A preparation method of slow-release flavor microcapsules for tobacco

A technology for tobacco flavor and microcapsules, which is applied in the preparation and application field of slow-release tobacco flavor microcapsules, which can solve the problems such as the decline in the ability to absorb oily flavors, and achieve the effects of reducing volatility, high loading, and prolonging the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

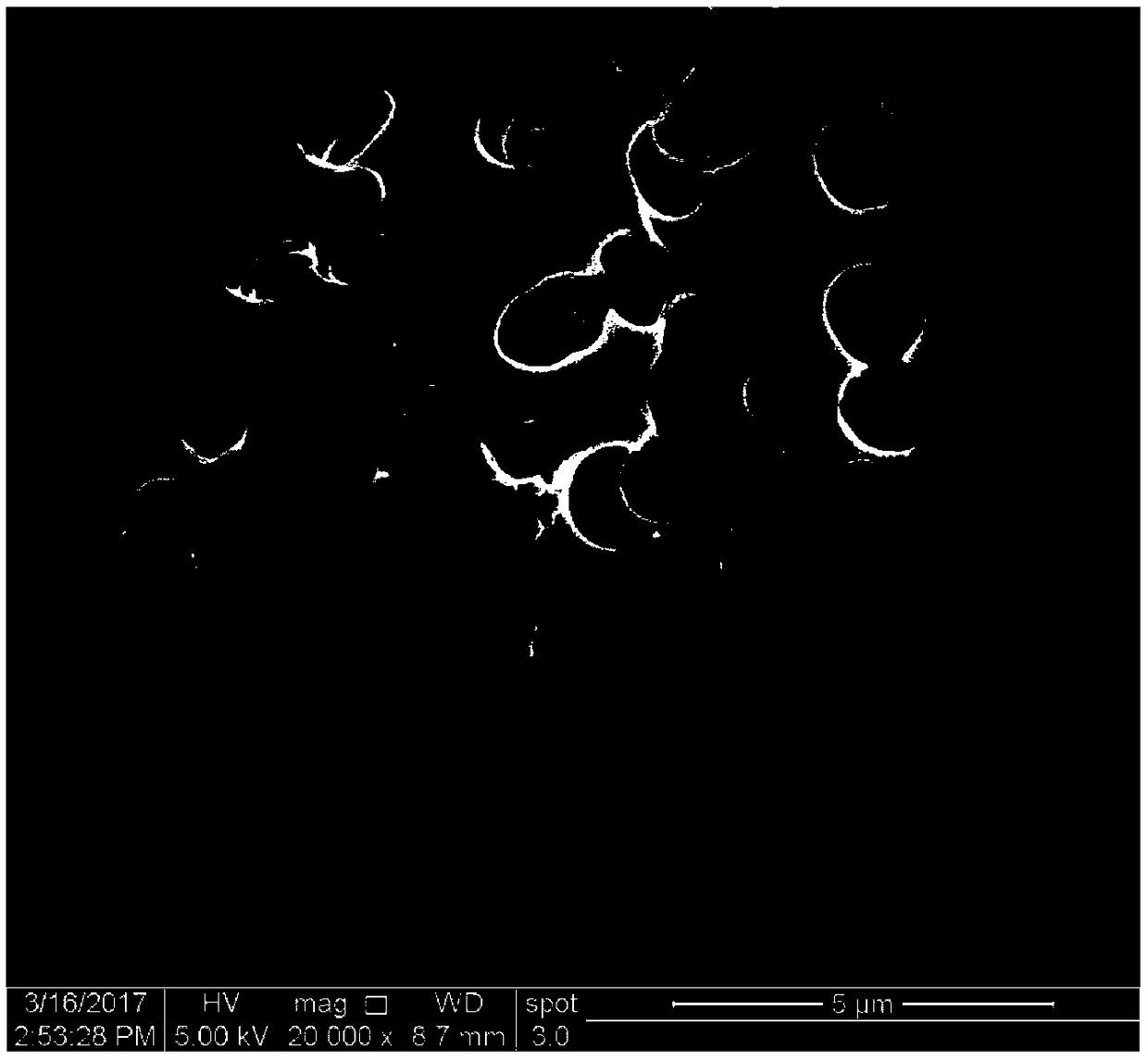

[0036] Example 1: Preparation of slow-release tobacco flavor microcapsules β-ionone

[0037] 1. Separately pulverize the acetylated porous starch and ethyl cellulose in a pulverizer, and pass through a 7000-mesh sieve;

[0038] 2. Disperse and dissolve 2g of ionone in 20ml of ethyl acetate, add 4g of dodecenyl succinic anhydride to esterify porous starch, and stir and absorb evenly at room temperature;

[0039] 3. Add 4g of ethyl cellulose to the above-mentioned porous starch carrier solution adsorbed with tobacco flavor, and stir evenly at room temperature;

[0040] 4. Freeze-drying for 24 hours to obtain dried slow-release tobacco flavor microcapsules β-ionone.

