Patents

Literature

112results about How to "No extrusion deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

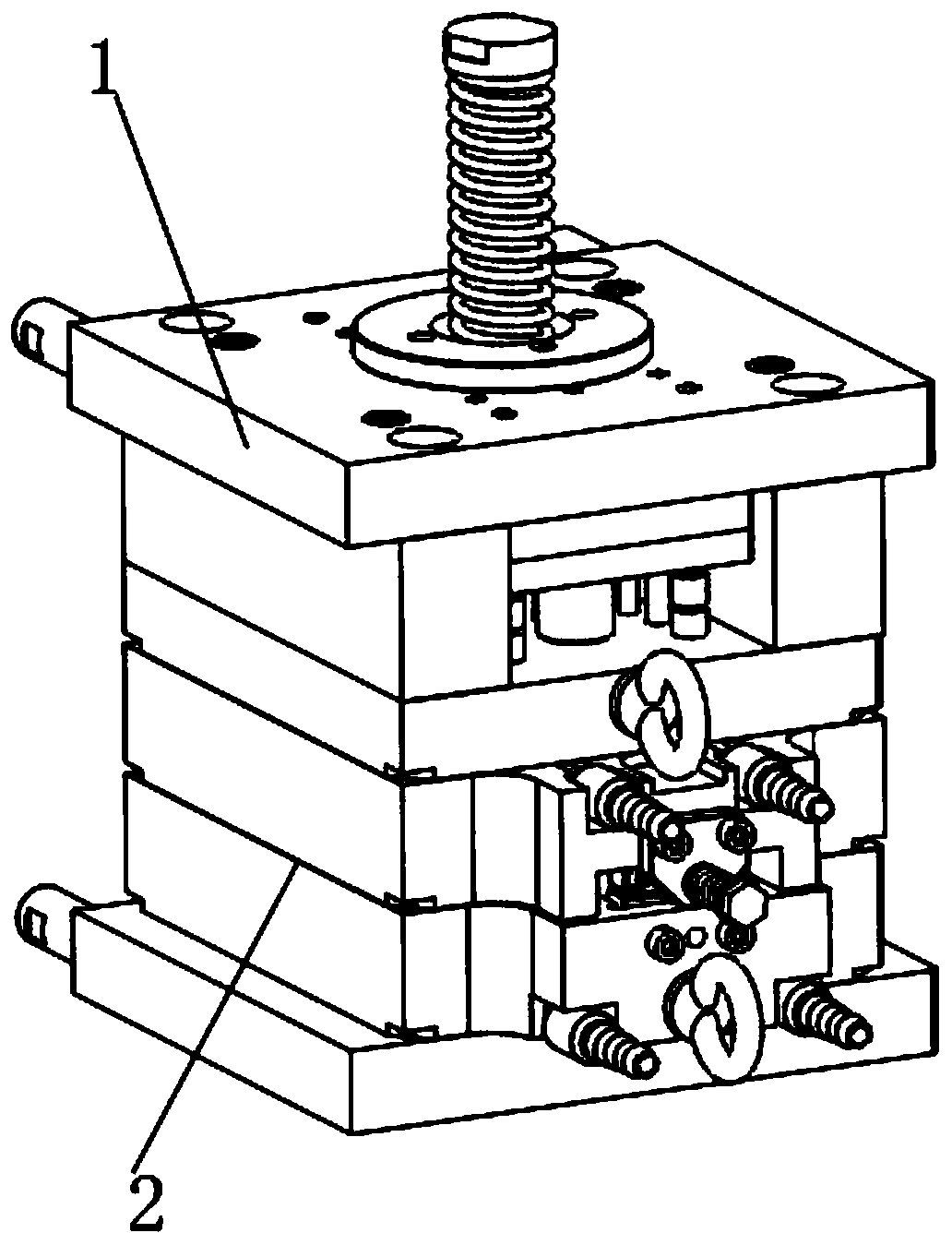

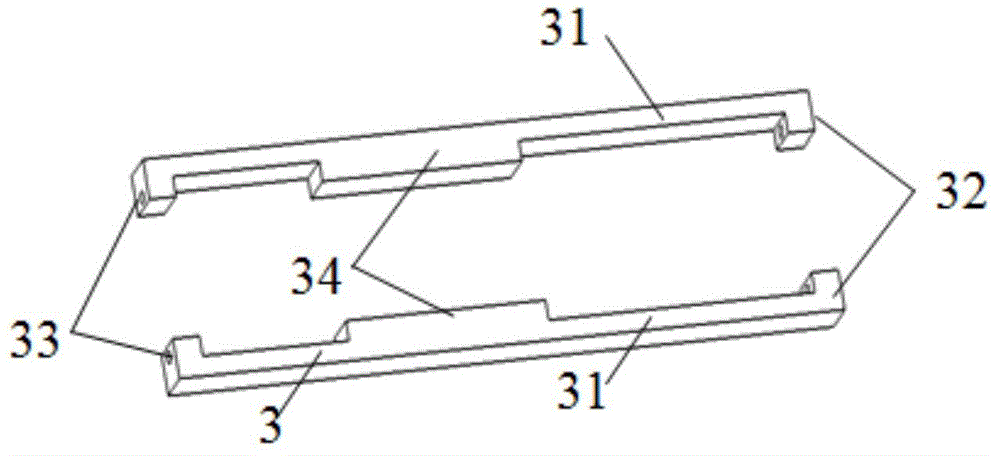

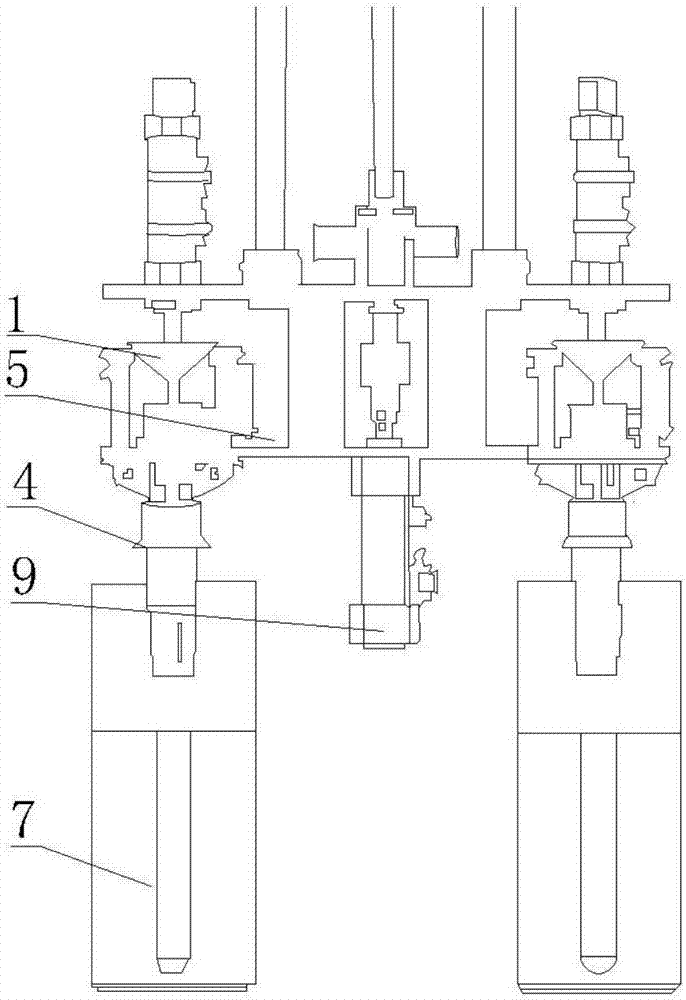

Caterpillar track link clamping device

InactiveCN103481077ANo extrusion deformationPositioning apparatusMetal-working holdersFlangeEngineering

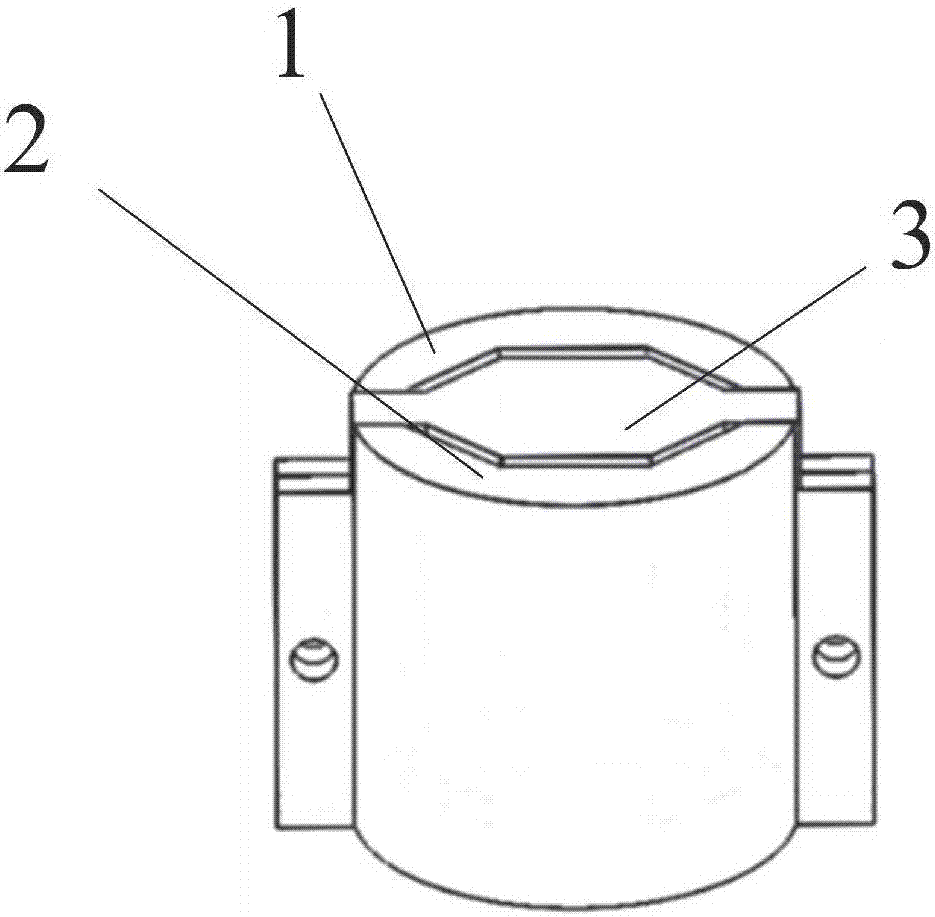

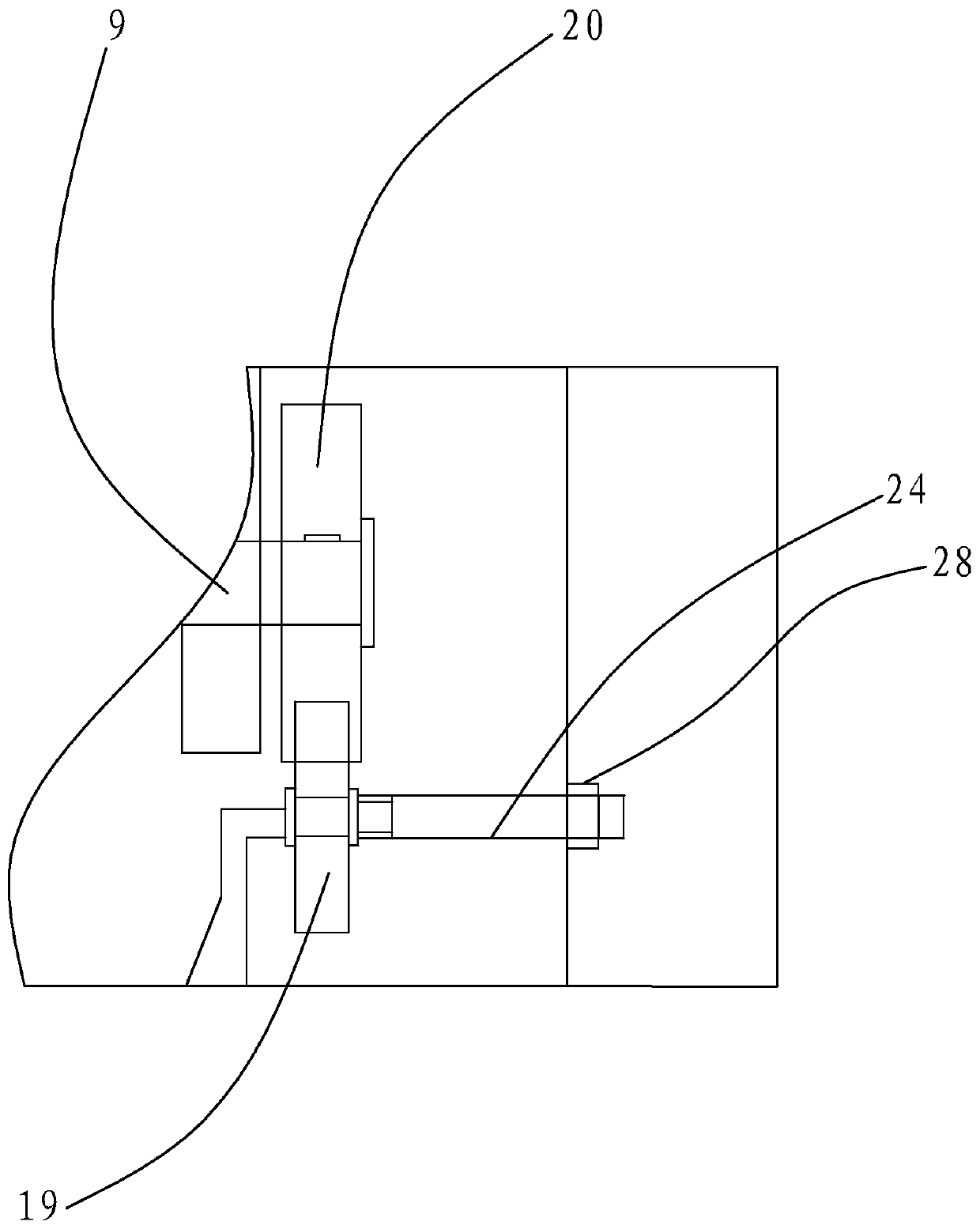

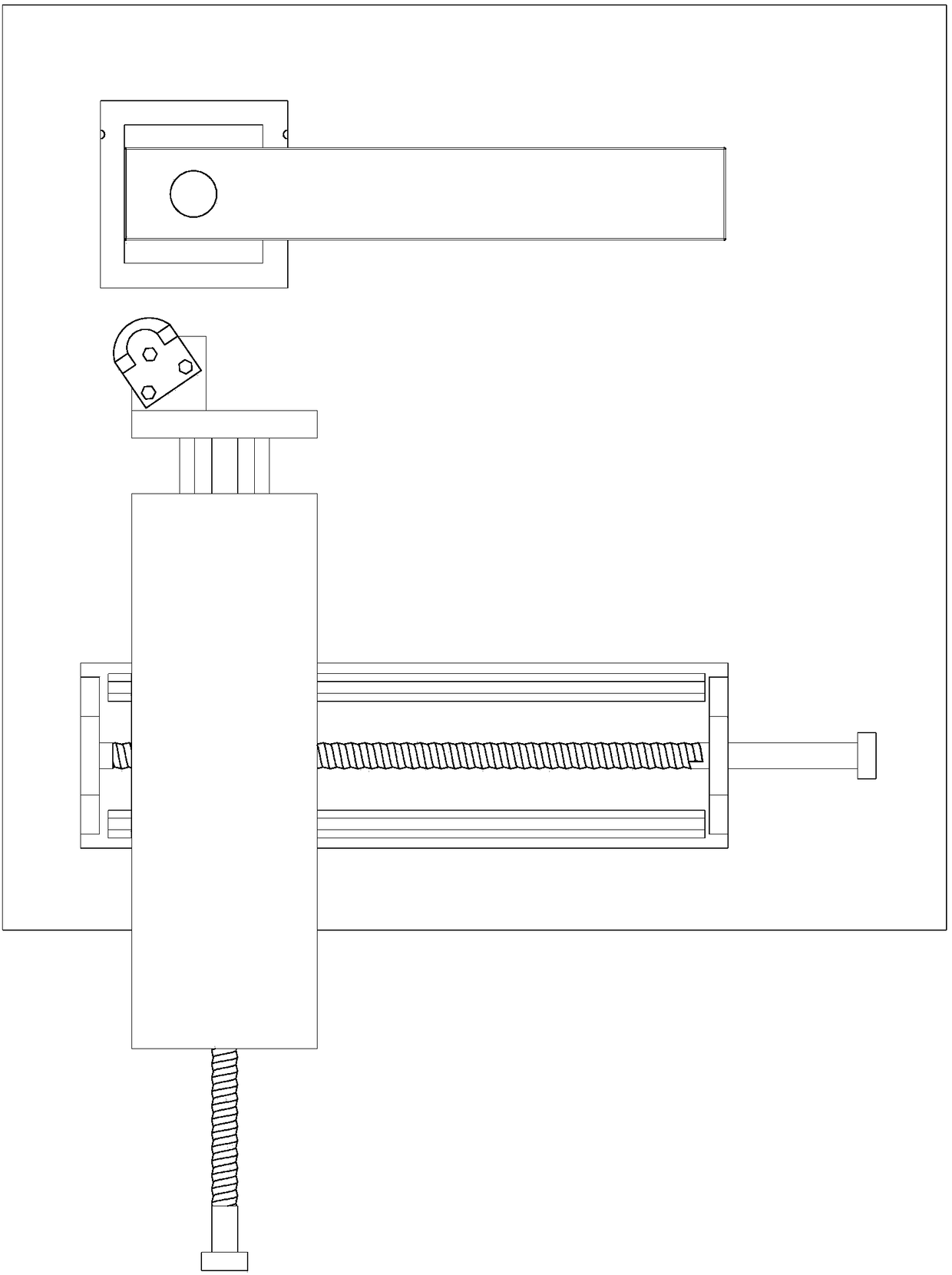

The invention relates to the technical field of caterpillar track link clamping, in particular to a caterpillar track link clamping device. The caterpillar track link clamping device comprises a device body, and further comprises a clamping component, a flange, a wedge block and an adjusting screw, wherein the adjusting screw is provided with an outer thread and is matched with an inner thread of a screw hole formed in the side wall of the device body through the outer thread; one end of the adjusting screw extends into the device body and is connected with the wedge block; an adjusting rotary knob arranged at the other end of the adjusting screw is located outside the device body; the flange is embedded in the upper portion of the device body; the clamping component is arranged in the flange in a penetrating mode, and the lower end of the clamping component is matched with the wedge face of the wedge block. An operator rotates the adjusting screw to move the wedge block, and the wedge block extrudes the clamping component to clamp workpieces; the operator can completely master the clamping process, and caterpillar track links are prevented from deforming when being extruded with overlarge clamping force.

