Special-shaped curtain wall system and construction method thereof

A technology of special-shaped curtains and purlins, which is applied to walls, roofs, building components, etc., and can solve problems such as unstable installation and fixation of curtain wall units, poor watertightness, and weak splicing of curtain wall units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0030] Example.

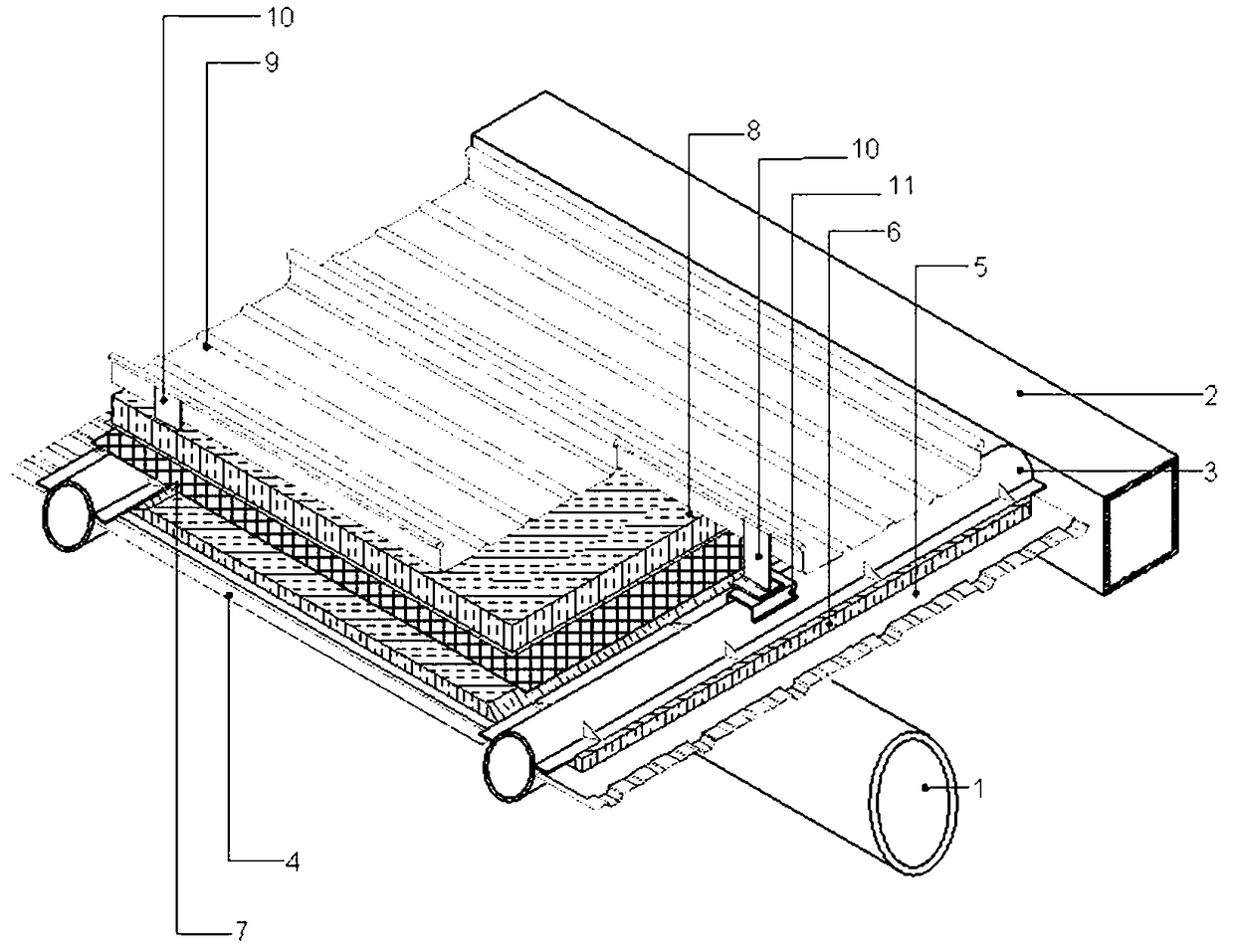

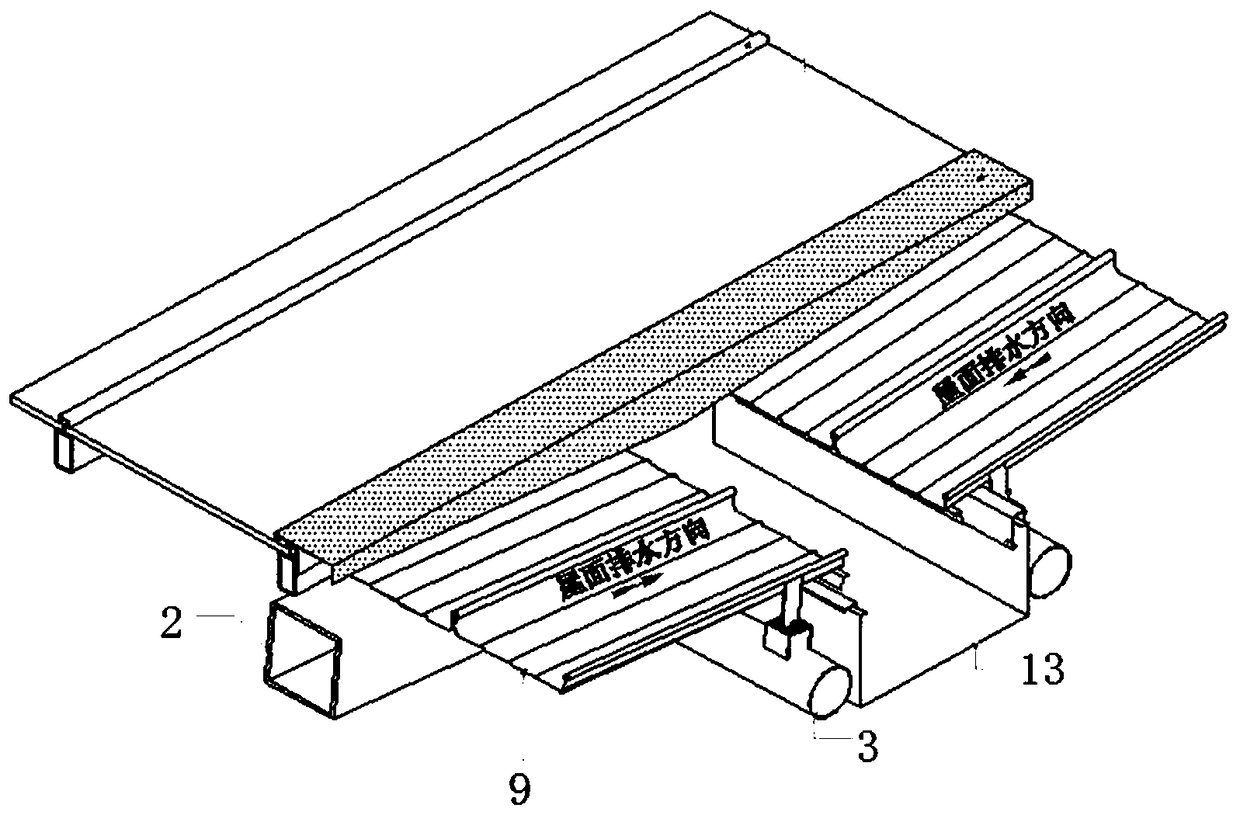

[0031] see Figure 1 to Figure 7 .

[0032] This embodiment is a special-shaped curtain wall system, which includes a petal-shaped main steel structure 1 and curtain wall unit panels sequentially spliced and fixed on the main steel structure 1. The curtain wall unit panels include main purlins 2, secondary purlins 3, and galvanized perforations. Bottom plate 4, non-woven fabric 5, glass wool 6, hot-dip galvanized steel wire mesh 7, rock wool 8, aluminum-magnesium-manganese alloy roof panel 9, inverted T-shaped aluminum alloy fixing support 10 and C-shaped fixing piece 11. The aluminum-magnesium-manganese alloy roof panel 9 is a standing seam aluminum-magnesium-manganese alloy roof panel.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com