Anti-corrosion concrete

A concrete and polymer emulsion technology, which is applied in the field of building materials, can solve the problems of easy wear and damage of surface membranes, affect the service life of buildings, and difficulty in concrete maintenance, and achieve low prices, reduced maintenance costs, and convenient use and maintenance. Effect

Inactive Publication Date: 2015-05-06

徐州逸刻新型墙体材料有限公司

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the material has problems such as fast reaction speed in concrete, poor permeability and formation of surface membranes that are easy to wear and tear due to the fact that the main body is sodium monosilicate.

[0003] On the other hand, as the concrete structure becomes more and more complex, some structural forms or special parts of the structure, such as vertical thin-walled structures such as the side walls of the concrete basement, etc., the maintenance of the concrete is very difficult, and the moisture is easily lost. Concrete roads, airport runways, port terminals and other projects constructed in summer, the water evaporates quickly at high temperature, which is easy to cause dry cracking of the concrete and affect the service life of the building

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0023] Example 3 is the best embodiment.

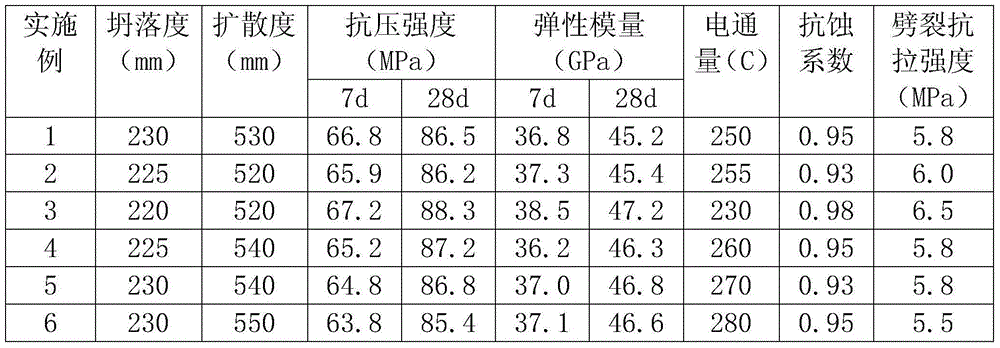

[0024] The performance indexes of the concretes prepared in Examples 1-6 are shown in Table 2.

[0025] The performance indicators of concrete are tested in accordance with "Experimental Methods for Long-term Performance and Durability of Ordinary Concrete" GBJ82-85.

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of building materials, and particularly relates to anti-corrosion concrete, which comprises the following components in parts by weight: 200-250 parts of portland cement, 60-80 parts of a polymer emulsion, 10-30 parts of a film-forming additive, 5-10 parts of a dispersant, 20-40 parts of mineral powder, 8-15 parts of a rust inhibitor, 6-8 parts of an air entraining and water reducing agent, 100-150 parts of water, 5-10 parts of sodium silicate, 1.5-3.5 parts of potassium silicate, 10-15 parts of wear-resistant corundum filler particles, 3-8 parts of an antifreeze and 2-5 parts of an accelerator. The anti-corrosion has the beneficial effects that the wear-resistant corundum filler particles as a wear-resistant component is matched with the mineral powder and the antifreeze, so that the wear resistance and corrosion resistance are greatly enhanced, the cost is low, the use and maintenance are also very convenient, the service life of a building can be effectively prolonged, and the maintenance cost is greatly reduced.

Description

technical field [0001] The invention relates to the technical field of building materials, in particular to an anti-corrosion concrete. Background technique [0002] At present, the protection of concrete structures often adopts many methods of coating materials on the outer surface of concrete. Among permeable materials, such as materials with sodium silicate as the main component, by coating or injecting silicon into waterproof and maintenance areas Sodium is the main component of the material to achieve the purpose of protecting the concrete structure. However, the material has problems such as fast reaction speed in concrete, poor permeability and easy wear and tear of the surface film formed because the main body is sodium monosilicate. [0003] On the other hand, as the concrete structure becomes more and more complex, some structural forms or special parts of the structure, such as vertical thin-walled structures such as the side walls of the concrete basement, etc.,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/26C04B28/04C04B24/24C04B24/26

Inventor 贾微

Owner 徐州逸刻新型墙体材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com