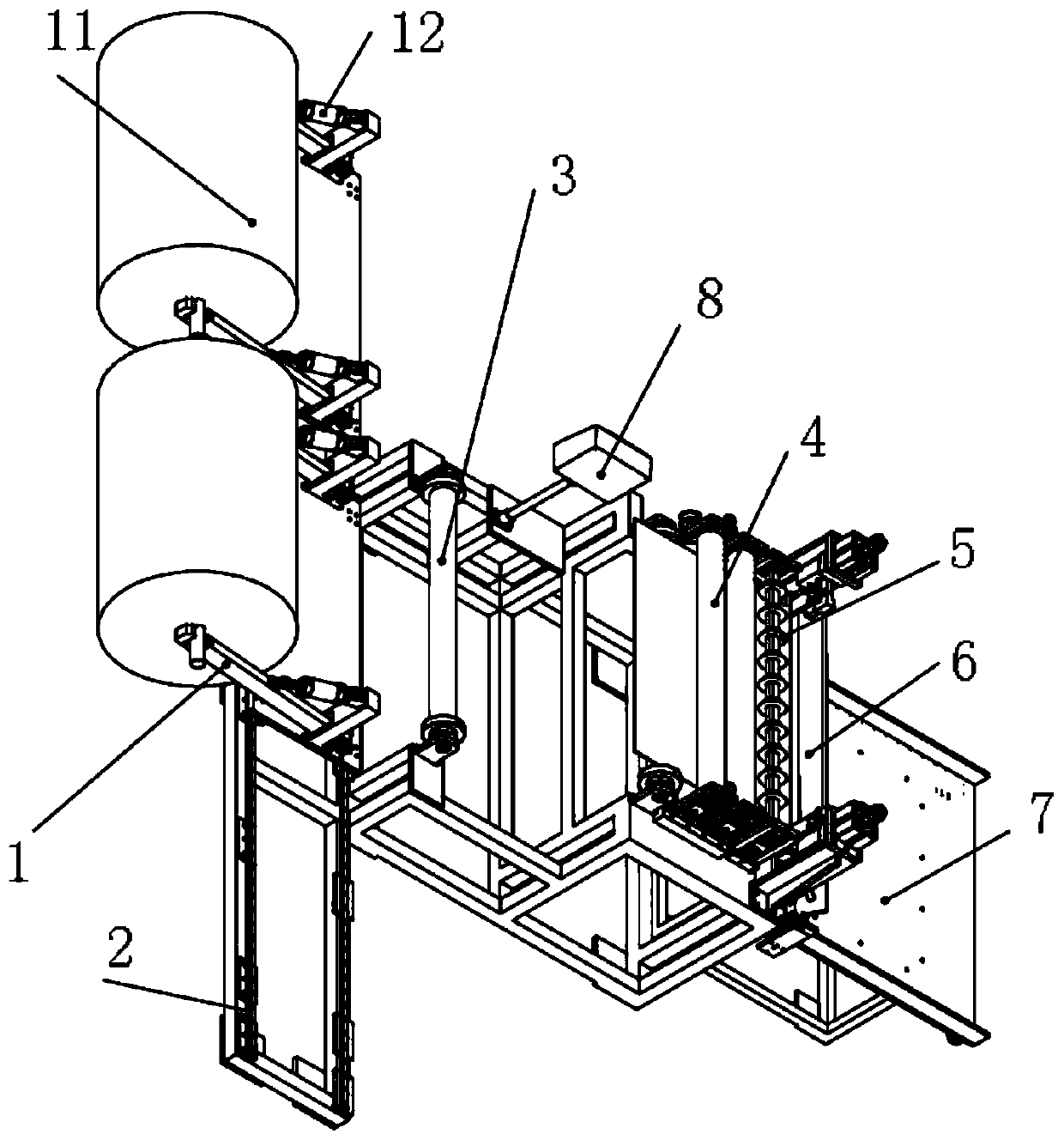

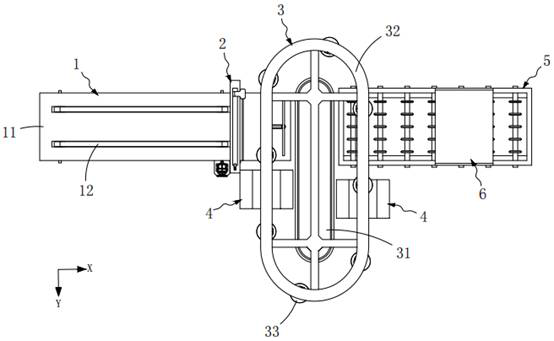

Full-automatic buffer feeding and discharging device for header long pipe bent pipe and feeding method of full-automatic buffer feeding and discharging device

PendingCN114644193AGuaranteed uptimePrevent slipping outConveyorsLoading/unloadingRobot handStructural engineering

The invention discloses a full-automatic buffer feeding and discharging device for header long pipe bent pipes and a feeding method of the full-automatic buffer feeding and discharging device, machined pipe joints are conveyed to a feeding supporting plate of a feeding mechanism through a mechanical arm, the feeding supporting plate is automatically controlled to move up and down and turn over, and a plurality of joint joints are stacked and placed on storage partition plates, at different heights, of a buffer frame. Therefore, by means of the three-dimensional temporary storage frame, the occupied area for temporarily storing the pipe joints is reduced, sealing, cooling and pipe bending of the long pipe bent pipe joints in automatic production line production are conducted at the same time, waiting time of all equipment is avoided, workpiece output is achieved with the best efficiency, and the continuous and automatic operation effect is achieved.

Owner:ZHEJIANG KING MAZON MACHINERY

A method for pre-drying, pulverizing and conveying raw coal and its special processing system

ActiveCN105255519BObvious advantages of environmental protection and energy savingImprove thermal efficiencyDrying solid materials with heatChemical industryFluidized bed dryingBunker

The invention discloses a method for predrying, powdering and conveying feed coal and a special processing system thereof. The method comprises the following steps that 1, coom in a predrying feeding bin is conveyed into a fluid bed drying oven to be predried, and the obtained predried coom enters a powdering feeding coal bunker; 2, the predried coom is fed into a coal pulverizer from the powdering feeding coal bunker to be pulverized to obtain pulverized coal to be fed into a pulverized coal bunker; 3, the