Patents

Literature

54results about How to "Improve corrosion resistance and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing anti-corrosion wear-resisting sintered Nd-Fe-B magnets

InactiveCN103996525AImprove corrosion resistance and wear resistanceImprove scratch resistanceInductances/transformers/magnets manufactureMagnetic materialsCorrosion resistantElectrophoreses

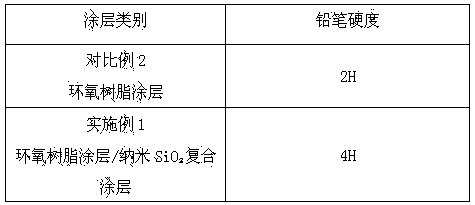

The invention discloses a method for preparing anti-corrosion wear-resisting sintered Nd-Fe-B magnets. The method includes the following steps that first, sintered Nd-Fe-B magnet blanks are placed in an oil removing solution so that oil on the surfaces of the sintered Nd-Fe-B magnet blanks can be removed, and sand blasting and ultrasonic cleaning are performed on the sintered Nd-Fe-B magnet blanks; second, phosphating is performed on the sintered Nd-Fe-B magnet blanks; third, the products subjected to phosphating and bottoming are immersed into an electrophoresis solution to be subjected to cathode electrophoresis; fourth, primary water washing, spraying and secondary water washing are performed sequentially, and dehydration is performed; fifth, softening braking, curing baking and cooling are sequentially performed. Through the method for preparing the novel sintered Nd-Fe-B magnets, a surface cathode electrophoresis epoxy resin / nano-SiO2 composite coating subjected to phosphating and bottoming is prepared. The corrosion resistance and the wear resistance of the composite coating are greatly improved compared with a traditional epoxy resin coating, and the scratch resistance of the coating can also be correspondingly enhanced.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

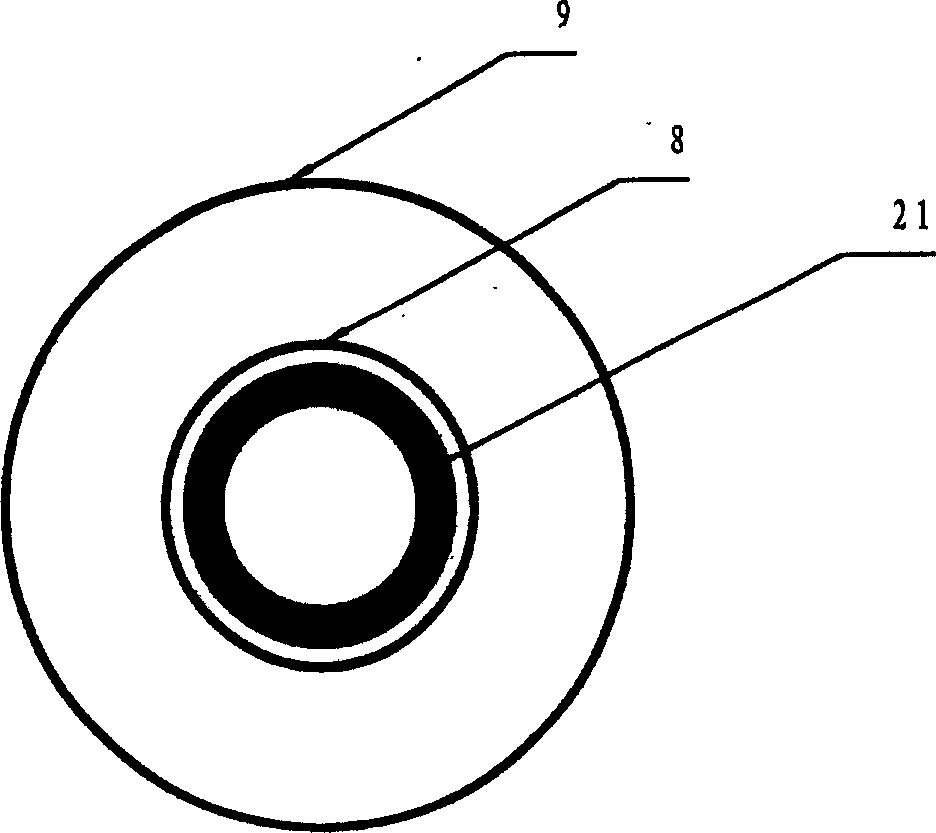

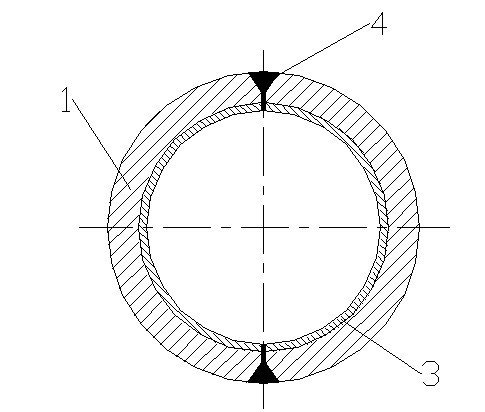

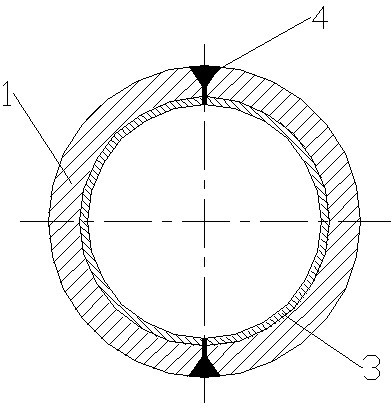

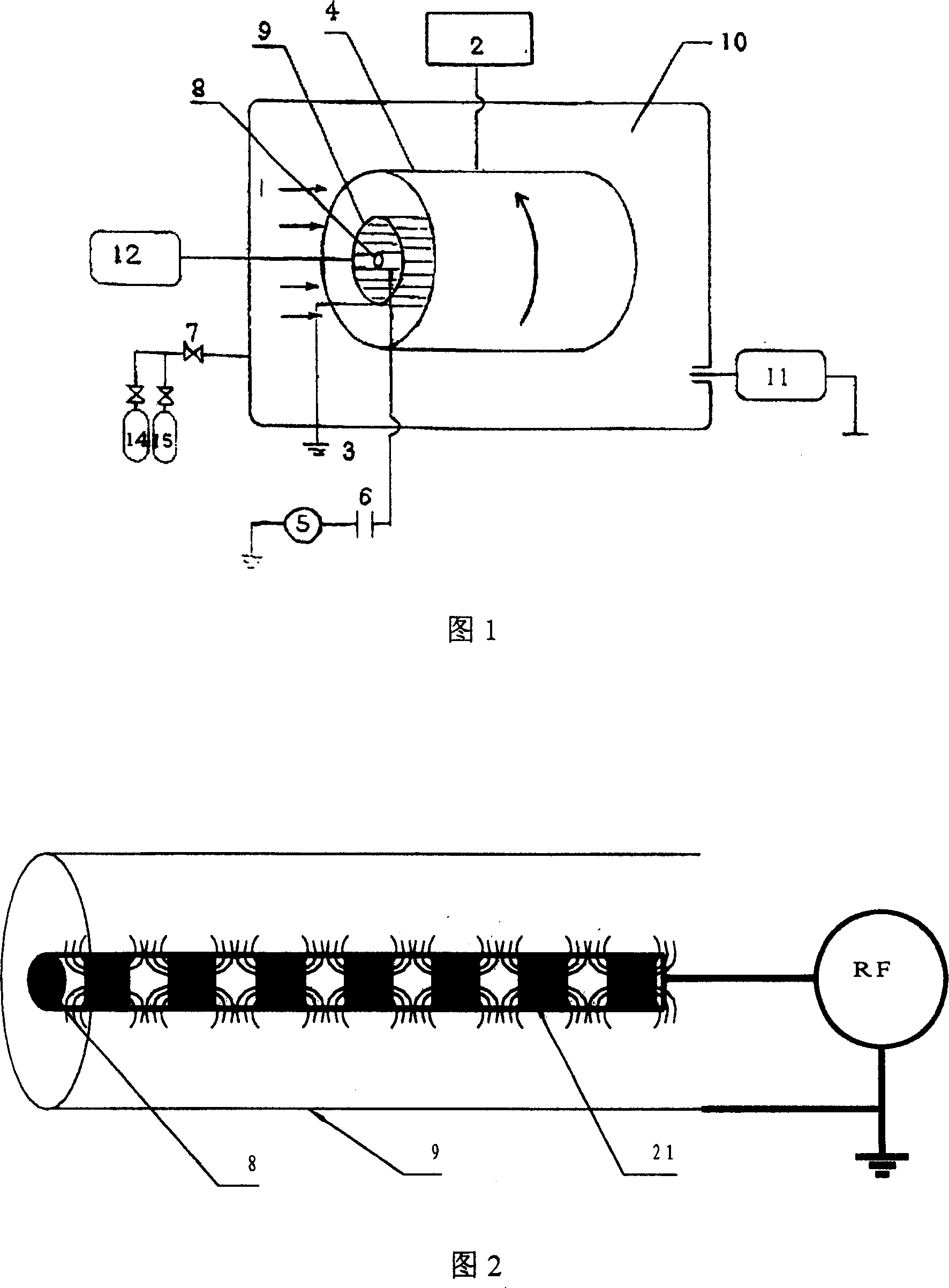

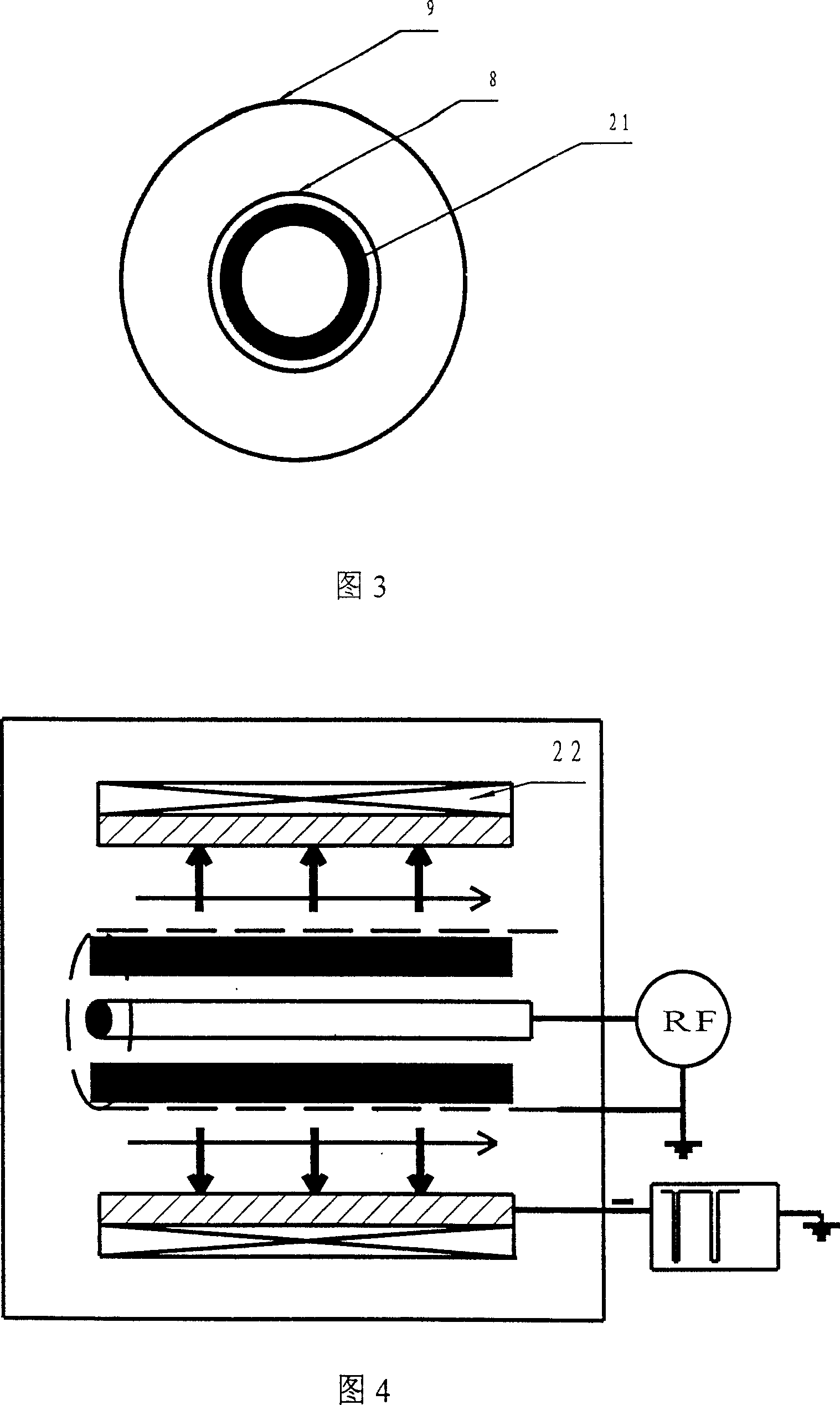

Apparatus for inner surface modification by plasma source ion implantation

InactiveCN1635177AImprove Surface Machining EfficiencyIncrease gas ionization rateVacuum evaporation coatingSputtering coatingPlasma diffusionType distribution

