A Method for Generating Curved Surface Machining Trajectories Based on Milling Force Prediction

A technology of trajectory generation and surface processing, which is applied in the field of metal cutting to achieve the effect of improving surface processing efficiency, improving surface quality and good surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

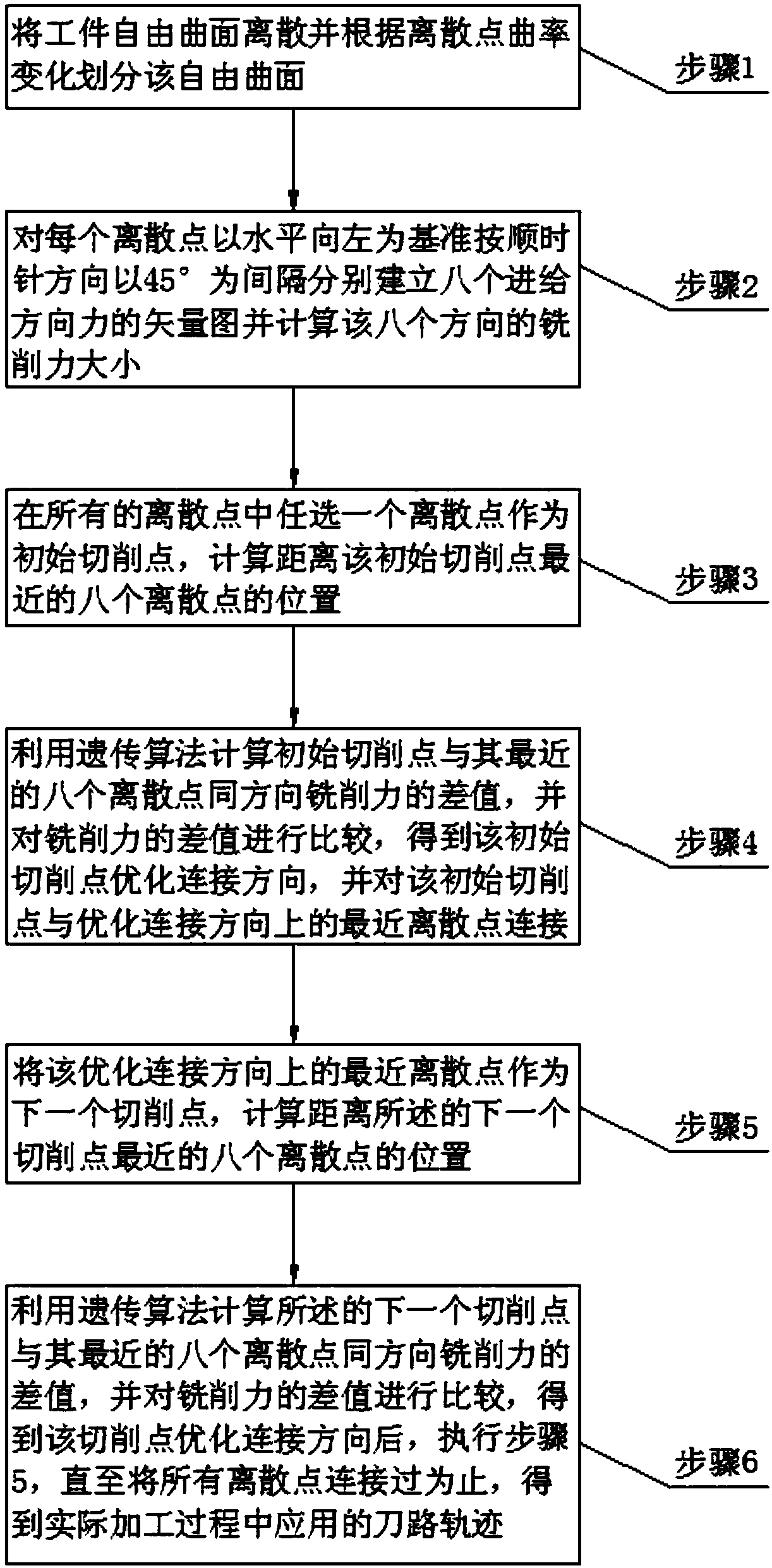

[0024] Specific implementation mode one: as figure 1 As shown, this embodiment discloses a method for generating curved surface machining trajectory based on milling force prediction, and the method includes the following steps:

[0025] Step 1: Discretize the free-form surface of the workpiece, and divide the free-form surface according to the curvature change of each discrete point;

[0026] Step 2: For each discrete point, take the horizontal left as the reference and clockwise at an interval of 45° to establish the vector diagrams of the eight feed direction forces and calculate the milling force in the eight directions;

[0027] Step 3: choose a discrete point among all the discrete points as the initial cutting point, and calculate the positions of the eight nearest discrete points from the initial cutting point;

