Patents

Literature

48results about How to "Change material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

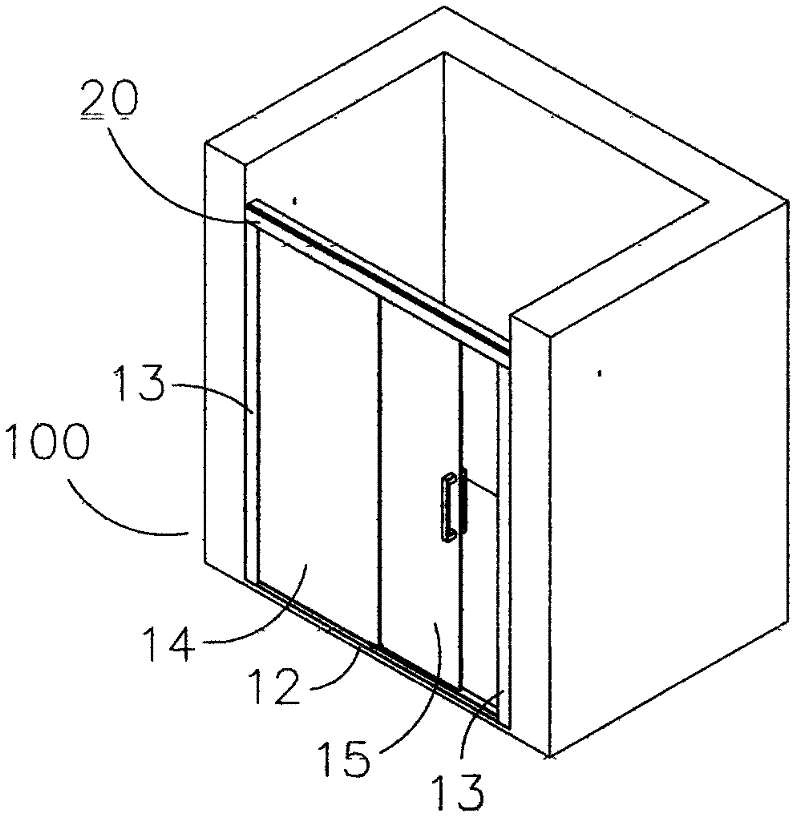

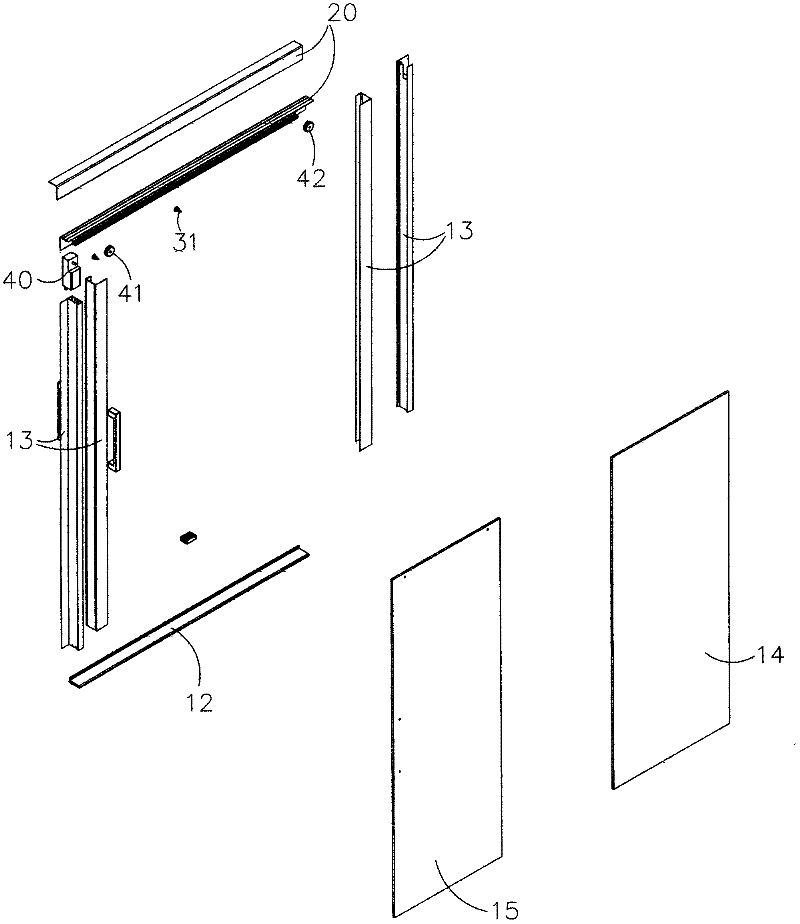

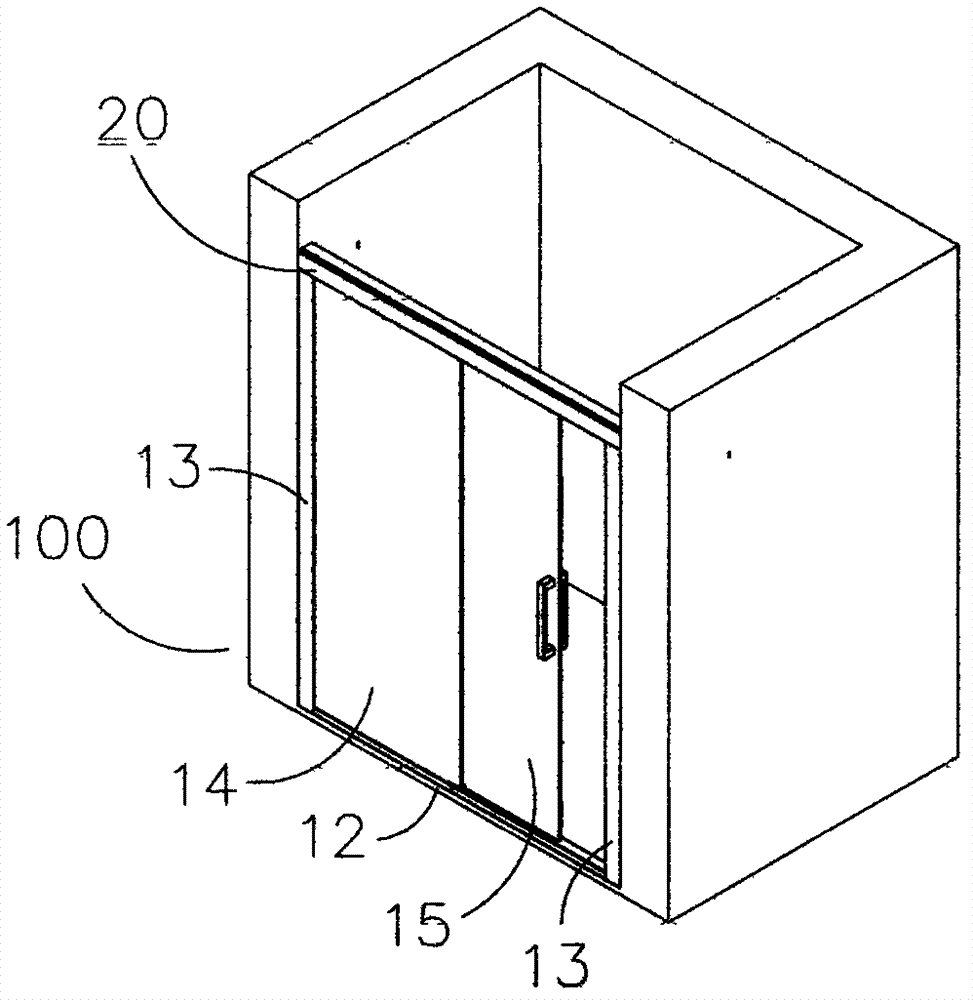

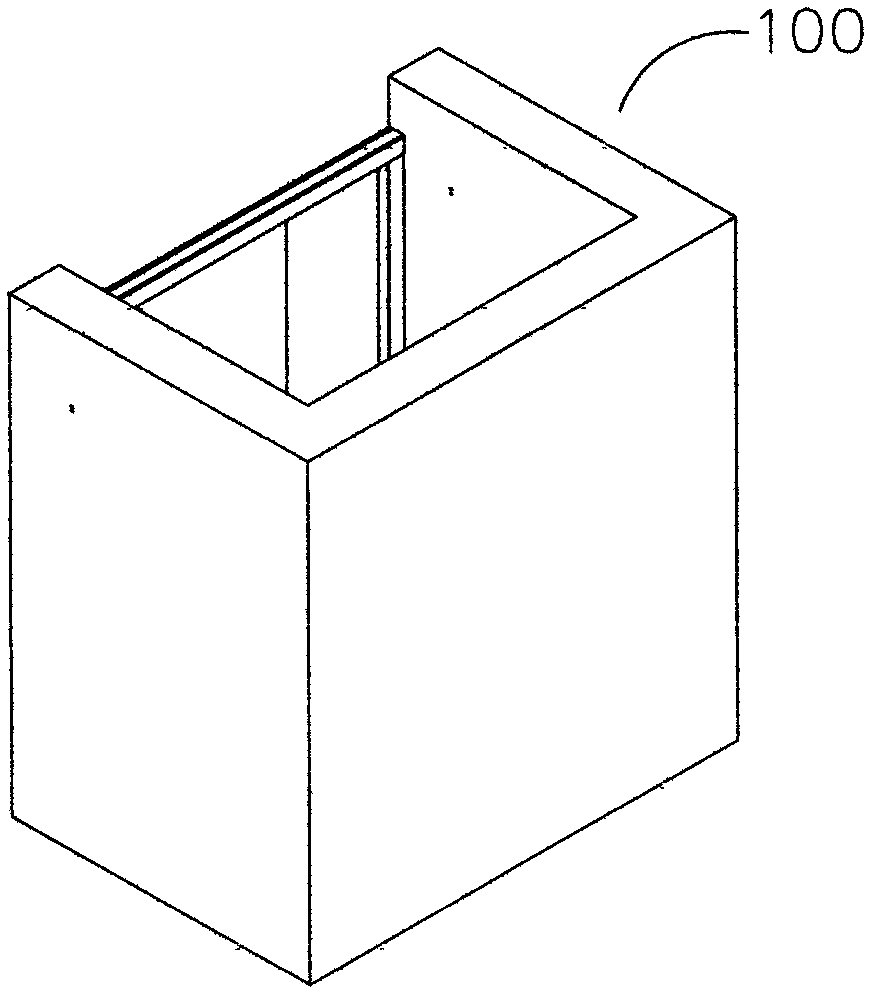

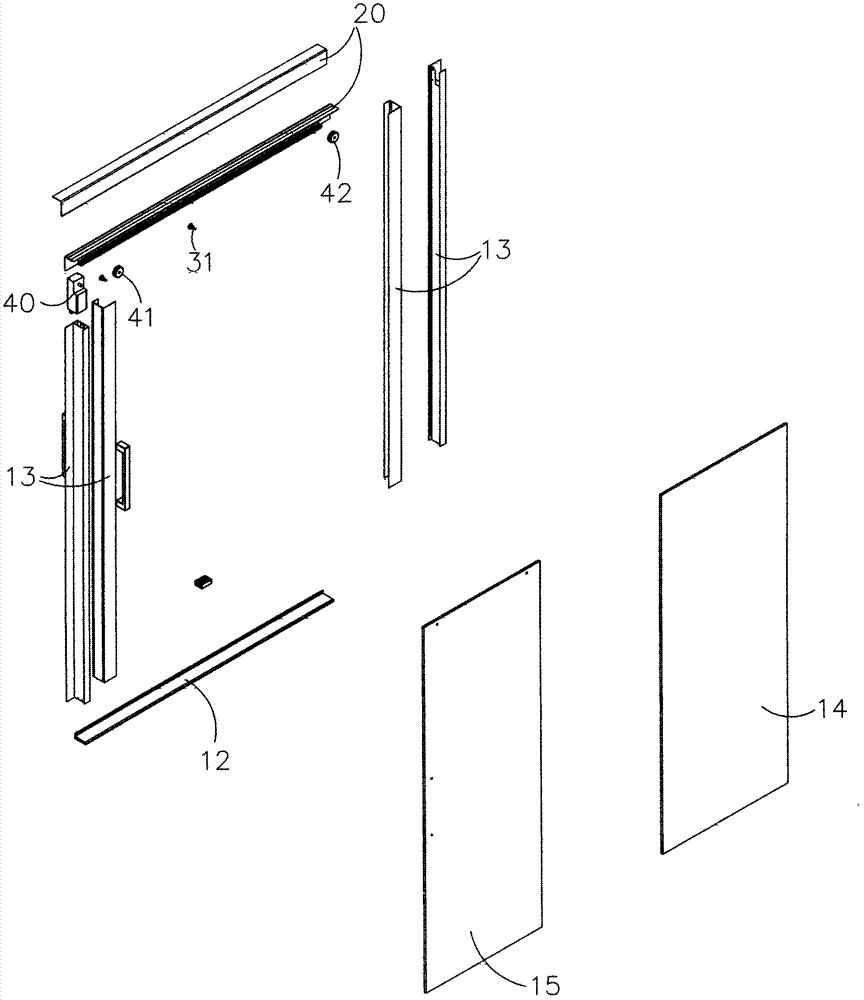

Intelligent induction shower cabin

The invention relates to an intelligent induction shower cabin, which comprises a shower cabin and an inductive control unit, wherein the inductive control unit is used for inducing the position of a human body so as to control the opening or the closing of the shower cabin, and comprises a driving motor, a microcomputer and an infrared inductive probe; when the shower cabin is in practical operation, firstly, the infrared inductive probe detects the existence of the human body and at this time sends a signal to the microcomputer, and the microcomputer commands a driver therein so as to drive the driving motor to work according to a compiled program and to drive a movable door to be opened or closed through the driving motor.