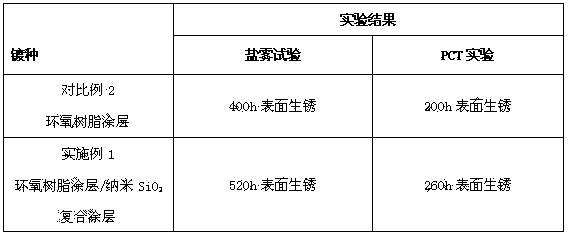

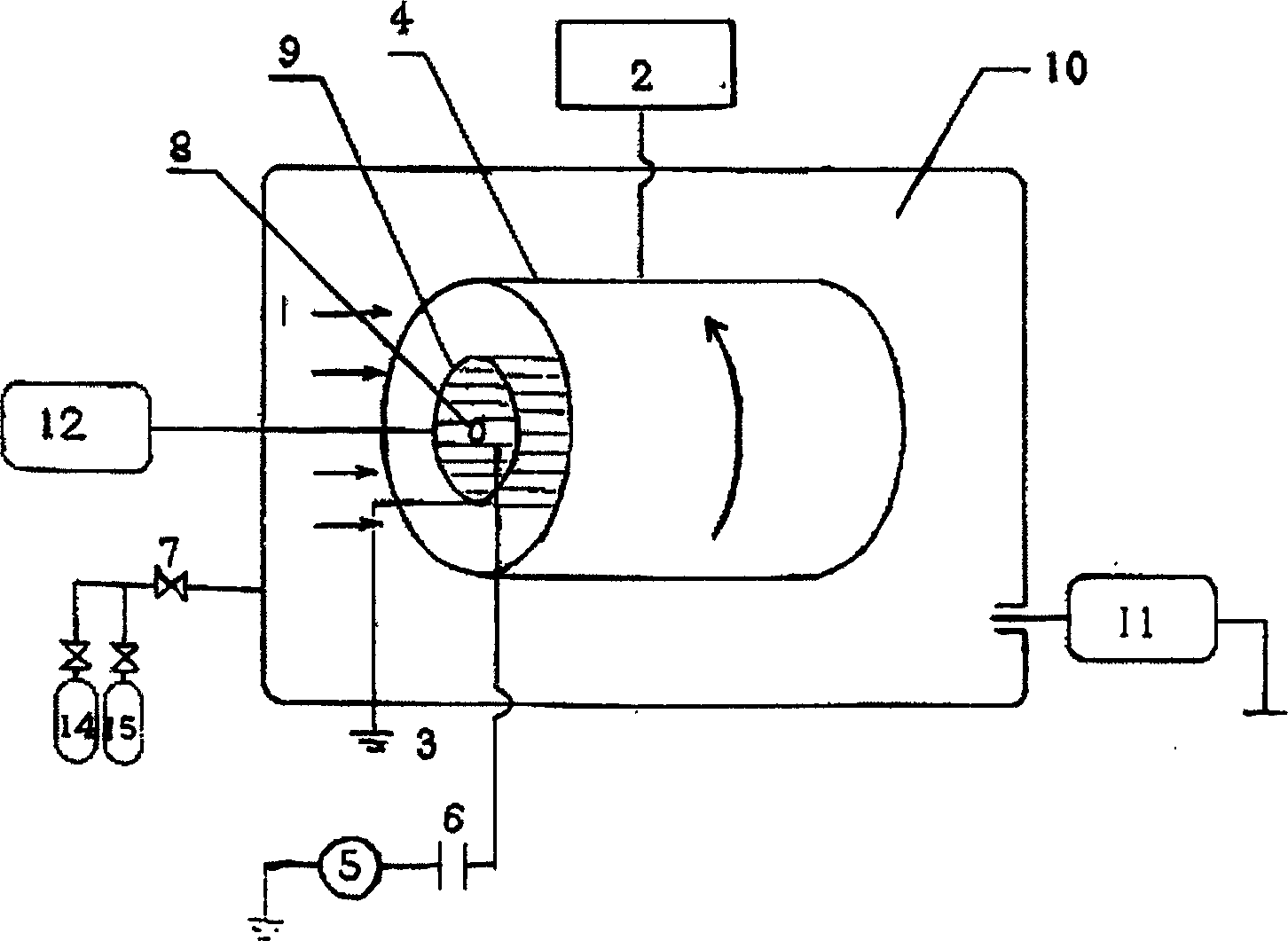

The invention relates to a device for inner surface modification by injecting plasma ion source, wherein: setting a tubular work-piece into a processing chamber, laying a columnar electrode and a tubular electrode allowing plasma diffusion in the tubular work-piece from inside to out side coaxially_ contacting the two electrodes with the radio frequency power supply, connecting a negative high tension supply between the tubular electrode and the tubular work-piece, also including a driving device capable of making relative rotation between tubular work-piece and tubular electrode; the tubular electrode is made up of electrode wires on the outer surface of tubular support, the electrode wires are in circumferential uniform distribution or screw-type distribution; the columnar electrode is a hollow tube with magnetic-irons in it; the tubular electrode is an interconnected hollow metal tube. the magnetic-irons are ring, and axially uniformly distributed with homopolarity opposition. The invention intensifies the sputtering of plasma to center electrode material by setting magnetic-irons in the tubular electrode, and improves the processing efficiency of tubular work-piece inner surface.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

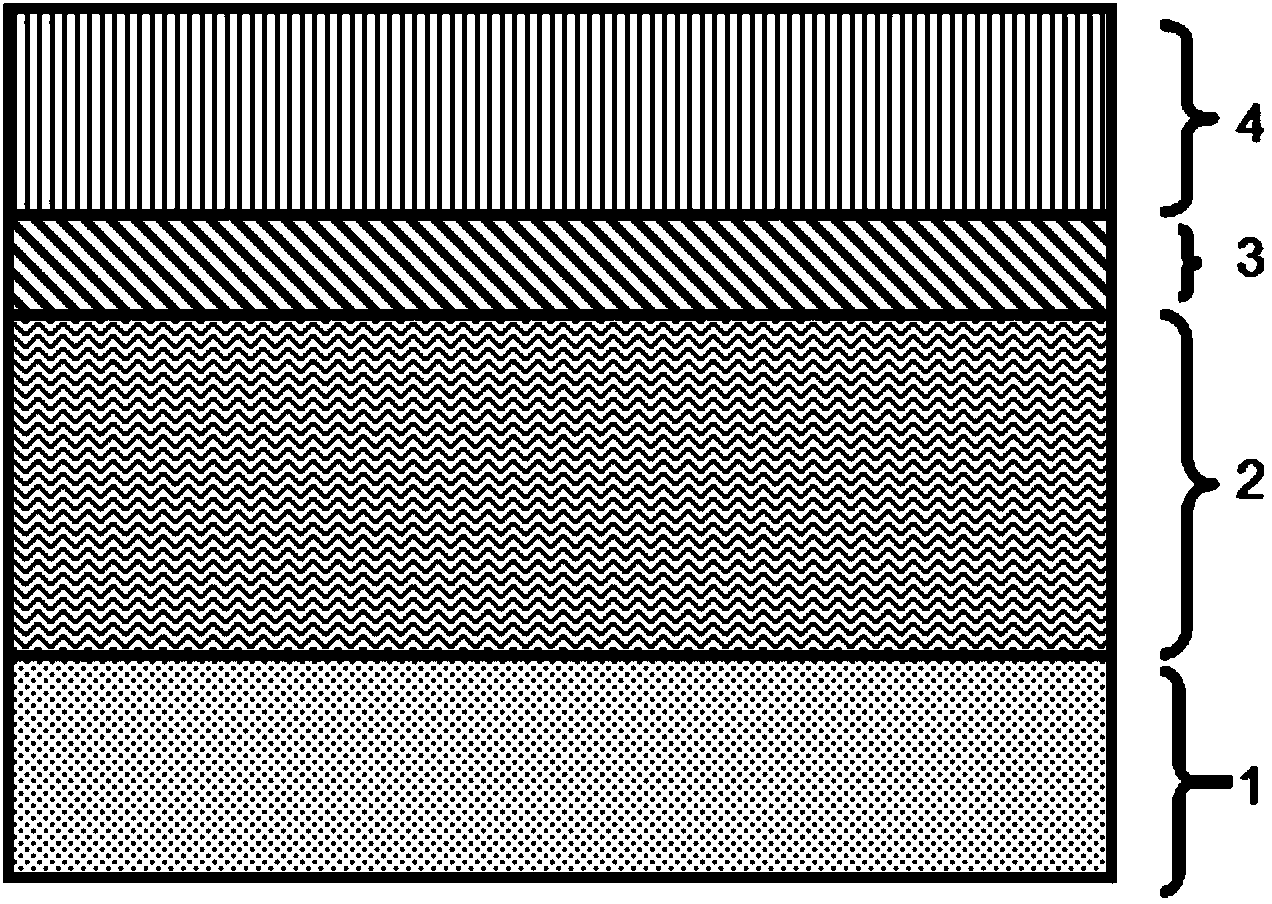

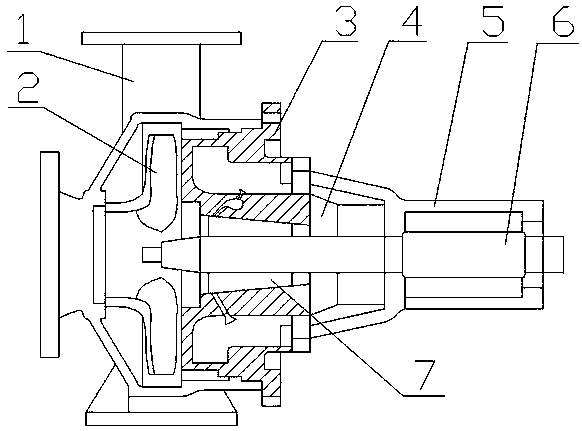

Medicinal titanium and titanium alloy surface oxidation-carbon plated-diamond-like composite film and manufacturing method thereof

ActiveCN104138616ACompact distributionGuaranteed total thicknessVacuum evaporation coatingSputtering coatingComposite filmFilm base

The invention discloses a medicinal titanium and titanium alloy surface oxidation-carbon plated-diamond-like composite film and a manufacturing method of the medicinal titanium and titanium alloy surface oxidation-carbon plated-diamond-like composite film. According to the composite film, an oxidation layer, a carbon / titanium carbide carbon plated layer and a diamond-like layer are sequentially manufactured on the medicinal titanium and titanium alloy surface. The invention further discloses the manufacturing method of the composite film. Based on in-situ growth, the manufactured composite film is large in film base binding strength and thickness and excellent in comprehensive performance, the technology is simple, the cost performance is high, and production in batches can be achieved.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Cyanide-free high-speed silver plating electroplating solution

The invention relates to the technical field of electrochemical silver plating, in particular to a cyanide-free high-speed silver plating electroplating solution, which solves the problem that the existing silver plating electroplating solution has high toxicity or low productivity and provides a cyanide-free high-speed silver plating electroplating solution. The electroplating solution comprises the following components in mass concentration: 40-60g / L of silver nitrate, 100-300g / L of sodium thiosulfate, 45-85g / L of sodium metabisulfite, 8-22g / L of sodium sulfate, 15-38g / L of boric acid and 0-2.5mg / L of brightener. The invention has low toxicity and high plating speed.

Owner:NINGBO SHUNJIA COMM TECH CO LTD

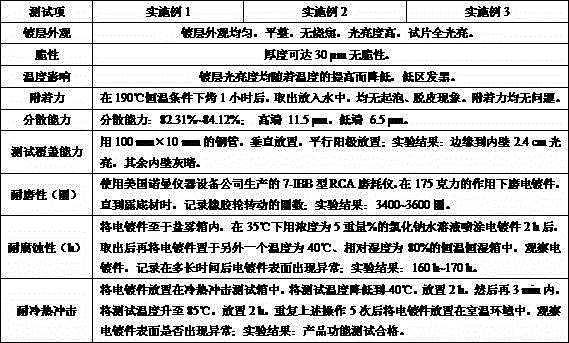

Environment-friendly cyanide-free alkaline galvanizing electroplating liquid and galvanizing technology

The invention relates to the technical field of electroplating, and discloses environment-friendly cyanide-free alkaline galvanizing electroplating liquid and a galvanizing technology. One liter of the cyanide-free alkaline galvanizing electroplating liquid comprises 10 g to 12 g of zinc, 130 g to 145 g of sodium hydroxide, 25 ml to 30 ml of a 51011 regulator, 6 ml to 8 ml of a 51012 preparing beginning agent, 1 ml to 3 ml of a 51015 brightener and 0.1 ml to 0.3 ml of a 51016 wetting agent. The brightener is prepared by polymine, imidazole propoxy condensation compounds, n-heterocyclic derivatives, modified aromatic aldehyde compounds, epoxy chloropropane and water. By means of the environment-friendly cyanide-free alkaline galvanizing electroplating liquid and the galvanizing technology, the brightness of a zinc coating is improved, the thickness can be 30 micrometers, fragility is avoided, and therefore the dispersing capacity and the covering capacity of the electroplating liquid are higher than the dispersing capacity and the covering capacity of traditional alkaline galvanizing brighteners.

Owner:广东比格莱科技有限公司

Process for preparing corrosion resistant metal material through coating tantalum or niobium with PVD (physical vapor deposition) method

InactiveCN103695854AImprove corrosion resistance and wear resistanceExcellent abrasion resistanceVacuum evaporation coatingSputtering coatingNiobiumGas phase

The invention relates to a process for preparing a corrosion resistant metal material through coating tantalum or niobium with a PVD (physical vapor deposition) method. The process is characterized by comprising a step of coating a tantalum or niobium protective layer on the surface of a metal material substrate through a magnetron sputtering way. The method disclosed by the invention improves anticorrosion and wear-proof performances of metal through a coating technology, and a required corrosion resistant coating is coated on surface of stainless steel or other metal surfaces through a physical vapor deposition (PVD) method; the PVD method includes a magnetron sputtering method, a multi-arc ion plating method, electron gun evaporation and the like. The method disclosed by the invention can improve abrasion and corrosion resistance of surface of a plated metal part, so as to prolong service life of metal or a metal container, and simultaneously improve application safety factor.