[0028] Step 4: use genetic algorithm to calculate the milling force difference between the initial cutting point and its eight nearest discrete points in the...

specific Embodiment approach 2

[0031] Embodiment 2: A method for generating curved surface machining trajectory based on milling force prediction described in Embodiment 1. In step 1, the free-form surface of the workpiece is discretized, and the free-form surface is divided according to the curvature change of each discrete point. The specific method steps are:

[0032] Step 1-1: The free-form surface of the workpiece is regarded as a patchwork of multiple simple surfaces, and the form of each simple surface is described as P(u, v), where P(u, v) is the parametric equation of the surface, u and v are two parameters satisfying 0≤u, v≤1;

[0033] In this embodiment, the selected surface parameter equation is as follows:

[0034]

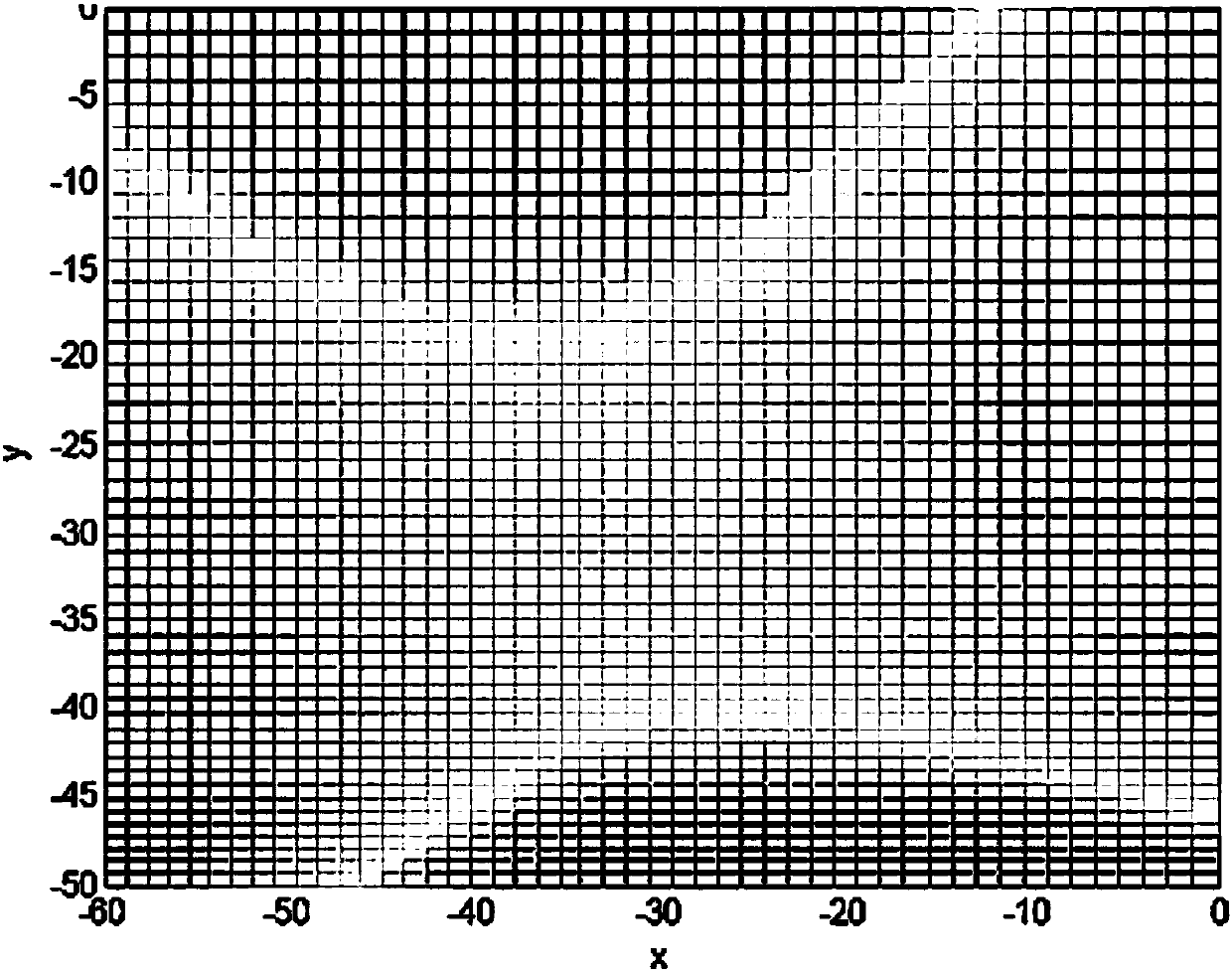

[0035] The discrete results of the MATLAB two-dimensional simulation of the selected surface instance are as follows: figure 2 shown;

