A lithium battery performance testing system

A test system and battery tester technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low dissolved oxygen in the electrolyte and high cost, and achieve the effect of simple structure, low cost, and accelerated reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

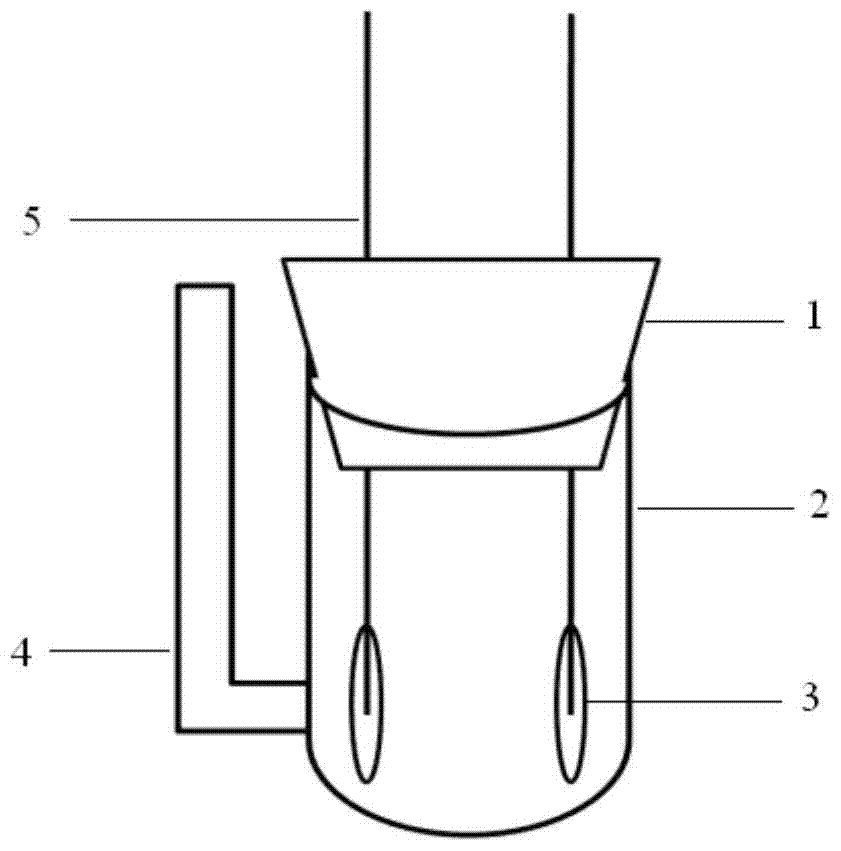

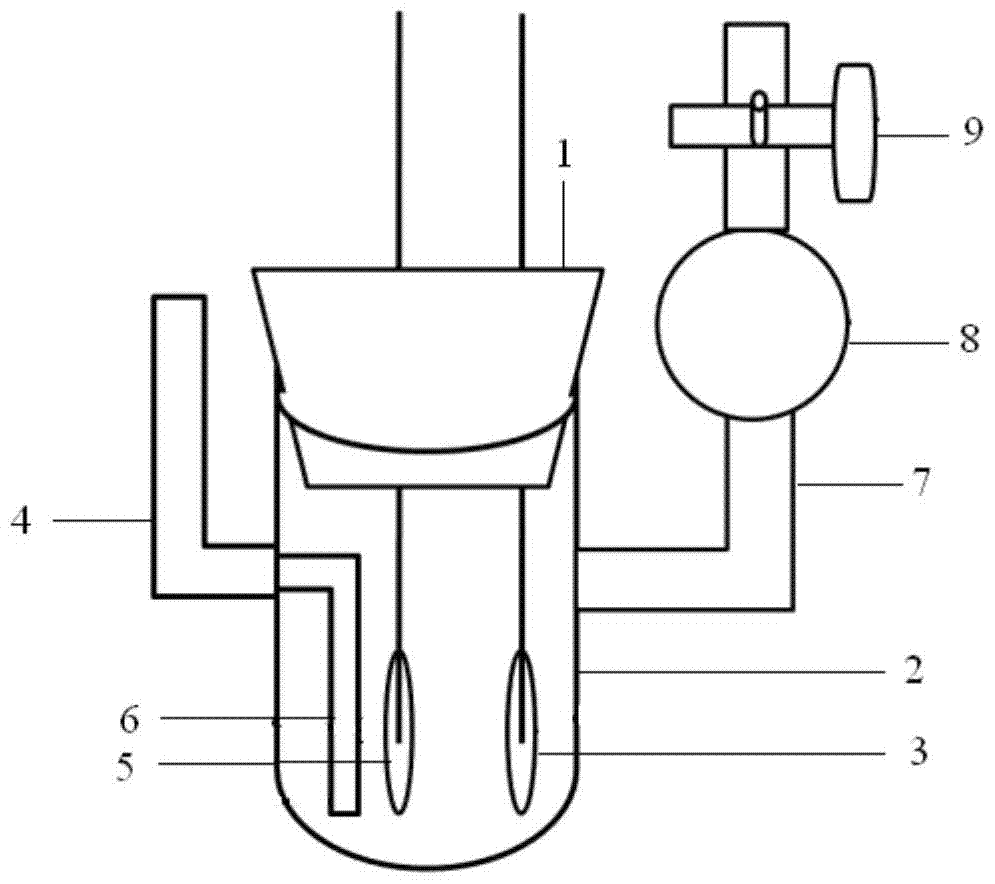

[0058] 1.1 Provide electrolytic cell figure 1 In the shown electrolytic cell, the electrolytic cell includes a cell body, an air inlet pipe communicating with the cell body, a rubber plug for closing the cell body, a capillary, and a positive electrode and a negative electrode, both of which are fixed on the rubber plug. Among them, the height of the cell body is 4.0 cm, the inner diameter is 2.0 cm, the air inlet at the upper end of the air inlet pipe is 1.0 cm higher than the cell body, the distance between the positive and negative electrodes is 1 cm, and the electrolyte is 3 ml.