Owner:KUNSHAN KAINUOER METAL PROD

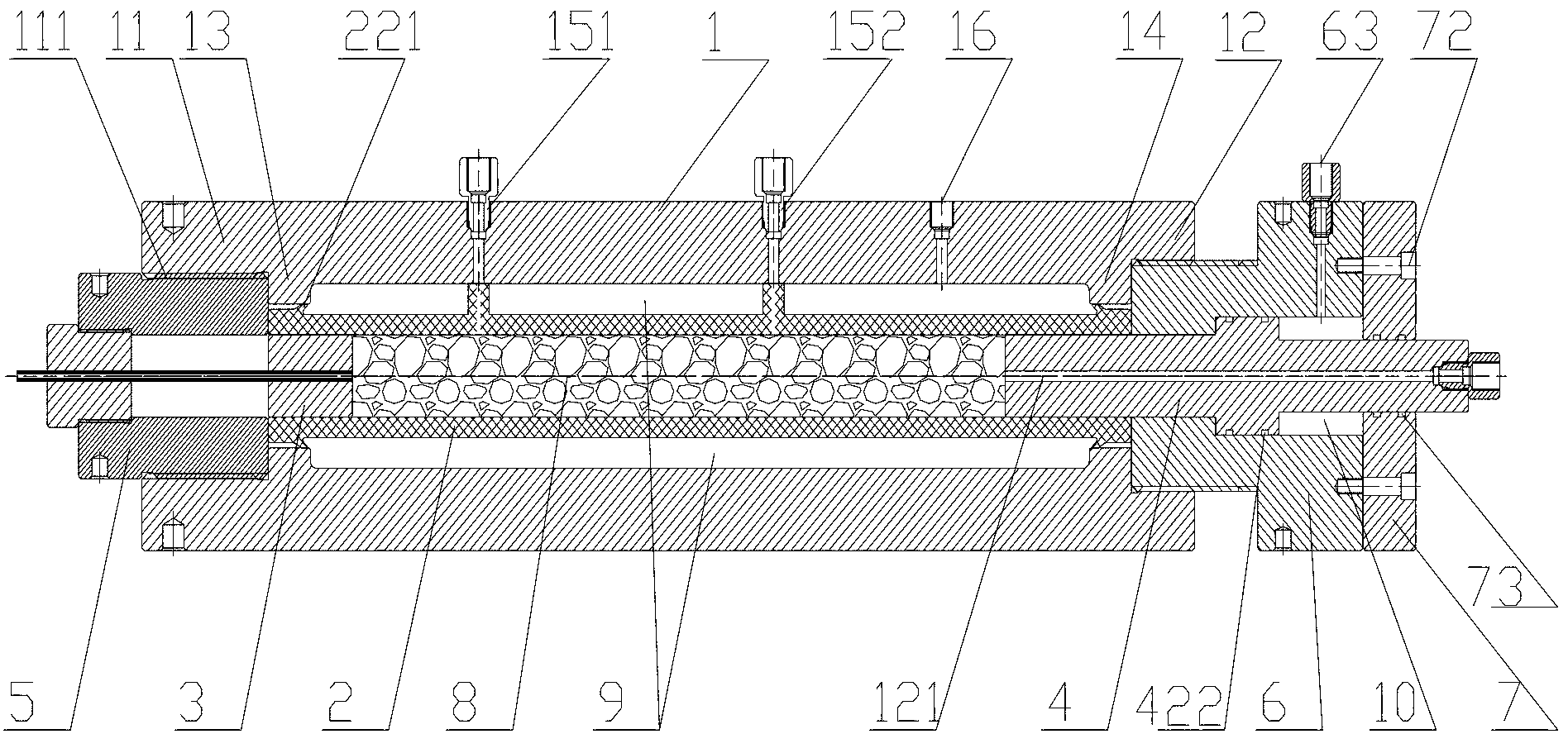

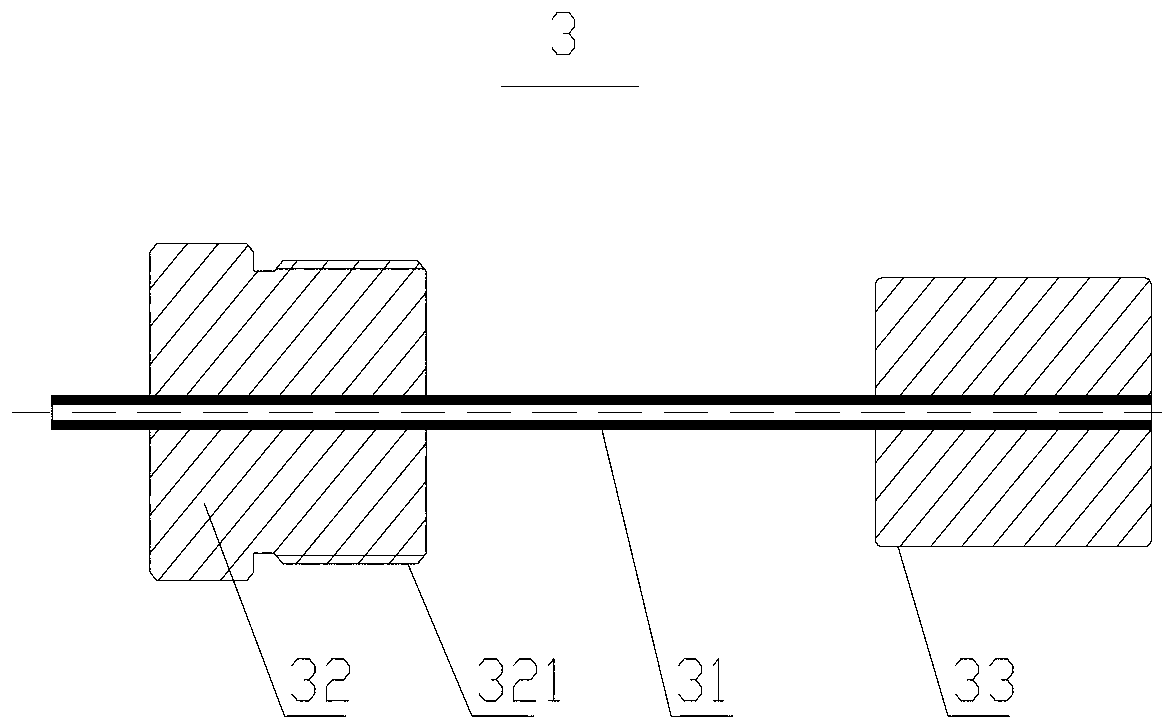

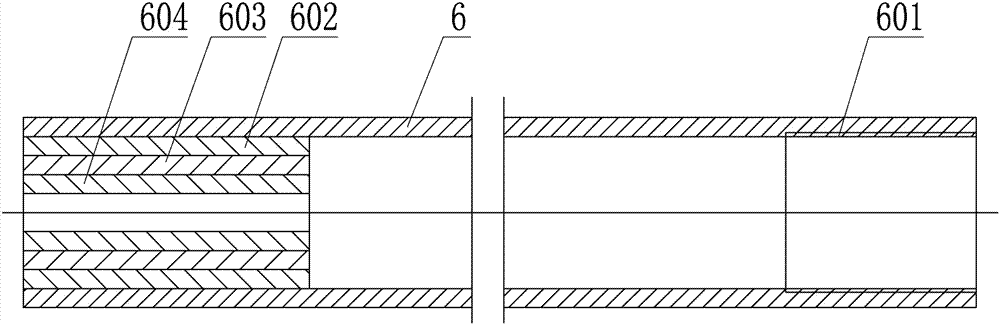

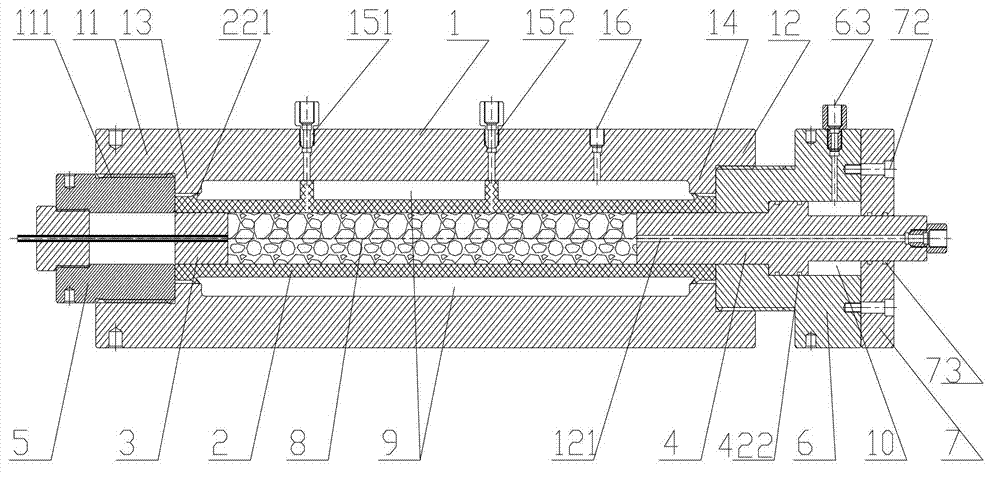

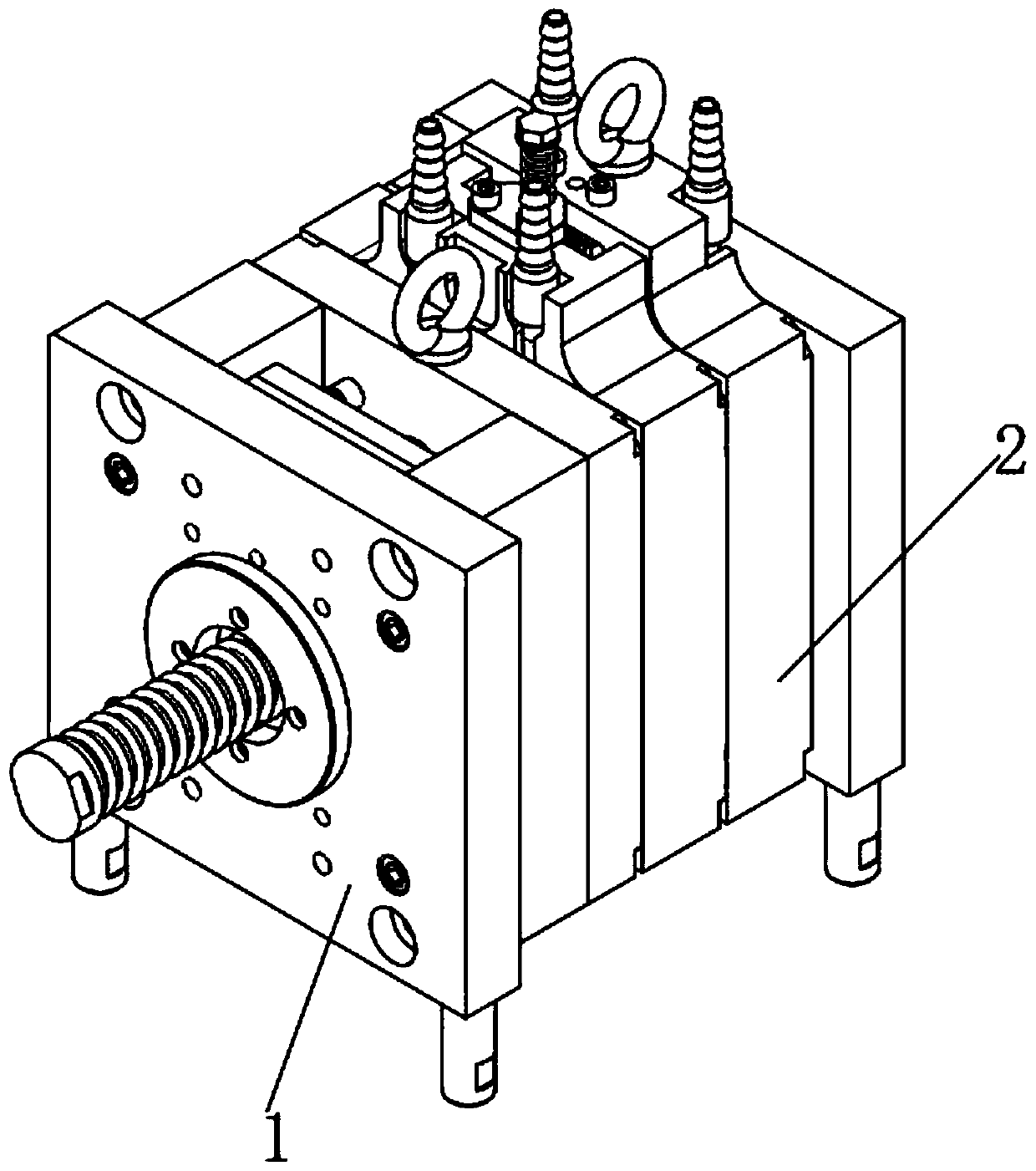

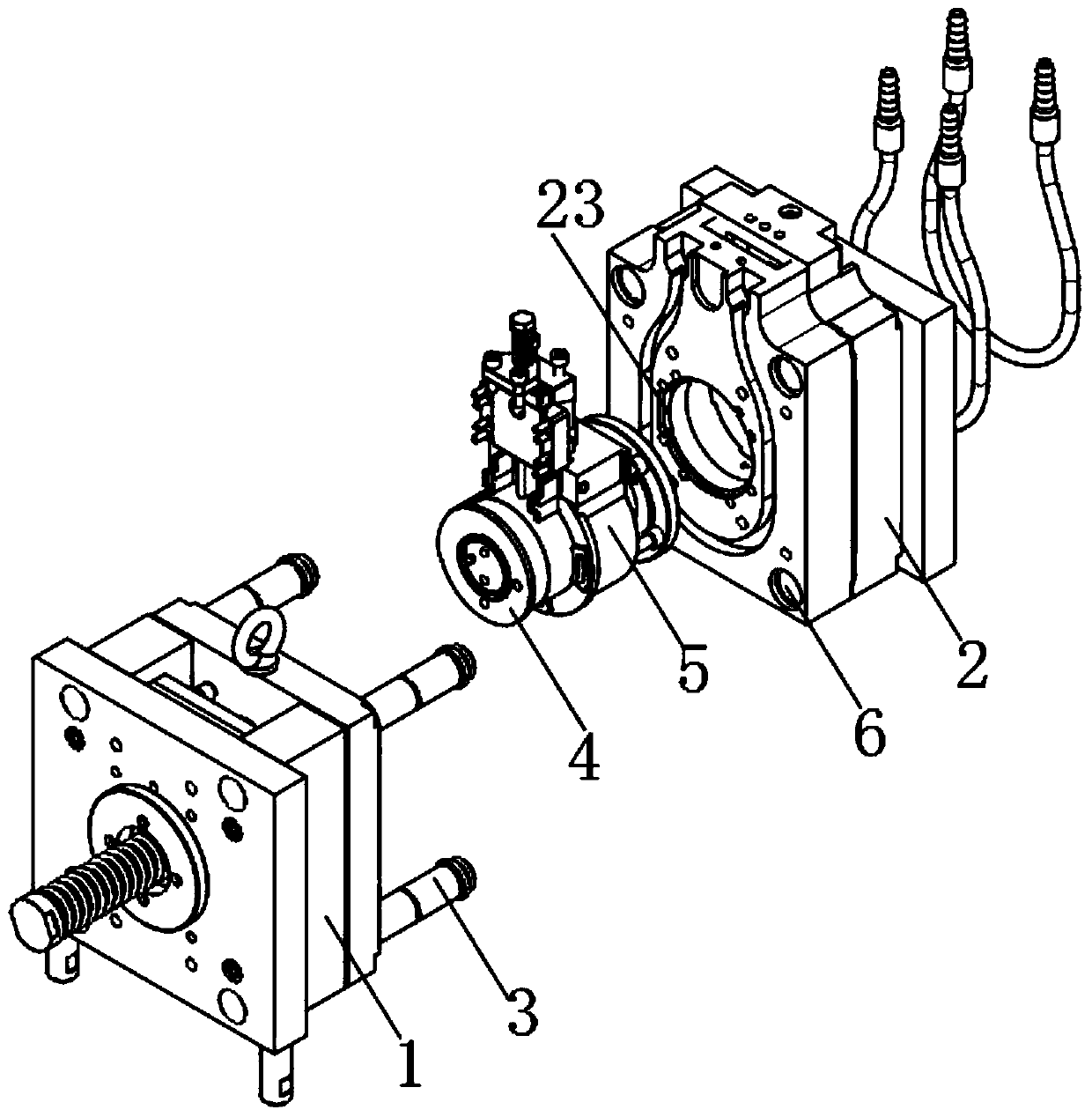

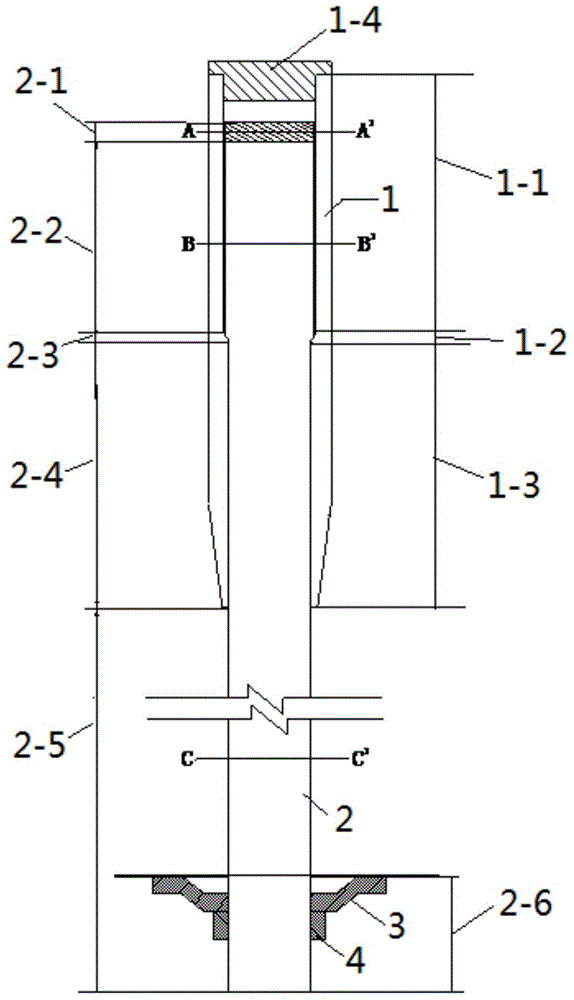

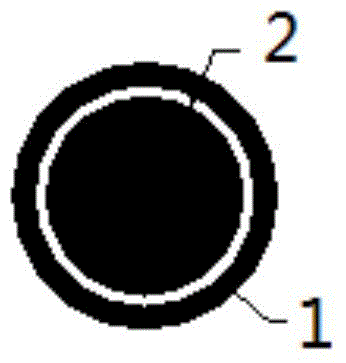

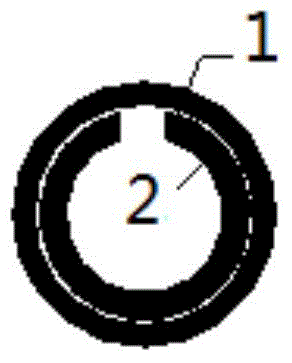

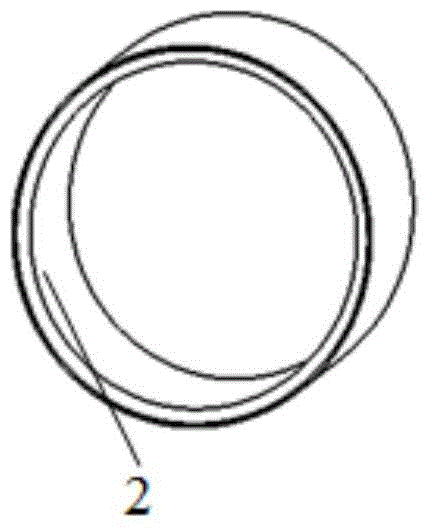

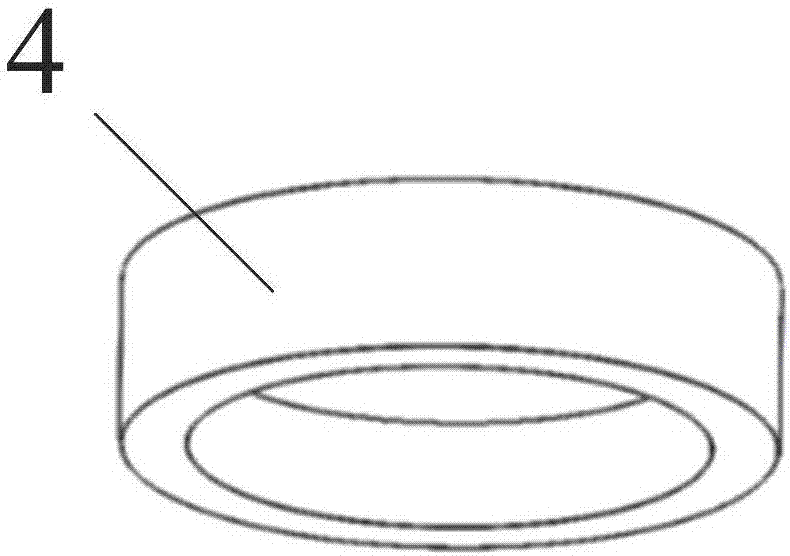

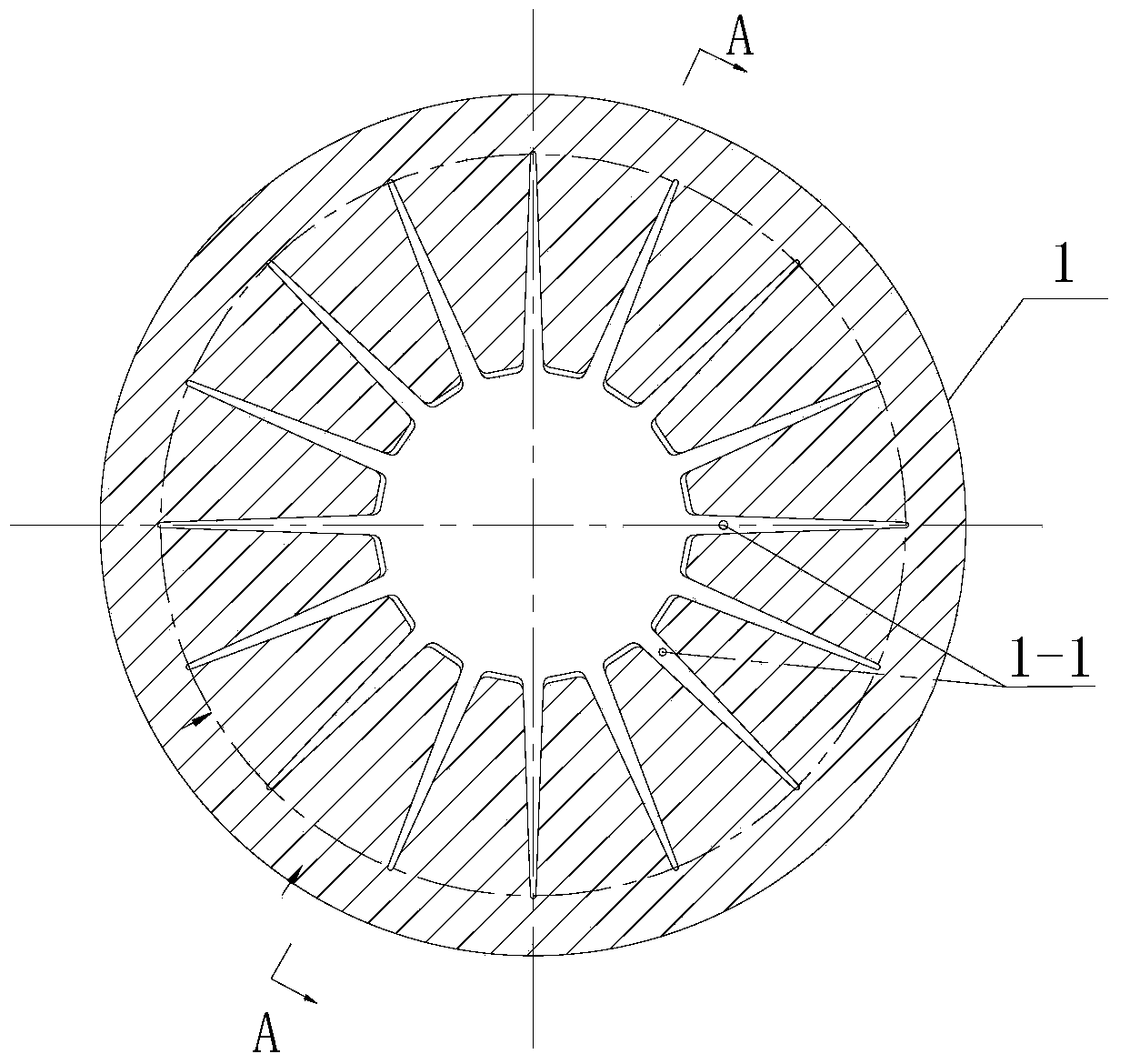

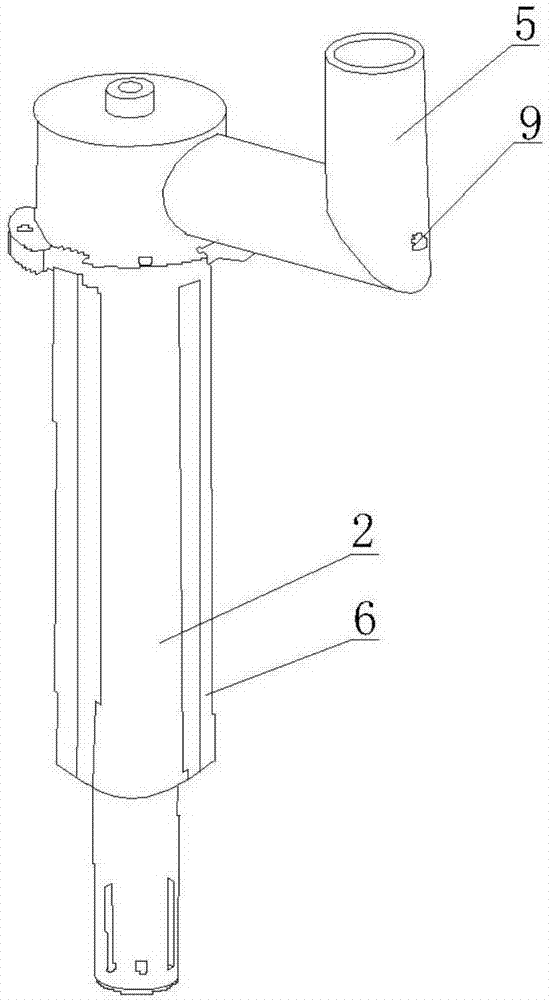

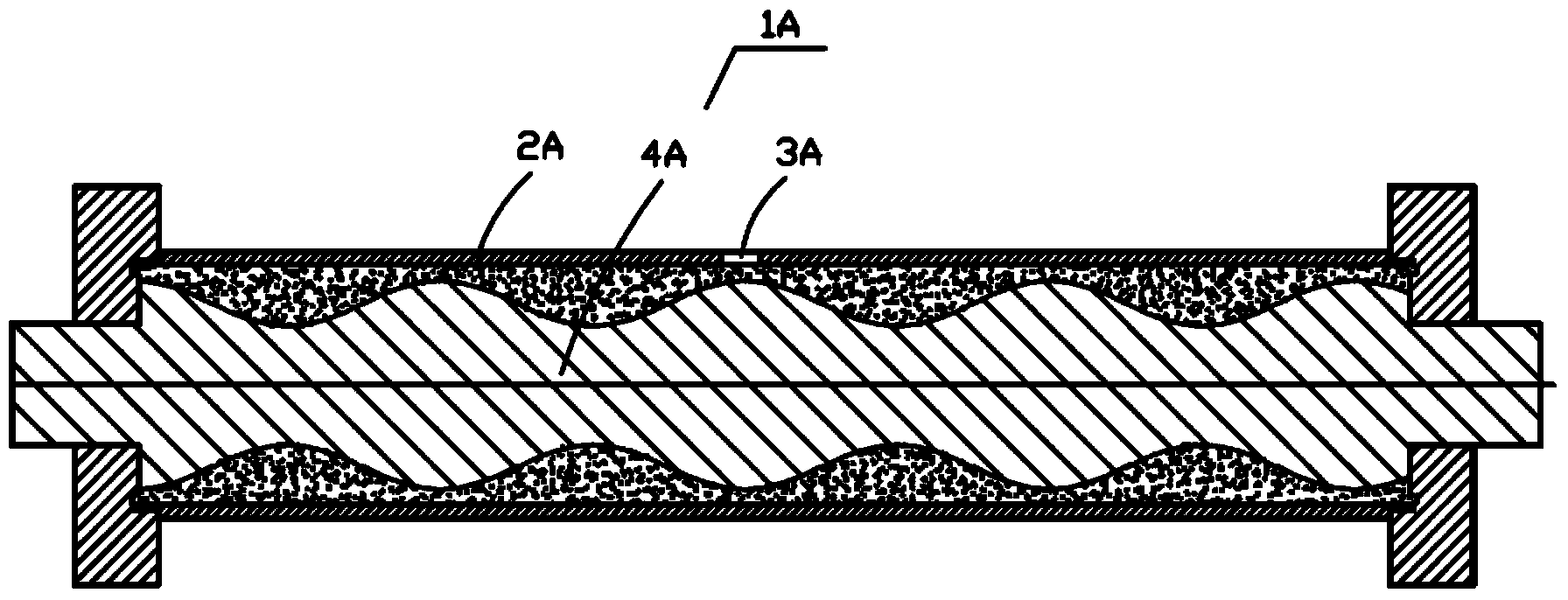

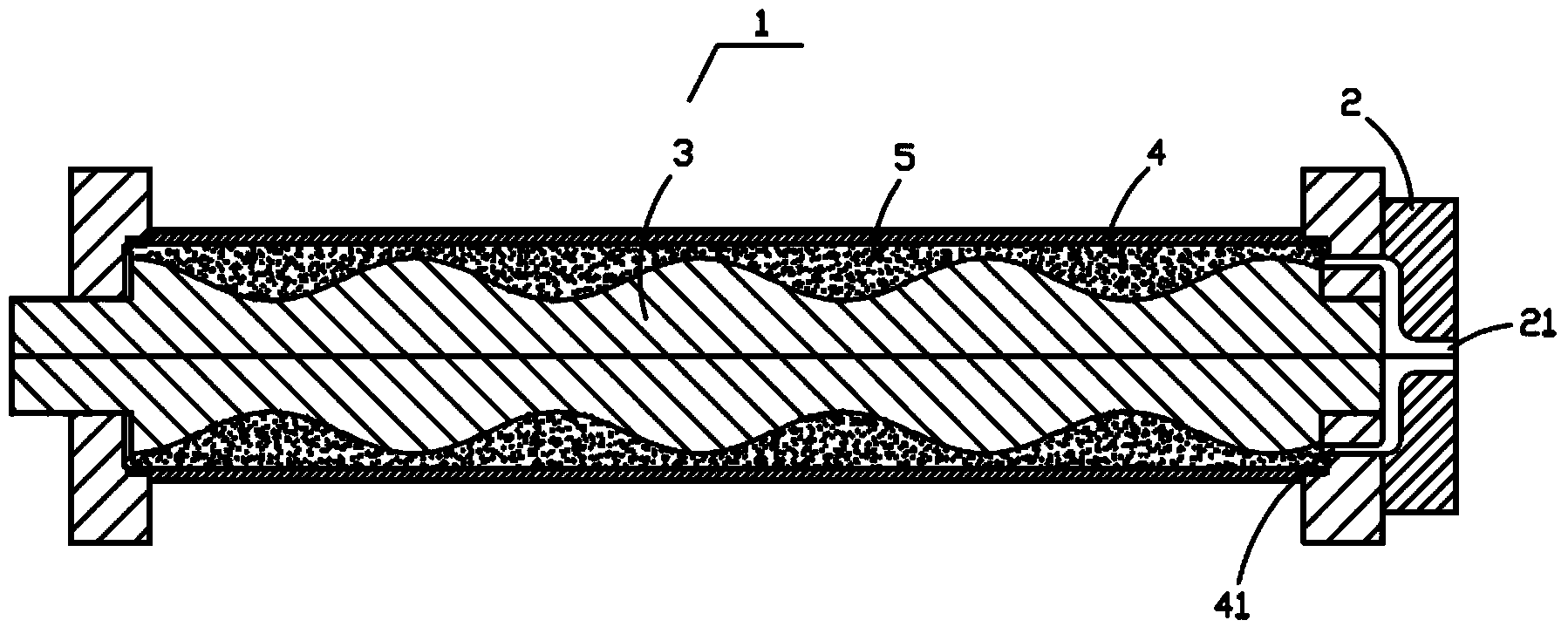

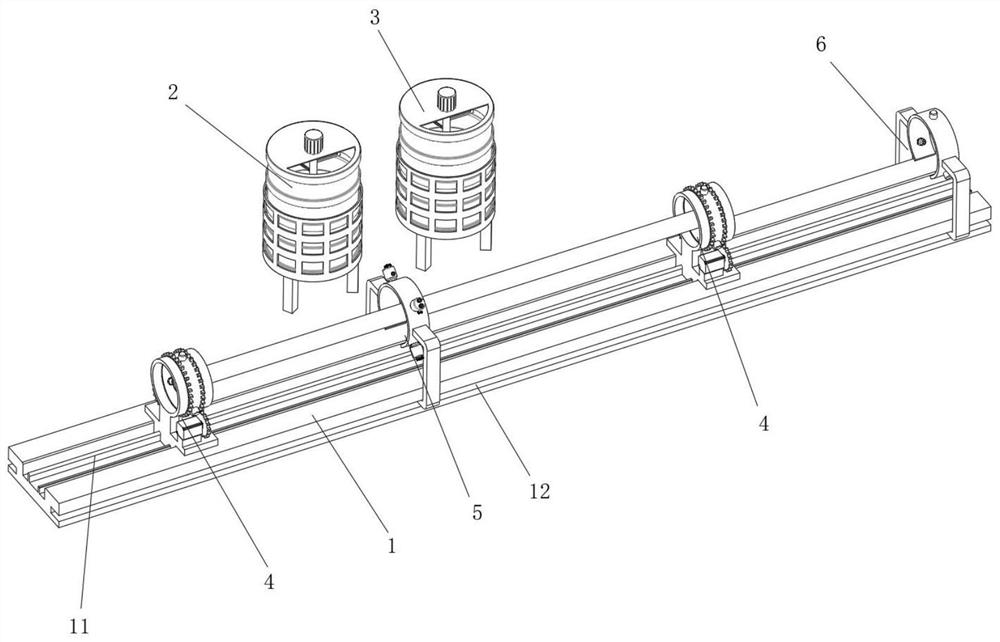

Long rock core holder

ActiveCN103234888AThick wallReduce wall thicknessPermeability/surface area analysisRock coreDead volume

The invention provides a long rock-core holder comprising a holder cylinder (1) and a high-pressure-resistant rubber sleeve cylinder (2) sleeved in the holder cylinder (1). The high-pressure-resistant rubber sleeve cylinder (2) comprises a cylinder wall (21), an inner cavity (23) positioned in the cylinder wall (21), and cylinder ports positioned on two ends of the inner cavity (23). The inner cavity (23) is in a shape of a straight cylinder. The inner diameter at the cylinder ports on the two ends equals the inner cylinder at the middle of the inner cavity (23). With the holder provided by the invention, long rock core axial multi-oressure-measuring-point detection can be carried out. The method has the advantages of low end face effect, small dead volume, high static confining pressure, and low measurement error.