Owner:ZHONGSHAN LENS HOME CO LTD

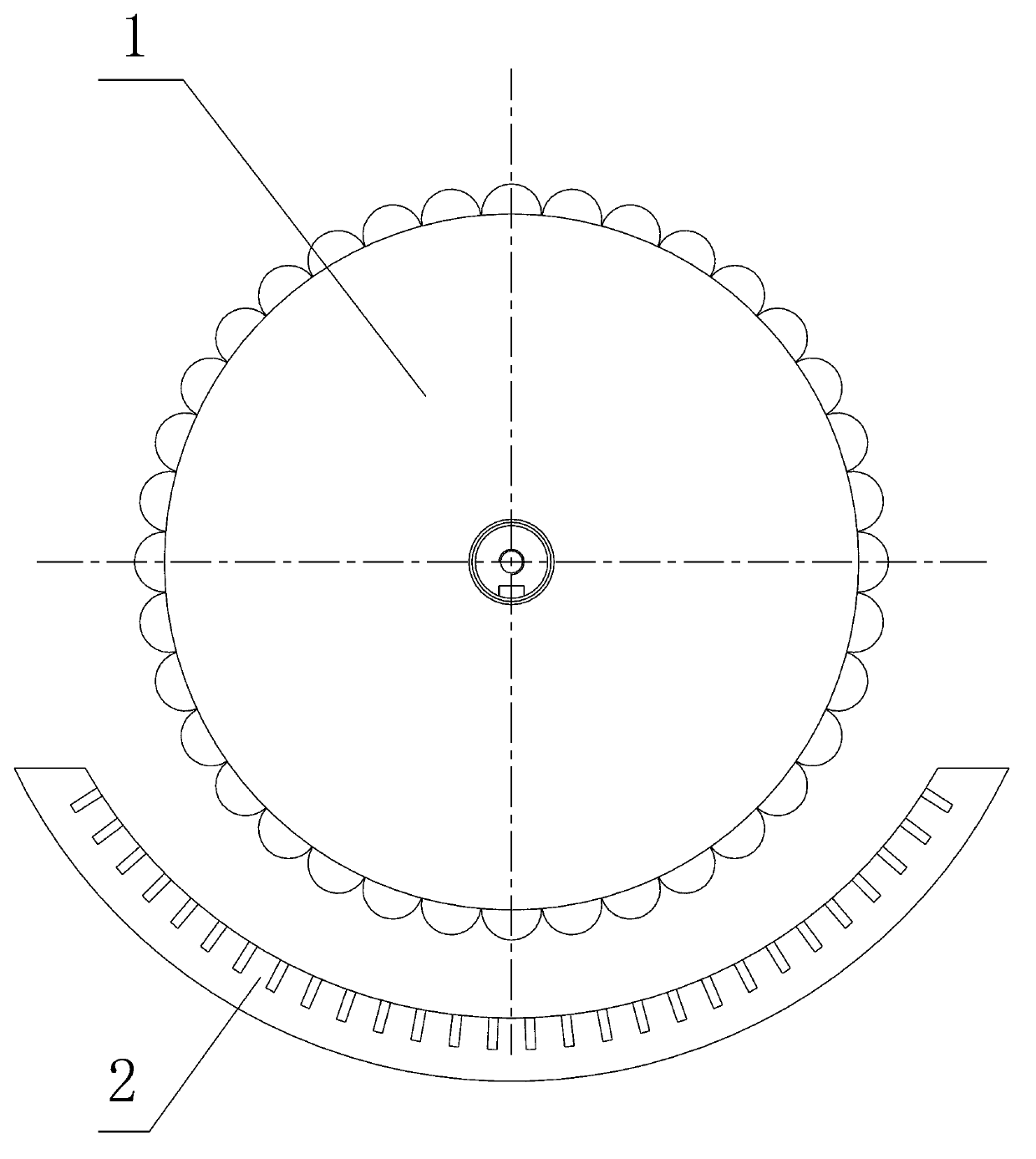

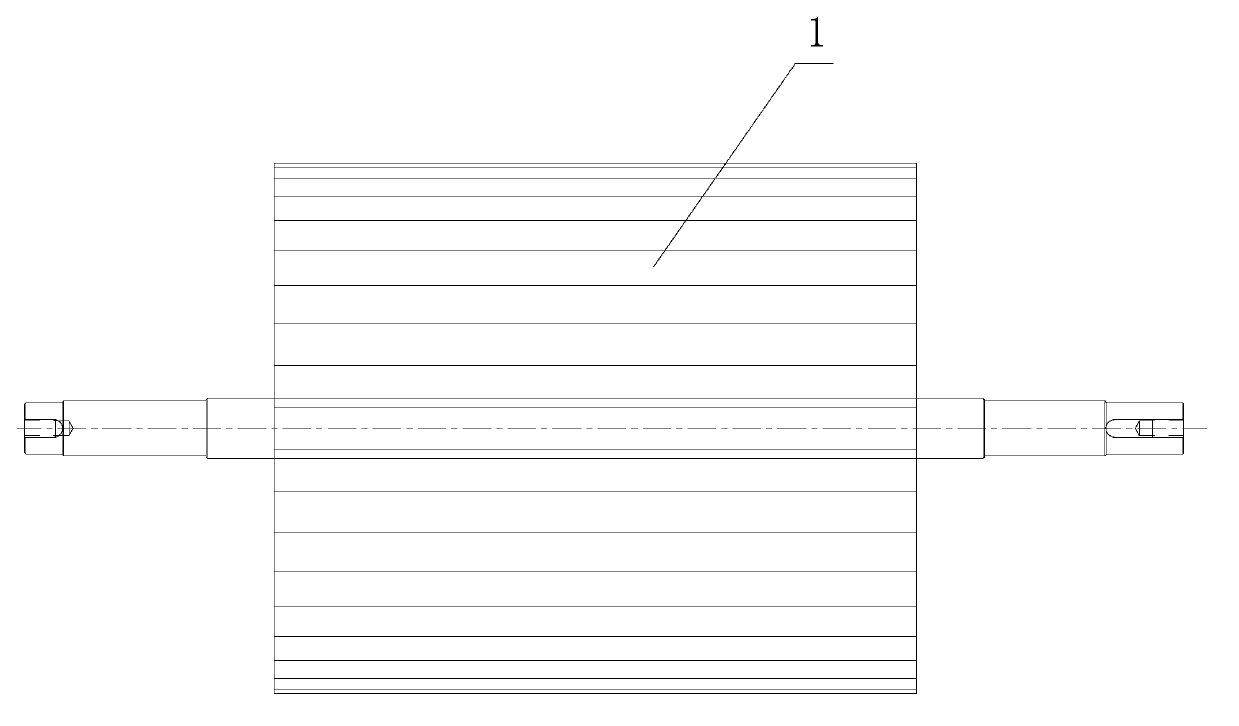

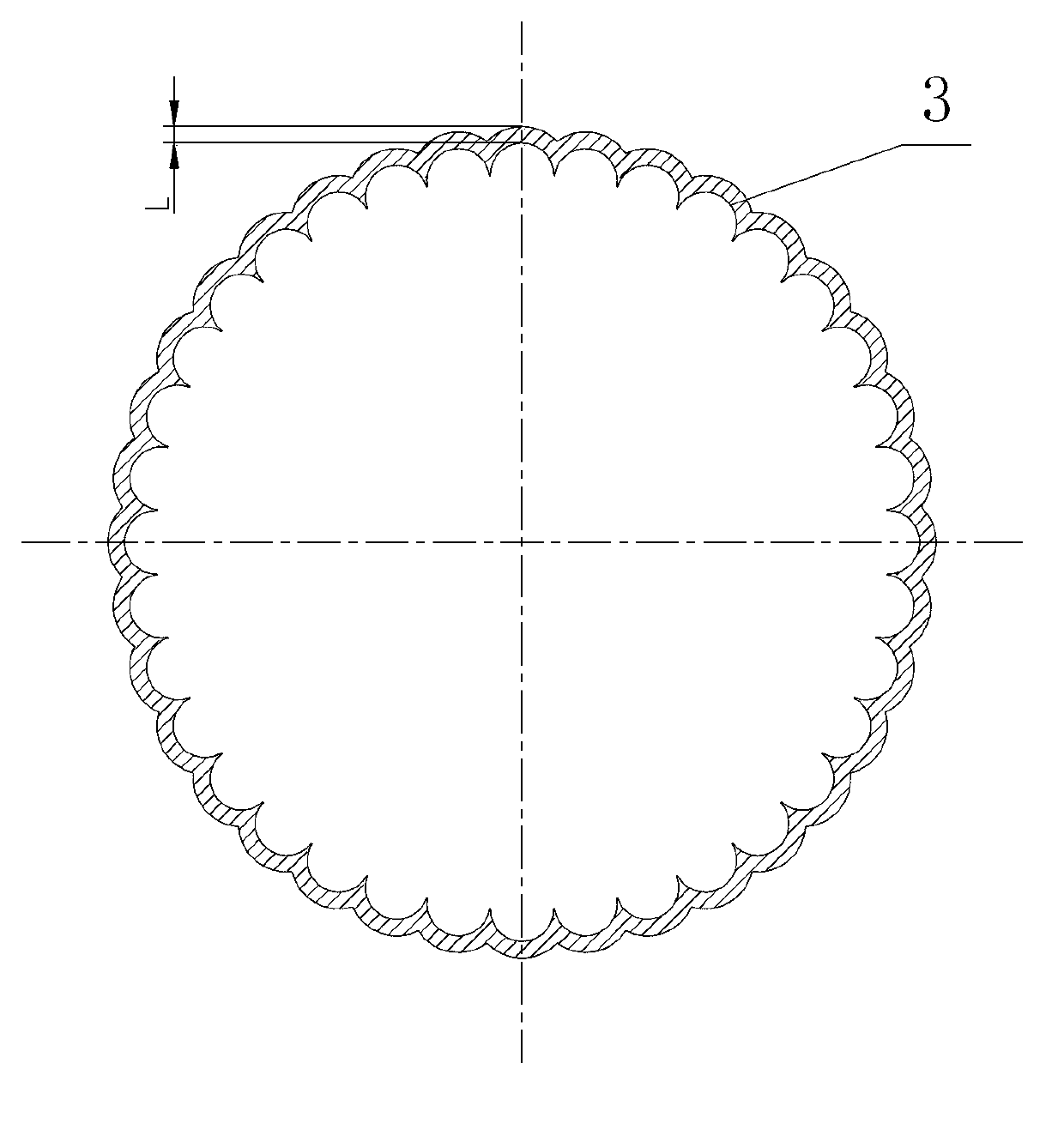

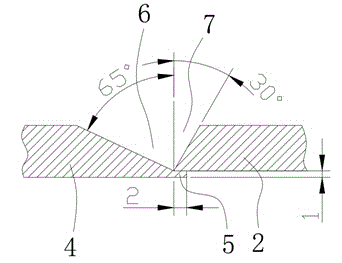

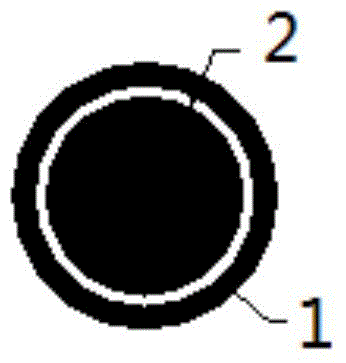

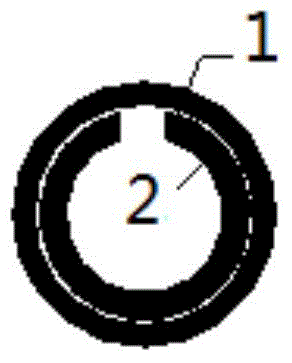

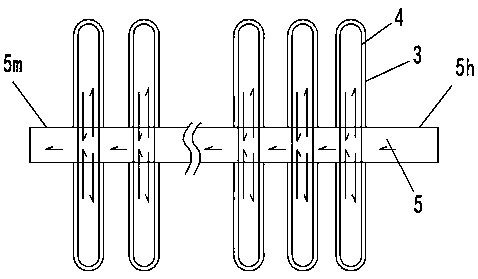

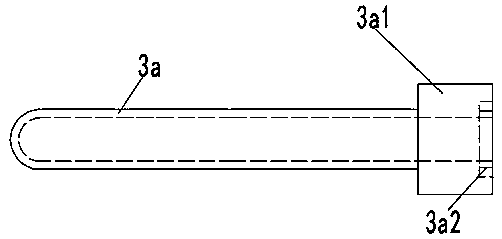

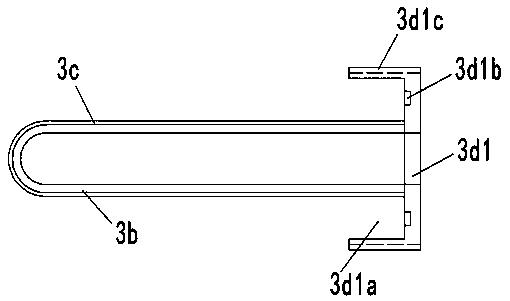

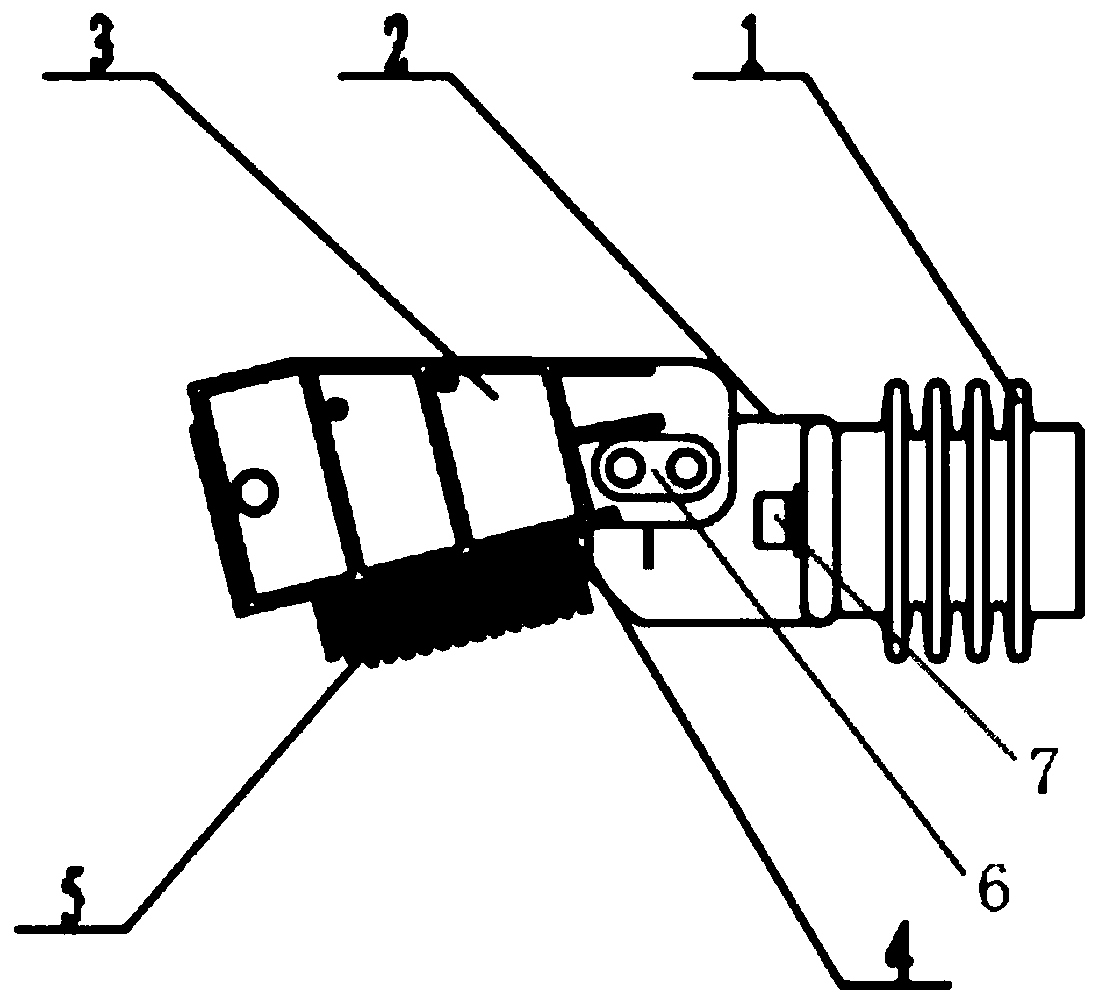

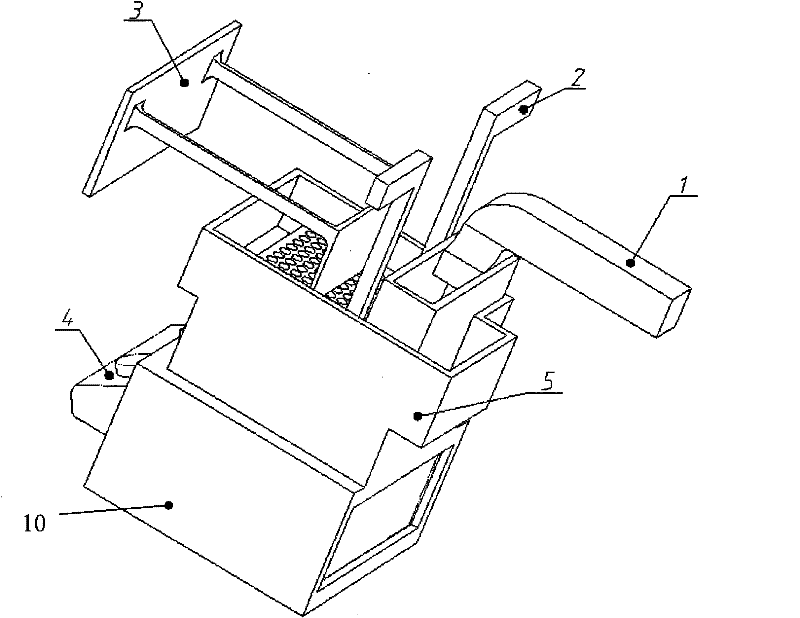

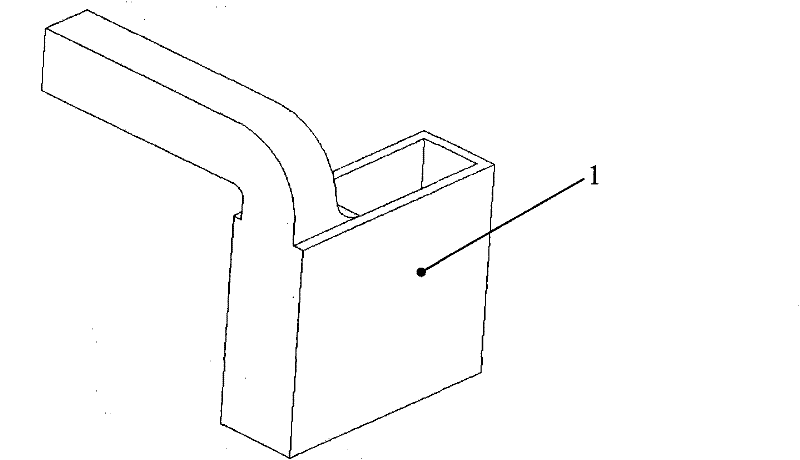

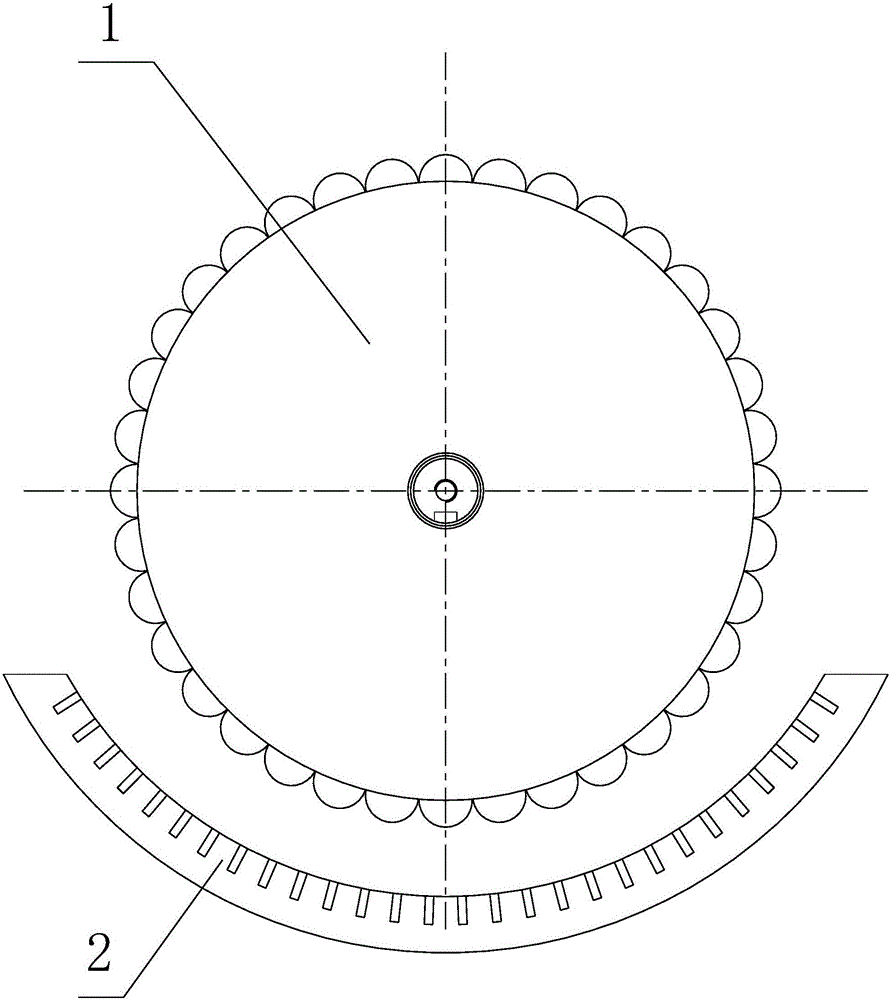

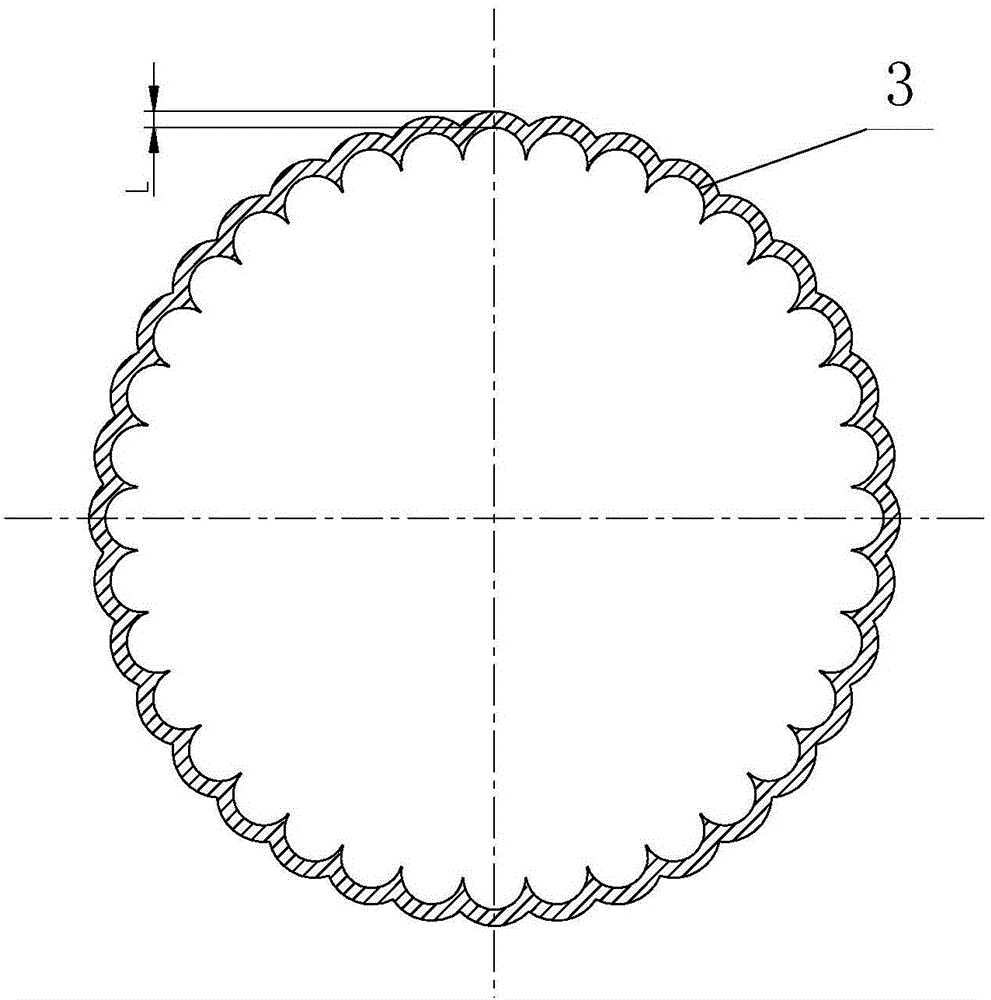

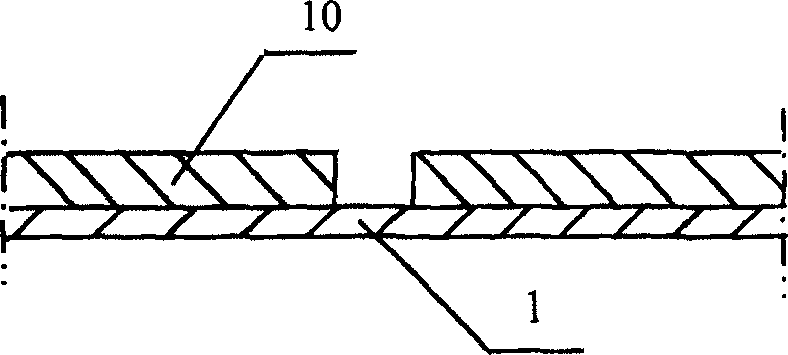

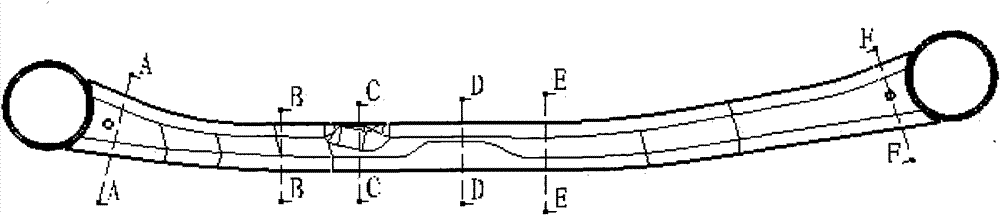

Flexible hitting-rod assembly structure for squeezing type breeding-peanut shelling machine

The invention relates to a component improvement structure for a peanut shelling machine particularly relates to a flexible hitting-rod assembly structure for a squeezing type breeding-peanut shelling machine, and belongs to the agricultural machinery. A hitting-rod roller (1) is a cylindrical soft elastomer, the middle part of the cylindrical soft elastomer is provided with a rotating shaft, and the periphery of the cylindrical soft elastomer is provided with semi-circular raided bars, i.e., the cross section of the cylindrical soft elastomer is in the shape of a flower disc, the middle part of the cross section is a circle, and a plurality of semi-circular raised sheets are raised outwards at the periphery of the circle, wherein the extradius of each semi-circular raised sheet is 1-2cm; a hitting-rod adjusting sleeve (3) can be used or not used according to the volume of the peanut pods; the hitting-rod adjusting sleeve (3) is a ringlike sleeve (soft elastomers) of different thickness; the inner circle of the hitting-rod adjusting sleeve (3) is a semi-circular groove, and the outer circle is a raised semi-circular sheet. The shape of the hitting rod of the existing hitting type peanut shelling machine is changed, the material of the hitting rod roller is changed, and the gap between an upper semi-circular raided bar and a lower concave grid can be adjusted conveniently and rapidly in a shorter time, the adaptability of the peanut shelling machine to the shelling of breeding peanuts of different varieties can be improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

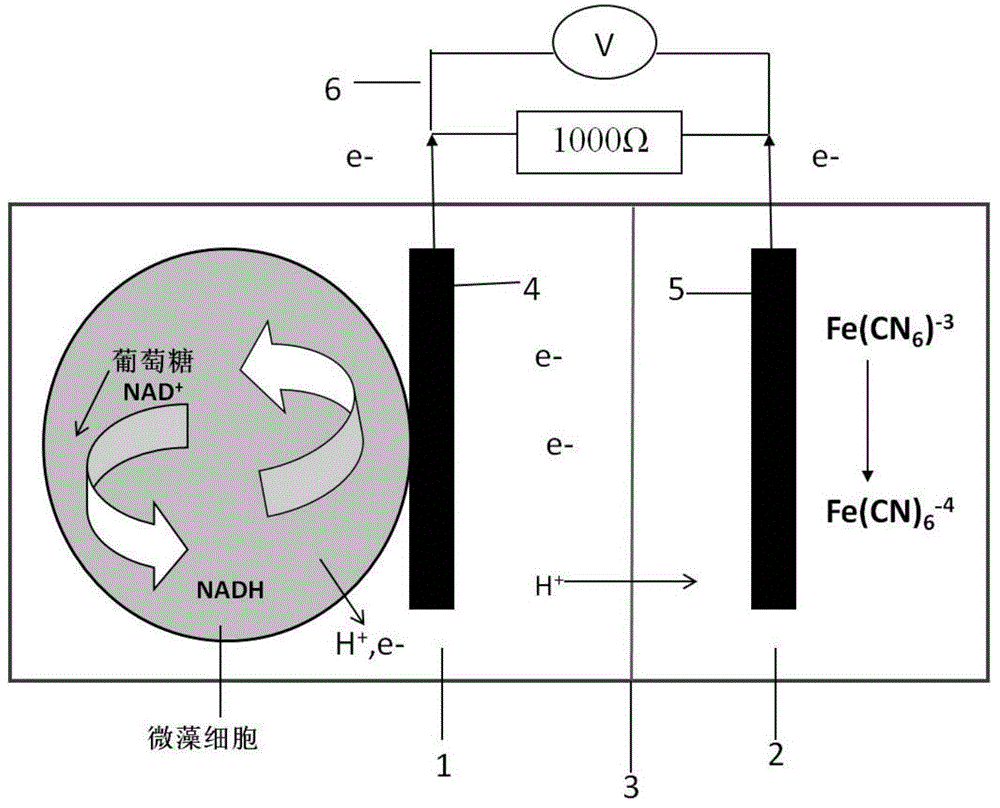

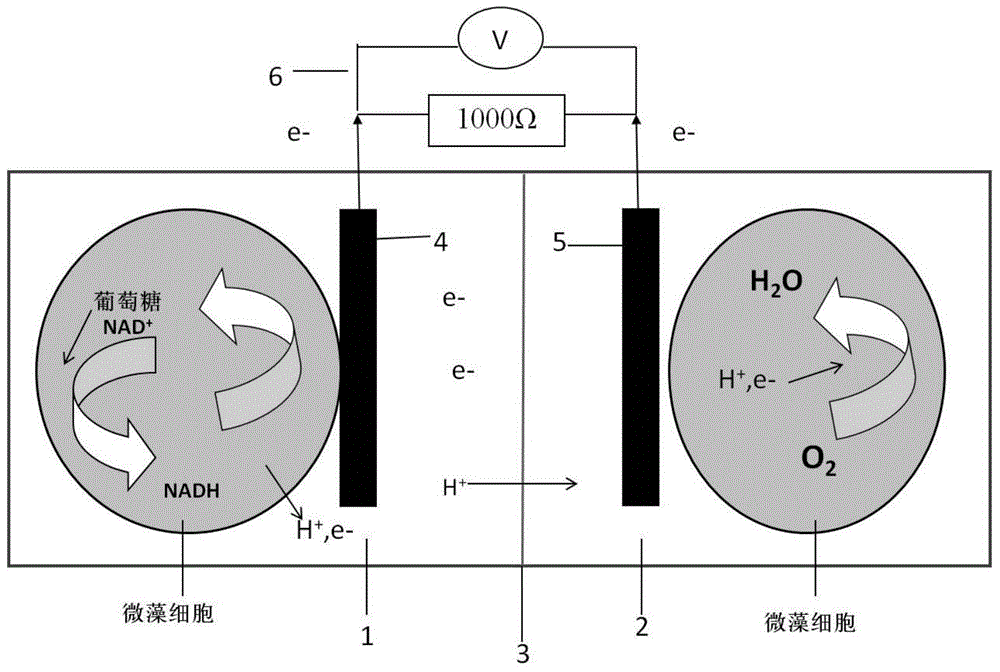

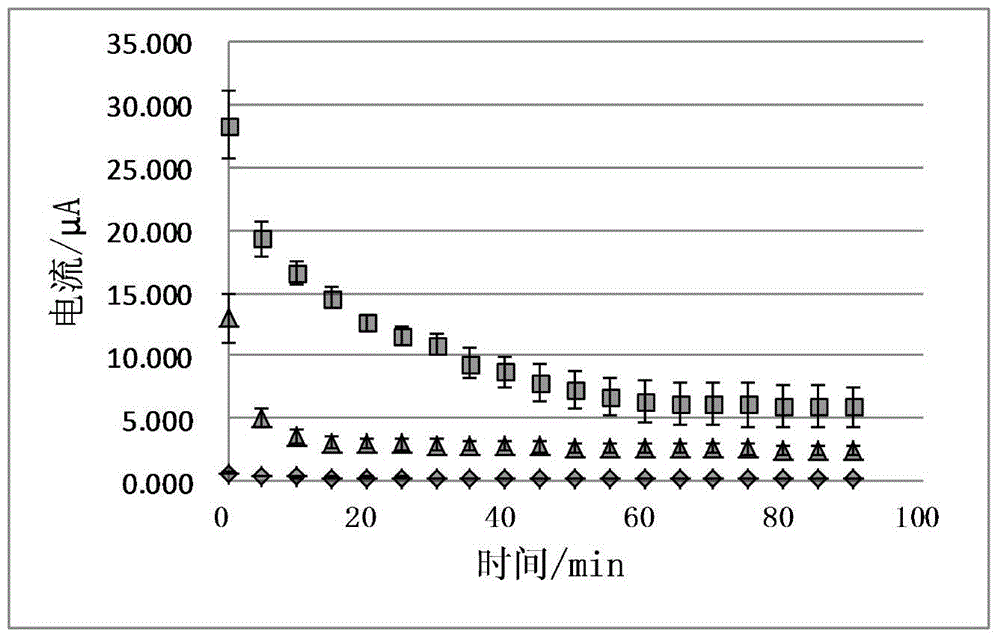

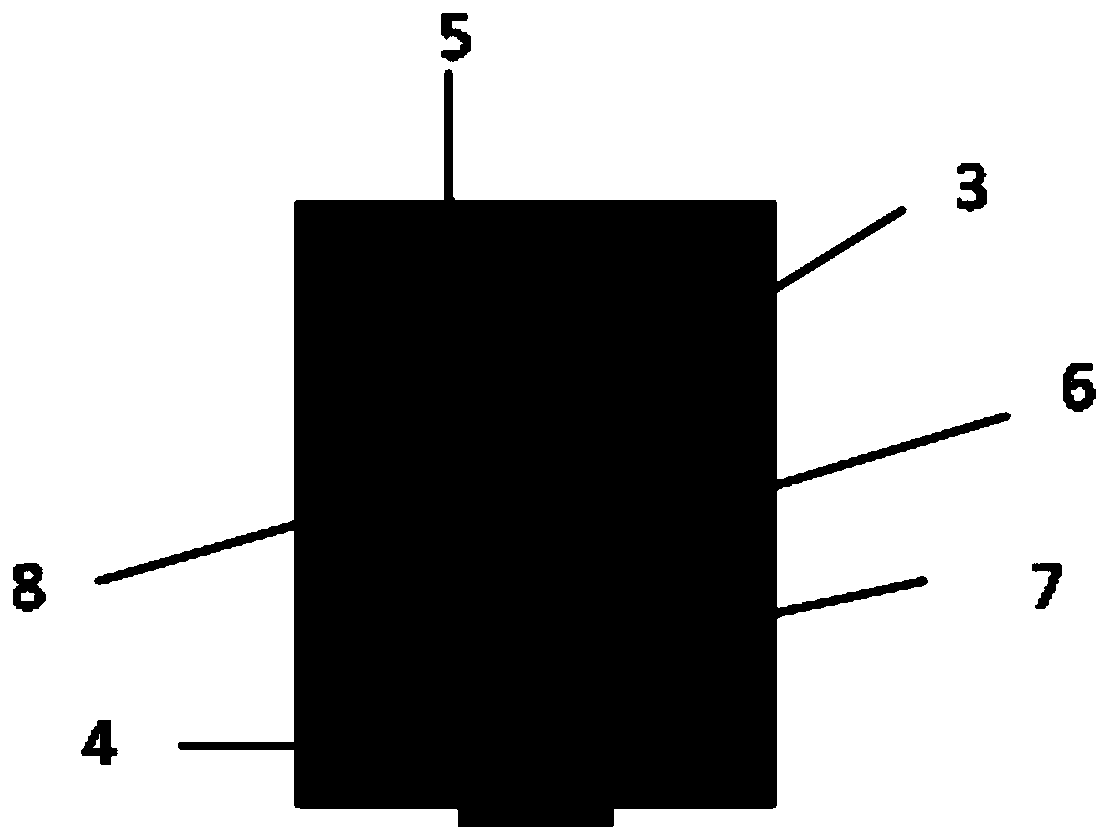

Microalgae biological direct-driven power generation battery

ActiveCN104701562AIncrease power generation capacityReduce distanceCell electrodesBiochemical fuel cellsElectron donorEngineering

The invention relates to a microbial fuel battery, and in particular to a biological fuel battery which takes chlorella pyrenoidosa as an anode electron donor. The microalgae biological direct-driven power generation battery comprises an anode cell and a cathode cell, wherein the anode cell and the cathode cell are partitioned by a proton exchange membrane; the anode and the cathode are respectively fixed inside the anode cell and the cathode cell and are connected through an external resistor; microalgae are adopted as the electron donor of the anode; an ordinary cathode chemical or microalgae are adopted as the electron donor of the cathode. By adopting a microalgae direct power generation mode, the chemical energy can be converted into electric energy, that is, live microalgae are taken as the anode, power can be directly generated by metabolizing carbohydrate in cells without a substrate substance, and a novel biological fuel battery system can be provided.