Owner:NINGXIA ORIENT TANTALUM IND +1

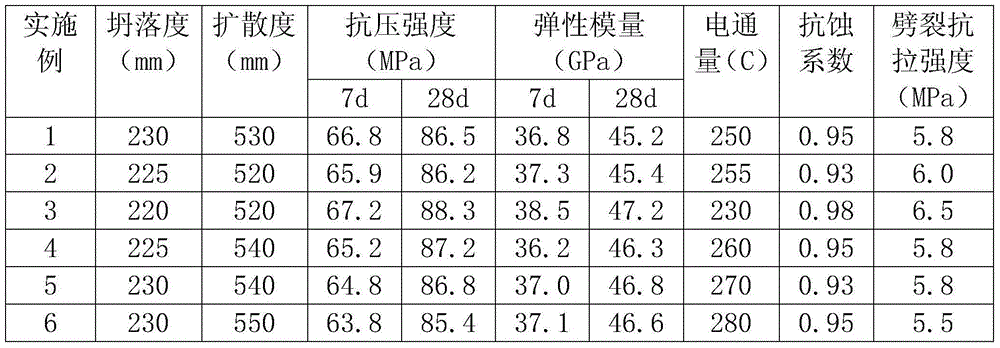

Anti-corrosion concrete

InactiveCN104591675AImprove corrosion resistance and wear resistanceLow costPortland cementPotassium silicate

The invention relates to the technical field of building materials, and particularly relates to anti-corrosion concrete, which comprises the following components in parts by weight: 200-250 parts of portland cement, 60-80 parts of a polymer emulsion, 10-30 parts of a film-forming additive, 5-10 parts of a dispersant, 20-40 parts of mineral powder, 8-15 parts of a rust inhibitor, 6-8 parts of an air entraining and water reducing agent, 100-150 parts of water, 5-10 parts of sodium silicate, 1.5-3.5 parts of potassium silicate, 10-15 parts of wear-resistant corundum filler particles, 3-8 parts of an antifreeze and 2-5 parts of an accelerator. The anti-corrosion has the beneficial effects that the wear-resistant corundum filler particles as a wear-resistant component is matched with the mineral powder and the antifreeze, so that the wear resistance and corrosion resistance are greatly enhanced, the cost is low, the use and maintenance are also very convenient, the service life of a building can be effectively prolonged, and the maintenance cost is greatly reduced.

Owner:徐州逸刻新型墙体材料有限公司

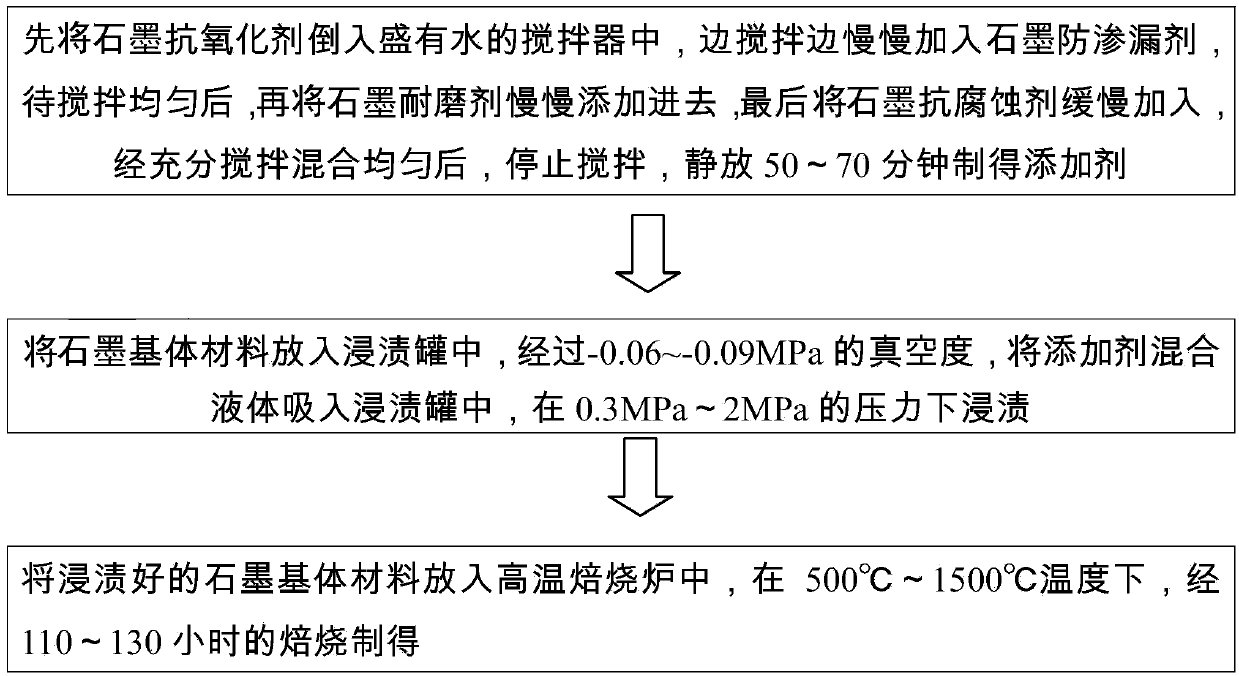

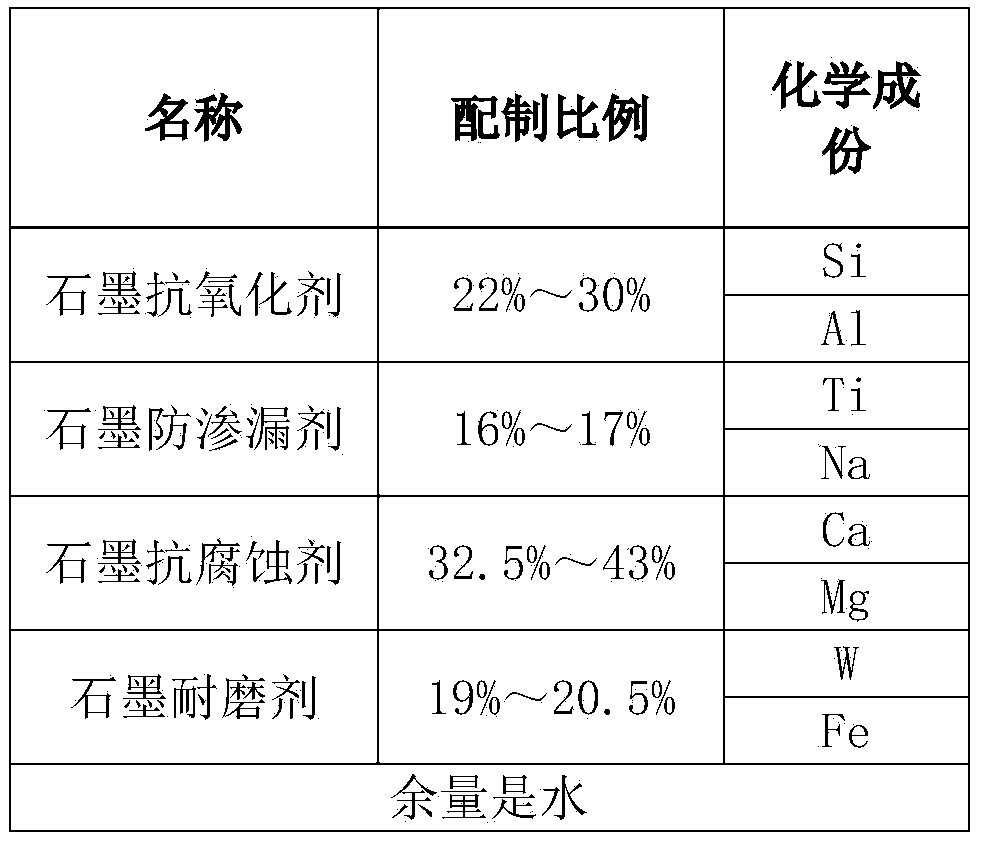

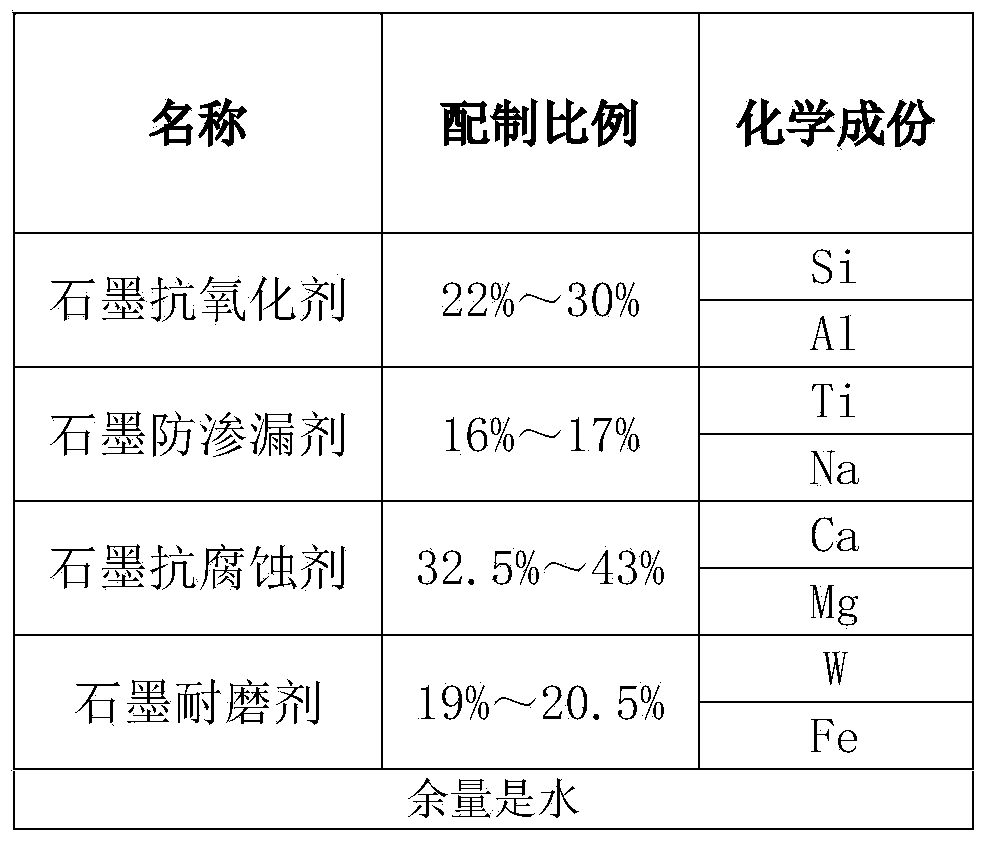

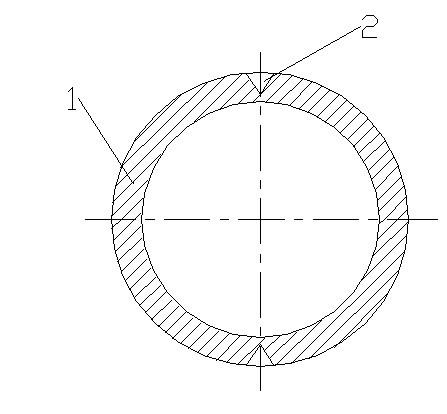

Special graphite carbon sleeved roller for corrosion-resistant and abrasion-resistant continuous annealing line and manufacturing process thereof

ActiveCN104177097AImprove product qualityImprove corrosion resistance and wear resistanceGraphite carbonStrip steel

The invention provides a special graphite carbon sleeved roller for a corrosion-resistant and abrasion-resistant continuous annealing line and a manufacturing process thereof, and relates to the technical field of non-oxidation continuous annealing production of strip steel, and the special graphite carbon sleeved roller is designed for solving the technical problems that an existing furnace roller is poor in corrosion resistance and abrasion resistance and high in cost. The special graphite carbon sleeved roller for the corrosion-resistant and abrasion-resistant continuous annealing line comprises the following components in percentage by mass: 80-90% of C, 1-3% of Al, 1.2-3.0% of Si, 0.4-1.3% of Ti, 2.5-3.5% of Mg, 1.8-3% of Ca, 0.9-1.8% of Fe, 1.2-2.1% of Na and 1-2.3% of W; and the manufacturing process of the special graphite carbon sleeved roller comprises the following steps: additive preparing, impregnation and roasting. The embodiments of the invention are used for improving the corrosion resistance and abrasion resistance of furnace rollers.

Owner:安阳市佰士特异型石墨制品有限责任公司

Manufacturing process for corrosion-resistant and wear-resistant steel pipe

InactiveCN102133699AImprove corrosion resistance and wear resistanceMeet the use requirementsPipe protection against damage/wearSteel tubeCorrosion resistant

The invention discloses a manufacturing process for a corrosion-resistant and wear-resistant steel pipe. The process comprises the following steps of: sectioning a steel pipe into two parts; performing spray coating; and welding. Thus, the aim of spray-coating an alloy protection layer on the inner surface of a long steel pipe, small steel pipe or bent steel pipe is fulfilled, the corrosion resistance and the wear resistance of the steel pipe are effectively improved, operating requirements under different working conditions are met, and manufacturing difficulty and production cost of the process are also reduced. The manufacturing process for the corrosion-resistant and wear-resistant steel pipe is simple in design, is easy to realize and has an obvious beneficial effect.