pulverized coal is conveyed into a high-pressure pulverized coal tank through a solid pulverized coal conveying pump. The special processing system comprises the feeding bin, the fluid bed drying furnace, the powdering feeding coal bunker, the coal pulverizer, the pulverized coal bunker, the solid pulverized coal conveying pump and the high-pressure pulverized coal tank which are connected in sequence. The feed coal drying effect is good, and energy is saved; the coal pulverizing and drying operation is safer, the pulverized coal conveying energy consumption is small, and efficiency is high.

Owner:SYNEFUELS CHINA

Positioning and clamping device for metal products and semi-automatic drawing method thereof

ActiveCN109227319BProblems preventing subsequent drawing errorsAvoid damageGrinding machinesGrinding work supportsRobot handSemi automatic

The invention relates to the technical field of drawing of metal products, in particular to a locating and clamping device for a metal product. The locating and clamping device comprises a floating locating plate and a clamping tool, the floating locating plate is used for placing the located metal product, and the clamping tool is installed on a mechanical arm and used for clamping the metal product. The invention further relates to a method for applying the locating and clamping device for the metal product to semi-automatic drawing of the metal product. The method comprises the following steps of S1, locating the metal product on the floating locating plate, and driving the clamping tool to clamp the metal product on the floating locating plate through the mechanical arm, and afterwardsmoving the metal product on a grass turbine; S2, utilizing the grass turbine for drawing the metal product, and driving the clamping tool to place the metal product on a turnover disc through the mechanical arm after drawing machining is completed. According to the locating and clamping device and the method, the metal product can be automatically taken and placed, semi-automatic drawing production is achieved, a large amount of labor is saved, and the production efficiency is improved.

