Polyimide non-woven fabric-based safe gel electrolyte material and preparation method thereof

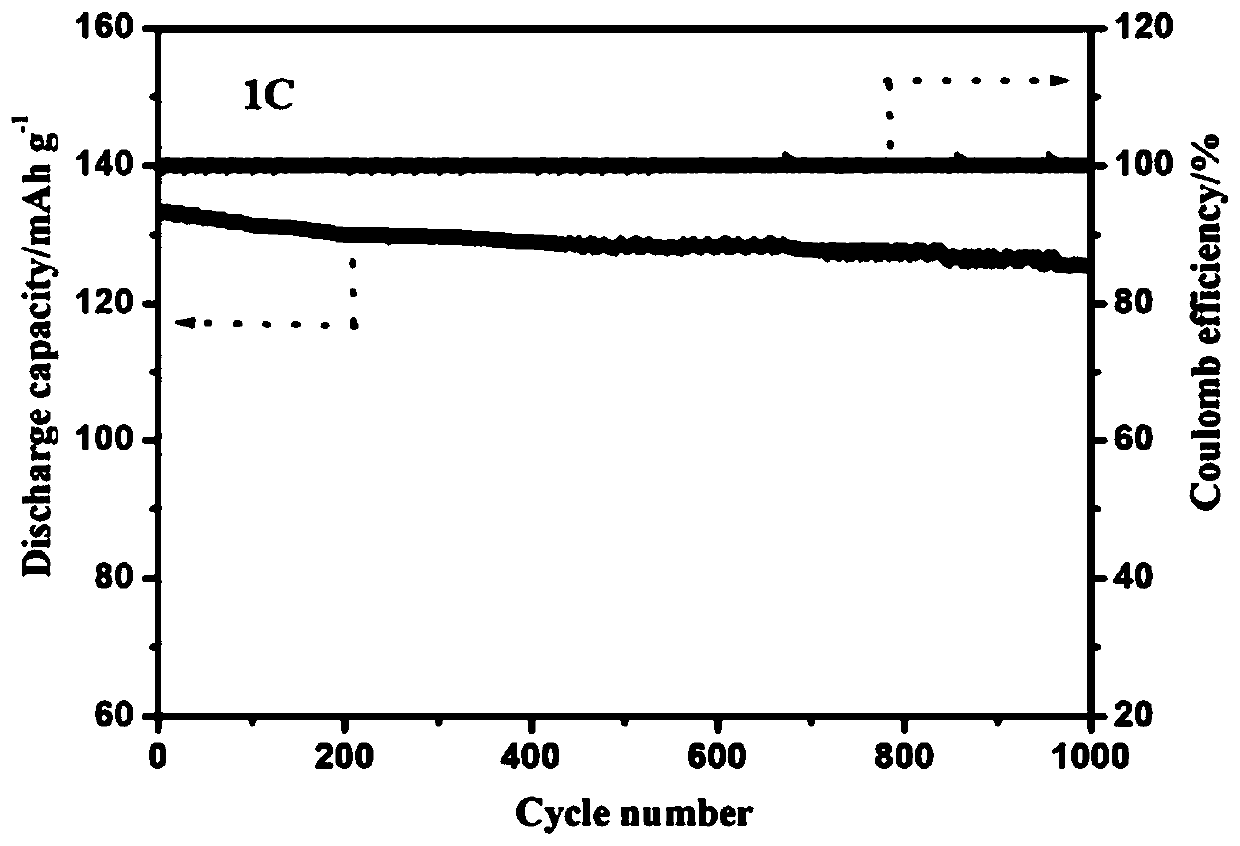

A technology of gel electrolyte and polyimide, applied in solid electrolyte, non-aqueous electrolyte, circuit, etc., can solve problems such as low temperature resistance, poor safety, and volatile electrolyte, so as to improve heat resistance stability, high Capacity retention rate, good working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

