Patents

Literature

55results about How to "Stable cutting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

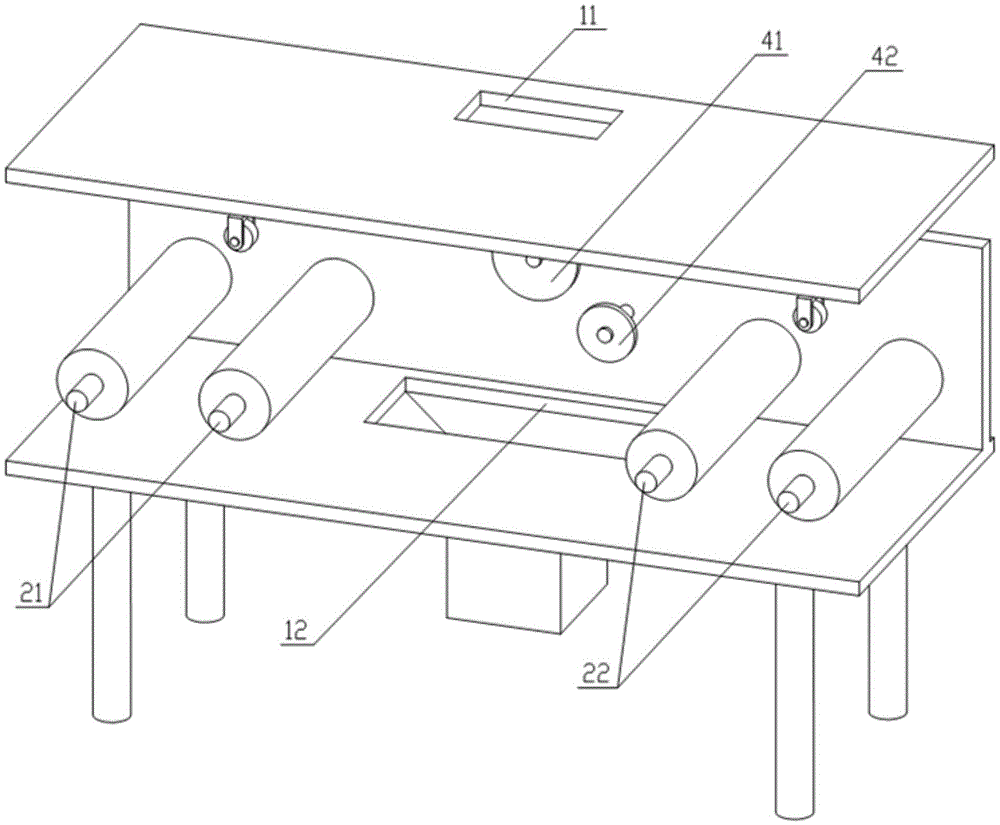

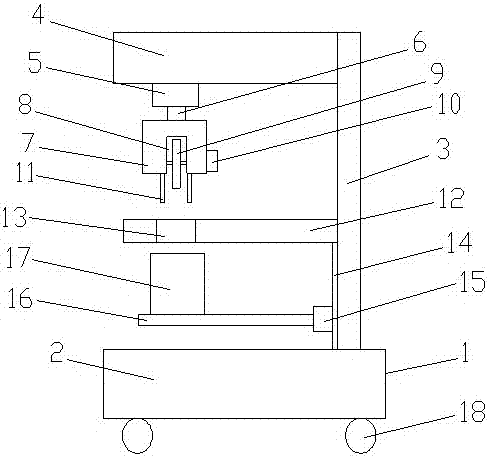

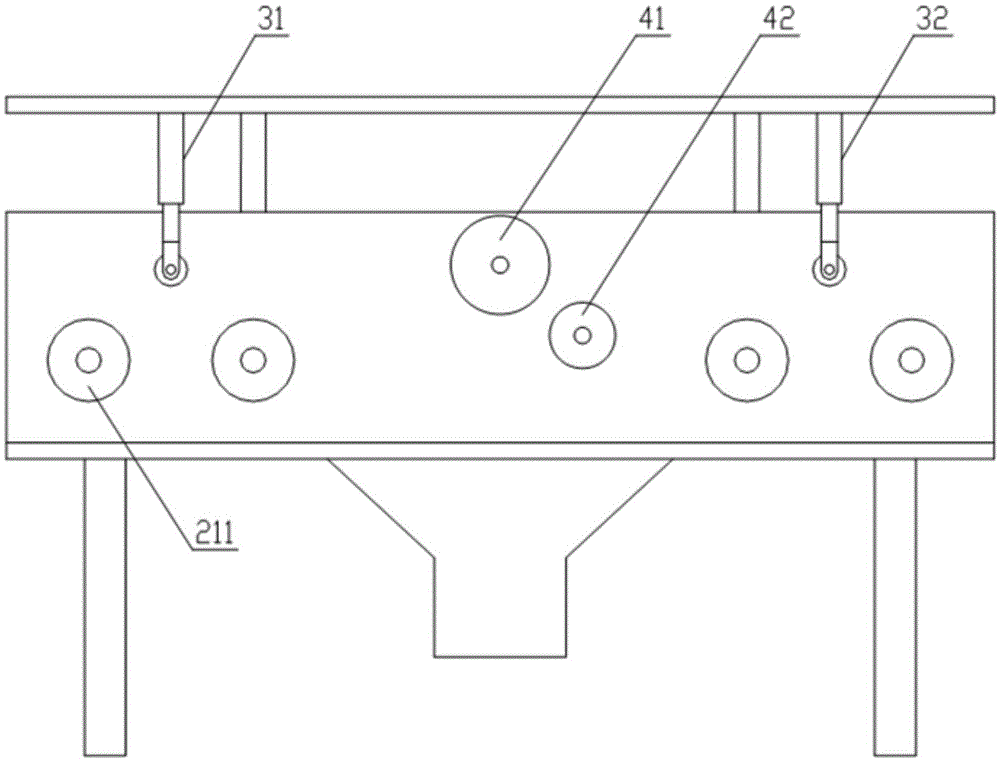

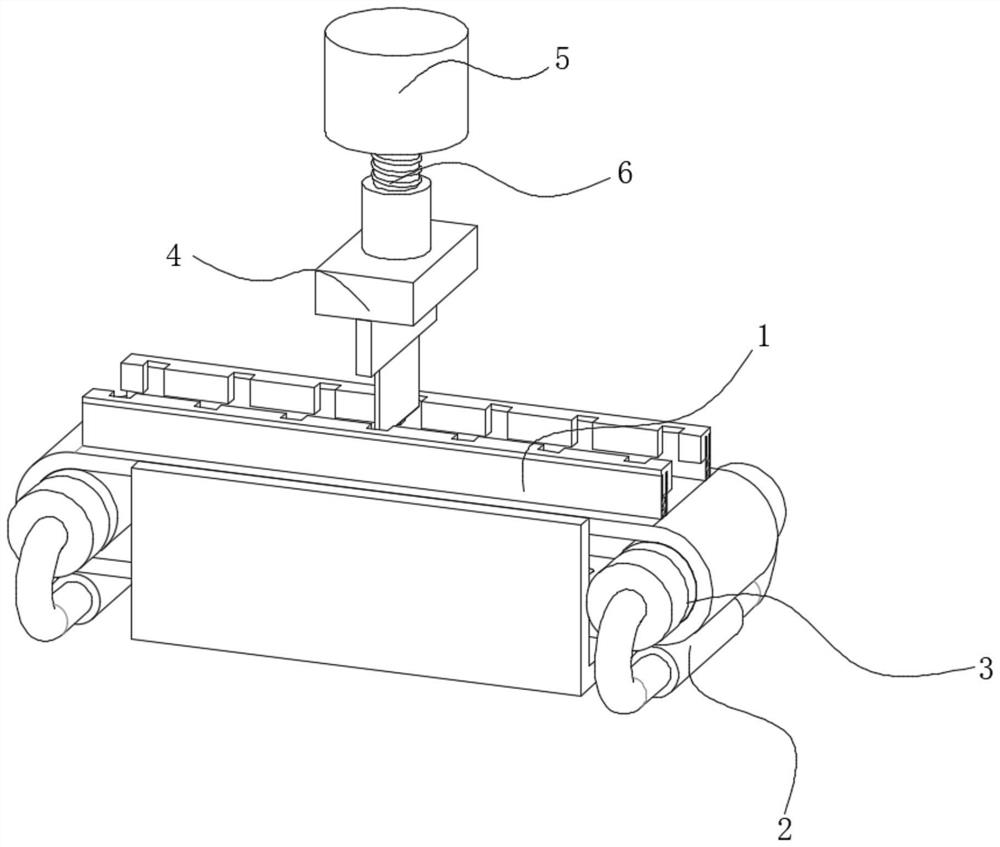

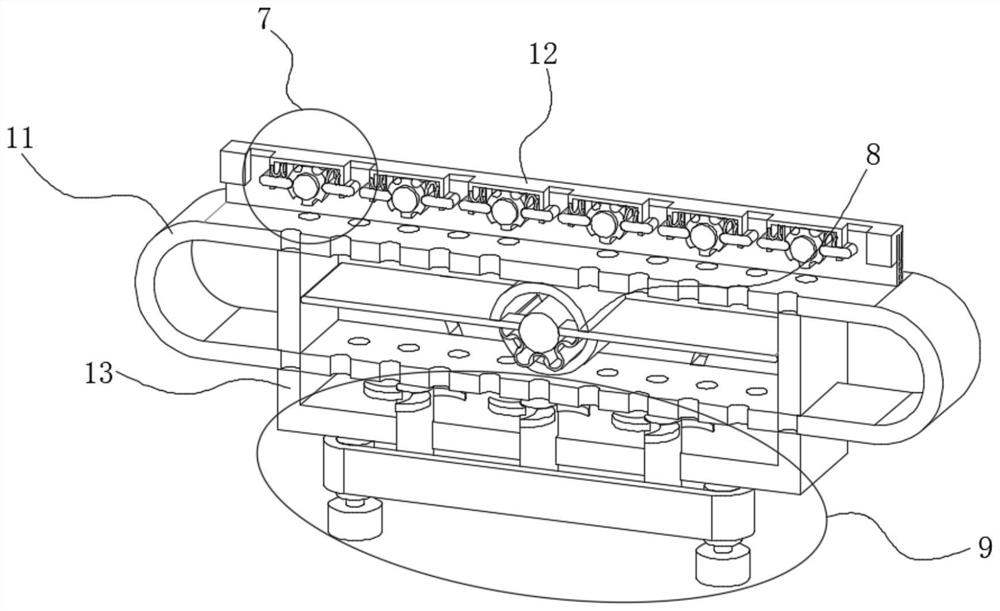

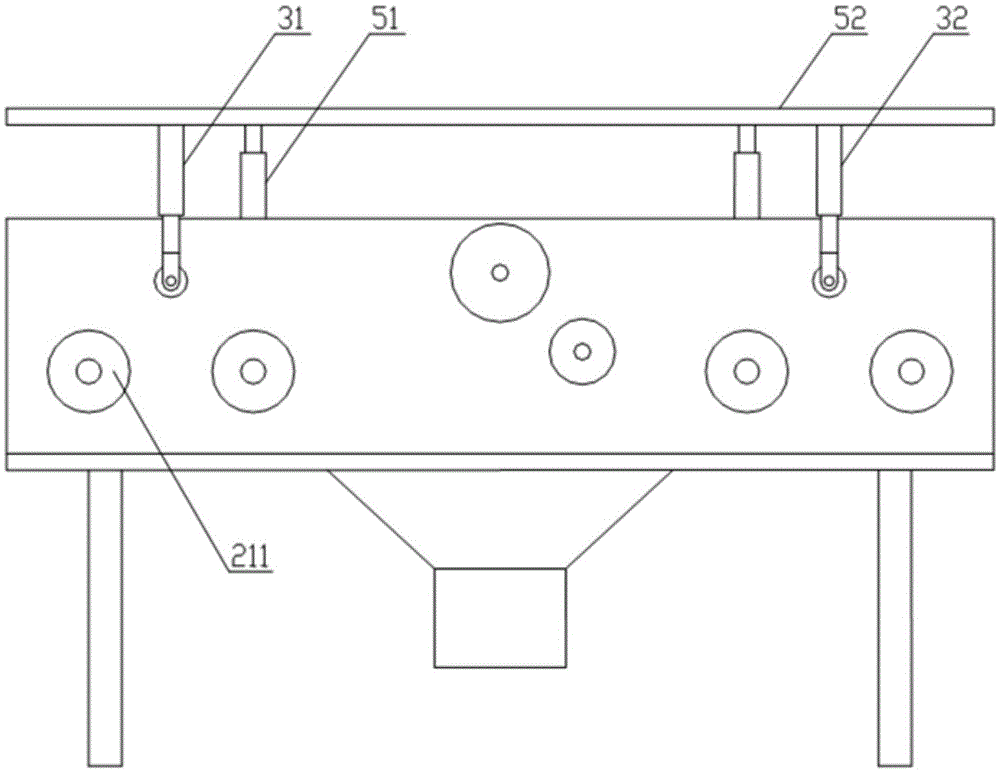

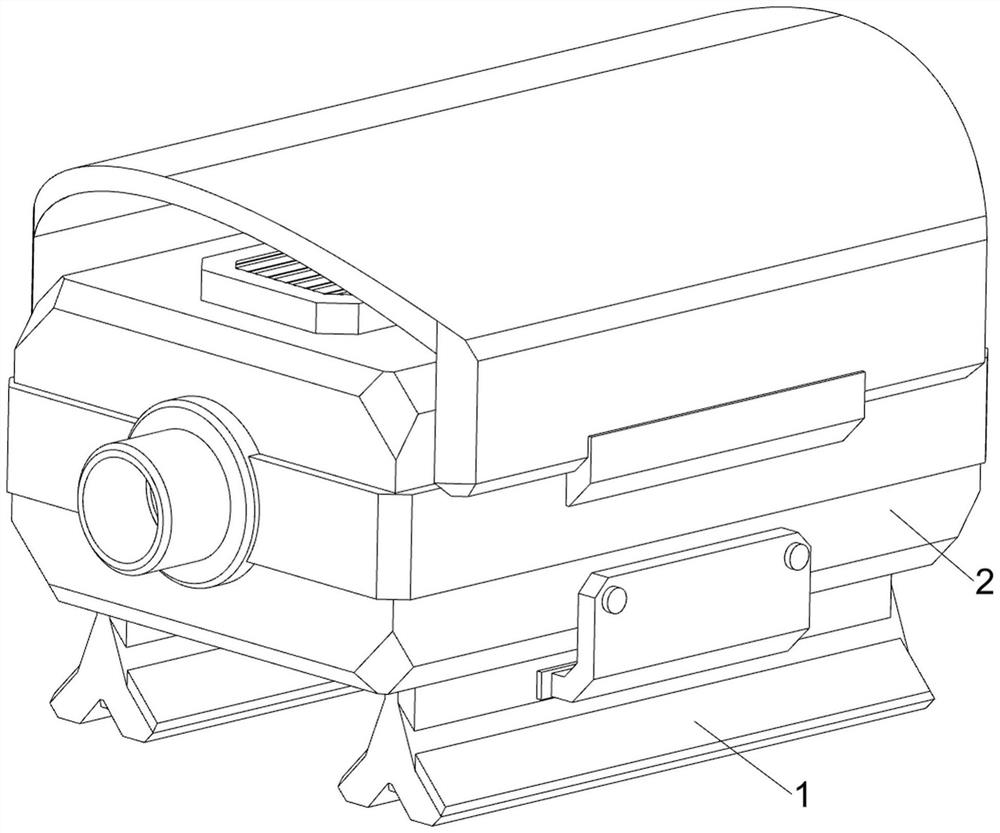

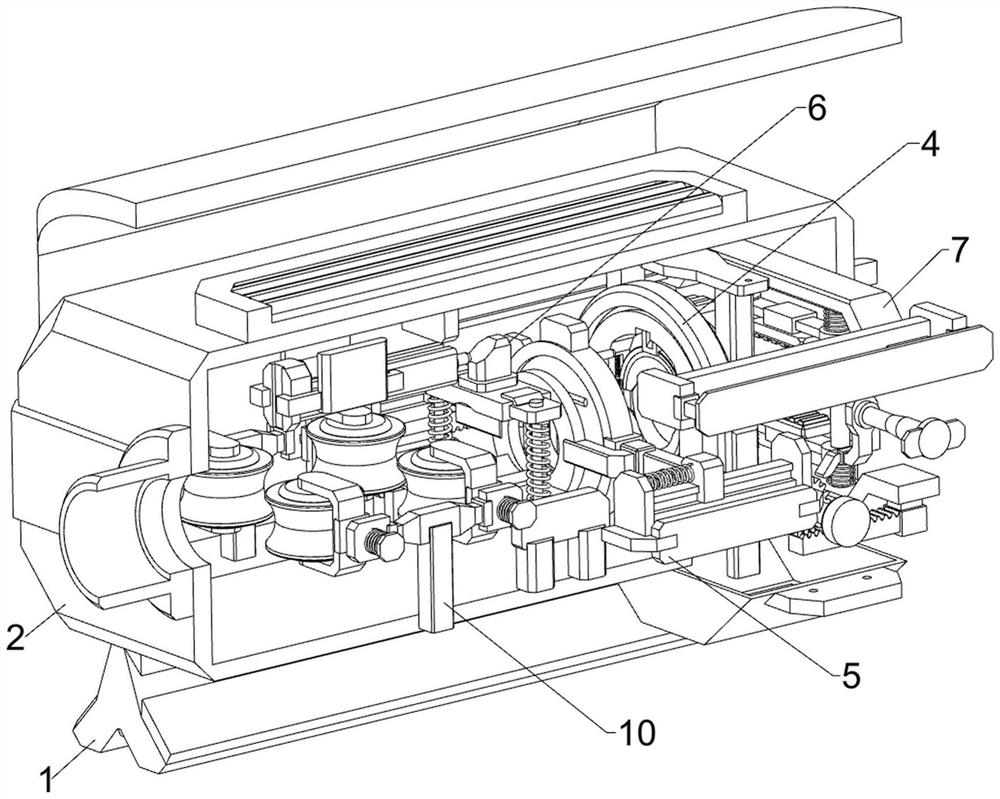

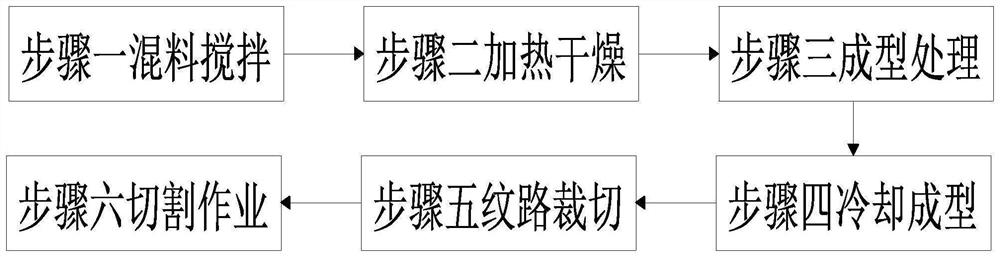

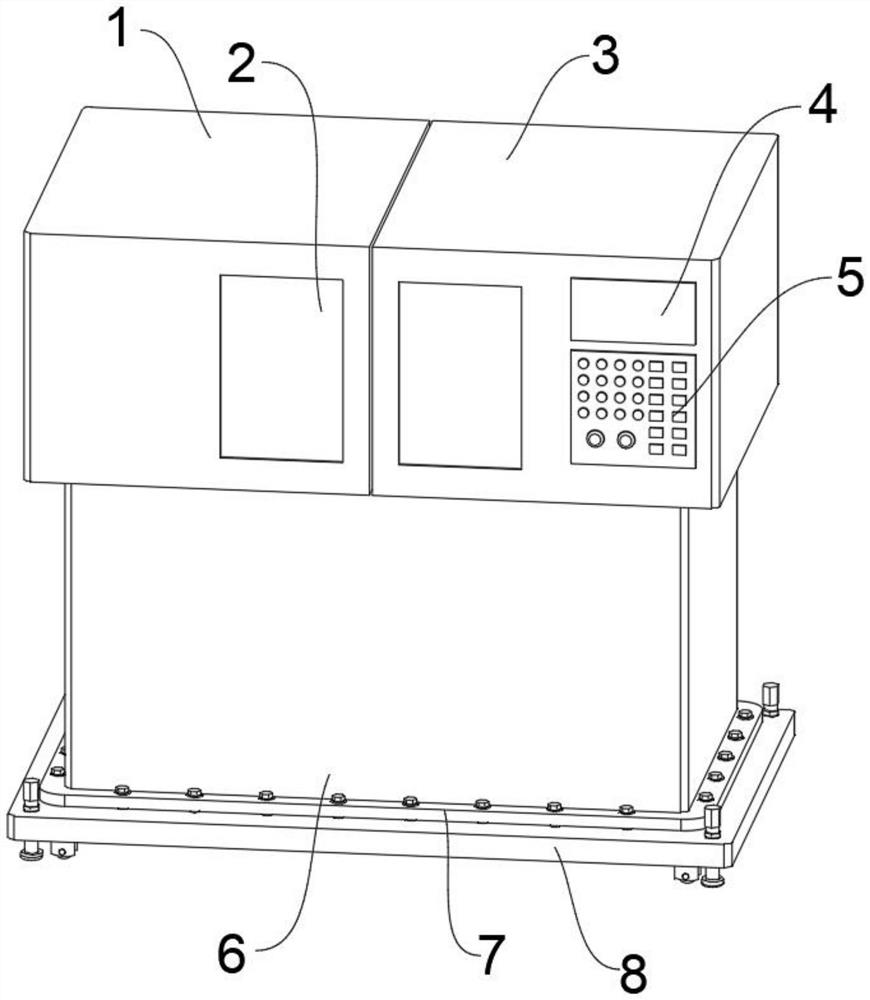

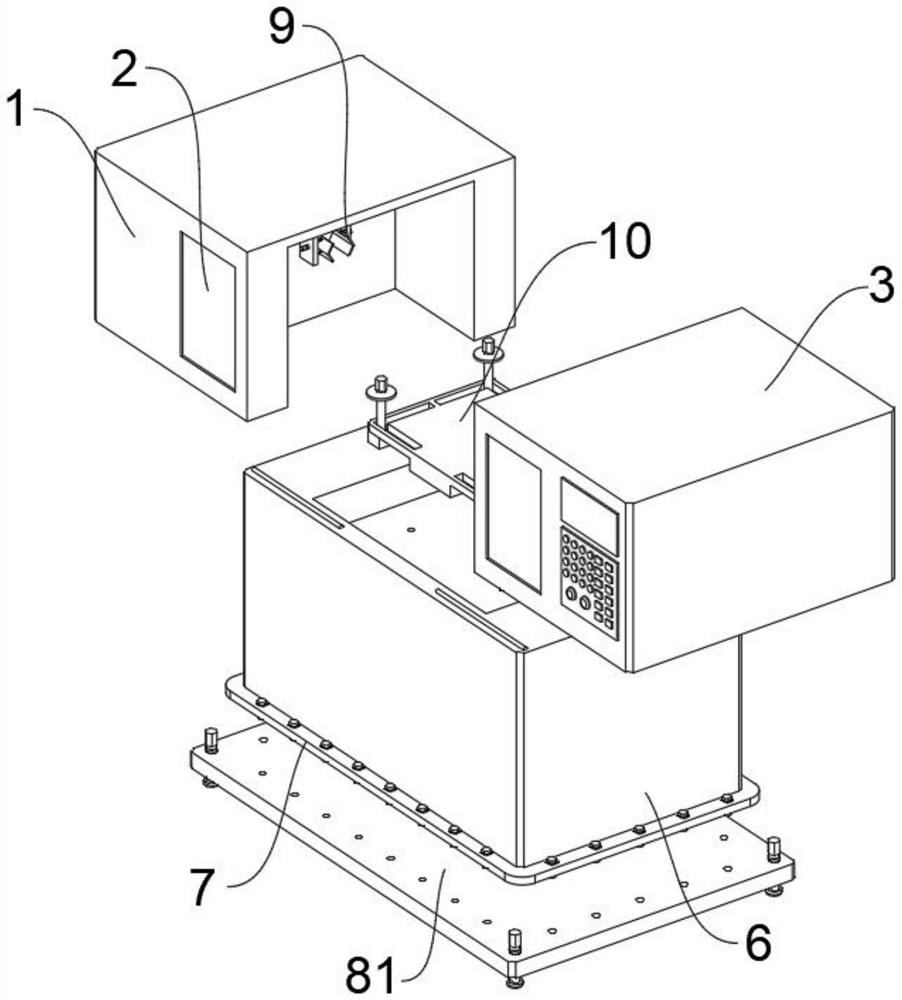

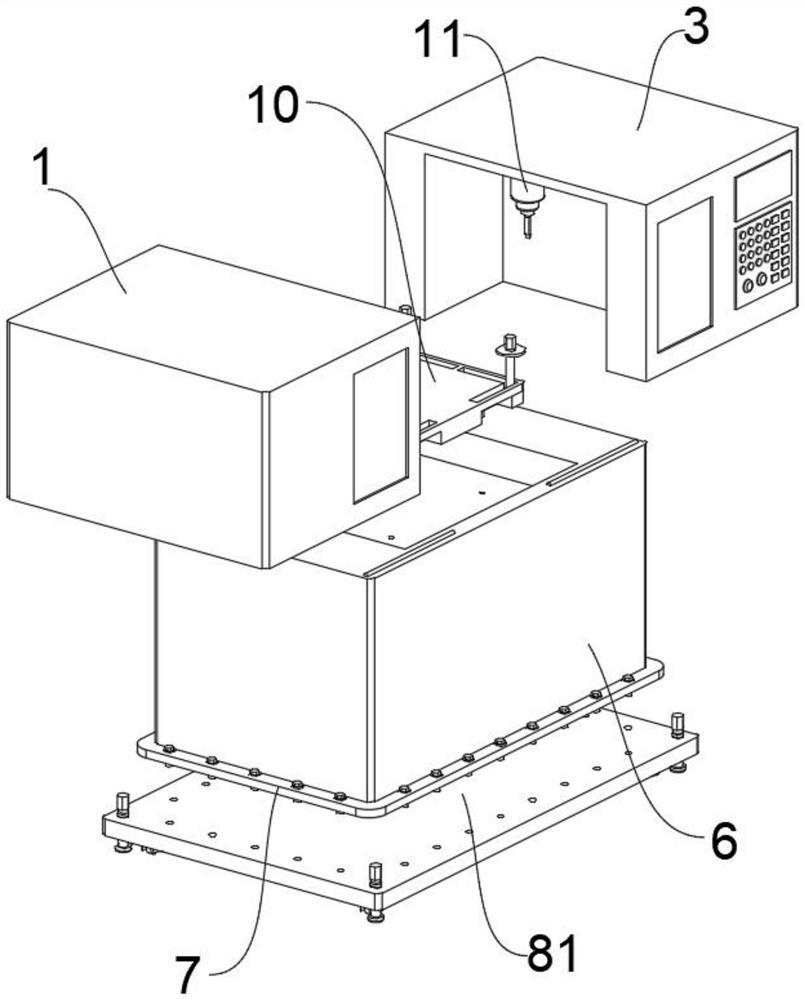

Novel wood cutting device

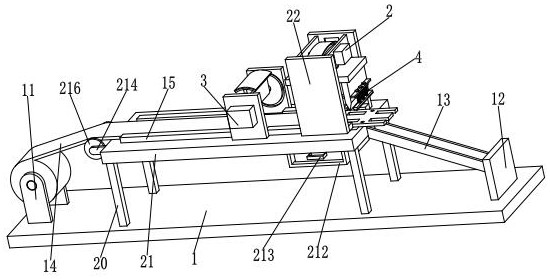

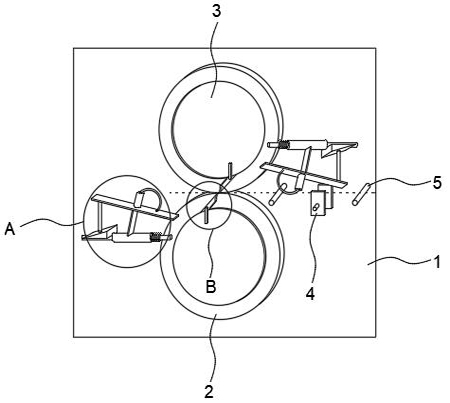

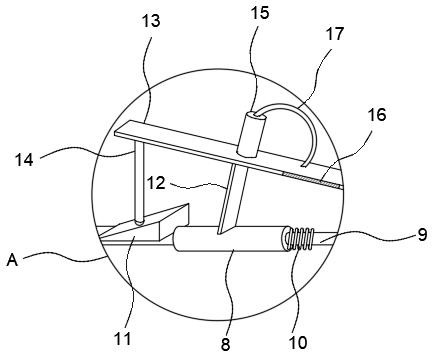

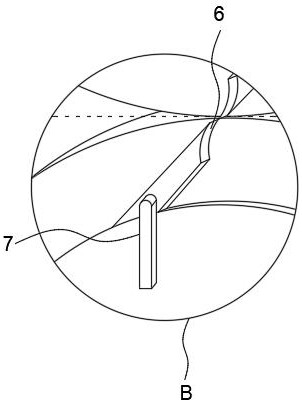

The invention discloses a novel wood cutting device. The novel wood cutting device comprises a machine body (1), a conveying device (2), a pressing device (3), a cutting device body (4) and a scrap blowing device (5). The pressing device (3) is located above the conveying device (2). The conveying device (2) comprises first conveying roller sets (21) and second conveying roller sets (22), wherein the first conveying roller sets (21) and the second conveying roller sets (22) are located on the same horizontal line. The cutting device body (4) is located between the first conveying roller sets (21) and the second conveying roller sets (22) in the horizontal direction and located between the conveying device (2) and the pressing device (3) in the vertical direction. The scrap blowing device (5) is aligned with the cutting device body (4) in the vertical direction. According to the novel wood cutting device, wood conveyed through the conveying device is cut via the cutting device body, the wood is pressed on the conveying device through the pressing device, and it is guaranteed that the cutting process is stably and automatically conducted. The whole device is simple in structure, high in stability and efficient in work and has application and popularization value.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