Owner:PETROCHINA CO LTD

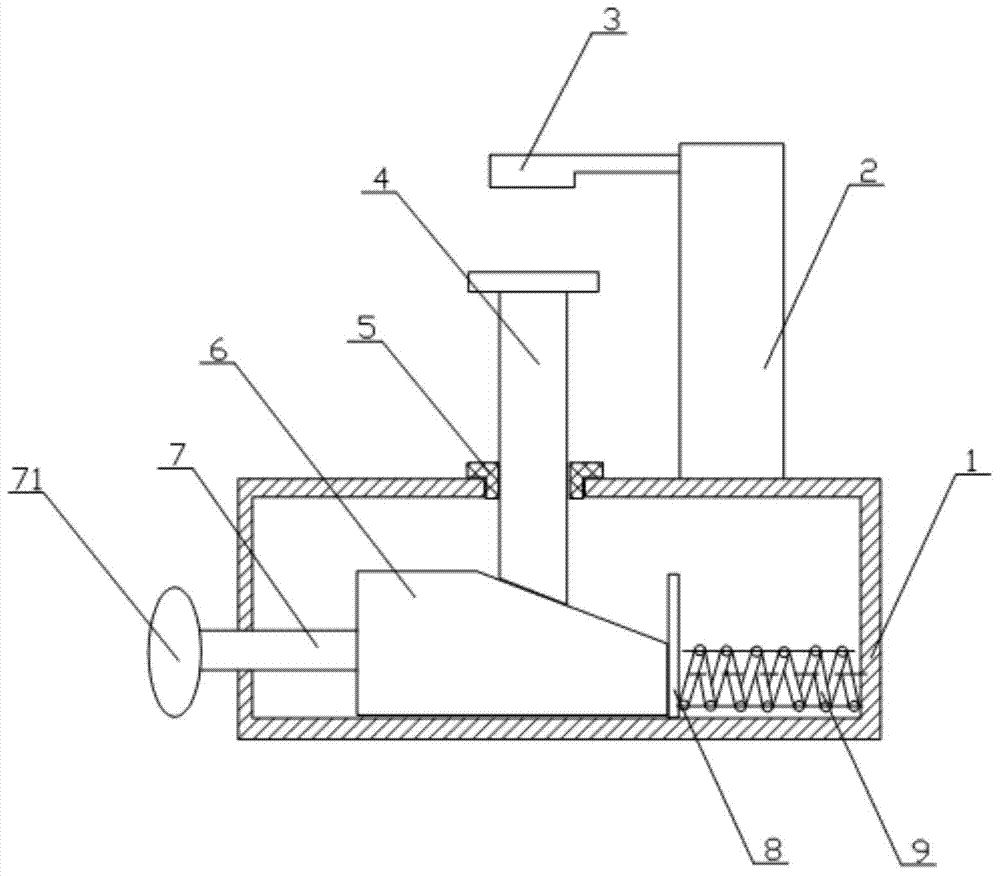

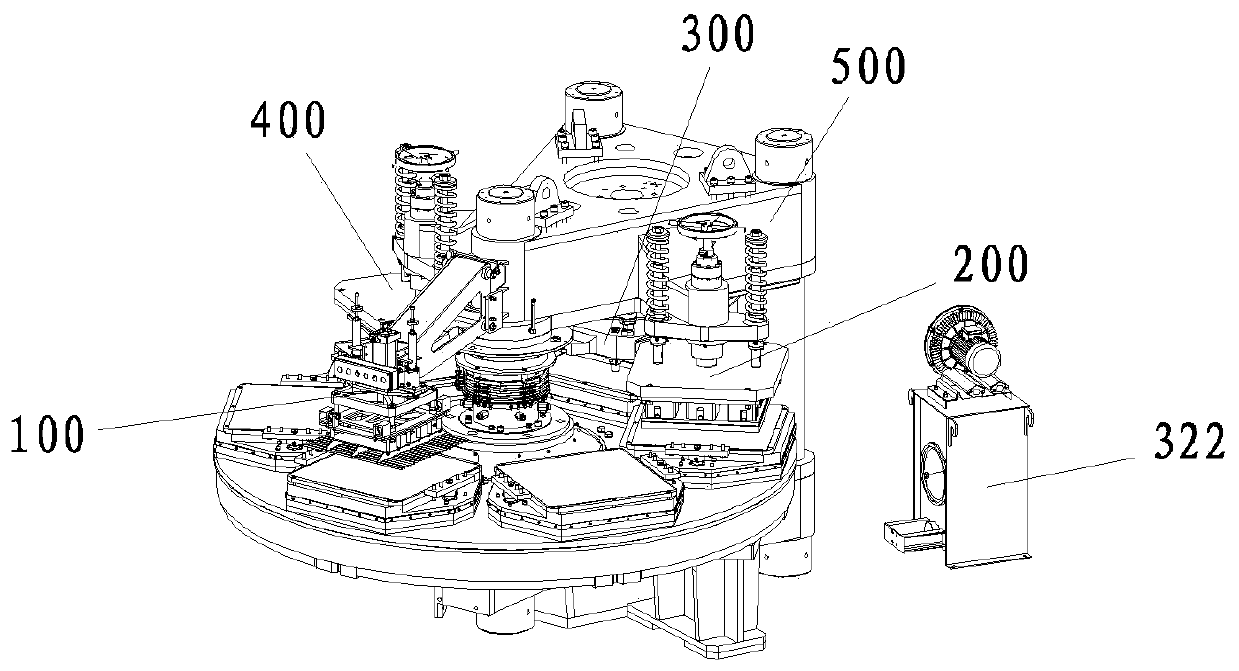

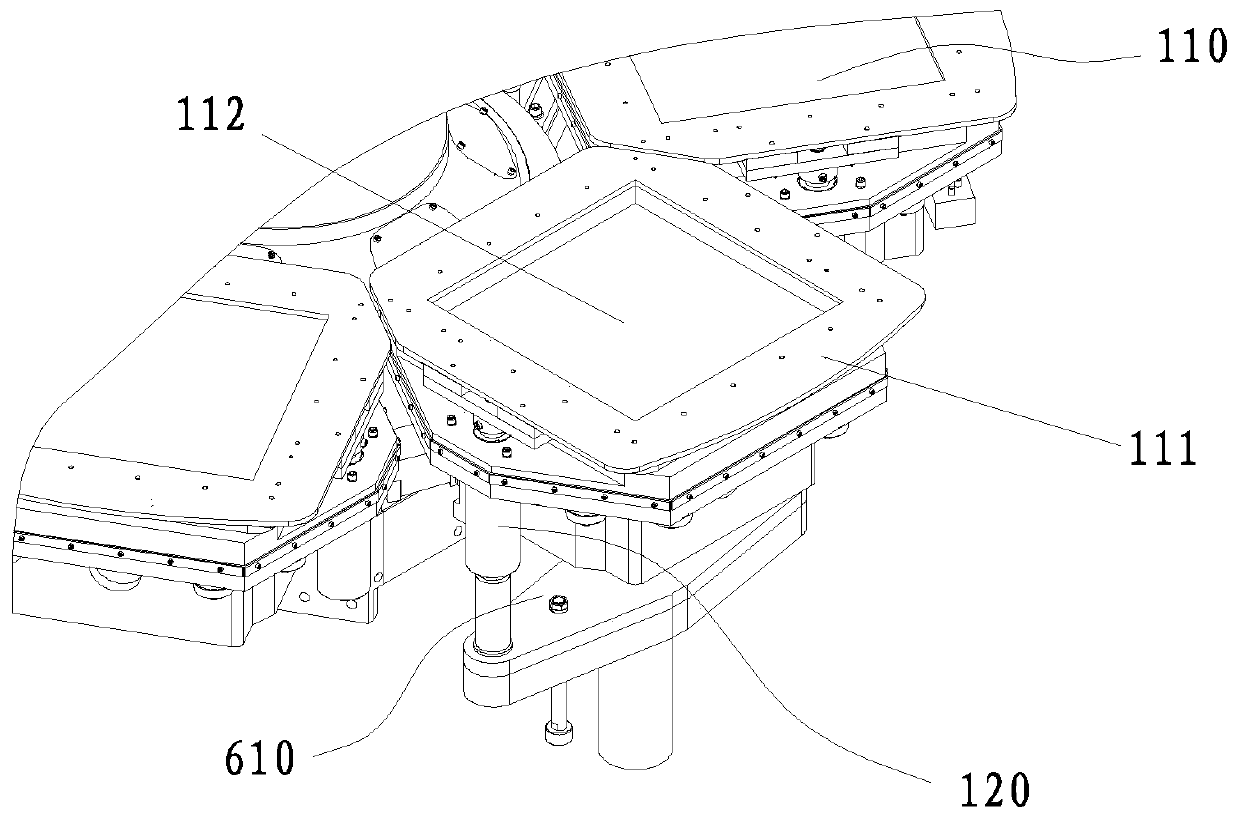

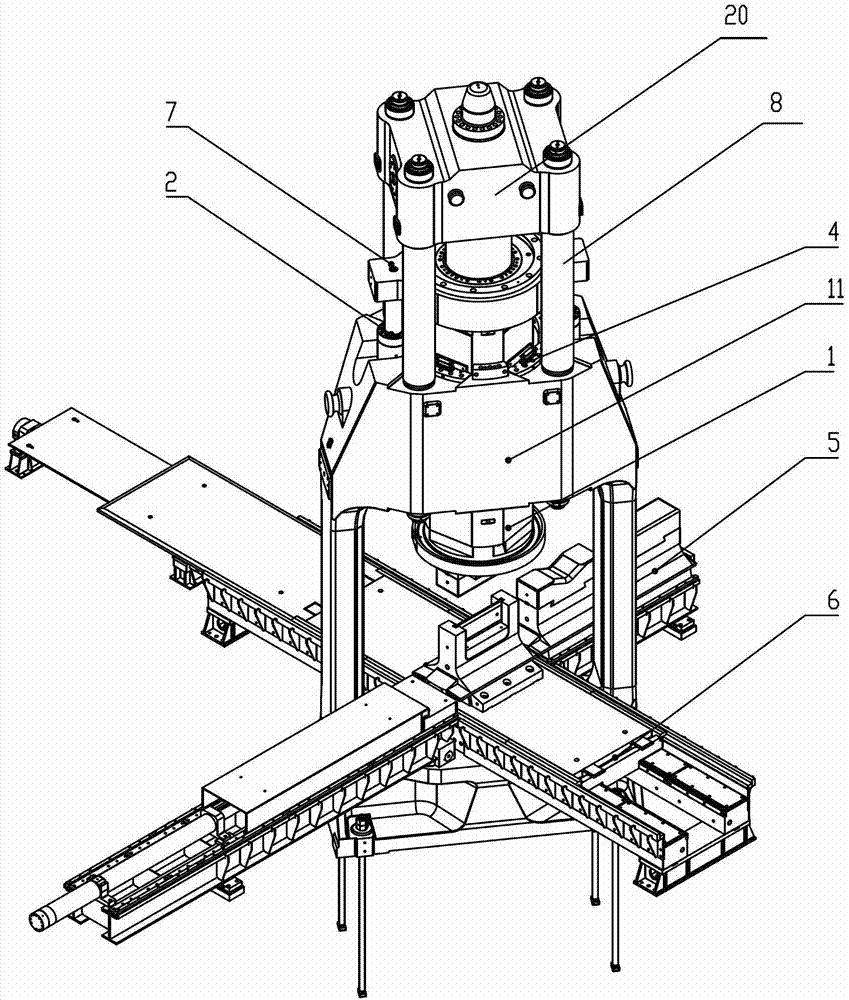

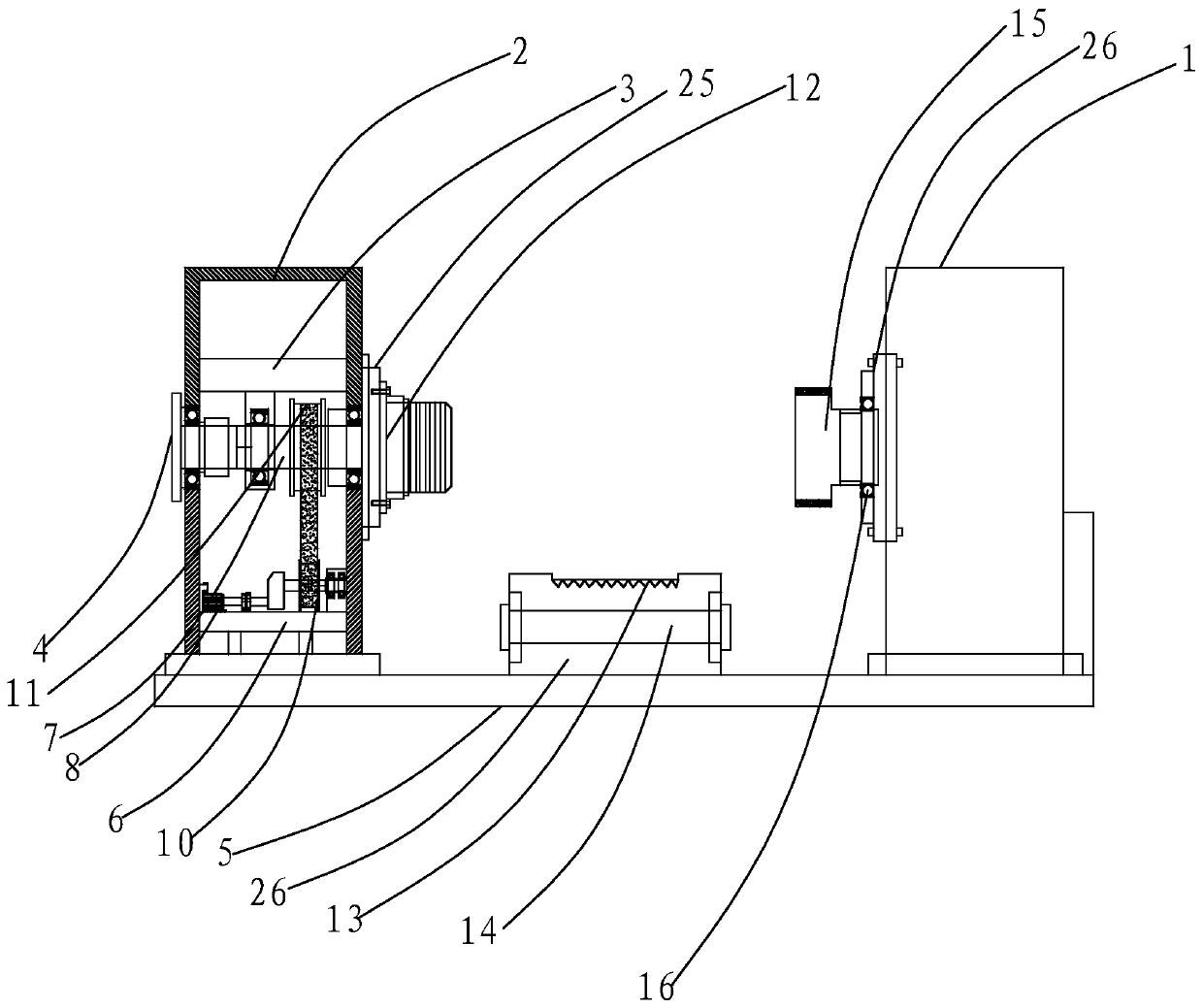

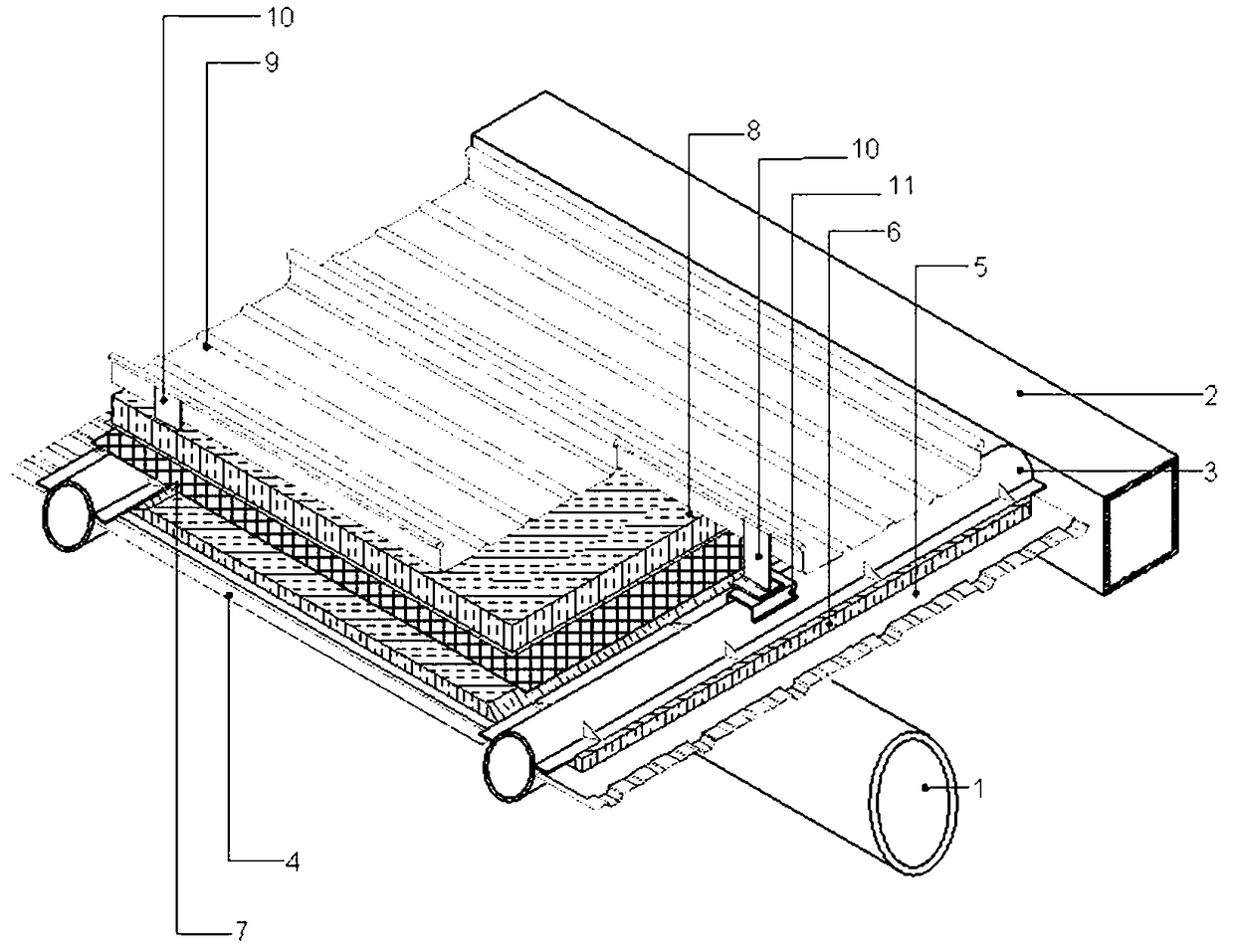

Forming mechanism of brick press

ActiveCN110883908AImprove molding qualityMany types of functionsDischarging arrangementShaping press ramBrickMolding machine

The invention discloses a forming mechanism of a brick press. The forming mechanism comprises a spreading mechanism for spreading raw materials, a prepressing mechanism for prepressing the raw materials, a main pressing mechanism for mainly pressing the raw materials, a demolding mechanism for demolding formed bricks, and a main bearing frame for bearing the spreading mechanism, the prepressing mechanism, the main pressing mechanism and the demolding mechanism. After the structure is adopted, compared with the prior art, the forming mechanism is provided with a brick making forming mold, the brick making forming mold sequentially passes through the spreading mechanism, the prepressing mechanism, the main pressing mechanism and the demolding mechanism, and the raw materials in the mold arepressed and formed in multiple processes. The forming mechanism is provided with the various processing mechanism, function types are rich, the raw materials in the mold can be spread, prepressed, mainly pressed, demolded and the like, the processing flow is finer, and therefore the forming quality of the bricks is improved.

Owner:FUJIAN QUNFENG MACHINERY

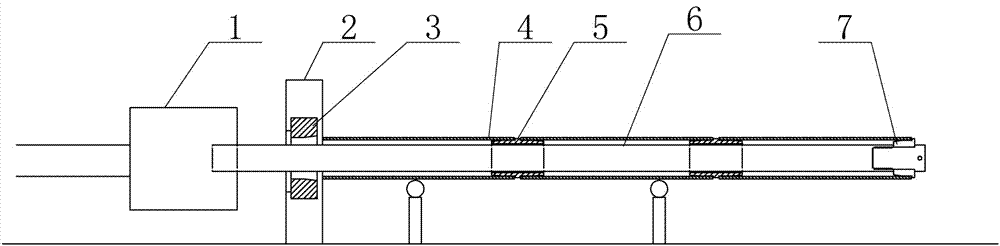

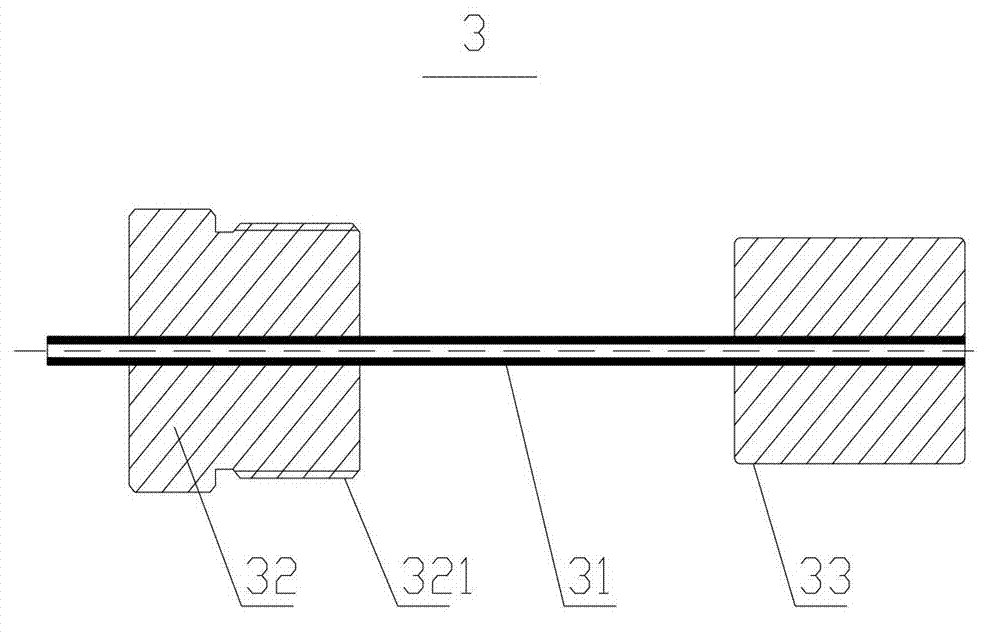

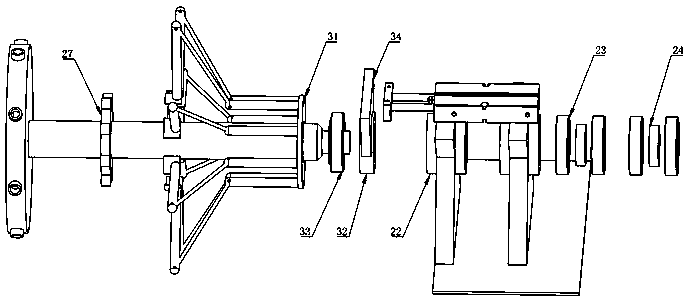

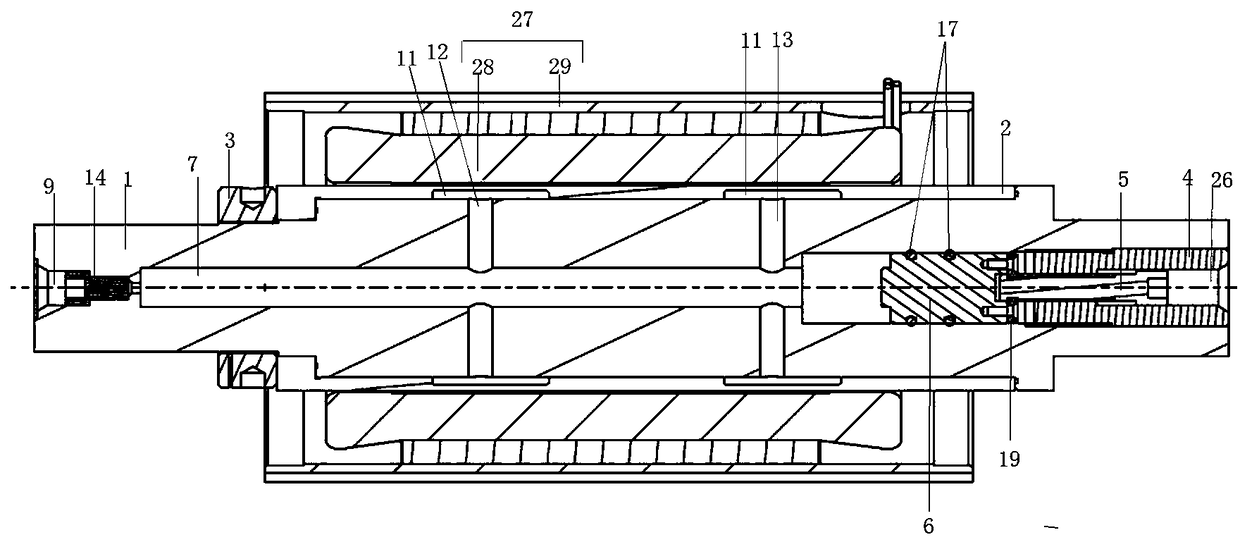

Precision steel pipe chuck-free cold drawing repairing device and method

The invention discloses a precision steel pipe chuck-free cold drawing repairing device and method. The precision steel pipe chuck-free cold drawing repairing device comprises a clamp cylinder, a mold base and an outer mold. One end of a pull rod is fixed to the clamp cylinder, and the other end of the pull rod is externally sleeved with a plurality of to-be-repaired steel pipes. The multiple to-be-repaired steel pipes are connected through intermediate connecting sleeves in a supported and matched mode. A back cover is fixedly installed at the other end of the pull rod. The tail section of to-be-repaired steel pipe is limited and installed on the pull rod in a sleeving mode through the back cover. When cold drawing repairing is conducted through the repairing tool, a chuck does not need to the manufactured, thus, the performance of the steel pipes cannot be changed, and the repairing rate and the yield of the steel pipes can be greatly increased.

Owner:宜昌中南精密钢管有限公司

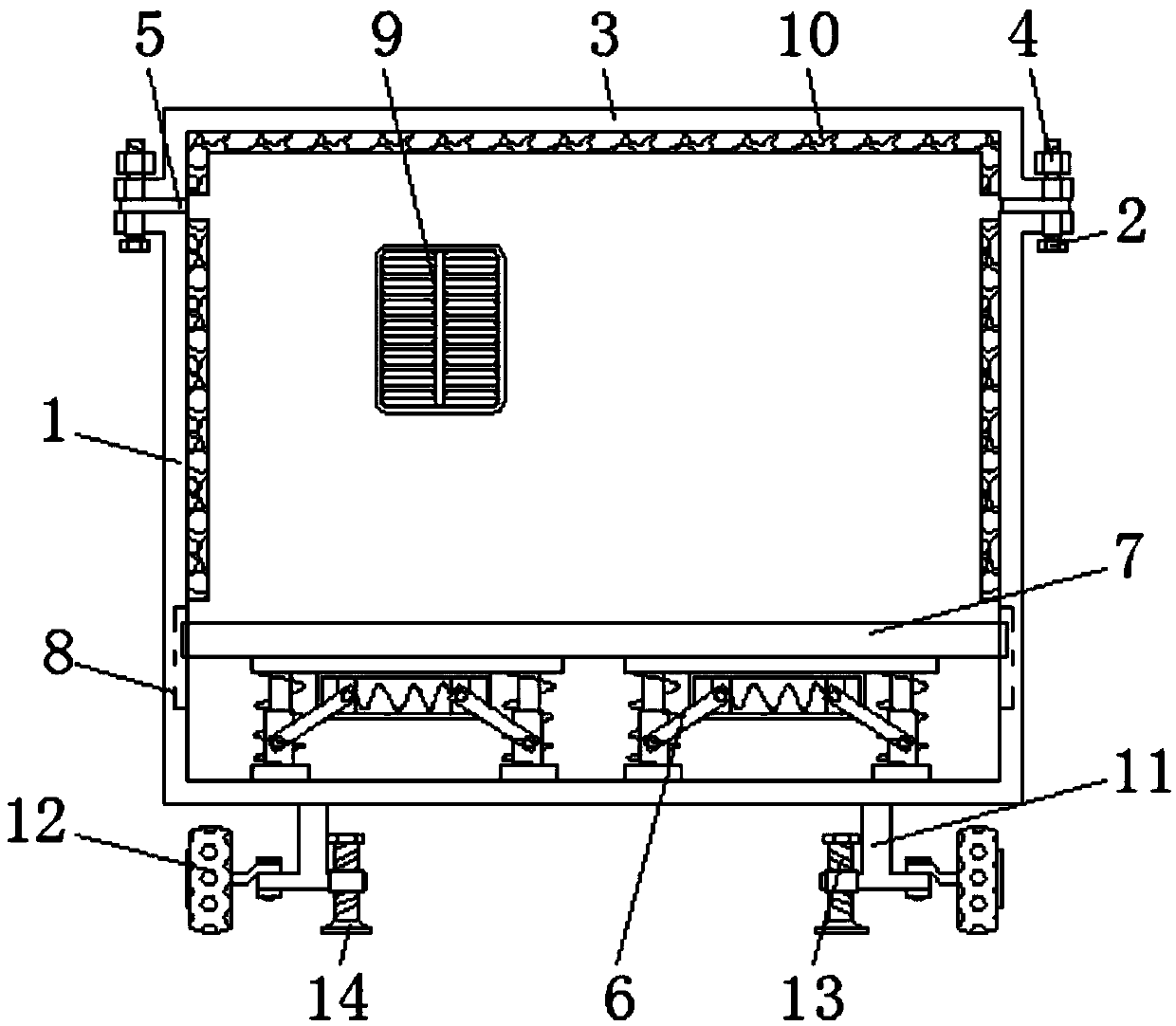

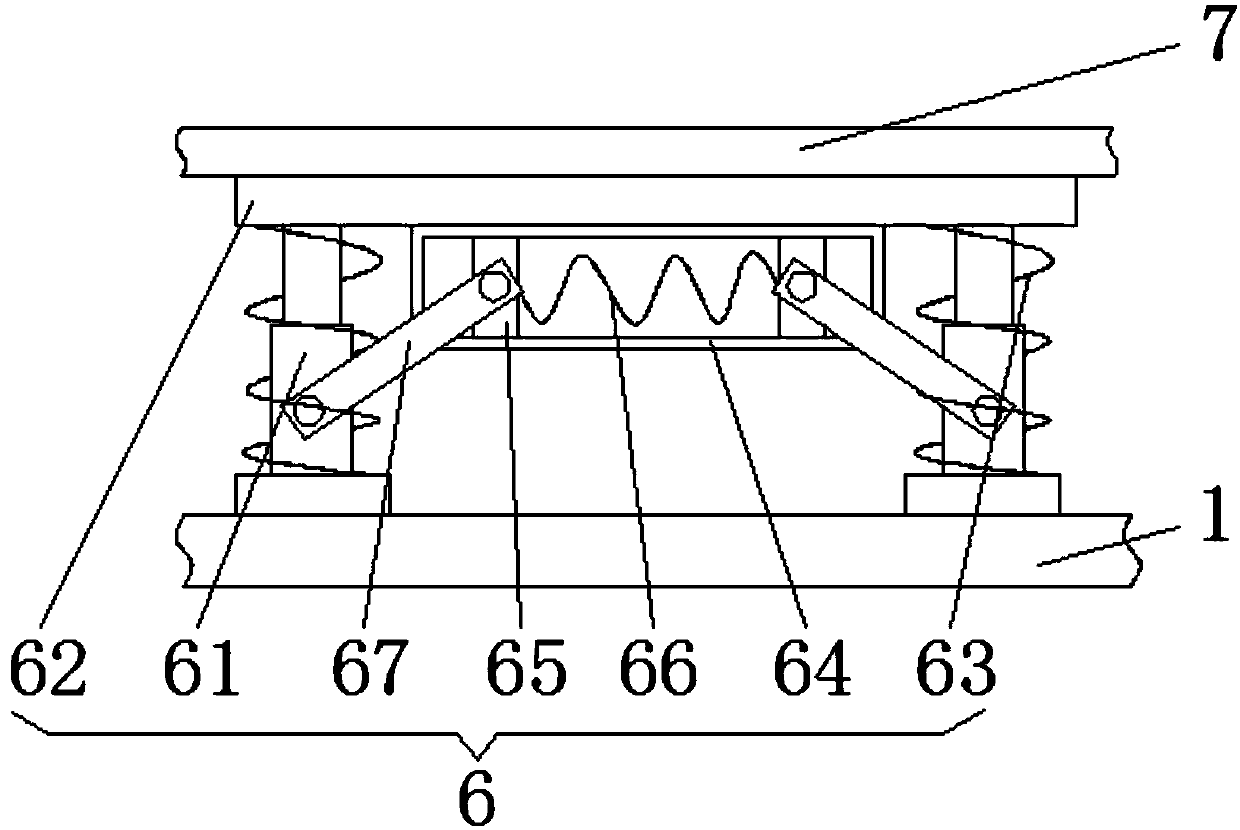

Lubricating oil transportation and storage device

InactiveCN107902261AEasy to moveEasy to fixContainers to prevent mechanical damageExternal fittingsCombustionFire retardant

The invention discloses a lubricating oil transportation and storage device, which comprises a box body. Both sides of the top of the box body are screwed with a box cover through bolts, and the surface of the bolt is screwed with a fixing nut. The bottom of the box cover is connected with the box cover A sealing gasket is fixedly connected between the boxes and on the surface of the box, the bottom of the box is fixedly connected with a shock absorber, and the top of the shock absorber is fixedly connected with a fixing plate, and both sides of the inner wall of the box are provided with A chute compatible with the fixing plate, an air filter is fixedly connected to the surface of the box body, and the inner walls of the box body and the box cover are coated with a flame-retardant glue layer. The invention relates to the technical field of lubricating oil. The lubricating oil transportation and storage device has a good protection ability, strong functionality, and shock-absorbing and buffering capabilities, which can ensure that the lubricating oil barrel will not be squeezed, deformed or leaked during transportation, and can block combustion and keep the internal air clean. Moisture-proof, ensuring the safety of lubricating oil.