Owner:GEER TECH CO LTD

Process for preparing trimethylolpropane by adopting centrifugal filtering calcium method

ActiveCN102795963BImprove separation efficiencyEasy to separateHydroxy compound separation/purificationCarboxylic compound separation/purificationCalcium formateTechnical grade

The invention discloses a process for preparing trimethylolpropane by adopting a centrifugal filtering calcium method. The preparation process is characterized by comprising the following steps of: condensing and performing a formic acid neutralization reaction by taking n-butyl aldehyde and formaldehyde as raw materials and taking technical grade calcium hydroxide as a basic catalyst to obtain acrude trimethylolpropane reaction liquid which contains di-trimethylolpropane and calcium formate serving as side products; and separating solid phase residues from the reaction liquid in a horizontal spiral centrifugal filtering way, concentrating, recovering, refining trimethylolpropane and tableting. Compared with a plate type filter press separating method, the process has the advantage: a settling process before separating and an extracting process after separating are reduced. The arrangement of a settling tank is saved, the floor area of the entire process is reduced, and over two hours of settling time is saved; the generation of a large amount of washing sewage in a production process is avoided; and due to the reduction in extraction, the consumption of an extracting agent is saved, and the production efficiency is increased.

Owner:江西高信前沿科技有限公司

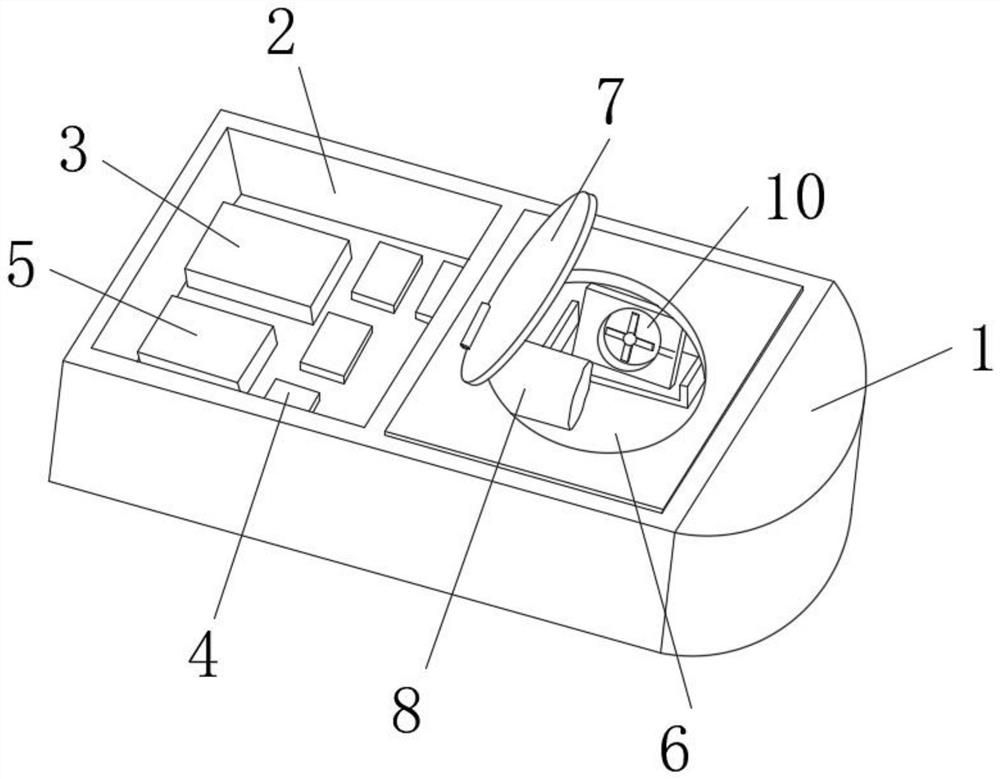

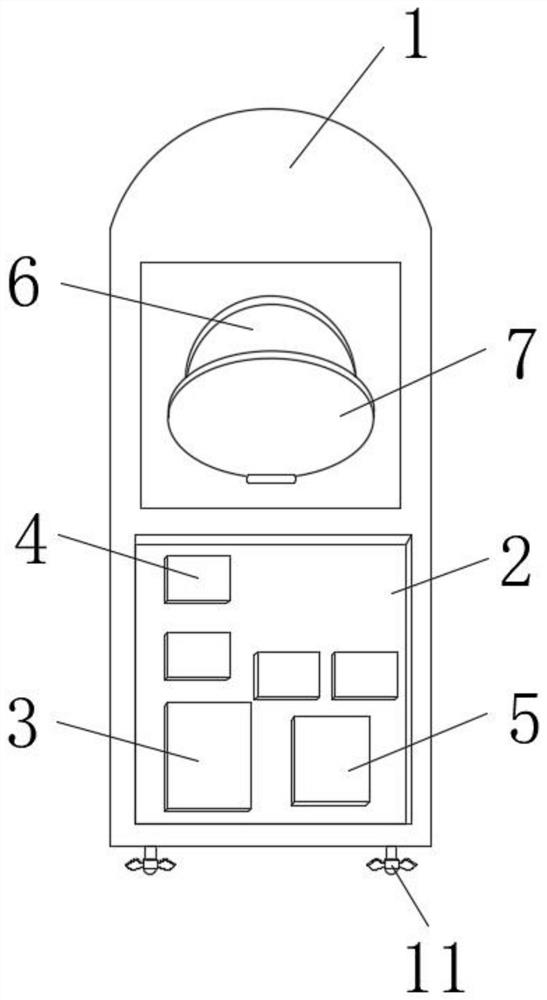

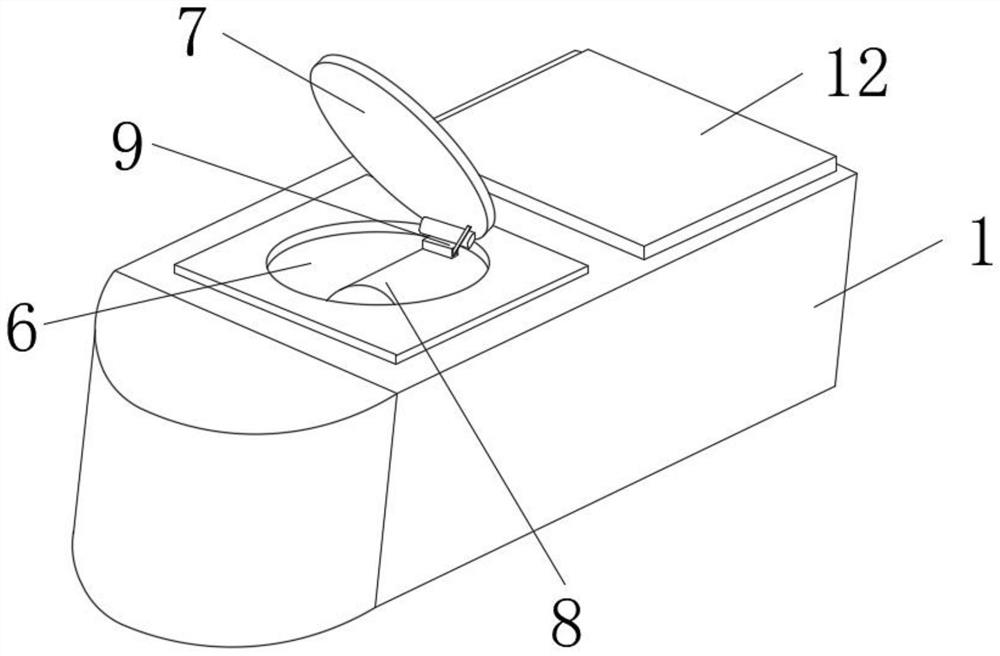

Measurement equipment for autonomously measuring radon concentration of water vapor interface