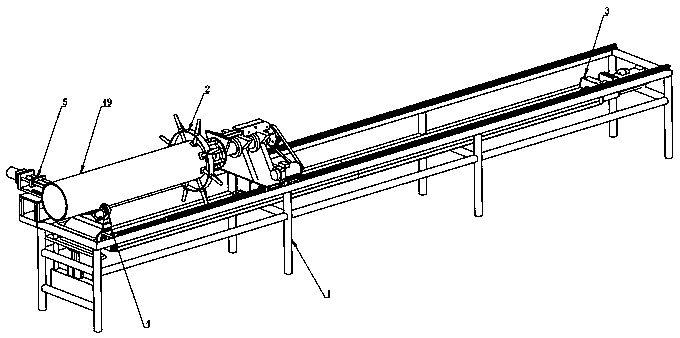

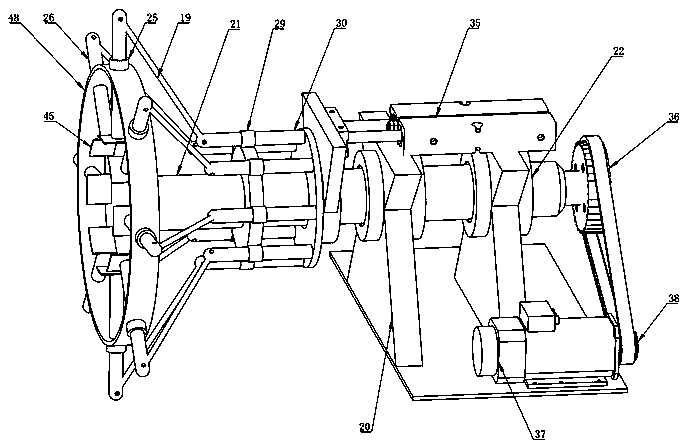

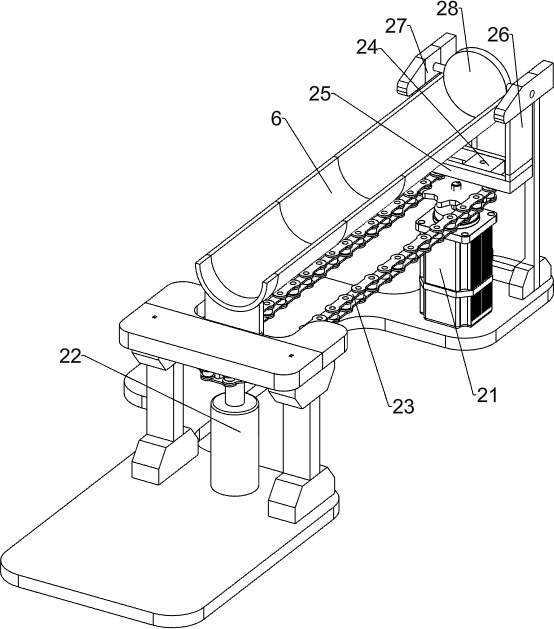

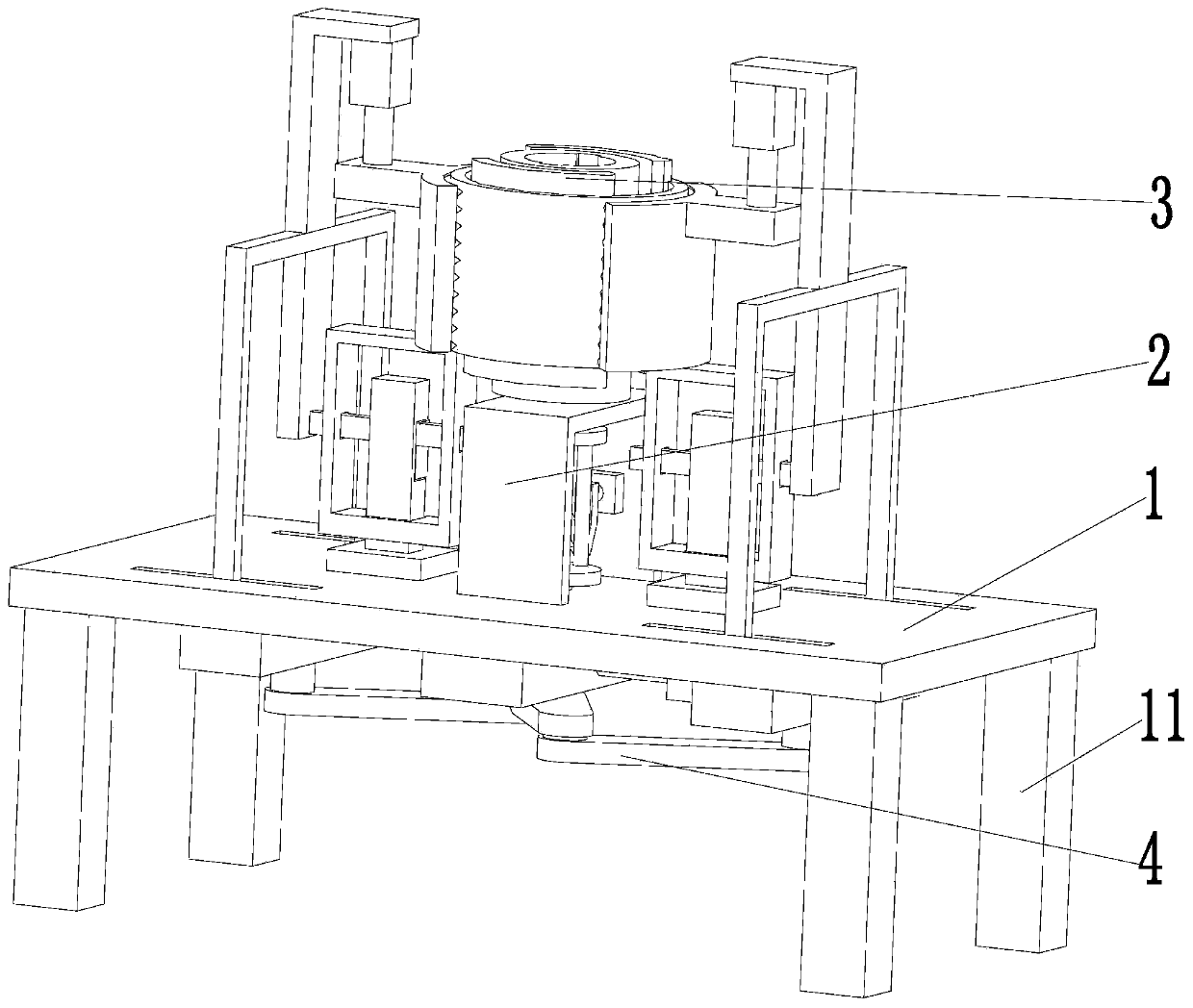

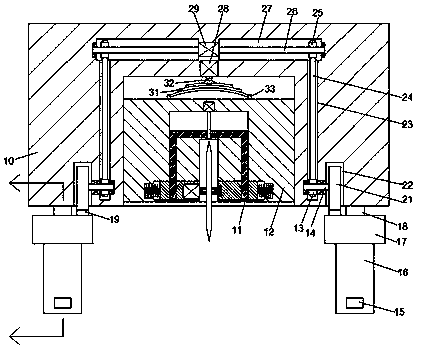

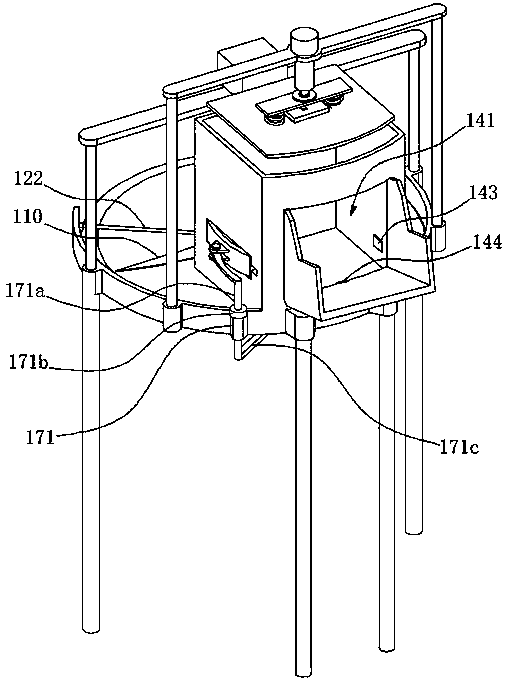

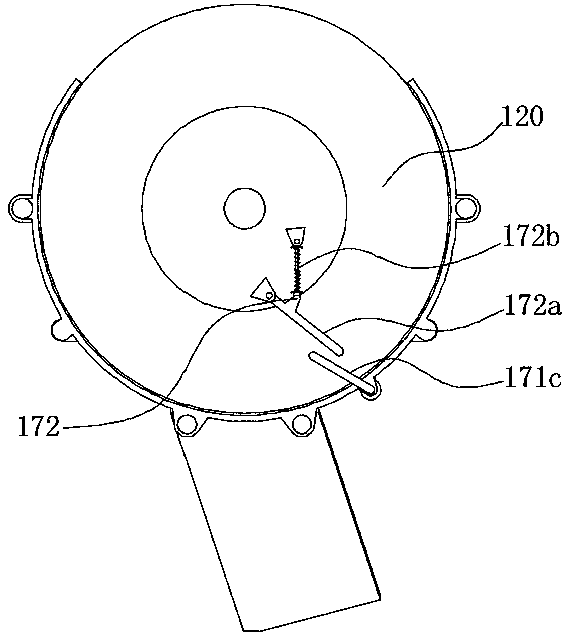

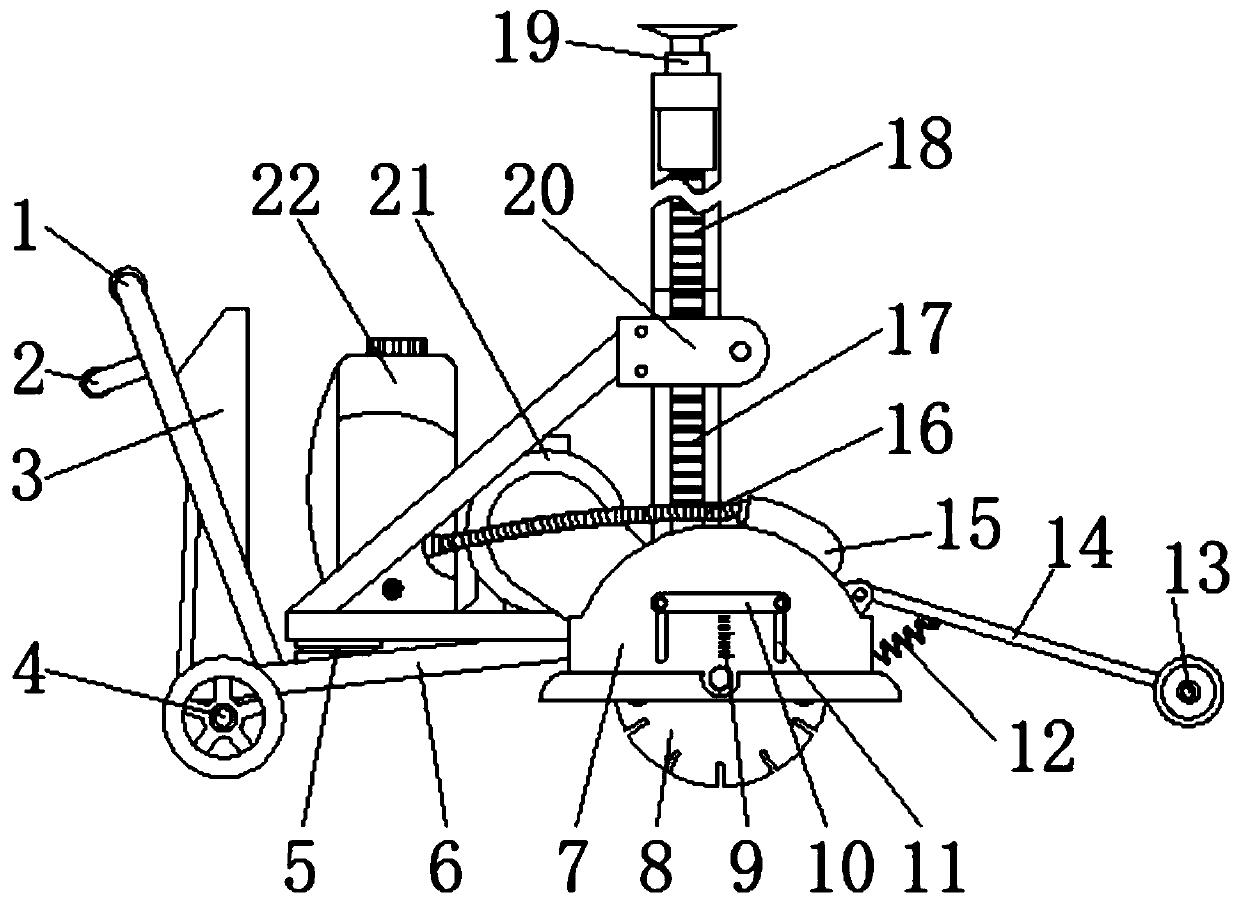

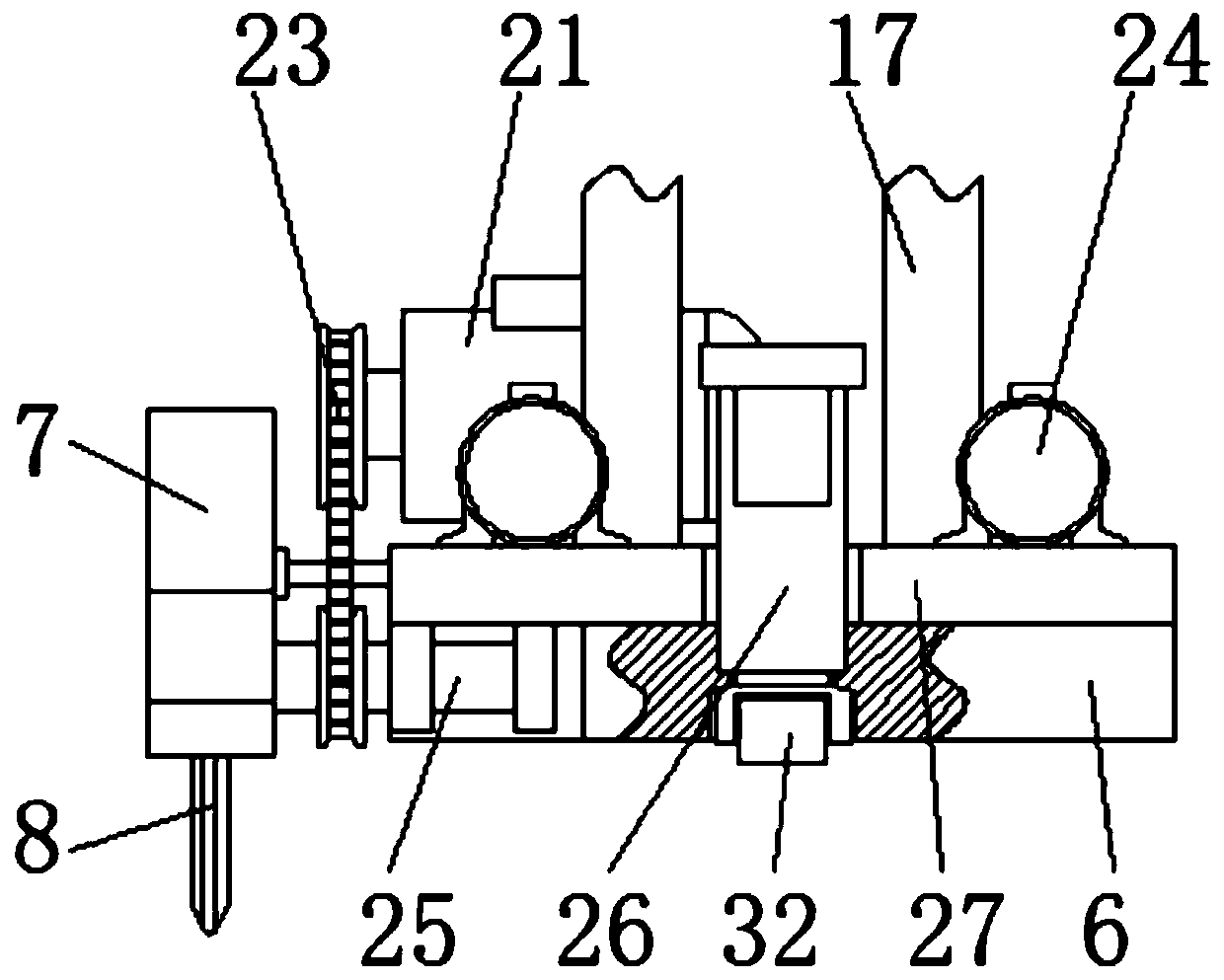

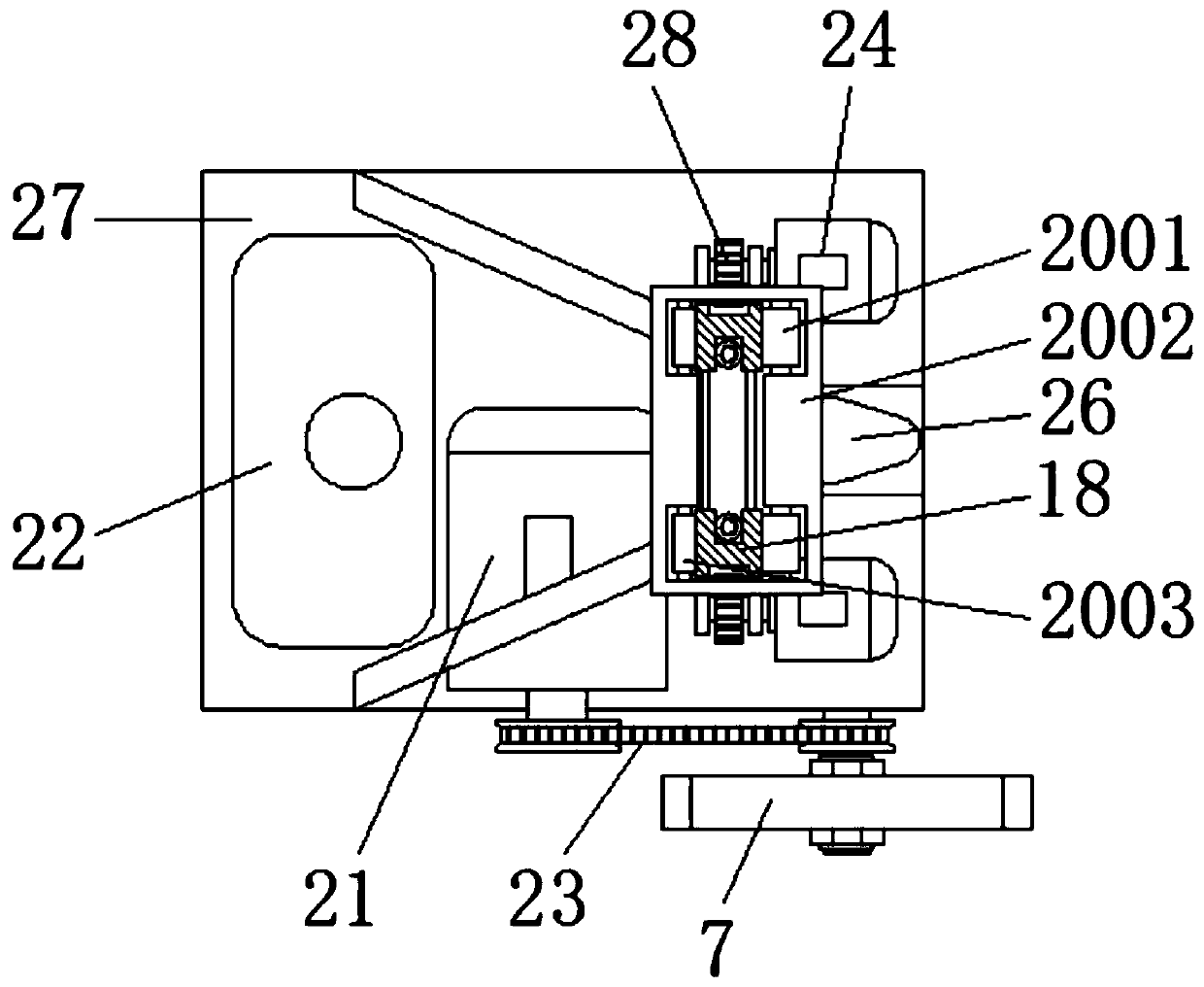

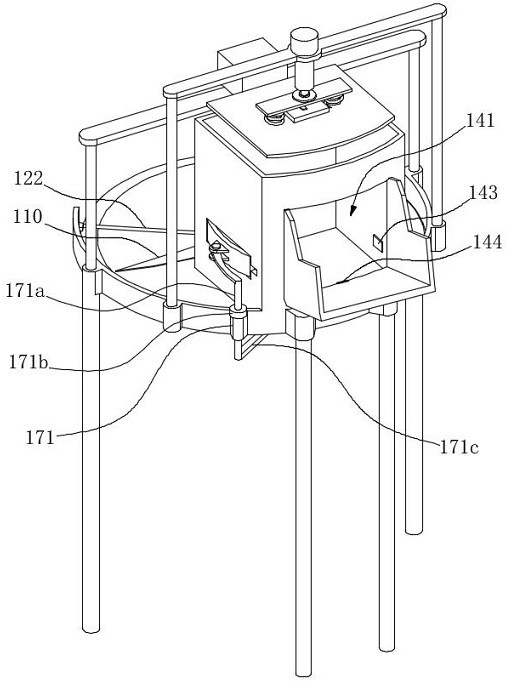

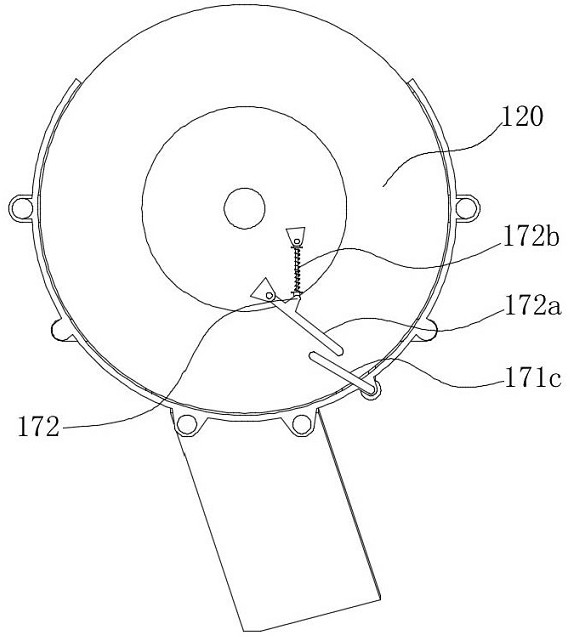