Owner:WUXI FEITIAN GREASE

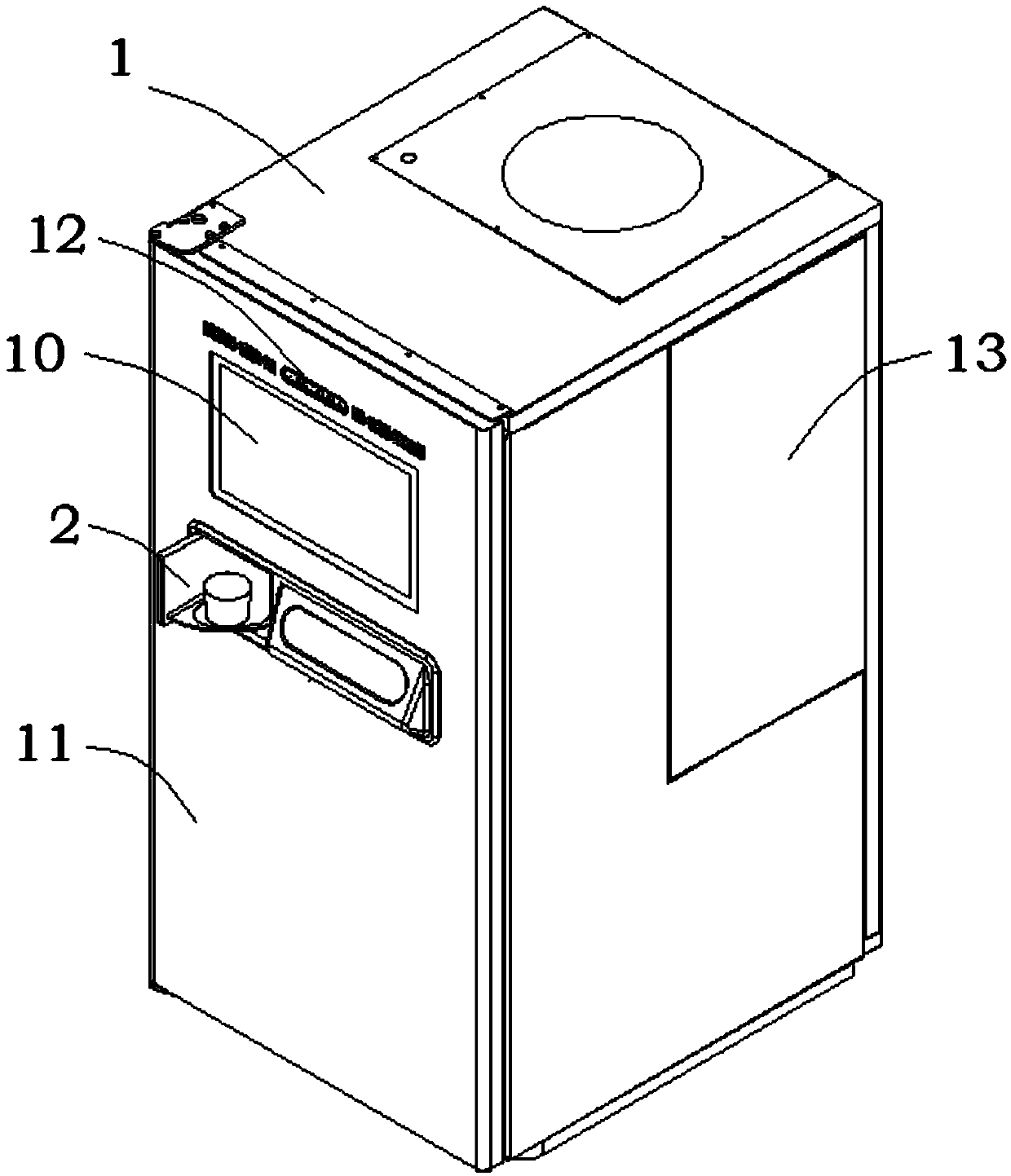

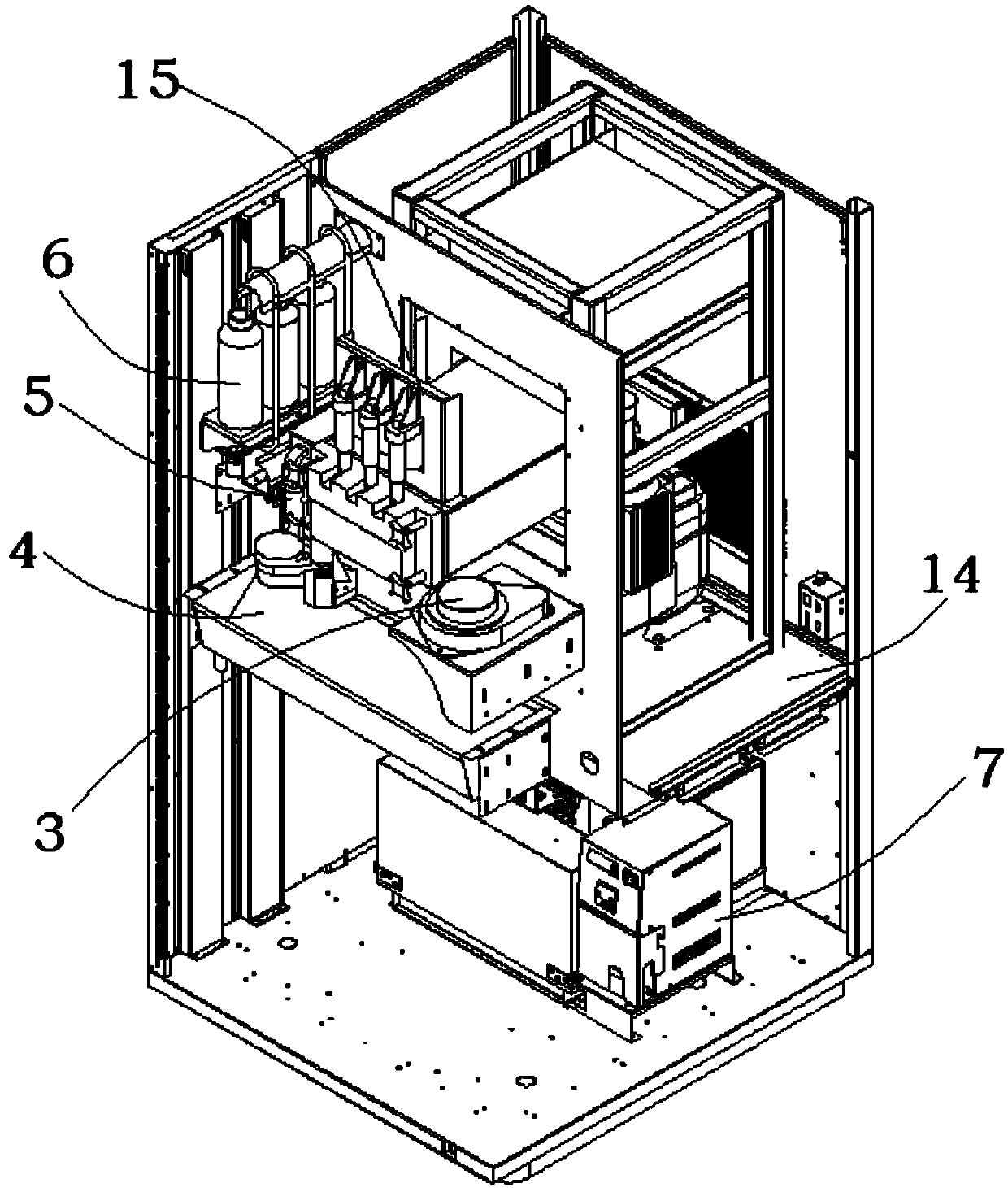

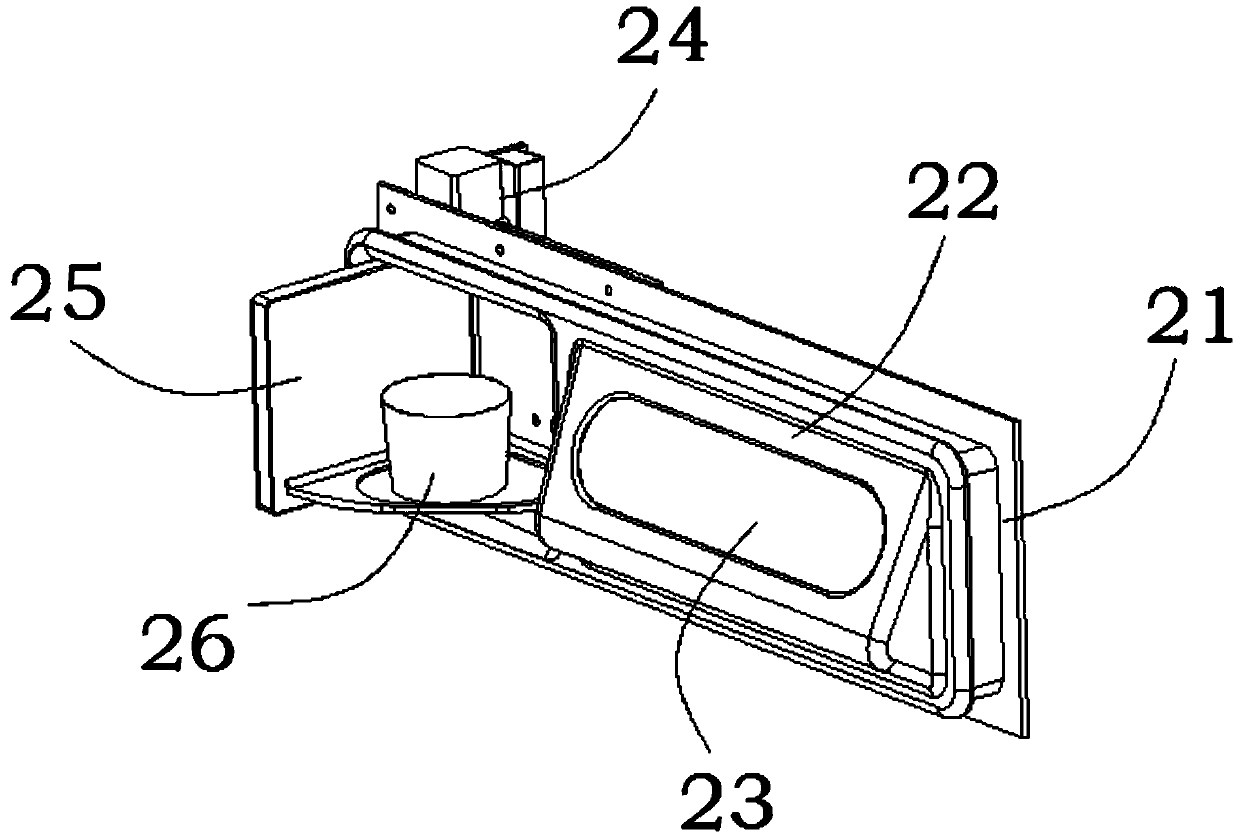

Ice cream self-service vending machine

PendingCN109685990AReduce labor costsReduce operating costsApparatus for meter-controlled dispensingApparatus for dispensing fluids/granular materialsAgricultural engineeringEngineering

The invention relates to an ice cream self-service vending machine. The machine comprises a frame, a front door and a side door which are opened or closed along the frame, a main machine supporting plate which is fixed at the middle part of the frame, wherein an ice cream main machine is fixedly arranged at the upper end of the main machine supporting plate, a refrigeration module is arranged below the main machine supporting plate, a cup dropping mechanism is arranged on one side of the ice cream main machine, a feeder is arranged on the other side of the ice cream main machine, a transmission mechanism is arranged below the cup dropping mechanism, a slurry feeding mechanism is arranged on one side of the feeder, a discharging mechanism fixed on a front door is correspondingly arranged below the slurry feeding mechanism, an operation panel and a face recognition payment system is fixedly installed on the front door, and inner side walls of the front door and the side door are both provided with constant-temperature foaming plates; according to the ice cream self-service vending machine, the refrigerating module is arranged below the inner part of the frame, so that the integral sealing and freezing of the ice cream self-service vending machine are realized by adopting the constant-temperature foaming plate matched with a metal plate at the outer side of the frame, the low-temperature and sterile environment in the cabinet body is ensured, raw materials for making the ice cream, including frozen raw materials, fruit pulp or cream, sugars, oatmeal, etc., are prevented from being deteriorated.

Owner:南京热冰科技有限公司

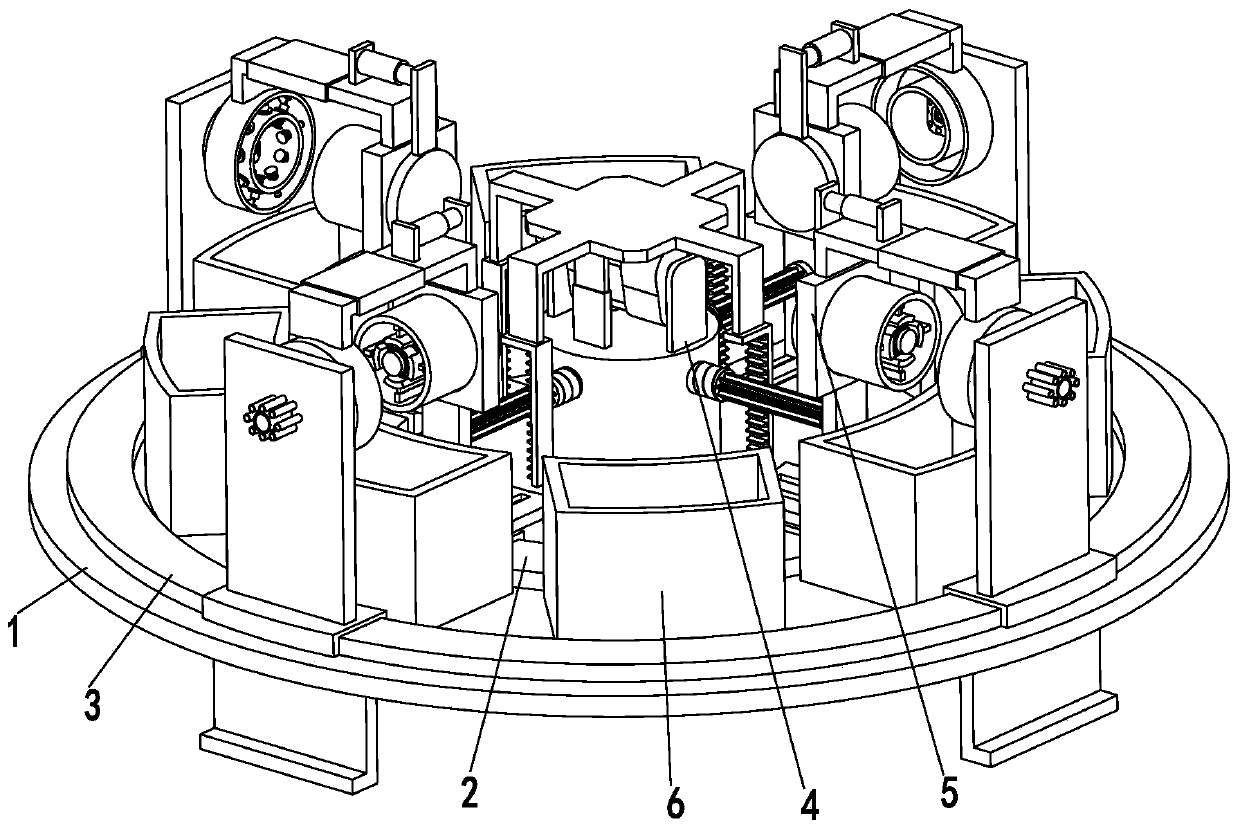

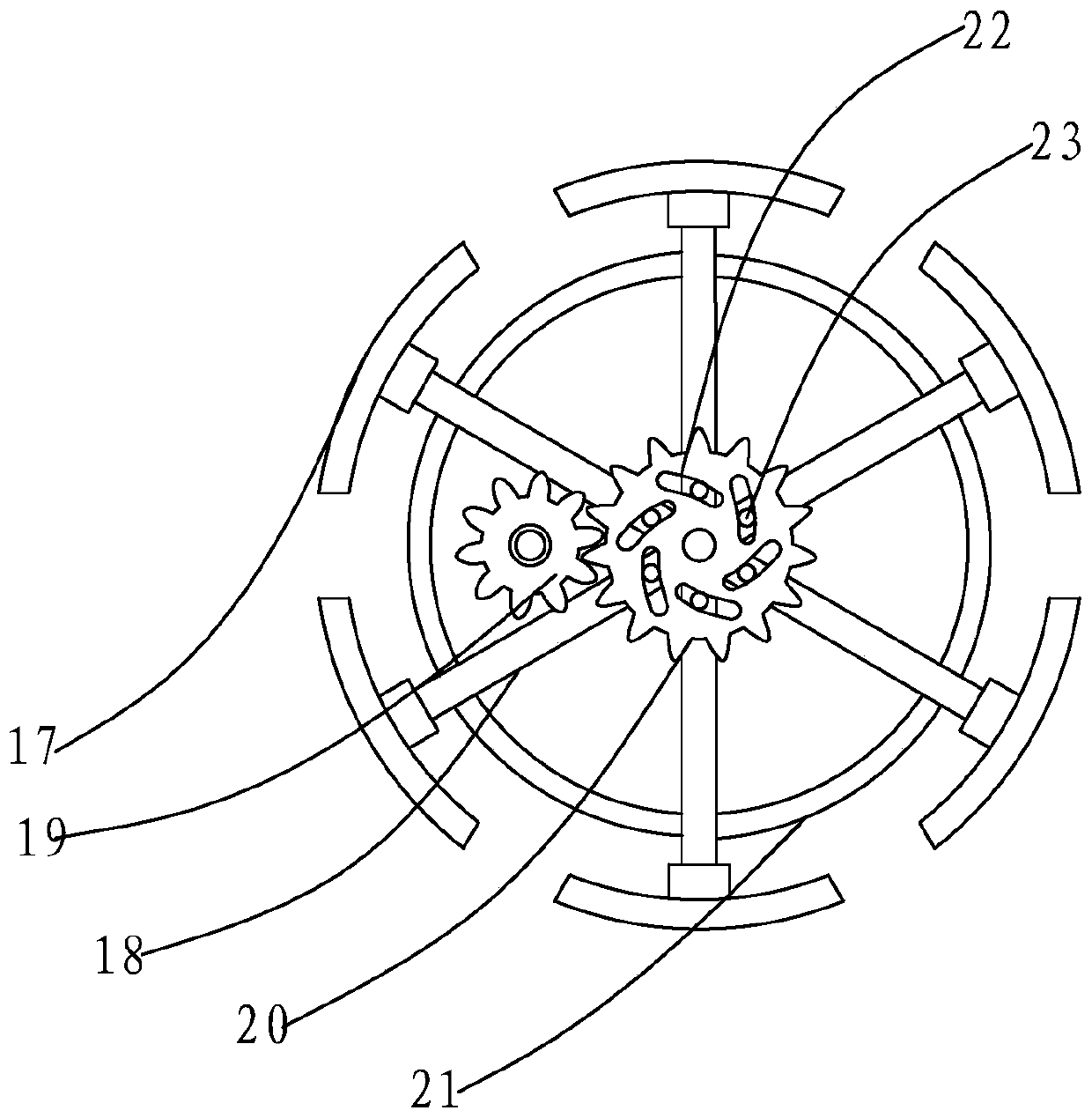

Anesthesia mask component connection firmness detecting device

InactiveCN109916720AImprove detection efficiencyReduce workloadDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesEngineeringAir tightness

The invention relates to an anesthesia mask component connection firmness detecting device. The device comprises a base frame, a No. 1 annular sliding rail, a No. 2 annular sliding rail, a stretchingmechanism, fixing mechanisms and collecting boxes; the upper end of the base frame is sequentially provided with the No. 1 annular sliding rail and the No. 2 annular sliding rail from inside to outside; the stretching mechanism is arranged in the No. 1 annular sliding rail; the side wall of the stretching mechanism is connected with the side walls of the fixing mechanisms; the collecting boxes arearranged between the No. 1 annular sliding rail and the No. 2 annular sliding rail; the collecting boxes are evenly arranged along the circumferential direction of the base frame; and the stretchingmechanism comprises a rotating motor, a working cylinder, a stretching rod, a stretching rack and an adjusting frame; and each fixing mechanism comprises a No. 1 sliding block, a hose fixing branch chain, an No. 2 sliding block, a mask fixing branch chain and a connecting frame. With the device of the invention adopted, problems such as low detection efficiency, little possibility of finding leakpoints during air impermeability detection and need for additionally collecting qualified products and unqualified products after detection of an existing anesthesia mask connection firmness detectingprocess can be solved.

