Precision steel pipe chuck-free cold drawing repairing device and method

A technology of precision steel pipes and chucks, applied in the field of lubrication systems, can solve problems such as changes in the mechanical properties of steel pipes in the weld area, impact on product quality, loss, etc., and achieve improved repair rate and yield, improved repair efficiency, and no loss of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

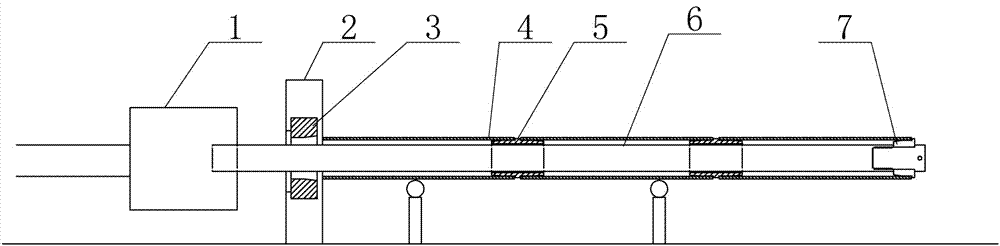

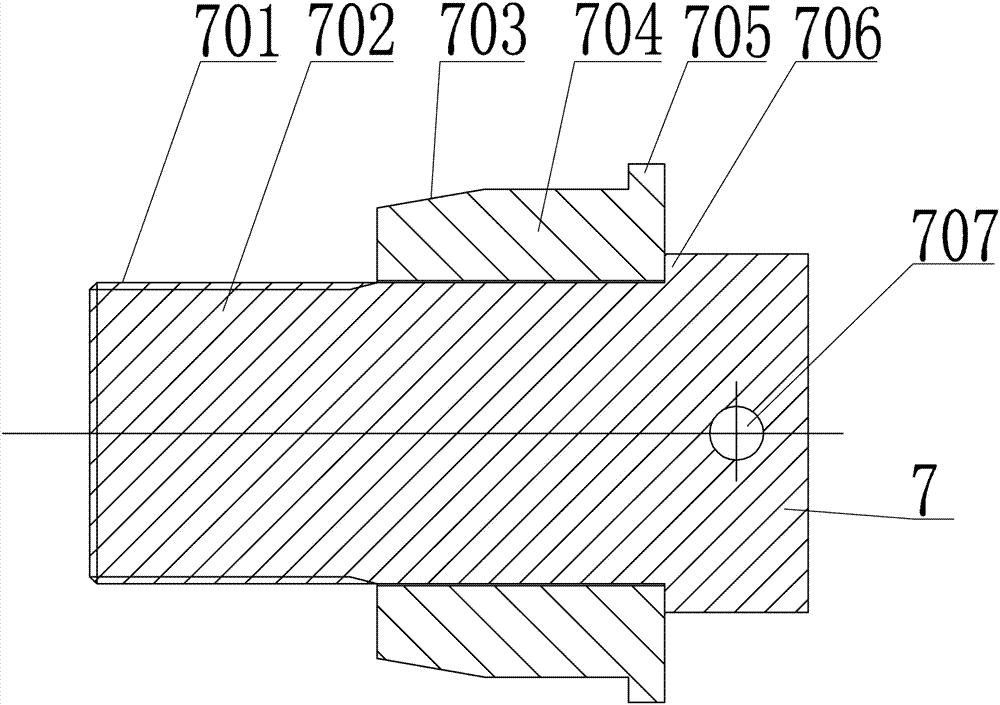

[0035] like Figure 1-3 As shown, the precision steel pipe chuck-free cold-drawing repair device includes a clamp cylinder 1, a mold base 2 and an outer mold 3, one end of the pull rod 6 is fixed on the clamp cylinder 1, and the other end of the pull rod 6 is externally The set has a plurality of steel pipes 4 to be repaired, and the plurality of steel pipes 4 to be repaired are supported and connected through the middle connecting sleeve 5, and a back cover 7 is fixedly installed on the other end of the pull rod 6, and the back cover 7 will be the last part to be repaired. Steel pipe 4 limit sleeves are on the pull rod 6.

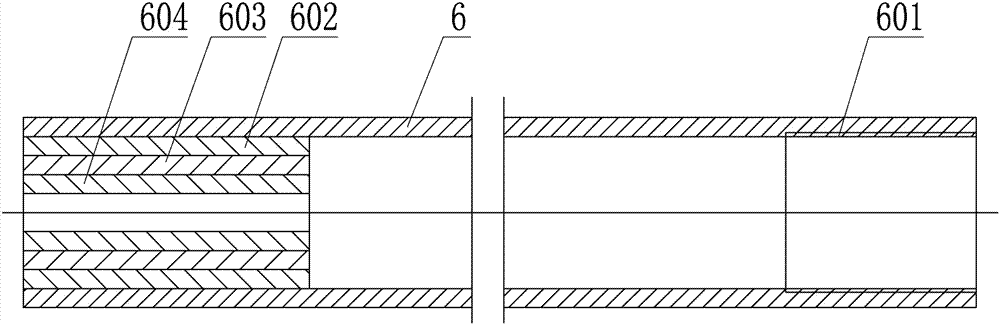

[0036] Further, the tie rod 6 is made of steel pipe material, and one end of the tie rod 6 is processed with an internal thread 601 , and the other end is plugged and welded and filled with multiple layers of short steel pipe materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com