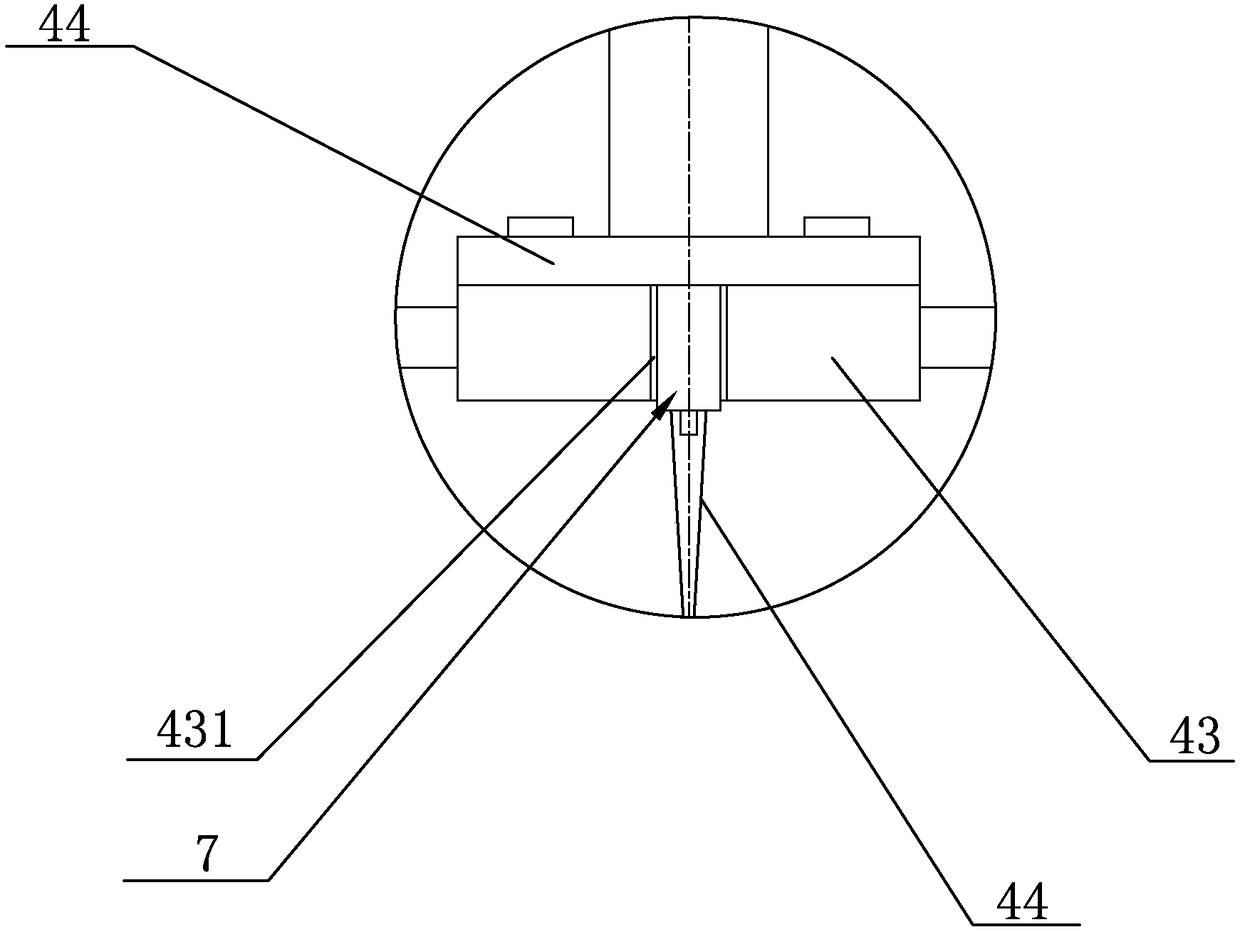

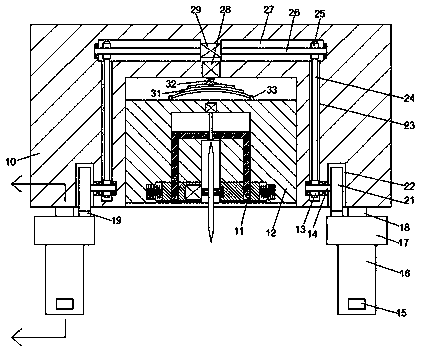

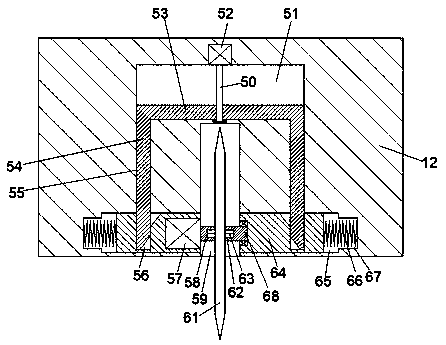

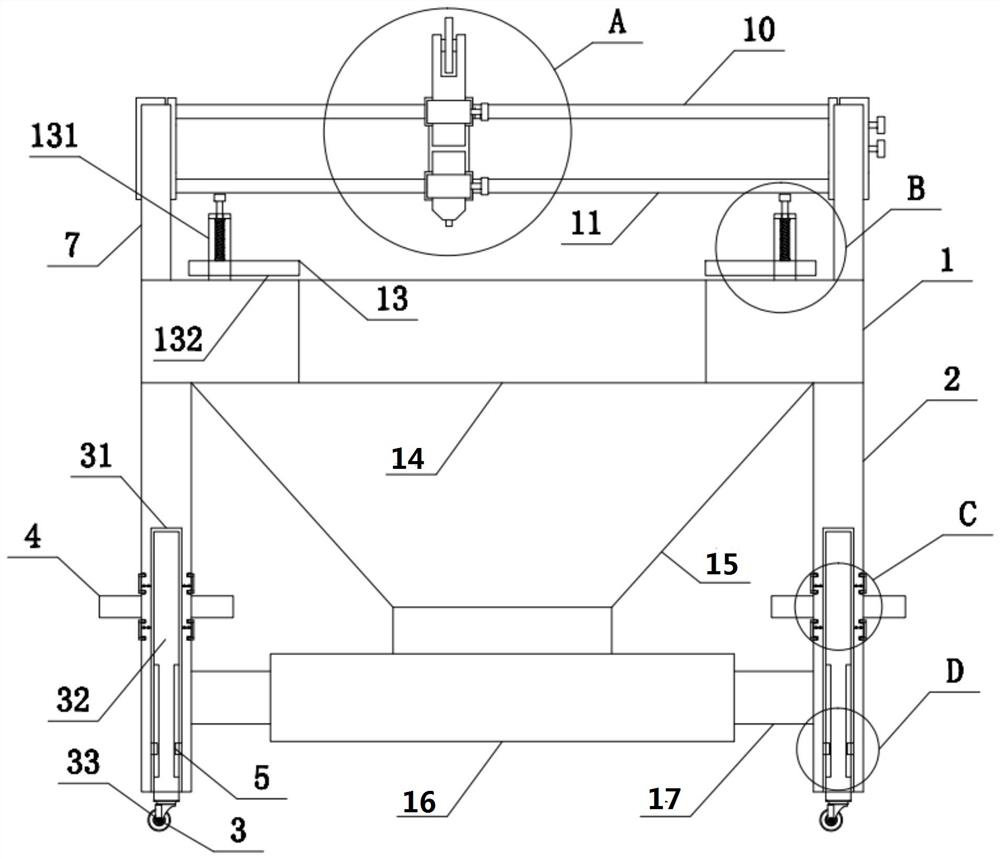

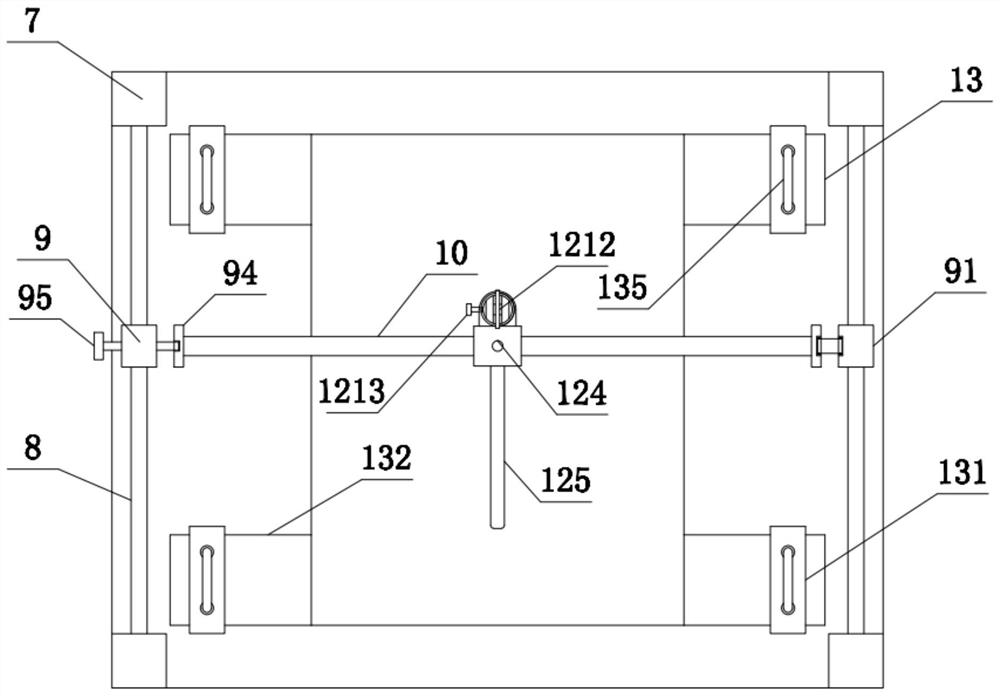

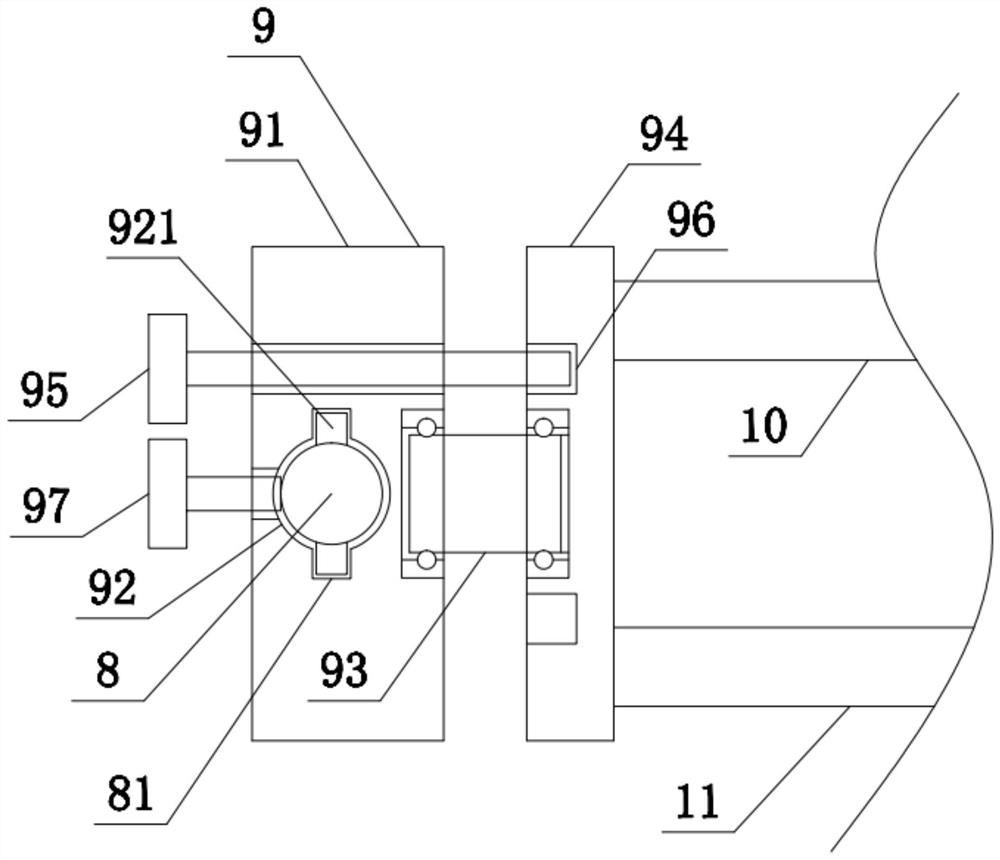

Special automatic circular pipe plasma cutting machine for expressway construction process and use method

ActiveCN109128460ANo extrusion deformationNo loosening of fixation occursWelding/cutting auxillary devicesAuxillary welding devicesGeneral assemblyMechanical equipment