Owner:自贡市巨光硬面材料科技有限公司

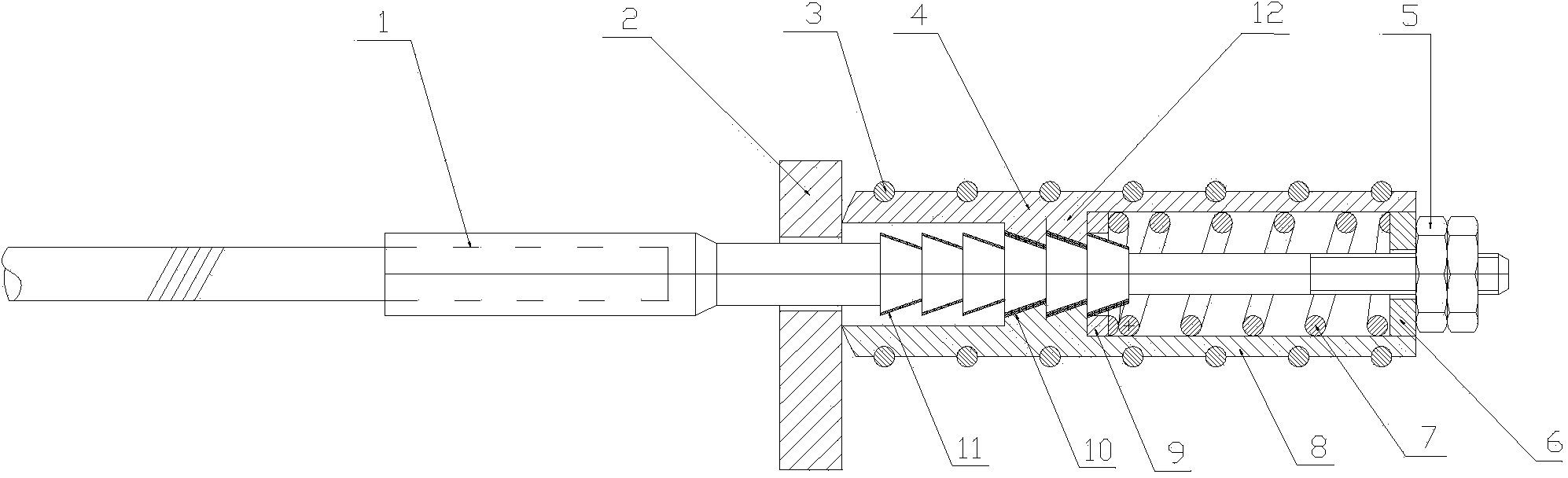

Self-adjusting preload steel wire rope rigging

Owner:山东鲁班机械科技有限公司

Environment-friendly brightener for non-cyanide alkaline zinc plating and preparation method thereof

The invention relates to the technical field of electroplating additives and discloses environment-friendly brightener for non-cyanide alkaline zinc plating and a preparation method thereof. The brightener is prepared through polymine, IMZE, nitrogen heterocyclic derivatives, modified aromatic aldehyde compounds, epoxy chloropropane and water. According to the environment-friendly brightener for non-cyanide alkaline zinc plating and the preparation method thereof, the brightness of a galvanization layer is improved, the thickness of the galvanization layer can reach 30 micrometers, the galvanization layer is free of frangibility, and the dispersing power and the covering power of plating solution exceed those of traditional alkaline zinc plating brightener.

Owner:广东比格莱科技有限公司

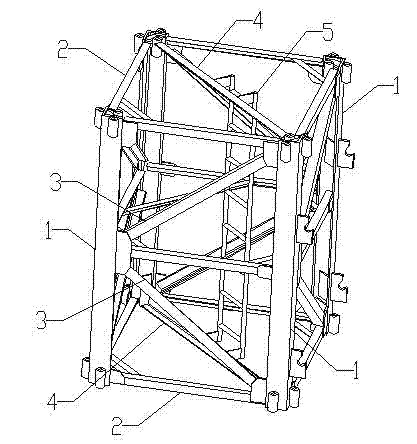

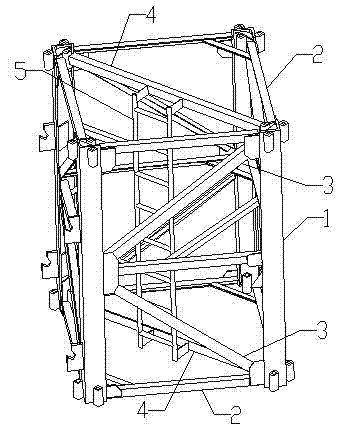

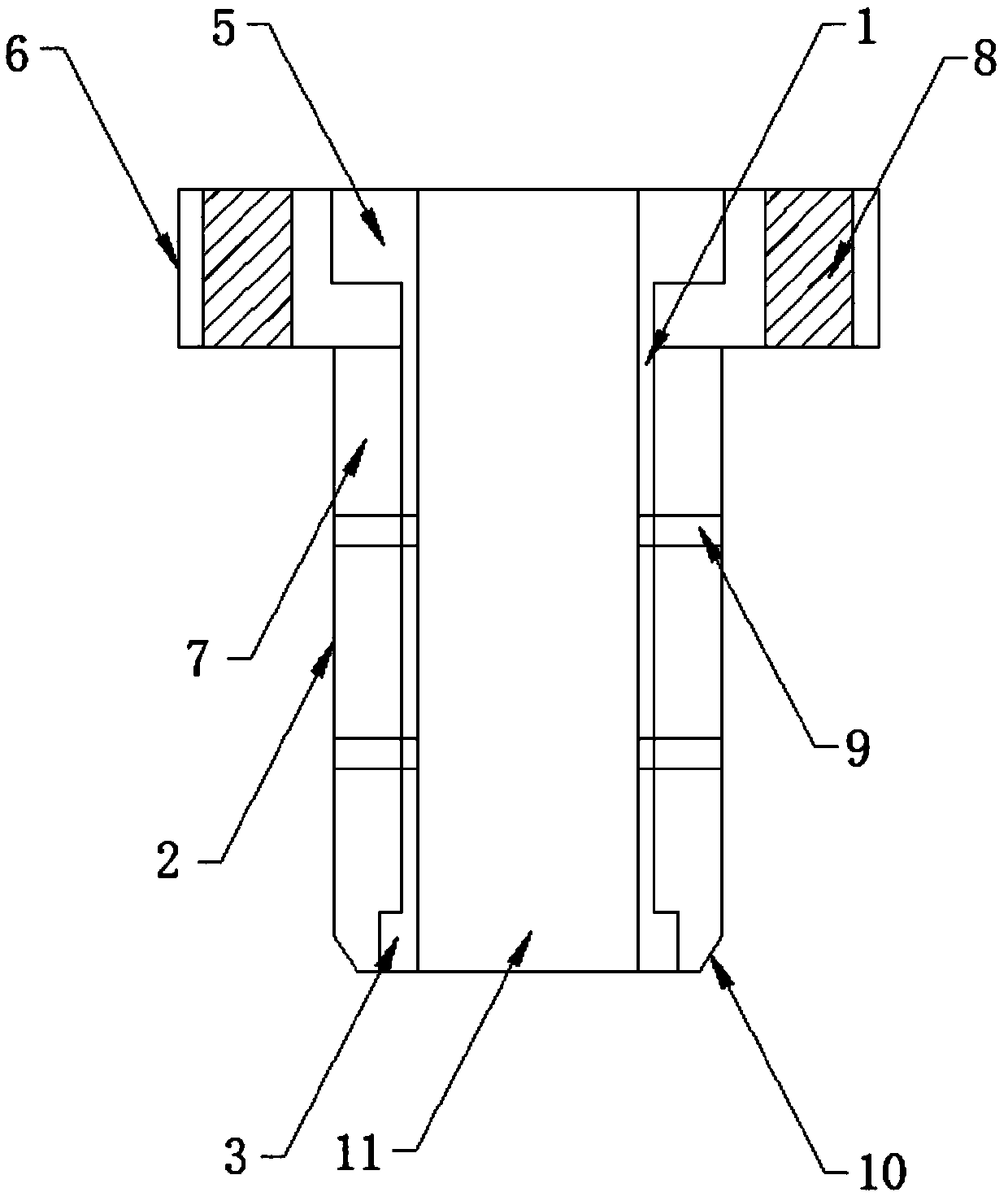

Standard knot with powder plastic surface for tower crane

InactiveCN103588107AStrong adhesionPlastic surface has high corrosion resistance and wear resistanceCranesCorrosionMechanical engineering

The invention discloses a standard knot with a powder plastic surface for a tower crane. The standard knot comprises four vertical main chord members, two connecting square frames, eight first reinforcing ribs, two second reinforcing ribs and a ladder. The upper end and lower end of each main chord member are respectively connected with the connecting square frames; both ends of each first reinforcing rib are connected with the main chord members; the second reinforcing ribs are connected to the square frames; the ladder is connected with the second reinforcing ribs; and the surface of the standard knot is provided with a powder plastic surface. The standard knot with the powder plastic surface for the tower crane disclosed by the invention has the advantages of no requirement on a thinner, no environmental pollution caused by construction and no harm to human body; and the plastic surface does not flow and has strong adhesion, high corrosion resistance and wear resistance and lower cost than a painting process.