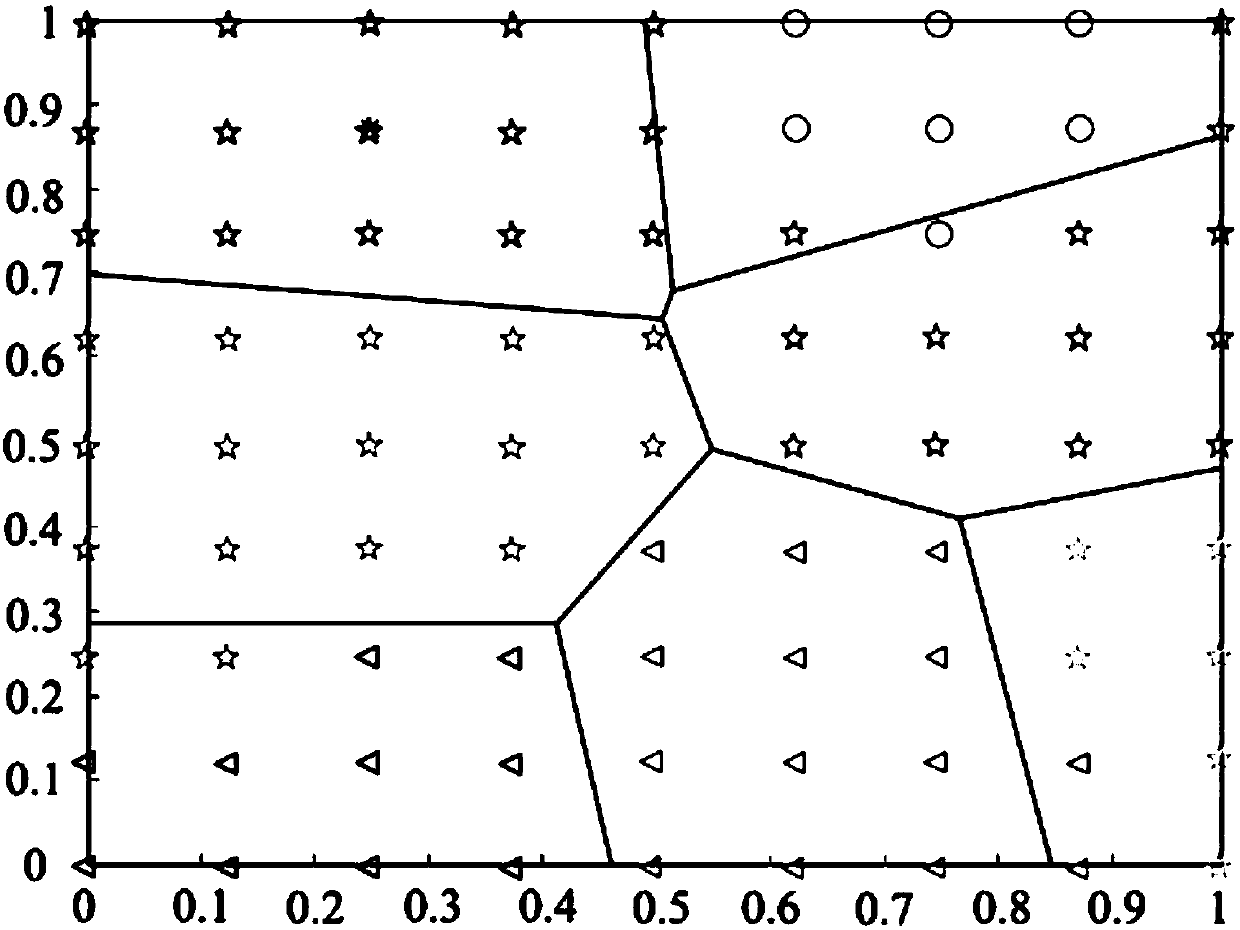

[0036] Step 1-2: According to the curvature of each discrete point, the free-form surface of the workpiece is divided into convex surface, ...

specific Embodiment approach 3

[0038] Specific embodiment three: a kind of method for generating curved surface machining trajectory based on milling force prediction described in specific embodiment one, in step 2, for each discrete point, take the horizontal direction to the left as the reference and clockwise with 45° as the interval respectively The specific method steps for establishing the vector diagrams of the eight feed direction forces and calculating the milling forces in the eight directions are:

[0039] Step 2-1: Approximately treat each simple surface as an inclined plane micro-element processing in any feed direction, and establish discrete points on this simple surface at intervals of 45° in a clockwise direction based on the horizontal to the left. The vector diagram of the force in the feed direction, such as Figure 4 shown;

[0040] Step 2-2: Since the microelement milling force calculation formula is established on the horizontal plane, and the conversion between the inclined plane an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com