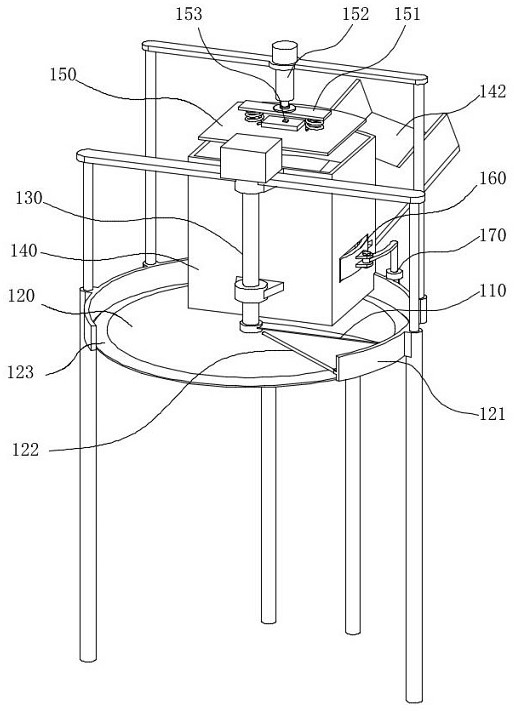

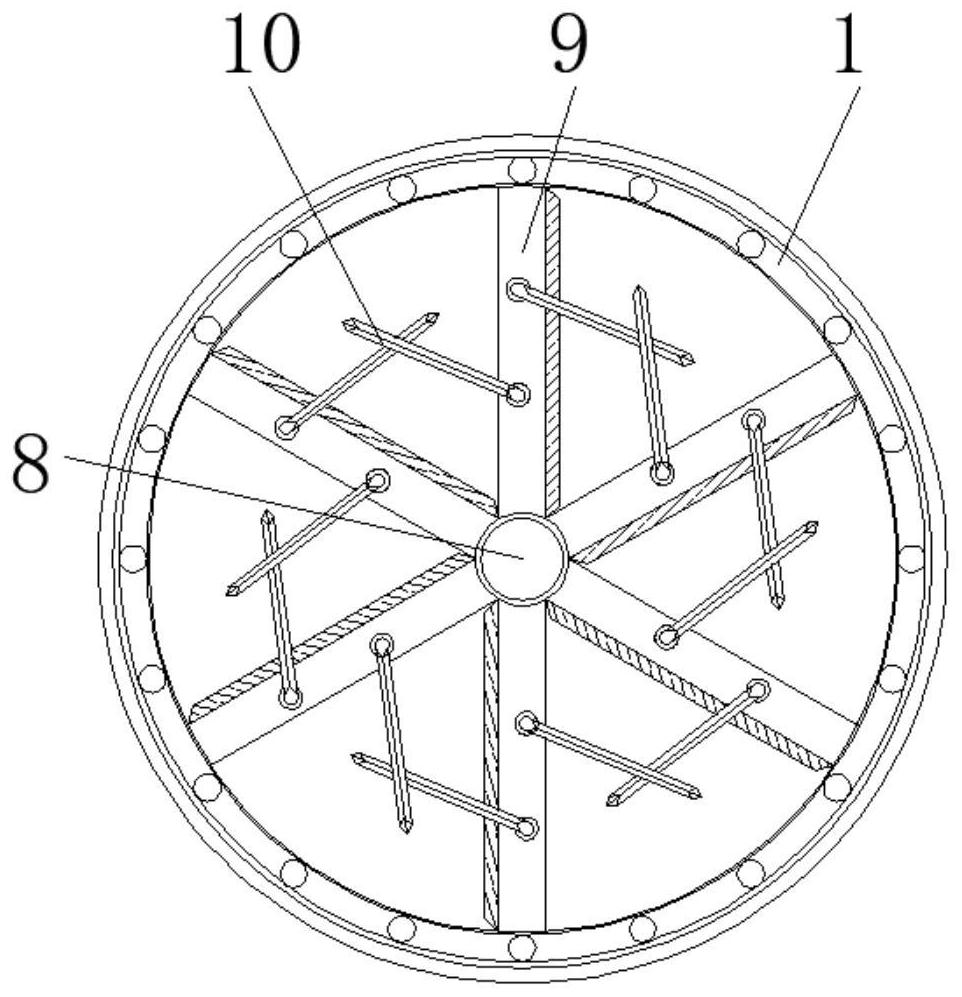

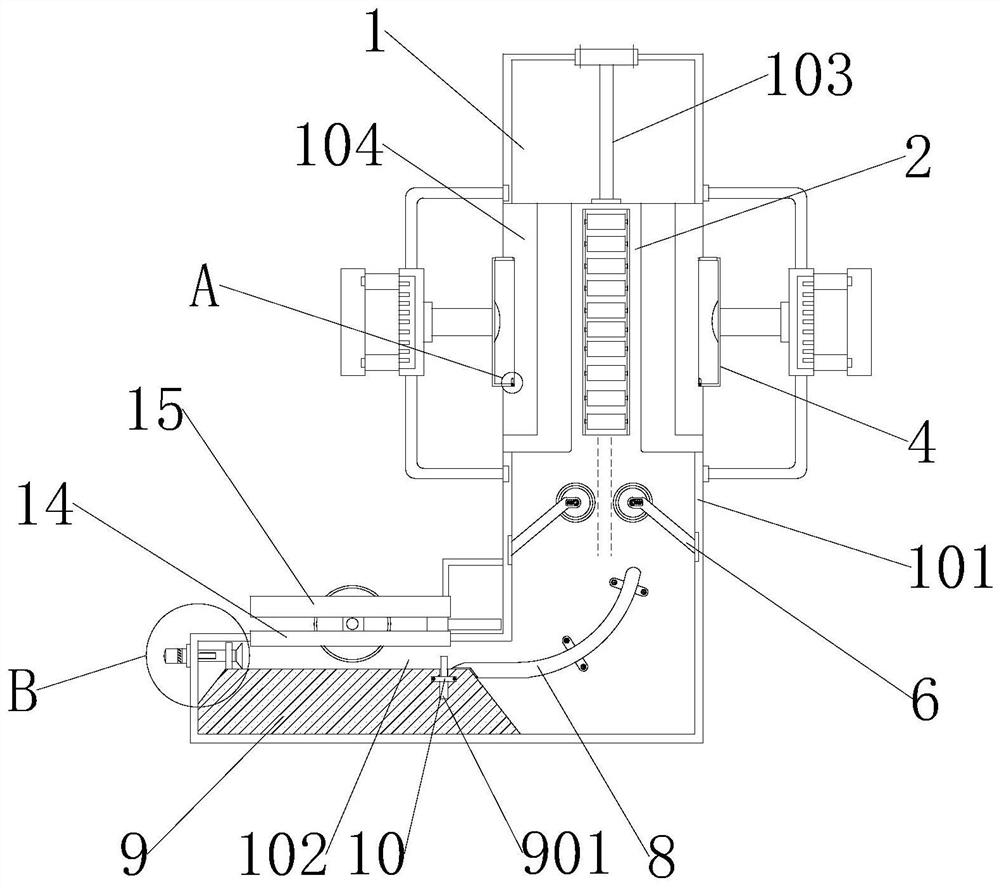

The invention relates to the technical field of mechanical equipment for expressway construction, and particularly relates to a special automatic circular pipe plasma cutting machine for an expresswayconstruction process and a use method. The machine is characterized in that a holding device is driven through a cylinder to hold and fix a circular pipe, thus the machine is applicable to circular pipes with different diameters; the circular pipe clamping pipe can be controlled by controlling air pressure, so that the problems that a thin circular pipe in cutting is pressed and deformed due to excessively high clamping force, the thin circular pipe cannot be tightly clamped due to excessively small clamping force, and the cutting process is dangerous, can be solved; a feeding device is arranged, so that the circular pipe feeding capacity is ensured, and quantitative cutting is realized; a supporting device is arranged, and the height of a supporting pulley can be automatically adjusted,and thus the circular pipe can be in a horizontal state during being cut; the overall fitting design realizes automatic cutting, and the circular pipe can be cut into different patterns; the working efficiency is high; and moreover, the safety in the construction process and the construction speed can be ensured.

Owner:王甜

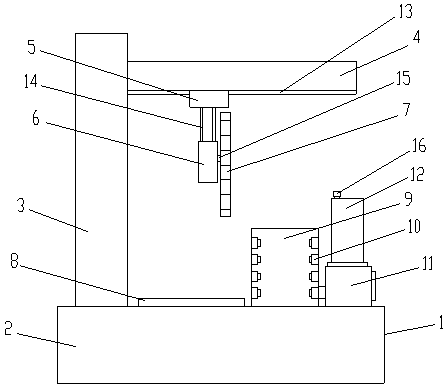

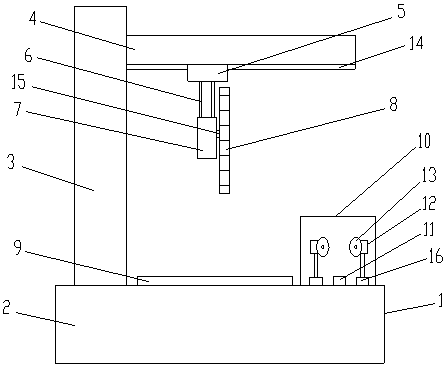

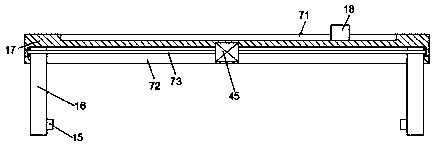

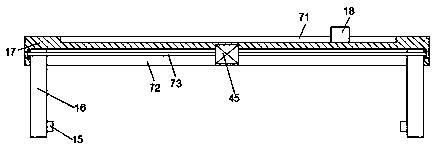

Wood decorative board cutting machine device preventing wood chips from flying all around

InactiveCN107225623AStable cutting workCircular sawsBark-zones/chip/dust/waste removalEngineeringWood plank

The invention discloses a wood decorative board cutting machine device preventing wood chips from flying all around. The wood decorative board cutting machine device preventing the wood chips from flying all around comprises a cutting machine frame body. A fixing seat is arranged at the lower end of the cutting machine frame body. One end of the fixing seat is vertically provided with a fixing support frame. The upper end of the fixing support body is horizontally provided with a cutting head installation suspension arm. The lower end of a telescopic rod of an air cylinder is fixedly provided with a cutting head box. A cutter tooth disk is connected into a concave lamping groove in a pivoted manner. The two sides of the cutting head box are provided with two protecting and shielding plates. A cutting platform is transversely and horizontally supported on the middle section of the fixing support body. The front end of a horizontal supporting arm is fixedly provided with a cutting opening base cover box. In this way, the wood decorative board cutting machine device preventing the wood chips from flying all around can stably conduct cutting work on wood boards, the two sides of the bottom of the cutting head box are provided with the protecting and shielding plates, the protecting and shielding plates shield tools on the upper portion during wood cutting, and the cutting opening base cover box capable of ascending and descending is further arranged on the lower side of the cutting platform and used for sealing a cutting opening.

Owner:无锡凯皓科技有限公司

Molybdenum alloy plate cutting machine with cutter retracting and high-pressure cleaning functions

PendingCN107626977AStable cutting workNot stickyMetal sawing devicesMaintainance and safety accessoriesEngineeringHigh pressure

The invention discloses a molybdenum alloy plate cutting machine with cutter retracting and high-pressure cleaning functions. The molybdenum alloy plate cutting machine comprises a rack body, a base platform is arranged at the lower end of the rack body, a support frame is vertically arranged at one end of the upper end face of the base platform, a cross beam cutting arm is fixedly installed on the side end face of the support frame, a mobile cutting cart is slidably connected to the bottom end of the cross beam cutting arm, a cutting machine device is installed at the lower end of the mobilecutting cart, a cutting sawtooth cutterhead is installed on the end face of one side of the cutting machine device, a cutting station platform and a high-pressure cleaning machine case are arranged onthe base platform located at the lower end of the cross beam cutting arm, and high-pressure water spray gun heads are installed on the case inner walls of the two sides of the high-pressure cleaningmachine case. In this way, the molybdenum alloy plate not only can be stably cut through the mobile cutting cart, but also can be guided into the high-pressure cleaning machine case by the cutting sawtooth cutterhead for cutter surface cleaning achieved through water spraying after the mobile cutting cart completes cutting work.