PendingCN113341449AEasy to measure on siteReduce measurement errorX/gamma/cosmic radiation measurmentStructural engineeringSingle chip

The invention relates to the technical field of measuring equipment, and discloses measuring equipment for autonomously measuring the radon concentration of a water vapor interface. The equipment comprises a measuring outer box, a mounting opening is formed in the left side of the top of the measuring outer box, a storage battery is bolted to the bottom of the inner wall of the mounting opening, four single chip microcomputers are bolted to the inner wall of the mounting opening and bolted to the right side of the storage battery; the position, located at the bottom of the storage battery, of the inner wall of the mounting opening is in bolted connection with a power bank, and a valve groove is formed in the right side of the top of the measuring outer box. By designing the measuring outer box, the mounting port, the storage battery, the single chip microcomputer and the power bank which are convenient to use, a measuring error can be reduced conveniently, the measuring accuracy is greatly improved, field measurement can be further facilitated, by designing the valve groove, a one-way valve, a radon eye, a steering engine and a fan which are convenient to use, measurement can be facilitated, drying is avoided, continuous automatic work is realized, the measuring efficiency is greatly improved, and the measurement equipment is worthy of popularization and application.

Owner:NANHUA UNIV

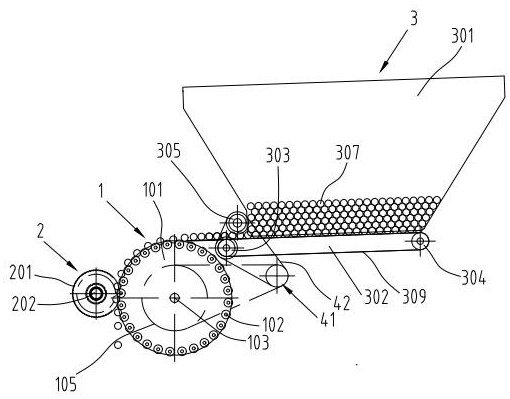

Rotating disc type bar-shaped food slitting device

PendingCN113510770ASolve the batch cutting problemContinuous automatic operationMetal working apparatusEngineeringFood item

The invention relates to a rotating disc type bar-shaped food slitting device. The device comprises a feeding component, a rotating disc component and a cutting component, wherein the cutting component comprises a cutting shaft and a cutting disc arranged on the cutting shaft; the feeding component is used for sequentially conveying long-strip-shaped food bars to the rotating disc component; the rotating disc component comprises a plurality of material distributing rods and two parallel rotating discs, the axes of the rotating discs are parallel to the axis of the cutting shaft, the material distributing rods are evenly distributed on the rotating discs around the axes of the rotating discs, the two ends of each material distributing rod are connected to the corresponding rotating disc, the distance between every two adjacent material distributing rods is smaller than the diameter of the food bars, the food bars are conveyed by the feeding component and then clamped and conveyed by the two adjacent material distributing rods, a notch corresponding to and matched with the cutting disc is formed in the outward side of each material distributing rod, and the food bars conveyed to the cutting component through the rotating disc component can be cut off through rotation of the cutting disc. Through rotary cutting of the cutting disc, the problem of batch cutting of the brittle laver compound food is solved, and the device has the technical characteristics of continuous and automatic operation, high production efficiency, good cutting effect and the like.

Owner:LIANYUNGANG HAIGONG MASCH CO LTD

High fructose syrup triple-effect concentration evaporator

InactiveCN104645644AContinuous automatic operationImprove work efficiencyFructose productionGlucose productionReboilerSingle effect

The invention provides a high fructose syrup triple-effect concentration evaporator. The evaporator comprises a first evaporator body, a second evaporator body, a third evaporator body, a material tank, an air pump, a cooling water tower, a vacuum pump and a finished product tank, wherein each evaporator body comprises a reboiler and an evaporation chamber, and the lower part of each reboiler is connected with the respective evaporation chamber; the bottom of the second reboiler is communicated with the bottom of the second evaporation chamber and is communicated to a fourth material pump; and the outlet of the fourth material pump is communicated to the finished product tank. The high fructose syrup triple-effect concentration evaporator can be used for overcoming the defects of low efficiency and long time of discharging of an existing single-effect evaporator and realizing continuous automatic operation and optimized utilization of vapor energy, and is high in production efficiency, energy-saving and environment-friendly.

