Laser surface processing device and method

A surface processing and optical device technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of low use efficiency and low service life of the laser source, and achieve the goal of improving efficiency, improving utilization, and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

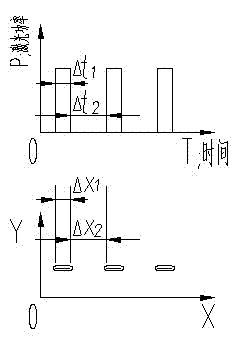

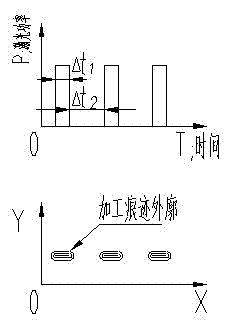

[0034] Laser surface processing devices, such as Figure 4 As shown, it includes a laser source 5 that emits three laser beams, a spectroscopic device (N≥2) that splits each laser beam into N groups of laser beams distributed along the time axis and irradiated circularly, and a focusing optical device. The spectroscopic device includes a scanning optical device for forming 3-way laser beams into a circular scanning laser, and a catadioptric optical device for changing the direction of the circular scanning laser. The scanning optical device is specifically a rotating polygonal mirror 1; the catadioptric optical device is three mirrors 2 with N surfaces; the focusing optical device is an optical element that can adjust the position and can gather or diverge 3×N groups of laser light, Convex lens 3 is specifically selected as the optical element in this implementation. By adjusting the position adjustment mechanism inside the focusing optical device ( Figure 4 The position ad...

Embodiment 2

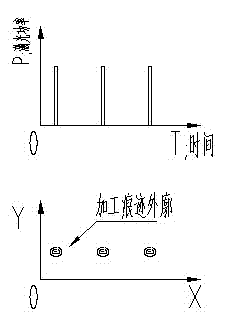

[0038] The laser surface processing device, this embodiment is basically the same as Embodiment 1, the difference is that the scanning optical device that forms the 3-way laser beam into the circular scanning laser in the beam splitting device does not use a rotating polygonal mirror, but a reciprocating swinging swing instead of a rotating polygonal mirror. Mirror, swing mirror is a reciprocating plane mirror, its working principle is as follows Figure 10 As shown, the reciprocating swing of the oscillating mirror 6 reflects the laser beam projected on the oscillating mirror 6 to form a laser scanning area with an included angle of θ.

[0039] In the laser surface processing device provided in this embodiment, under the condition that the focusing optical device remains fixed, the processing marks projected onto the surface of the workpiece 4 have Figure 11 As shown in the processing traces, the processing traces in each processing cycle have higher disorder compared with E...

Embodiment 3

[0041] Laser surface processing device, this implementation example is basically the same as Embodiment 1, the difference is that the optical element of the focusing optical device adopts such as Figure 12 The combined optical element 7 shown is composed of a plurality of optical elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com