Owner:TAI ZHOU TENG DA CONSTR ENG MACHINERY

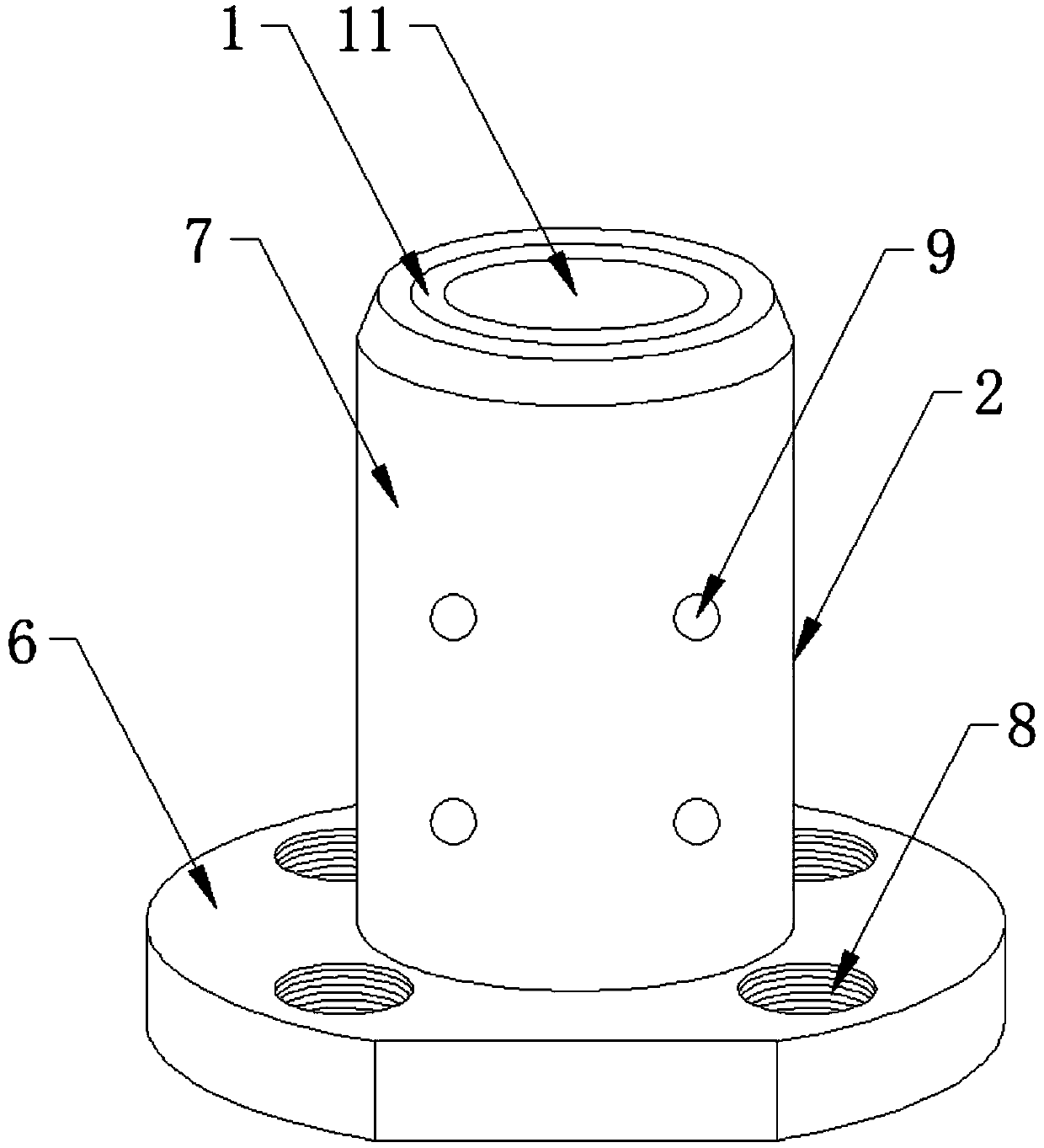

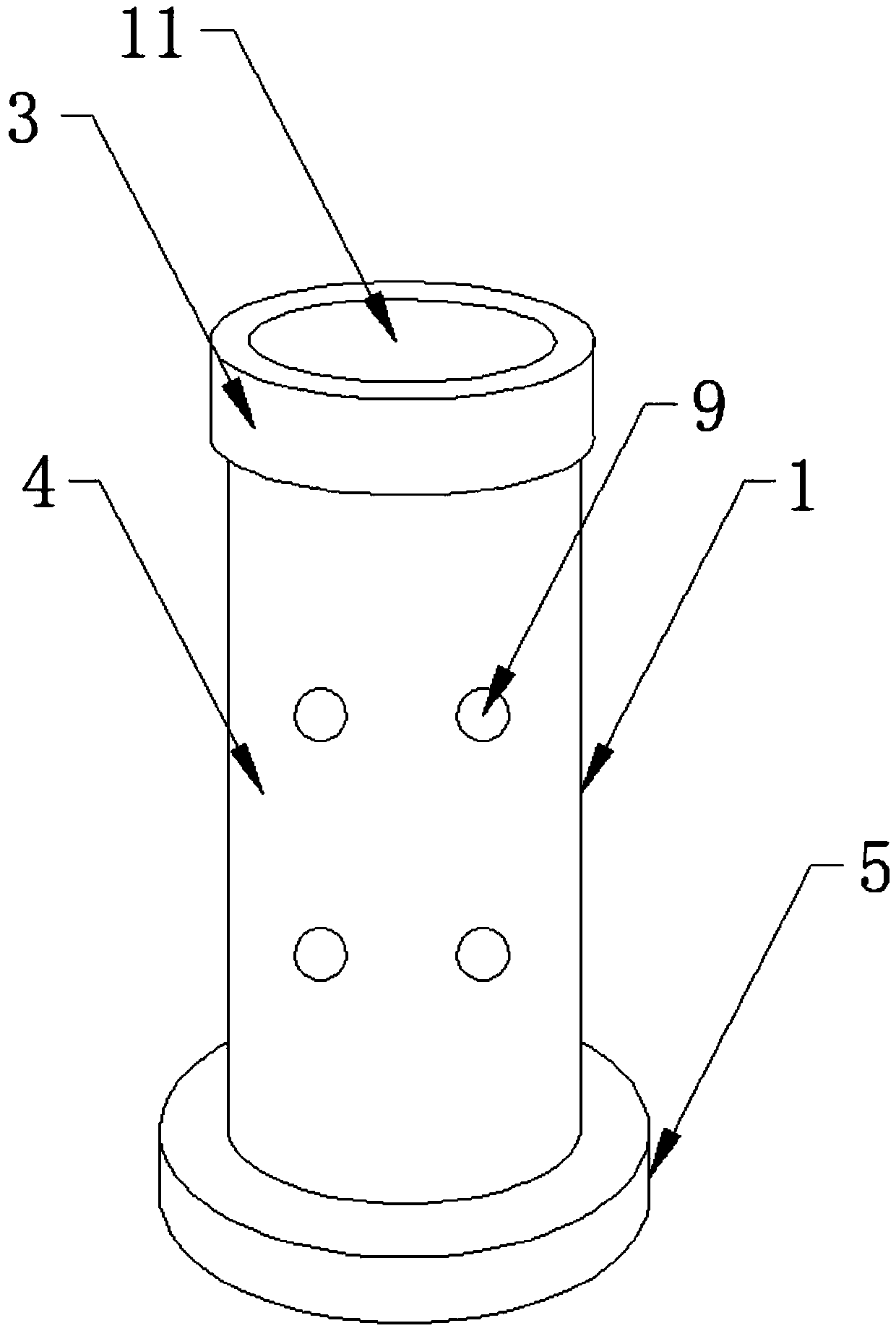

Copper sleeve structure with an integrated sleeve base

InactiveCN109630548AExtended service lifeImprove reliabilityBearing componentsAgricultural engineeringFlange

The invention discloses a copper sleeve structure with an integrated sleeve base. The copper sleeve structure with the integrated sleeve base comprises an inner sleeve and an outer sleeve, the inner sleeve comprises an upper sleeve base, a middle shaft sleeve and a lower sleeve base, and the outer sleeve sleeves the outer side end of the inner sleeve. The outer sleeve comprises a flange base and an outer sleeve body, the flange base is arranged at the bottom end of the outer sleeve body in a surrounding mode, mounting screw holes are formed in the four corner ends of the flange base, the outersleeve body and the flange base are of an integrated structure, and a plurality of oil injection holes are formed in the outer side ends of the outer sleeve body and the middle shaft sleeve. According to the copper sleeve structure with the integrated sleeve base, a copper sleeve is divided into the inner sleeve structure and the outer sleeve structure, the inner sleeve is prepared from copper alloy, the outer sleeve is prepared from stainless steel materials, and the production cost is reduced; an existing pure copper sleeve can be replaced, and economy and practicability are achieved; compared with the existing pure copper sleeve, the requirements of abrasion resistance and various properties are met, the corrosion resistance and abrasion resistance performance is improved, copper raw materials are saved; and the copper sleeve and the flange base are of an integrated structure, installation is convenient, time is shortened, labor is saved, the service life of the copper sleeve is prolonged, and the using reliability of the copper sleeve is greatly improved.

Owner:嘉兴丰盈科技股份有限公司

Aluminum-plastic wood sectional material

InactiveCN107152213AImprove mechanical propertiesExtended service lifeWindow/door framesAnti-corrosive paintsLow-density polyethyleneFiber

The invention provides an aluminum-plastic wood profile, comprising a wood-plastic layer and an aluminum alloy layer; the wood-plastic layer is composed of the following raw materials in parts by weight: 10-30 parts of sarin resin, 5-15 parts of plant fiber powder, wood powder 40-50 parts, 20-40 parts of polyurethane foam powder, 5-15 parts of inorganic filler, 3-10 parts of flame retardant, 1-3 parts of lubricant, 0-2 parts of antioxidant, ethylene-vinyl acetate copolymer 2-7 parts of mixture with ethylene-acrylic acid copolymer, 1-3 parts of cold resistance agent M711, 1-2 parts of light stabilizer GW-540, 5-15 parts of inorganic filler, 3-10 parts of flame retardant, 1 part of lubricant ‑5 parts, 1‑3 parts of colorant, 3‑10 parts of bentonite, 20‑40 parts of low density polyethylene. In the present invention, the wood-plastic layer and the aluminum alloy layer are used in combination, and the advantages and disadvantages of the wood-plastic layer and the aluminum alloy layer are complemented. Weather resistance, wear resistance and other properties, in the natural environment, aluminum-plastic wood profiles have good mechanical properties, are not easy to age, and have a long service life.

Owner:合肥市旺友门窗有限公司

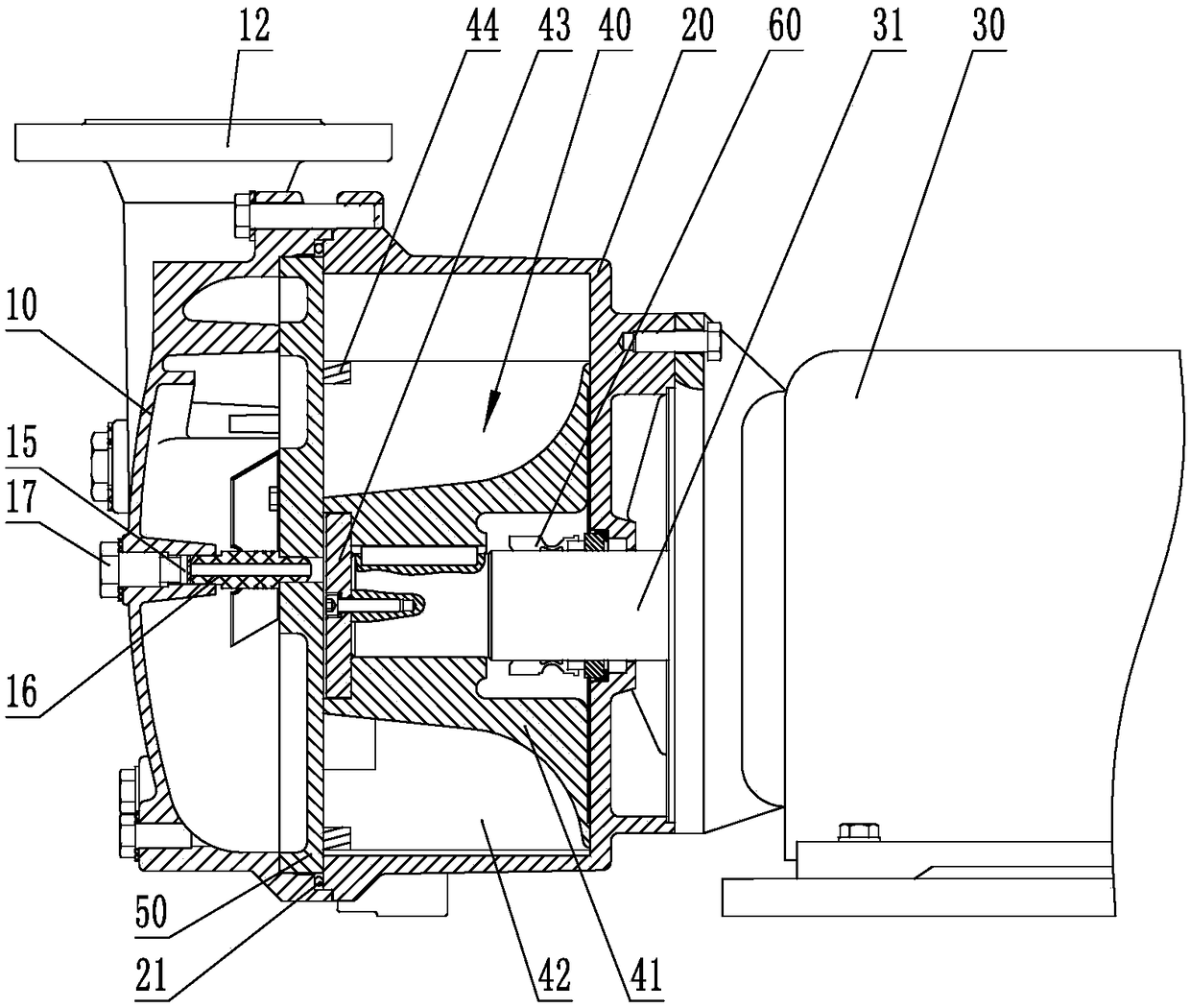

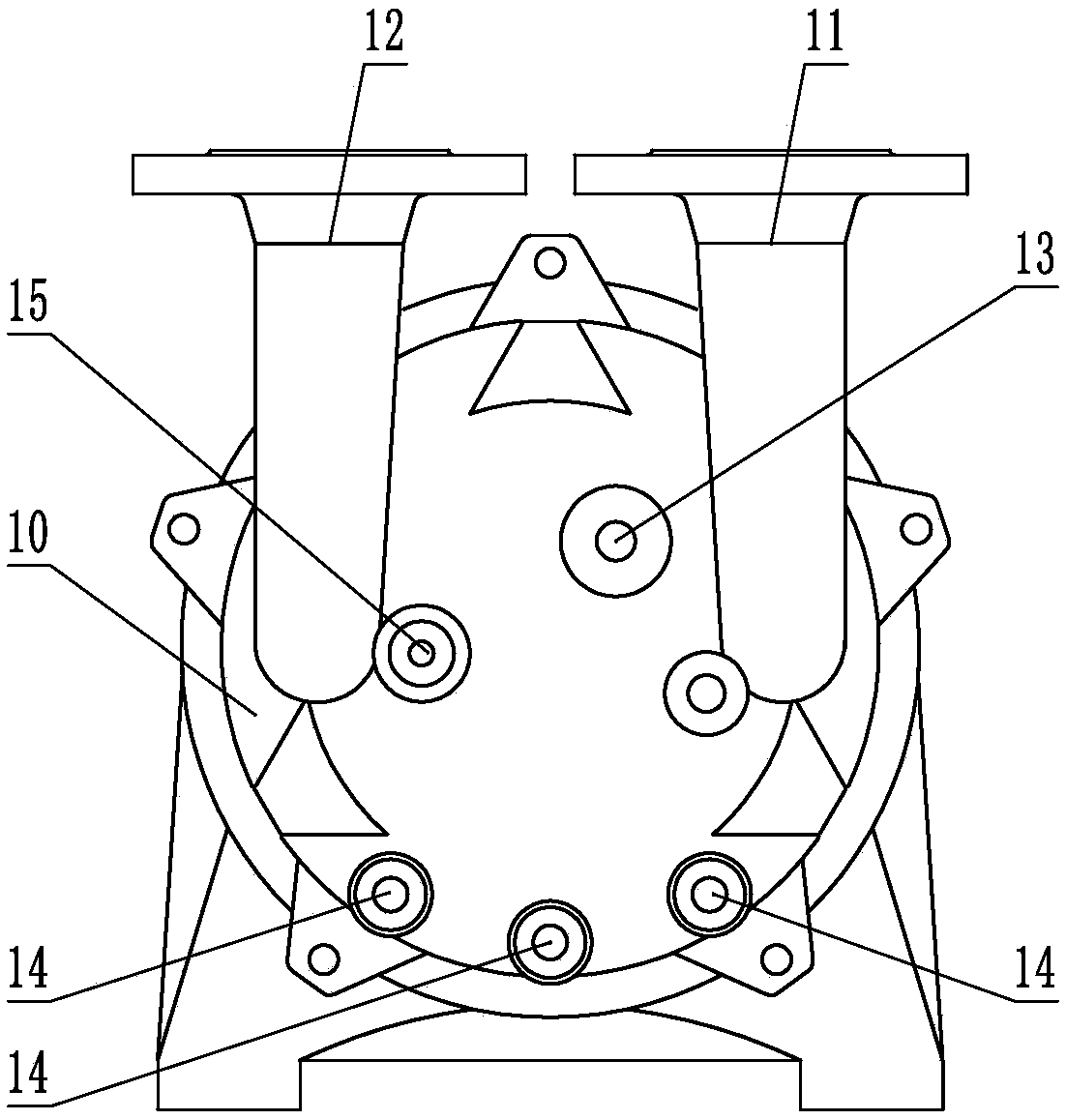

Anti-corrosive anti-wear water-ring vacuum pump

PendingCN108412763AImprove corrosion resistance and wear resistanceIncrease productivityRotary/oscillating piston combinations for elastic fluidsCorrosion preventionImpellerCorrosion

The invention belongs to the technical field of vacuum equipment, in particular to an anti-corrosive anti-wear water-ring vacuum pump which comprises a pump body and a pump cover fixedly connected together, and a motor. A rotary shaft of the motor penetrates through the pump body so as to be inserted into a pump cavity enclosed by the pump body and the pump cover; an impeller arranged on the rotary shaft, a circular disc fixed between the pump body and the pump cover, and a seal suite arranged between the rotary shaft and the pump body are arranged in the pump cavity; the impeller comprises ahub, and multiple blades arranged along a circumferential direction of the hub in a spaced manner; each blade is arranged along an axial direction of the hub; an included angle is arranged between each blade and a radial direction of the hub; a reinforcement hoop is connected between the end parts, close to one side of the circular disk, of each two adjacent blades; the pump body, the pump cover,the impeller and the circular disk are integrally injection-molded by nylon or PPS (Polyphenylene Sulfite) plastics. According to the anti-corrosive anti-wear water-ring vacuum pump, the problems of poor corrosion resistance and wear resistance and poor impeller stability of an existing water-ring vacuum pump are solved, the production efficiency is improved, and the production cost is reduced.