Owner:张彩虹

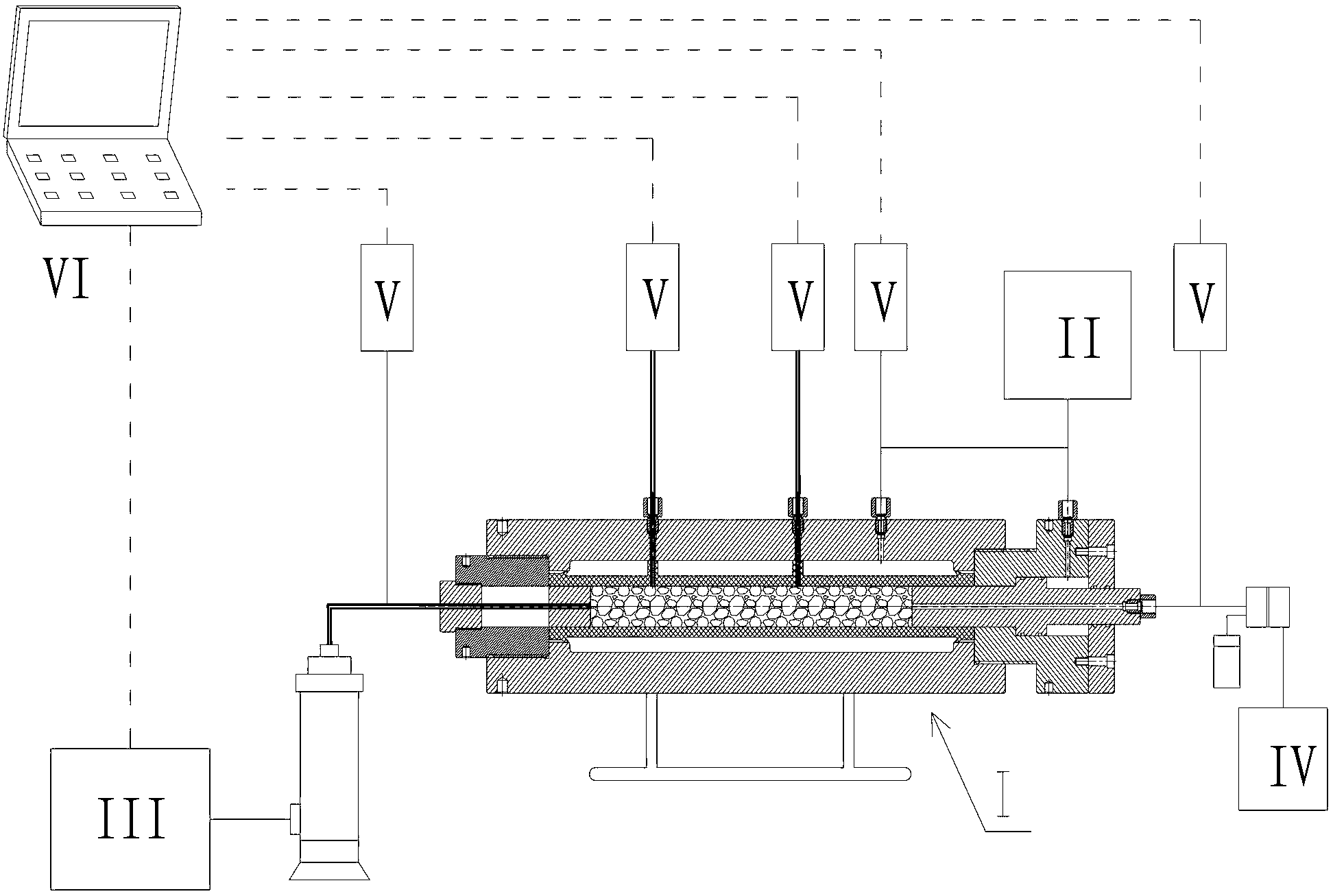

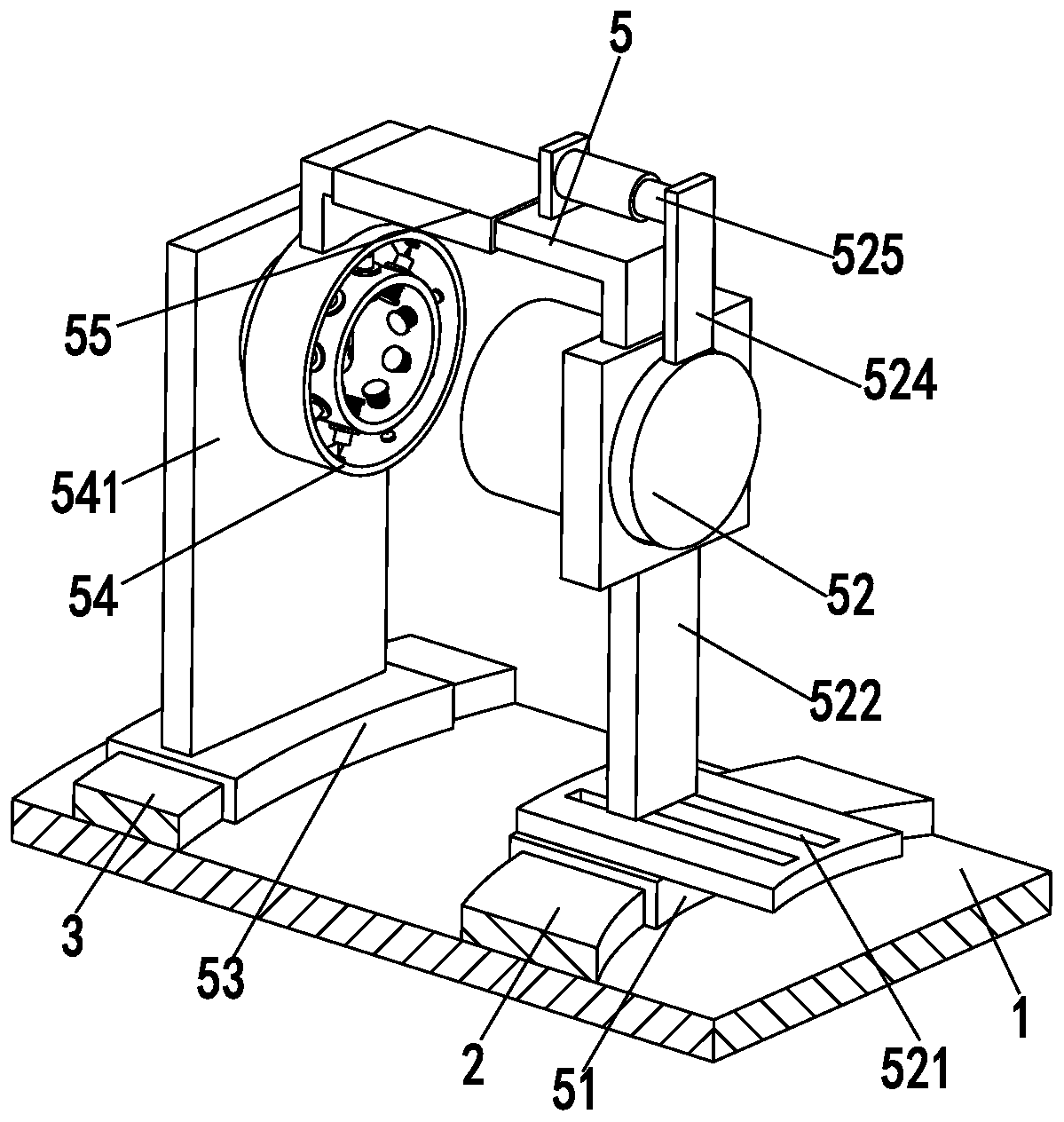

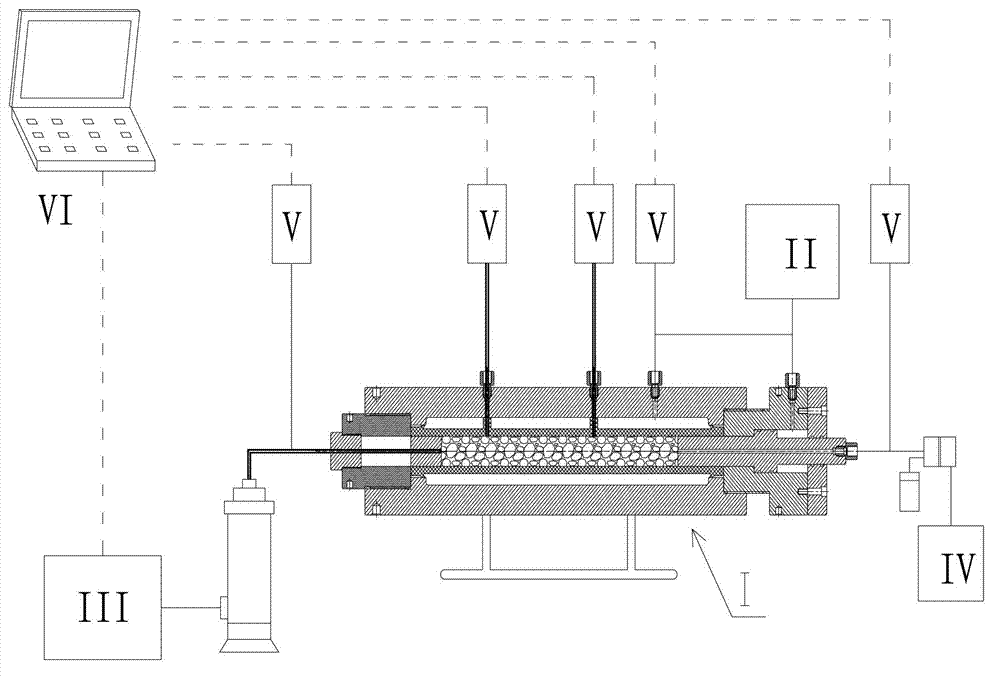

Long core water injection test simulation system

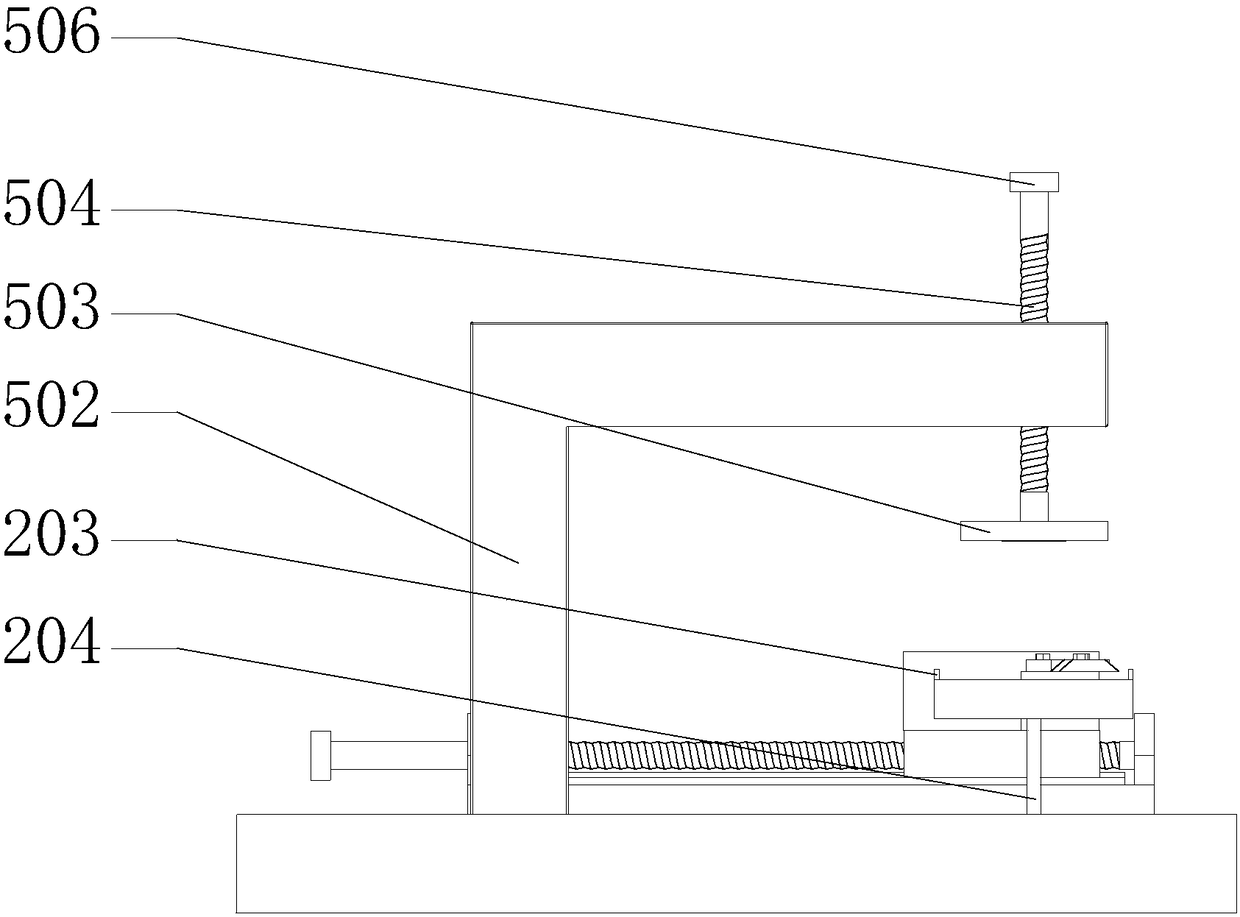

ActiveCN103245769ASmall dead volumeNo extrusion deformationEarth material testingVertical tubeDead volume

The invention provides a long core water injection test simulation system. The long-core water injection test simulation system comprises a long core clamper, a pressure pump, as well as a displacement pump, a manometer and a voltage return pump, wherein the pressure pump is connected with the long core clamper, and is used for applying confining pressure and axial compressive force to the long core clamper, and the displacement pump, the manometer and the voltage return pump are connected with the long core clamper; the long core clamper comprises a clamper barrel (1) and a high-pressure-resisting rubber sleeve (2) sleeved in the clamper barrel (1); the high-pressure-resisting rubber sleeve comprises a wall (21), an inner cavity (23) positioned in the wall (21) and ports positioned at two ends of the inner cavity (23); and the inner cavity (23) is vertical-tube-shaped, and the inner diameters of the ports at the two ends are equal to the inner diameter in the middle of the inner cavity (23). The long core water injection test simulation system can be used for performing axial detection at multiple pressure monitoring points on long cores, has a small end surface effect, small dead volume, large static confining pressure and small measurement error.

Owner:PETROCHINA CO LTD

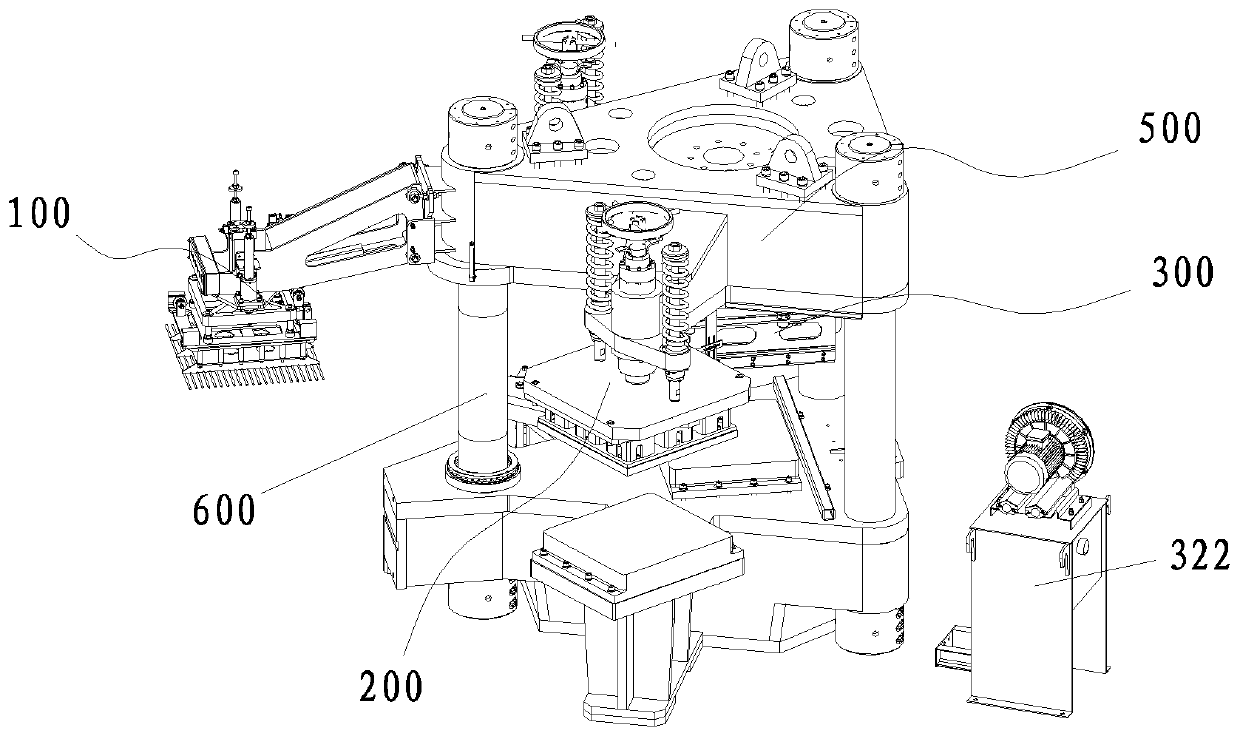

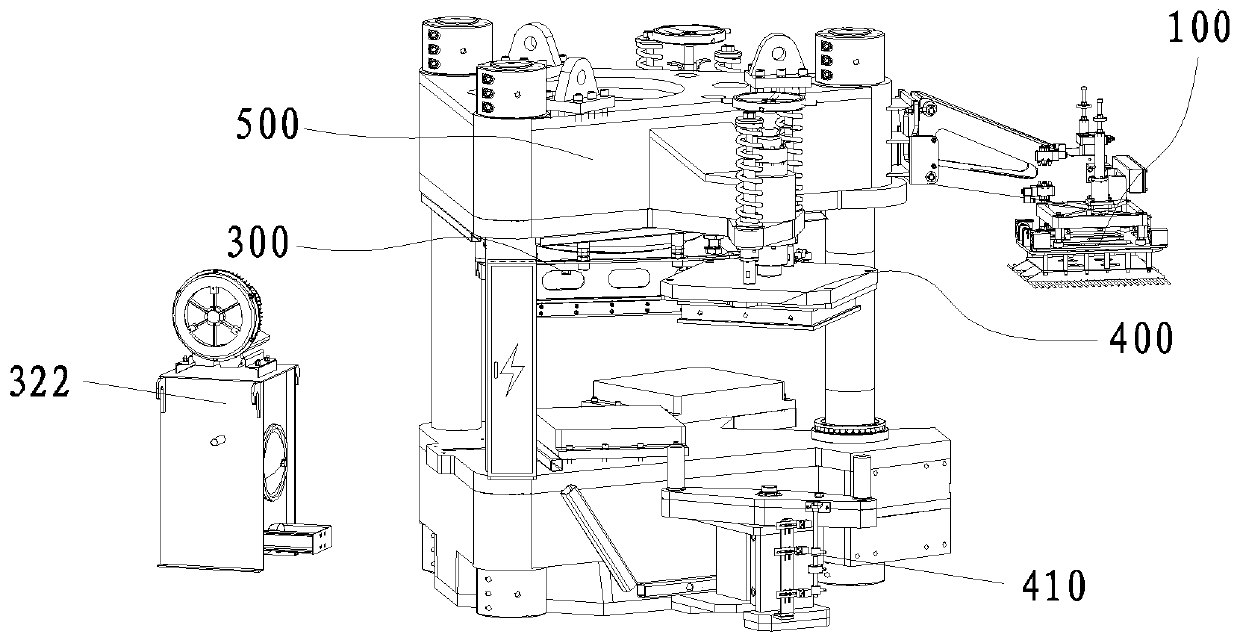

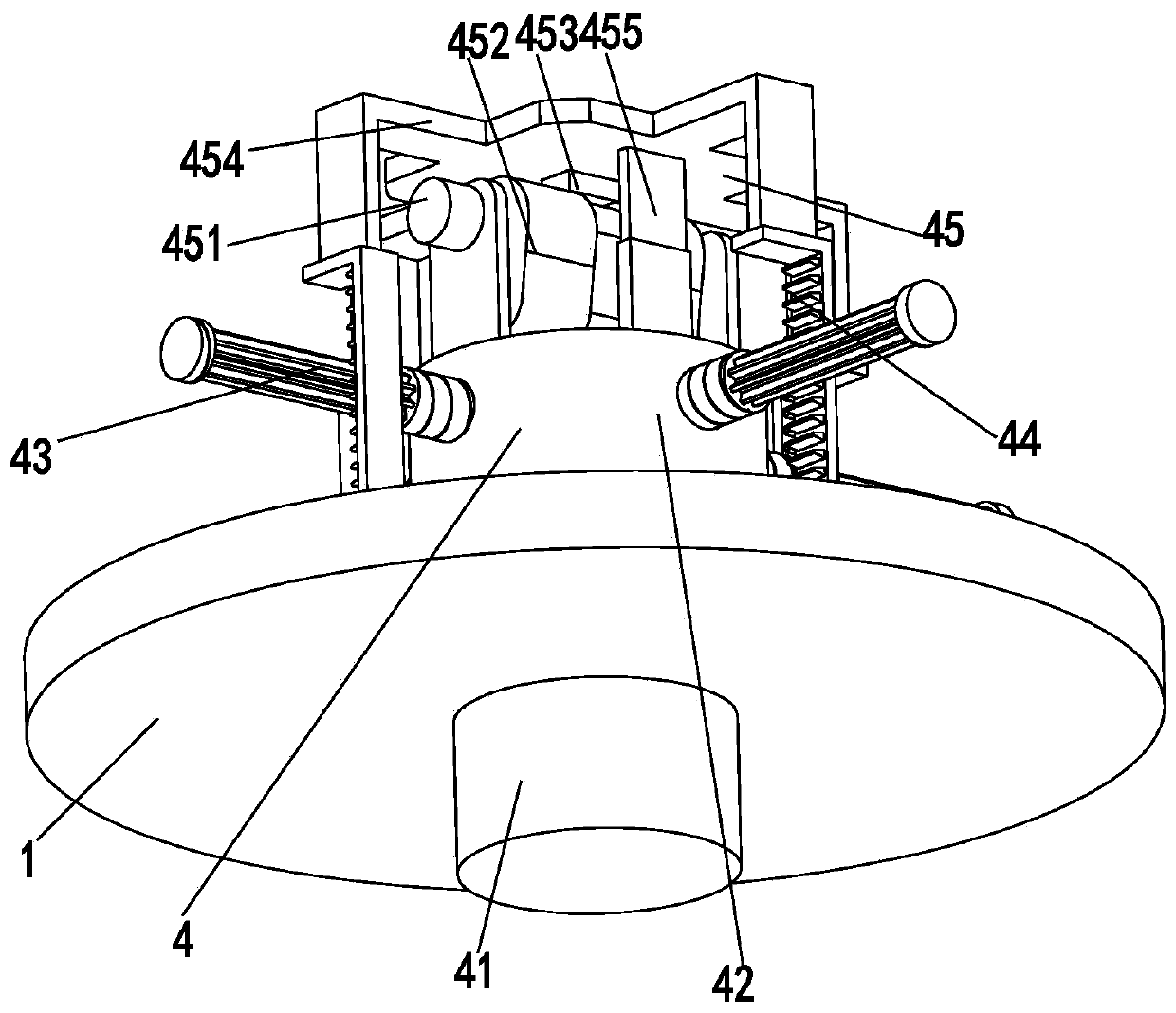

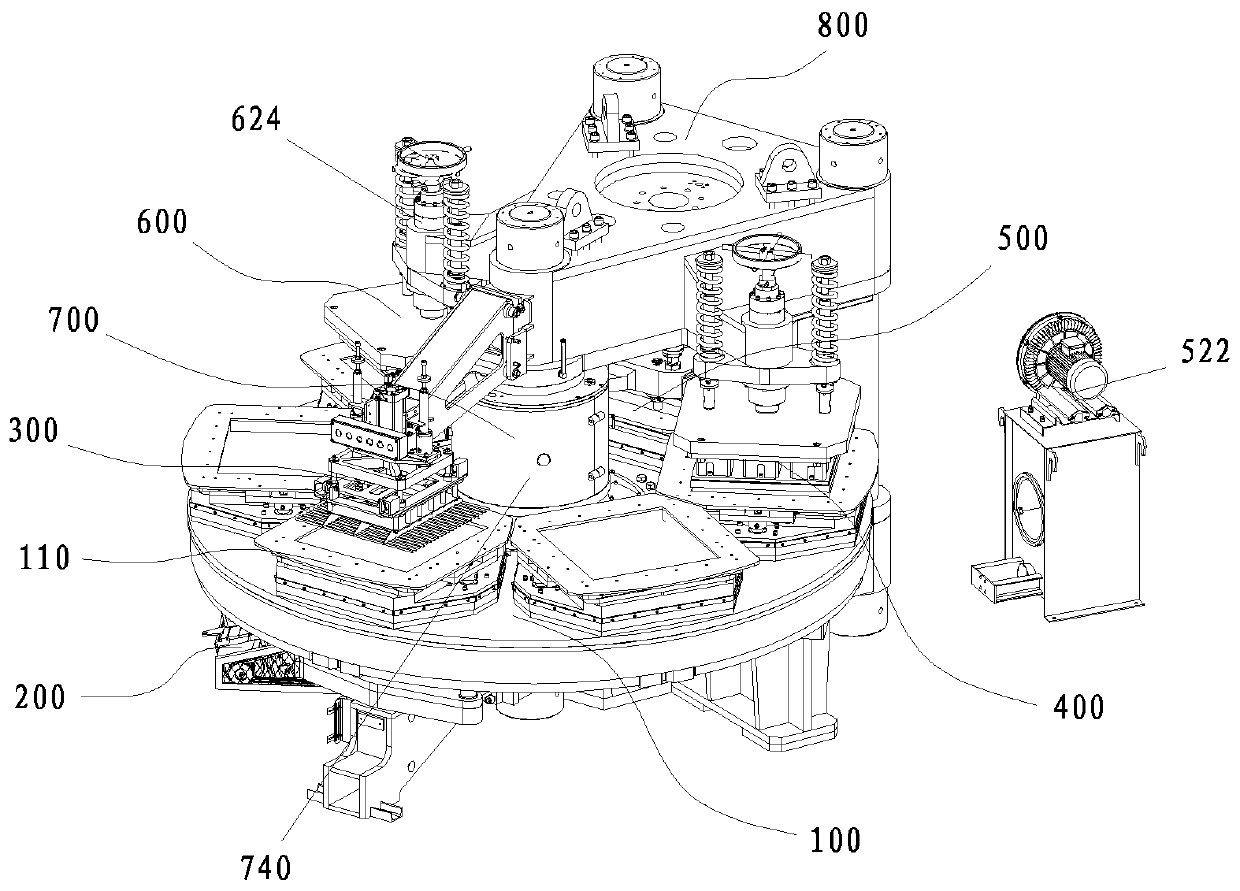

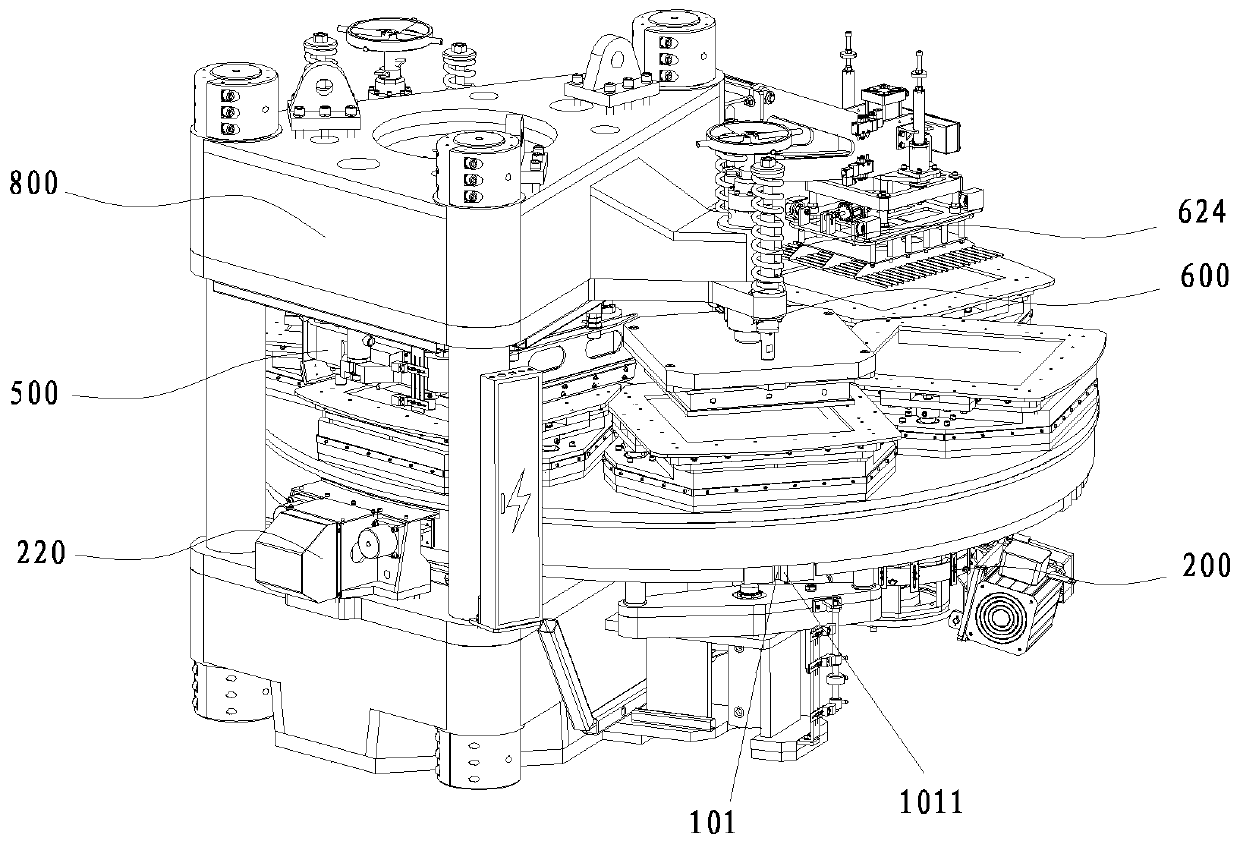

Disc rotary type brick press

The invention discloses a disc rotary type brick press, which comprises a turntable and a plurality of molds arranged on the turntable, wherein the brick press further comprises a controller, a rotarydrive mechanism of driving the turntable, a material spreading mechanism for spreading raw materials, a pre-pressing mechanism for pre-pressing the raw materials, a main pressing mechanism for pressing the raw materials mainly, a demolding mechanism for demolding formed bricks, a main shaft mechanism at the center of the turntable, and a main bearing frame for bearing the material spreading mechanism, the pre-pressing, the main pressing mechanism and the demolding mechanism. After adopting the above structure, compared with the prior art, the brick press drives the turntable for intermittentcircular rotation through the rotary drive mechanism, the mold on the drive turntable completes the pressing and molding of the raw materials by the raw material feeding device, the material spreadingmechanism, the pre-pressing mechanism, the main pressing mechanism and the demolding mechanism successively, the automatic mechanical production of bricks is realized, and the production efficiency and production are improved greatly.

Owner:FUJIAN QUNFENG MACHINERY

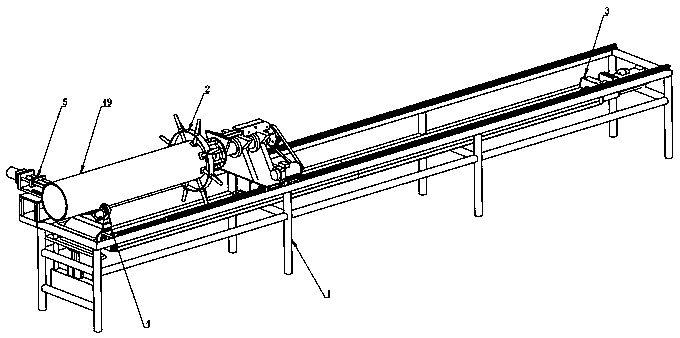

Special automatic circular pipe plasma cutting machine for expressway construction process and use method

ActiveCN109128460ANo extrusion deformationNo loosening of fixation occursWelding/cutting auxillary devicesAuxillary welding devicesGeneral assemblyMechanical equipment

The invention relates to the technical field of mechanical equipment for expressway construction, and particularly relates to a special automatic circular pipe plasma cutting machine for an expresswayconstruction process and a use method. The machine is characterized in that a holding device is driven through a cylinder to hold and fix a circular pipe, thus the machine is applicable to circular pipes with different diameters; the circular pipe clamping pipe can be controlled by controlling air pressure, so that the problems that a thin circular pipe in cutting is pressed and deformed due to excessively high clamping force, the thin circular pipe cannot be tightly clamped due to excessively small clamping force, and the cutting process is dangerous, can be solved; a feeding device is arranged, so that the circular pipe feeding capacity is ensured, and quantitative cutting is realized; a supporting device is arranged, and the height of a supporting pulley can be automatically adjusted,and thus the circular pipe can be in a horizontal state during being cut; the overall fitting design realizes automatic cutting, and the circular pipe can be cut into different patterns; the working efficiency is high; and moreover, the safety in the construction process and the construction speed can be ensured.

