Apparatus for inner surface modification by plasma source ion implantation

A technology of plasma source and ion implantation, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems that cannot be used to treat the inner surface of pipe fittings, etc., and achieve a modified inner surface of tubular workpieces Uniformity, improve anti-corrosion and wear resistance, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

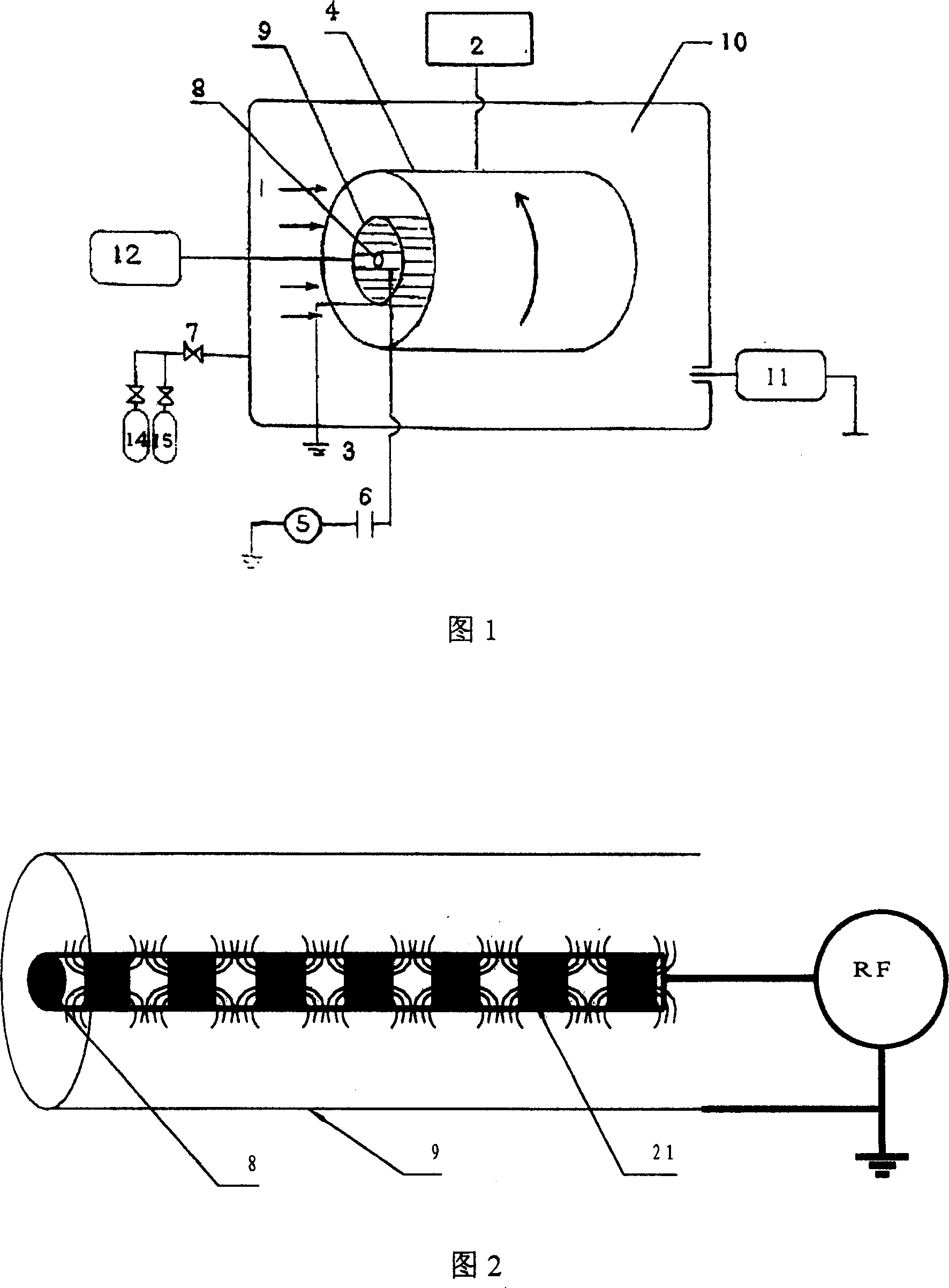

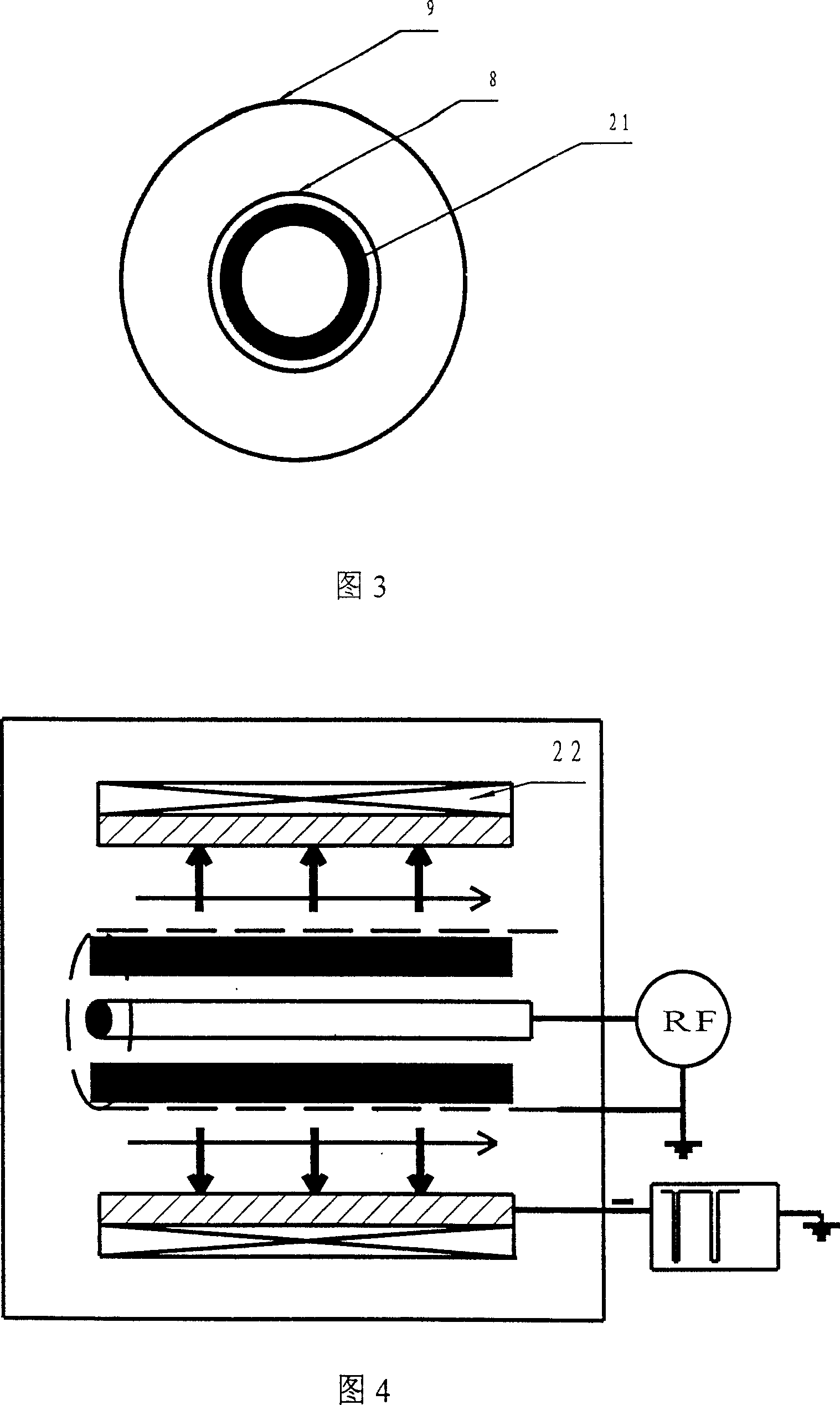

[0024] The plasma source ion implantation internal surface modification device of the present invention, as shown in FIG. 1, mainly includes a processing chamber 10 with a vacuum device 11, and the processing chamber 10 is connected to a working gas source argon cylinder 14 through a fine-tuning needle valve 7 And the nitrogen cylinder 15; in the processing chamber 10, the cylindrical electrode 8, the tubular electrode 9 and the tubular workpiece 4 are arranged coaxially from the inside out, and the columnar electrode 8 is placed in the center of the tubular workpiece 4, between the cylindrical electrode 8 and the tubular workpiece 4 A tubular electrode 9 composed of electrode wires uniformly distributed in the circumferential direction is set; the tubular electrode 9 and the cylindrical electrode 8 are connected to a radio frequency power supply 5, wherein the cylindrical electrode 8 is connected to the power electrode of the radio frequency power supply 5 through a DC blocking c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com