Owner:BEI JING NORMAL UNIV HONG KONG BAPTIST UNIV UNITED INT COLLEGE +2

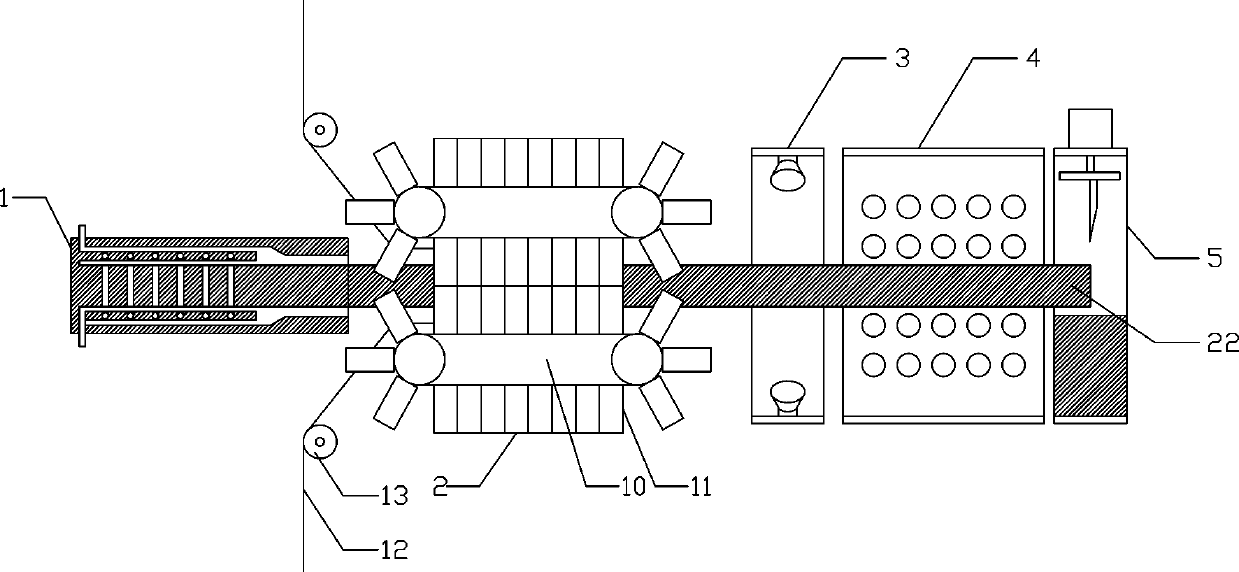

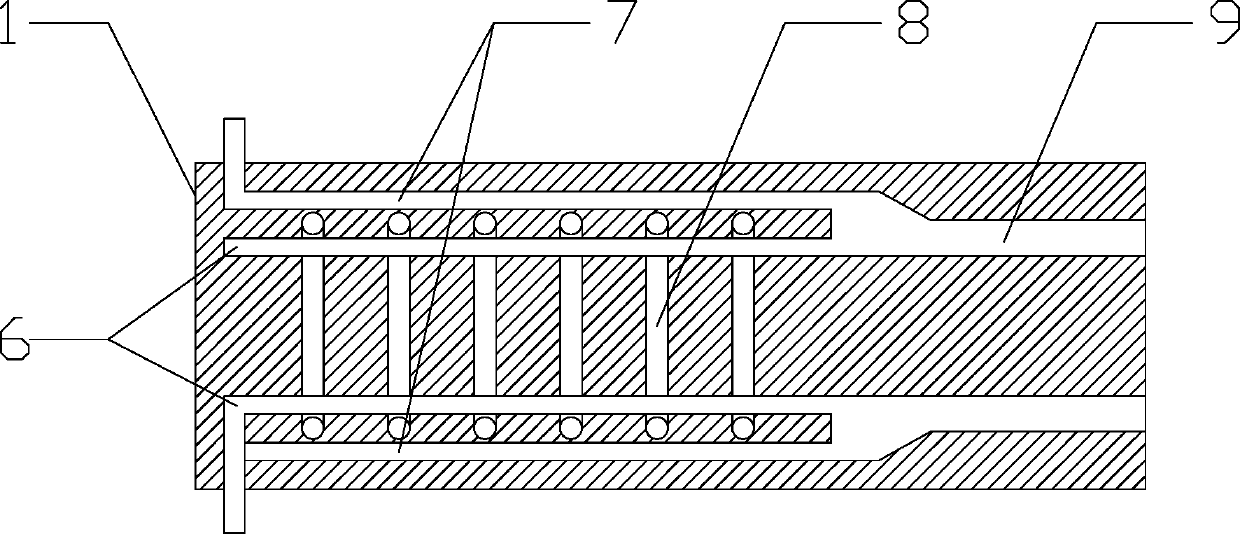

Processing and forming device for PE double-wall corrugated pipe

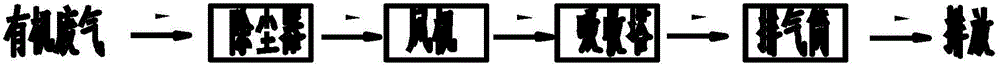

InactiveCN110091458AChange materialImprove wear resistanceMetal working apparatusTubular articlesEngineeringDouble walled

A processing and forming device for a PE double-wall corrugated pipe includes an injection mold, an output end of the injection mold is provided with a molding device, the output end of the molding device is provided with a cutting device, and a cooling device and a drying device are disposed between the molding device and the cutting device; and a guide block is disposed on the output end of theinjection mold, and the guide block is horizontally arranged and sequentially passes through the molding device, the cooling device, the drying device, and the cutting device. Through adoption of thestructure, the production processing efficiency can be improved, the product quality can be ensured, and the performance of the double-wall corrugated pipe can be improved, so that a produced finishedproduct can meet various demands.

Owner:宜昌承轩灌溉科技有限公司

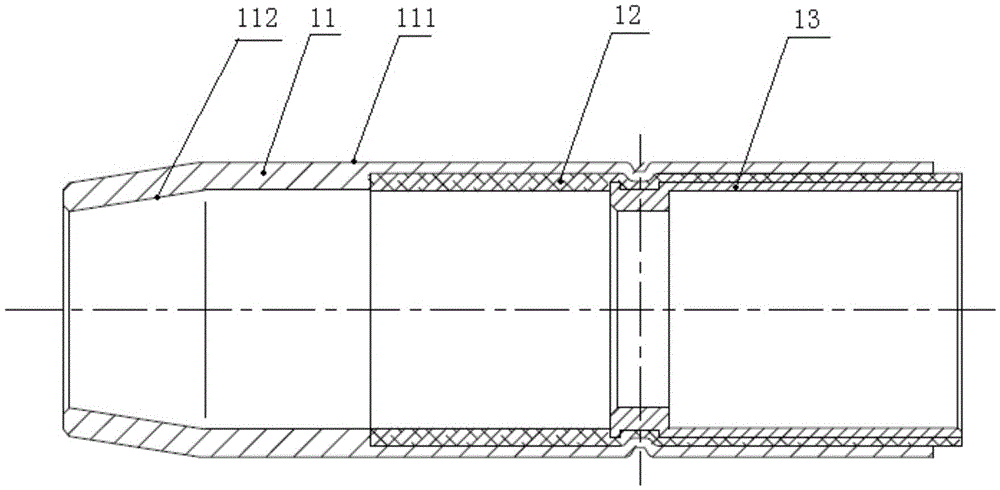

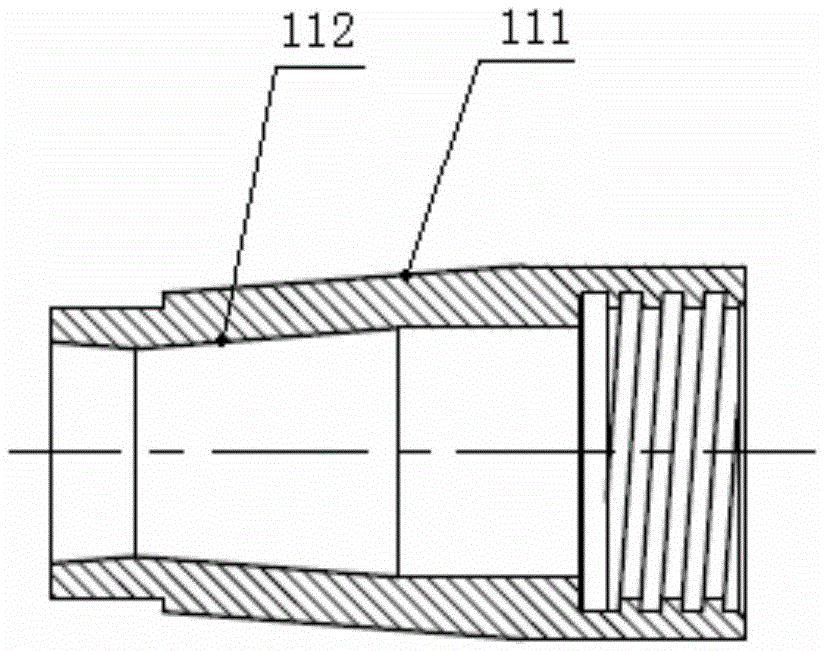

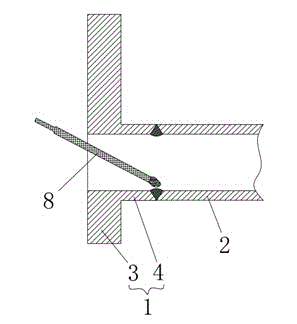

Vulnerable part of welding gun and surface treatment method of vulnerable part

InactiveCN105108403AHigh refractory temperatureSmall specific heat and thermal conductivityMolten spray coatingWelding/cutting auxillary devicesSurface finishingAluminium oxide

The invention discloses a vulnerable part of a welding gun and a surface treatment method of the vulnerable part. The vulnerable part of the welding gun is of a hollow structure and comprises an outer surface and an inner surface. A metal oxide coating is arranged on the outer surface. Metal oxide powder of the metal oxide coating includes 89%-91% of zirconium dioxide powder and 9%-11% of aluminum oxide powder. According to the vulnerable part of the welding gun and the surface treatment method of the vulnerable part, metal oxide powder is sprayed onto the surface of the vulnerable part of the welding gun, zirconium dioxide is high in fire-resistant temperature, small in specific heat coefficient and heat conductivity coefficient, good in comprehensive mechanical property and high in chemical stability, the abrasion resistance of the coating can be improved through aluminum oxide, and the thermal shock resistance is improved; in this way, the surface materials of the vulnerable part can be changed, the coating has a good heat dissipation effect, the temperature of a workpiece can be decreased, the durability and fire resistance of the high-temperature part are remarkably improved, the probability of slag hanging of the workpiece is greatly lowered, and the problem that an airflow path is blocked or wire feeding cannot be achieved due to the fact that the workpiece is burn down or slag hanging occurs is solved.

Owner:常州特尔玛科技股份有限公司

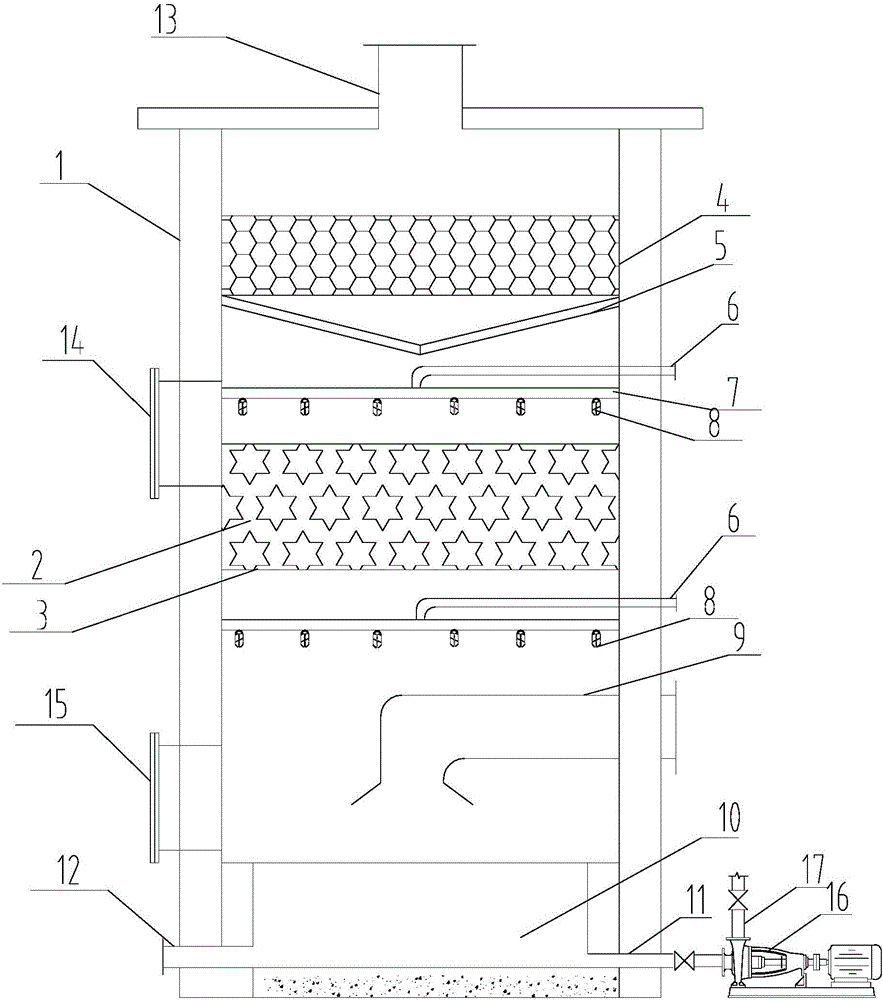

Waste gas absorption tower and waste gas absorption method

InactiveCN106039937AHigh removal rateGood removal effectGas treatmentDispersed particle separationTowerExternal connection

The invention provides a waste gas absorption tower. The waste gas absorption tower comprises an adsorption tower body and a tower body external connection device, wherein the adsorption tower body adopts a hollow structure made of a steel concrete material, a gas outlet pipe is arranged on the upper end surface of the adsorption tower body, and a circulating water tank is arranged at the bottom of the adsorption tower body and connected with the tower body external connection device; a primary spraying layer and a secondary spraying layer arranged below the primary spraying layer in parallel are arranged in the middle of the adsorption tower body, and the spraying layers are adsorption layers; demisting layers are arranged at the upper part in the adsorption tower body; a waste gas inlet pipe is inserted into the lower part in the adsorption tower body. A treatment process is simple and convenient to operate, limitation of materials to process parameters is eliminated, and the pollutant removal efficiency and the demisting effect of the waste gas are improved.

Owner:广州益方田园环保股份有限公司

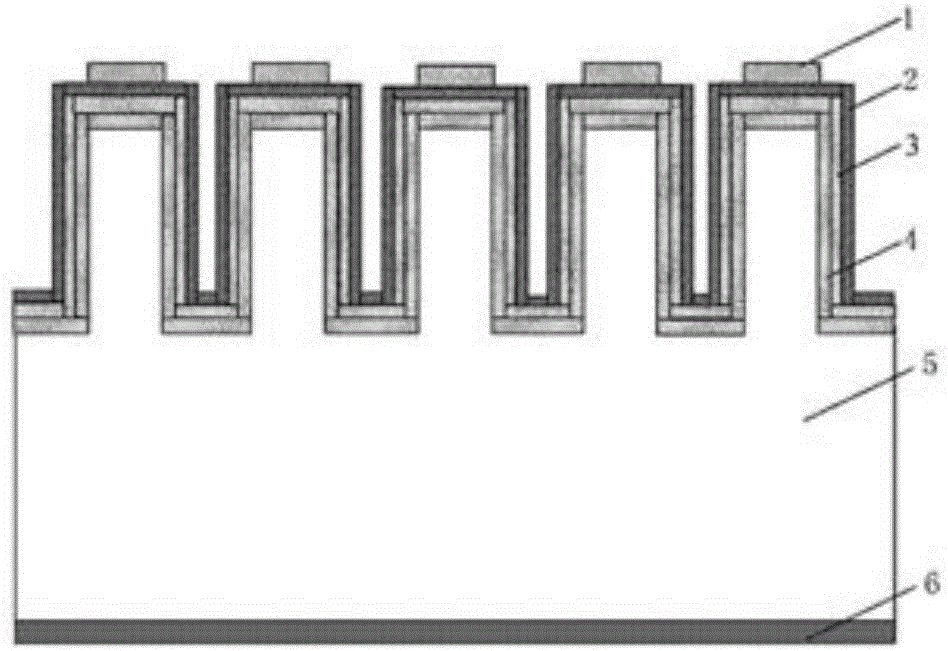

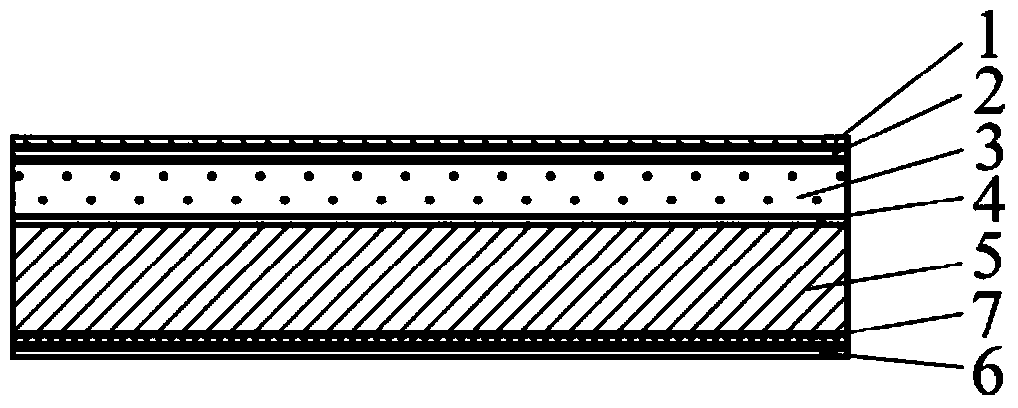

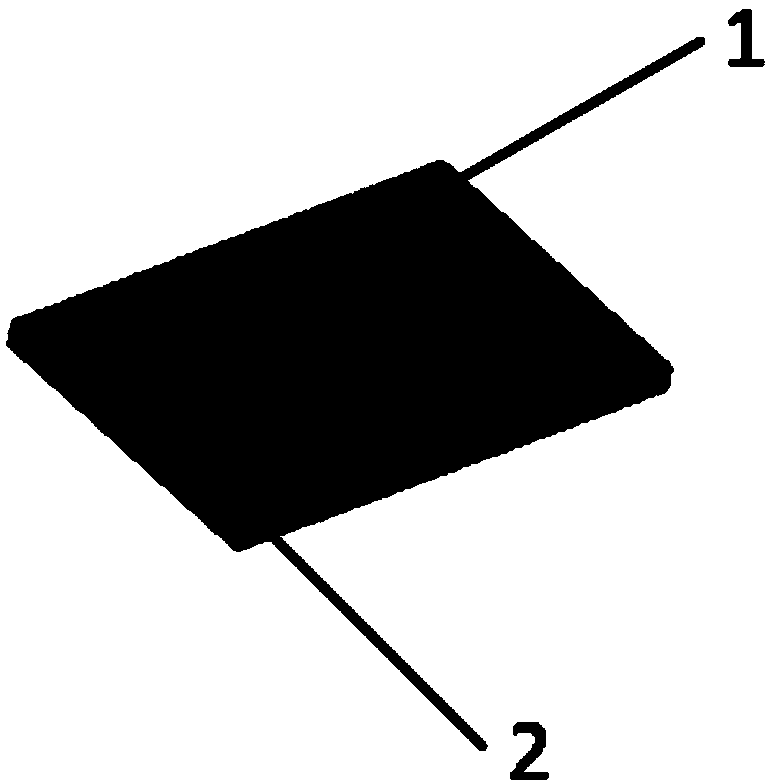

Solar cell based on silicon nanowires

InactiveCN105789346AImprove collection efficiencyChange structurePhotovoltaic energy generationSemiconductor devicesTrappingP type silicon

The invention discloses a solar cell based on silicon nanowires. The solar cell comprises a back electrode (6) and a P-type silicon substrate (5), and is characterized in that: the upper surface of the P-type silicon substrate (5) adopts a silicon nanowire array structure, an i-type layer (4), an N-type amorphous silicon layer (3) and an indium tin oxide transparent conductive film (2) are laminated on the surface of the silicon nanowire array structure in sequence, the top end of the silicon nanowire array structure is provided with a positive electrode (1), the i-type layer (4) comprises a microcrystalline silicon intrinsic layer, an amorphous silicon germanium intrinsic layer, an amorphous silicon intrinsic layer and a microcrystalline silicon carbide intrinsic layer which are laminated on the surface of the silicon nanowire array structure in sequence. Since the surface of the P-type silicon substrate adopts the nanowire structure, the solar cell based on the silicon nanowires has good light trapping effect, increases carrier collection efficiency, changes structure and materials of the i-type layer, improves its passivation property, and improves energy conversion efficiency of the solar cell.

Owner:黄广明

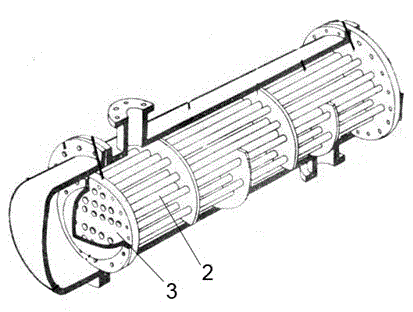

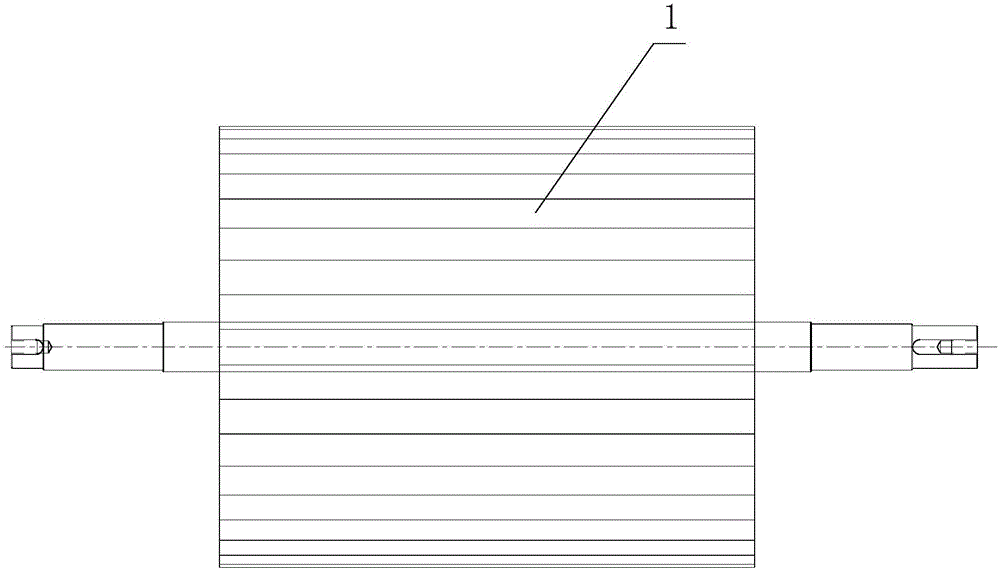

Process for machining heat exchange device of heat exchanger

ActiveCN104690524AGuaranteed quality and reliabilityImprove quality reliabilityHeat exchange apparatusMetal working apparatusPlate heat exchangerEngineering

The invention relates to the field of mechanical machining and manufacturing, in particular to a process for machining a heat exchange device of a heat exchanger. The process is characterized by comprising the following steps in sequence: (1) section manufacturing, to be specific, the section manufacturing is performed according to a design structure of a heat exchange device, wherein the components for section manufacturing comprise a tube base and several heat exchange tubes connected with the tube base, the tube base comprises a tube plate and several joints corresponding to the heat exchange tubes, and the joints are integrated with the tube plate; (2) connection of the joints and the heat exchange tubes, to be specific, the several heat exchange tubes are welded with the corresponding joints respectively, the heat exchange device of a heat exchanger is obtained after welding all the components. With adoption of the process, the machining procedure of the heat exchange device can be simplified greatly, the machining cost can be reduced, and the quality and reliability of the obtained heat exchange device are also improved greatly.