Owner:武汉市金德戈糖业有限公司

Automatic cutting equipment for non-woven cotton cloth

ActiveCN110405847ASimple structureEasy to operateMetal working apparatusWebs handlingCotton clothMechanical engineering

The invention provides automatic cutting equipment for non-woven cotton cloth. The equipment comprises a rack, wherein material frames and a fixed-distance discharging mechanism are arranged on the rack, a material frame conversion mechanism, a guide roller, fixed-distance feeding rollers and a cutter mechanism are arranged among the material frames and the fixed-distance discharging mechanism insequence, the two material frames are symmetrically arranged, the material frames are provided with non-woven cotton cloth rolls, and the material frames are arranged at the upper end of the materialframe conversion mechanism; and the material frame conversion mechanism is in a rectangular shape, a sliding rail is arranged at the upper end of the material frame conversion mechanism, and the material frames are connected with the material frame conversion mechanism in a sliding mode. According to the automatic cutting equipment for the non-woven cotton cloth, the structure is simple, the operation is convenient, and the continuous automatic operation is realized; the double-material frame structure is adopted, so that the cotton cloth rolls can be replaced while the machine works, and theproduction efficiency is further improved; and intelligent constant-tension mechanisms are adopted, so that the consistency of the product size and specification is further ensured.

Owner:昆山特力佳机电设备有限公司

A radar for accurate measurement of river surface flow field based on computational intelligence

ActiveCN113820708BSimple designSolve the real problemFull-field flow measurementRadio wave reradiation/reflectionRadar systemsAlgorithm

The invention discloses a radar for accurately measuring river surface flow field based on computational intelligence, and specifically relates to the technical field of flow measurement, including software structure and hardware structure. The radar system adopts encoding technology on the signal waveform to achieve anti-interference, adopts fuzzy clustering intelligent algorithm to ensure the stability and reliability of observation data, adopts polyline array weighted optimization to realize high-precision river surface vector field synthesis under the condition of large viewing angle, and adopts variance weighted intelligent algorithm to reduce Data jitter improves the stability of observation vector data, and remote data analysis based on big data and artificial intelligence technology is adopted. The present invention integrates anti-jamming means, intelligent processing technology, high-resolution polyline array angle resolution technology, fuzzy clustering technology and filtering jitter reduction technology and other intelligent algorithms, and designs a corresponding hardware structure for related intelligent technologies, effectively solving the problem of Problems with traditional equipment.

Owner:南京微麦科斯电子科技有限责任公司

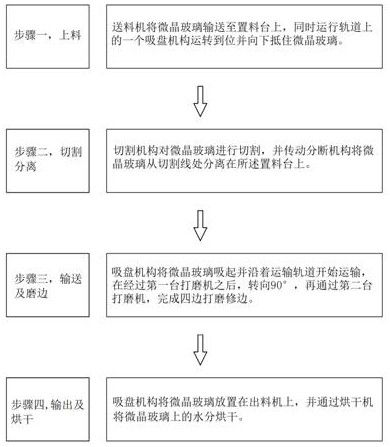

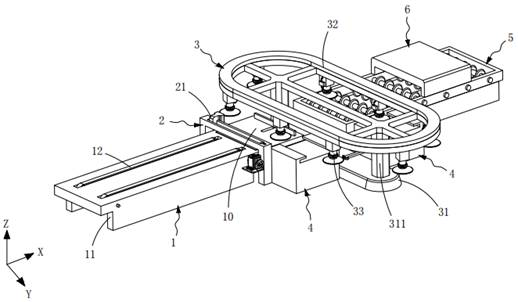

A kind of glass-ceramic continuous production equipment and method

ActiveCN113320029BContinuous automatic operationImprove work efficiencyEdge grinding machinesWorking accessoriesMechanical engineeringCeramic