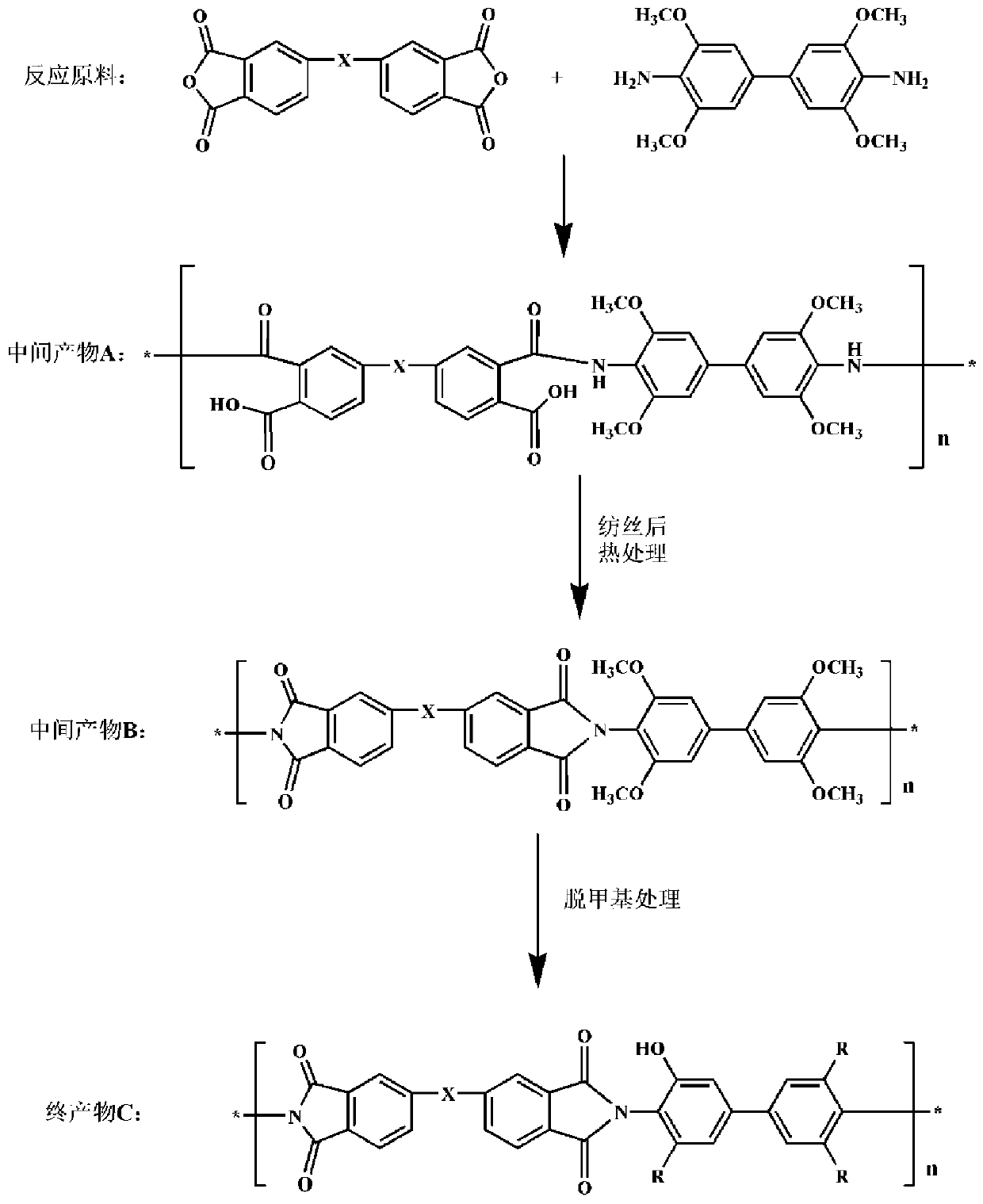

[0031] Example 1: Preparation of polyimide non-woven fabric with tetramethoxy pendant groups

[0032] Prepare tetramethoxybenzidine and bistrifluoromethyldiphthalic anhydride into a polyamic acid NMP solution with a mass fraction of 5%, and adjust the electrospinning equipment parameters to prepare it to have a porosity of 55% to 70% , Polyamic acid non-woven fabric with an average pore diameter of 0.5 to 1.5 μm. Further, the prepared polyamic acid non-woven fabric is heated at 350-500°C for 4-6 hours, and finally a polyimide non-woven fabric material with methoxy side groups is obtained

Embodiment 2

[0033] Example 2: Preparation of polyimide non-woven fabric with hydroxyl active sites

[0034] The methoxy side group non-woven fabric prepared in Example 1 is soaked in 1M boron tribromide solution or pyridine hydrochloride solution for demethylation, ensuring that the amount of demethylation reagent is at least 5 times larger The molar content of methoxy groups in the non-woven fabric. Keep the reaction temperature at 0-20°C, take out the material after 24 hours of reaction, and rinse the material with a large amount of deionized water, quench the reaction reagents until the product becomes neutral, and dry it for later use

Embodiment 3

[0035] Example 3: Preparation of electrolyte

[0036] A: Take tetraethylene glycol dimethyl ether (TEGDME) and γ-butyrolactone to prepare a mixed solution at a mass ratio of 1:1, and then add lithium perchlorate to prepare a 1.5M electrolyte for use.

[0037] B: Take ethylene carbonate (EC) and γ-butyrolactone to prepare a mixed solution with a mass ratio of 6:4, and then add LiTFSI to finally prepare a 1M electrolyte for use.

[0038] C: Take propylene carbonate (PC) and tetraethylene glycol dimethyl ether (TEGDME) into a mixed solution at a mass ratio of 4:6, and then add lithium hexafluorophosphate to finally prepare a 2M electrolyte for use.

[0039] D: Take propylene carbonate (PC) and ethylene carbonate (EC) to prepare a mixed solution at a mass ratio of 5:5, and then add lithium tetrafluoroborate to finally prepare a 1.5M electrolyte for use.

[0040] E: Take propylene carbonate (PC) and diethylene glycol dimethyl ether according to the mass ratio of 4:6 to prepare a mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com