[0059] The negative electrode is a lithium sheet.

[0060] The positive electrode was prepared as follows: nickel foam was punched into 1cm 2 A circular current collector welded to stainless steel wire; super-P carbon, MnO 2 , PTFE was mixed according to the mass ratio of 6:2:2, diluted with NMP, and ultrasonicated for 10 minutes; the welded nickel foam current collector was dipped into the pas...

Embodiment 2

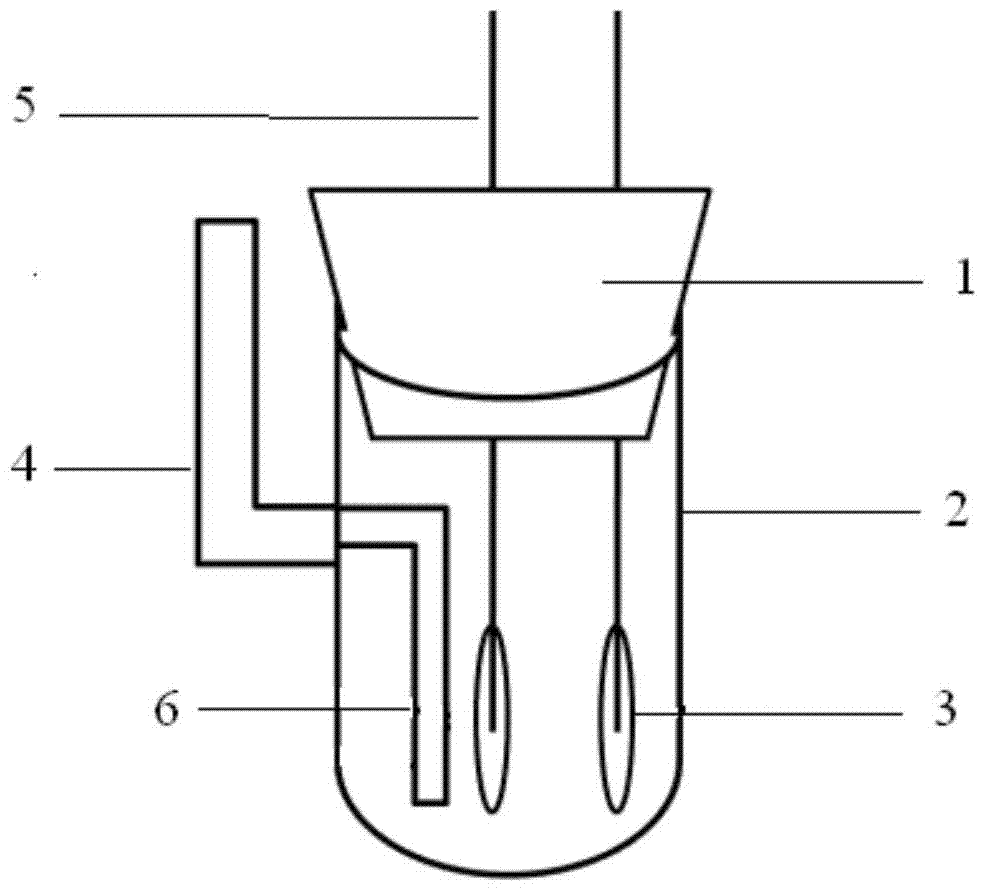

[0071] 2.1 Provide an electrolytic cell, assemble the electrolytic cell according to the method of Example 1, the capillary is inverted L-shaped, its vertical part is located between the positive electrode and the negative electrode, the capillary is 1.0 cm high, the bottom is close to the bottom of the cell body, and the inner diameter is 0.1 cm. A photo of the electrolytic cell body is shown in Figure 10 shown.

[0072] 2.2 Assemble a lithium battery performance testing system according to the method steps in Example 1, and transfer the electrolytic cell provided in 2.1 to a glove box.

[0073] After ventilating for 20 minutes, the test was carried out at a current density of 80mA / g, and the voltage-specific capacitance curve was obtained, as shown in Figure 11 As shown, curve 1 is the specific capacitance curve of the first charge and discharge, curve 2 is the specific capacitance curve of the second charge and discharge, curve 3 is the specific capacitance curve of the ...

Embodiment 3

[0075]3.1 Provide an electrolytic cell, assemble the electrolytic cell according to the method of Example 1, the capillary is inverted L-shaped, its vertical part is located between the positive electrode and the negative electrode, the capillary is 1.0 cm high, the bottom is close to the bottom of the cell body, and the inner diameter is 0.1 cm. photos such as Figure 12 shown.

[0076] 3.2 Assemble a lithium battery performance testing system according to the method steps in Example 1, and transfer the electrolytic cell provided in 3.1 to a glove box.

[0077] After ventilating for 20 minutes, the test was carried out at a current density of 100mA / g, and the voltage-specific capacitance curve was obtained, as shown in Figure 13 As shown, curve 1 is the specific capacitance curve of the first charge and discharge, curve 2 is the specific capacitance curve of the second charge and discharge, curve 3 is the specific capacitance curve of the third charge and discharge, and cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com