Cooling drum for smelting

A cooling cylinder and cylinder technology, applied in the field of smelting equipment, can solve the problems of easy loosening and falling off of the lining plate, heavy workload of lining plate fastening, poor corrosion resistance and wear resistance, etc., to change the traditional structure and layout, ensure The effect of continuous normal production and enhanced corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

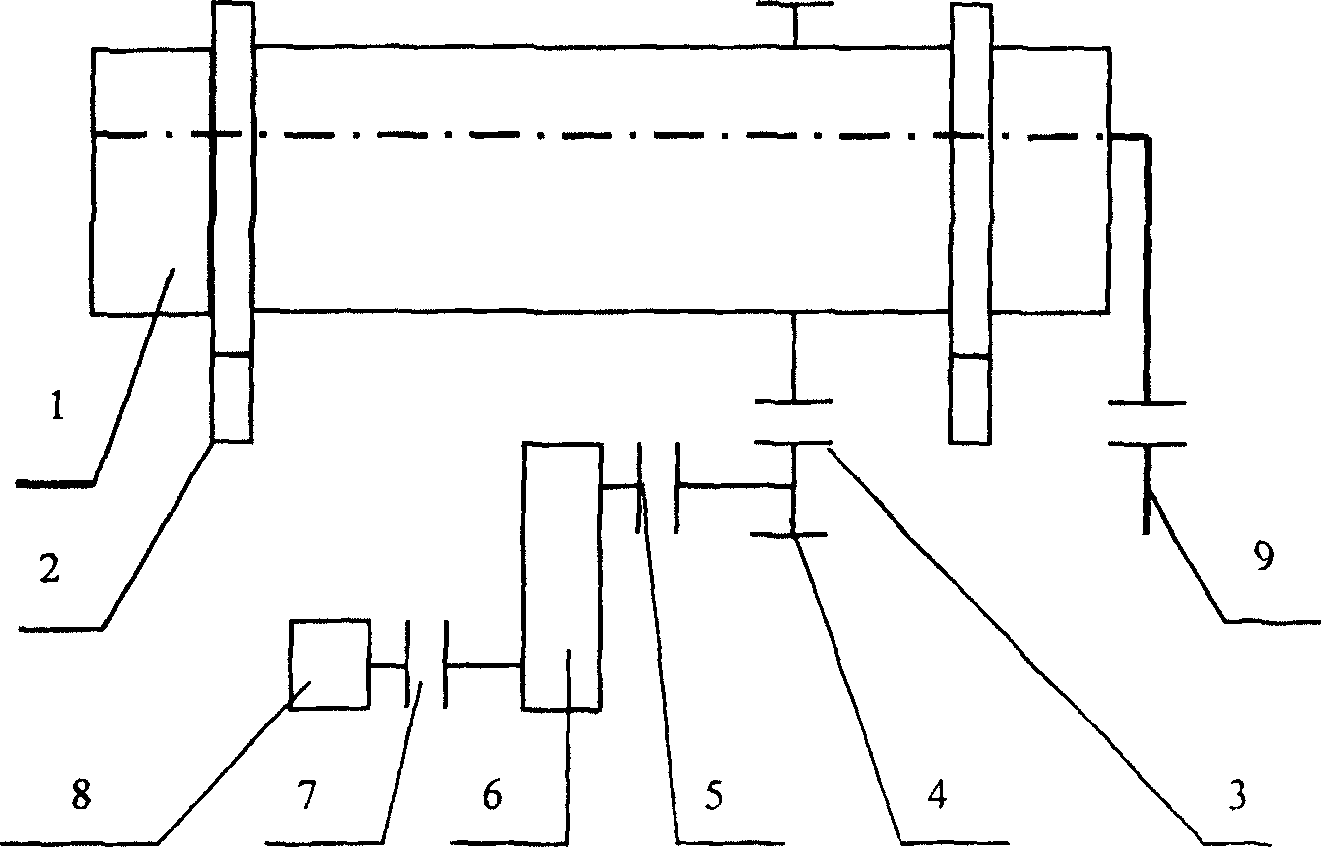

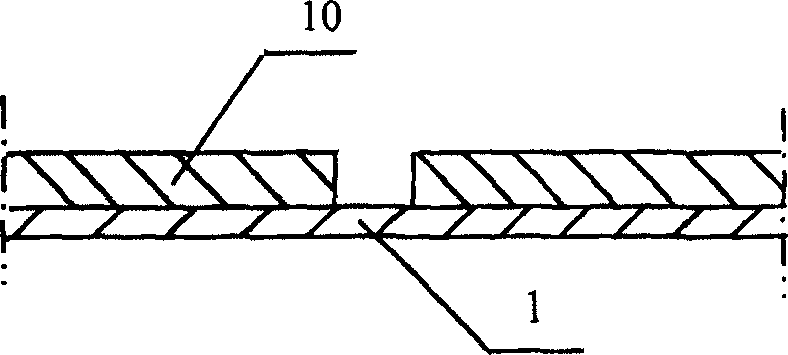

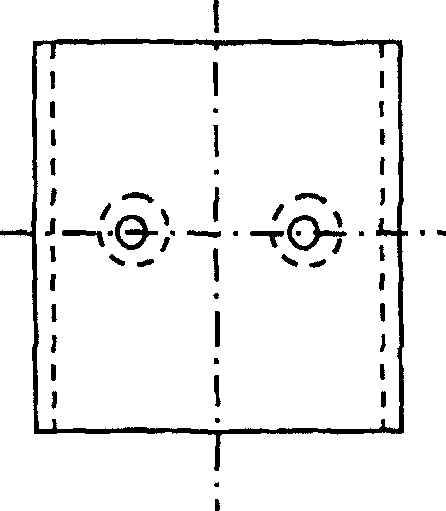

[0029] A cooling cylinder for smelting, consisting of a transmission device, a cylinder device and a cooling device 9, the cylinder device is driven to rotate by the transmission device, and the material in the cylinder body 1 is cooled by the cooling device 9, and the transmission device is composed of a motor 8, Reducer 6, hydraulic coupling 7, supporting wheel 2 and pinion 4, cylinder large gear 3 and gear coupling 5, motor power 45kw, cooling device 9 consists of cooling water pipes and nozzles extending into cylinder 1 and a manual adjustment valve placed outside the cylinder 1. The cylinder 1 is a cylinder with openings at both ends with a length of 9 meters. The cylinder 1 is composed of the front section 1-1 of the cylinder, the middle section 1-2 of the cylinder, and the rear Sections 1-3 are welded. The front section 1-1 of the cylinder is 1.5 meters long and the material is Q235. The middle section 1-2 of the cylinder is 6 meters long, which is 2 / 3 of the total lengt...

Embodiment 2

[0031] A cooling cylinder for smelting, consisting of a transmission device, a cylinder device and a cooling device 9, the cylinder device is driven to rotate by the transmission device, and the material in the cylinder body 1 is cooled by the cooling device 9, and the transmission device is composed of a motor 8, Reducer 6, hydraulic coupling 7, supporting wheel 2 and pinion 4, cylinder large gear 3 and gear coupling 5, motor power 45kw, cooling device 9 consists of cooling water pipes and nozzles extending into cylinder 1 and a manual adjustment valve placed outside the cylinder 1. The cylinder 1 is a cylinder with openings at both ends with a length of 12 meters. The cylinder 1 consists of a front section 1-1, a middle section 1-2, and a rear section. Sections 1-3 are welded. The front section 1-1 of the cylinder is 1.5 meters long and the material is Q235. The middle section 1-2 of the cylinder is 9 meters long, which is 3 / 4 of the total length of the cylinder 1. The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com