Owner:无锡华美钼业有限公司

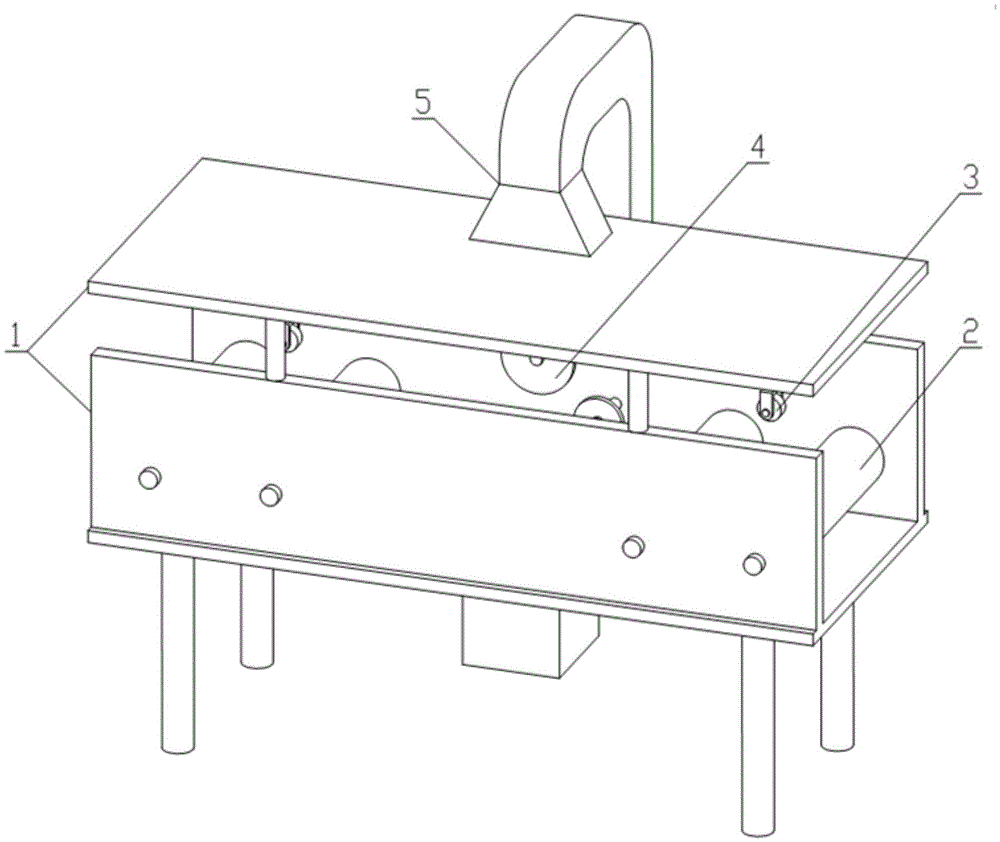

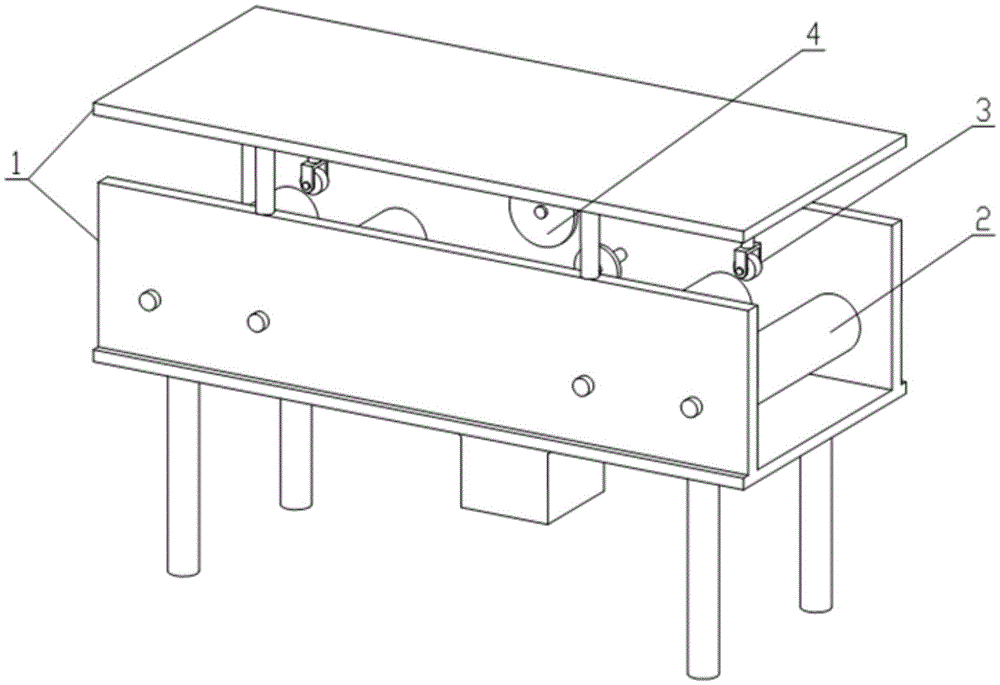

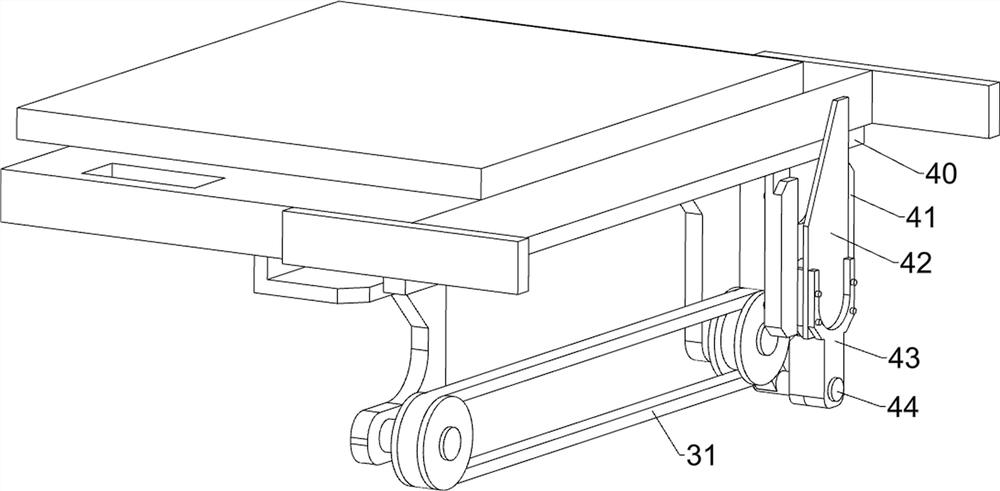

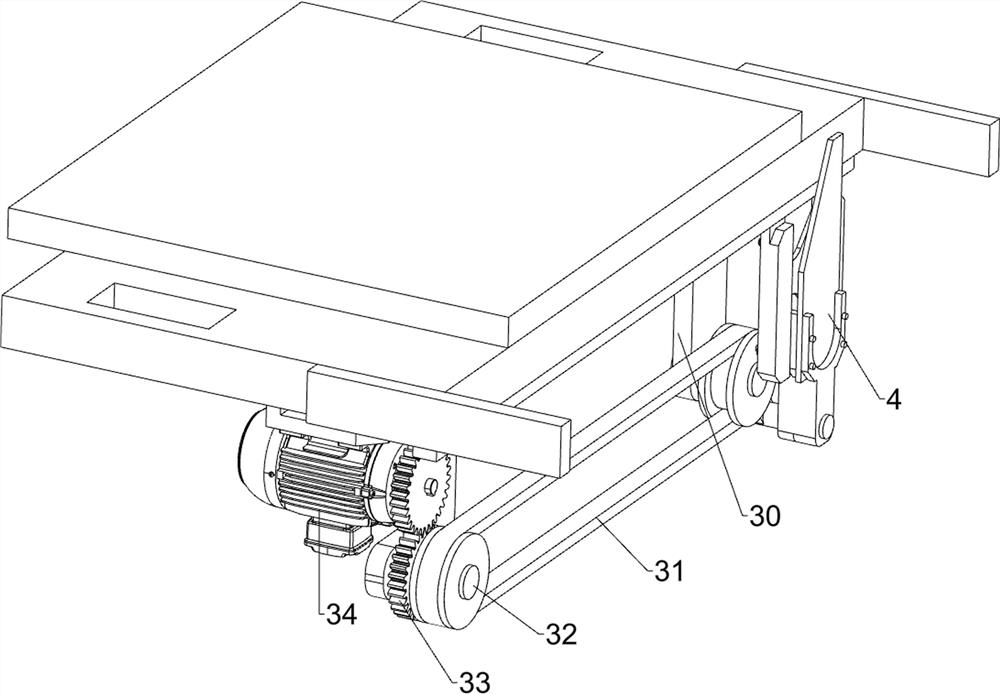

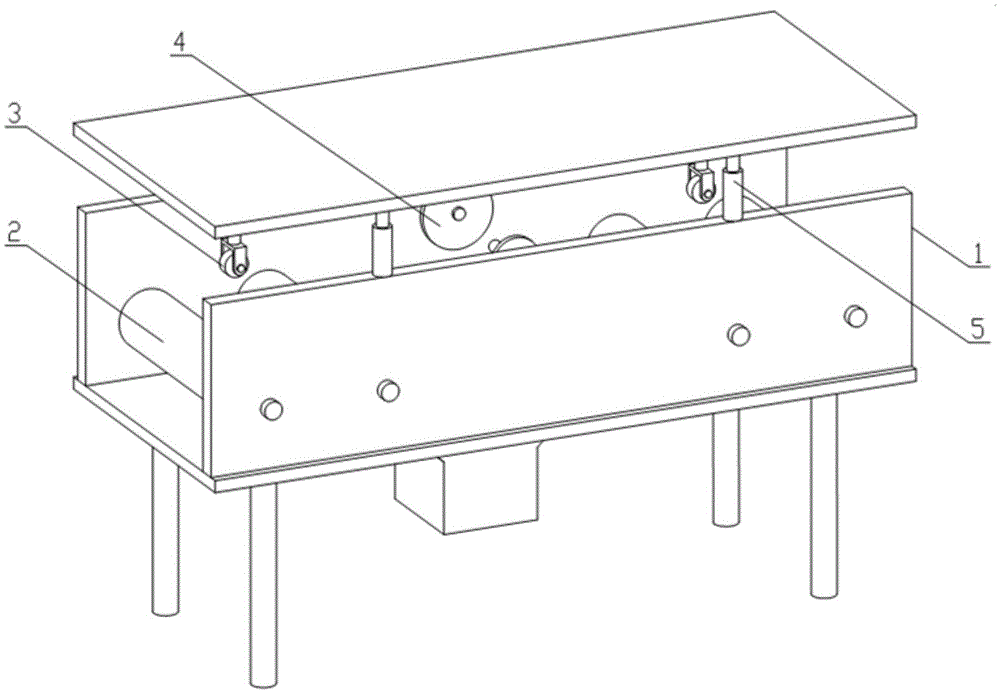

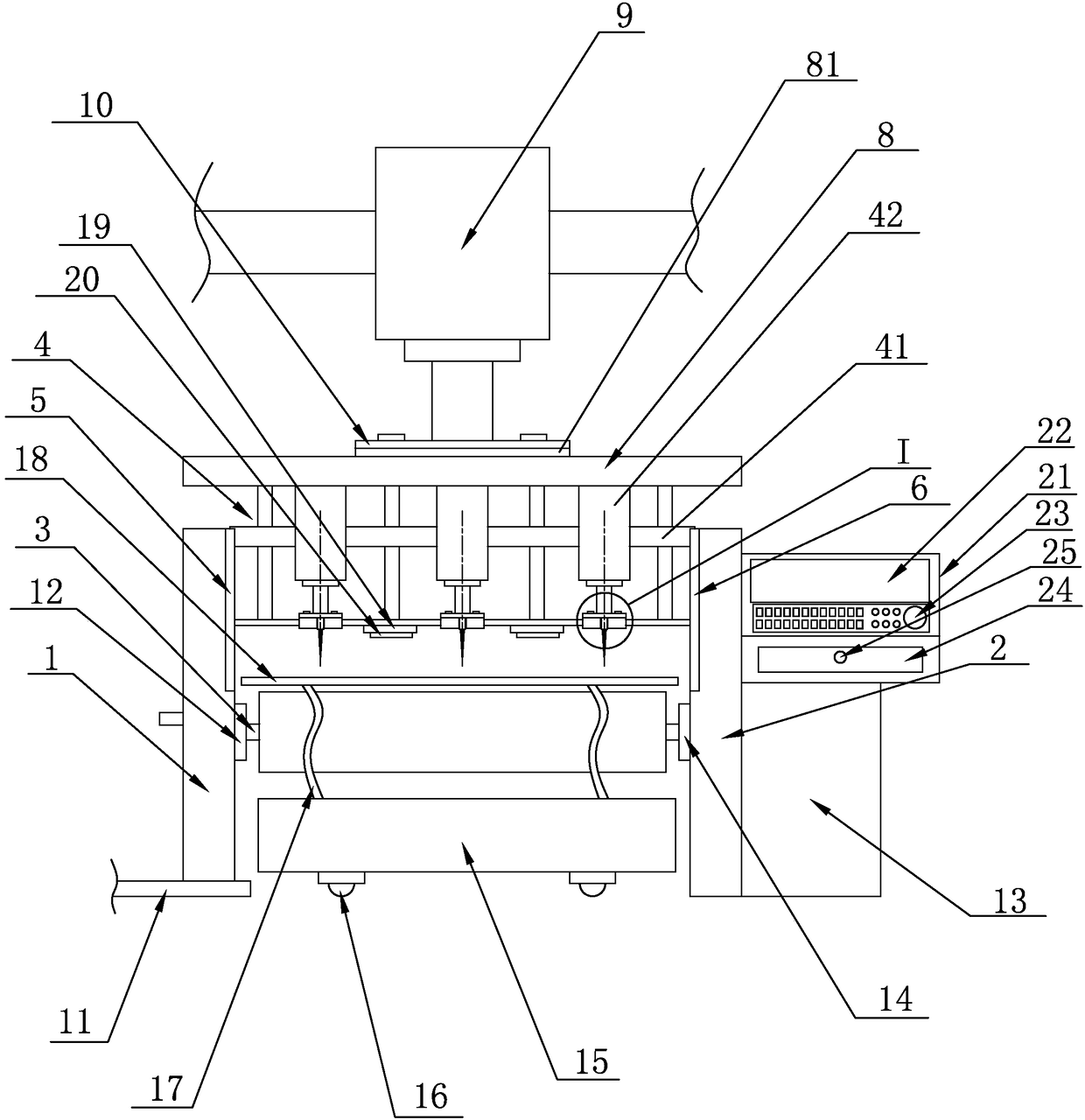

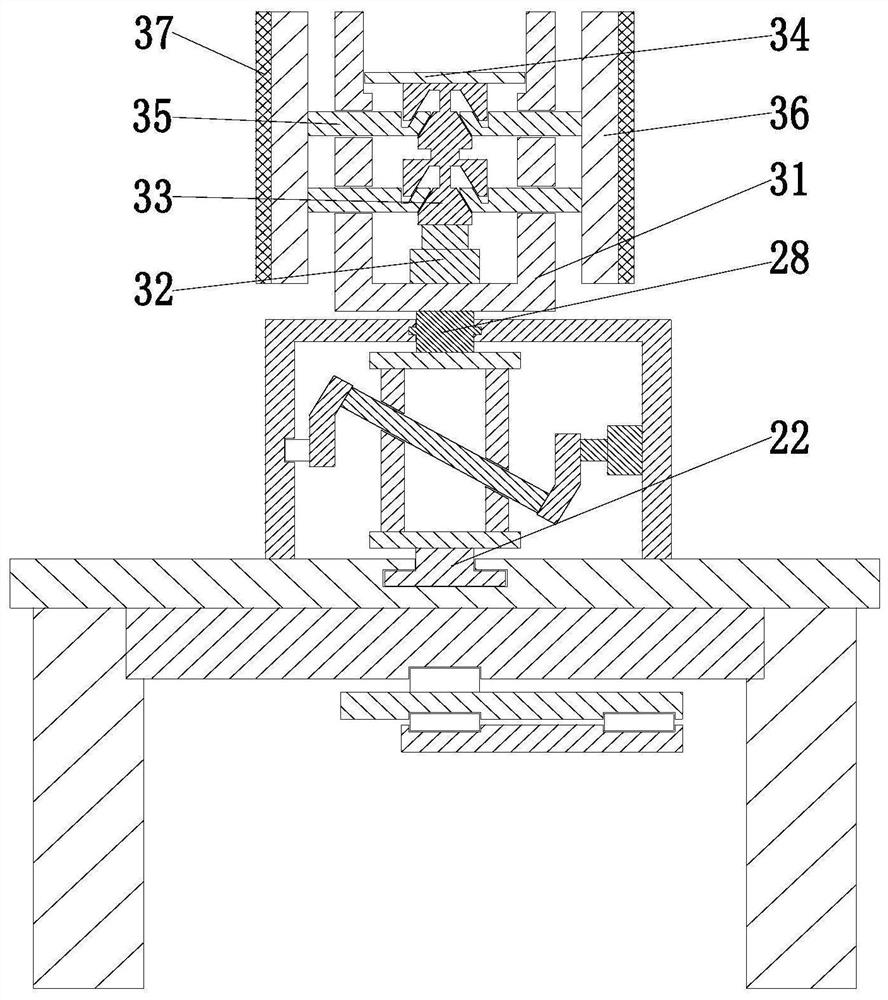

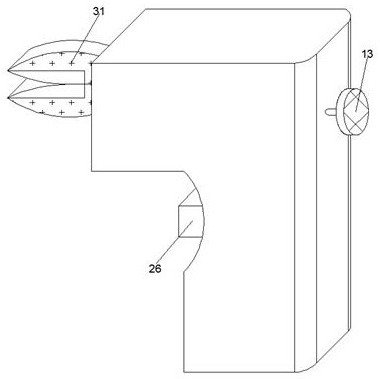

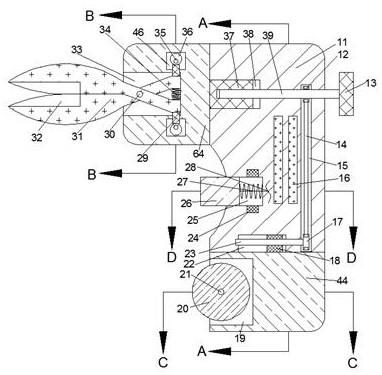

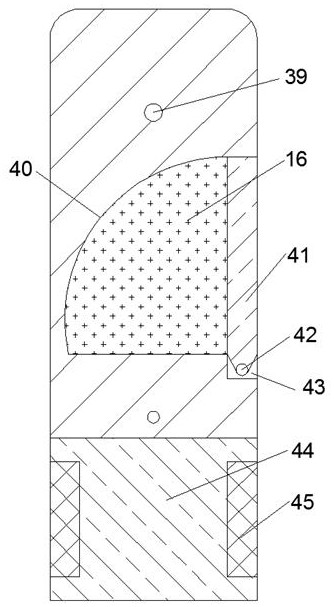

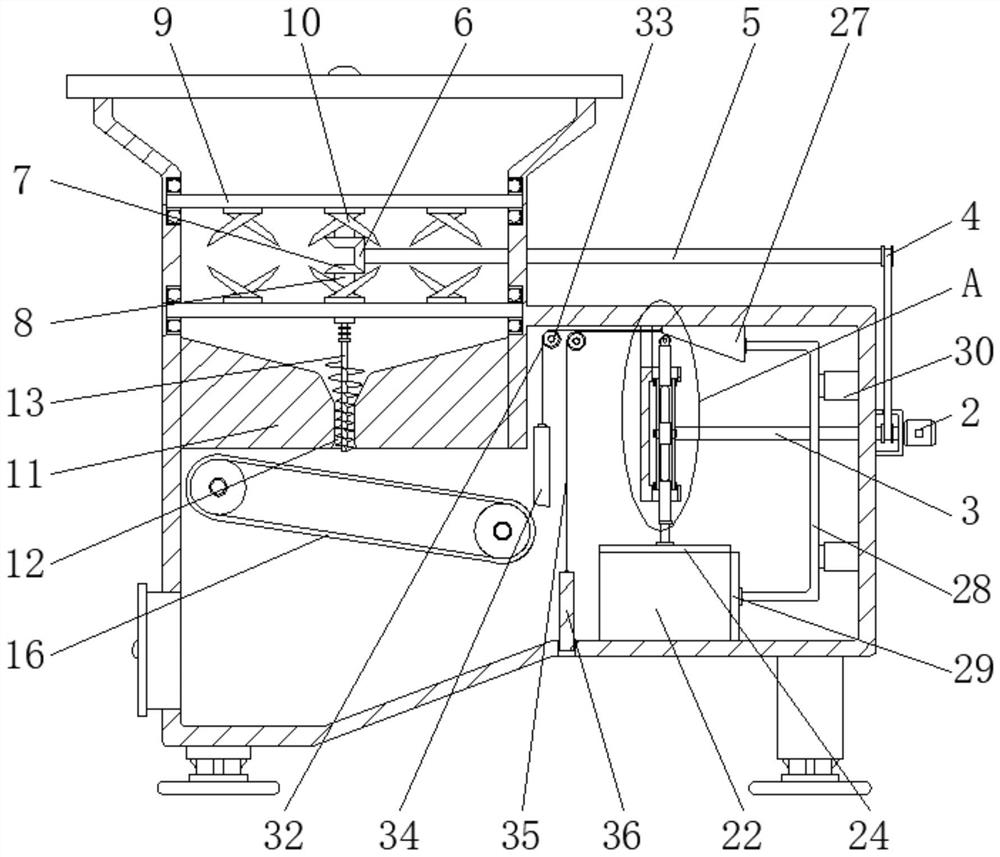

Wood cutting device

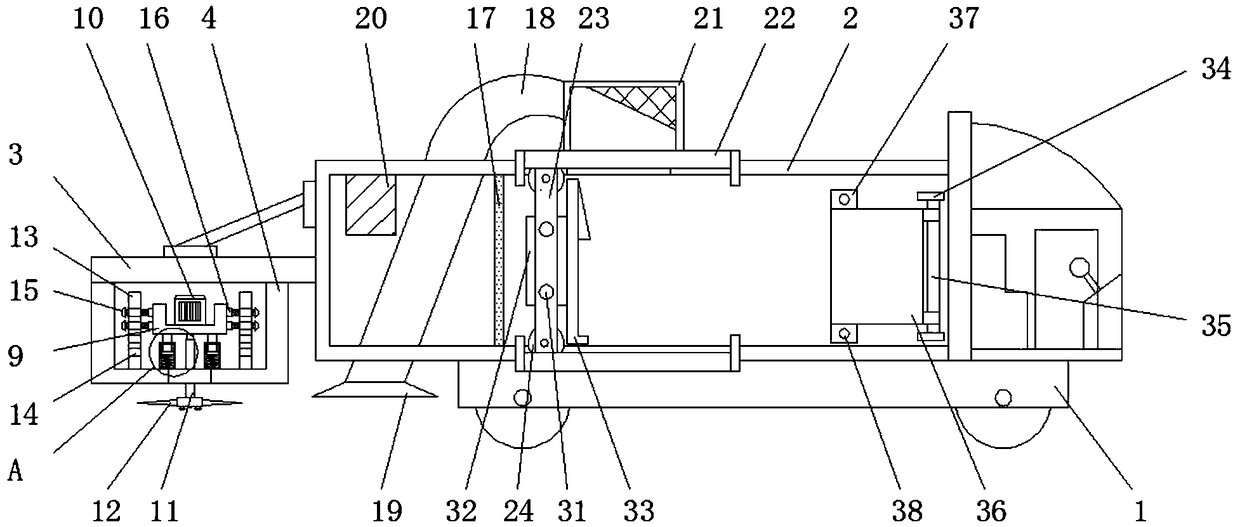

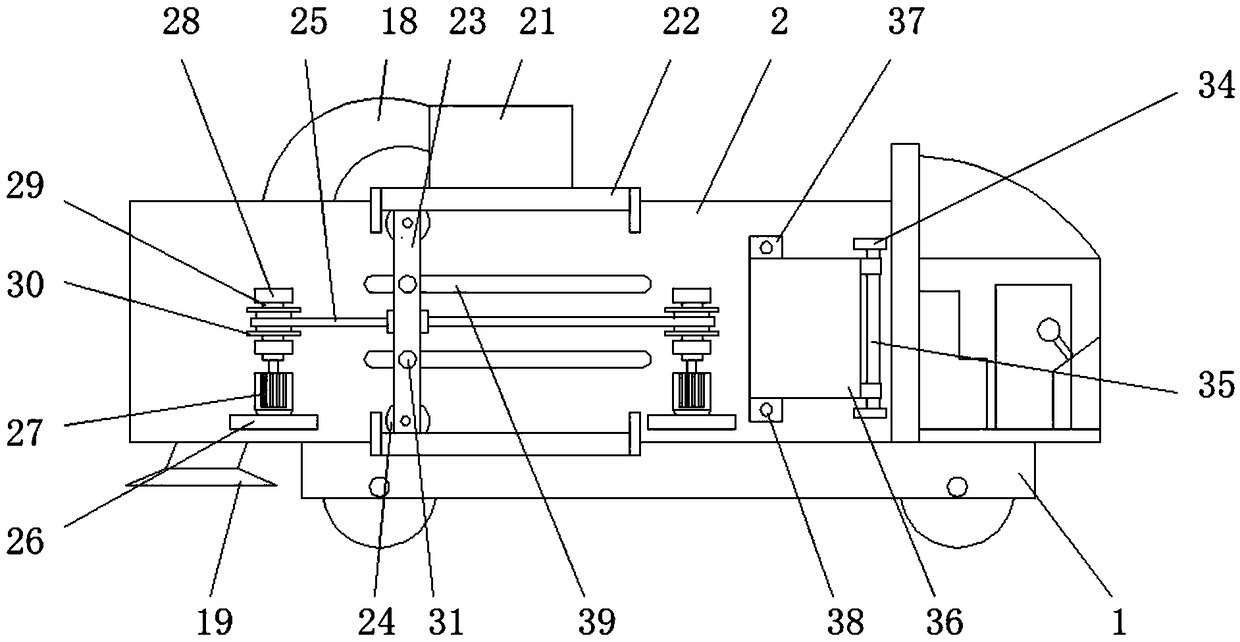

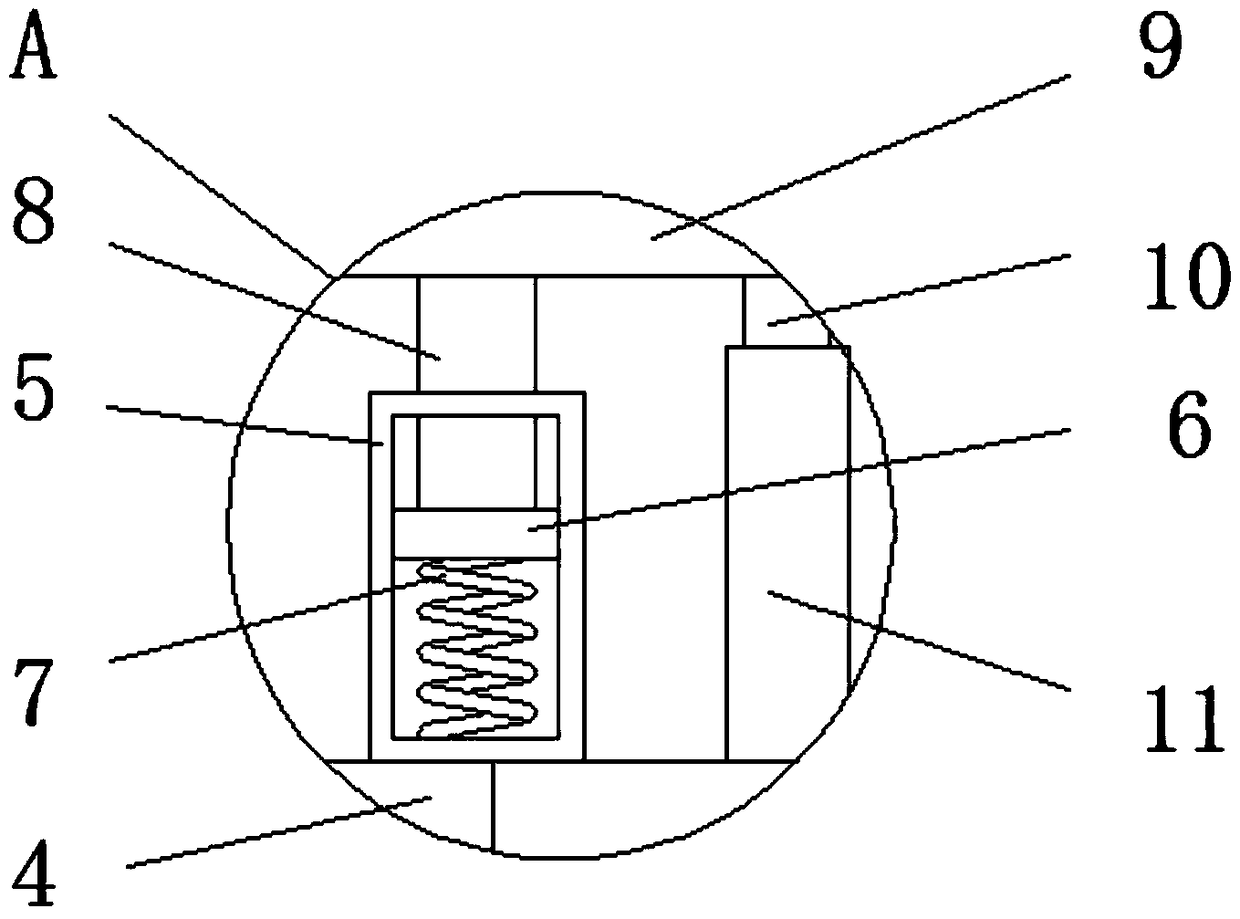

InactiveCN105643724AStable positionStable cutting workGuide fencesFeeding devicesEngineeringWood cutting