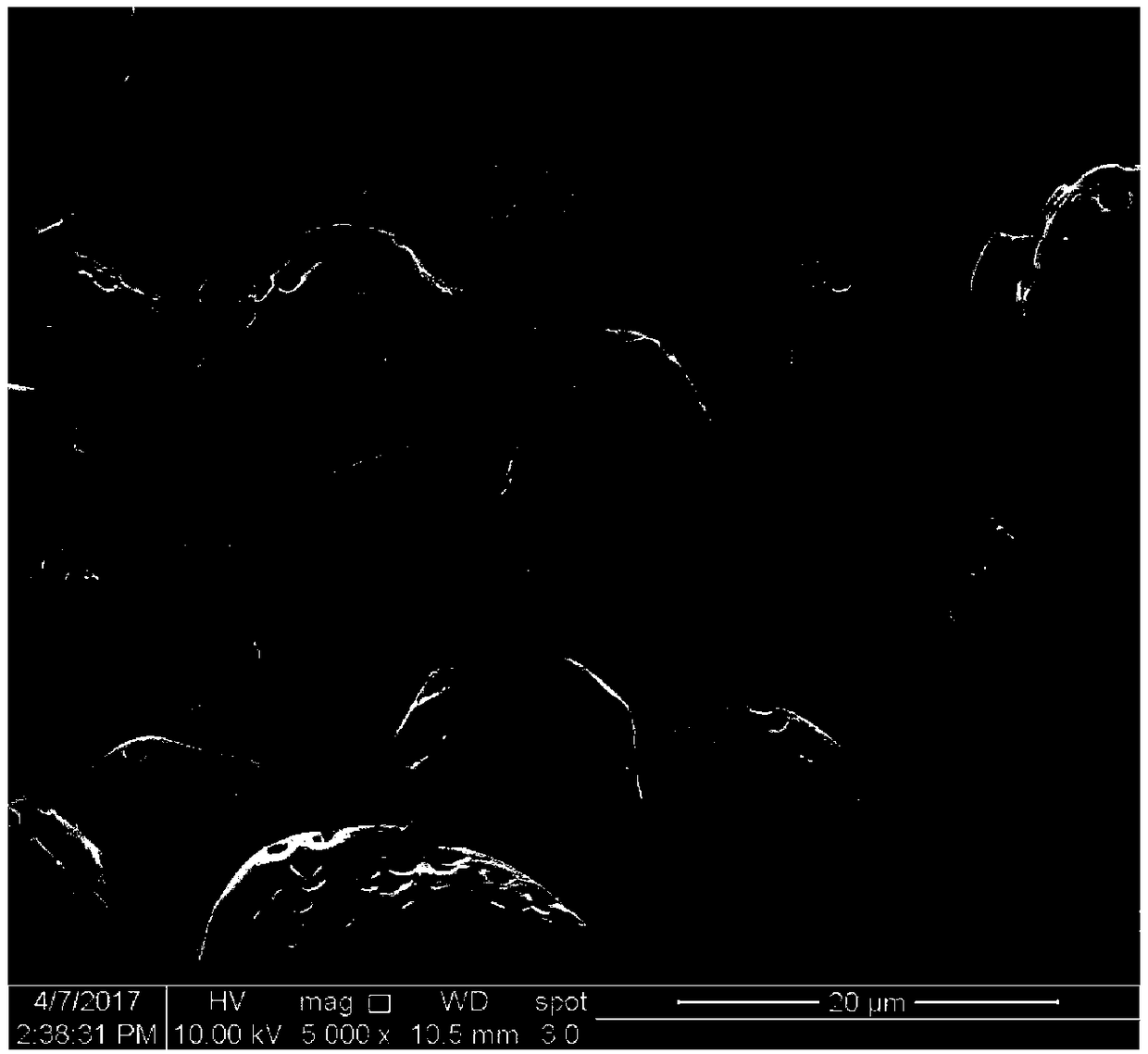

Embodiment 2-4

[0042] The porous starch acetylated porous starch in Example 1 was replaced with octenyl succinic anhydride esterified porous starch, dodecenyl succinic anhydride esterified porous starch, and esterified crosslinked porous starch.

Embodiment 5-6

[0044] The sealing material ethyl cellulose in Example 1 was replaced with polyethylene-vinyl acetate and polymethyl methacrylate.

[0045] Loading rate of slow-release flavor microcapsules β-ionone prepared in Examples 1-6

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com