Owner:SICHUAN BLUSR MACHINERY

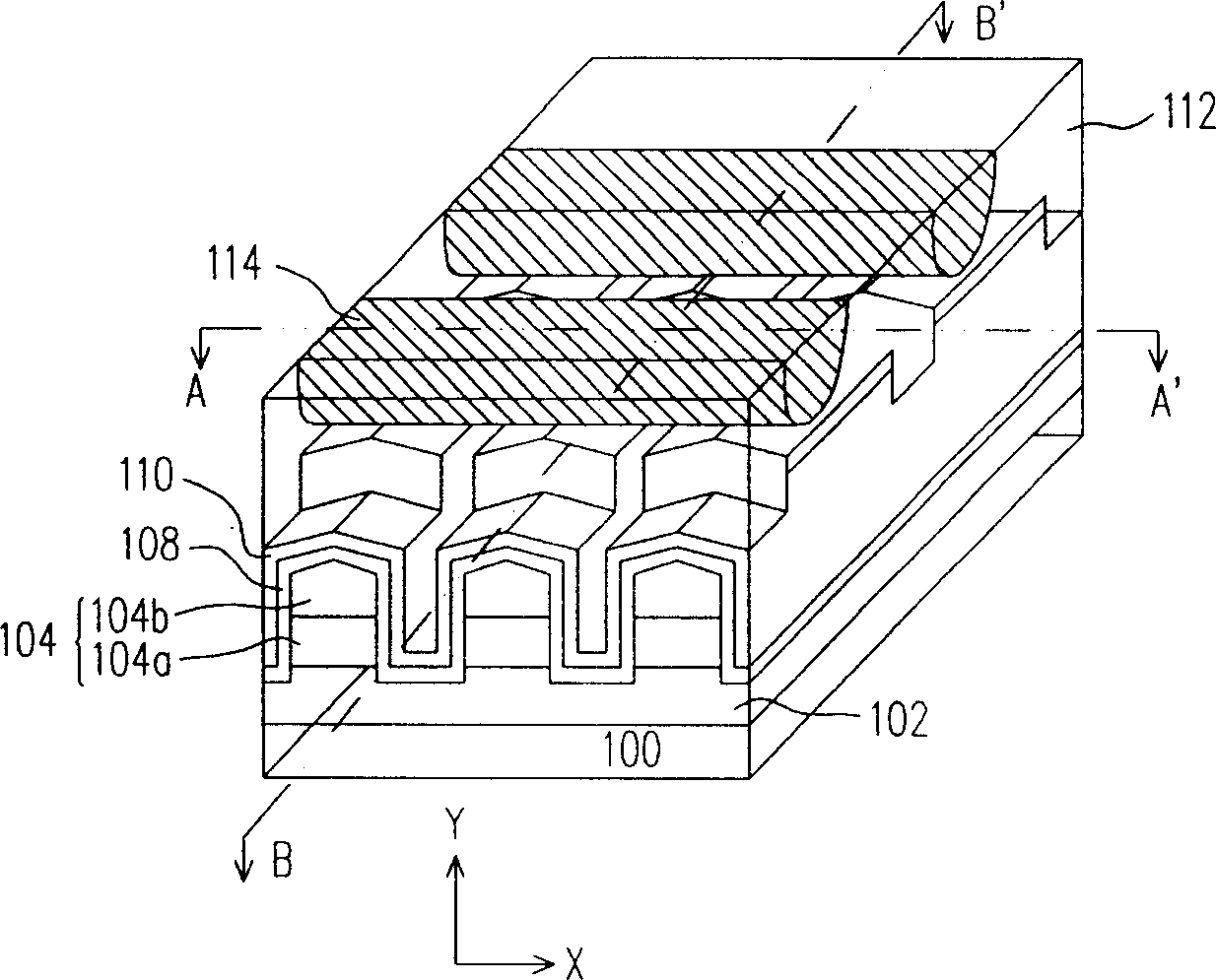

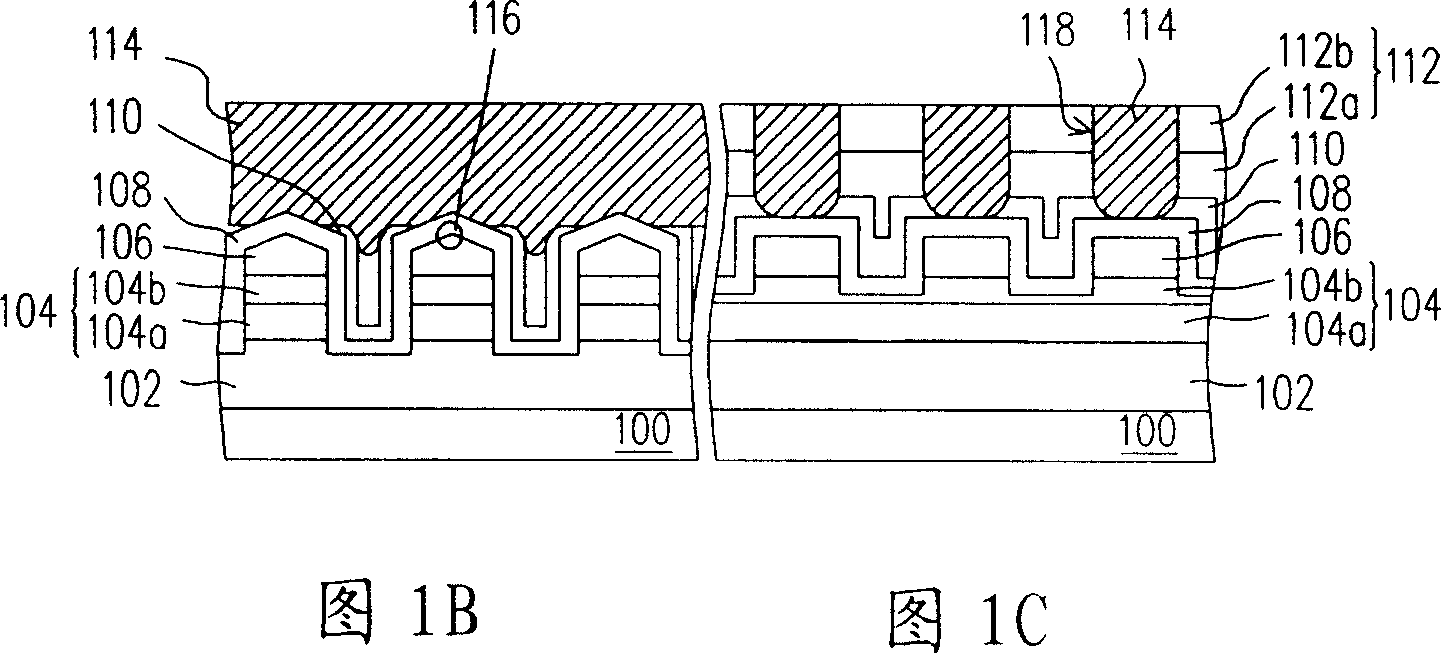

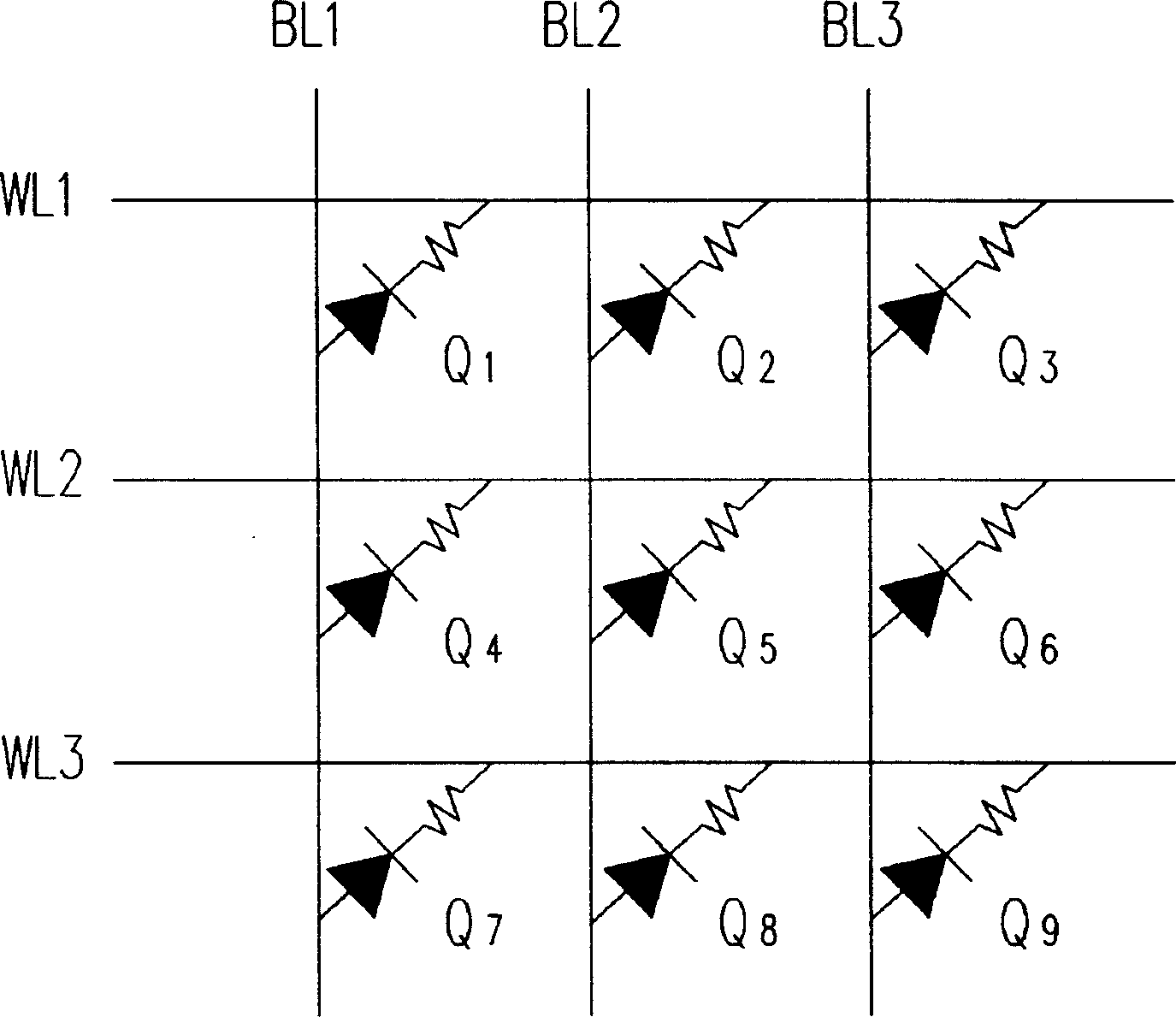

Single programmable read-only memory and method of manufacture

InactiveCN1841752AControl breakdown voltageControl Component EfficiencySolid-state devicesRead-only memoriesBit lineProgrammable read-only memory

The invention relates to a single time programmer read-only memory and it's making method. The single time programmer read-only memory at least comprises a P-type semiconductor base, a N-type doping area, a P-type first doping layer, a P-type second doping layer, a conductive layer, a N-type first doping layer and an inverse fuse layer. The N-type doping area is positioned on the P-type semiconductor base. The P-type first doping layer is positioned in the P-type semiconductor base upper than the N-type doping area. The P-type second doping layer has a high doping density which is positioned between the N-type doping area and the P-type first doping layer; the P-type second doping layer is bar type as a bit line. The conductive layer is positioned on the P-type semiconductor base which is bar type and is vertical to the P-type first doping layer. The N-type first doping layer is positioned on the P-type semiconductor base. The inverse fuse layer is positioned between the conductive layer and the N-type first doping layer.

Owner:MACRONIX INT CO LTD

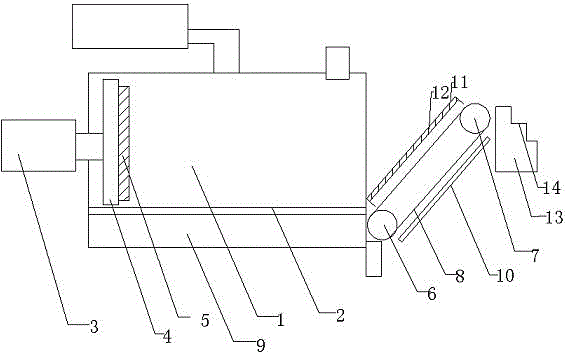

Delivery device capable of reducing damage to biomass particles

InactiveCN104534497ASuspendedChange materialConveyor partsMechanical conveyorsDrive wheelEngineering

The invention relates to a delivery device capable of reducing damage to biomass particles. The delivery device comprises a material collection box connected to a particle producing machine. A material bearing plate with a leakage hole is arranged in the material collection box. A material pushing plate driven by a cylinder is arranged on one side of the material bearing plate and penetrates the material collection box. An air tank is arranged below the material bearing plate. A driving wheel and a driven wheel are arranged on one side of the material collection box. A breathable mesh fabric is arranged between the driving wheel and the driven wheel to form a conveying belt. An air blowing pipe is arranged below the breathable mesh fabric. A protective cover is arranged above the breathable mesh fabric in a covering mode. A material hopper connected to a cooling unit is arranged at one end of the driven wheel. The delivery device capable of reducing damage to the biomass particles cools biomass particle fuel before delivering the biomass particle fuel to enable the biomass particle fuel to be compact in structure as well as uses a flexible delivery structure and the suspension design in a delivery process to reduce the damage rate of the biomass particle fuel during delivery and improve the quality of products.

Owner:安徽广德文光生物能源有限公司

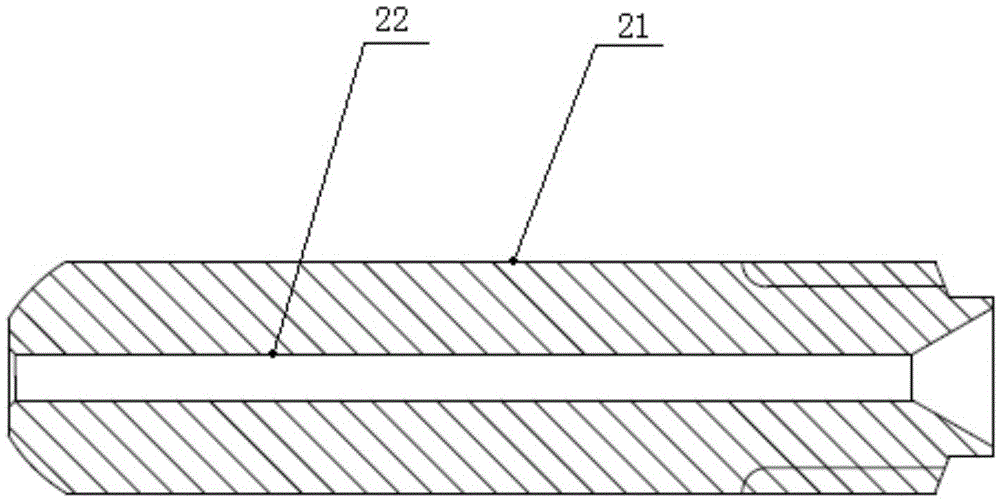

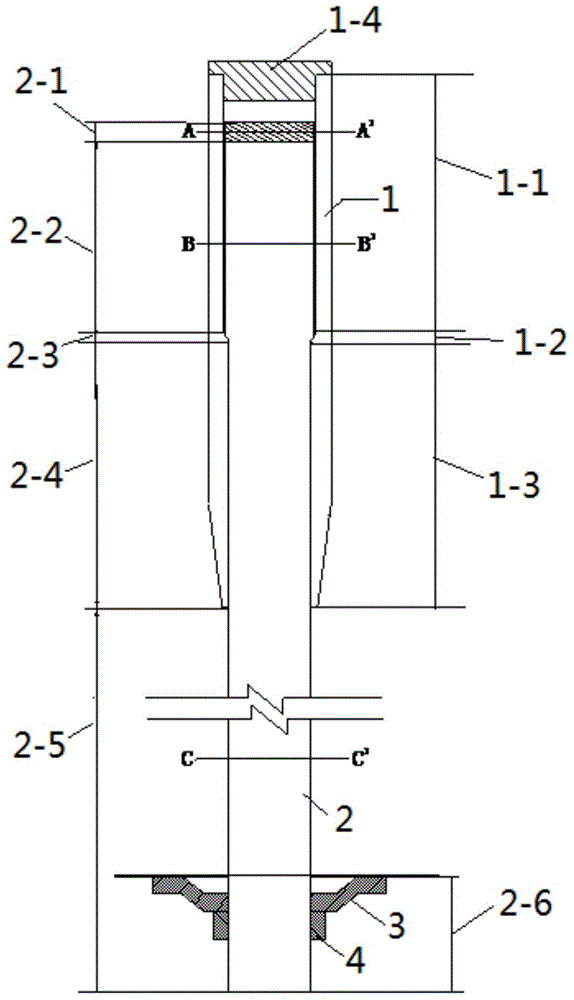

Pressing seam type friction type constant-resistance anchor rod

ActiveCN104453961AImprove work performanceSimple structureAnchoring boltsSolid structureStructural engineering

The invention relates to the technical field of engineering supporting, in particular to a pressing seam type friction type constant-resistance anchor rod. By means of the anchor rod, the technical problems that in the prior art, the ultimate tensile length of an anchor rod is small, function overload failure occurs easily, and the flexible supporting capacity is not achieved are solved. The anchor rod structurally comprises a sleeve, a rod body, a tray and a pressing block. The rod body comprises an entity segment, a constant-resistance segment, a conical segment, a friction resistance segment and a free segment from top to bottom. The entity segment is of a cylindrical solid structure. The side walls of the constant-resistance segment, the conical segment and the friction resistance segment are provided with gaps with the same width from top to bottom in the axial direction. The outer diameter of the constant-resistance segment is larger than that of the friction resistance segment. The outer diameter of the axial section of the rod body gradually diseases continuously and is in transition to the outer diameter of the friction resistance segment from the outer diameter of the constant-resistance segment in the axial direction through the conical segment The sleeve comprises a rough-hole segment, a conical-hole segment and a thin-hole segment and is matched with the rod body in inner diameter. The anchor rod is not damaged when a surrounding rock is greatly deformed, larger displacement of the rod body is allowed so as to adapt to deformation of the surrounding rock, the surrounding rock deformation energy can be continuously absorbed, and the stability of the surrounding rock is maintained.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Electrode structure and method of manufacture thereof

ActiveCN107112143AUse controlUse to limit and/or minimizeHybrid capacitor electrodesElectrode collector coatingStructure basedMaterials science

An electrode structure comprises a conductive substrate or current collector and a first layer comprising a first electrochemically active material, the first active material being characterized by one or more first electrochemical properties. A second layer comprises a second electrochemically active material, the second active material being characterized by one or more second electrochemical properties, at least one of which is different from said one or more first electrochemical properties. The first and second layers are provided at predefined locations within the electrode structure based on the respective first and second electrochemical properties of the first and second electrochemically active materials to maximise the performance of each of the first and second layers. A method of fabricating such an electrode structure is also provided.

Owner:OXFORD UNIV INNOVATION LTD

Solar heat collector

PendingCN110715459AReduce heating depthImprove heating convection capacitySolar heating energyFluid circuit connectionsThermodynamicsCollector device

The invention discloses a solar heat collector and relates to the technical field of transformation from solar energy into heat energy. The solar heat collector consists of a bracket, a V-shaped corrugated light reflecting plate, a solar vacuum heat collecting tube, a heated core, a central connection box and another solar vacuum heat collecting tube in a fixation manner; each solar vacuum heat collecting tube is a double-layer heterogeneous vacuum tubular component and consists of an outer layer glass tube, an inner layer oxygen-free copper tube, a selective heat absorbing material layer, a vacuum sealing device, a drying agent, a moisture absorption membrane and a positioning plate, wherein the selective heat absorbing material layer is attached to the outer wall of the inner layer oxygen-free copper tube; the heated core is a U-shaped hollow copper tube of which the section is annular and consists of a water feeding tube, a heated core body, a water discharging pipe and an expansionspring; and the central connection box is a rectangular box body which consists of an upper box body and a lower box body which are combined with each other in a buckling manner. The solar heat collector has the advantages of reasonable structure, short and quick temperature increment, high photo-thermal transformation efficiency and the like.