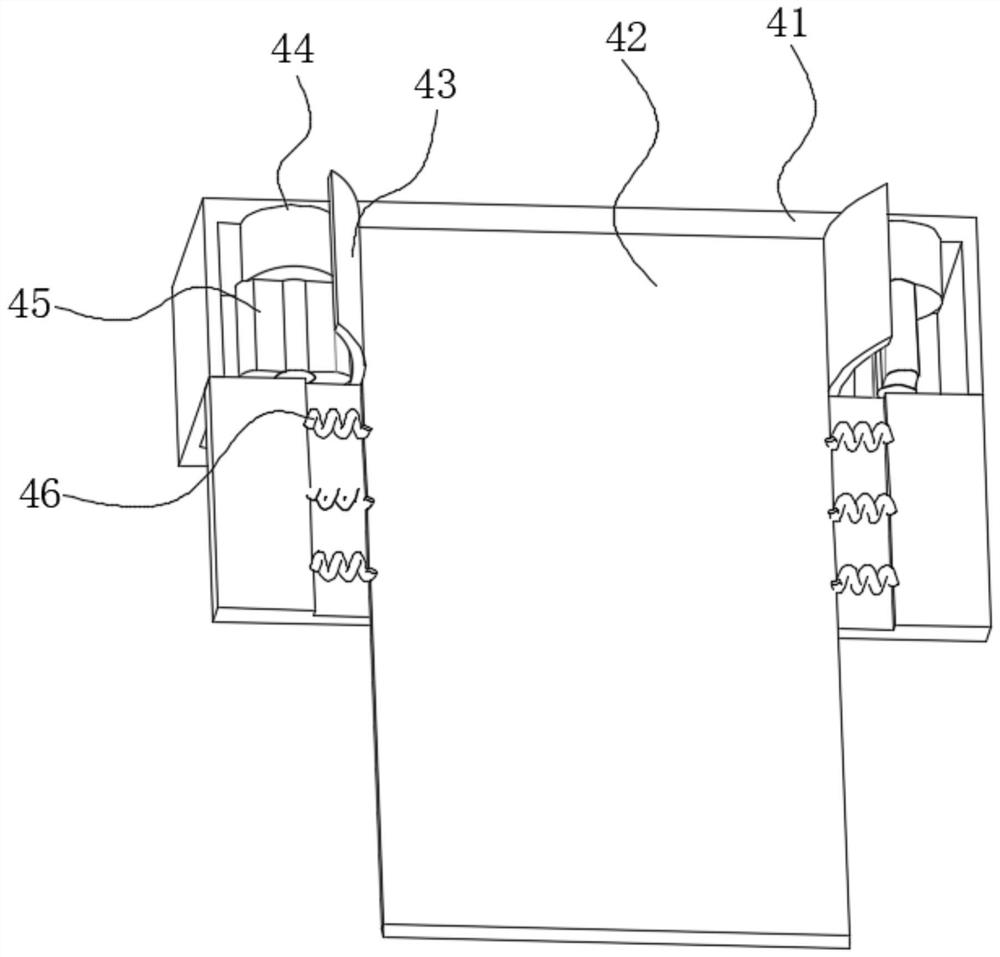

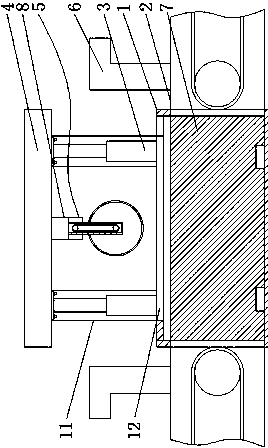

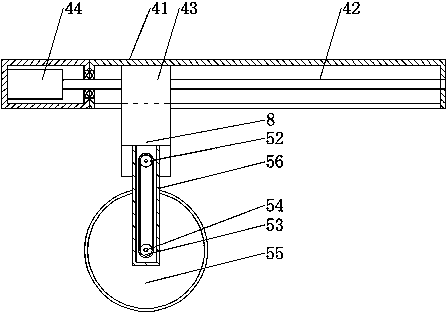

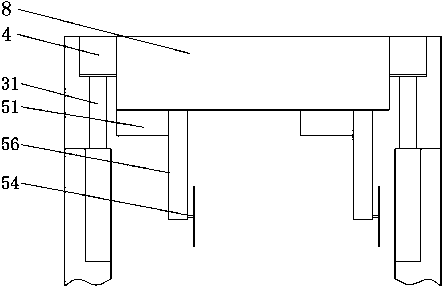

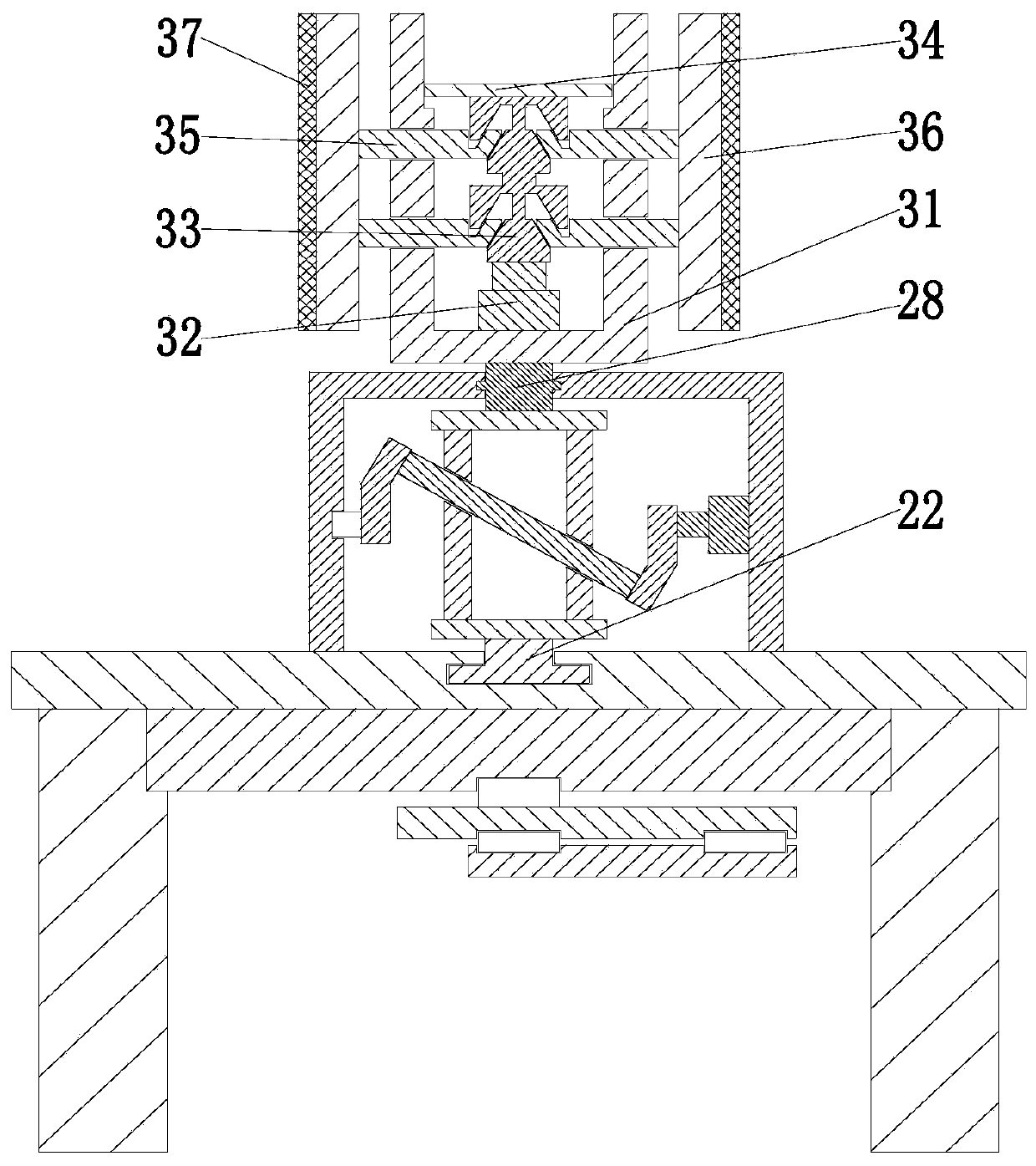

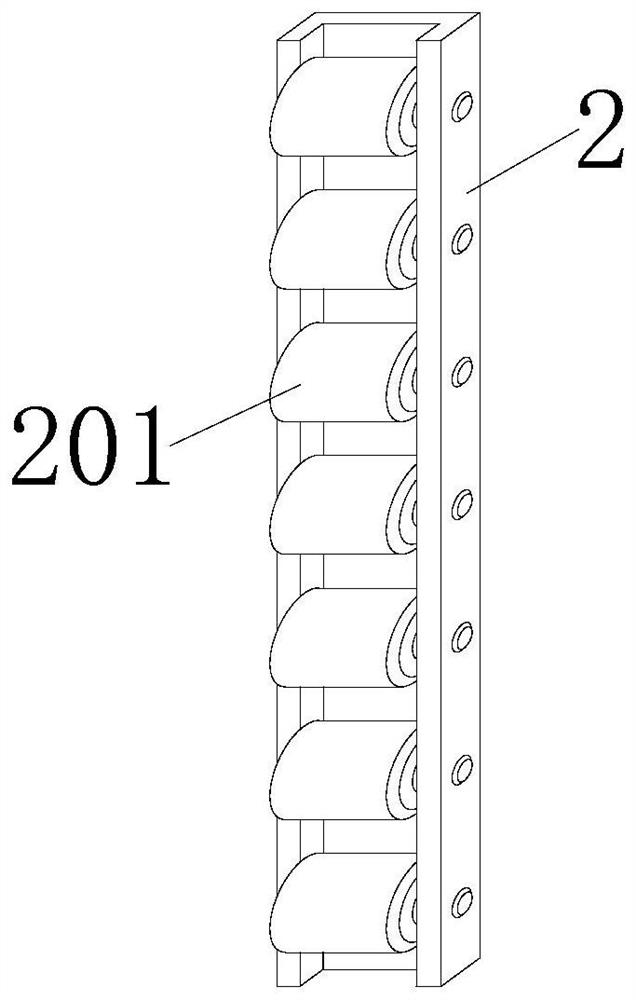

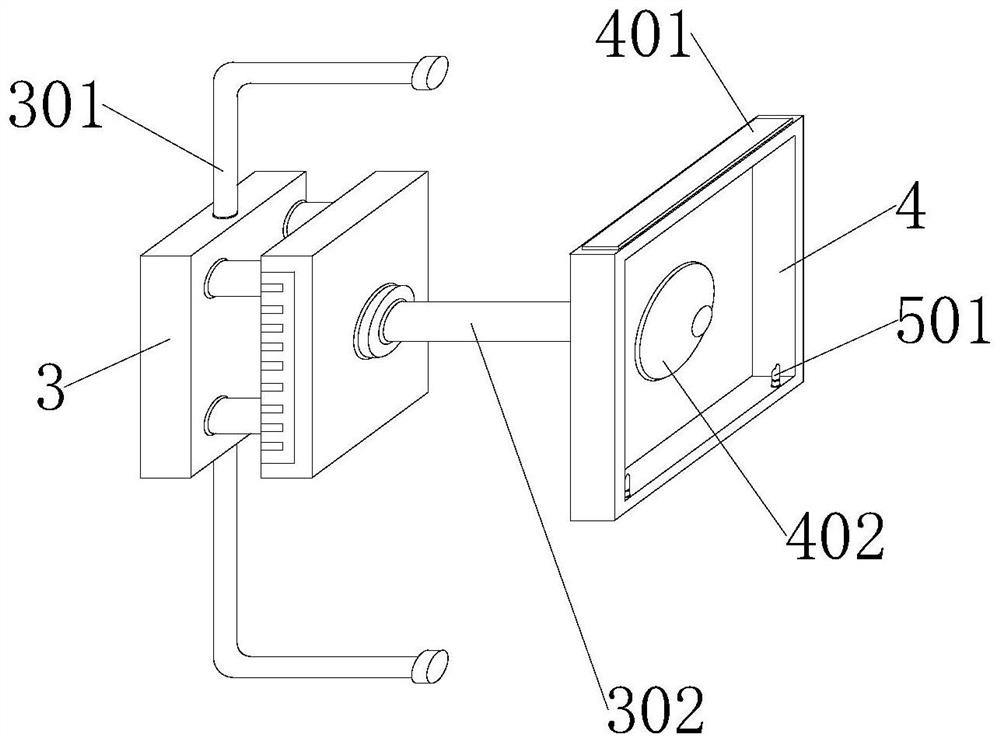

The invention discloses a wood cutting device comprising a machine body (1), a conveying device (2), a pressing device (3) and a cutting device (4), wherein the conveying device (2) and the pressing device (3) are both fixedly arranged on the machine body (1); the pressing device (3) is located above the conveying device (2); the conveying device (2) comprises a first conveying roller group (21) and a second conveying roller group (22) which are arranged on the same horizontal line; and the cutting device (4) is arranged on the machine body (1), is located between the first conveying roller group (21) and the second conveying roller group (22) in the horizontal direction and is located between the conveying device (2) and the pressing device (3) in the vertical direction. By using the wood cutting device, woods conveyed by the conveying device are cut through the cutting device and are pressed on the conveying device through the pressing device, so that the cutting process is stably and automatically carried out; and the whole device is simple in structure, high in stability and efficient in working and has popularization and application values.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

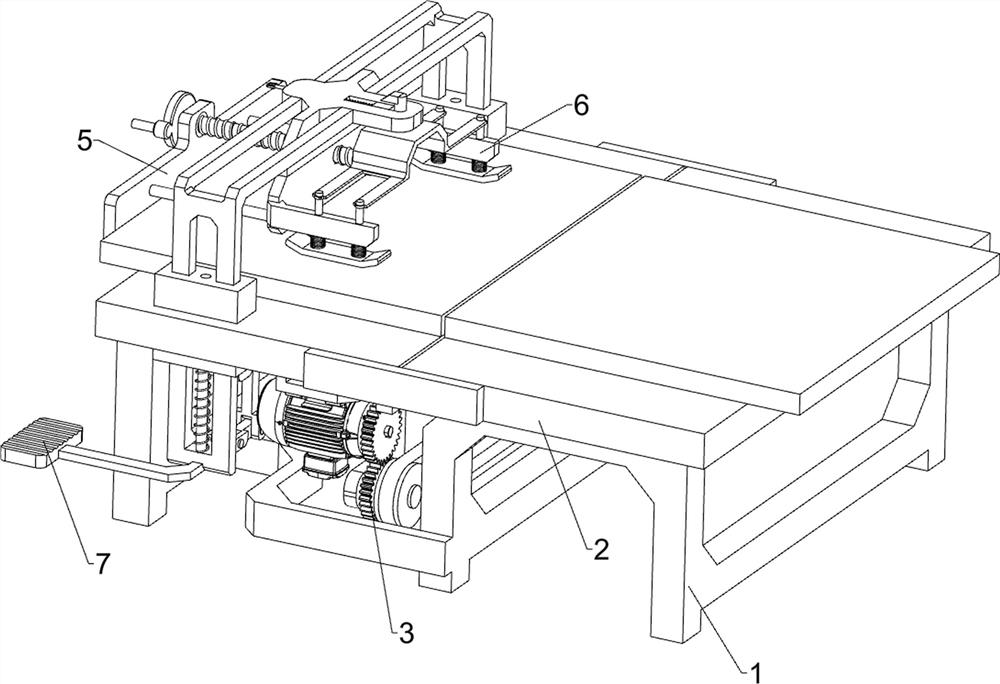

Composite material plate cutting device

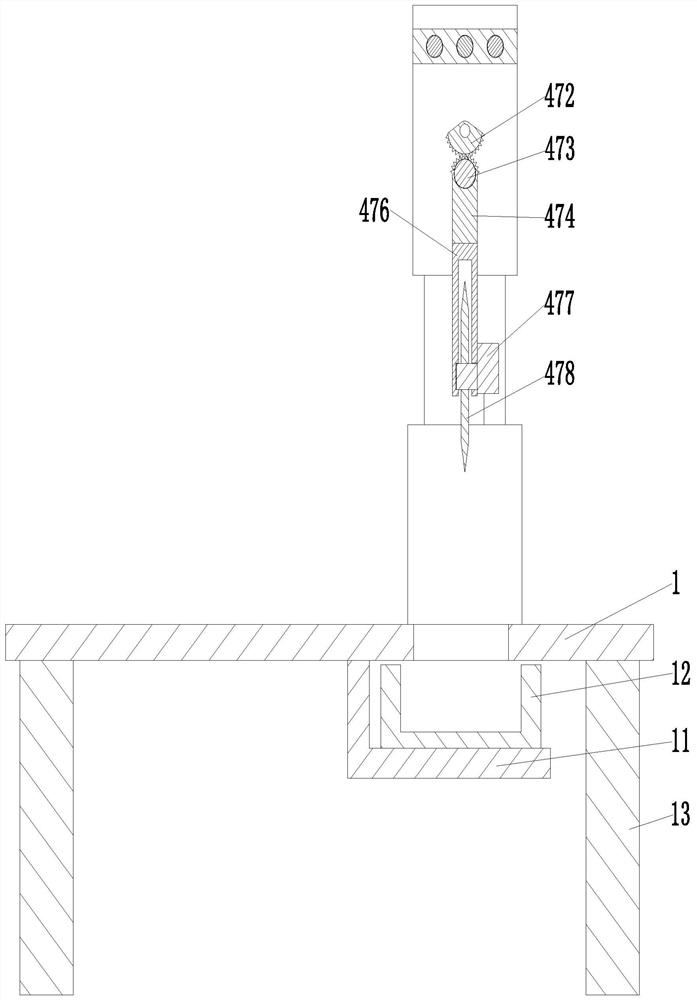

InactiveCN112809758AImprove work efficiencyHigh precisionMetal working apparatusElectric machineryWorkbench

The invention relates to a cutting device, in particular to a composite material plate cutting device. The composite material plate cutting device is high in wood cutting precision and has a clamping function. According to the technical scheme, the composite material plate cutting device comprises supporting legs, a workbench, a transmission mechanism and a cutting mechanism, wherein the workbench is arranged at the tops of the supporting legs, the transmission mechanism is arranged at the bottom of the workbench, the cutting mechanism is arranged on the rear side of the bottom of the workbench, and the transmission mechanism is matched with the cutting mechanism. A cutter is driven to cut a composite material plate under the action of an output shaft of a motor, the cutter can be aligned with the composite material plate upwards for cutting under the action of a belt pulley set, and after the composite material plate is cut, the cutter moves downwards under the action of the belt pulley set to stop cutting the composite material plate, so that the cutting working efficiency is effectively improved.

Owner:南京伟悦烨电子商务有限公司

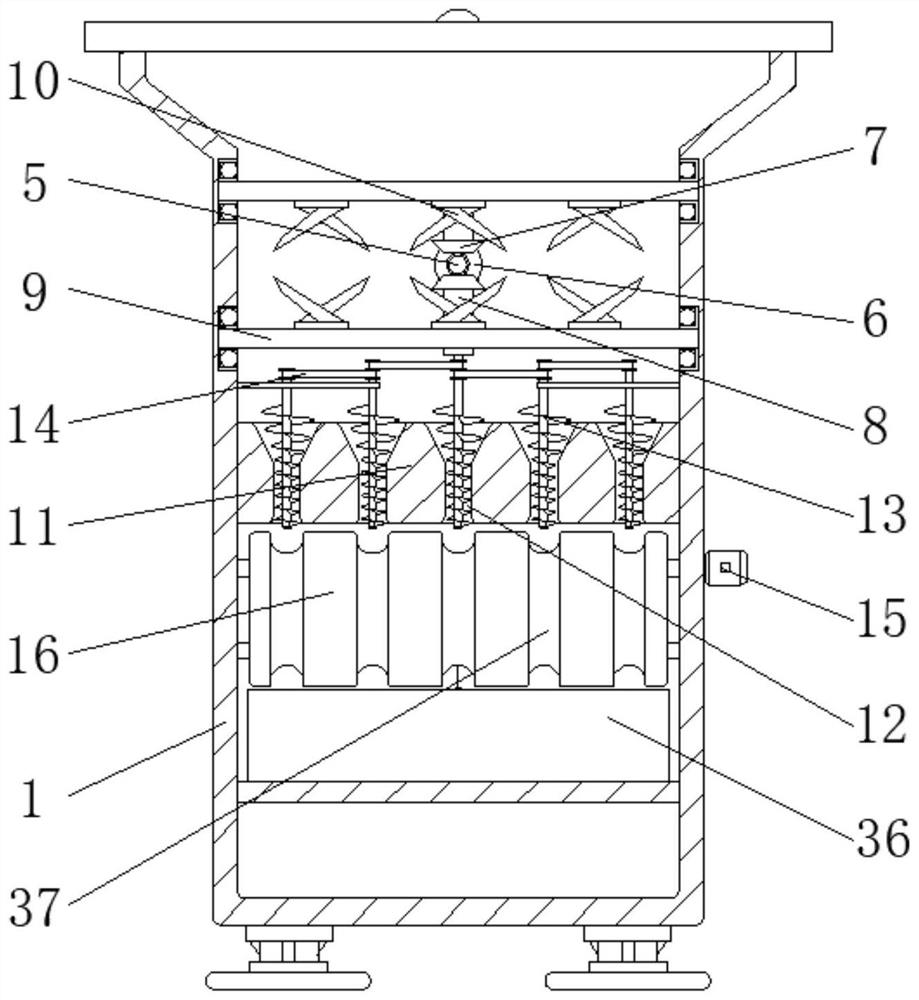

Foaming cement board cutting device

PendingCN114571587AAvoid offsetGuaranteed stabilitySolid waste managementCleaningTorque motorCement board

The invention belongs to the technical field of foamed cement board production and processing equipment, and particularly relates to a foamed cement board cutting device which comprises a conveying device, torque motors are symmetrically arranged on the left side and the right side of the inner wall of the conveying device, and an adjusting connecting rod is fixedly connected to one side of the outer surface of a motor shell of each torque motor. A cutting device is clamped to the upper surface of the conveying device, a threaded sleeve is fixedly connected to the upper surface of the cutting device, and an adjusting rotary column is rotationally connected to the upper portion of the inner wall of the threaded sleeve. According to the device, in the plate blank conveying process, plate blanks can be cut, due to the fact that in the moving process of the plate blanks, the plate blanks are conveyed in parallel all the time under the guiding effect of the inner walls of the guiding side rails on the two sides and cannot deviate, and the stability of the plate blanks in the moving process can be guaranteed through the rolling and extruding effect of concave wheels; and in the plate blank cutting process, the plate blank can be pressed, and the plate blank is prevented from deviating in the cutting process.

Owner:沭阳苏星包装材料有限公司

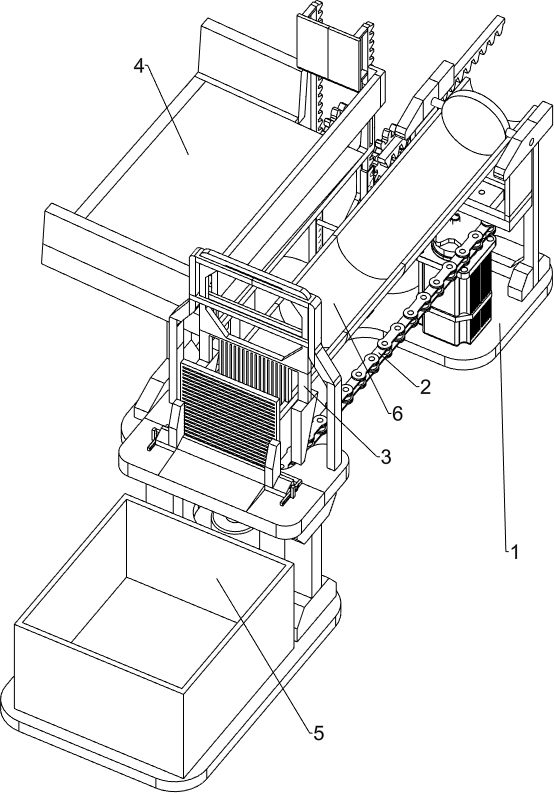

Wood cutting device for active carbon processing

InactiveCN107914324AEasy to cutExtended service lifeProfiling/shaping machinesActivated carbonTransport system

The invention relates to a wood cutting device for activated carbon processing, comprising: a material conveying channel; a group of material conveying channels are respectively arranged at both ends of the collecting box, and a material conveying belt is arranged in the material conveying channel, and a material conveying channel is also provided in the material conveying channel Preheating and drying device, one end of the material conveying channel is provided with a feeding trough, the other end of the material conveying channel is connected with the collecting box, one end of the collecting box is provided with a pressing device, and the two sides of the collecting box are respectively provided with an installation frame, and the installation frame There is a lifting device inside, and the lifting device is fixedly connected with the mobile device. The mobile device is equipped with a mounting beam, and several sets of cutting devices are installed on the mounting beam. Several sets of cutting waist-shaped holes are processed on the top of the collecting box. The invention uniformly transports the wood into the collecting box through two groups of material conveying channels, compresses the wood through the compacting device in the collecting box, and then cuts the wood through the cutting device to complete the overall cutting process.

