Rotating disc type bar-shaped food slitting device

A turntable and turntable technology, applied in metal processing, etc., to achieve stable production process, high production efficiency and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

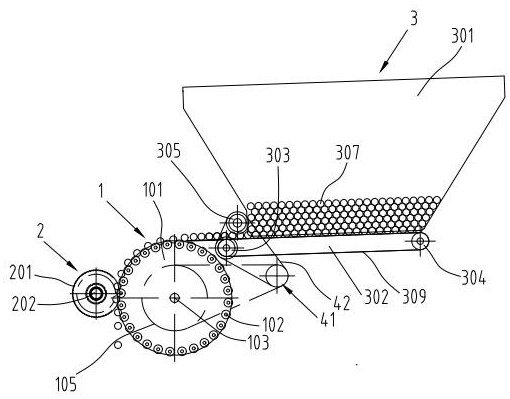

[0029] like figure 1 As shown, the slitting device of the present embodiment is used to cut the long-shaped food rod 307, such as a rosewood, sandwich purple stick, and the like. The dividing device includes a feed assembly 3, a turntable assembly 1, and a cutting assembly 2, and the food rod 307 is delivered to the turntable assembly 1 via the feed assembly 3, and then transported by the turntable assembly 1 to the cutting assembly 2 position to cut into multiple segments.

[0030] The cutting assembly 2 includes a cutting shaft 202 and a cutting disk 201 disposed on the cutting shaft 202, and the cutting shaft 202 is rotatably fixed to the rack through the bearing, and the corresponding motor is rotated, the cutting shaft 202 rotates the cutting disk 201 rotation, The cutting tray 201 is preferably a disc type toothed knife, and the rotating cutting disc 201 can be cut off the food rod 307 through the cutting disc.

[0031] The feed assembly 3 includes a tip 301, a feed belt 302...

Embodiment 2

[0036] like Image 6 , Figure 7As shown, the dividing device of the present embodiment, on the basis of the first embodiment, and includes a radial limit piece 10403, a radial limit member 10403 is a curved plate-like structural member, and the radial limit piece 10403 is set at least. At the outer side of the turntable assembly 1 from the feed assembly 3 to the cutting assembly 2, the food rod 307 on the turntable assembly 1 does not detach from the turntable assembly 1 during the transmission process.

[0037] It may also include a two-axial limit piece 10402, and the axial limit member 10402 is an arcuate plate structure member, which corresponds to the radial limit member 10403, and is limited to the food rod 307, so that the food rod 307 The length of the length is the same.

[0038] It may also include a restricted plate 308, which is disposed in the feed assembly 3, and the length of the food rod 307 that is greater than the two axial limit piece 10402 is prevented from ente...

Embodiment 3

[0044] The division device of the present embodiment is the same as that of the above-described embodiment, and distinguishes that the turntable assembly of the present embodiment is different.

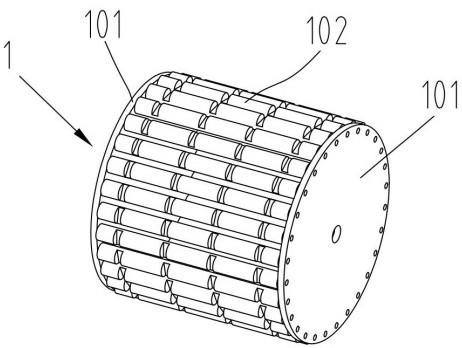

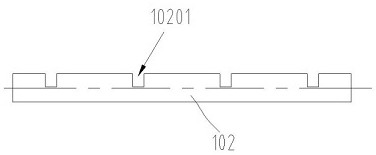

[0045] like Figure 8-10 As shown, the turntable assembly 1 of the present embodiment includes a plurality of tooth discs 106, and the outer peripheral surface of the toothed disk 106 has a circular arc groove pit 10601, and a plurality of toothed trays are connected together by the coaxial shaft 103, which can be The center shaft 103 is rotated together, and the turntable assembly 1 can be rotatable on the rack through the central shaft 103. The center of the circular arc groove pit 10601 on each tooth disc 106 is arranged in the axial direction of the center shaft 103, which constitutes a housing groove that houses the food rod 307, and a gap between the adjacent coil group is provided. The gap 10201 is used to accommodate the cutting disc 201.

[0046] The same side of the turntable ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com