Owner:王甜

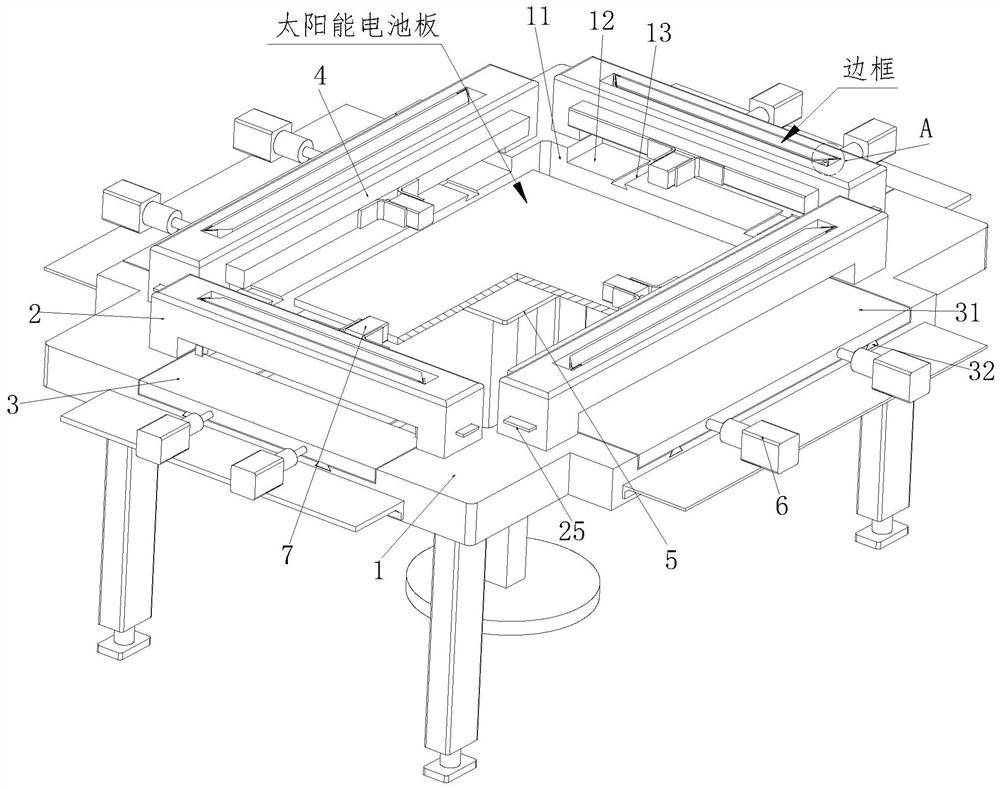

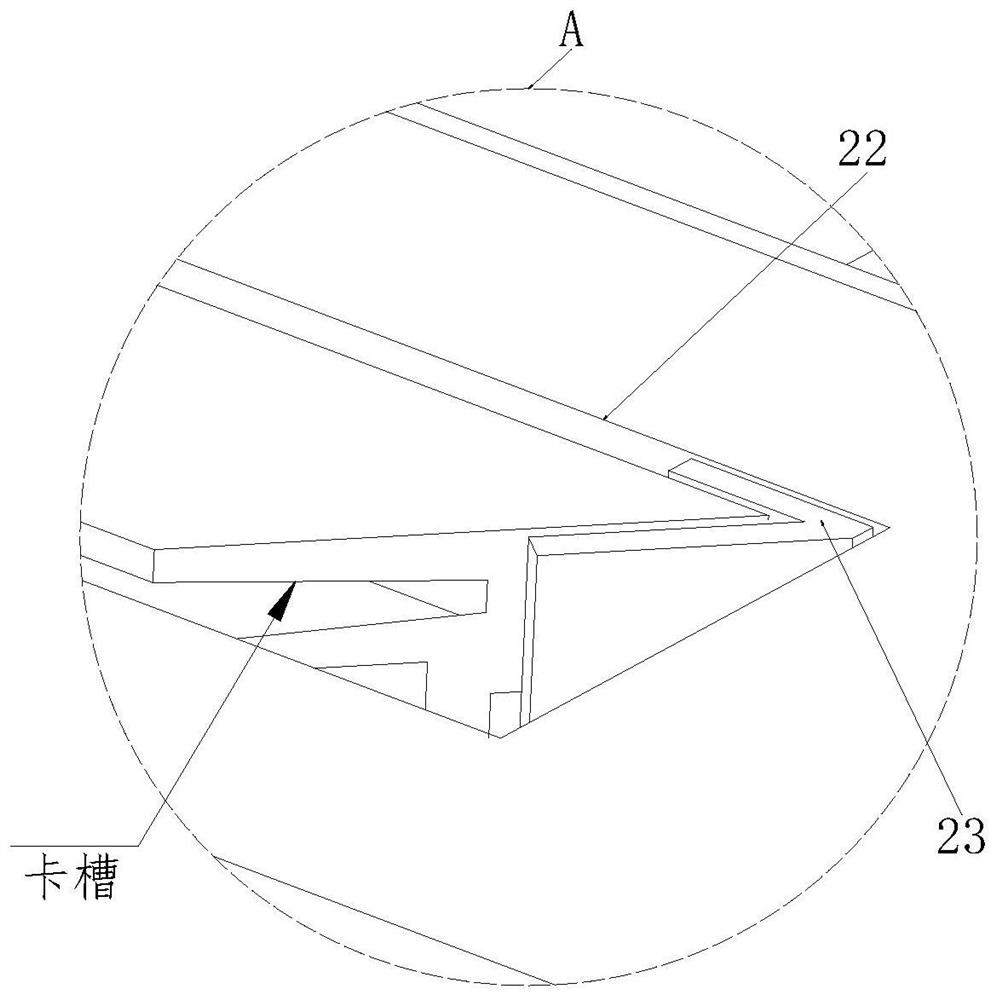

Solar cell module assembling device and assembling method thereof

ActiveCN112701178AImprove connection stabilityReduce wasteFinal product manufactureSemiconductor devicesEngineeringSolar cell

The invention relates to a solar cell module assembling device and an assembling method thereof. The solar cell module assembling device comprises a workbench surface, outer frame placing mechanisms, an assembling mechanism, gluing mechanisms, a supporting table, an electric push rod A and electric push rods B. A rectangular hole is formed in the center of the top of the workbench surface, and movable grooves are formed in the outer walls of the periphery of the workbench surface; mutual communication between the movable grooves and the rectangular hole is realized. The top of each movable groove is provided with a trapezoidal limiting groove, one outer frame placing mechanism is arranged at the position, located over each movable groove, of the top of the workbench surface, the gluing mechanism is installed on one side of each outer frame placing mechanism, and the electric push rod B is installed on one side of each gluing mechanism; and the assembling mechanism is arranged under the outer frame placing mechanisms, one end of the assembling mechanism is connected with the electric push rod A, and a supporting table is arranged in the center of the rectangular hole. The solar cell module assembling device has the characteristics of being high in assembling precision and rapid in gluing, and is high in gluing uniformity and low in glue waste rate.

Owner:江苏悦阳光伏科技有限公司

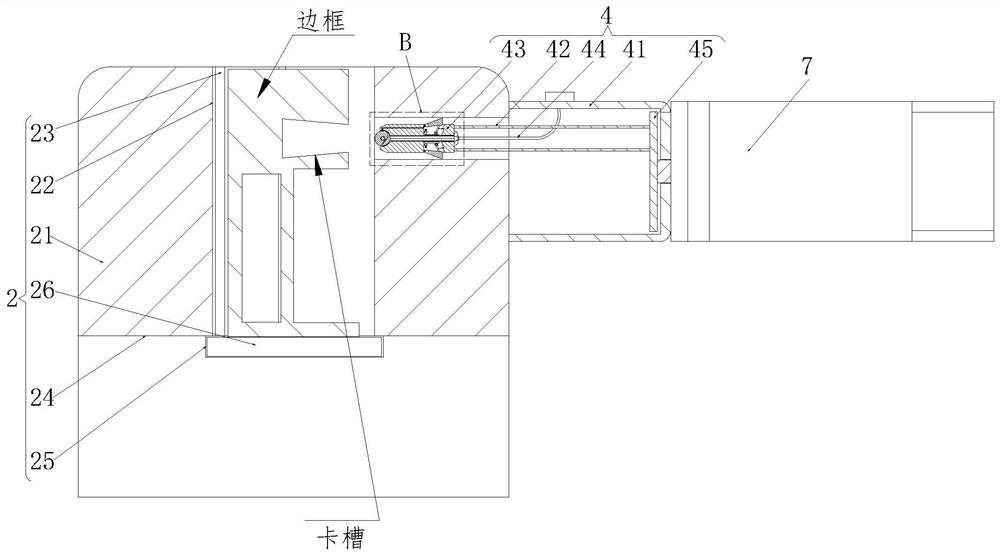

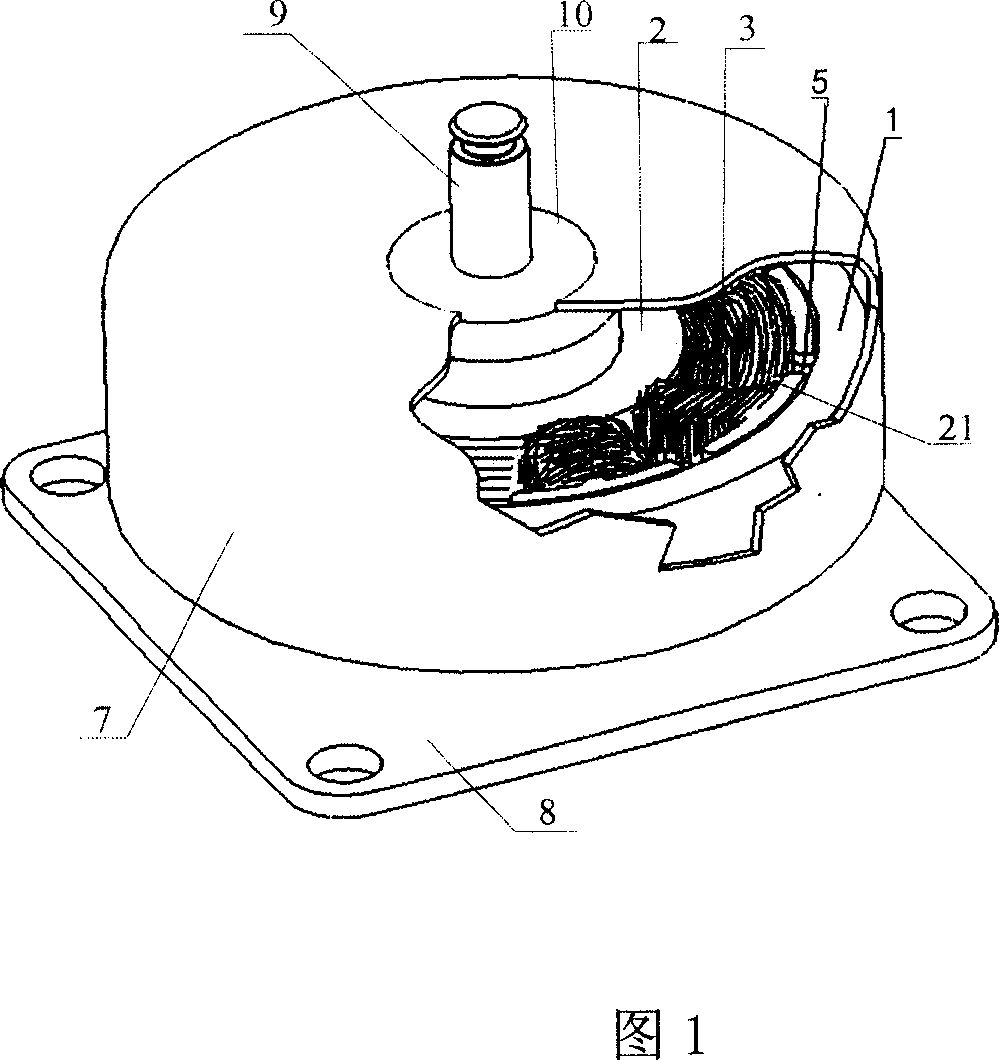

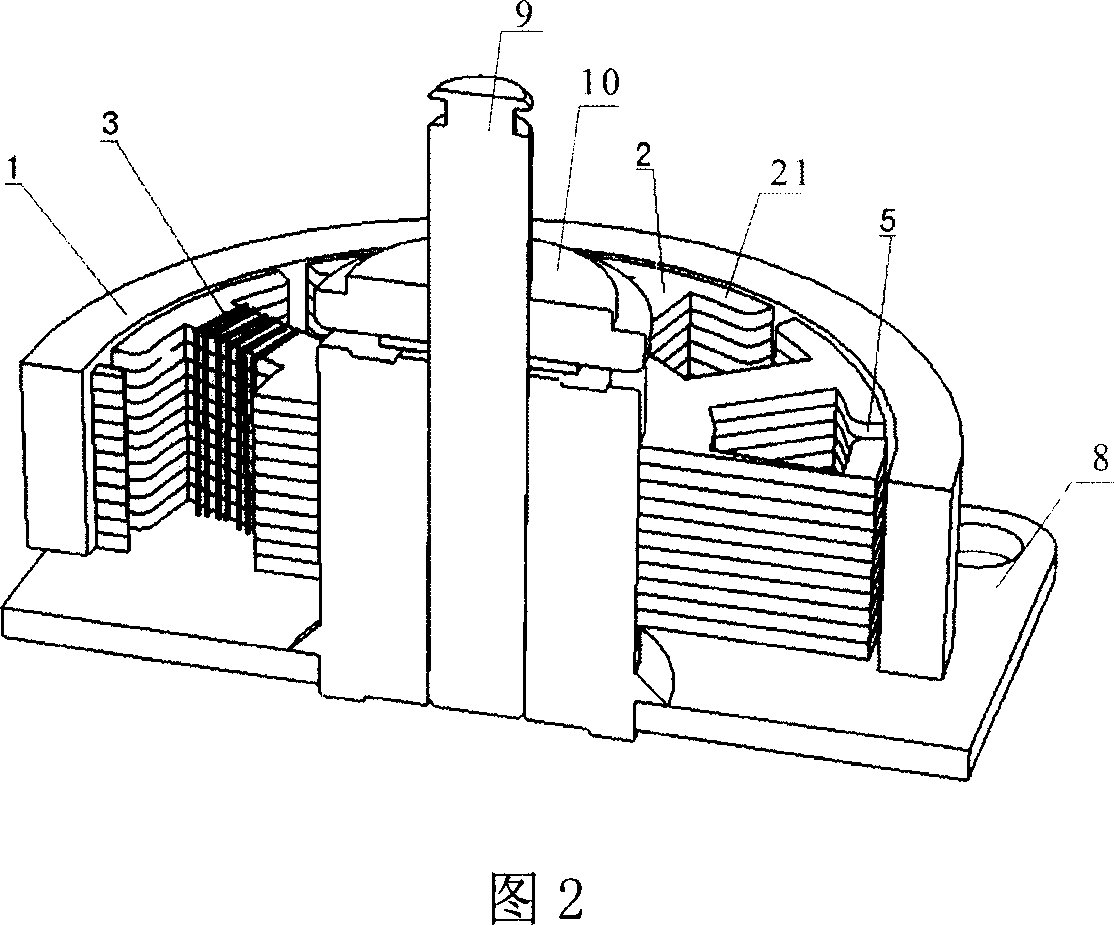

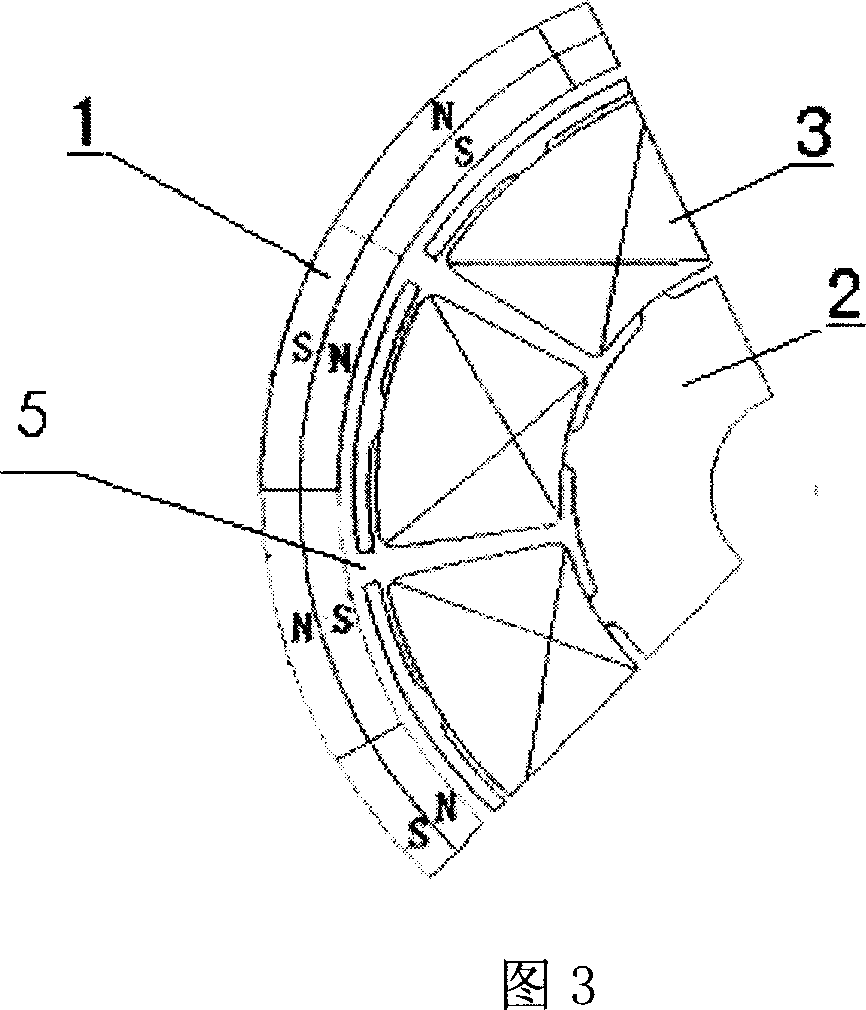

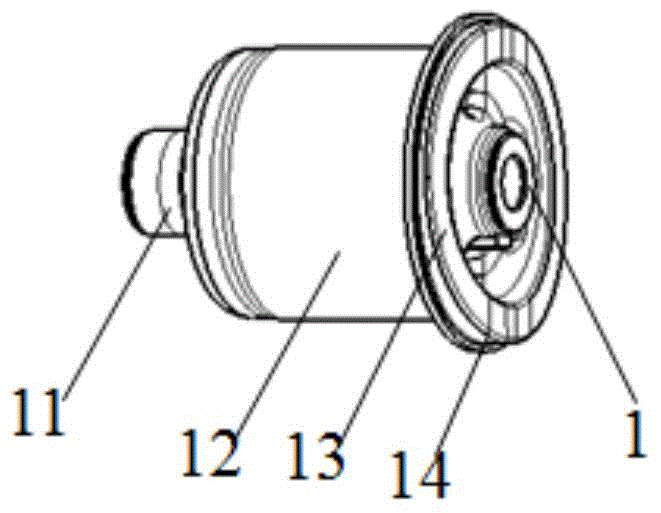

Method for making generator and generator

InactiveCN1945938AReduce resistanceDoes not directly affect spin speedMagnetic circuit rotating partsManufacturing dynamo-electric machinesEngineeringMagnet

This invention relates to a processing method for generators, which gets iron core claw poles winded with wire bags on the core together to form a relatively closed core ring, then a shield ring is set at the side of a magnet generating a rotating magnetic field, the total width of the ring is the same with the thickness of the core. This invention also discloses a generator applying said method including multiple slots set on the magnet and the core, each winded wire bag is mounted on the core by the slot, the core claw is formed by overlapping multiple core claw plates passing through the wire bag to be plugged in the slots corresponding to the core to fix the wire bags, and the adjacent core claws get close to form a closed core ring.

Owner:石为民

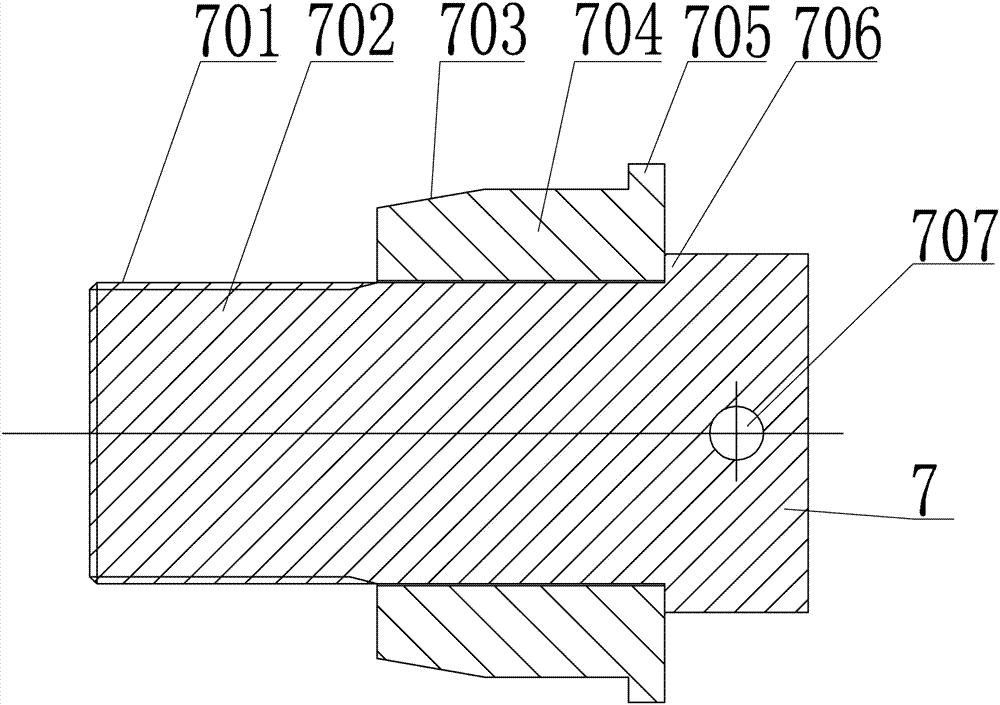

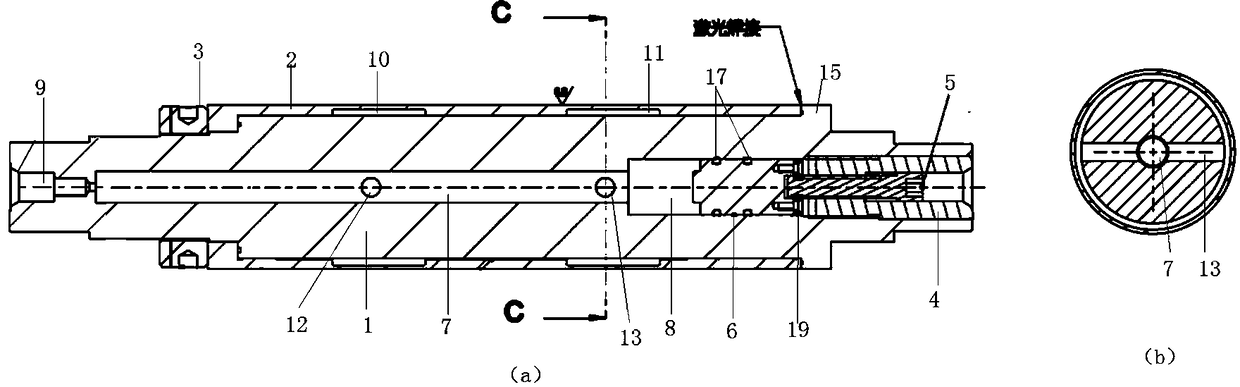

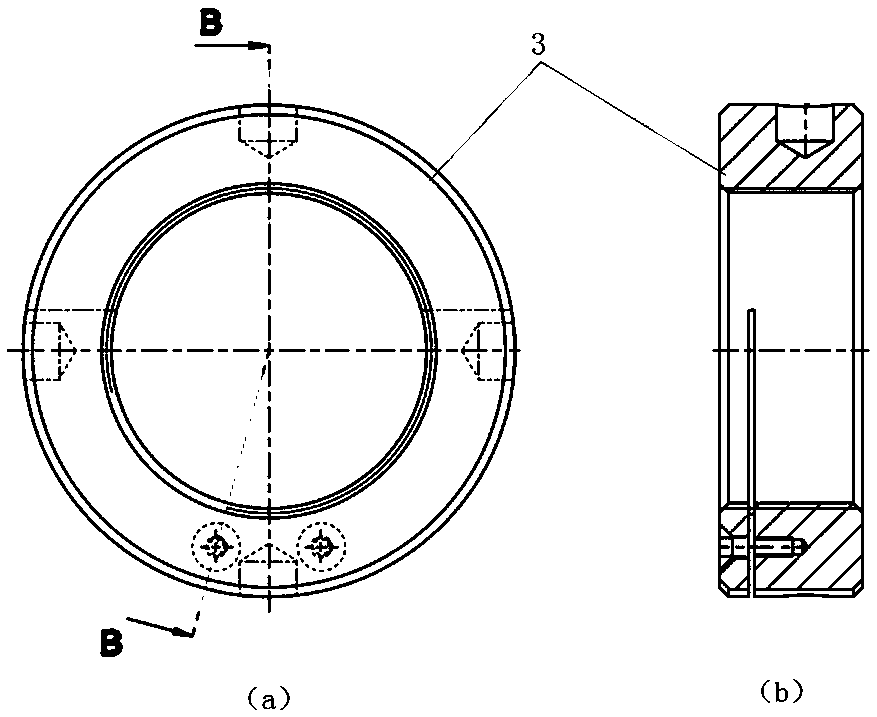

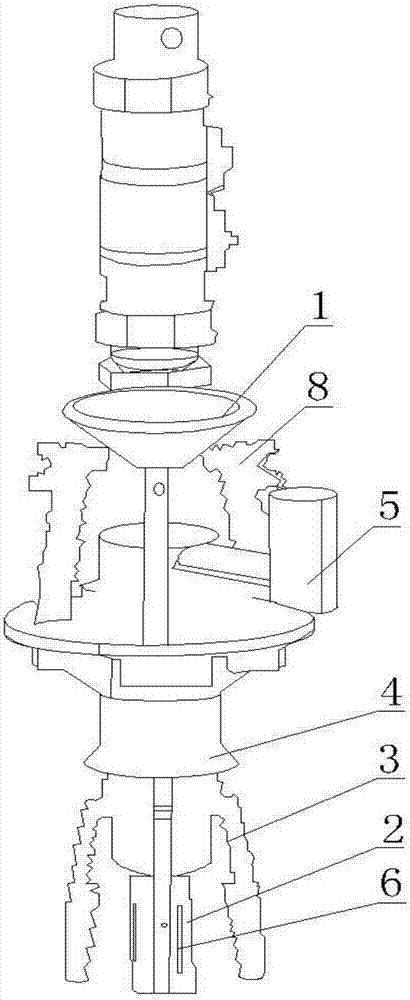

Hydraulic tensioning sleeve tool

PendingCN109332739AControllable expansion sizeEasy to controlExpansion mandrelsEngineeringScrew thread

The invention discloses a hydraulic tensioning sleeve tool which comprises a core shaft, a hydraulic tensioning sleeve, a locking nut, a piston connecting sleeve, a bolt and a piston, wherein an innerhole I and an inner hole II communicating with each other are formed in the core shaft in the axial direction; an oil supply hole is formed in the left end of the core shaft, is a threaded hole and communicates with the inner hole I; the hydraulic tensioning sleeve is arranged on the outer side of the core shaft in a sleeving manner; the two ends of the hydraulic tensioning sleeve are fixedly connected with the core shaft; an annular oil storage cavity I and an annular oil storage cavity II are formed in the inner hole wall of the hydraulic tensioning sleeve; the piston is connected with thehole wall of the inner hole II in a sliding and sealing manner; the piston connecting sleeve is fixed in the inner hole II of the core shaft; a bolt through hole is formed in the piston connecting sleeve in the axial direction; the bolt through hole is in threaded connection with the bolt; and the bolt bar end part of the bolt is connected with the piston. The hydraulic tensioning sleeve tool expands the hydraulic tensioning sleeve through hydraulic pressurization; and as the intensity of the oil pressure is controllable, the expanding size of the hydraulic tensioning sleeve is controllable,the problem that tensioning cannot be realized between the hydraulic tensioning sleeve tool and a product or the product has compressional deformation is avoided and the product quality is improved.