Owner:SUZHOU SHUYUE CARBON ADSORBENT CO LTD

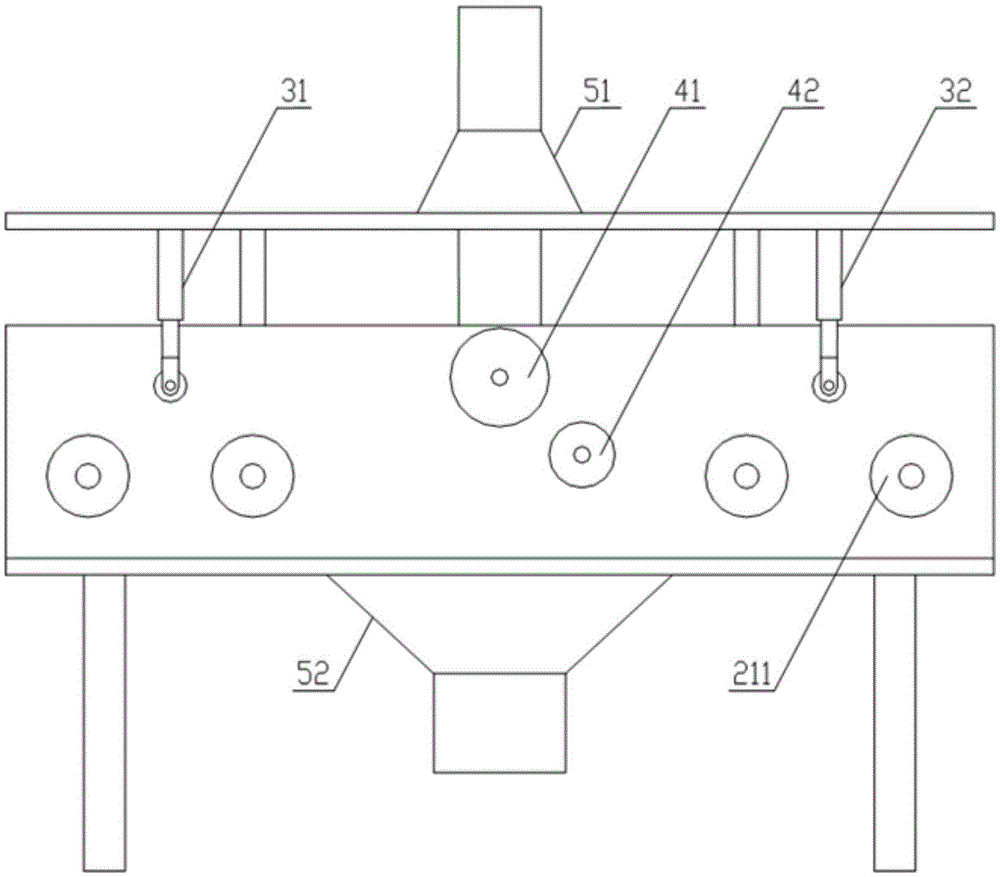

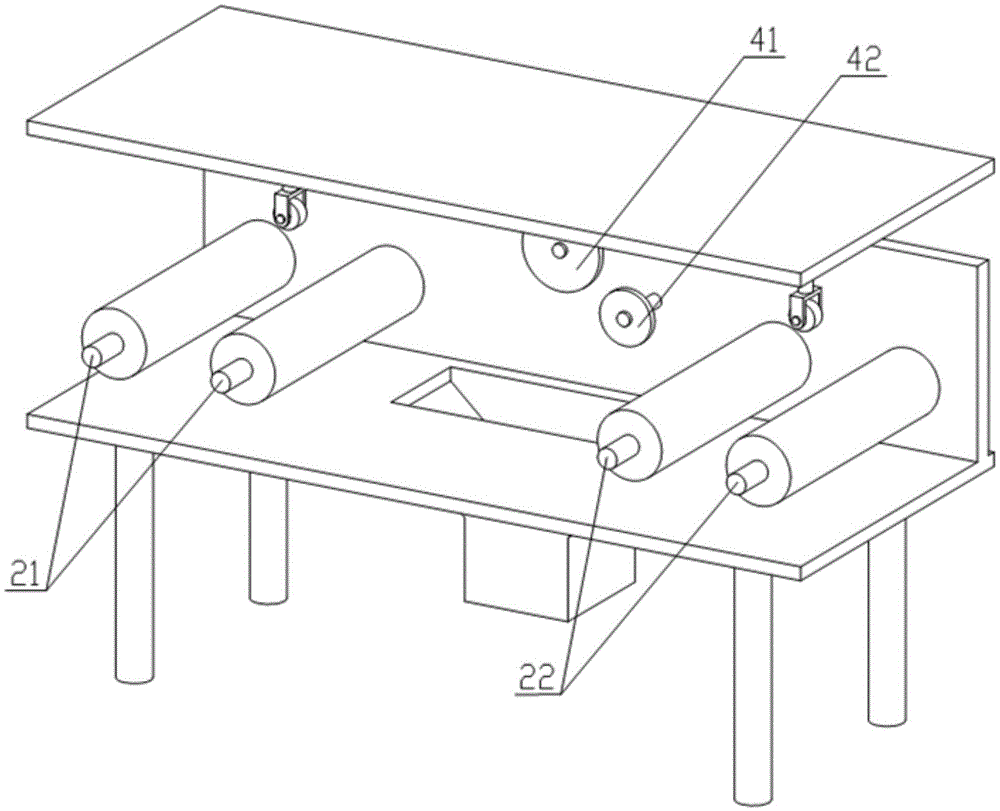

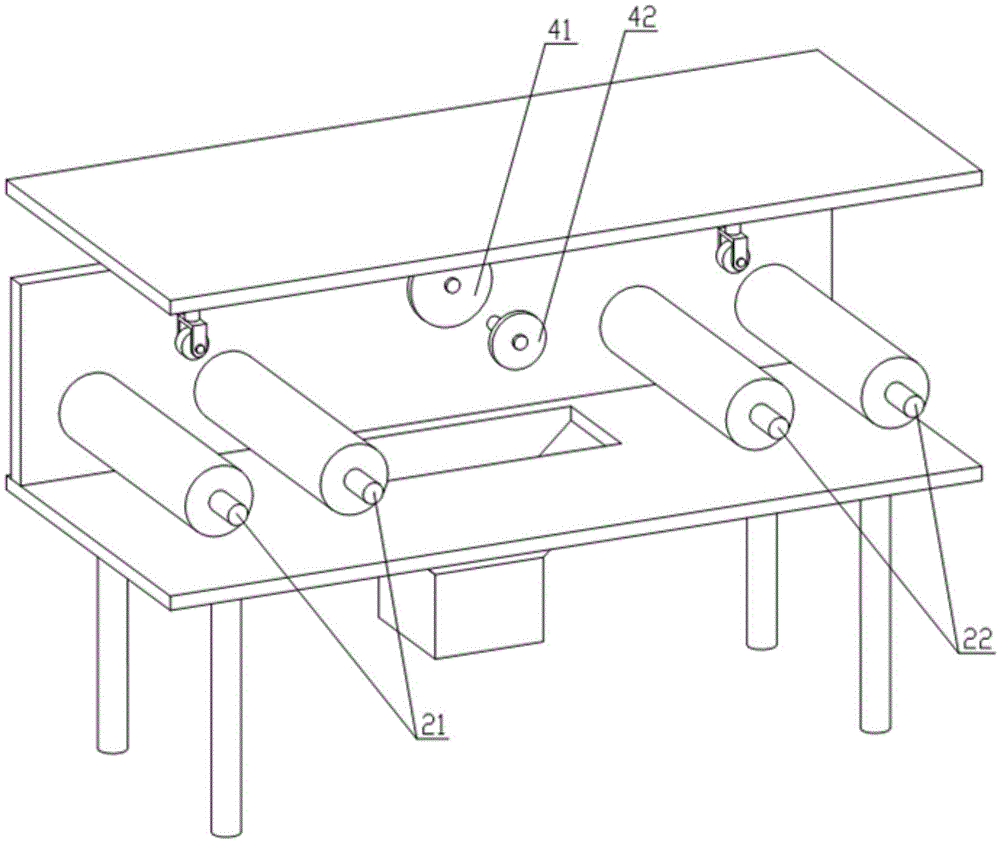

Cutting device for solid wood

InactiveCN105538419AStable positionStable cutting workFeeding devicesCircular sawsSolid woodMechanical engineering

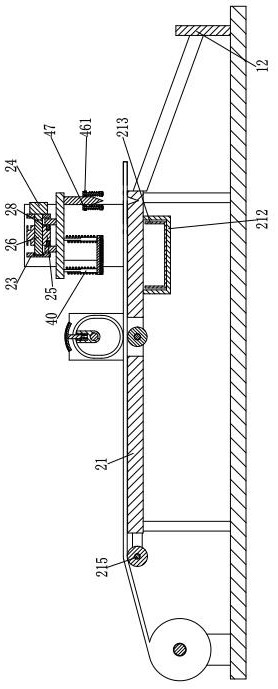

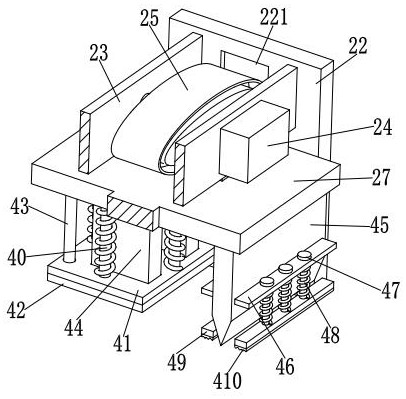

The invention discloses a cutting device for solid wood. The cutting device comprises a machine body (1), a conveying device (2), a compressing device (3), a cutting device and a lifting device (5), wherein the compressing device (3) is arranged on the lifting device (5) and is positioned above the conveying device (2); the conveying device (2) comprises a first conveying roller set (21) and a second conveying roller set (22) which are horizontally arranged; and the cutting device (4) is positioned between the first conveying roller set (21) and the second conveying roller set (22) in the horizontal direction, and is positioned between the conveying device (2) and the compressing device (3) in the vertical direction. According to the cutting device disclosed by the invention, wood conveyed by the conveying device is cut by the cutting device, and is compressed on the conveying device by the compressing device, so that cutting process is enabled to be performed stably and automatically; and the whole device is simple in structure, high in stability and efficient in working and has popularization and application values.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Molybdenum alloy sheet cutter with tool cleaning box

InactiveCN107553203AStable cutting workGuaranteed cleanlinessMaintainance and safety accessoriesStructural engineeringAlloy

The invention discloses a molybdenum alloy sheet cutter with a tool cleaning box. The molybdenum alloy sheet cutter comprises a cutter rack body, wherein the lower end of the cutter rack body is equipped with a base table; a supporting floor stand is vertically arranged at one end of the upper end surface of the base table; a beam cutting beam is mounted on the rack body at the upper side end of the supporting floor stand; a movable type lifting cutter is in sliding connection on the bottom end surface of the beam cutting beam; a cutting station table and a tool cleaning box are separately arranged on the base table at the lower end of the beam cutting arm; the tool cleaning box is arranged on the outer side of the cutting station table; a flame jet orifice is formed in the center on the bottom end of the tool cleaning box; lifting type polishing machines are arranged at the two ends of the bottom end of the tool cleaning box; and polishing rollers are mounted at the upper ends of thelifting type polishing machines. In this way, the molybdenum alloy sheet cutter can perform stable molybdenum alloy sheet cutting work through the movable type lifting cutter, and also can clean a cutting saw-tooth cutter head subjected to cutting and retracting.

Owner:无锡华美钼业有限公司

Straw recycling device

InactiveCN108633446AStable cutting workRealize the function of free conversion of cutting heightMowersTransverse planeEngineering

The invention relates to the technical field of waste recycling equipment and discloses a straw recycling device. The straw recycling device comprises a locomotive, a recycling box is fixedly mountedon the upper surface of the locomotive, a transverse plate is fixedly connected to the other side of the recycling box, a groove-shaped plate is fixedly connected with the lower surface of the transverse plate, and fixed cylinders are fixedly connected to the bottom of an inner cavity of the groove-shaped plate. Through an elastic deformation function of retractable springs, movable plates can conduct displacement transformation in the vertical direction, movable rods are driven to perform vertical displacement transformation at the same time, and finally a U-shaped plate is driven to performvertical displacement transformation at the same time, so that the function of free conversion of the cutting height of cutting blades is achieved, and crops different in height and type can be be cutdown. Through the action of threaded rods, the U-shaped plate can be fixed at a suitable height position, displacement changes in the vertical direction cannot occur again, and the cutting blades cancut the straw more stably.

Owner:刘陈

Device for conveniently cutting radish to small strips

InactiveCN112140215AEasy to cleanAvoid lostMetal working apparatusFood treatmentAgricultural engineeringStructural engineering

The invention relates to a small strip cutting device, in particular to a device for conveniently cutting radish to small strips. According to the radish convenient small strip cutting device, radishes do not need to be pushed manually to be cut into strips, dangers are avoided, the lengths of the tails of the cut radishes are consistent, and sun-drying treatment is facilitated. In order to solvethe technical problem, the device for conveniently cutting radish into small strips comprises a power mechanism, a shredding assembly and a working table; the power mechanism is connected between thetwo sides of the top of a mounting base; the shredding assembly is arranged on one side of the top of the mounting base; and the working table is connected between the two sides of the top of the mounting base through supporting rods. Through the arrangement of a cutter, residual radish leaves on radishes can be cut, after radish heads with the radish leaves are cut, the radishes are cut into strips, the loss of the radishes due to rotting of the radish leaves is avoided, and meanwhile strip cutting work can be better conducted conveniently.

Owner:胡德涛

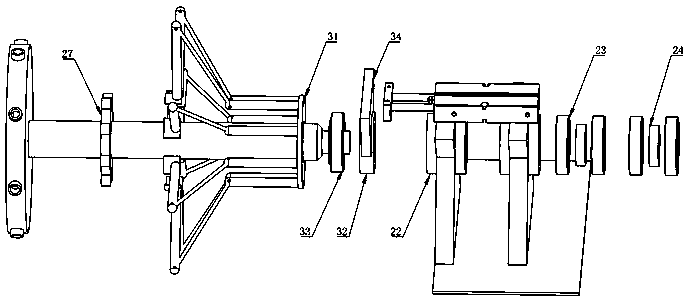

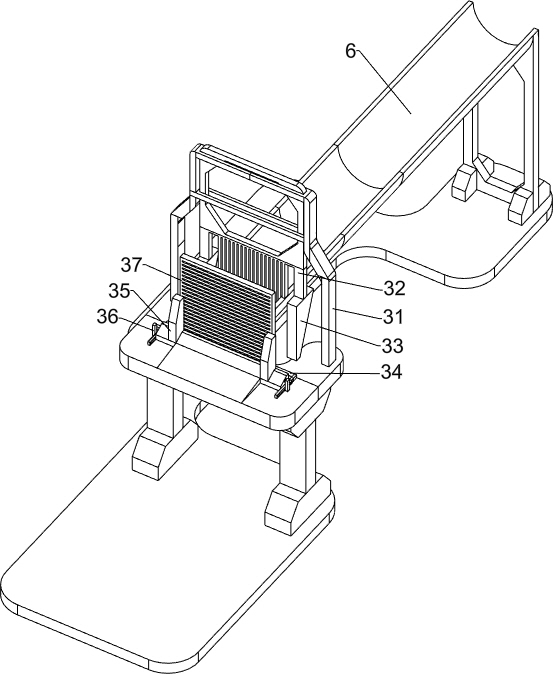

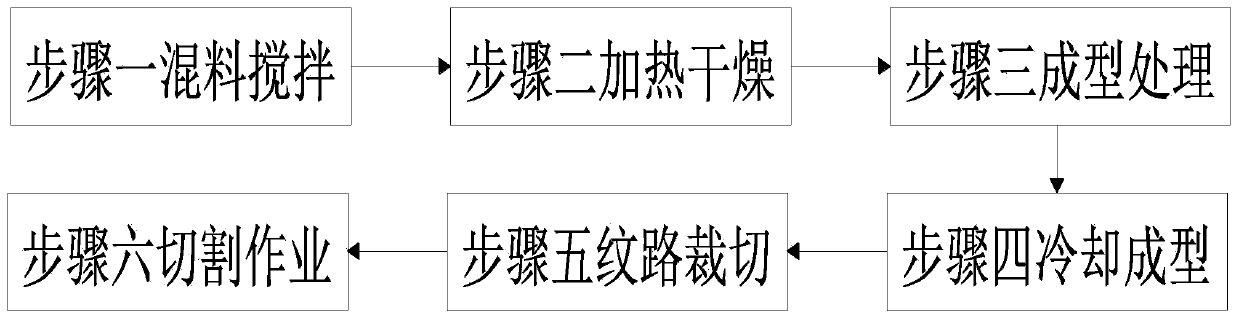

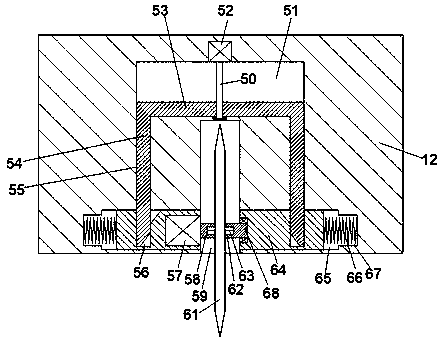

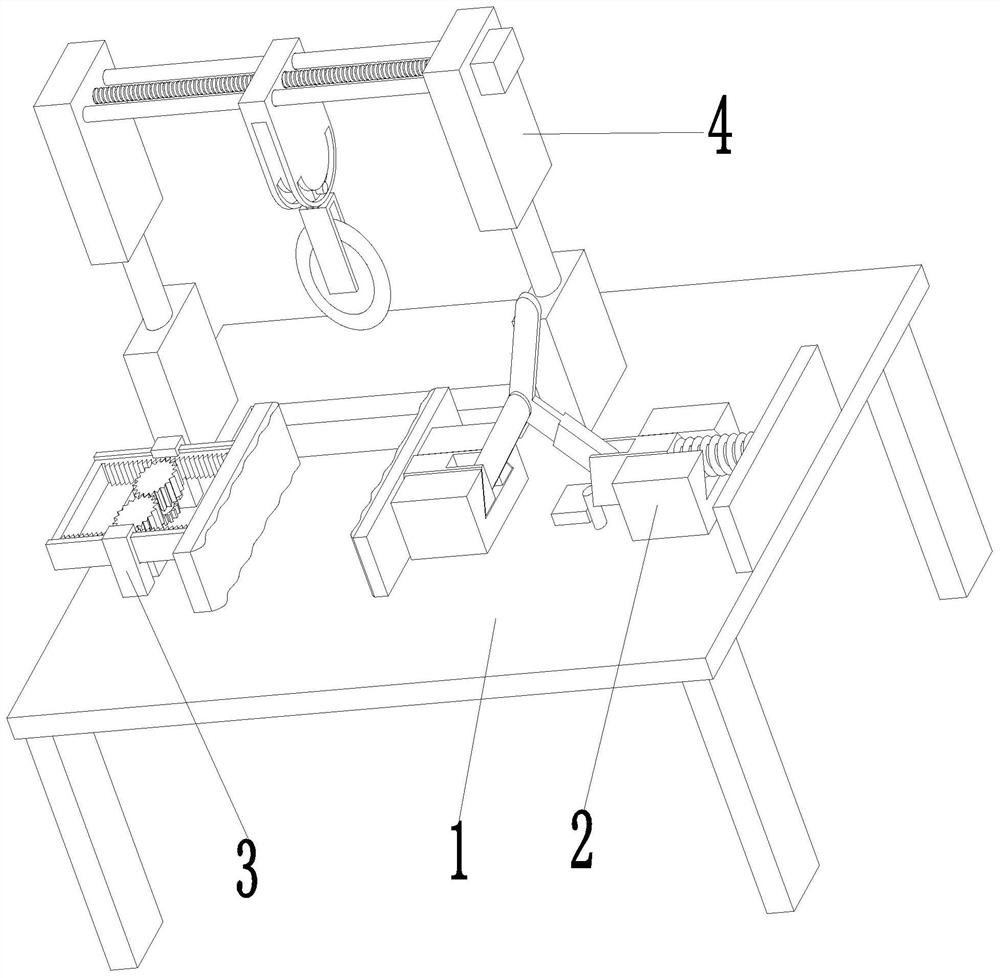

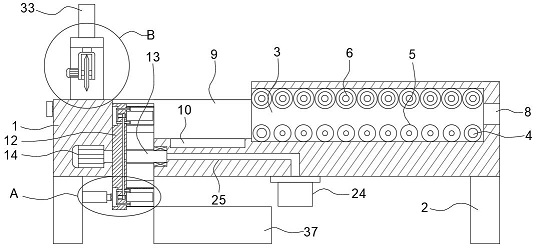

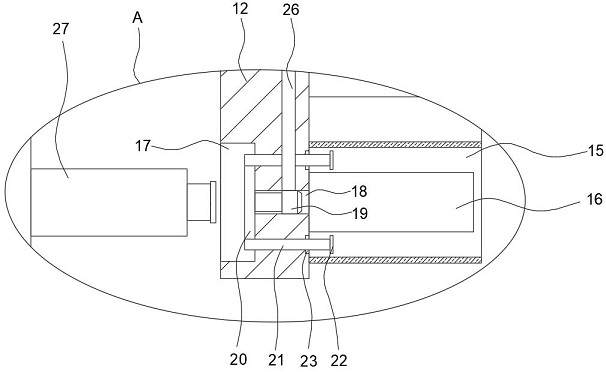

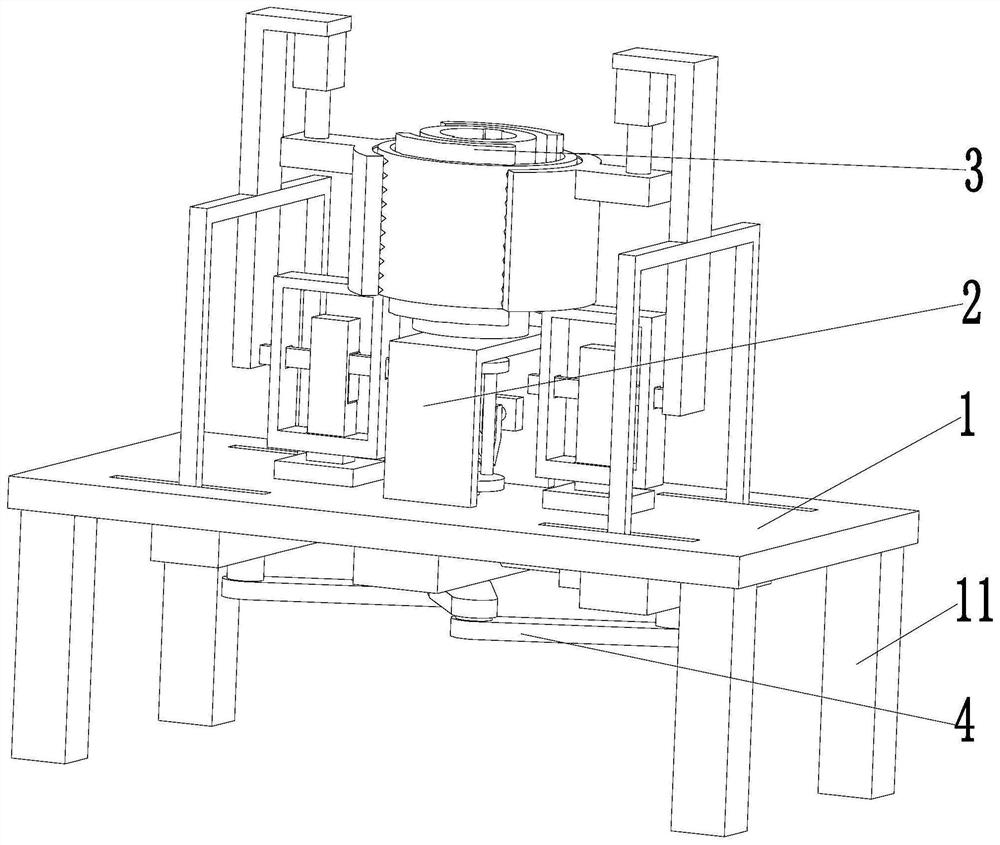

Plastic corrugated pipe forming processing method

ActiveCN111438970AReduced service lifeStable cutting workMetal working apparatusTubular articlesMolding machineMachining

The invention relates to a plastic corrugated pipe forming machining method. The method mainly comprises the following steps: mixing and stirring, heating and drying, forming treatment, cooling forming, grain cutting, cutting operation and the like; and used corrugated pipe grain cutting equipment comprises a bottom plate, a rotating device, a clamping device and an abutting device. The followingproblems that during existing in existing corrugated pipe grain cutting, a, a production technology of traditional corrugated pipe manufacturing equipment is not mature enough, the operation is not stable enough, the grain quality of a corrugated pipe is seriously influenced, the corrugated pipe can only be manufactured through turning, but the wall thickness of the manufactured corrugated pipe isnot uniform easily due to the existing turning mode, and the service life of the corrugated pipe is shortened; and b, a traditional corrugated pipe forming machine is single in forming specification,the depth of corrugations on a pipe is low in the forming process, and the requirements in actual work cannot be met can be solved, corrugated pipe grains can be evenly and stably cut, and the production quality of the corrugated pipe is improved.

Owner:安徽惠聚管道科技有限公司

Transformer silicon steel sheet manufacturing and forming machining machine and machining method

ActiveCN113441609AImprove punching qualityImprove punching efficiency and qualityPerforating toolsMetal-working feeding devicesManufacturing engineeringTransformer

The invention relates to the technical field of transformer silicon steel sheet blanking machining, in particular to a transformer silicon steel sheet manufacturing forming machining machine and a machining method. The transformer silicon steel sheet manufacturing and forming machining machine comprises a base plate, a blanking device and a feeding device, the blanking device is installed on the base plate, and the feeding device is installed on the blanking device. According to the transformer silicon steel sheet manufacturing and forming machining machine and the machining method, the following problems existing in the transformer silicon steel sheet blanking forming process can be solved. The problems include that firstly, when a transformer silicon steel sheet is blanked through blanking equipment, deviation is generated when the transformer silicon steel sheet is blanked due to the fact that most of transformer silicon steel sheets are not subjected to stable positioning operation, the blanking quality of the transformer silicon steel sheet is reduced, if a positioning mechanism is used for positioning treatment, the operation time is additionally increased, and the machining efficiency is reduced; and secondly, manual feeding operation is needed, the blanking position of the transformer silicon steel sheet deviates due to the fact that the manual feeding distance is difficult to control, and waste of the transformer silicon steel sheet is caused.