Owner:马冲生

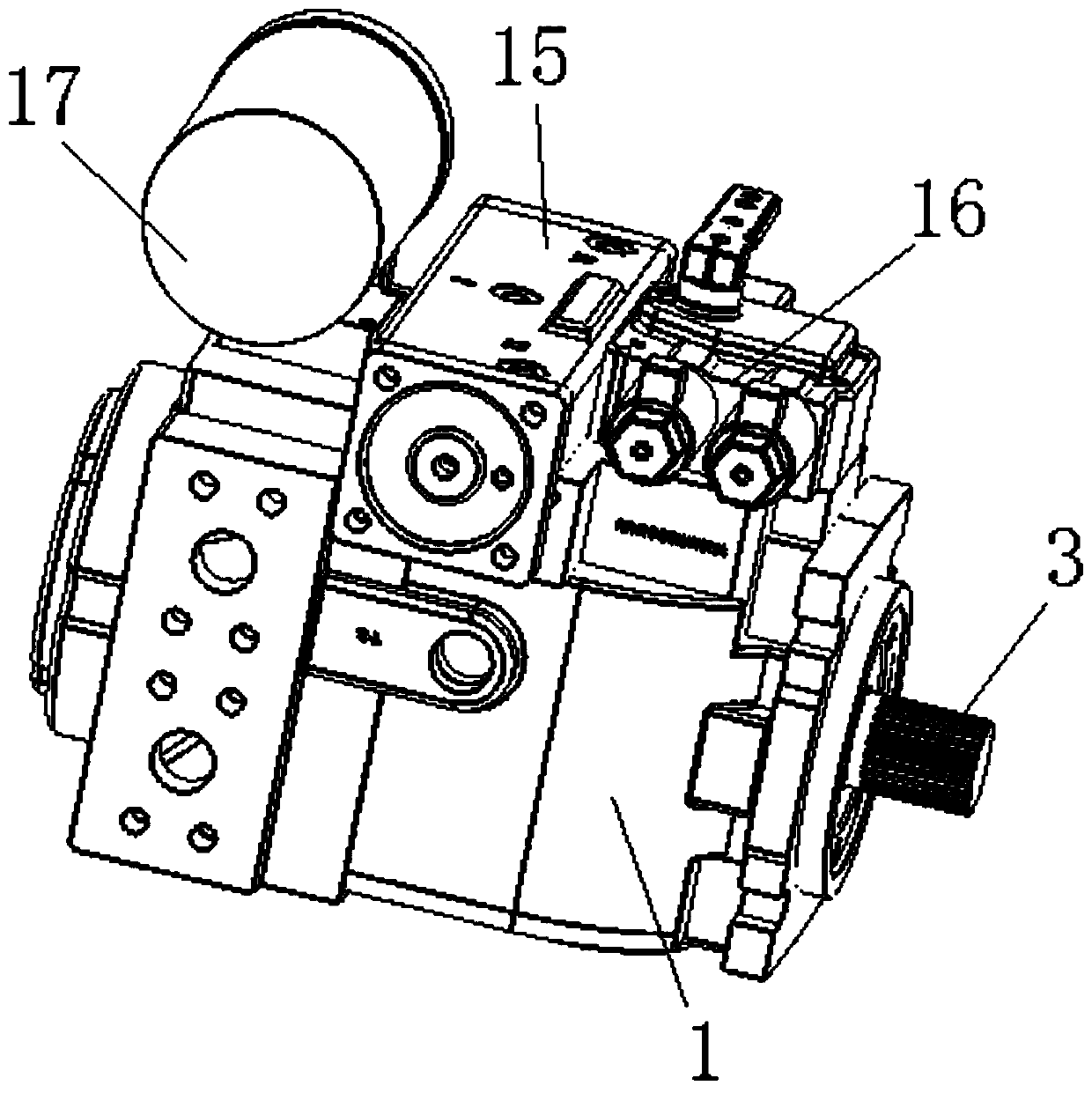

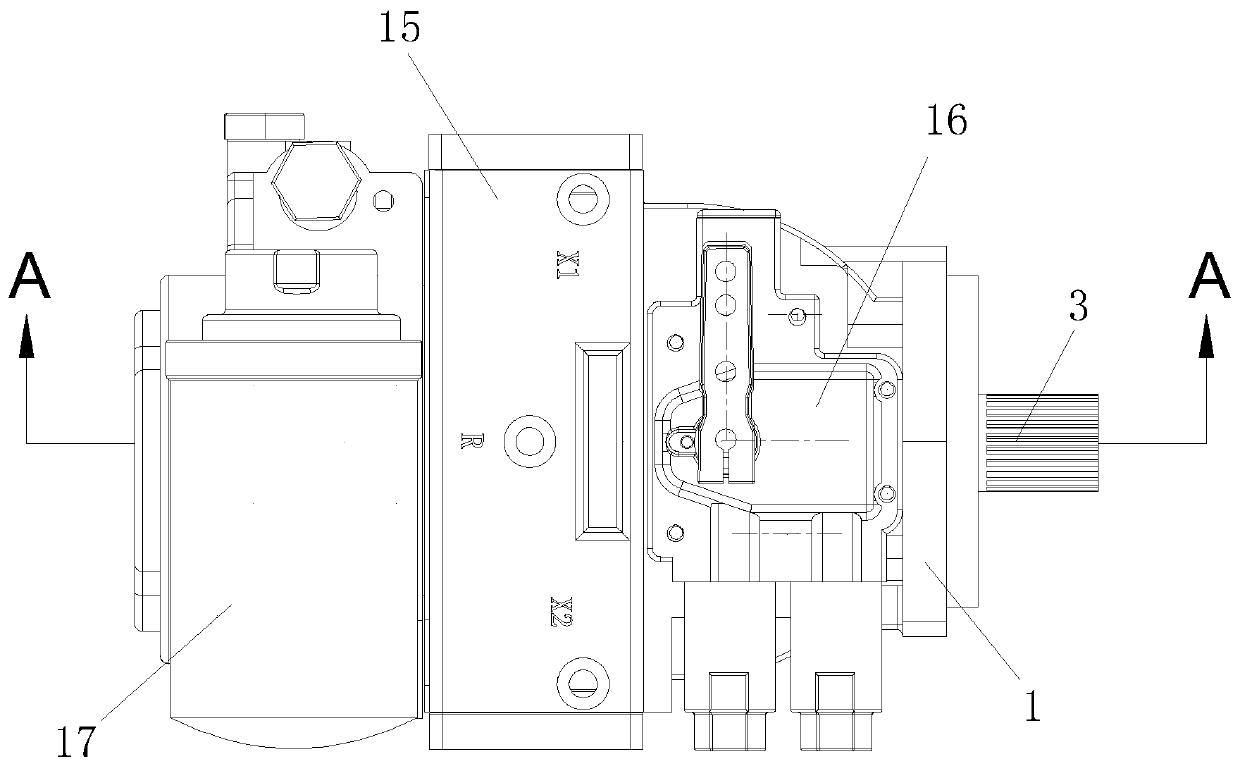

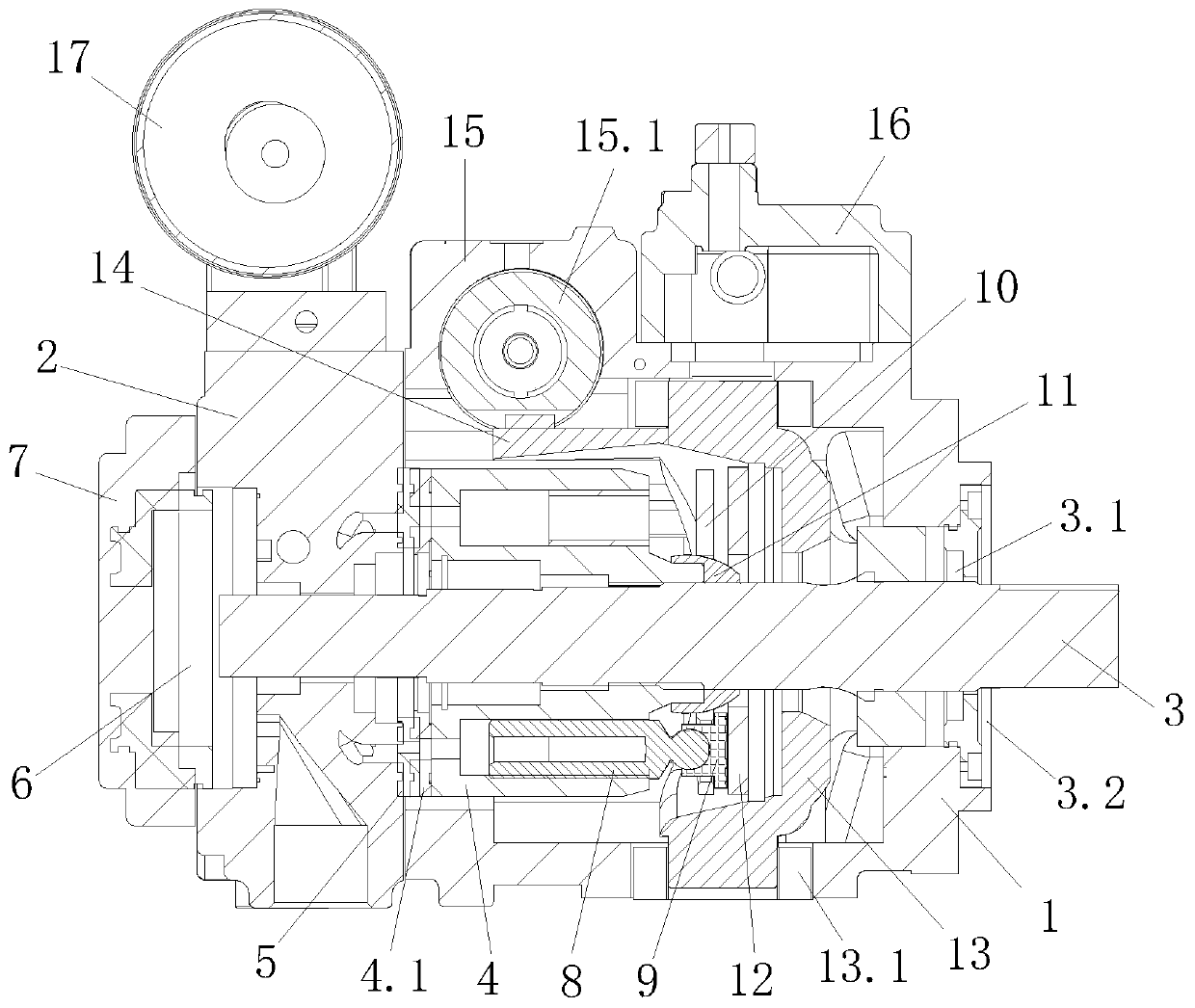

Novel high-pressure plunger pump

PendingCN110307134ASolve the problem that the volume is too large and the rated pressure is not highReduce volumePositive displacement pump componentsPiston pumpsDrive shaftCylinder block

The invention relates to the technical field of high-pressure plunger pump equipment, and provides a novel high-pressure plunger pump. The novel high-pressure plunger pump comprises a shell and a rearcover connected to the shell, wherein the shell is movably inserted with a transmission shaft, a plurality of transmission shaft splines are arranged on the transmission shaft, a cylinder body is sleeved on a section, located in the shell, of the transmission shaft, the cylinder body is provided with an inner hollow structure, an inner sleeve is connected to the inner side wall of the cylinder body, cylinder body splines are arranged on the inner side wall of the inner sleeve, and the cylinder body splines are meshed with the transmission shaft splines on the shell. According to the plunger pump, the defects in the prior art are overcome, the design is reasonable, the structure is compact, the problem that an existing plunger pump is too large in size is solved, and the problem that the rated pressure is not high is solved; a simple structure combination is adopted, so that the volume of the cylinder body, a ball hinge and a variable cylinder are reduce, meanwhile, the material of a plurality of parts is changed, on one hand, the volume of the plunger pump is reduced, so that the application range is enlarged, in addition, the service life of the plunger pump is prolonged, and theplunger pump has strong practicability.

Owner:山东兰徳液压精工有限公司

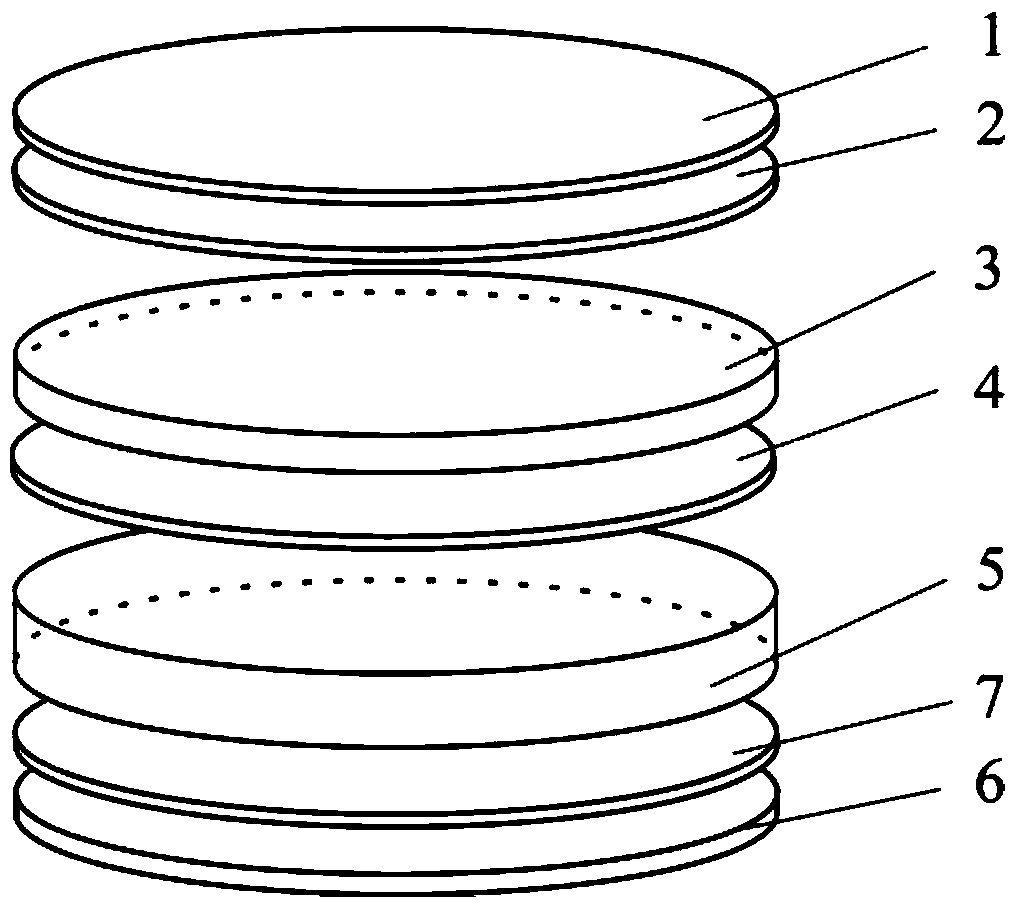

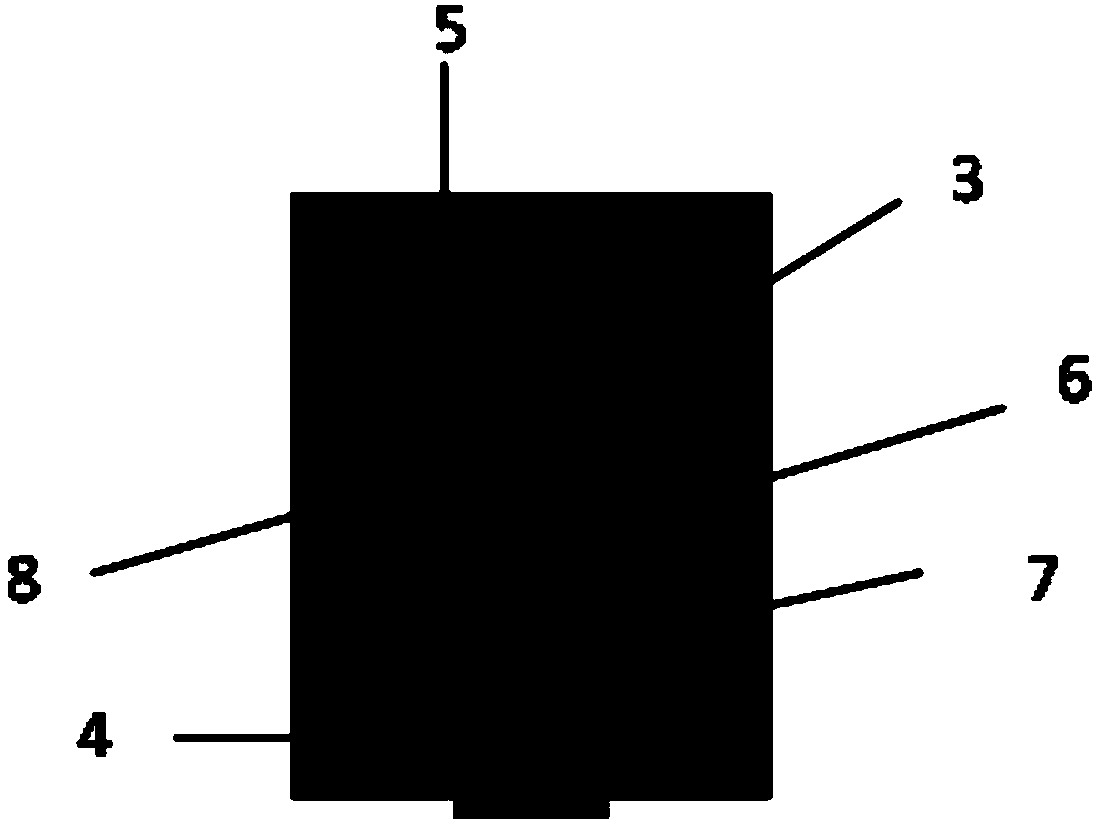

A fully flexible touch-pressure sensor based on capacitance-resistor composite

ActiveCN105606270BGuaranteed resolutionGuaranteed accuracySynthetic resin layered productsForce measurement using piezo-resistive materialsCapacitanceElectrical resistance and conductance

The invention discloses a composite capacitor-resistor type full-flexibility touch and pressure sensor. With the sensor, a problem that the touch and the pressure can not be detected simultaneously by the existing sensor can be solved. The sensor is characterized in that a capacitor layer and a resistor layer are arranged on a flexible substrate in an up-down structure mode; the capacitor layer is used for sensing touch information and the resistor layer is used for sensing pressure information; and the capacitor layer is arranged on the resistor layer. Compared with the common touch sensor and the pressure sensor, the provided composite capacitor-resistor type full-flexibility touch and pressure sensor is not only capable of distinguishing a small touch force but also is capable of realizing measurement of a large pressure, so that the resolution and sensitivity of the sensor in the small range can be improved and the resolutions and precision of sensor at different ranges can be guaranteed. All materials employed by the sensor have high flexibility and all leads are led to the bottom, so that an array form of the sensor can be realized well and thus the maintenance of the sensor can be realized conveniently.

Owner:合肥庐阳科技创新集团有限公司

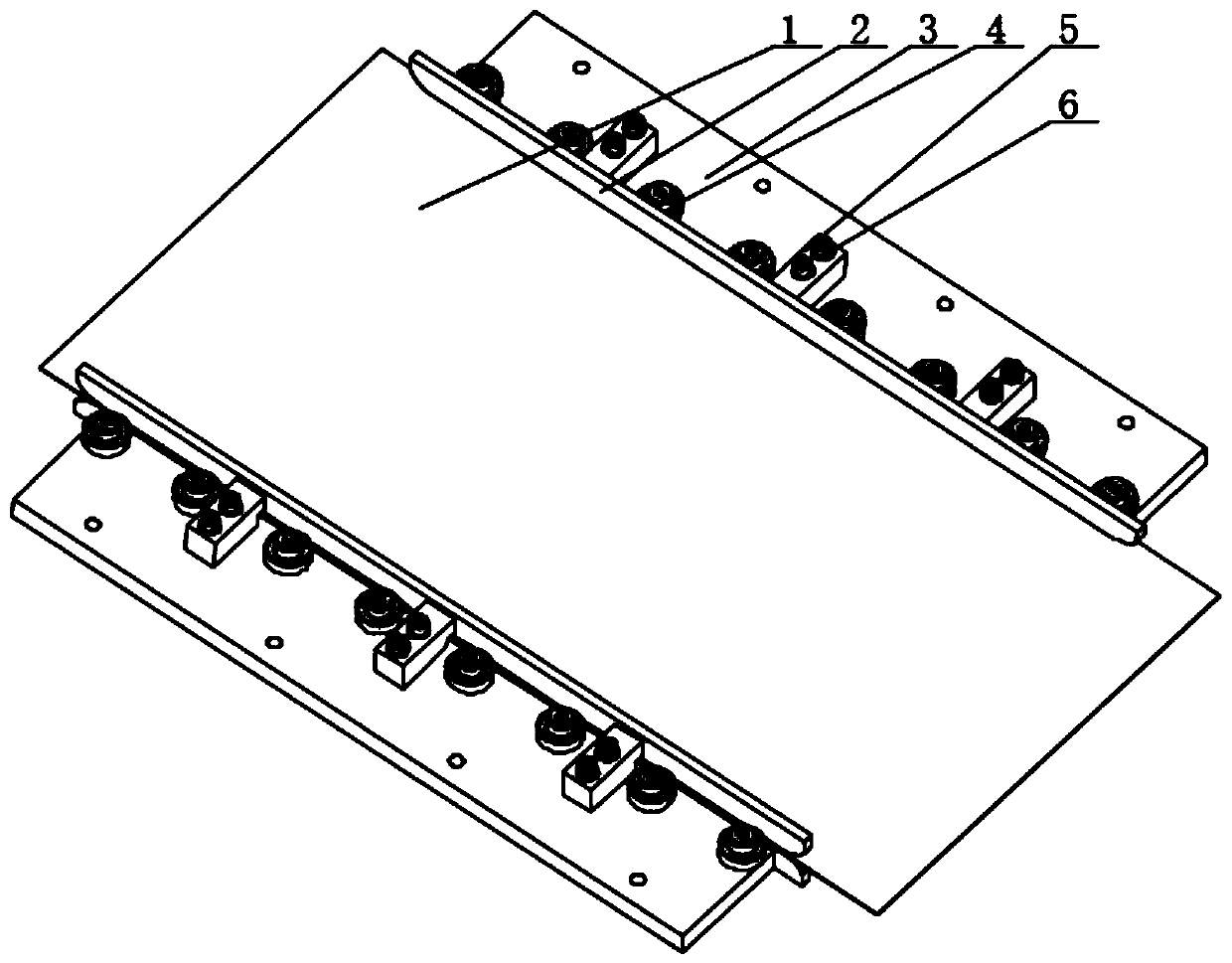

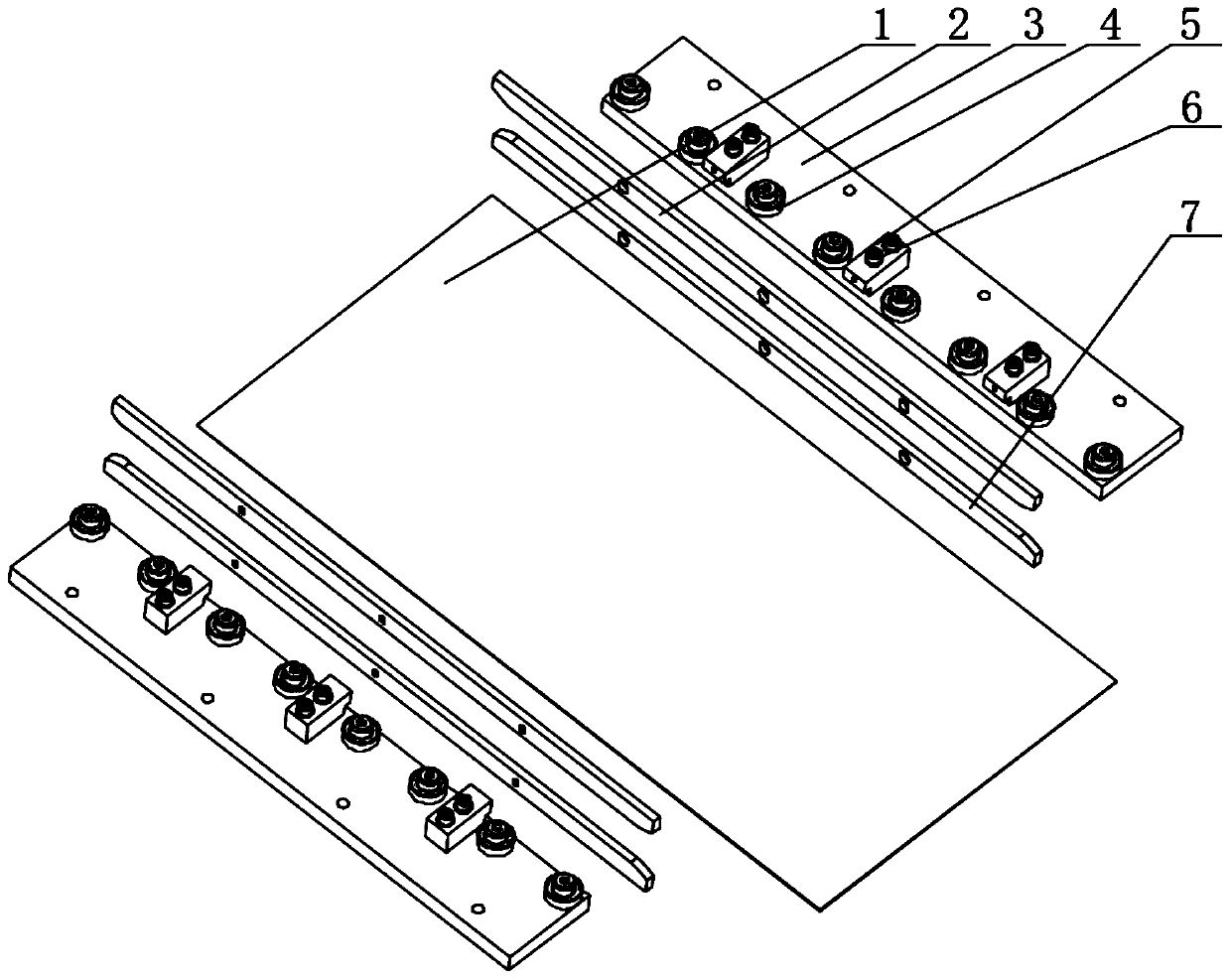

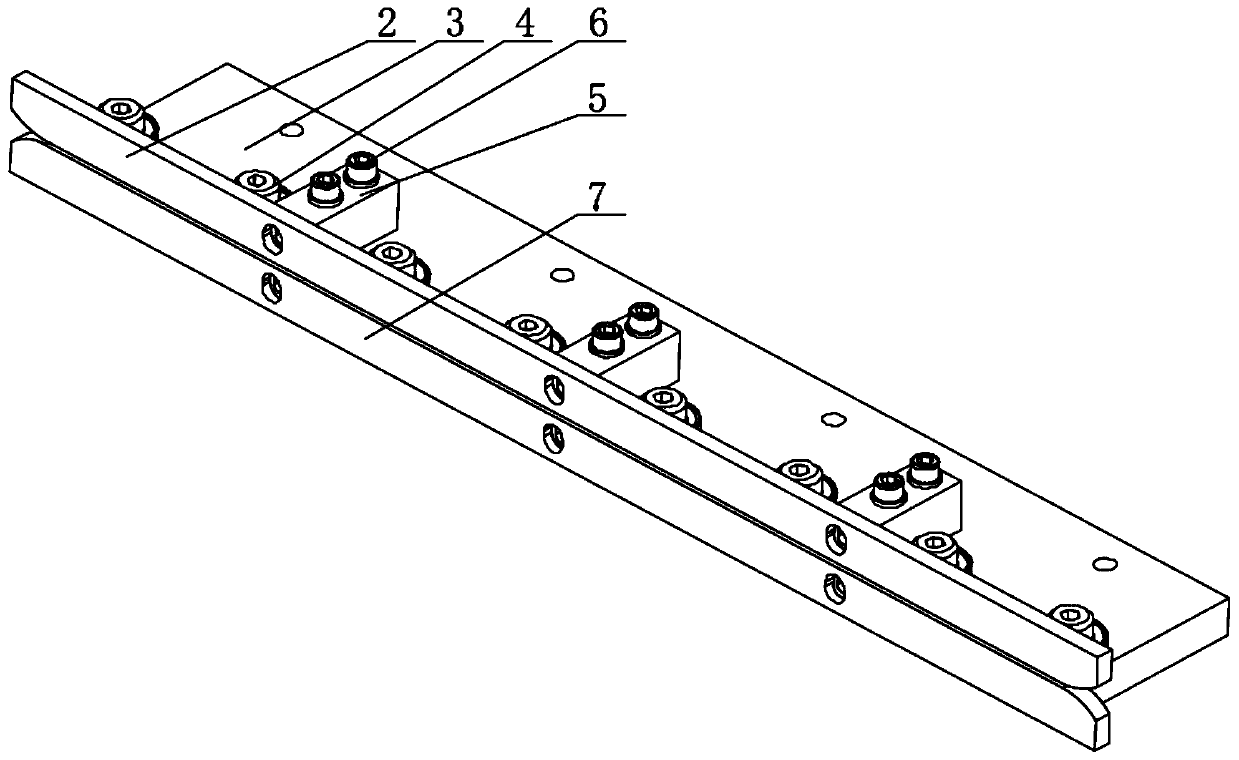

Core limb shearing length-cutting line guiding device

PendingCN110802270AEasy to navigateEasy to transportInductances/transformers/magnets manufactureMetal working apparatusElectrical steelFastener

The invention provides a core limb shearing length-cutting line guiding device. The core limb shearing length-cutting line guiding device comprises two working tabletops arranged in a spaced manner. The two working tabletops are located at the position of the same plane, lower rails are mounted on the inner side faces of the two working tabletops through fasteners, multiple spaced fixing blocks are mounted on the upper surface of each working tabletop through locking bolts, upper rails are mounted on the end faces of the fixing blocks through fasteners, the upper rails and the lower rails areoppositely arranged and correspond to gaps reserved between the upper rails and the lower rails, the gaps are through from front to back, multiple guiding wheel assemblies are further mounted on the portions, at same straight line position, of the upper surfaces of the working tabletops in a spaced manner, an electrical steel sheet penetrates through the portion between the two working tabletops,the two sides of the electrical steel sheet simultaneously stretch into the portions between the upper rails and the lower rails on the inner side faces of the two working tabletops, and meanwhile theedges of the two sides of the electrical steel sheet make contact with the guiding wheel assemblies. Guiding can be observed at any time, and the working reliability is greatly improved.