The invention relates to the field of glass-ceramic production and processing, in particular to a continuous production equipment for glass-ceramic, comprising a feeder, a cutting and dividing machine, a suction cup conveyor, two grinders, a discharger and a dryer, and the end of the feeder A feeding table is connected and installed; the cutting and breaking machine is installed at the end of the feeding machine, which consists of a cutting mechanism and a breaking mechanism. During operation, the cutting mechanism and the breaking mechanism cut and separate the glass-ceramic on the feeding table through transmission cooperation; the suction cup The conveyor is set at the end of the feeder, and its main body is a straight notch type, and the glass-ceramics on the feeding table are continuously conveyed through several suction cup mechanisms evenly distributed, and at the same time, the surrounding of the glass-ceramic is completed during the conveying process. The edging and trimming also provides a continuous production method for glass-ceramic, which solves the technical problem of automatically cutting and separating the glass-ceramic and continuously conveying the glass-ceramic during the production and processing of the glass-ceramic, and improves the production efficiency.

Owner:ZHEJIANG CHANGXING NOVATECH GLASS

A method of continuous deep dehydration and solar energy synergistically drying sludge

ActiveCN105819663BImprove distributionImprove dehydration effectSludge treatment by de-watering/drying/thickeningResource utilizationMoisture

The invention belongs to the technical field of sludge treatment and disposal, and relates to a continuous-deep-dewatering and solar-energy synergy sludge drying method. The continuous-deep-dewatering and solar-energy synergy sludge drying method includes the steps that primarily-dewatered sludge is subjected to continuous deep dewatering, and then subjected to solar-energy drying treatment, wherein continuous deep dewatering treatment comprises the sludge modifying treatment process and the squeezed dewatering treatment process. The invention further provides a continuous-deep-dewatering and solar-energy synergy sludge drying system. The continuous-deep-dewatering and solar-energy synergy sludge drying method can be widely applied to dewatering treatment of primarily-dewatered sludge of a sewage treatment plant, the moisture content of the primarily-dewatered sludge is reduced to 30% to 40% from 75% to 85%, and reduction, harmless and resource utilization of sludge is finally achieved.

Owner:TONGJI UNIV +1

A washing method for genetically engineered inclusion bodies

ActiveCN102977183BWon't clogHigh purityPeptide preparation methodsInclusion bodiesGenetic engineering

The invention discloses a washing method of a genetic engineering inclusion body. According to the washing method, the genetic engineering inclusion body is washed by adopting a hollow fiber membrane, and therefore the continuous automatic operation can be realized. The washing method has the advantages of being simple in process and convenient for operation, and improving the production efficiency; and the genetic engineering inclusion body has the advantages of high yield and high purity, and is especially suitable for application in the large-scale industrial production.

Owner:鲁南新时代生物技术有限公司

Cell culture pipeline device and automatic cell culture system

ActiveCN103031250BEffective trainingGuaranteed normal growthBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpCulture fluid

The invention discloses a cell culture pipeline device, which comprises a main circulating pump, a gas exchange tube, a culture tube and a culture solution main library which are sequentially connected through a guide tube, wherein a micro-pore exhaust hole communicated with the atmosphere is formed on the culture solution main library; the gas exchange tube is a cured silicone tube; and the main circulating pump is a finger peristaltic pump. The invention also discloses an automatic cell culture system, which comprises a sensor arranged nearby a transparent testing container, and also comprises a liquid filling device which is connected with a first guide tube through a fifth guide tube and a waste liquid recovery device which is connected with a third guide tube through a sixth guide tube. The cell culture pipeline device is simple in structure, easy and convenient to operate and high in culture efficiency, as well as the automatic cell culture system employing the cell culture pipeline device.

Owner:浙江赛尚医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com