Owner:NINGBO PHASE MOTION CONTROL

Supported carbon aerogel-porous silicon dioxide composite material and preparation method thereof

ActiveCN110862258AImprove stress resistanceGood application prospectSupercritical dryingPorous silicon

The invention discloses a supported carbon aerogel-porous silicon dioxide composite material and a preparation method thereof. The preparation method comprises the following steps: preparing blocky porous silicon dioxide by using a microwave foaming method; then with the blocky porous silicon dioxide as a carrier, adding the blocky porous silicon dioxide into a carbon aerogel precursor solution; performing gelatinizing, and then performing solvent replacement; and performing supercritical drying and carbonization so as to allow a carbon aerogel material to be internally supported by a blocky porous silicon dioxide material skeleton inside and the pores of the blocky porous silicon dioxide material to be uniformly filled with carbon aerogel particles. With the method in the invention, the mechanical properties of carbon aerogel are effectively improved, and the supported carbon aerogel-porous silicon dioxide composite material is formed and can be applied to the fields of heat insulation, catalysis, adsorption materials and the like.

Owner:CHINA BUILDING MATERIALS ACAD

Extrusion forming device for injection mold and work method thereof

The invention discloses an extrusion forming device for an injection mold. The device comprises an upper mold and a lower mold, the middle of the bottom end of the upper mold and the middle of the top end of the lower mold are provided with a fixed base and a base correspondingly through mold cavities, an upper mold core is installed in the middle end of the bottom of the fixed base, a lower mold core is installed in the middle end of the top of the base, a mounting groove is formed in the middle end of the top of the base, the outer portion of the top end of the base is provided with a protection sleeve in a threaded manner, multiple bushings are arranged in the protection sleeve in a sleeved manner, the lower mold core is arranged in the protection sleeve, the forming device can adapt to machining needs of different injection molding products, under the condition of not replacing the mold core, the injection molding products in different sizes can be machined, the machining precision is high, adjusting is rapid and convenient, and operation is easy. Use cost is saved, production cost is reduced, and work efficiency is improved.

Owner:宏阜精密零组件(深圳)有限公司

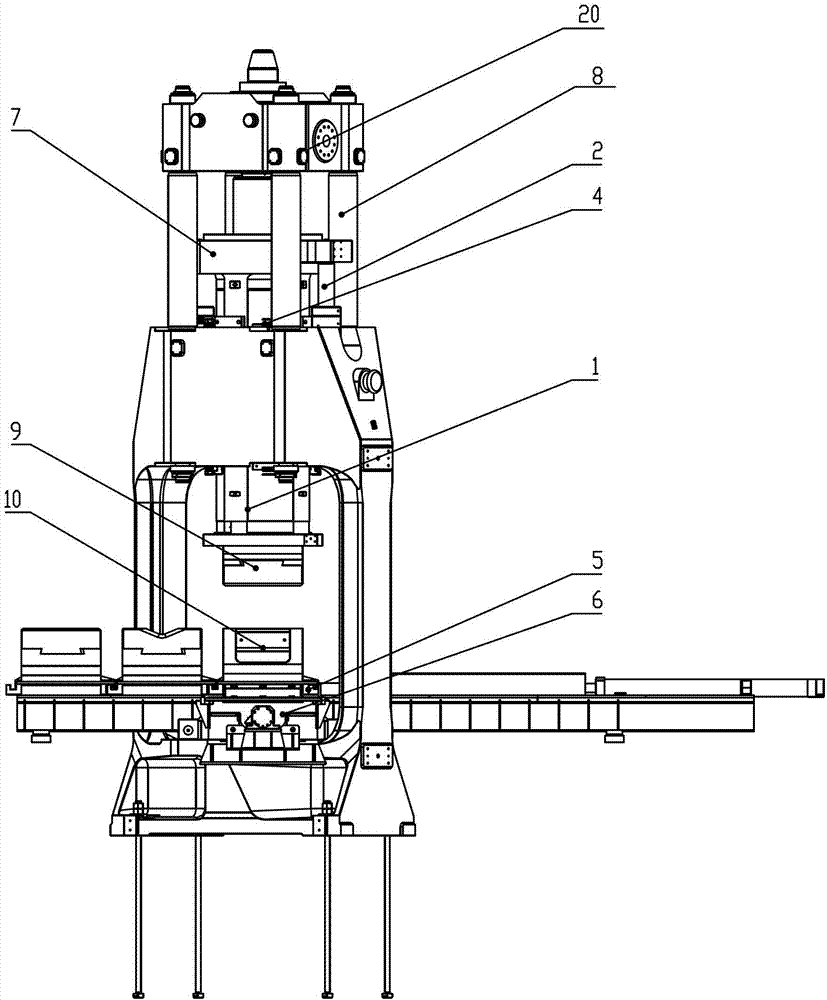

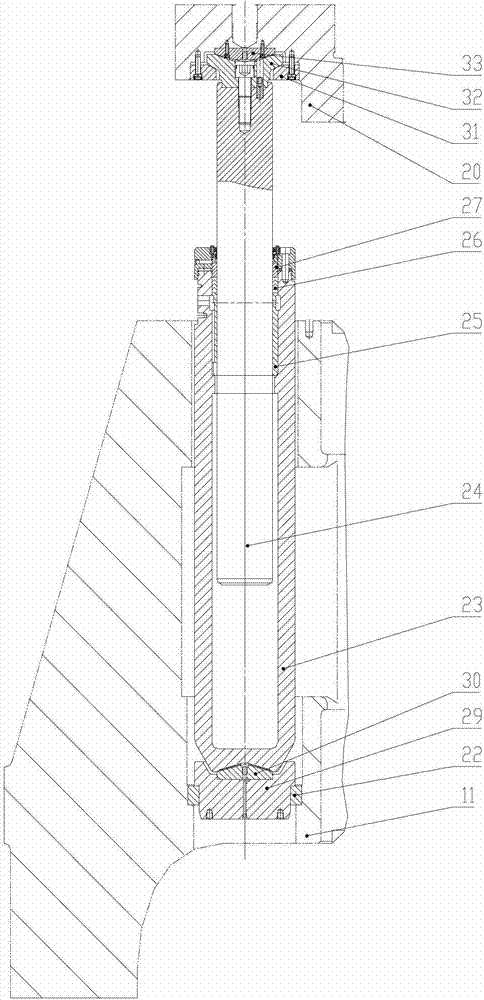

Forging machine with return cylinder anti-unbalance-loading mechanisms and assembling method and using method thereof

ActiveCN103111573AExtended service lifeExtend your lifeFluid-pressure actuatorsForging press drivesPre stressingPiston cylinder

The invention relates to a forging machine with return cylinder anti-unbalance-loading mechanisms and an assembling method and a using method of the forging machine. The forging machine comprises a main machine frame, an upper fixed beam, a pre-stressed pull rod, a movable beam, a return cylinder, a plunger piston cylinder, a guiding device, a mobile working table, a transverse moving anvil, an upper anvil and a lower anvil. The return cylinder comprises a return cylinder body and a return cylinder plunger piston, wherein the return cylinder body and the return cylinder plunger piston are matched with each other. The anti-unbalance-loading mechanisms are respectively arranged between the upper end of the return cylinder plunger piston and the upper fixed beam and between the lower end of the return cylinder body and the main machine frame, wherein spherical surfaces of the anti-unbalance-loading mechanisms contact each other, and the anti-unbalance-loading mechanisms are displaced relatively. The forging machine with the return cylinder anti-unbalance-loading mechanisms and the assembling method and the using method of the forging machine have the advantages that the upper end and the lower end of the return cylinder are both provided with the anti-unbalance-loading mechanisms, and therefore when the return cylinder receives unbalance loading, the return cylinder plunger piston is guaranteed to move freely and cannot suppress strength, and the service life of the return cylinder plunger piston is prolonged. The return cylinder plunger piston sealing and each part of sealing inside an inner cavity are protected, and the service life of a sealing element and a copper bush is prolonged. The anti-unbalance-loading capacity of a return cylinder plunger piston structure is strengthened, and the stationarity of forging machine running is strengthened.

Owner:青岛海德马克智能装备有限公司

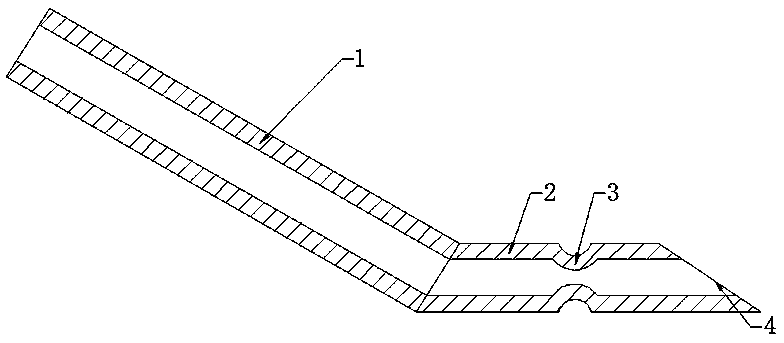

Pressing seam type friction type constant-resistance anchor rod

ActiveCN104453961AImprove work performanceSimple structureAnchoring boltsSolid structureStructural engineering

The invention relates to the technical field of engineering supporting, in particular to a pressing seam type friction type constant-resistance anchor rod. By means of the anchor rod, the technical problems that in the prior art, the ultimate tensile length of an anchor rod is small, function overload failure occurs easily, and the flexible supporting capacity is not achieved are solved. The anchor rod structurally comprises a sleeve, a rod body, a tray and a pressing block. The rod body comprises an entity segment, a constant-resistance segment, a conical segment, a friction resistance segment and a free segment from top to bottom. The entity segment is of a cylindrical solid structure. The side walls of the constant-resistance segment, the conical segment and the friction resistance segment are provided with gaps with the same width from top to bottom in the axial direction. The outer diameter of the constant-resistance segment is larger than that of the friction resistance segment. The outer diameter of the axial section of the rod body gradually diseases continuously and is in transition to the outer diameter of the friction resistance segment from the outer diameter of the constant-resistance segment in the axial direction through the conical segment The sleeve comprises a rough-hole segment, a conical-hole segment and a thin-hole segment and is matched with the rod body in inner diameter. The anchor rod is not damaged when a surrounding rock is greatly deformed, larger displacement of the rod body is allowed so as to adapt to deformation of the surrounding rock, the surrounding rock deformation energy can be continuously absorbed, and the stability of the surrounding rock is maintained.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Automotive rear bridge torsion beam hinged lining assembling and disassembling tool

ActiveCN104874992AGuaranteed installation accuracySimple structureVehicle componentsMetal working apparatusMachine pressCushion

The invention discloses an automotive rear bridge torsion beam hinged lining assembling and disassembling tool. The automotive rear bridge torsion beam hinged lining assembling and disassembling tool is characterized by comprising an assembling and disassembling support, a first counter-force seat, a second counter-force seat, a straight-barrel type mechanical press and an extrusion cushion block, wherein the first counter-force seat and the second counter-force seat are respectively fixed at two ends of the assembling and disassembling support; the first counter-force seat, the second counter-force seat and the assembling and disassembling support form a closed frame; the straight-barrel type mechanical press is placed in the assembling and disassembling support and comprises a retractable front end, a barrel body and a rear seat which are connected to one another sequentially; the rear seat is abutted to the inner end surface of one of the counter-force seats; and the retractable front end is connected with the inner end surface of the extrusion cushion block. The various components are connected to one another to form the assembling and disassembling tool and are assembled into the disassembling tool or the assembling tool as needed, and by the assembling and disassembling tool, a lining can be disassembled from a sleeve or can be arranged in the sleeve. The automotive rear bridge torsion beam hinged lining assembling and disassembling tool is simple in structure, convenient to operate, small in size and convenient to carry, and can be disassembled and stored when not used.

Owner:DONGFENG MOTOR CORP HUBEI

Embedding mould suitable for anaerobic resins

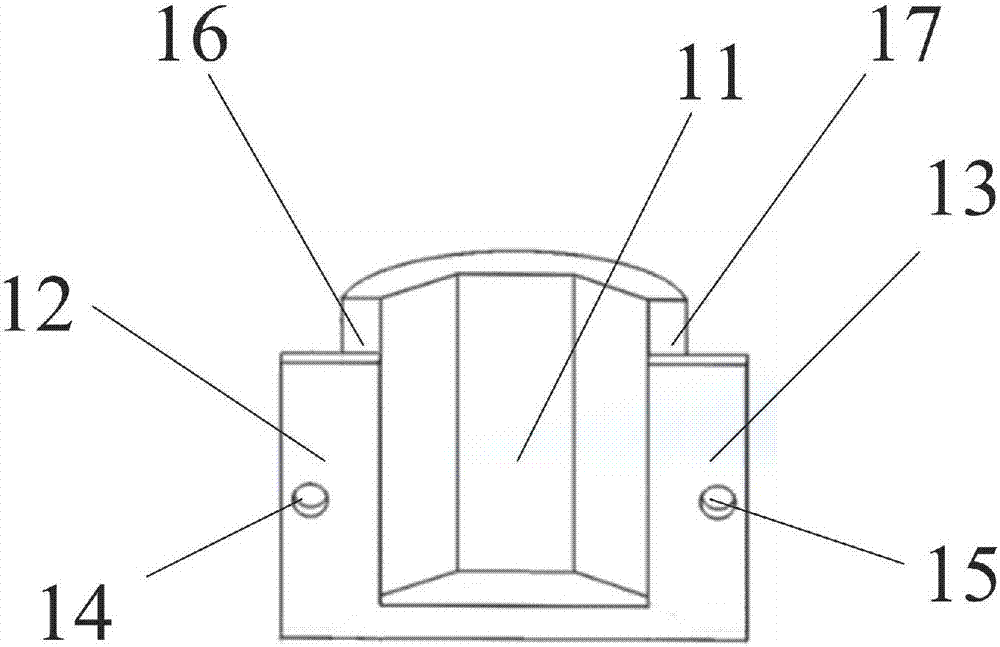

ActiveCN107053543AEasy to placeNo extrusion deformationPreparing sample for investigationOctahedronPrism

The invention discloses an embedding mould suitable for anaerobic resins. The embedding mould comprises a left mould main body, a right mould main body, a solid octahedron and a top cover, wherein the two sides of the solid octahedron are respectively connected with the left mould main body and the right mould main body; the left mould main body, the right mould main body and the solid octahedron are all connected with the top cover; the left mould main body comprises an eight-prism groove, a left raised line, a right raised line, a left threaded hole, a right threaded hole, a left gap and a right gap; the left raised line and the right raised line are both connected with the eight-prism groove; the left raised line is positioned on the left side of the right raised line; the left threaded hole is formed in the left raised line; and the right threaded hole is formed in the right raised line. According to the embedding mould, the placement of samples is easy, samples cannot be extruded and deformed in an embedding process and can be detached; polymerized resin samples are convenient and easy to take, an airtight system is formed, and the mould is suitable for polymerizing anaerobic resins; the limitation to the size is avoided, and the embedding mould can be adapted to biological tissue sample embedding of different sizes, is easy to operate, and is suitable for being popularized and used in a general laboratory.

Owner:HUAZHONG UNIV OF SCI & TECH

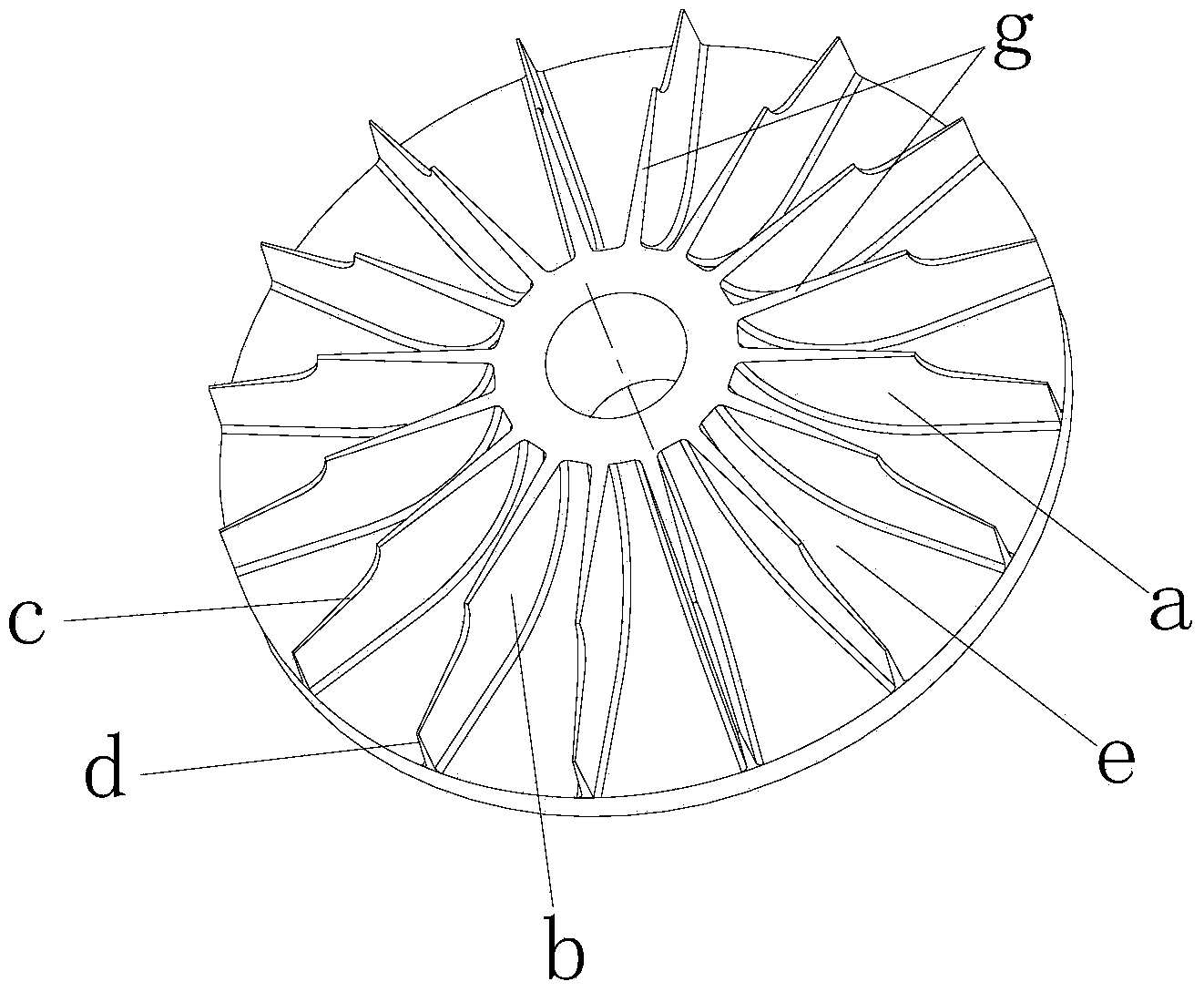

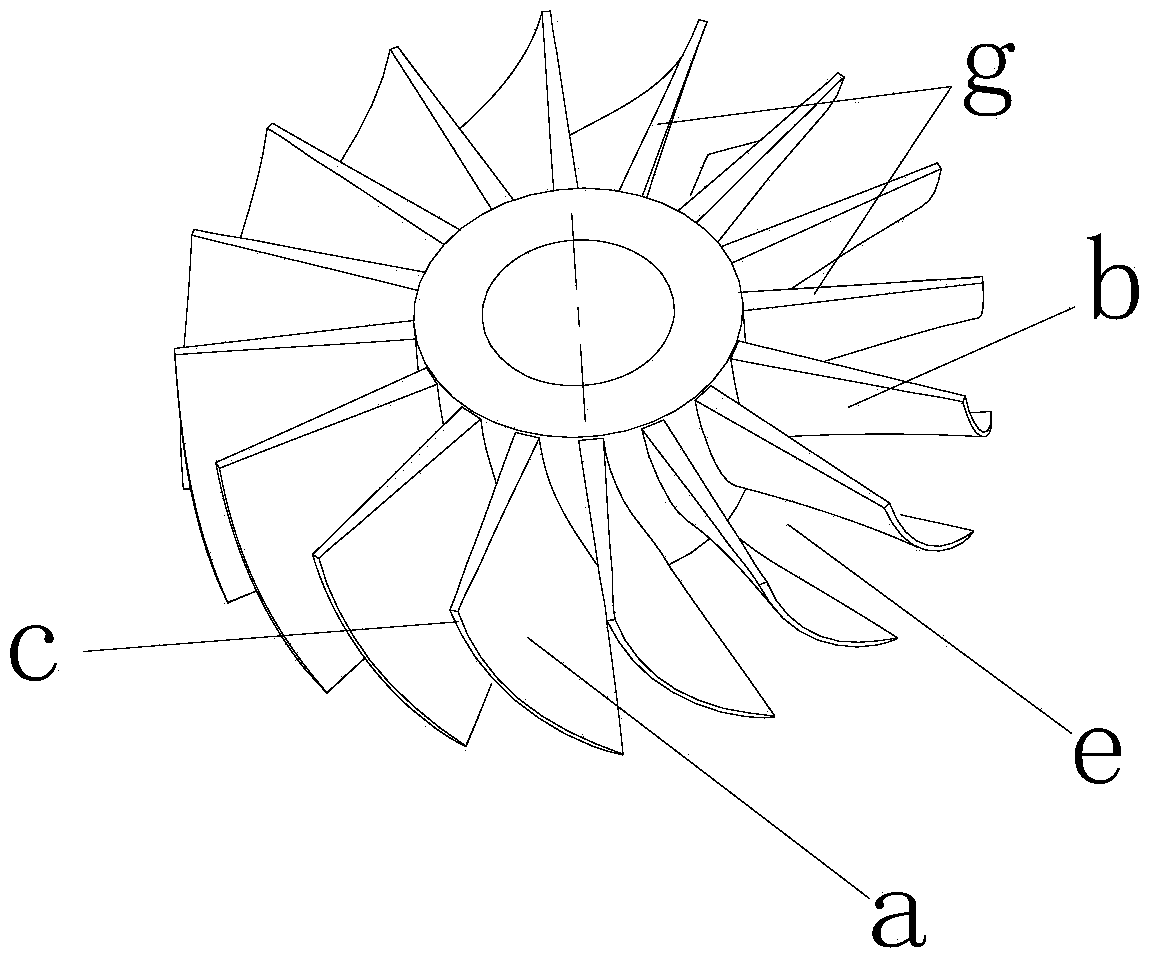

Sand-blasting protective clamp for centrifugal impeller combination

ActiveCN103707198AShorten the processing cycleAvoid scratchesAbrasive machine appurtenancesGrinding/polishing apparatusImpellerSand blasting

The invention relates to a sand-blasting protective clamp for centrifugal impeller combination. The sand-blasting protective clamp comprises a first protective clamp and a second protective clamp, wherein the first protective clamp comprises a first annular cover plate; a plurality of isosceles triangle notches are formed in the inner ring of the first annular cover plate; the distribution of each notch on the first annular cover plate and a surface to be sand-blasted on each vane of the impeller is in a one-to-one correspondence manner; the surface to be sand-blasted on each vane of the impeller is suitable for being embedded in each notch on the first annular cover plate; the assembling gap between each notch on the first annular cover plate and the surface to be sand-blasted arranged in the notch is 0.3-0.6 mm; the size of the gap facilitates the assembling and also can prevent sand from passing through a non-sand-blasting surface scratched by the gap. With the clamp, the labor intensity of workers is greatly alleviated, the production efficiency and product quality are improved, the production cost is reduced, and the processing cycle of parts is shortened.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

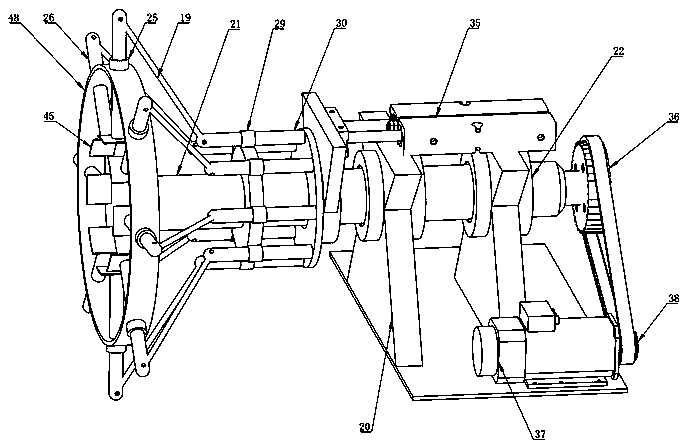

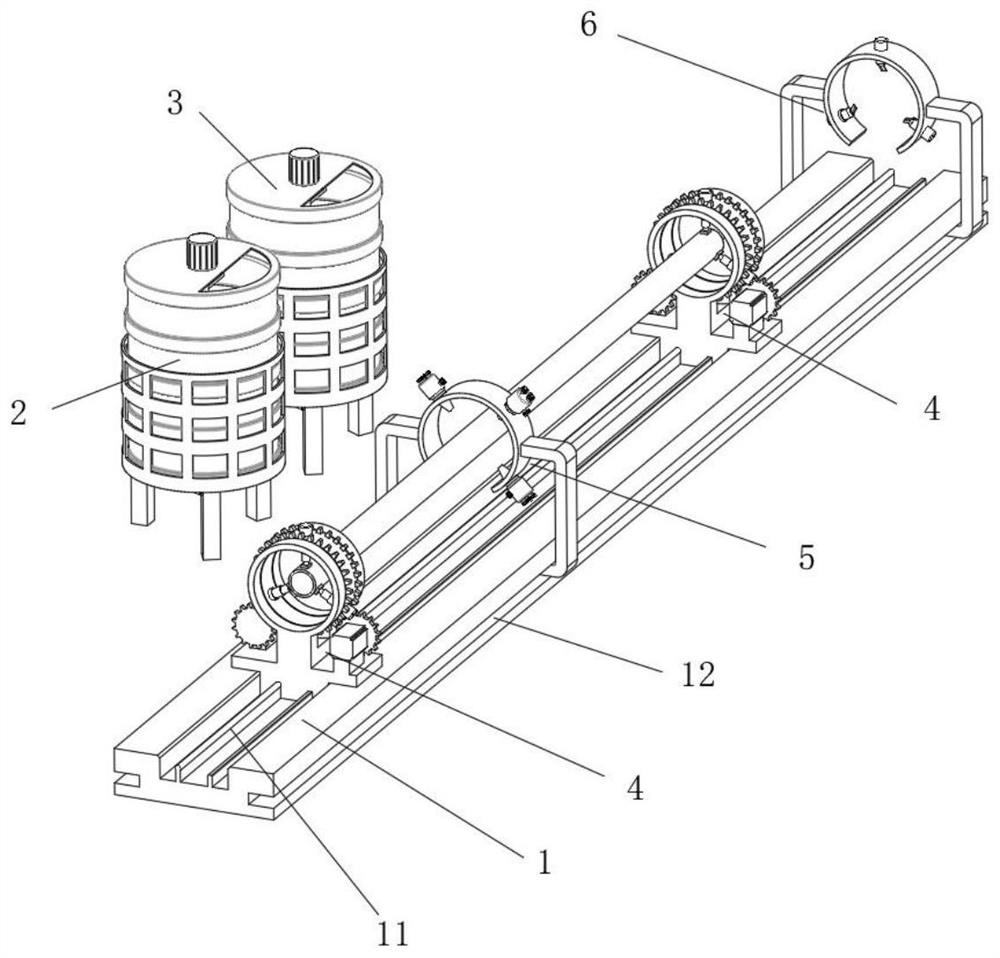

Coil winding equipment with self-expansion type winding shaft

ActiveCN109755016AAdapt to processingNo extrusion deformationCoils manufactureTransformerMechanical equipment

The invention discloses a coil winding equipment with a self-expansion type winding shaft. The equipment comprises a workbench, a power clamping table arranged on the workbench, a fixed clamping tablewhich is symmetric with the power clamping table, a winding shaft device used for fixing a coil shaft, a rotation seat arranged on the end surface of the power clamping table, a driven seat arrangedon the end surface of the fixed clamping table, and a tooth-shaped box used for clipping an insulated rubber tape on the outer edge of a transformer. The equipment abandons a traditional mechanical equipment principle, adopts a self-expansion design, can effectively adapt to the coiling machining operation of the coil shafts of different sizes and model numbers, avoids a situation that a traditional fixing way extrudes and damages the coil shaft, and also greatly improves machining efficiency.