Owner:ZIBO LIAN BANG PUMP IND CO LTD

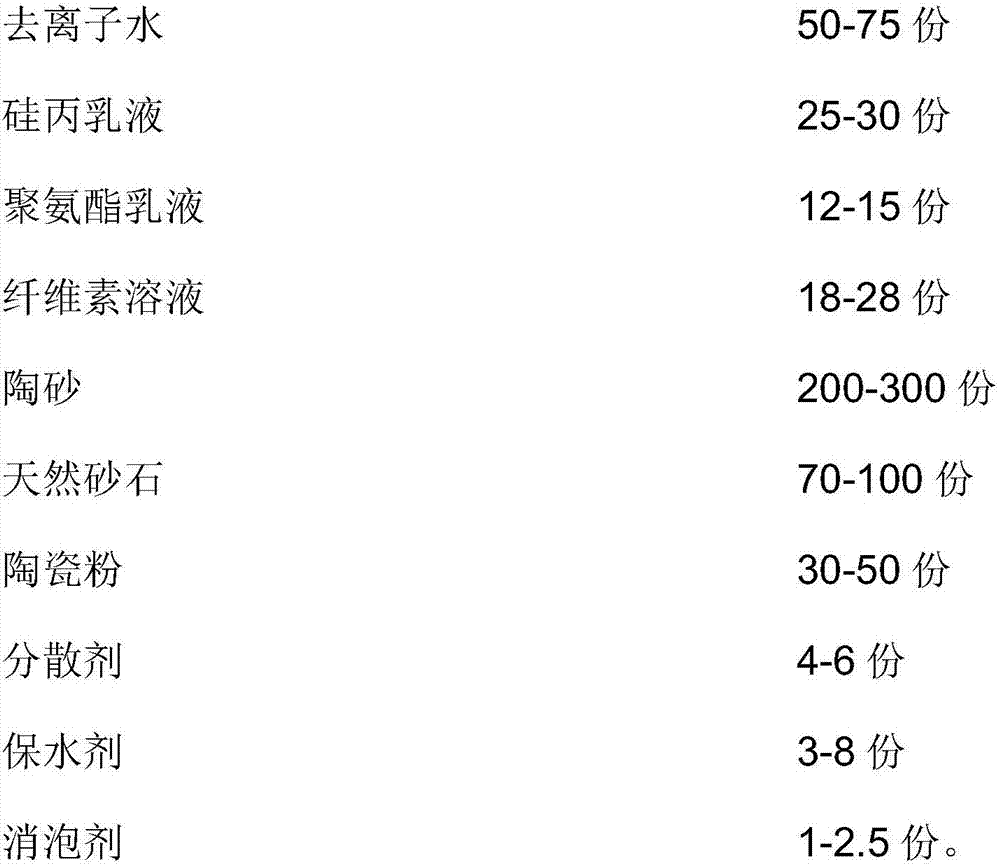

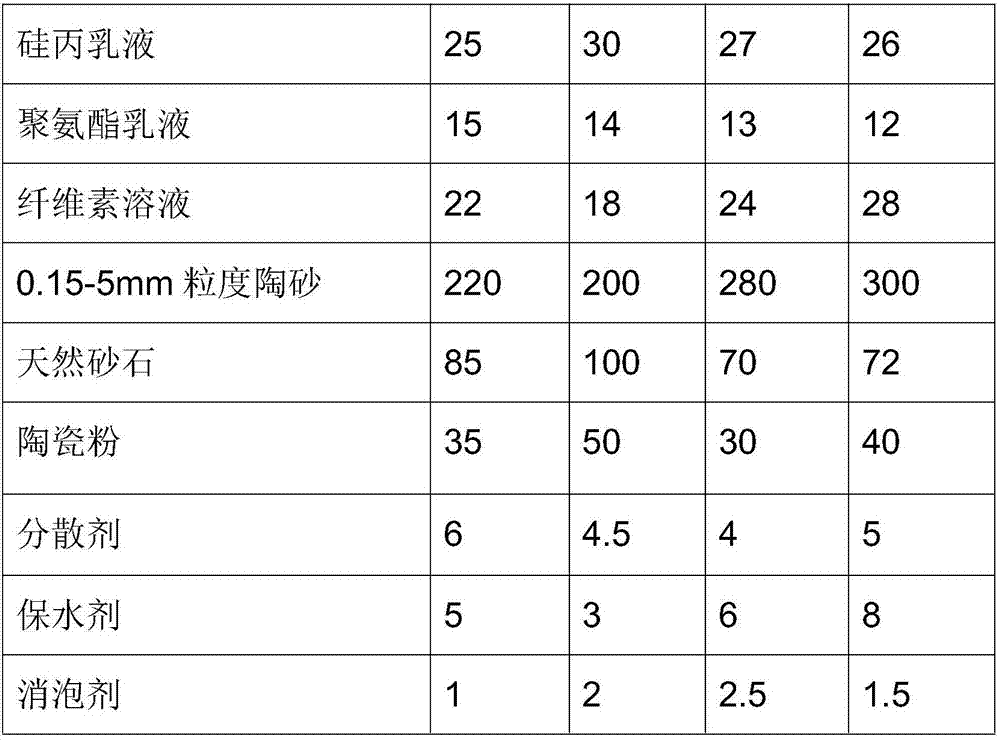

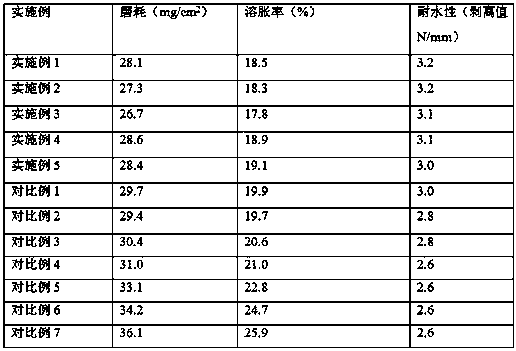

Ceramic-based aggregate texture stone-like coating

The invention discloses a ceramic-based aggregate texture stone-like coating, which contains, by weight, 50-75 parts of deionized water, 25-30 parts of a silicone-acrylic emulsion, 12-15 parts of a polyurethane emulsion, 18-28 parts of a cellulose solution, 200-300 parts of pottery sand, 70-100 parts of natural sandstone, 30-50 parts of ceramic powder, 4-6 parts of a dispersant, 3-8 parts of a water-retaining agent and 1-2.5 parts of an antifoaming agent. With the ceramic matrix as the main material, use of color sand is saved, and a reasonable space structure after formation of a stone-like coating is achieved. By combining the ceramic matrix with color sand and other components, a unique compact structure with pores is formed. The coating of the invention has toughness, wear resistance, crack resistance and tight and nice texture.

Owner:苏州振振好新型建材科技有限公司

Method for deposition modeling of guide roller based on cobalt-chromium-tungsten alloy

ActiveCN106086597AImprove corrosion resistance and wear resistanceAccelerated corrosionFoundry mouldsArc welding apparatusCemented carbideScrap

The invention discloses a method for deposition modeling of a guide roller based on a cobalt-chromium-tungsten alloy. The method comprises the following steps: step I: raw material preparation: taking the following materials by weight: 70 to 75% of Cr12MoV cold work die steel waste, 5 to 9% of 1Cr18Ni9Ti, and the balance of Q235 steel scrap; step II, smelting; step III, casting and rough machining; step IV, preheating treatment; step V, preparation of a deposition modeling material; step VI, deposition modeling; and step VII, nitriding treatment. The guide roller made of Cr12MoV cold work die steel waste, 1Cr18Ni9Ti, and the balance of Q235 steel scrap has structural strength and performance as those of a common hard alloy; and by forming a cladding layer on the surface of the guide wheel in a shielded metal arc welding manner, the guide wheel made of the cobalt-chromium-tungsten alloy is greatly higher in corrosion resistance and wear resistance.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

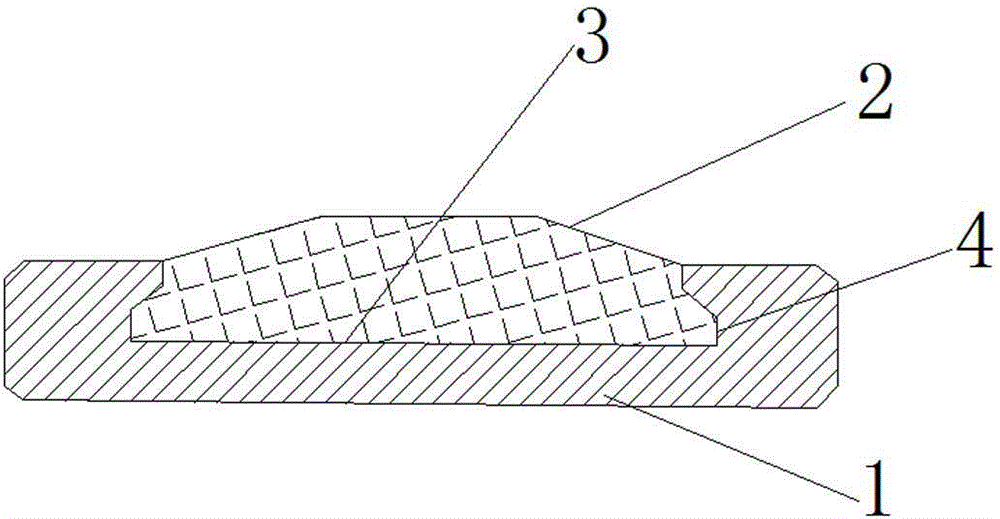

A self-adjusting pretension steel wire rope sling

ActiveCN103818839BAvoid early damageNo pollution in the processWinding mechanismsCoil springArchitectural engineering

The invention relates to a self-adjusting preload steel wire rope rigging. The self-adjusting preload steel wire rope rigging comprises a rigging body, wherein the middle part of the rigging body is provided with a plurality of outer coniform trapezoidal bulges, an upper semicircular body and a lower semicircular body which are buckled together are arranged at the outside of the outer coniform trapezoidal bulges; one end of each of the upper semicircular body and the lower semicircular body is provided with a fixing plate, and each of the other ends of the upper semicircular body and the lower semicircular body is provided with an external spring support; the rigging body penetrates through the fixing plate and the external spring support and then is fixed by a locking nut; the middle parts of the inner sides of the upper semicircular body and the lower semicircular body are provided with projected blocks; a cavity is formed between the projected blocks and the spring support; the rigging body is sleeved with a spiral spring; the upper semicircular body and the lower semicircular body are compressed on the fixing plate under the function of the preload of the spiral spring. The self-adjusting preload steel wire rope rigging provided by the invention automatically adjusts through the spiral spring, which is timely and reliable; and the cumbersome labor is saved, and the performance reduction due as a telescopic boom is not in place due to the untimely adjusting as well as the not smooth operation and the early damage of the parts due to the impact can be avoided; electrostatic spray is performed on the surfaces of the outer coniform trapezoidal bulges and the inner coniform trapezoidal bulges, so that the friction resistance of the automatic adjustment can be reduced.

Owner:山东鲁班机械科技有限公司

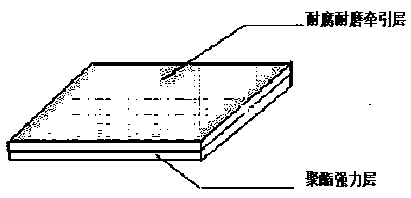

Corrosion-resistant and wear-resistant roll wrapper

ActiveCN109485887AImprove corrosion resistance and wear resistanceExtended service lifeCoatingsPolyesterVulcanization

The invention provides a corrosion-resistant and wear-resistant roll wrapper. The corrosion-resistant and wear-resistant roll wrapper comprises two layers of structures including a traction layer anda polyester strong layer, the traction layer consists of a main body material, a reinforcing system, a vulcanization system, an anti-ageing system and a plasticizer according to the mass ratio of 100:50-70: 8-12: 2-4: 15-25, and the polyester strong layer is activated and modified. On the basis of an existing product, the corrosion resistance and the wear resistance of the traction layer are greatly improved, and the service life is prolonged twice; and the adhesion power between the strong layer and the traction layer of the polyester fabric is improved, functions of vibration reduction andnoise reduction are fulfilled, and the problems that delaminating of a wide-width fabric is easily caused under the condition of rolling by large tension, and thus the wide-width fabric is short in service life are solved.

