Method for operating a dc/dc voltage step-down converter

A step-down converter and output voltage technology, which is applied in the direction of battery/battery traction, control/regulation system, output power conversion device, etc., can solve the problems of uncontrollable and other problems, and achieve simple control device and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

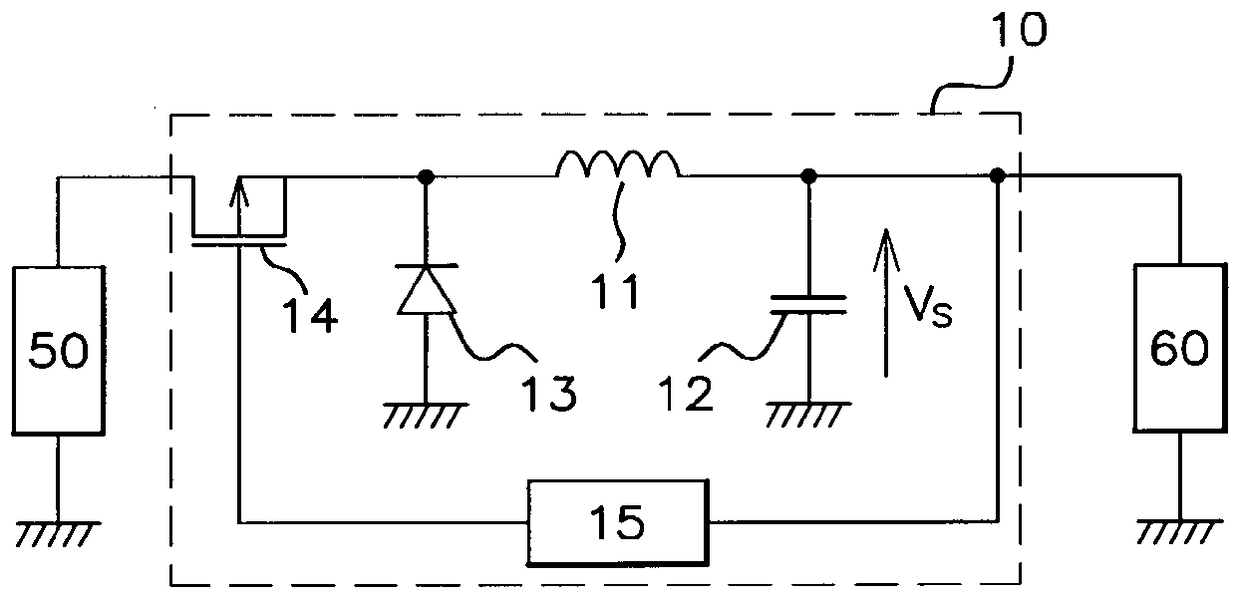

[0046] image 3 An implementation example of the DC / DC step-down converter 20 is shown.

[0047] The buck converter 20 is implemented for supplying an output voltage V having a regulated value from a power source 50 to the terminals of a load 60 S . In the ensuing description, in a non-limiting manner, in the case of a buck converter 20 installed in a motor vehicle, the power source 50 is, for example, the battery of the motor vehicle, or a voltage regulator connected to said battery ,etc. Load 60 is, for example, a microcontroller of the electronic computer of the motor vehicle.

[0048] Depend on image 3 The illustrated buck converter 20 comprises an inductive component 21 one terminal of which is connected to a capacitive component 22 at the output of the buck converter 20 . More particularly, capacitive component 22 includes two terminals, one of which is connected to inductive component 21 and the other of which is connected to electrical ground.

[0049] The other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com