Owner:江苏华祥电子有限公司

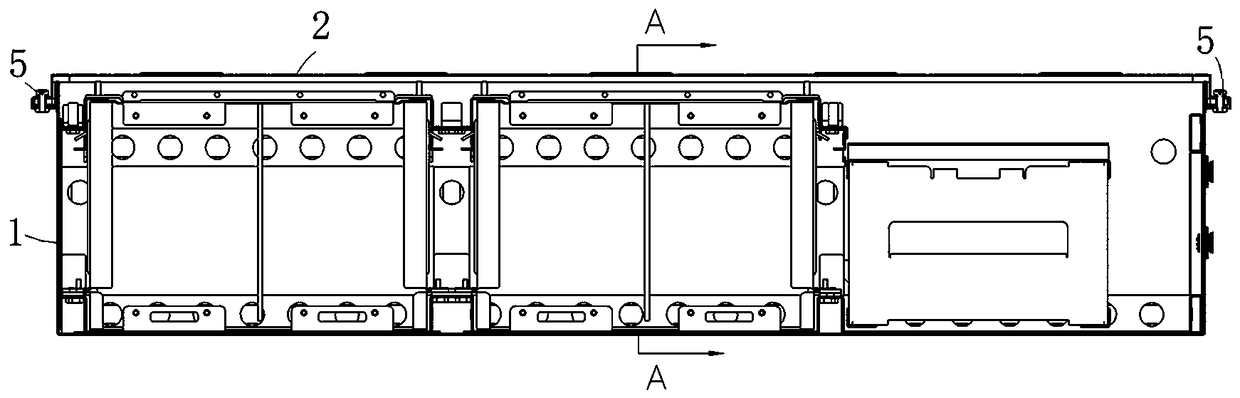

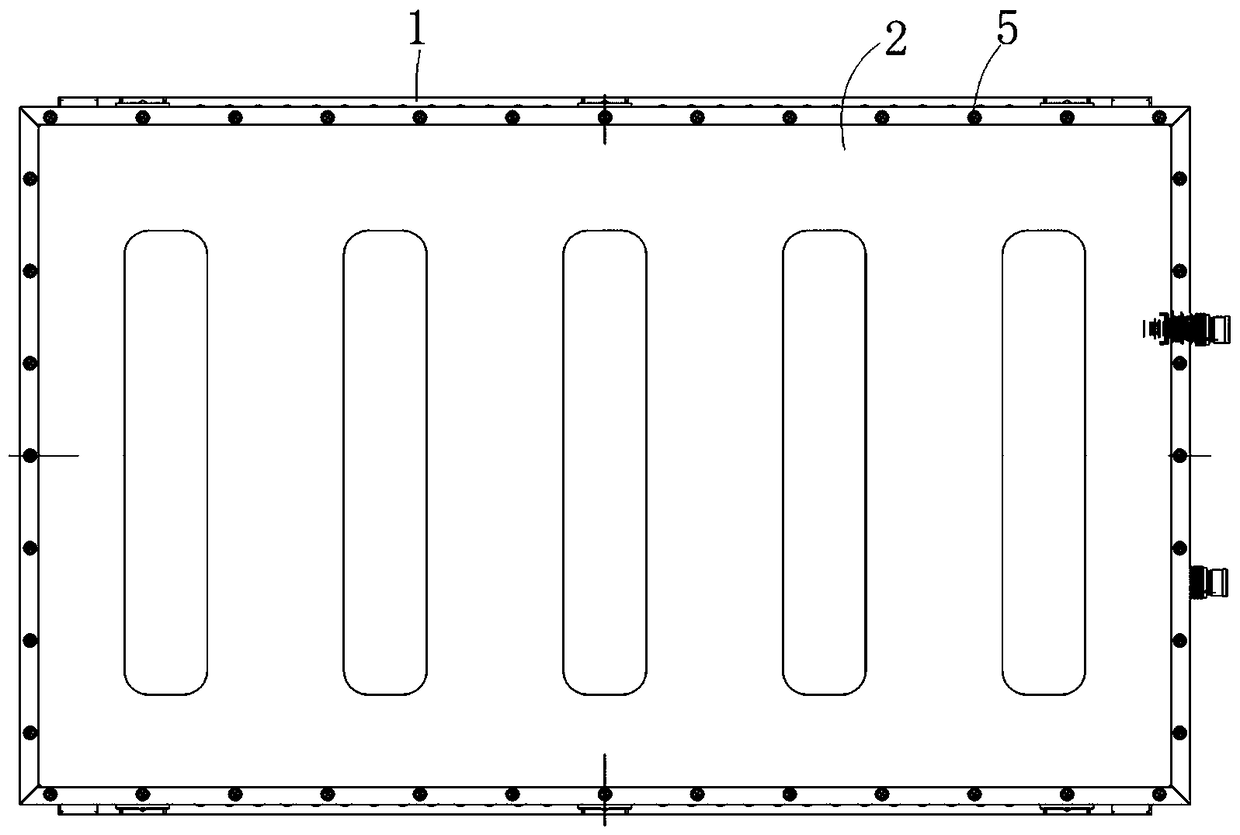

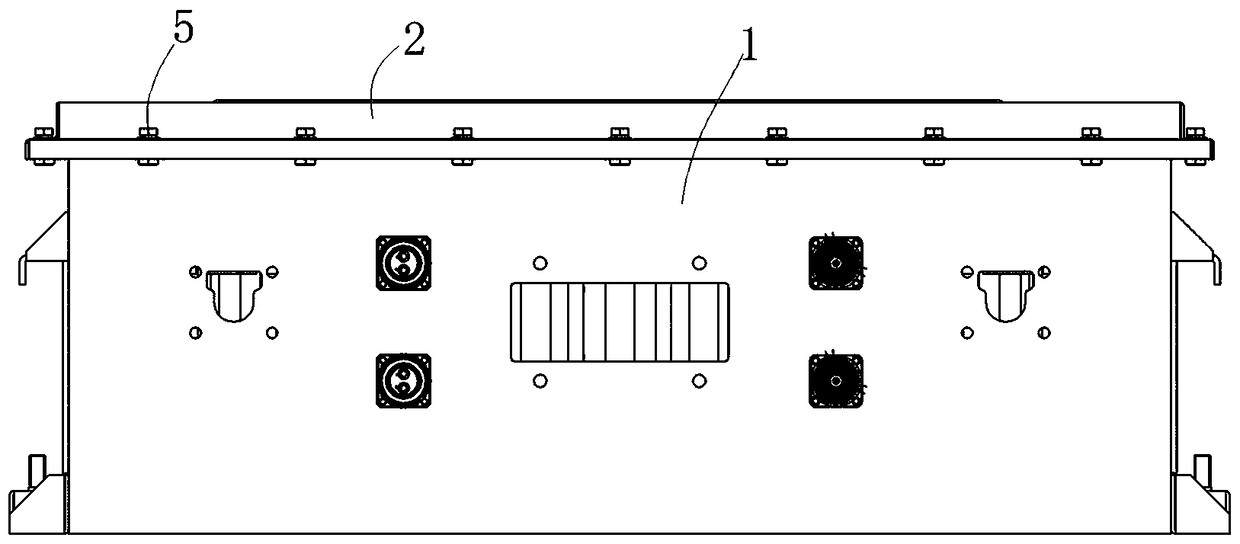

A box body and a battery box using the box body

The invention relates to a box body and a battery box using the box body, the top end of the box side plate of the box body is pressed down to form a first pressed edge of the box body, A low end of that first dead edge of the box body is bent outwardly to form an outwardly flanged edge of the box body, one end of the outer flanged edge of the box away from the first flanged edge of the box is pressed inward to form a second flanged edge of the box, An upper cover of the battery case comprises an upper cover top plate, the edge of the upper cover top plate is bent downward to form an upper cover lower flange, the low end of the upper cover lower flange is bent outward to form an upper cover outer flange, and the upper cover outer flange is connected with a double-layer connecting plate formed by an outer flange of the case and a second pressurized dead edge of the case. When the double-layer connecting plate is connected with the outer flanging edge of the upper cover, the double-layerconnecting plate and the outer flanging edge of the upper cover can withstand enough extrusion force to avoid extrusion deformation, thereby ensuring the sealing effect between the upper cover and the box.

Owner:XJ ELECTRIC +2

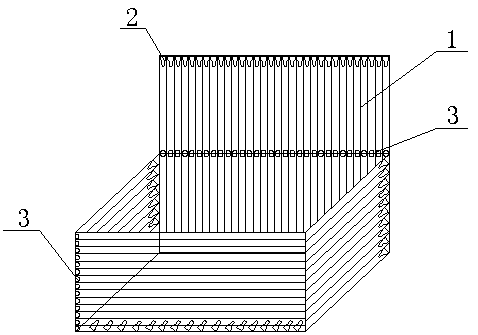

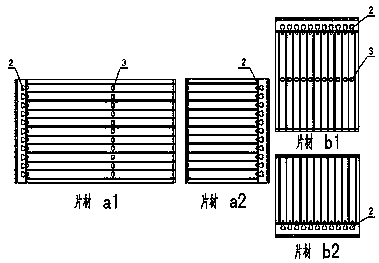

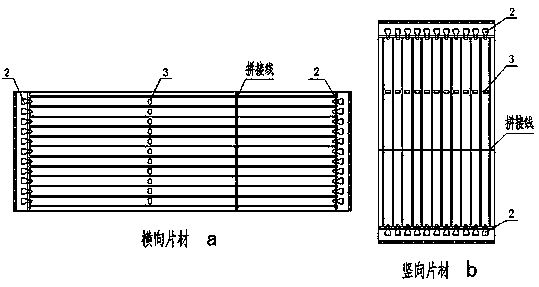

Large-specification square packaging air column box and preparation method thereof

PendingCN108792276ANo extrusion deformationGuarantee the safety of useContainers to prevent mechanical damageEngineeringLarge size

The invention belongs to the technical field of compound soft packaging and discloses a large-specification square packaging air column box and a preparation method of the air column box. The air column box is of a cuboid structure, the top of the air column box is provided with a folded cover cap, and six faces of the cuboid are all composed of air column faces. The air column box is provided with four charging ports, the four charging ports correspond to four air column bag sheets, each air column bag sheet is of an independent air column bag structure, and the width of air columns is the same. The air column box is further provided with two rows of foldable heat seal points. The large-specification square packaging air column box is simple in structure, good in airtightness, high in anti-shock strength and capable of packaging large-size products in regular shapes.

Owner:杭州巨杰包装科技有限公司

Full-automatic tying and ring-sleeving device and operation method for same

InactiveCN107396756AFor subsequent cappingAvoid cloggingCultivating equipmentsMushroom cultivationEngineeringAutomatic testing

The invention discloses a full-automatic beam mouth collar device and its operation method, which include a centering adsorption tube, a first jaw, a first cylinder, and a second cylinder, and the upper periphery of the centering adsorption tube is provided with a first jaw and a The first cylinder, the first cylinder brings the mouth of the material bag into the gap opened by the first jaw; the upper end of the centering adsorption tube and the position where the first jaw is located is provided with a second jaw and a lower pressing block 1. The second air cylinder, the lower pressing block is connected with the centering adsorption pipe, and the second air cylinder drives the lower pressing block to move to control the closing of the second clamping jaw. Set the first cylinder, the second cylinder, the centering adsorption tube, the lower pressing block, the first jaw, the second jaw, the centering adsorption tube absorbs the bag mouth, and the first cylinder drives the bag mouth into the first clamp In the gap between the claws, the bag mouth is tightly adsorbed on the centering adsorption tube. After the collar is closed, the first jaw opens and expands the inside of the bag mouth; the second cylinder drives the second jaw to move, pressing down on the unfolded bag mouth to turn over the bag , which is convenient for subsequent capping.

Owner:四川哈贝智能科技有限公司

Rubber stator forming fixture and rubber stator forming process

InactiveCN103831930AAvoid leakage of materials, etc.Solve complexityCoatingsInjection portEngineering

The invention provides a rubber stator forming fixture and a rubber stator forming process and overcomes the defects of complex glue-injection process and inaccurate stator forming size in the prior art caused by restoration of a glue injection port after glue is injected into a stator of a screw pump. The rubber stator forming fixture provided by the invention comprises a fixture, a mold core, a metal steel sheath and rubber, wherein the fixture is arranged at two ends of the mold core; the metal steel sheath is arranged on the periphery of the mold core; the rubber is filled between the metal steel sheath and the mold core; and an opening is horizontally formed in one end of the metal steel sheath. The process is simple in steps, the stator size is accurate and the phenomenon of material leakage generated in the running course of the screw pump is avoided.

Owner:GUANGDONG STANDARD FLUID SYST

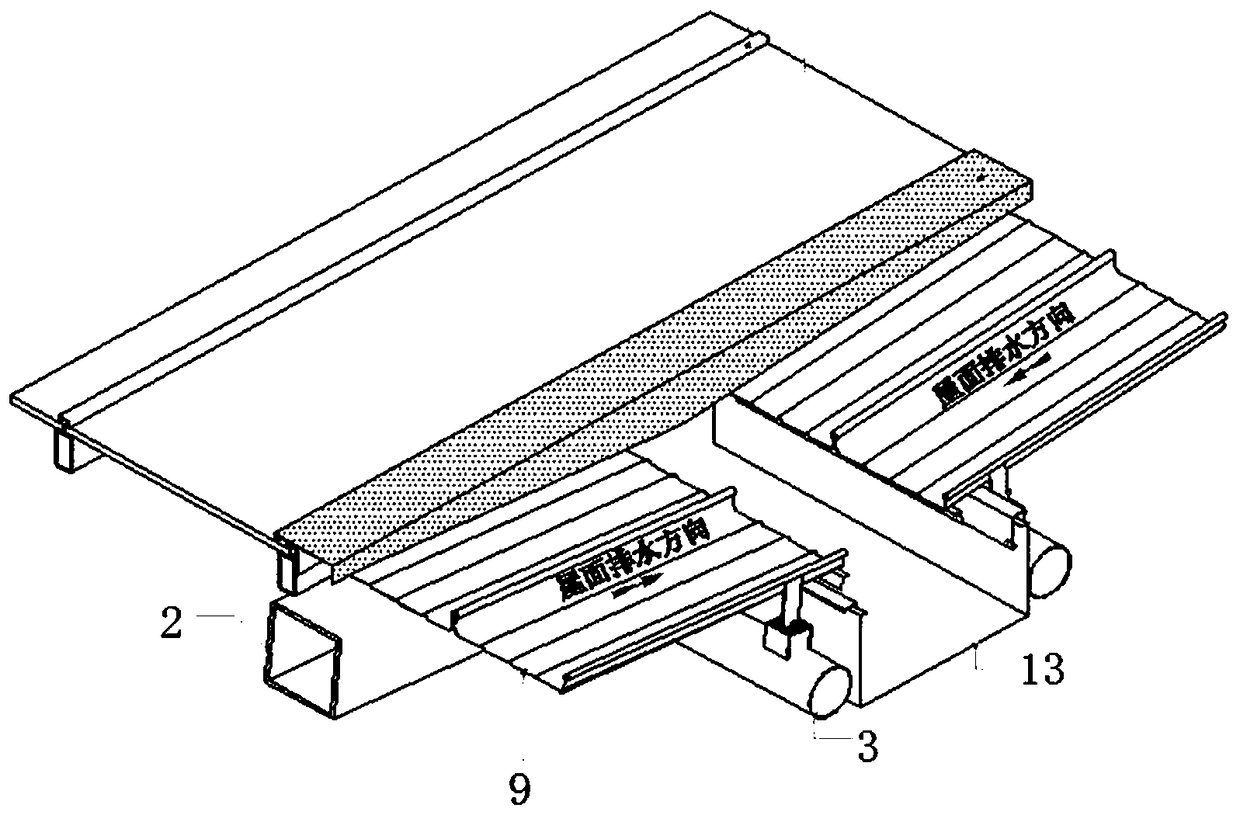

Special-shaped curtain wall system and construction method thereof

ActiveCN109469233ANo extrusion deformationWon't crackRoof covering using slabs/sheetsWallsManganeseInverted-T shape

The invention relates to a special-shaped curtain wall system and a construction method thereof. Main purline and secondary purline are fixedly arranged on a main steel structure; one end of the secondary purline is fixedly connected with the main purline, and the main purline is perpendicular to the secondary purline; zinc aluminized perforated bottom plates are tiled and fixed on the secondary purline, C-shaped fixing members penetrate through the zinc aluminized perforated bottom plates to be fixedly connected with the secondary purline, and inverted T-shaped aluminum alloy fixing supportsare fixed on the C-shaped fixing members; a non-woven fabric is laid on the zinc aluminized perforated bottom plates, glass wool is laid on the non-woven fabric, a hot galvanizing steel wire mesh is laid on the glass wool, rock wool is laid on the hot galvanizing steel wire mesh, an aluminum-magnesium-manganese alloy roof plate is laid on the rock wool, and the upper ends of the inverted T-shapedaluminum alloy fixing supports support the aluminum-magnesium-manganese alloy roof plate. The curtain wall system is safe and reliable, and can meet the technical requirements of national regulationsin different wind pressures, heights and shapes.

Owner:ZHEJIANG CENT SOUTH CONSTR GROUP

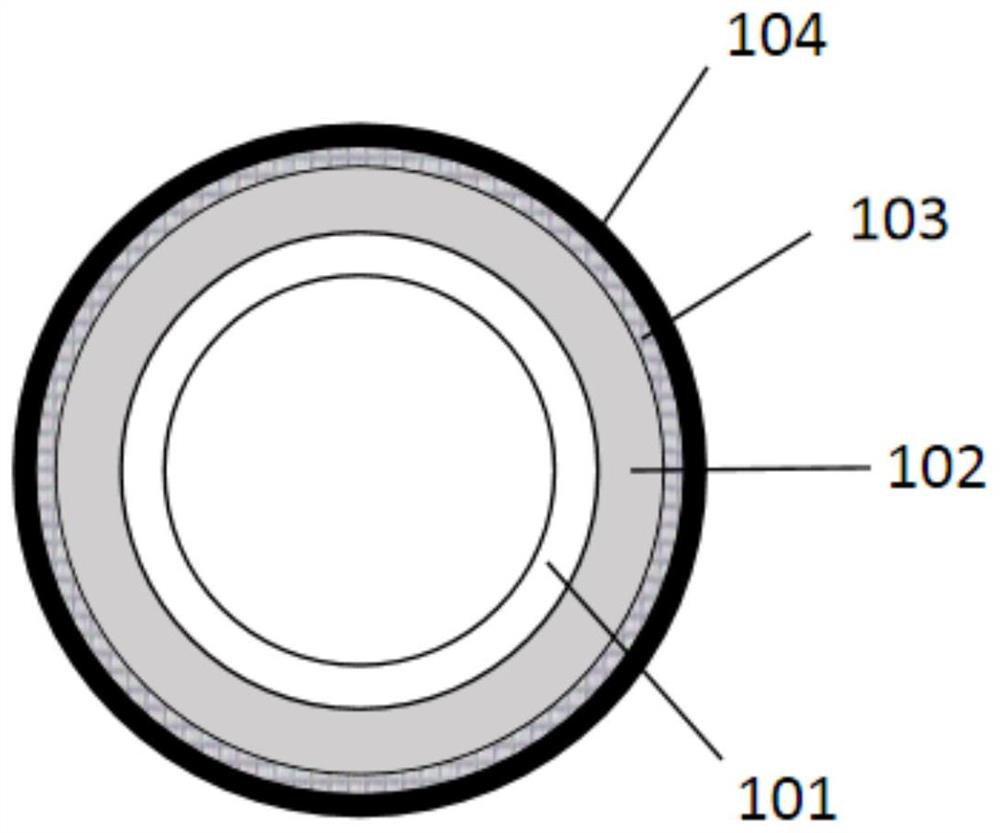

ESEPI prefabricated heat-preservation directly-buried heat-resistant high-density polyethylene low-temperature heat supply composite pipe

ActiveCN113719670AImprove corrosion resistanceExtended service lifeThermal insulationGeothermal energy generationInsulation layerPhysical chemistry

The invention discloses an ESEPI prefabricated heat-preservation directly-buried heat-resistant high-density polyethylene low-temperature heat supply composite pipe which is composed of an outer protective pipe, a heat-preservation layer and a working pipe. The outer protective pipe is a high-density polyethylene pipe, the heat-preservation layer is hard polyurethane foam plastic, and the working pipe is a heat-resistant polyethylene (PE-RT II type) pipe. The ESEPI prefabricated heat-preservation directly-buried heat-resistant high-density polyethylene low-temperature heat supply composite pipe prepared by the invention has excellent heat resistance, corrosion resistance, impact resistance and sealing performance, and is convenient to construct and maintain, beneficial to reducing heat loss in a conveying link, long in service life, and suitable for a secondary pipe network system for central heating and cold and hot water systems for life, air conditioners, solar energy and the like.

Owner:黑龙江贞财管道有限公司

Fixing needle for mouse embryo amnion cavity microinjection and preparing method thereof

The invention relates to a fixing needle for mouse embryo amnion cavity microinjection and a preparing method thereof, and belongs to the technical field of medical apparatuses. The technical problems are solved that gel micropores applied in a mouse amnion cavity injection technology do not easily fix embryos, operation cannot be carried out under a high-power lens, and the difficulty in the injection process is large. According to the scheme, the fixing needle comprises an inclined part and a horizontal part, one end of the inclined part is fixedly connected with one end of the horizontal part, the inclined part is communicated with the horizontal part, the end portion of the free end of the horizontal part is aslant provided with a cutting edge with an upward opening, and the middle of the horizontal part is further provided with a reducing part which is sunken towards the inner side of the horizontal part. Through the process of needle drawing, needle grinding and needle forging, the fixing needle is prepared. The fixing needle is low in cost, the preparing process is simple and feasible, the prepared fixing needle can simplify the operation process, in the process of transferring the embryos after injection, the embryos are not easily influenced by the external environment in the fixing needle, and the fixing needle can better protect the embryos.

Owner:SHANXI MEDICAL UNIV

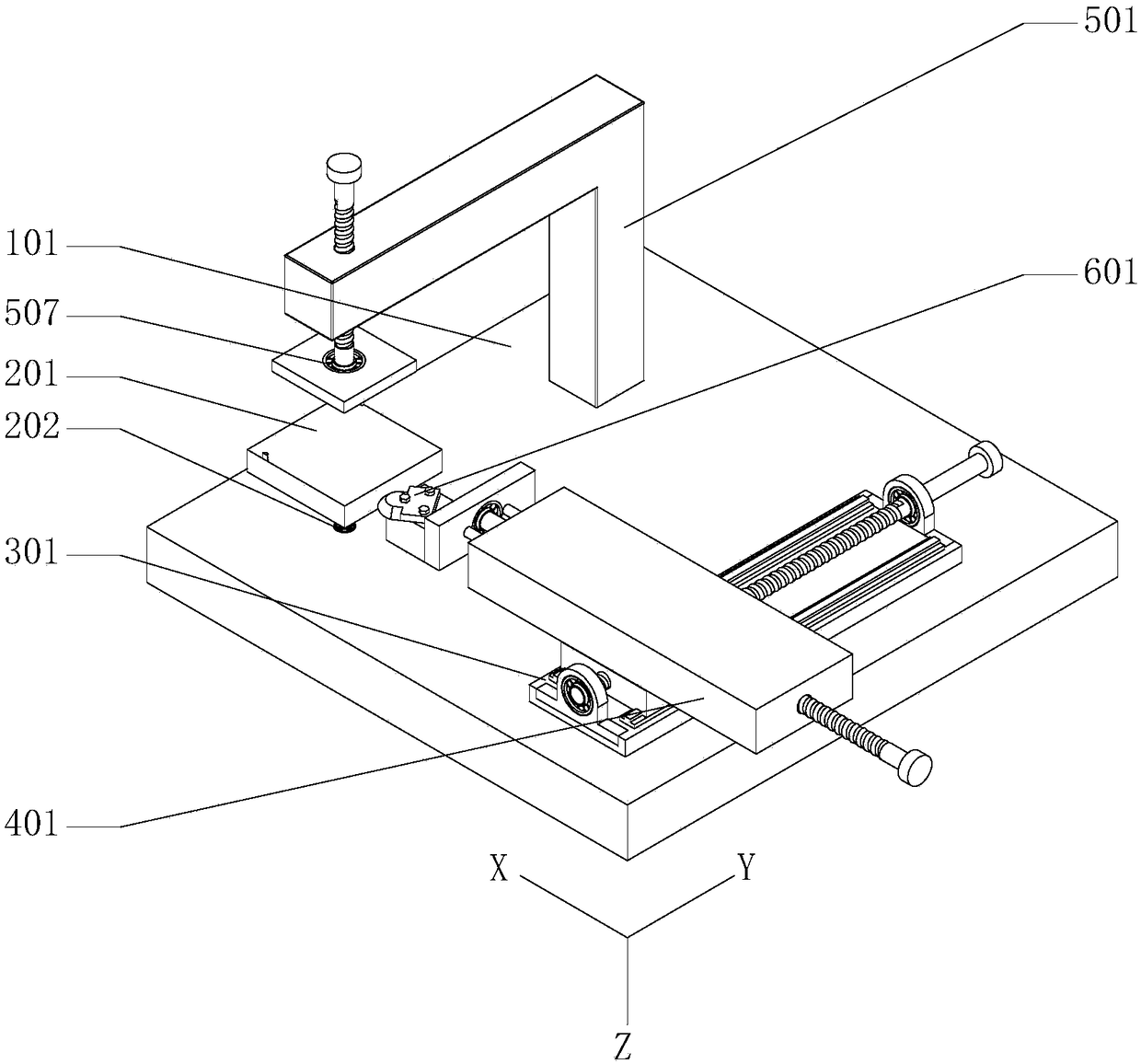

Auxiliary device and method for secondary packaging of CPU

ActiveCN108347830AAvoid scrappingSelf-centeringPrinted circuit non-printed electric components associationEngineeringComputer equipment

The invention relates to an auxiliary device and method for secondary packaging of a CPU, and belongs to the related field of computer equipment. The device mainly comprises a pedestal; a rotary tablewhich is rotatably connected with the pedestal; a Y-axis sliding table which is fixedly connected with the pedestal; an X-axis sliding table driven by the Y-axis sliding table to operate; a blade installed on the Y-axis sliding table; and a Z-axis positioning mechanism located at one side of the rotary table. The Z-axis positioning mechanism is provided with a Z-axis press block, and the Z-axis press block is provided with a groove for accommodating a metal cover. The sum of the width of the X-axis sliding table and the width of the blade is less than the distance between the Z-axis positioning mechanism and the rotary table. The device can cut a part of an adhesive layer through the design of a brand-new structure, and guarantees the accurate positioning of the metal cover and a PCB. Moreover, the device can guarantee that the moving direction of the blade is parallel to the PCB in an adhesive cutting process, and causes no damage to the PCB while the cover of the CPU is opened.

Owner:周伟冬

Separating method for living cells in ship ballast tank sediments

The invention discloses a separating method for living cells in ship ballast tank sediments. The method comprises the steps that (1) the ship ballast tank sediments are collected and placed into a petri dish; (2) filtrated sea water is used for washing the sediments, and a first bolting cloth is adopted for filtration, and liquid obtained after washing is reserved; (3) the reserved liquid is filtered by a second bolting cloth, and residues on the second bolting cloth are reserved; (4) a saturated sucrose solution is used for washing the residues on the second bolting cloth to a centrifuge tube; (5) the centrifuge tube is centrifuged; (6) supernatant liquid on the centrifuge tube is absorbed, a third bolting cloth is adopted for filtration, and residues on the third bolting cloth are reserved; (7) the filtered sea water is used for rinsing the residues on the third bolting cloth to a petri dish, separation of the living cells is achieved, and the living cells are observed under a microscope. The method is easy to implement, convenient and easy to operate, and capable of achieving rapid separation.

Owner:山东恒诚检测科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com