Owner:济南天齐特种平带有限公司

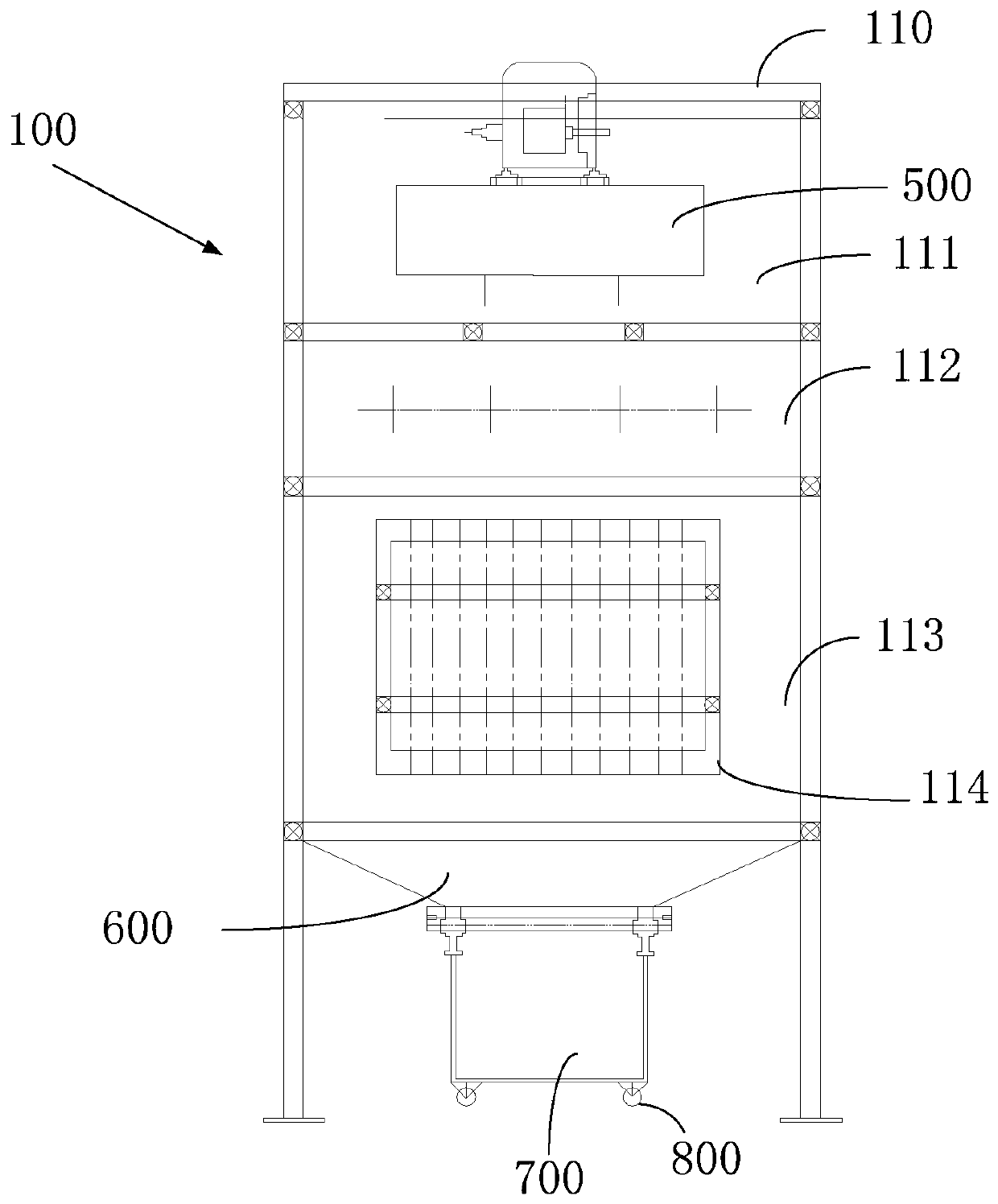

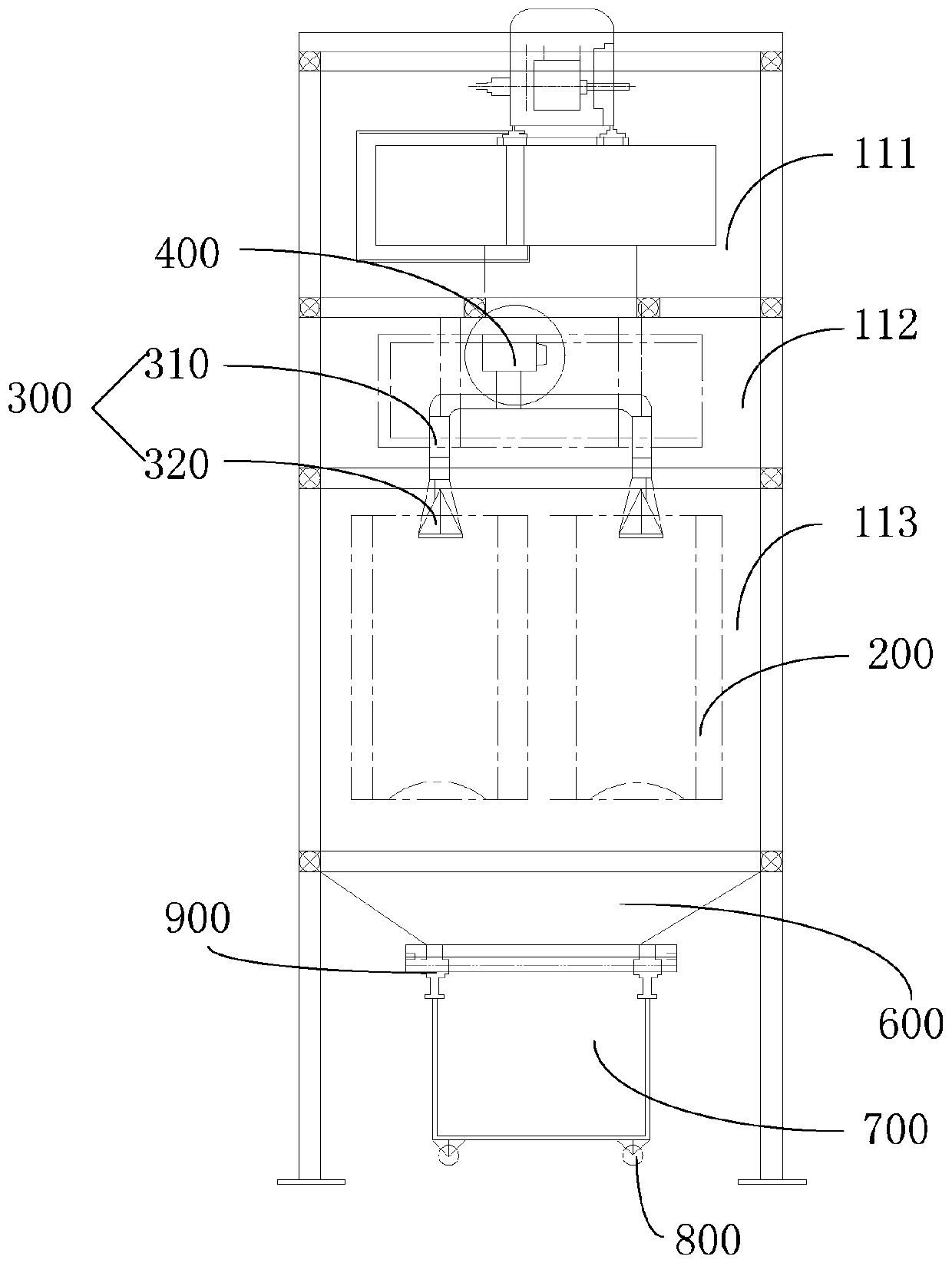

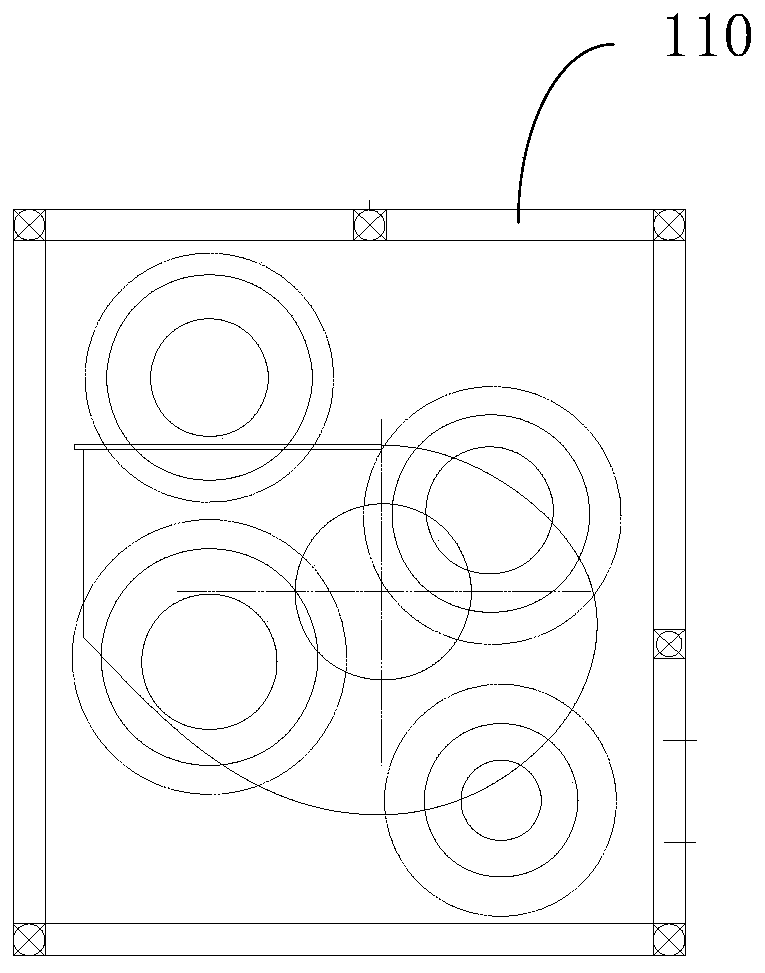

Powder recovery device and powder recovery system of spraying equipment

PendingCN109847965AKeep in circulation for a long timeLong-term purificationLiquid spraying plantsBrickBiochemical engineering

The invention provides a powder recovery device and a powder recovery system of spraying equipment, and relates to the technical field of industrial metallurgy. The powder recovery device comprises arecovery isolation unit, a filter element and a maintenance assembly for ensuring normal work of the filter element; the filter element and the maintenance assembly are arranged in the recovery isolation unit; and the maintenance assembly acts on the filter element so as to ensure the air permeability of the filter element, so that the filter element has good filtering performance. The technical problem in the prior art that dust-containing waste gas generated during electrostatic spraying on a brick body cannot be recycled is solved.

Owner:CHONGQING ROAD TECH CO LTD

Rigid wear-resistant material with high strength

InactiveCN106119683AImprove corrosion resistance and wear resistanceExtended service lifeWear resistantHigh intensity

Owner:蚌埠市光辉金属加工厂

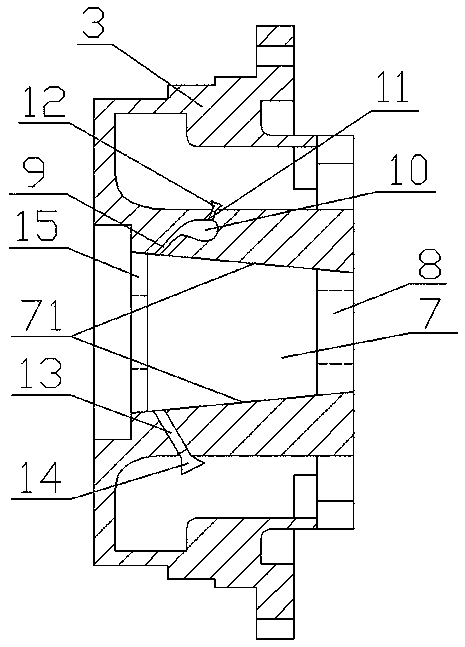

Valve seat of double-clip type butterfly valve for coal cinder pipeline

InactiveCN104405907ANot easy to fall offIncrease corrosion resistance and wear resistanceLift valveEngineeringAlloy

The invention relates to a valve seat of a double-clip type butterfly valve for a coal cinder pipeline. The valve seat comprises a framework and a rubber liner; a cavity is formed in one surface of the framework; a groove is formed in the cavity; the rubber liner is located inside the cavity and fixed on the framework by use of the groove. The valve seat of the double-clip type butterfly valve for the coal cinder pipeline has the beneficial effects that the existing structure that the valve seat is covered with the rubber liner is broken through, instead, the structure is so designed that the valve seat is covered with the rubber liner, the valve seat framework is made of 153 cast alloy iron instead of common carbon steel so that the corrosion resistance and the wear resistance can be improved, the groove is formed in the framework so that the rubber liner can be prevented from falling, and the rubber liner is made of high-abrasion resistance rubber high in rubber content and is not easy to tear.

