A kind of glass-ceramic continuous production equipment and method

A technology for glass-ceramics and production equipment, applied in stone processing equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of increasing labor costs and affecting production efficiency, so as to improve work efficiency and save labor costs , the effect of preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

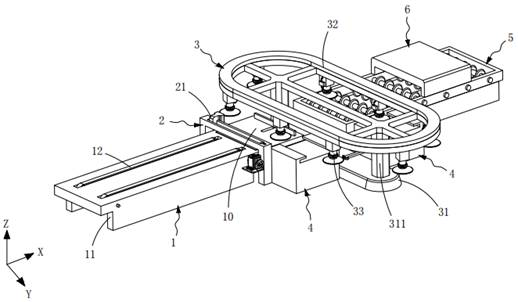

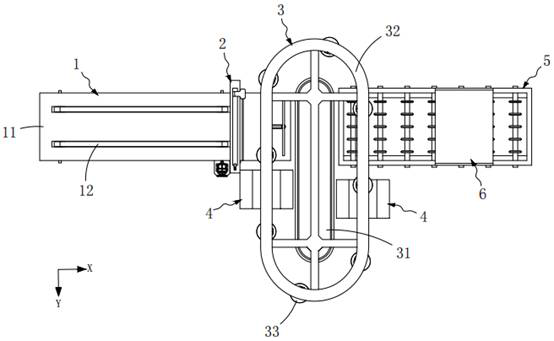

[0070] like figure 2 , image 3 As shown, a continuous production equipment for glass-ceramic includes a dividing device, a transferring device, a softening device, a forming device and a post-processing device sequentially arranged from front to back along the processing direction of the glass-ceramic, and the dividing device includes:

[0071] The feeder 1, the end of which is connected and installed with a feeding table 10;

[0072] The cutting and breaking machine 2, the cutting and breaking machine 2 is installed at the end of the feeder 1, and is composed of a cutting mechanism 21 and a breaking mechanism 22. During operation, the cutting mechanism 21 and the breaking mechanism 22 are connected by transmission. The glass-ceramic is cut and separated on the loading table 10;

[0073] Suction cup conveyor 3, the suction cup conveyor 3 is arranged at the end of the feeder 1, and its main body is a straight notch type, which continuously conveys the glass-ceramic on the f...

Embodiment 2

[0115] like figure 1 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

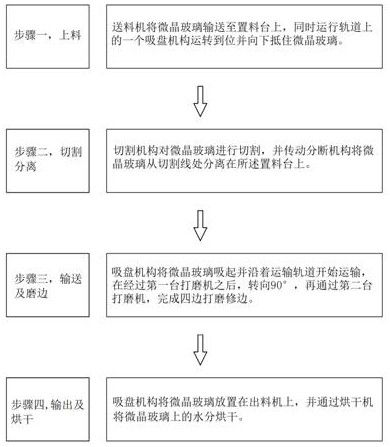

[0116] A method for continuous production of glass-ceramic, comprising a glass plate cutting process, an edge grinding and trimming process, a process of placing a mold on a rotary mold car, a preheating process in a tunnel kiln, a hot bending softening process, and a vacuum pump suction in the mold. The forming process, the thermal insulation crystallization process, the cooling process and the finished glass-ceramic product process, the glass plate cutting process includes the following steps:

[0117] Step 1, feeding: the feeder 1 transports the glass-ceramic to the feeding table 10, and at the same time, one of the suction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com