Owner:WUXI PUTIAN IRON CORE CO LTD

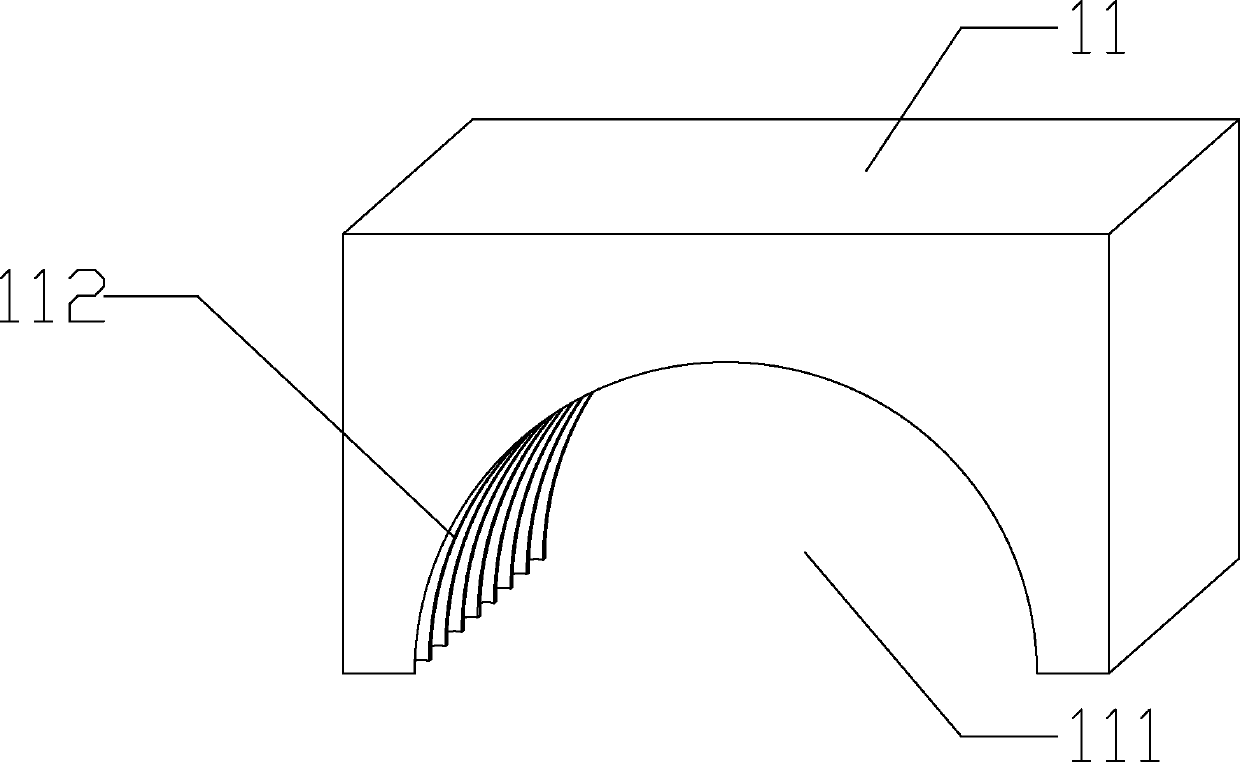

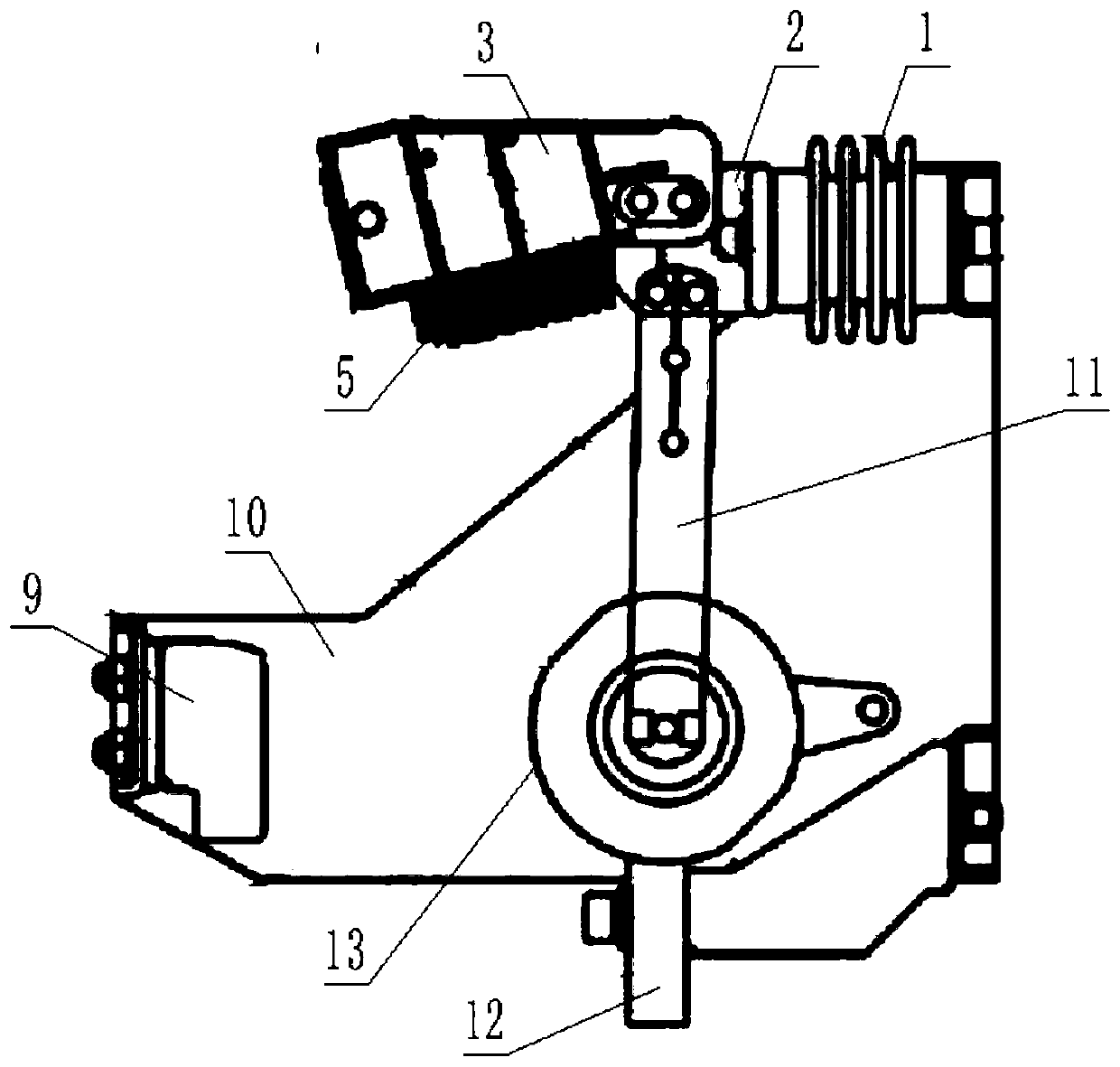

Novel arc extinguishing grid type load switch suitable for C4F7N environment-friendly gas

PendingCN110581042AImprove breaking capacityReduce fly-outHigh-tension/heavy-dress switchesAir-break switchesCopper–tungstenGround contact

The invention relates to a novel arc extinguishing grid type load switch suitable for C4F7N environment-friendly gas. The load switch comprises an installation seat, wherein an arc extinguishing mechanism and a grounding contact seat are installed on the installation seat, the arc extinguishing mechanism comprises a supporting insulator, a static contact seat and an arc extinguishing chamber, thearc extinguishing chamber comprises an arc extinguishing grid frame and a plurality of arc extinguishing grid sheets installed on the arc extinguishing grid frame, the static contact seat is a right-angle plate, one right-angle side of the static contact seat is connected with the arc extinguishing grid frame, the other right-angle side of the static contact seat is connected with the supporting insulator, the supporting insulator is connected with the mounting seat, and a current blocking groove and a copper-tungsten arc contact are arranged on the right-angle side of the static contact seatconnected with the arc extinguishing grid frame. The load switch is advantaged in that the load switch is a special load switch developed for being matched with the novel environment-friendly gas C4F7N, a three-station knife type load switch is adopted, arc extinguishing gate type arc extinguishing is adopted in an arc extinguishing mode, and the requirement for the breaking capacity of the load switch in the C4F7N gas is met by adjusting the structure of the load switch.

Owner:山东泰开电力开关有限公司

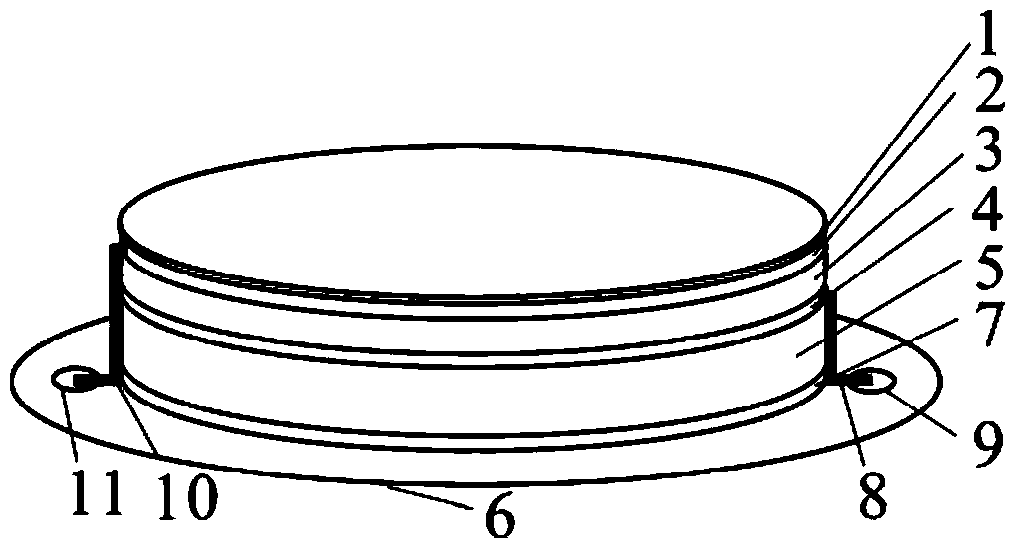

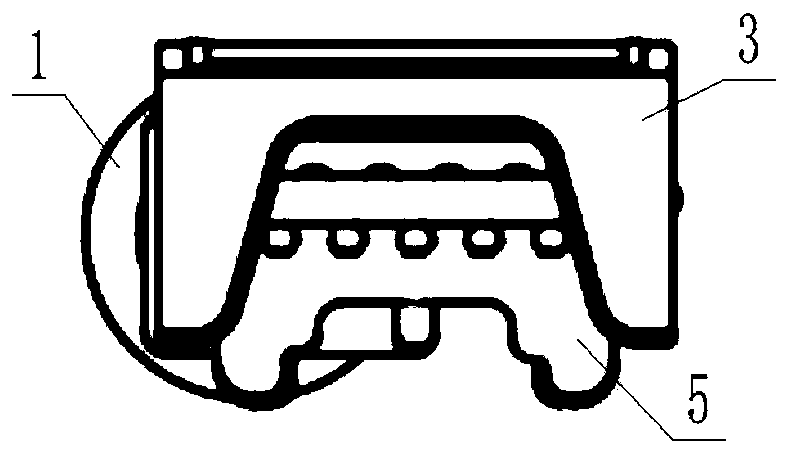

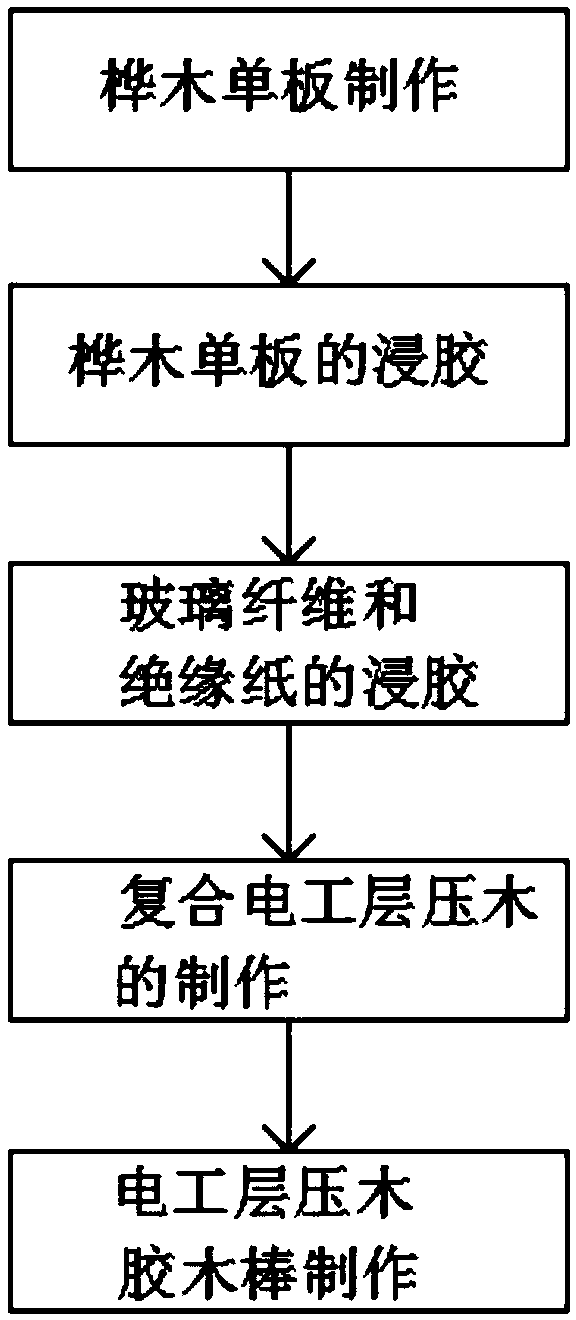

Production method of electrical laminated wood-rubber stick

InactiveCN110394864AChange materialImprove stress resistanceOther plywood/veneer working apparatusWooden sticks manufactureGlass fiberWood veneer

The invention discloses a production method of an electrical laminated wood-rubber stick. The electrical laminated wood-rubber stick is manufactured through five steps of manufacturing a Chinese woodveneer, dipping the Chinese wood veneer, dipping glass fibers and insulating paper, manufacturing a composite electrical laminated wood and manufacturing the electrical laminated wood-rubber stick, and the material of the electrical laminated wood-rubber stick is changed, so that the compression resistance and the voltage breakdown resistance of the electrical laminated wood-rubber stick are remarkably improved, the mechanical property and the dielectric property of the electrical laminated wood-rubber stick are improved, and the voltage laminated wood-rubber stick has good heat resistance andmoisture resistance. The voltage laminated wood-rubber stick manufactured by the production method is good in appearance quality and high in insulation performance and cannot break and be broken downunder the action of external force and a strong electric field, and the wood-rubber stick is suitable for a larger range.

Owner:康利源科技(天津)股份有限公司

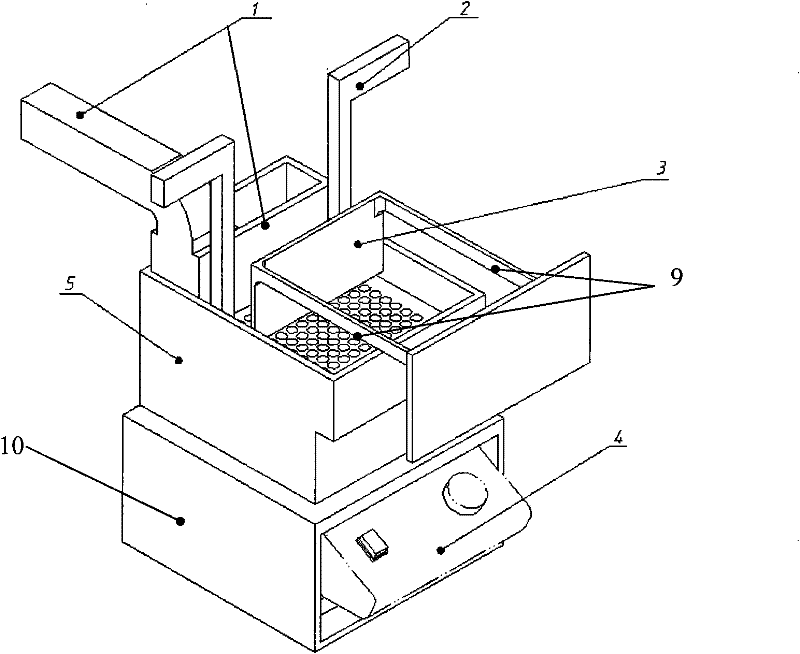

Magnetic Stirring and Liquid Level Regulating Device for Light-curing Rapid Prototyping Ceramic Slurry

InactiveCN101733839BPrevent precipitationGuaranteed uniformityClay processing apparatusSlurryEngineering

The invention discloses a device for magnetic stirring and liquid level adjustment of light-cured rapid prototyping ceramic slurry, which comprises a rectangular slurry tank, a mesh plate and a scraper arranged in the slurry tank, and the slurry tank is also provided with There is a floating block that can move up and down vertically. There is a magnetic stirrer under the slurry tank. There is a circular blind slot for setting the rotor of the magnetic stirrer on the bottom of the inner tank of the slurry tank. The upper side of one end of the slurry tank protrudes as a scraper. The plate cavity and the upper part of the other end of the slurry tank protrude to form a liquid level detection cavity, and a liquid level detection device is arranged in the liquid level detection cavity; the slurry tank and the mesh plate are both made of magnetically permeable materials. In view of the problem that slurry precipitation is easy to occur in the process of light-curing and forming ceramic products, which leads to the problem of affecting the production accuracy, the device proposes to use a magnetic stirring device in the production process to stir the ceramic slurry evenly, which can effectively light-cure and directly form ceramics The ceramic slurry is easy to precipitate and deteriorate during the process.

Owner:XI AN JIAOTONG UNIV +1

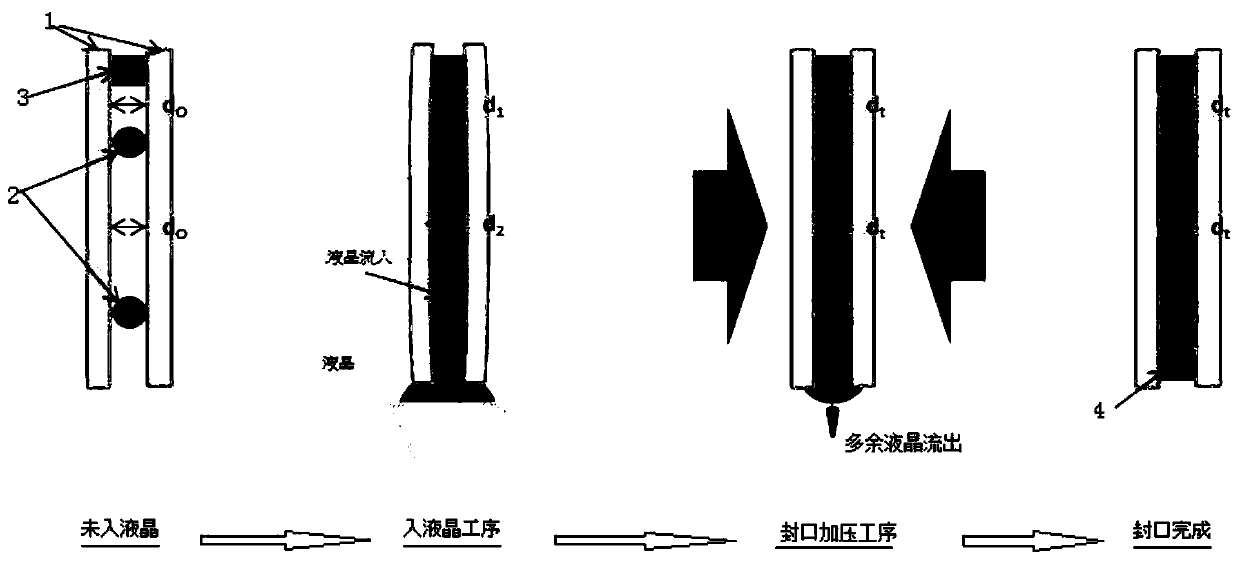

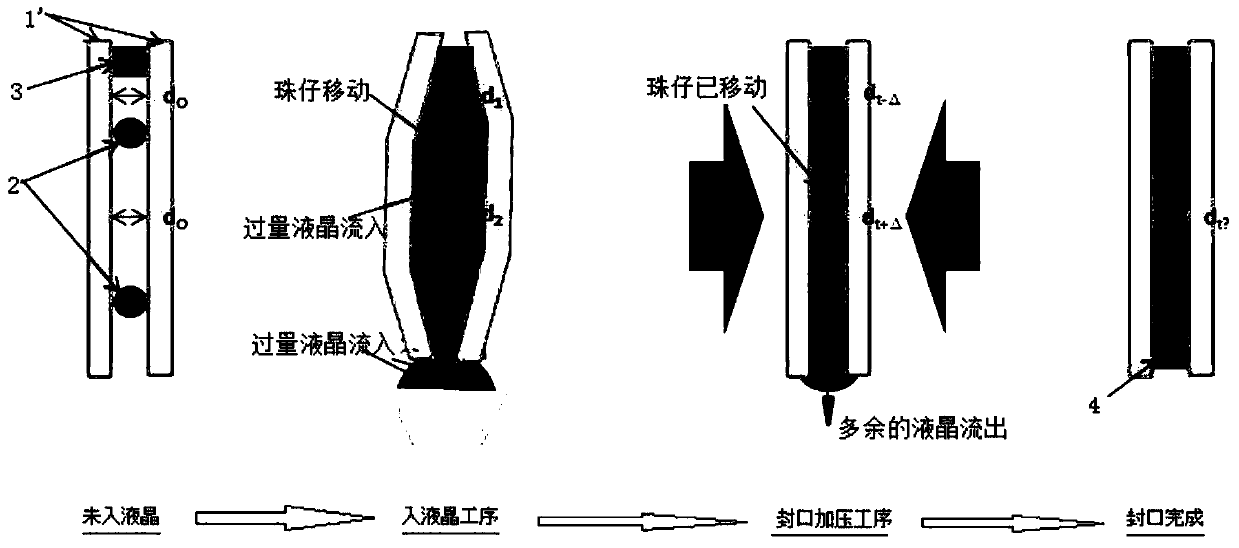

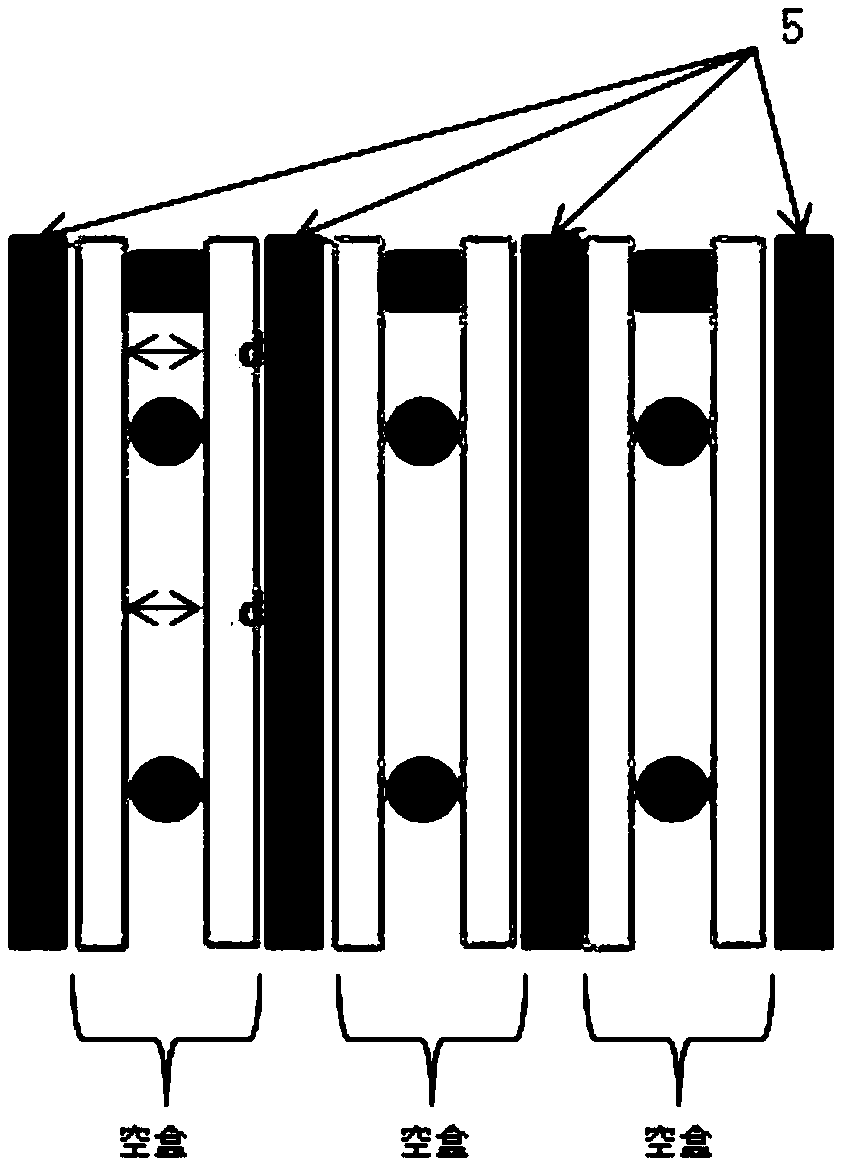

A flexible liquid crystal display into liquid crystal and sealing production process