Owner:江苏明江阀业有限公司

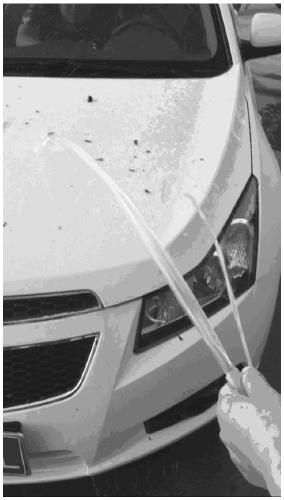

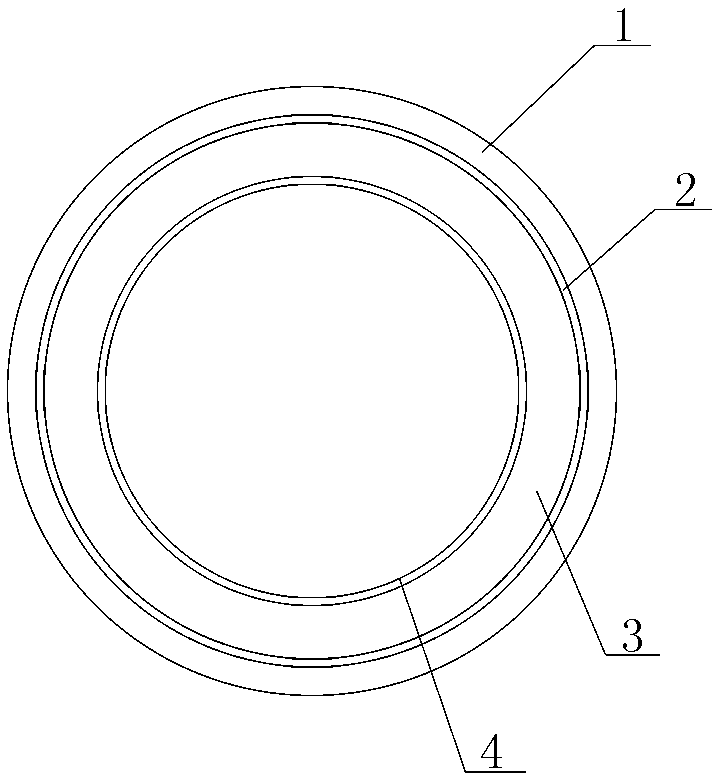

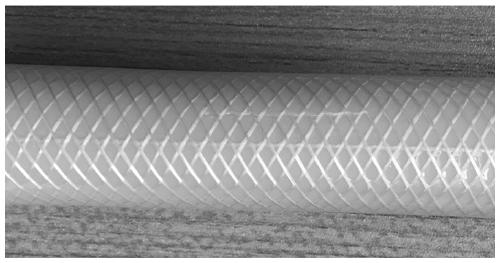

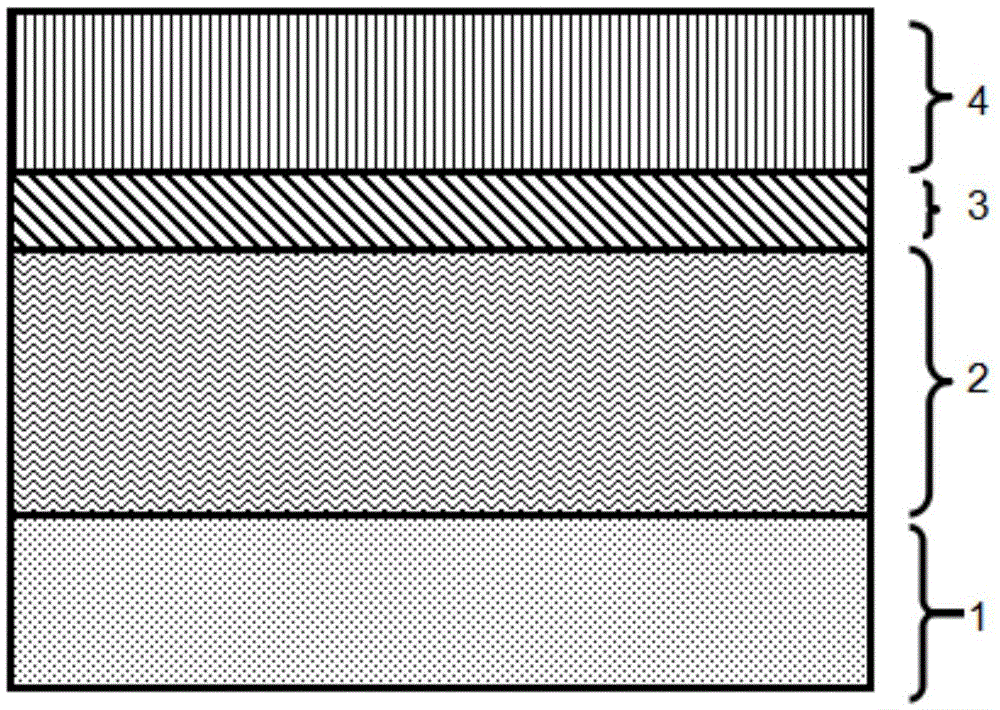

Water delivery pipe with antibacterial inner layer

ActiveCN109488818AHas anti-wear effectImprove pressure resistanceGeneral water supply conservationFlexible pipesBiochemical engineeringWear resistant

The invention discloses a water delivery pipe with an antibacterial inner layer. The water delivery pipe with the antibacterial inner layer comprises a wear-resistant outer layer, an anti-compressionlight-shielding layer is arranged on the inner wall of the wear-resistant outer layer, and a net wire pressure-resistant layer is arranged between the wear-resistant outer layer and the compression-resistant light-shielding layer; the antibacterial inner layer is arranged on the inner wall of the anti-compression light-shielding layer, and the wear-resistant outer layer, the net wire pressure-resistant layer, the compression-resistant light-shielding layer and the antibacterial inner layer are co-extruded into a combined integrated structure through a co-extrusion machine. The water delivery pipe has relatively good bacteriostasis and algae inhibition performance, is further capable of resisting compression, anti-bending and resisting corrosion, and is long in service life.

Owner:山东名气管业有限公司

Oxidation-carbon-coating-diamond-like composite film on the surface of medical titanium and titanium alloy and its preparation method

ActiveCN104138616BCompact distributionGuaranteed total thicknessVacuum evaporation coatingSputtering coatingDiamond-like carbonComposite film

The invention discloses an oxidation-carbon-coated-diamond-like composite film on the surface of medical titanium and titanium alloy. carbon layer and a diamond-like layer. The invention also discloses a preparation method of the composite membrane. The composite film prepared by the present invention has relatively large film-base binding force and large film thickness based on in-situ growth, and has excellent film comprehensive performance, and the present invention has simple process, high cost performance and can be mass-produced.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

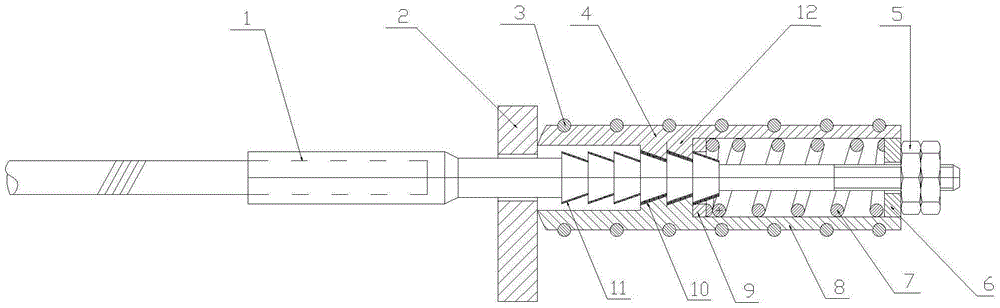

Apparatus for inner surface modification by plasma source ion implantation

InactiveCN100368590CImprove Surface Machining EfficiencyIncrease gas ionization rateVacuum evaporation coatingSputtering coatingPlasma diffusionType distribution

The invention relates to a device for inner surface modification by injecting plasma ion source, wherein: setting a tubular work-piece into a processing chamber, laying a columnar electrode and a tubular electrode allowing plasma diffusion in the tubular work-piece from inside to out side coaxially_ contacting the two electrodes with the radio frequency power supply, connecting a negative high tension supply between the tubular electrode and the tubular work-piece, also including a driving device capable of making relative rotation between tubular work-piece and tubular electrode; the tubular electrode is made up of electrode wires on the outer surface of tubular support, the electrode wires are in circumferential uniform distribution or screw-type distribution; the columnar electrode is a hollow tube with magnetic-irons in it; the tubular electrode is an interconnected hollow metal tube. the magnetic-irons are ring, and axially uniformly distributed with homopolarity opposition. The invention intensifies the sputtering of plasma to center electrode material by setting magnetic-irons in the tubular electrode, and improves the processing efficiency of tubular work-piece inner surface.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

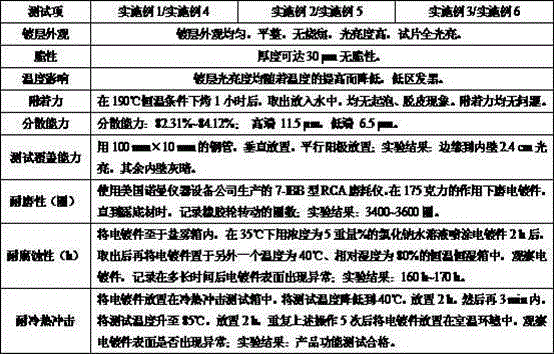

Non-cyanide alkaline silver plating method

The invention provides an environmentally-friendly non-cyanide alkaline silver plating electroplating liquid having a dispersive capacity reaching up to 84.12 percent, which is considerably higher than a dispersive capacity being 59.4 percent to 72.7 percent in the same domestic industry, and is approximate to a dispersive capacity being 86.04 percent in the foreign advanced technology; a platingliquid performance is greatly improved compared with a domestic company, and the surface gloss and the stability of a plating layer are remarkably improved; compared with the foreign advanced technology, the invention still has a margin but undoubtedly has a great pioneering significance and enthusiasm on improving a domestic non-cyanide alkaline silver plating technology and breaking a foreign high-technology monopoly, and has a wide market prospect; a full silver plating layer with a bright mirror surface can be obtained, a current density range is wide, a surface is smooth, an anti-tarnishproperty is good, the corrosion resistance and the wear resistance are high, a binding force of the plating layer is good, a dispersive capacity and a covering capacity are excellent, electroplating wastewater is treated easily, the maintenance is simple, and the economy and the practicability are realized.

Owner:张达

Novel environment-friendly chromium-free passivator and preparation method thereof

ActiveCN109267055AStrong adhesionImprove corrosion resistance and wear resistanceMetallic material coating processesChemistryGlycol synthesis

The invention provides a novel environment-friendly chromium-free passivator. The passivator comprises, by weight, 30-35 parts of water-based acrylic resin, 15-20 parts of laponite, 3.5-4 parts of citric acid, 10-12 parts of phytic acid, 7-8 parts of zinc chloride, 3-5 parts of ethylene glycol phenyl ether, 8-12 parts of glycine, 3.5-4 parts of sodium molybdate, 8-12 parts of polyaspartic acid, 4-6 parts of oxidized starch, 4-7 parts of sodium citrate, 3-3.5 parts of amine oxide and 50-55 parts of deionized water. The passivator can form a dense protective film on the surface of a plated part,the formed protective film has excellent adhesion and can be closely attached to the surface of the plated part, and thus the corrosion resistance and wear resistance of the plated part are greatly improved.

Owner:CHONGQING GUANGREN TOWER MFG

Cable sleeve pipe

InactiveCN108148236ACompatibility is reasonableAccelerated corrosionPlastic/resin/waxes insulatorsPalygorskiteChlorinated paraffins

The invention belongs to the field of an electric material and discloses a cable sleeve pipe. The cable sleeve pipe is prepared from the following raw materials: polyethylene resin, chloric ether resin, phenolic resin, chlorinated paraffin, borax, sepiolite, glass fiber, magnesium hydroxide, palygorskite, zinc borate and sodium dodecyl sulfate. The cable sleeve pipe provided by the invention has high acid, alkali and salt resistance and high high-temperature and cold resistance.

Owner:苏永义

Centrifugal pump low in failure rate

ActiveCN109236662AReduce noiseImprove stabilityPump componentsSolid state diffusion coatingFailure rateEngineering

The invention discloses a centrifugal pump low in failure rate. The centrifugal pump comprises a pump body, an impeller, a pump cover, a machine seal gland, a suspension frame and a rotating shaft, wherein the pump cover is fixed to one side of the pump body, a pump cavity for installing the impeller is formed between the pump cover and the pump body, the suspension frame is fixed to one side of the pump cover, and the rotating shaft is supported in the suspension frame through a bearing; one end of the rotating shaft extends into the pump cavity, the impeller is arranged in the pump cavity ofthe pump body and is fixed at the end of the rotating shaft, and a machine sealing cavity is in a circular truncated cone shape; the cross section of the machine sealing cavity is in a trapezoid shape, and an air guiding channel is formed in the inner wall of the machine sealing cavity; the air guiding channel is connected with an air storage cavity in the pump cover, the upper portion of the airstorage cavity is connected with an exhaust channel, and a drainage channel is further formed in the inner wall of the machine sealing cavity; a cooling plate is further arranged in the machine sealing cavity, and the inner wall of the machine sealing cavity is subjected to surface enhanced modification. The centrifugal pump is low in fault rate, and has high market competitiveness and application and popularization value.

Owner:ANHUI WOLONG PUMP & VALVE CO LTD

Preparation method of TiSi-GrAl-N nanometer coating

InactiveCN105002459AImprove corrosion resistance and wear resistanceImprove high temperature resistanceVacuum evaporation coatingSputtering coatingIonTemperature resistance

The invention relates to a preparation method of a TiSi-GrAl-N nanometer coating. The method comprises the first step of preprocessing, the second step of washing, the third step of ion nitriding, the fourth step of transition layer preparing and the fifth step of surface layer preparing. By means of the method, the bonding strength between the nanometer coating and a matrix can be improved through nitriding treatment, TiSi adopted in the nanometer coating is used for improving the corrosion resistance and the abrasion resistance of the nanometer coating, GrAl is used for improving the high-temperature-resistance of the nanometer coating, guaranteeing the bonding tightness of the nanometer coating, improving the rigidity of a workpiece and reducing the brittleness of the workpiece. According to the method, the production efficiency is high, and cost is low.

Owner:合为真空纳米(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com