Pressing seam type friction type constant-resistance anchor rod

A seam-pressing and bolting technology, which is applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problems of small ultimate tensile length of bolts, easy function overload failure, and lack of flexible support capabilities, etc., to achieve The effect of keeping the surrounding rock stable, simple structure and stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

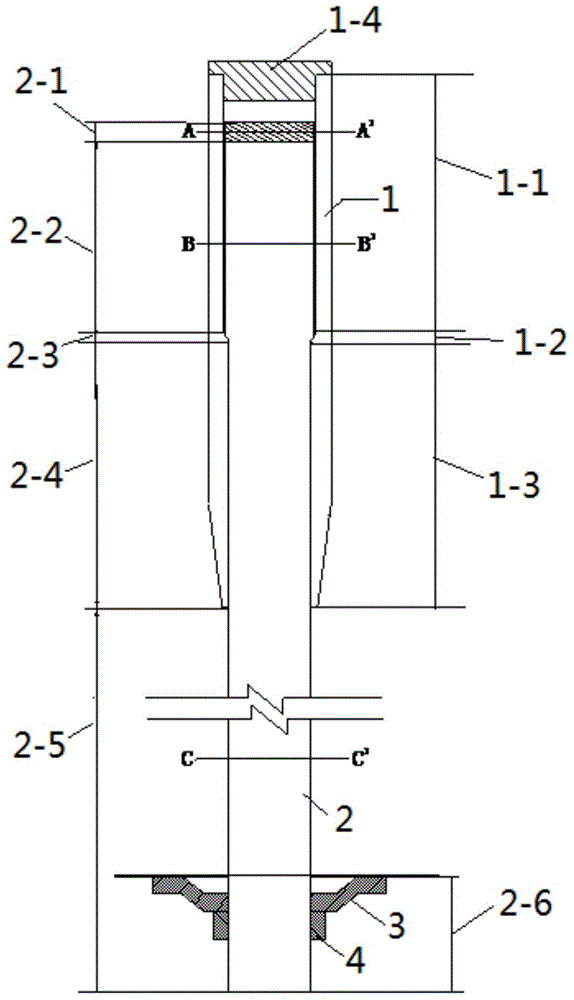

[0054] Without loss of generality, figure 1 As shown, the present invention provides a seam-type frictional constant resistance anchor rod, including: a sleeve 1, a rod body 2, a tray 3 and a pressure block 4;

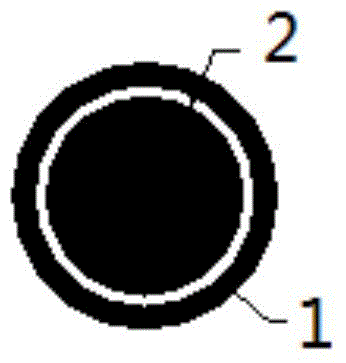

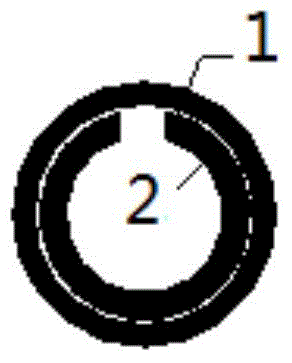

[0055] Rod body 2 comprises from top to bottom: solid section 2-1, constant resistance section 2-2, conical section 2-3, friction section 2-4 and free section 2-5 (cross-section as Figure 4 shown); figure 2 As shown, the solid section 2-1 is a cylindrical solid structure, and is tightly connected with the upper end of the constant resistance section 2-2 by threads or welding (the solid section 2-1 and the constant resistance section 2-2 of the present invention can also be made into integrated structure); solid section 2-1, constant resistance section 2-2, conical section 2-3 and friction section 2-4 are integrated structure; constant resistance section 2-2, conical section 2-3, The friction section 2-4 and the free section 2-5 are metal pipes with the same wall th...

Embodiment 2

[0060] Image 6 As shown, on the basis of Example 1, the side wall of the friction section 2-4 of the rod body 2 is processed from top to bottom in the axial direction with a notch having the same width as the tapered section 2-3, and the further extended notch length Provides structural support for deformation.

[0061] It should be noted that in the above technical solution, the sidewalls of the constant resistance section 2-2, the tapered section 2-3 and the friction section 2-4 have the same width of the gap from top to bottom in the axial direction. The length of the constant resistance section 2-2, the tapered section 2-3, the friction section 2-4 and the free section 2-5 is designed according to the depth of the plastic zone of the surrounding rock.

[0062] Further, in a preferred technical solution of this embodiment, the top end of the sleeve 1 is fastened with a top cover 1-4 that seals its inner cavity, so that when it is inserted into the grouting anchor hole, it...

Embodiment 3

[0064] Figure 7 As shown, in order to allow the rod body 2 to extend better, the present invention also includes a PVC pipe 2-7 on the basis of Embodiment 1; The taper required for extrusion sealing is formed at the place, and the PVC pipe 2-7 is socketed at the lower end of the fine hole section 1-3, and heat sealing or binding sealing is adopted at the socketing place. The required rope for binding and sealing can be hemp rope. In this embodiment, the briquetting block 4 is threadedly connected to the connecting end; in this embodiment, the sealing cover 5 of the sealing tray 3, the briquetting block 4 and the connecting end is also included, and the sealing cover 5 is connected between the sealing tray 3, the briquetting block 4 and the connecting end. When the ends are connected, the remaining voids in the inner cavity are filled with cement mortar. In this embodiment, the material of the sleeve 1 is hard alloy or high-quality steel; the side wall of the sleeve 1 is eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com