ActiveCN106896590BReduce flowControl deformationNon-linear opticsManufacturing technologyLiquid-crystal display

The invention discloses a liquid crystal adding and sealing manufacturing technology for flexible liquid crystal display. The technology comprises the first step of placing a rigid cushion on a flexible substrate material surface of a liquid crystal empty box; the second step of exerting pressure on the rigid cushion so that the rigid cushion can be attached to the flexible substrate material surface to form into one with the liquid crystal empty box, and subsequently maintaining the pressure stable; the third step of continuing to maintain the pressure stable, injecting liquid crystal into the liquid crystal empty box, moving off the rigid cushion after the liquid crystal empty box is filled with the liquid crystal, and conducting sealing treatment on the liquid crystal empty box which is filled with the liquid crystal. According to liquid crystal adding and sealing manufacturing technology for flexible liquid crystal display, by arranging the rigid cushion on the flexible substrate material surface of the liquid crystal empty box, and exerting pressure on the rigid cushion, the rigid cushion and the liquid crystal empty box are formed into one, in this way, the texture of the flexible substrate material can be ingeniously changed, thus in the process of injecting the liquid crystal into the liquid crystal empty box, deformation cannot occur, the amount of the liquid crystal in the liquid crystal empty box is improved, unnecessary liquid crystal flow is reduced, the flatness of liquid crystal displaying in the flexible substrate material is improved, and the opportunity of generating bubbles is reduced.

Owner:VARITRONIX HEYUAN DISPLAY TECH

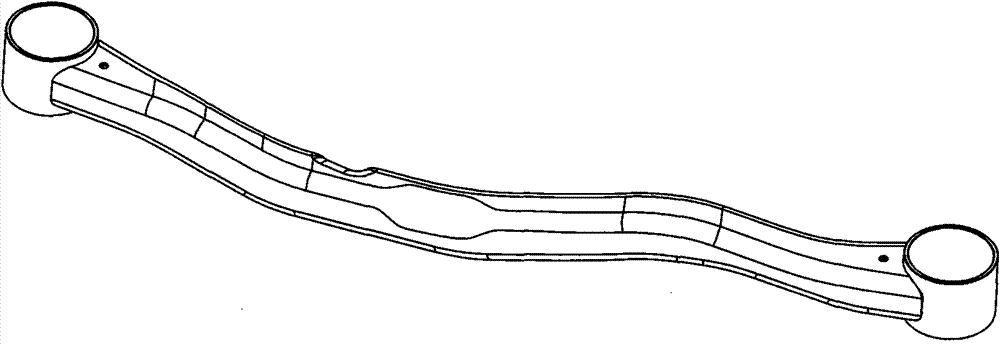

Structure of flexible rod-stripping part of extruding peanut shelling machine

The invention relates to a component improvement structure for a peanut shelling machine particularly relates to a flexible hitting-rod assembly structure for a squeezing type breeding-peanut shelling machine, and belongs to the agricultural machinery. A hitting-rod roller (1) is a cylindrical soft elastomer, the middle part of the cylindrical soft elastomer is provided with a rotating shaft, and the periphery of the cylindrical soft elastomer is provided with semi-circular raided bars, i.e., the cross section of the cylindrical soft elastomer is in the shape of a flower disc, the middle part of the cross section is a circle, and a plurality of semi-circular raised sheets are raised outwards at the periphery of the circle, wherein the extradius of each semi-circular raised sheet is 1-2cm; a hitting-rod adjusting sleeve (3) can be used or not used according to the volume of the peanut pods; the hitting-rod adjusting sleeve (3) is a ringlike sleeve (soft elastomers) of different thickness; the inner circle of the hitting-rod adjusting sleeve (3) is a semi-circular groove, and the outer circle is a raised semi-circular sheet. The shape of the hitting rod of the existing hitting type peanut shelling machine is changed, the material of the hitting rod roller is changed, and the gap between an upper semi-circular raided bar and a lower concave grid can be adjusted conveniently and rapidly in a shorter time, the adaptability of the peanut shelling machine to the shelling of breeding peanuts of different varieties can be improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Miniaturized antenna compatible with 5g and wi-fi/wimax frequency bands

ActiveCN108682943BRespond to commercial needsEase of conformal designRadiating elements structural formsAntennas earthing switches associationSoftware engineeringCoplanar waveguide

The invention discloses a miniaturized antenna compatible with 5G and Wi-Fi / WiMax frequency bands, comprising a bottom-up dielectric coating and a metal radiating surface; the metal radiating surface comprises a coplanarly mounted Y-shaped plane monopole coplanar waveguide with the feeder, as well as the trident feeder and ribbon tuning arms connected to the Y-shaped planar monopole, the folded metal frame connected to the ground plane of the feeder coplanar waveguide, and loaded on the Y-shaped planar monopole, respectively. The radiating slot on the coplanar waveguide between the pole and the feed. The antenna can meet the application requirements of terminals that are compatible with 5G frequency bands and existing operating frequency bands that must be faced by 5G commercial use. It has the advantages of small size, convenient processing, easy conformal installation, and stable radiation performance in a wide frequency band.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

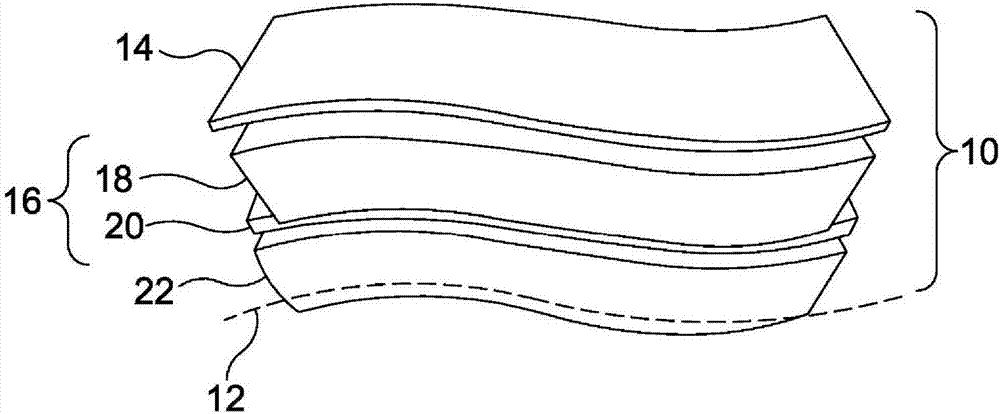

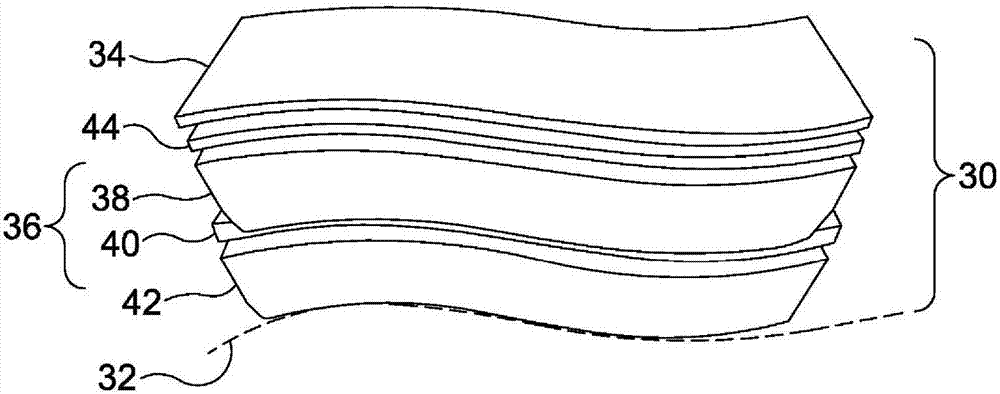

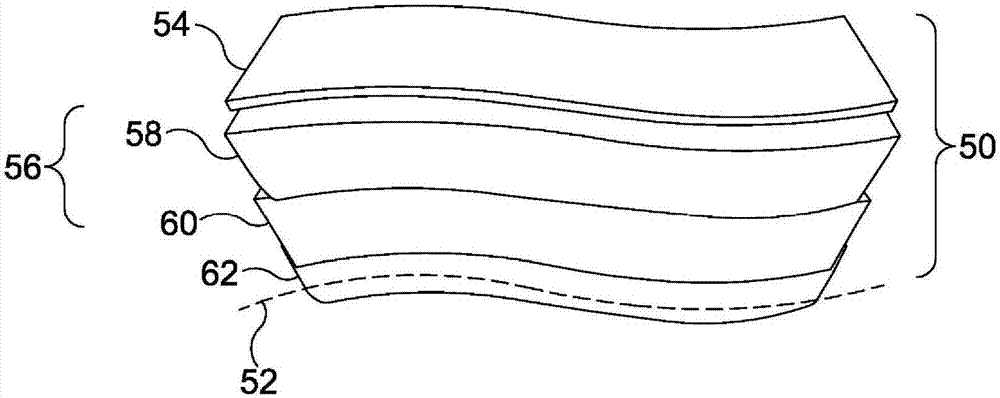

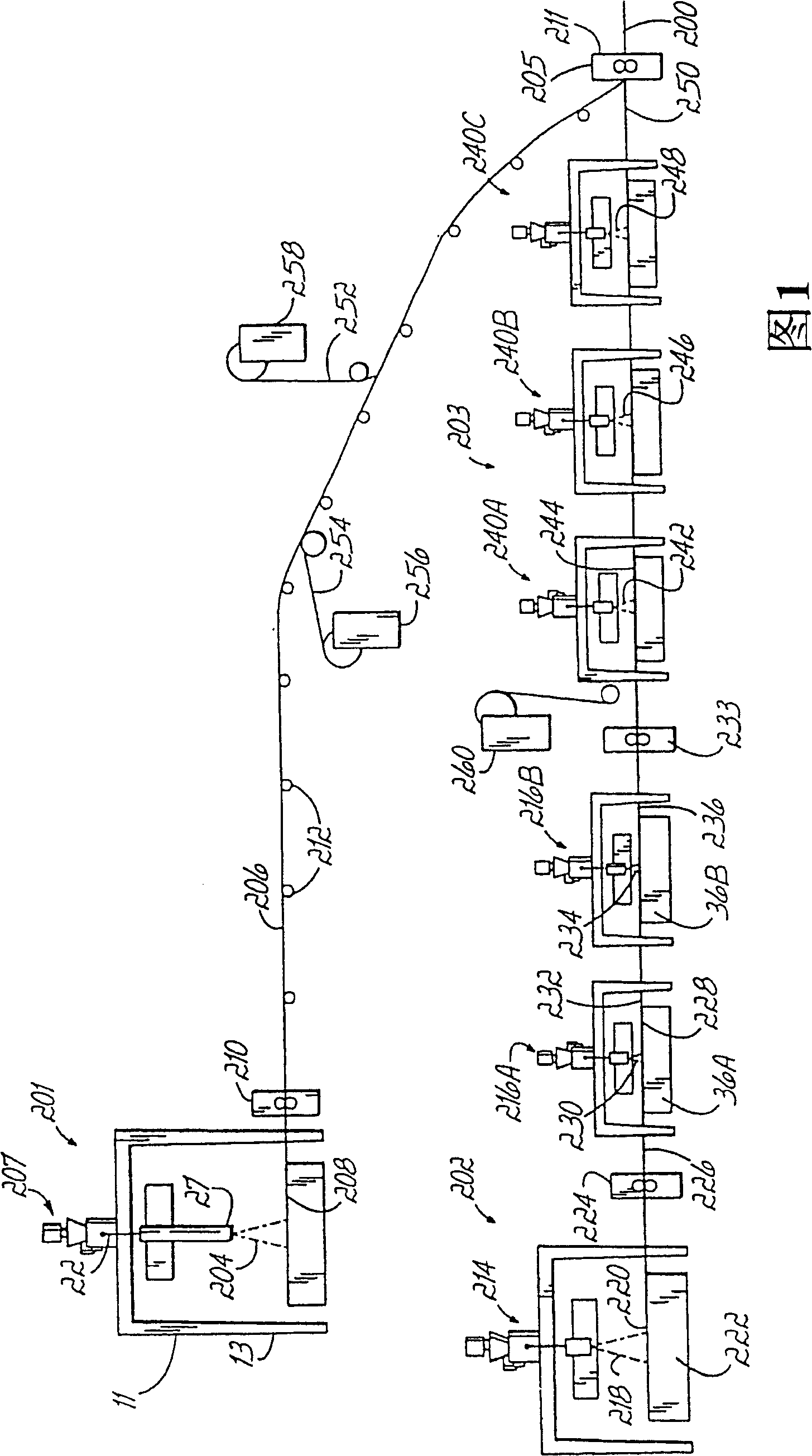

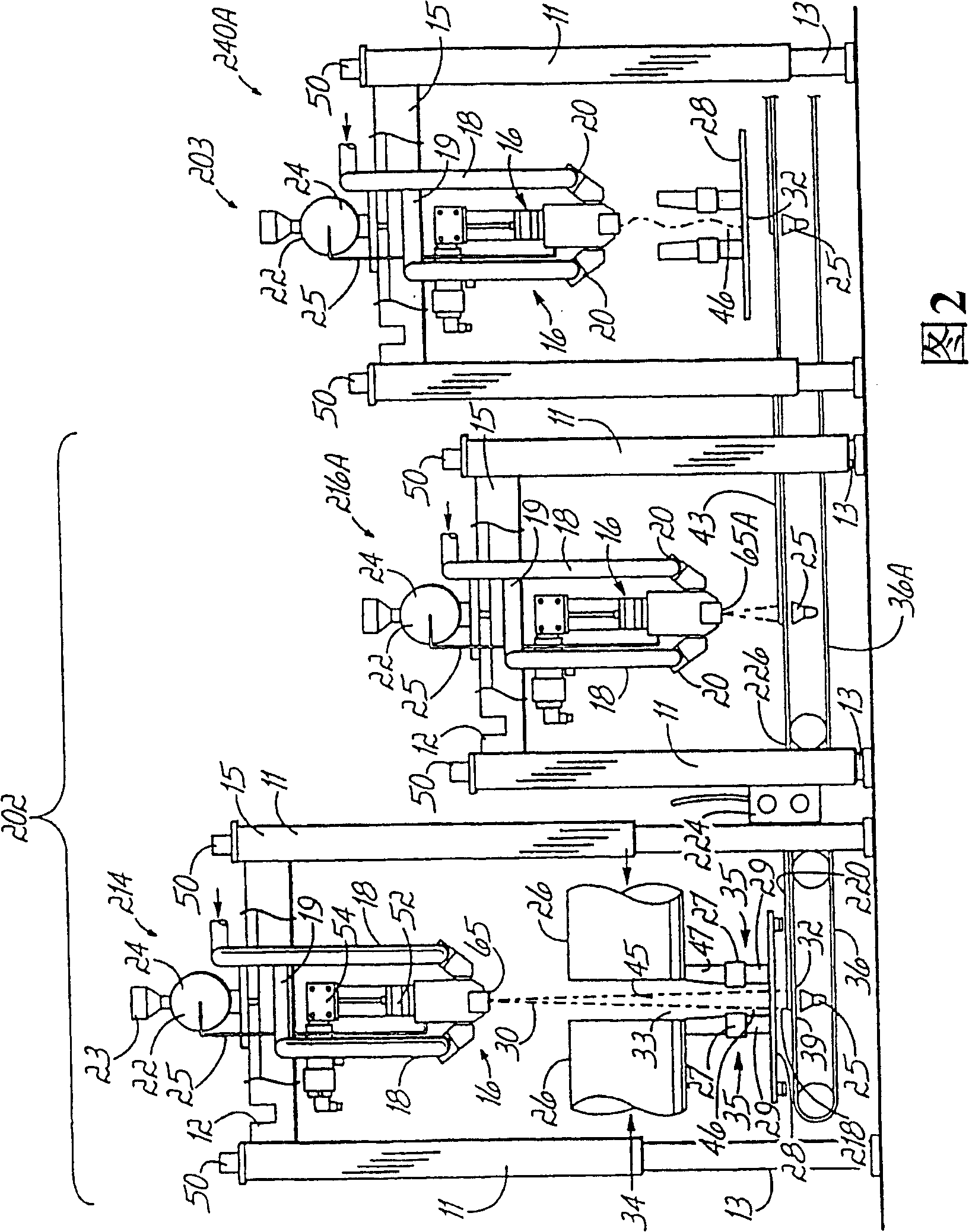

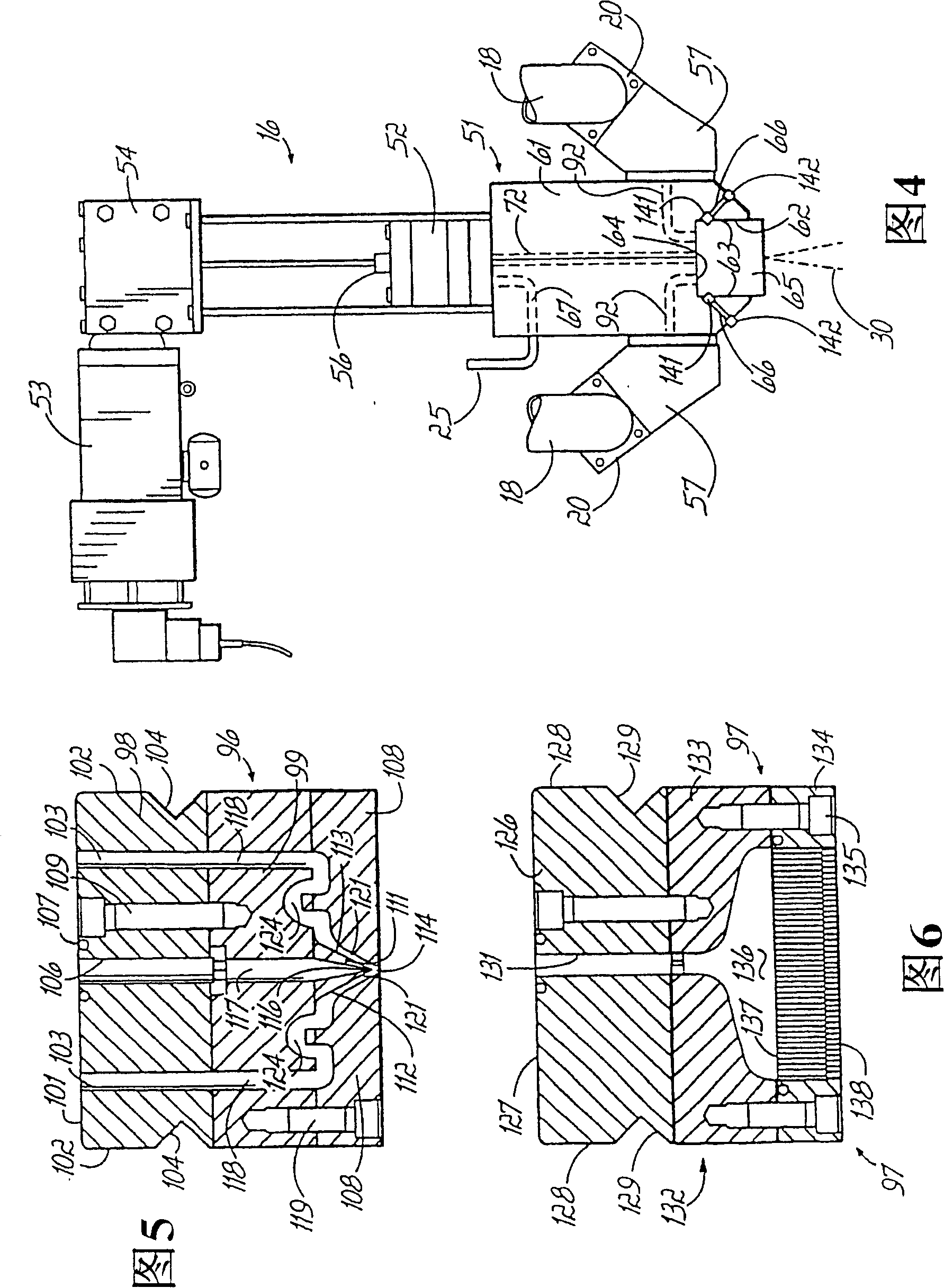

Absorbent composite product and process and apparatus for manufacture thereof

InactiveCN100430035CChange materialChange propertiesAbsorbent padsBaby linensEngineeringMechanical engineering

A multi-layer absorbent product includes a fibrous nonwoven top sheet, a fibrous nonwoven absorbent core layer, and a fibrous nonwoven substantially water-impervious back sheet. Each component layer or sheet is manufactured at a fiberizing station and laminated together at a combining station. The preferred melt spinning apparatus is spunbond for the top sheet, meltblowing for the core layer, and a combination of spunbond and meltblowing for the bottom sheet.

Owner:NORDSON CORP

Cooling drum for smelting

ActiveCN100491551CImprove corrosion resistance and wear resistanceAvoid wear and tearEngineeringWear resistance

This invention relates to a cooling device for smelting. It comprises gearing, cylinder equipment and cooling equipment; the cylinder equipment is composed of a cylinder with a certain length and two openings at two ends and lining board placed on the inner surface, the rotation of said cylinder equipment is drove by gearing, the materials in the cylinder is cooled by cooling equipment, said cylinder comprises front, middle and rearbarrel made from different materials; said the middle part is stainless steel and its length is 2 / 3-3 / 4 of that of whole cylinder. The invention is characterized in that the materials, traditional structure and disposal mode of cylinder and scaleboard are all changed, the integrity of cylinder is optimized, the corrode resisting and wear resisting property are enhanced, the service life is prolonged, the maintenance cost is saved, and continuous and normal production of device is ensured.