Owner:江苏保庆电器设备有限公司

Ventilating duct construction method

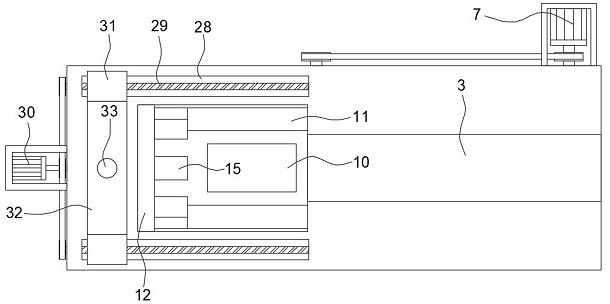

InactiveCN109158685AImprove construction efficiencyEasy to replaceTube shearing machinesShearing machine accessoriesArchitectural engineeringEngineering

The invention discloses a ventilating duct construction method. According to the method, a construction frame body and a clamping and fixing assembly installed on the lower side of the construction frame body are involved, wherein a containing cavity is formed in the end surface of the bottom of the construction frame body, a cutting machine body is installed in the containing cavity in a slidingfit mode, convex blocks are bilaterally symmetrically and fixedly arranged on the end surface of the top of the cutting machine body, a buffering elastic piece is installed on the convex blocks, a piston rod is fixedly arranged in the right center of the top end of the buffering elastic piece, the top end of the piston rod is in power fit connection with an air pressure cylinder, the air pressurecylinder is fixedly arranged in the top wall of the containing cavity, concave cavities are bilaterally symmetrically formed in the positions, on the left side and the right side of the containing cavity, in the bottom end surface of the construction frame body, vertical transmission cavities are arranged in the positions, on the inner sides of the containing cavity, in the construction frame bodyin an up-and-down extension mode, the tail ends of the tops of the vertical transmission cavities communicate with transverse transmission cavities extending leftwards and rightwards, and a driving motor is fixedly arranged between the transverse transmission cavities on the left side and the right side.

Owner:俞耀

Traditional Chinese medicine raw material slicing device

InactiveCN110465979AStable structureRun smoothlyMetal working apparatusSlice thicknessChinese herbology

The invention relates to a traditional Chinese medicine raw material slicing device. The traditional Chinese medicine raw material slicing device comprises a rack. A conveying belt is arranged on therack. The feeding end of the conveying belt is provided with a hopper used for restraining medicinal materials to horizontally move. An opening allowing the medicinal materials to descend is formed inthe lower end of the hopper. A slicing knife and a material supporting surface which are arranged at intervals up and down are arranged at the lower end of the hopper and are horizontally arranged. The distance between the slicing knife and the material supporting surface is consistent with the slice thickness of the medicinal materials. The material supporting surface is used for supporting themedical materials. The slicing knife and the material supporting surface are connected with a driving mechanism. The driving mechanism is used for driving the slicing knife and the material supportingsurface to horizontally move. The slicing knife horizontally moves to slice the medicinal materials. The material supporting surface horizontally moves to transfer the sliced medicinal materials to the conveying belt. The traditional Chinese medicine raw material slicing device is stable in structure, reasonable in layout, stable in operation, high in slicing efficiency, low in slicing crushing rate and capable of realizing automatic slicing processing and meeting existing use requirements.

Owner:安徽亳药千草中药饮片有限公司

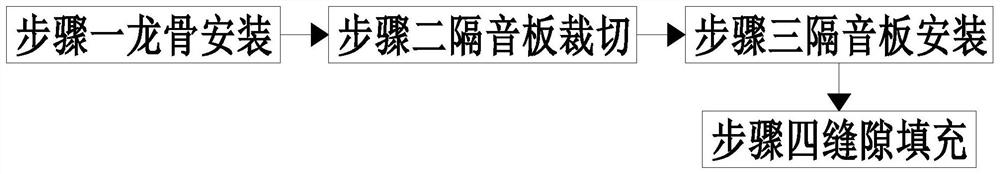

A cutting device for building sound insulation panels

InactiveCN111997213BReduce installation efficiencyImprove crop qualitySound proofingClassical mechanicsEngineering

The present invention relates to a cutting device for building sound insulation panels. The method for installing the sound insulation panels using the cutting equipment for building sound insulation panels mainly includes the following steps: keel installation, sound insulation panel cutting, and sound insulation panel installation As well as various processes such as gap filling, the sound insulation panel cutting equipment used includes a bottom plate, a positioning device, a pressing device and a cutting device. The present invention can solve the following problems existing in the existing sound insulation panel cutting, a. Traditional When cutting the sound insulation board, it is necessary to manually hold the cutting tool to cut the sound insulation board. The safety hazard of manual cutting of the sound insulation board is relatively large, and the labor intensity of manual cutting is high, and the cutting efficiency is low, which reduces the quality of the sound insulation board. For the efficiency of installation, the manually cut sound insulation panels often have burrs, which affects the use of the sound insulation panels.

Owner:安徽中南天开建设集团有限公司

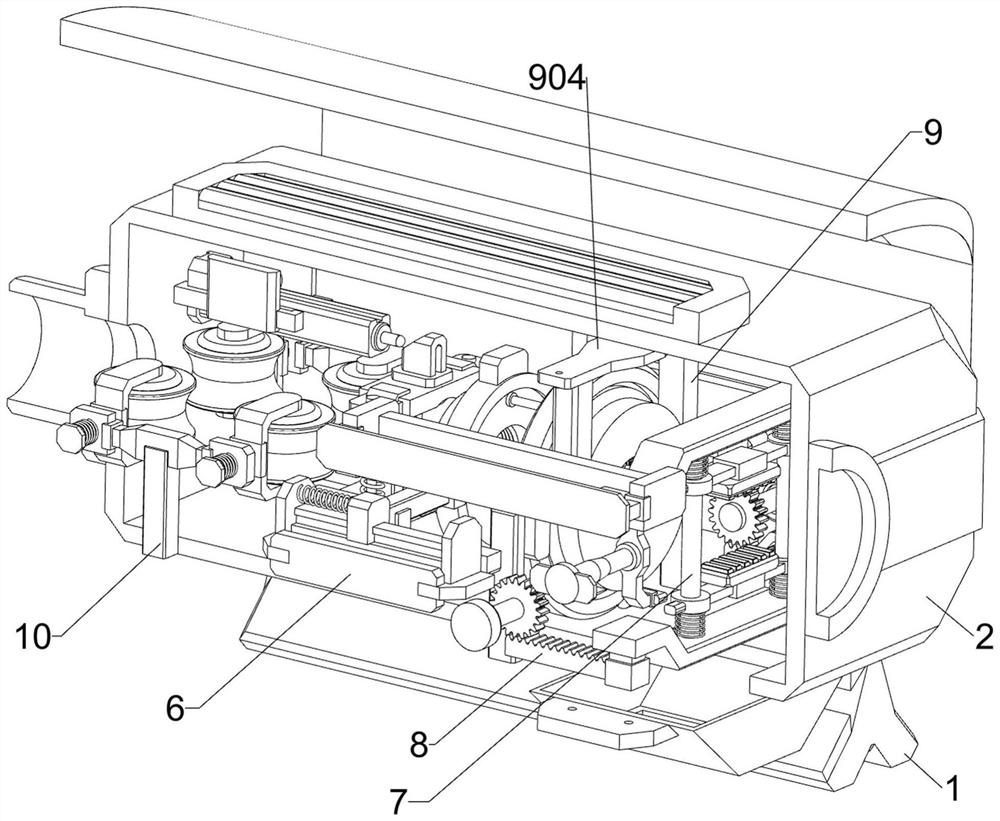

A construction cutting machine capable of converting and cutting walls and grounds

ActiveCN108356991BEffective size controlReduce mistakesWorking accessoriesStone-like material working toolsArchitectural engineeringWater spray

The invention discloses a building cutting machine capable of conducting conversion cutting on the wall surface and the ground. The building cutting machine comprises a main handle and a protection shell. A cutting blade is mounted on the inner side of the protection shell, and the outer side of the protection shell is provided with a scale line, a positioning plate and sliding grooves; the positioning plate is arranged on the sliding grooves, and the scale line is arranged in the middle of the positioning plate; a water-spraying electromagnetic valve is fixed to the upper side of the protection shell, and the outer side of the water-spraying electromagnetic valve is connected with a water-guiding hose; and a main moving rod and an auxiliary moving rod are connected through a connecting bottom plate, and fastening bolts are mounted on the connecting bottom plate. According to the building cutting machine capable of conducting conversion cutting on the wall surface and the ground, corresponding adjusting work can be conducted on different working faces of a building, and accordingly, cutting work on the different working faces of the building is completed; and the size of cutting work can further be controlled effectively in the cutting process, and thus the cutting work error of the device is reduced effectively.

Owner:扬州市生态科技新城润业中小企业服务中心有限公司

Steel coil flying shear transverse cutting device with positioning structure

InactiveCN114700552AAvoid offsetImprove cut qualityMetal-working feeding devicesStock shearing machinesReciprocating motionEngineering

The invention discloses a steel coil flying shear transverse cutting device with a positioning structure, which comprises a rack, two meshed fluted discs are mounted on the outer wall of the rack, cutter heads are fixed on the outer walls of the fluted discs, cutters are fixed on the outer walls of the cutter heads, conveying rollers are mounted on the rack, and the conveying rollers are fixed on the rack. The outer wall of the rack is further provided with a positioning device located between the conveying rollers. And a cooling mechanism located on the outer sides of the two cutters is arranged on the outer wall of the rack, the cooling mechanism comprises a fixed pipe, a movable rod is arranged in the fixed pipe in a sliding mode, and the outer wall of the movable rod is sleeved with a telescopic spring. A steel coil is positioned through the positioning mechanism, the steel coil is prevented from deviating, the stability of transverse cutting work is guaranteed, in the reciprocating motion process of the cutter, through contact between a coating layer and the cutter, contact between cooling liquid and a cutting edge is achieved, cooling and lubricating of the cutting edge are conducted, damage to the cutting edge is avoided, and the service life is prolonged.

Owner:南通宏久金属制品有限公司

A device for slicing raw materials of traditional Chinese medicine

InactiveCN110465979BAvoid fragileRealize functionMetal working apparatusMedicinal herbsConveyor belt

The invention relates to a traditional Chinese medicine raw material slicing device, which includes a frame, on which a conveyor belt is installed, and a hopper for constraining the horizontal movement of the medicinal material is installed at the feeding end of the conveyor belt. There are slicing knives and supporting surfaces arranged at intervals up and down. The slicing knives and supporting surfaces are arranged horizontally. The distance between the slicing knives and the supporting surface is consistent with the slice thickness of the medicinal materials. The driving mechanism is connected with the supporting material surface, and the driving mechanism is used to drive the slicing knife and the supporting material surface to move horizontally. The slicing knife moves horizontally to slice the medicinal materials, and the supporting material surface moves horizontally to transfer the sliced medicinal materials to the conveyor belt. The structure of the invention is stable. , reasonable layout, stable operation, high slicing efficiency, low slicing breakage rate, automatic slicing processing can be realized, which meets the current use requirements.

Owner:安徽亳药千草中药饮片有限公司

Peeling device for assembling connecting wire of electrical equipment

PendingCN113659409AImprove cutting efficiencyImprove peeling efficiencyLine/current collector detailsApparatus for removing/armouring cablesEngineeringStructural engineering

The invention relates to a peeling device, in particular to a peeling device for assembling a connecting wire of electrical equipment, and aims to provide the peeling device for assembling the connecting wire of the electrical equipment, which has pressing and fixing effects and can quickly separate a rubber skin. According to the technical scheme, the peeling device for assembling the connecting wire of the electrical equipment comprises a shell and first supports arranged at the two sides of the bottom of the shell; a cutting assembly arranged at one side in the shell; cutting knives symmetrically connected to the cutting assembly; and a downward pressing assembly arranged on the inner side of the shell, and matched with the cutting assembly. A telescopic rod of an electric push rod makes contact with a third contact block, the third contact block and a first clamping plate are driven to move downwards, the first clamping plate presses a connecting wire downwards, the connecting wire can be stably cut, and the cutting efficiency of the connecting wire is effectively improved.

Owner:江西兰丰科技有限公司

Adjustable high-precision biaxial slitting machine

PendingCN108515552AStable cutting workEasy to replaceMetal working apparatusArticle deliveryAgricultural engineeringLaser

The invention discloses an adjustable high-precision biaxial slitting machine comprising a left bracket, a right bracket and a film roller. A cutter device is arranged above the film roller, and comprises a cylinder frame, cutter adjusting cylinders, cutter fixing blocks and cutters; the cylinder frame is removably provided with a plurality of cutter adjusting cylinders, and the lower end of a piston rod of each cutter adjusting cylinder is welded with a connecting plate; the lower end face of each cutter fixing block is welded with one cutter, and the front end face of each cutter fixing block is provided with a storage groove; and each storage groove is provided with a laser sight in an embedded manner; a waste collecting box is arranged below the film roller, and the upper ends of stainless steel flexible conduits welded with the front end face of the waste collecting box are welded with a stainless steel measuring scale arranged transversely. According to the technical scheme, theslitting machine has the advantages of rational structure design, simple structure, easy replacement of the cutters, easy control over film sizes, stable cutting quality and easy operation.

Owner:YONGYI GRP

Stainless steel section bar cutting device

ActiveCN112108926AWon't fall offQuality assuranceFeeding apparatusLarge fixed membersElectric machineryStructural engineering

The invention discloses a stainless steel section bar cutting device which comprises a processing table and two supporting bases fixedly mounted at the two sides of the lower end of the processing table, wherein a conveying box is embedded into the right side of the upper end of the processing table; a conveying device is arranged inside the conveying box; the conveying device comprises drive rollers which are rotatably connected to front and rear inner walls of the conveying box and are separately positioned at the two ends below the inner part of the conveying box; a plurality of guide rollers are uniformly arranged on positions, between the two drive rollers, in the conveying box; the guide rollers are flush to the upper ends of the drive rollers; ends, at the rear side, of the two drive rollers penetrate through the rear side wall of the conveying box and extend to positions behind the processing table; and a first motor is fixedly mounted at the rear end of the processing table. The stainless steel section bar cutting device has the advantages of high degree of automation, automatically regulating and cutting by the conveying device and an unloading device, greatly improving cutting efficiency, guaranteeing quality of stainless steel section bars and improving safety.

Owner:张严艳

A kind of plastic bellows forming processing method

ActiveCN111438970BReduced service lifeStable cutting workMetal working apparatusTubular articlesMolding machineMachining

The invention relates to a plastic corrugated pipe forming machining method. The method mainly comprises the following steps: mixing and stirring, heating and drying, forming treatment, cooling forming, grain cutting, cutting operation and the like; and used corrugated pipe grain cutting equipment comprises a bottom plate, a rotating device, a clamping device and an abutting device. The followingproblems that during existing in existing corrugated pipe grain cutting, a, a production technology of traditional corrugated pipe manufacturing equipment is not mature enough, the operation is not stable enough, the grain quality of a corrugated pipe is seriously influenced, the corrugated pipe can only be manufactured through turning, but the wall thickness of the manufactured corrugated pipe isnot uniform easily due to the existing turning mode, and the service life of the corrugated pipe is shortened; and b, a traditional corrugated pipe forming machine is single in forming specification,the depth of corrugations on a pipe is low in the forming process, and the requirements in actual work cannot be met can be solved, corrugated pipe grains can be evenly and stably cut, and the production quality of the corrugated pipe is improved.

Owner:安徽惠聚管道科技有限公司

Intelligent plate processing numerical control machine tool for furniture production

InactiveCN114523525AReduce the probability of misuseImprove efficiencyProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlMachine

The intelligent plate machining numerical control machine tool for furniture production comprises a numerical control machine tool body, guide sliding ways are arranged on the two sides of the front face and the back face of the top end of the numerical control machine tool body correspondingly, and a left side machining frame is slidably connected to the exteriors of the two guide sliding ways located on the left side; a display screen is arranged at the top of one side of the front face of the right side machining frame, a control panel is arranged at the bottom of one side of the front face of the right side machining frame, a cutting mechanism is arranged at the top of the inner side of the right side machining frame, and a round piece fixing mechanism is arranged on one side in the left side machining frame. A plate fixing mechanism is arranged at the top of the numerical control machine tool body, the control panel is operated, so that the cutting mechanism is controlled to precisely machine plate wood fixed to the plate fixing mechanism and cylindrical wood fixed to the round piece fixing mechanism, the machining precision is improved, and the production efficiency is guaranteed.

Owner:NANJING FORESTRY UNIV

Flexible metal sheet cutting and processing method

ActiveCN113547166AImprove clippingEasy cuttingShearing machine accessoriesEngineeringMetallic materials

Owner:安徽大东新材料科技有限公司

Ventilation pipeline construction equipment

InactiveCN109162427AImprove construction efficiencyEasy to replaceBuilding material handlingVertical ductsArchitectural engineeringAtmospheric pressure

The invention discloses ventilation pipeline construction equipment which comprises a construction frame body and a clamping component installed on a lower side of the construction frame body. The bottom end face of the construction frame body is internally provided with a receiving cavity, a cutting machine body is installed in the receiving cavity with a sliding fit, the left and right sides ofthe top end face of the cutting machine body are symmetrically and fixedly provided with convex blocks which are equipped with buffer elastic pieces, the top end center of the buffer elastic pieces are fixedly provided with a piston rod, the top end of the piston rod is equipped with a pneumatic cylinder with a power fit which is fixedly arranged in the top wall of the receiving cavity, and concave cavities are left and right symmetrically arranged in a bottom end face of the construction frame body at left and right sides of the receiving cavity. Vertical transmission cavities extend up and down in the construction frame body at the inner sides of the concave cavities, ends of the vertical transmission cavities communicate with left and right extending lateral transmission cavities, and adriving motor is fixedly arranged between the lateral transmission cavities at left and right sides.

Owner:俞耀

A feeding device for a straw baler and its application method

The invention discloses a feeding device of a straw baler and a method for using the same, comprising a device casing, a cutting blade, a side clamping plate and a feeding plate, a first servo motor is welded and fixed on the device casing, and a second The output end of a servo motor is rotatably connected with a fixed shaft, the turntable is movably connected in the device casing, and a cutting blade is welded and fixed on the turntable, and a blanking plate is screwed in the casing of the device, and the blanking plate is provided with a The feeding trough, the bottom end of the driven shaft is welded and fixed with a screw rod, and the second transmission belt is meshed and connected to the screw rod. The feeding device of the straw baler and its use method are provided with screw rods, and the driven shaft combined with the transmission belt can drive each screw rod to rotate in the corresponding feeding trough on the cutting board, thereby stably conveying the cut straw In the subsequent extrusion process, it can effectively prevent the straw from being blocked during the feeding process, and increase the use stability of the device.

Owner:宿州市泰泓顺机械股份有限公司

Wooden floor processing machine and cutting control method thereof

InactiveCN112025861AControl angleImprove processing efficiencyProfiling/shaping machinesStructural engineeringMechanical engineering

The invention provides a wooden floor processing machine and a cutting control method thereof, and relates to the technical field of floor processing. A composite cavity is formed in the top end of the interior of a processing box; a feeding port penetrating through the composite cavity downwards is formed in the top of the processing box; side material ports are formed in the positions, corresponding to the composite cavity, on the left side and the right side of the processing box; the side material ports penetrate through the composite cavity from outside to inside; fixing plates are oppositely welded to the front end and the rear end of the inner wall of the composite cavity; a plurality of vertically-arranged pressing plate shafts are rotationally connected to the inner sides of the fixing plates; air cylinders are arranged on the left side and the right side of the processing box and located on the outer sides of the side material openings; supports are welded to the upper ends and the lower ends of the air cylinders; a cutting cavity is formed in the bottom end of the interior of the processing box; a cutting platform is fixedly connected to the bottom wall of the interior of the cutting cavity; vertical grooves are formed in the right side of the top of the cutting platform and the left side of the bottom of the front end of the processing box; and therefore, compounding and cutting works of floors can be completed at the same time, a tray bears cutting equipment, manual holding is not needed, the cutting action is more stable, and the problems of low processing efficiency and inconvenience in cutting are solved.

Owner:宿州洛通木业有限公司

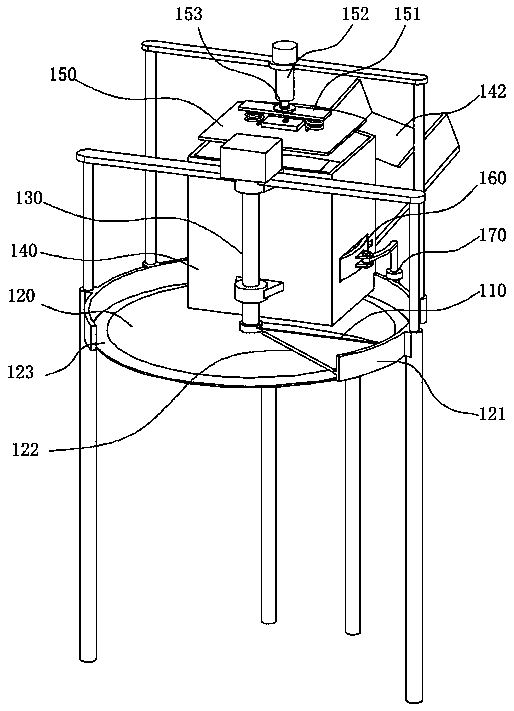

A plasma cutting auxiliary platform

ActiveCN113134735BEasy to moveEasy cutting workEdge grinding machinesGrinding carriagesThin slabEngineering

The invention discloses a plasma cutting auxiliary platform, which comprises a table board, the lower end of the table board is fixedly connected with outriggers, the lower end of the outriggers is fixedly installed with a moving mechanism, and the chamfers at the upper end of the table board are all fixedly installed There is a column, the side wall of the column is fixedly connected with a first sliding rod, and the outer wall of the first sliding rod is slidably connected with a positioning mechanism; the movement of the table can be facilitated by moving the assembly, and the height of the legs can be adjusted to facilitate the table to always Keeping the level, the positioning mechanism can facilitate the cutting and grinding switching of the cutting and grinding mechanism, and can drive the cutting and grinding mechanism to move, and the thin plate can be cut and polished through the cutting and grinding mechanism, ensuring that the cutting and grinding mechanism maintains the same height and stability when moving The movement of the machine can improve work efficiency and ensure work quality. The residue generated by cutting and grinding enters the inclined bucket through the opening and then enters the collecting box to prevent the residue from affecting the surrounding environment.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com