Owner:株洲冶炼集团有限责任公司

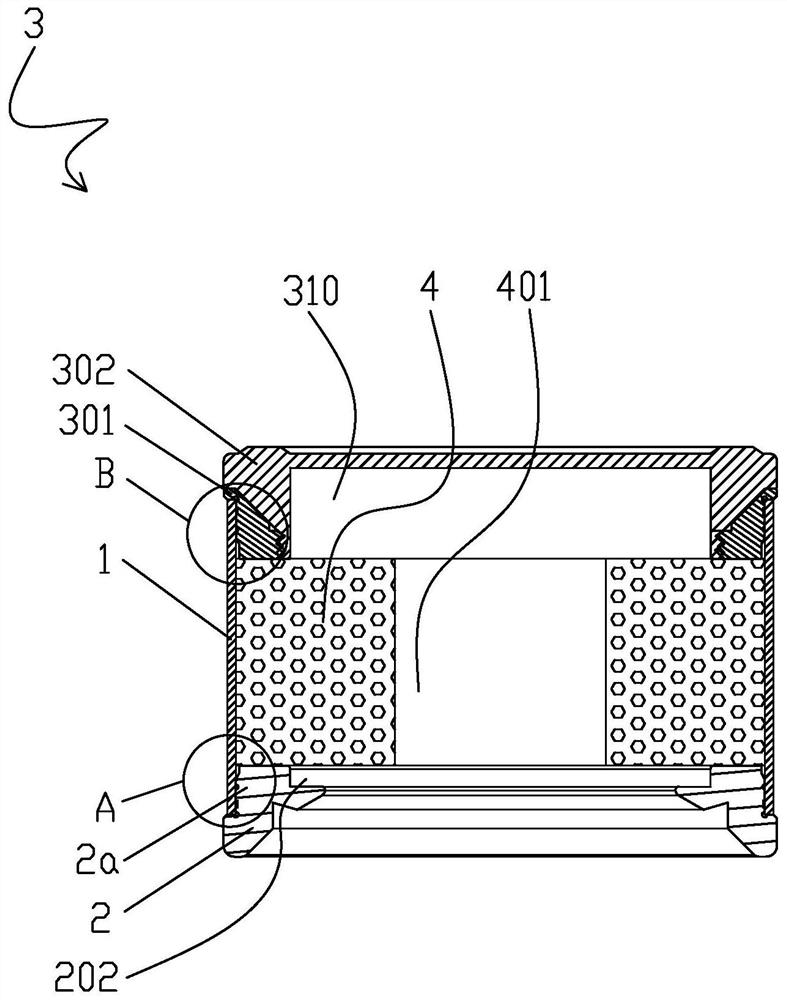

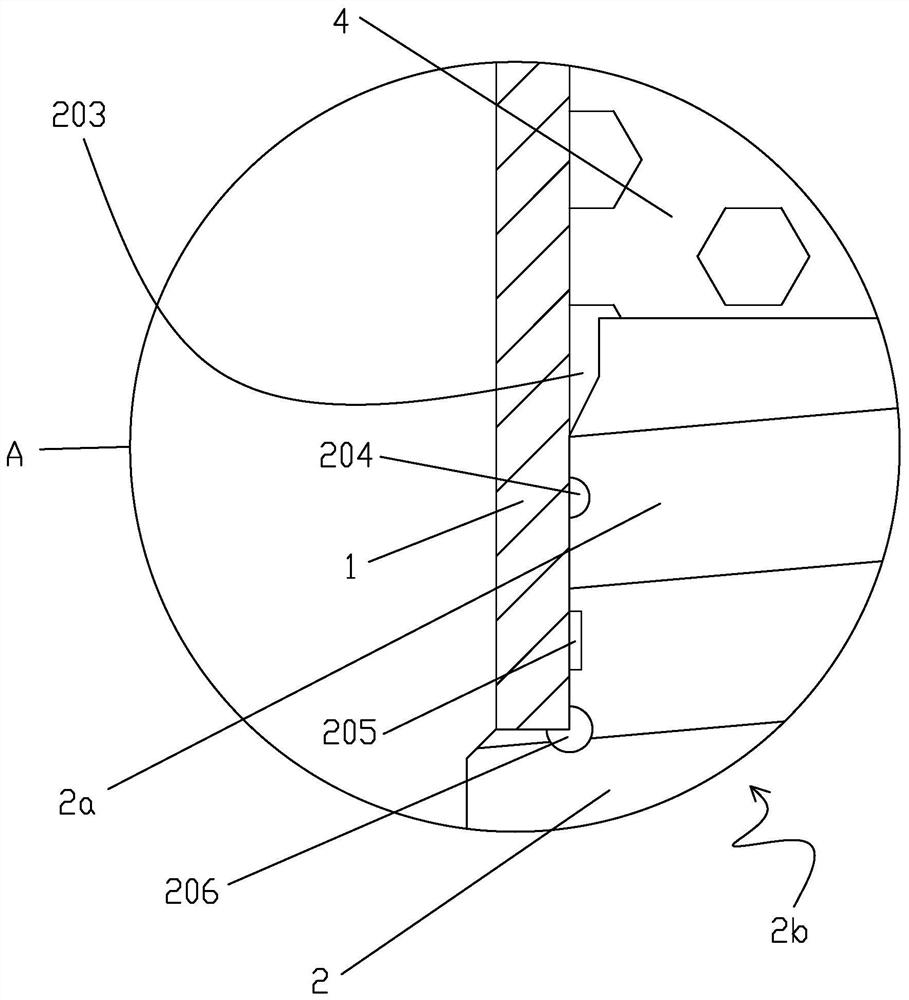

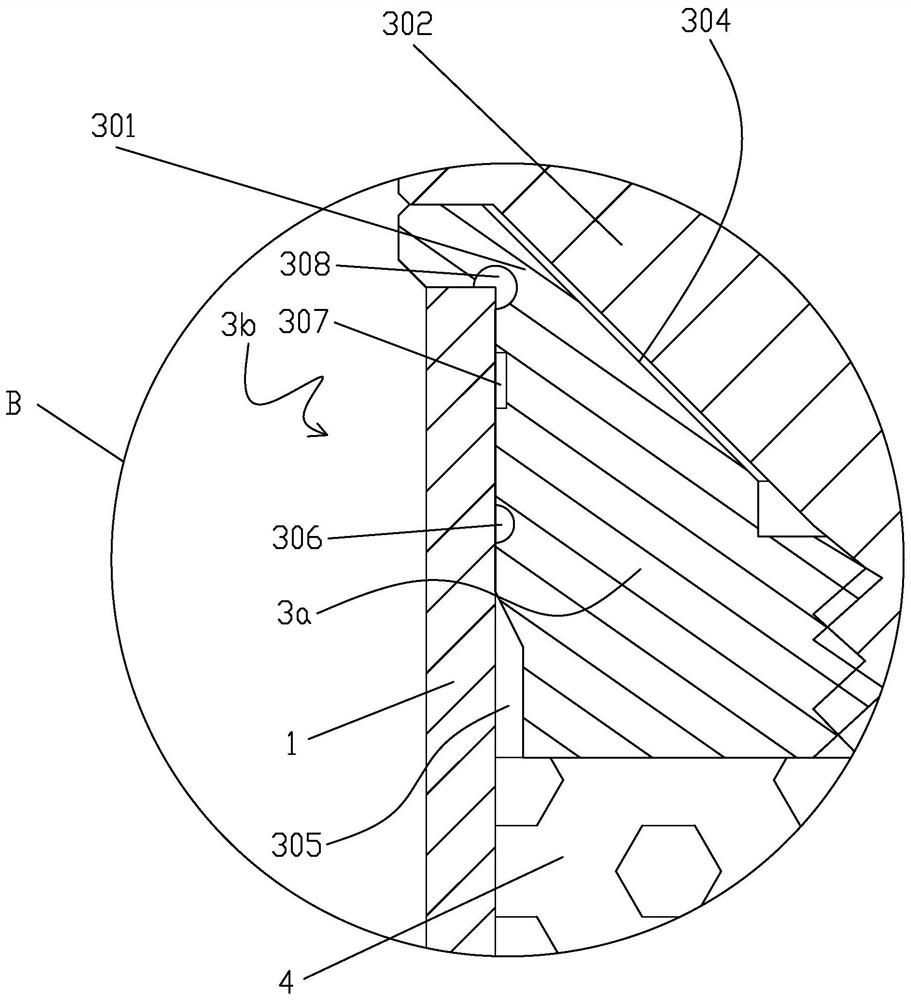

Protective device for commercial lighting

ActiveCN108033135BChange materialImprove protectionContainers to prevent mechanical damageRigid containersLight fixtureManufacturing engineering

The invention discloses a commercial lighting lamp protecting device. A body 1 is included, and is internally provided with a containing cavity 101, and a product can be placed in the containing cavity 101; one end of the body 1 is provided with a fixed supporting base 2 connected with the body 1 in a split manner and capable of preventing the product from falling out of one end of the body 1; theother end of the body 1 is provided with a packaging assembly 3 connected with the body 1 in a split manner and capable of being matched with the fixed supporting base 2 to seal the product in the containing cavity 101; a buffering protecting device 4 capable of protecting the product and fixing the position of the product is arranged in the containing cavity 101; a product containing position 401 for the product to be inserted in is arranged in the buffering protecting device 4; and the buffering protecting device 4 is connected with the body 1 in a split manner and is arranged between the fixed supporting base 2 and the packaging assembly 3.

Owner:国网山西省电力公司超高压变电分公司

Intelligent induction shower cabin

The invention relates to an intelligent induction shower cabin, which comprises a shower cabin and an inductive control unit, wherein the inductive control unit is used for inducing the position of a human body so as to control the opening or the closing of the shower cabin, and comprises a driving motor, a microcomputer and an infrared inductive probe; when the shower cabin is in practical operation, firstly, the infrared inductive probe detects the existence of the human body and at this time sends a signal to the microcomputer, and the microcomputer commands a driver therein so as to drive the driving motor to work according to a compiled program and to drive a movable door to be opened or closed through the driving motor.

Owner:ZHONGSHAN LENS HOME CO LTD

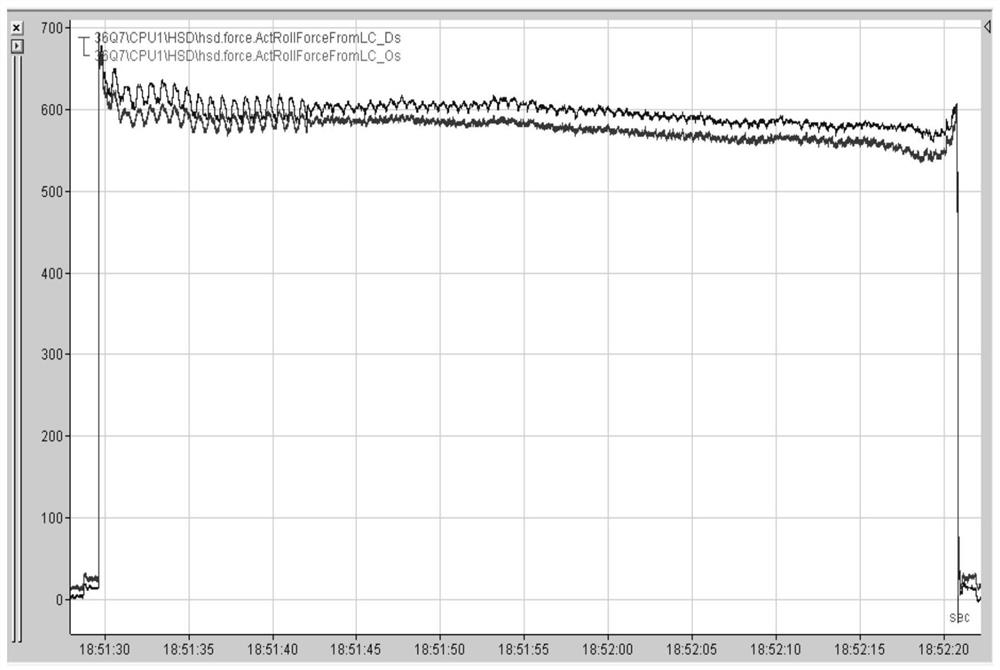

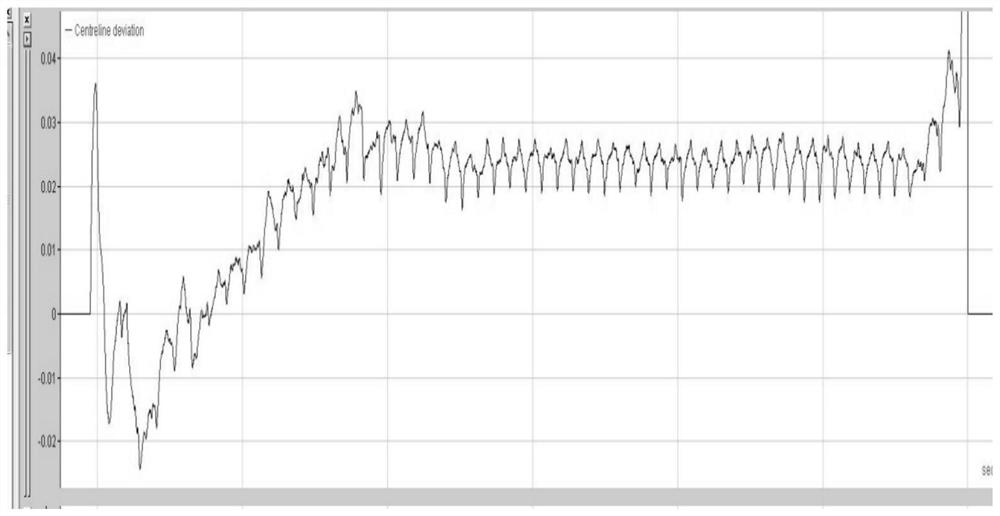

Centrifugal composite roller

ActiveCN112264465AChange materialHigh shape precisionRollsMetal rolling arrangementsStructural engineeringStrip steel

The invention discloses a centrifugal composite roller. The roller comprises a roller body, the thickness of a supporting layer of the roller body is larger than 5 mm and smaller than or equal to 20 mm, and the hardness of a roller shoulder portion of the roller body is larger than HSD60. The roller has the beneficial effects that the material of the roller shoulder is further changed by changingthe size of the roller shoulder, so that the hardness and the wear resistance are improved, and the roundness precision keeping capability in the life cycle of the roller is ensured; and not only canaccidental consumption caused by grinding roundness precision be reduced, but also the rolling stability and the plate shape precision of strip steel can be improved.

Owner:武汉钢铁有限公司

Wooden violin freeing left hand in holding

Disclosed is a wooden violin freeing the left hand in holding, relating to the technical field of wooden violin head and neck weight change, especially material change. The total length of the wooden violin is controlled, the weights of the head and the neck are reduced (by changing the material), and the weight difference between the head and the neck is expanded, wherein the key is reducing the weights of the head and the neck (by changing the material). Compared with the existing wooden violin, a wooden violin produced or manufactured according to the invention frees the left hand in holding.

Owner:李德灿

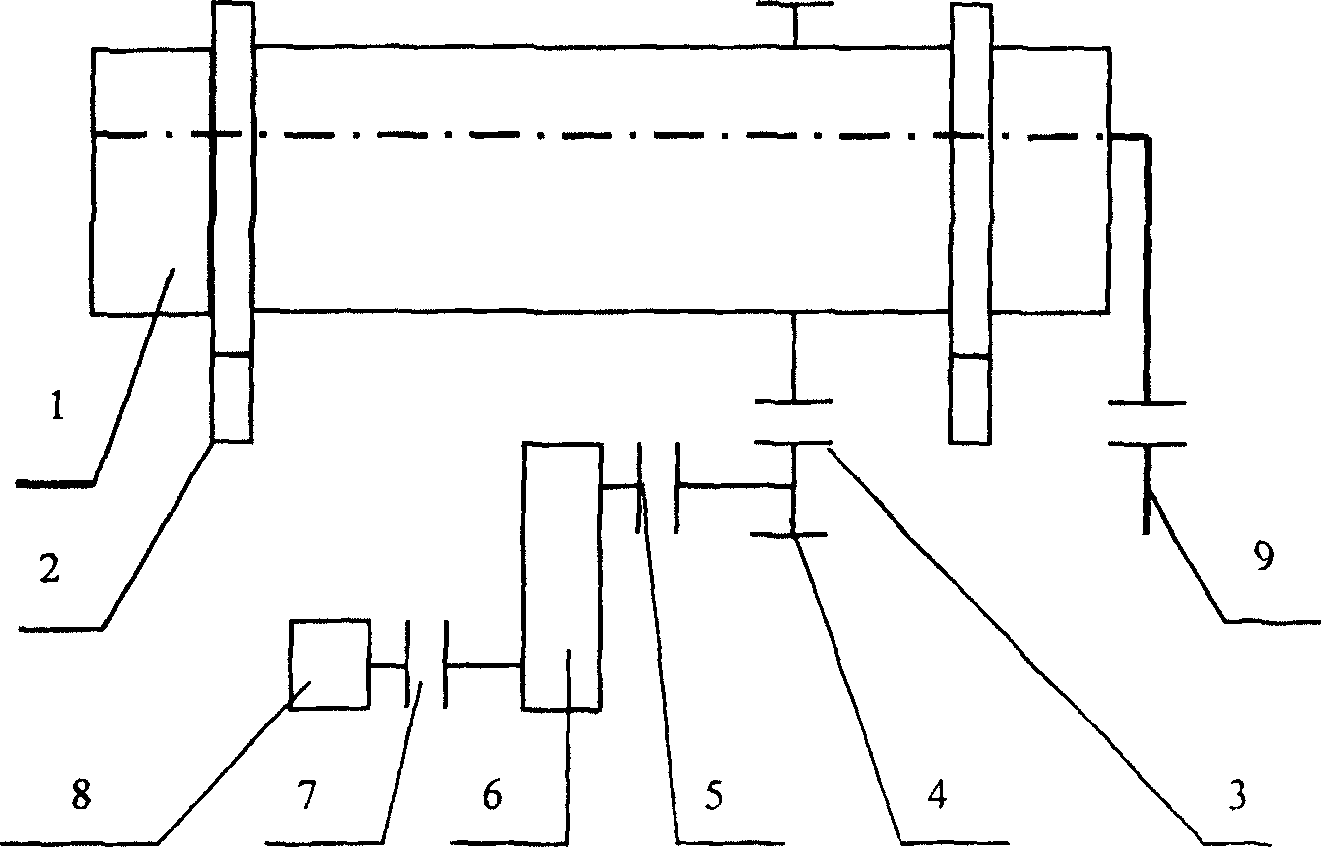

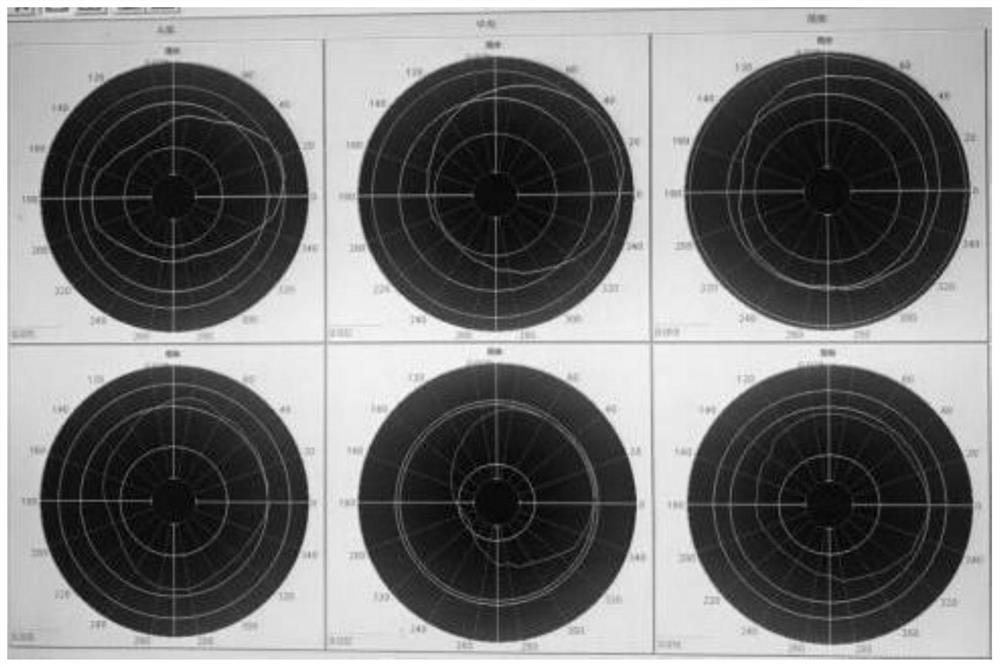

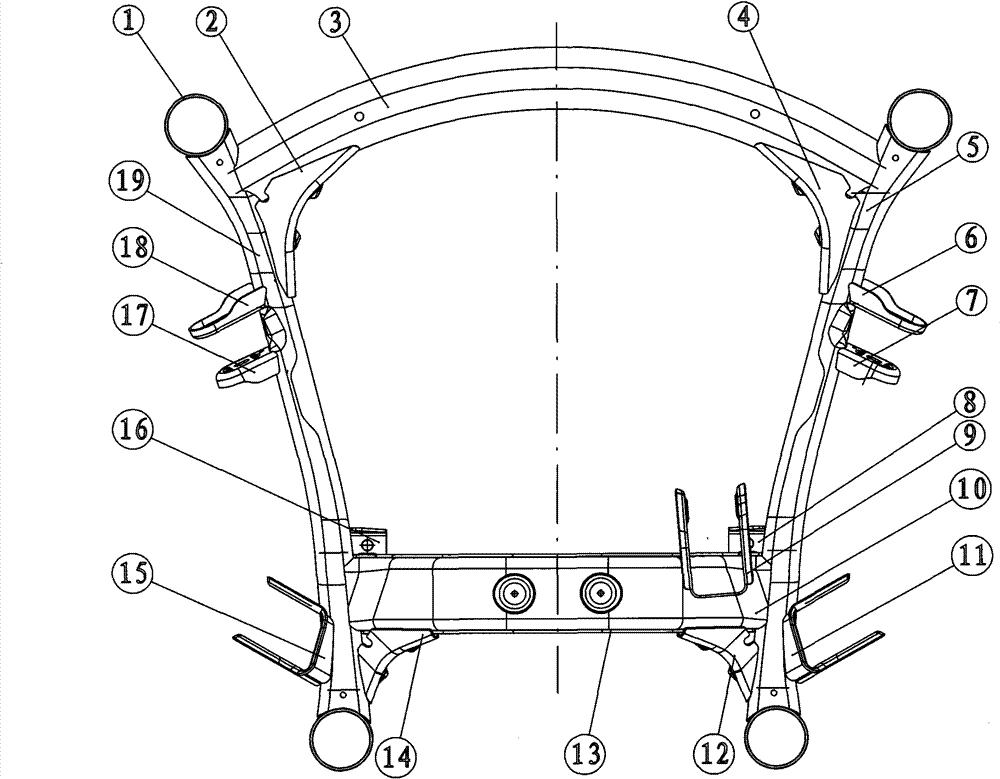

Internal high-pressure formed auxiliary frame and forming method thereof

The invention relates to an internal high-pressure formed auxiliary frame and a forming method thereof. The auxiliary frame has a groined main structure and is formed by welding two longitudinal beams (5 and 19), a front cross beam (3) and a back cross beam. The longitudinal beams (5 and 19) have an internal high-pressure formed cast structure, wherein the cross section thereof is of an irregular shape with a small middle part and two big ends. The internal high-pressure forming method comprises the following steps of: (1) bending a pipeline; (2) flattening a workpiece; (3) hydroforming; (4) scraping edges and processing an auxiliary hole; and (5) washing and treating the surface. The internal high-pressure formed longitudinal beams and the front cross beam can be prevented from being formed by welding upper and lower two stamping parts, so that the materials are saved, the design space is obtained and a light, high-strength, high-precision, energy-saving auxiliary frame device is formed.

Owner:WUXI TONGJIE AUTO DESIGN

Miniaturized antenna compatible with 5G and Wi-Fi/WiMax frequency bands

ActiveCN108682943ARespond to commercial needsEase of conformal designRadiating elements structural formsAntennas earthing switches associationHorizonBand shape

The invention discloses a miniaturized antenna compatible with 5G and Wi-Fi / WiMax frequency bands, comprising a dielectric coating and a metal radiating surface assembled from the bottom to the top; the metal radiating surface comprises a Y-shaped planar monopole and a feeder coplanar waveguide which are mounted in a coplanar manner, a trifurcated feeder and a ribbon-shaped tuning arm which are connected to the Y-shaped planar monopole, a folded metal frame which is connected to the horizon of the feeder coplanar waveguide, and radiating gaps which are respectively loaded on the Y-shaped planar monopole and the feeder coplanar waveguide. The antenna can meet the application requirements of the terminal that is compatible with the 5G frequency band and the existing working frequency band that the 5G commercial enterprise must face, and has the advantages of small size, convenient processing, easy conformal installation, stable radiation performance in a wide frequency band, and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com